3 minute read

Service

9. Service

Only adequately trained people are allowed to carry out daily and weekly maintenance. The terms of the warranty prescribe appropriate maintenance of the truck. All spare parts must be original ones. It is recommended that you sign a maintenance agreement with the truck dealer, who can also supply spare parts. Only professional service ensures long-term, trouble-free truck operation. Service program monitoring becomes easier if you enter the service dates in a service logbook. Contact our maintenance department or your truck dealer for qualified, authorized and efficient maintenance service.

Semi-annual inspection service (or 600 h)

Check and, if necessary, adjust or repair:

• Connections of the drive motor and pump motor. • Operation of the accelerator. • Operation of the microswitches or inductive sensors. • Operation of the contactors and solenoids. • Cables. • Tiller arm gas spring. • Function of the lift cylinder. • Play of the fork carriage, and the slope of the forks and their condition.

2000 kg capacity truck

• Air gap in the brake: 0.2 mm when new, maximum gap 0.55 mm. • Brake pad thickness: 8.5 mm when new, minimum thickness 5.5 mm.

1300 and 1600 kg capacity trucks

• Air gap in the brake cannot be modified. • Brake pad thickness: 7.6 mm when new, minimum thickness 7.4 mm.

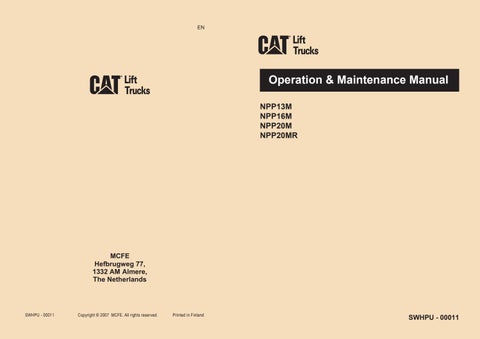

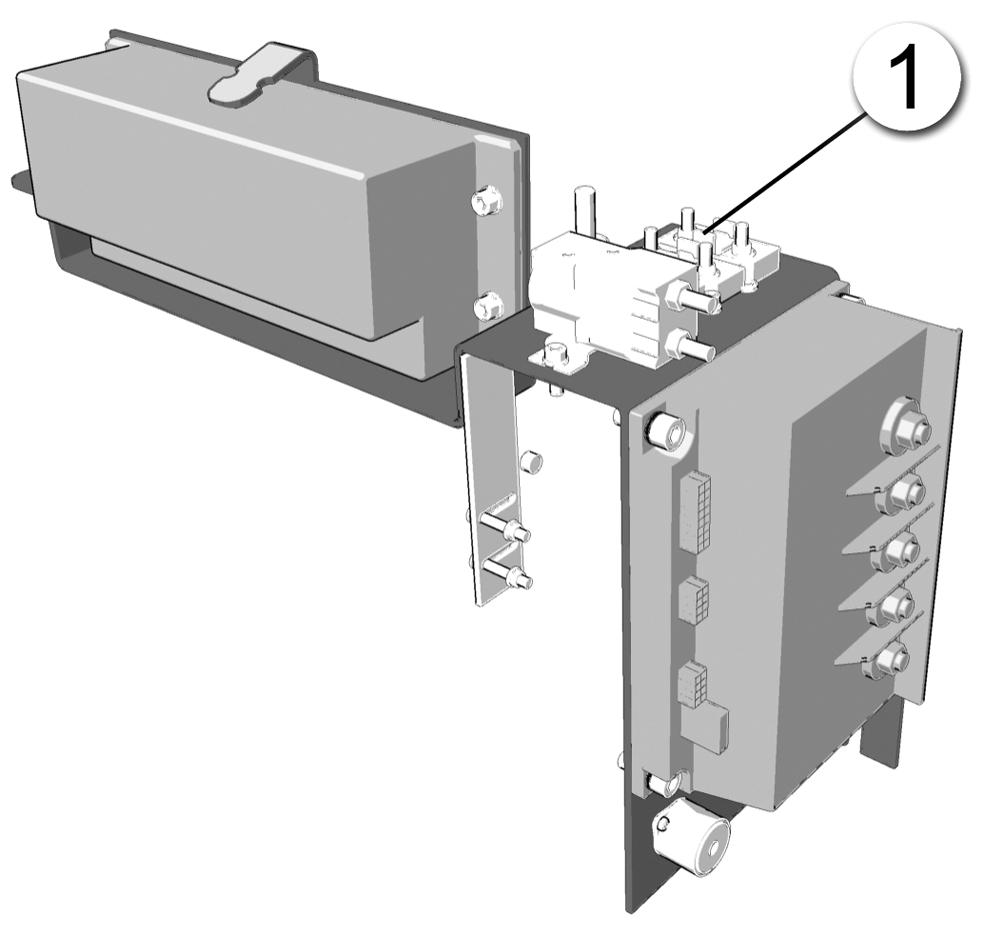

Opening the covers

Open the mounting screws (1) to remove the covers on both sides of the truck.

Monthly lubrication

The following lubricating points of the truck should be lubricated once a month:

• Turning bearings of the drive unit (2000 kg capacity trucks).

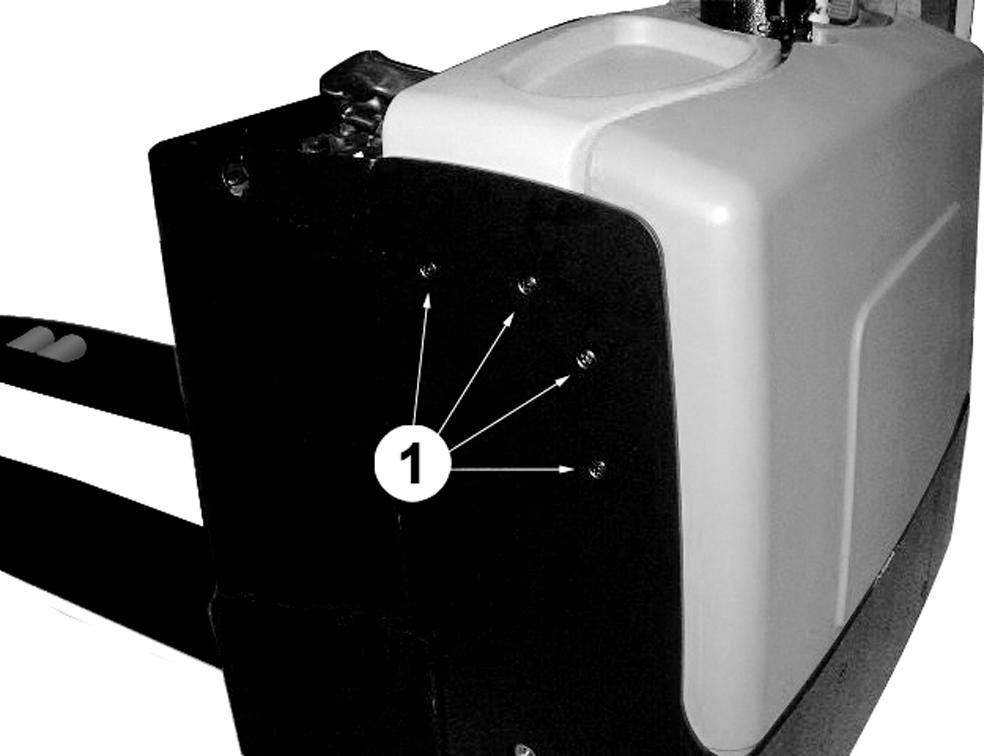

Filling hole for hydraulic oil (1)

• Hydraulic oil: ISO 11158 HM/HV/HR - VG 32. • In freezer warehouses: ISO 11158 HM/HV/HR - VG 15. • Fill the tank to the volume of ¾.

