4 minute read

Batteries

7. Batteries

Only appointed and trained personnel may replace and recharge batteries. Individuals maintaining batteries must have sufficient protective clothing and eye gear.

• Do not handle a naked flame in the vicinity of batteries because of a risk of explosion. • Do not smoke when working with batteries. • Do not leave tools or other metal implements on top of the battery. Sparking or a short-circuit may cause the battery to explode. • When batteries are recharged, the cell plugs must be closed firmly to prevent splashing of battery fluid. • Battery fluid is a corrosive acid solution; avoid getting it on your skin or in your eyes. The battery fluid develops explosive gas at the end phase of recharging. Therefore, make sure that the battery has sufficient ventilation (this does not apply to maintenance-free batteries). • A low battery charge status may damage the battery during long-time use. • 1600 and 2000 kg capacity trucks 2 V/cell. • 1300 kg capacity trucks 10.5 V/battery (1.75 V/cell).

Recharging the battery

Make sure that the charger is the appropriate model and that the battery has sufficient ventilation.

1. Park the truck in a reserved recharging place. 2. Switch off the power from the key switch. 3. Make sure that the charger has been switched off. 4. Disconnect the battery connector and connect it to the charger. 5. Switch on the charger.

After recharging

1. Switch off the charger. 2. Disconnect the battery connector from the charger. Grab the plugs; do not pull the cables. 3. Check the battery according to the battery manufacturer's maintenance instructions.

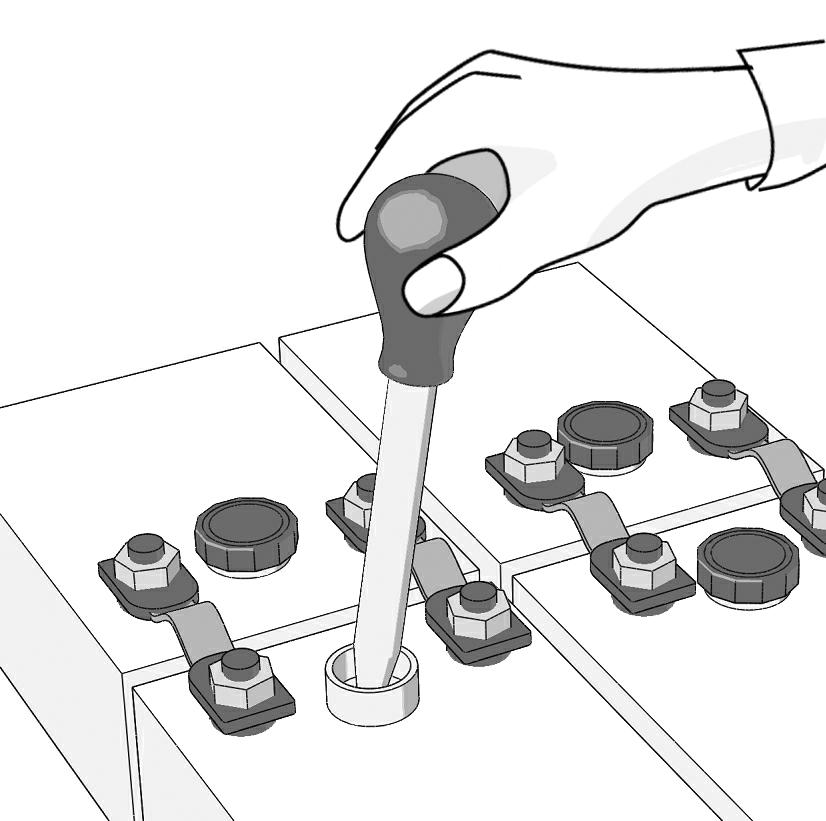

Measuring the battery's specific gravity

Measure the specific gravity of the battery fluid according to the manufacturer's instructions. The acid density of a fully charged battery is 1.28 to 1.30 at +30°C. The gravity is

• 1.24 when the battery is 3/4 charged. • 1.20 when the battery is 1/2 charged. • 1.16 when the battery is 1/4 charged. • 1.15 when the battery is empty. Charge the battery immediately.

Replace the battery according to the manufacturer's instructions. When reinstalling batteries, use the appropriate tools for moving, connecting and fastening the battery securely. Do not keep the tools or other metal implements on top of uncovered batteries. When replacing the battery, use one with similar dimensions and weight so that the stability or braking properties of the truck are not weakened. The minimum weight of the battery is indicated on the identification plate of the truck. When you use a lifting device for lifting the battery, place a non-conductive plate on top of the battery to avoid the risk of a short circuit. This is not necessary if the lifting device has sufficient insulation and is equipped with a distributor, or if the pole shoes and cell combinations are fully protected.

Acquiring a new battery

When acquiring a battery for the truck, pay attention to the following sections of the standard EN 1175-1:

• 5.1 Traction batteries (includes the requirements for the protective cover of the battery case, ventilation and interior surface treatment) • 7.4 Minimum markings (includes the requirements specified on the truck battery plate).

The battery plate should provide at least the following information:

• Manufacturer • Type • Serial number • Nominal voltage • Capacity (Ah / 5h) • Service weight.

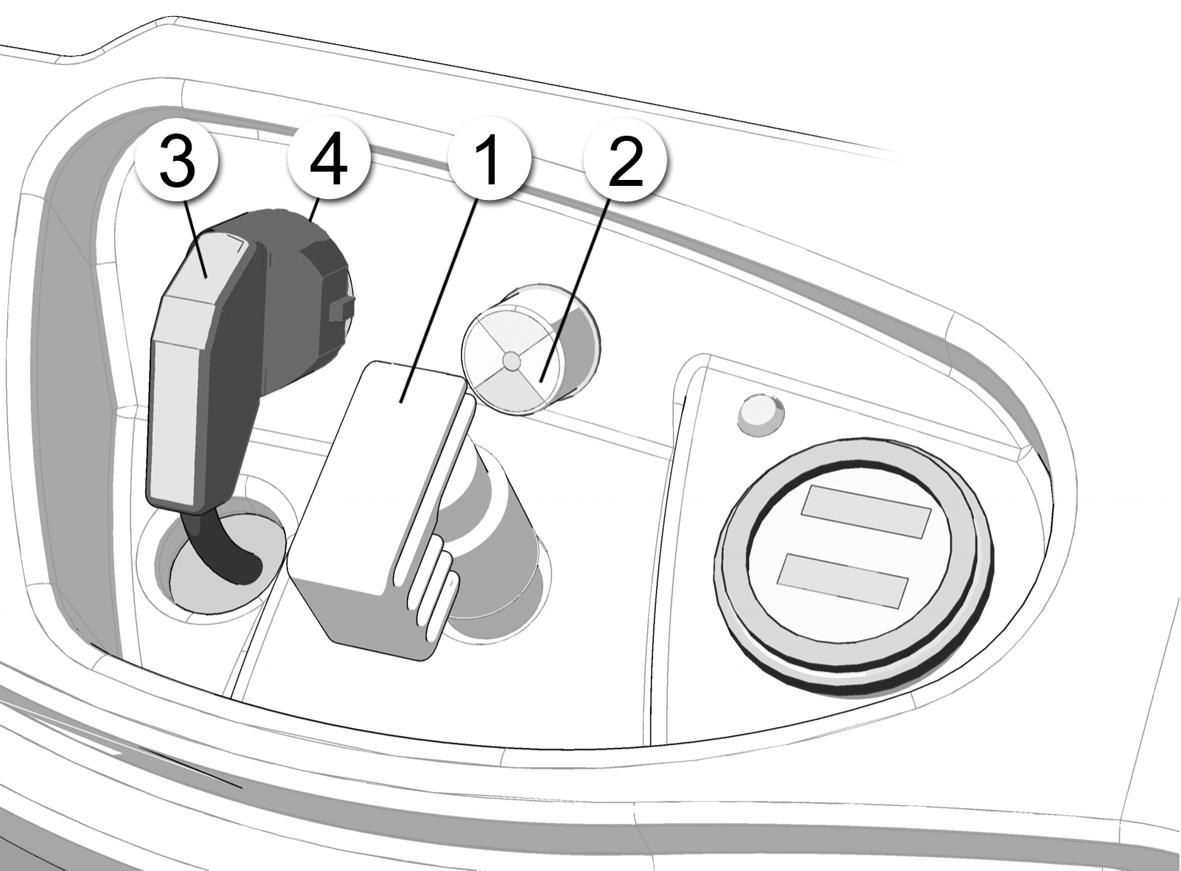

Battery charging with an inbuilt charger

You can access the plug (3) for the power supply of the integrated charger from the outside of the truck. To activate the charger, extract the plug for the power supply from the safety socket (4) on the machine and insert it into the correct outlet (230 V ±10% / 50 Hz). During charging the main switch (1) must be pushed down so that the power is switched off. After activating the charger, charging starts automatically.

The charging phase is indicated with a three-colour indicator light (2):

• Red (empty battery) • Flashing red (charging has begun) • Yellow (80% charged) • Green (fully charged, the charger plug (3) can be unplugged and connected to the safety socket of the truck (4) • Flashing red, yellow, and green indicates a fault in the system and charging is stopped automatically.