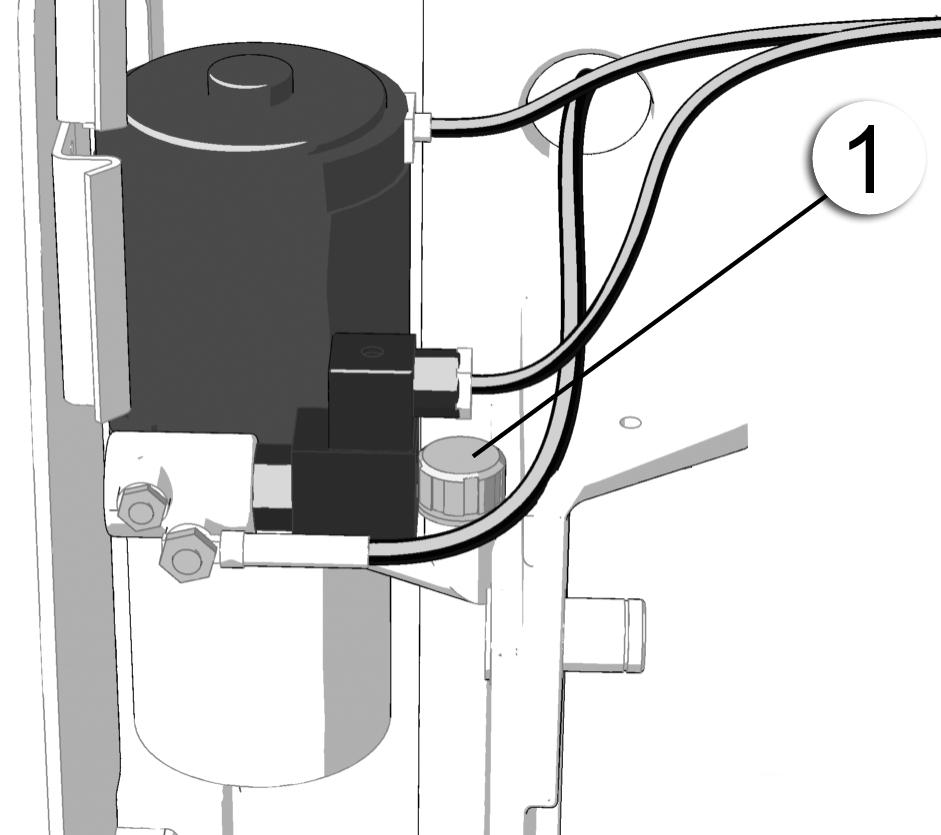

Transmission lubricant recommendation for 2000 kg capacity trucks

• Transmission oil: EP 80/90. • In freezer warehouses: NLGI No. 1 or No. 0. • Fill to the volume of 0.6 l. The oil level must reach the lower edge of the checking hole.

NOTE

Use grease as the transmission lubricant in 1300 and 1600 kg capacity trucks. You do not need to change it at all during the truck's useful lifetime.

Filling hole for transmission oil (1) Opening to check the oil level (2) Oil outlet (3)

Additional maintenance work for service personnel

• Change the hydraulic oil once a year (or 1200 h).

• Change the transmission oil once a year (or 1200 h), 2000 kg capacity truck. • Clean the oil filter. • Check the operation of the hydraulics and the pressure relief valves. • Check the fastening of the gearbox and the amount of transmission oil ( 2000 kg capacity truck); add if necessary. • Check the fastening of the tiller arm. • Check the condition of the side castor wheels and load wheels. • Check the wear of the drive wheel: • Drive wheel diameter is 230 mm when new • Drive wheel has to be replaced when its diameter is 218 mm.

Location of fuses in el-panel

1F1

2F1

3F1

4F1

5F1 10A

10A

10A

200A

100A Line contactor fuse

Control circuit fuse

Aux. device circuit fuse

Drive motor fuse

Pump motor fuse

NOTE

The tightening momentum of the fuse (1) terminals is 4.5 ±1 Nm.

Ordering spare parts

When ordering spare parts, always contact your dealer or the maintenance centre. Only use original spare parts. To ensure that you receive the correct parts, include the following information in the order:

1. Truck type 2. Serial number of the truck 3. Order number of the part 4. Name of the part 5. Number of parts ordered.

The truck's type and serial number are listed on the front page of the manual or on the identification plate of the truck. The order number and name of the parts are listed on the spare part pages of the manual supplied with the truck.

Hydraulic and transmission oil, as well as batteries are hazardous waste that must be disposed of accordingly. The truck itself is not hazardous waste, and can be recycled.