The charger will stop automatically after the charging is complete and you can unplug the charger plug and connect it to the safety socket of the truck. NOTE If the plug is not connected to the safety socket, all electrical functions will remain switched off and the truck cannot be used.

WARNING!

No inflammable materials are allowed within two meters of the truck under charge or the charger.

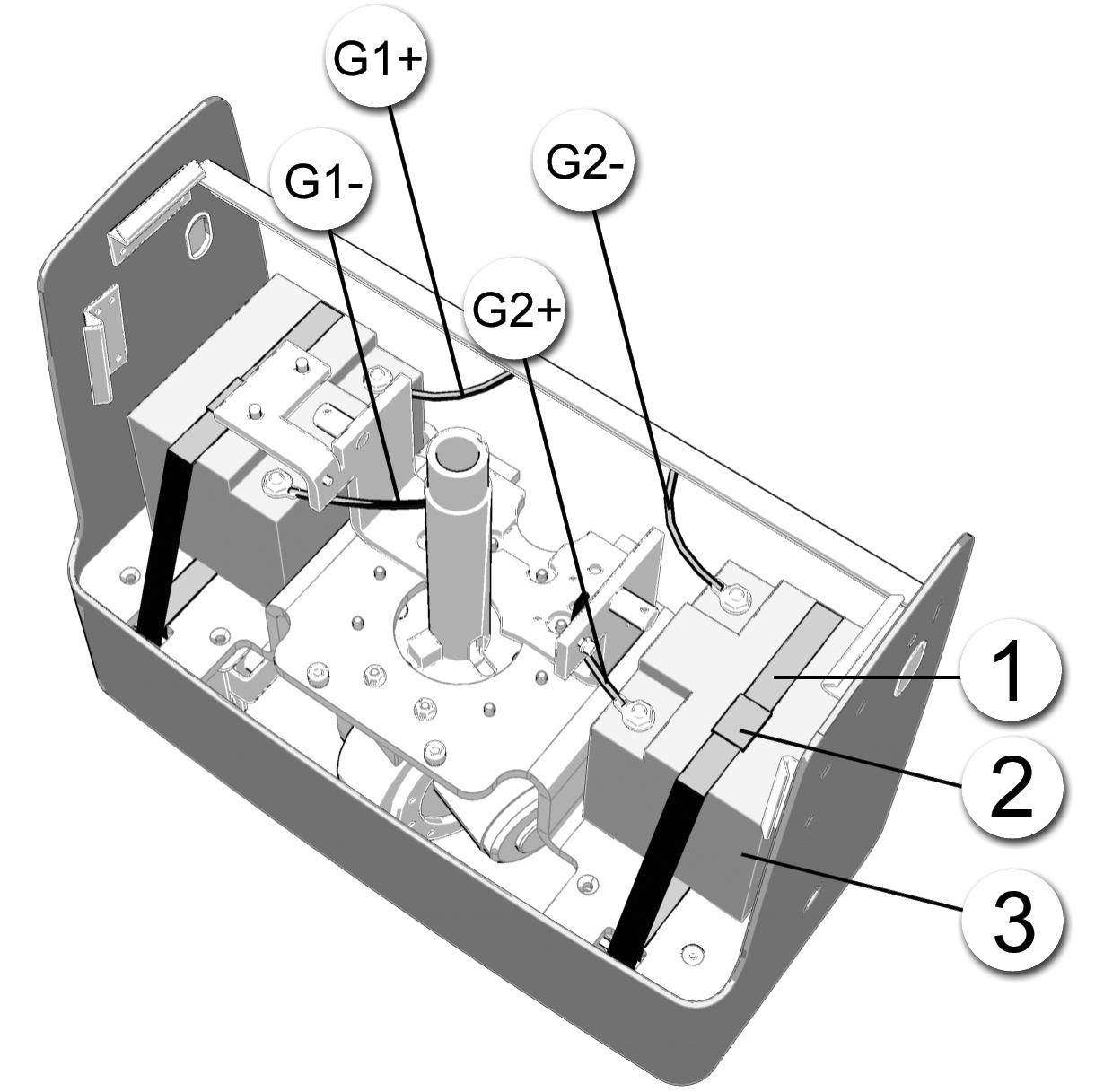

Fastening batteries

1300 kg capacity trucks

1. Connect the batteries (2 pcs.) according to the picture. 2. Fasten the battery (3) with belts (1) as shown in the picture. 3. Make sure that the belts are tight, and secure them with their own locking mechanism (2).