1 minute read

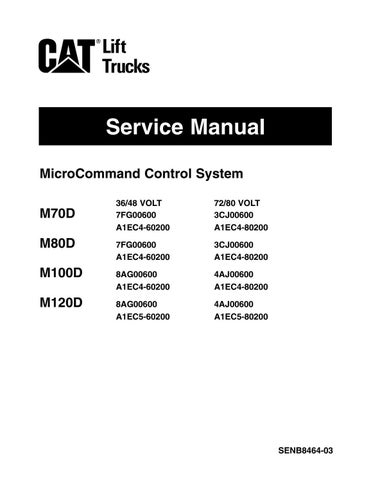

Power Circuit

Control Circuit

E366

Advertisement

Drive Control Circuit

With the actuation circuit complete, the logics supplies a HIGH voltage (15 volts) to the direction switch at P1-11 and P1-12. A HIGH voltage is also supplied to the accelerator control at P1-10, P1-9, P1-8 and P1-7. Battery voltage is supplied to the accelerator at P1-9.

Releasing the park brake closes the park brake switch and provides a path to battery negative. Selecting a direction with the service brake OFF (switch closed) will change the voltage from HIGH to LOW on P1-12 for forward or P1-12 for reverse. Depressing the accelerator pedal will cause the accelerator voltage pattern on P1-7, P1-8, P1-9 and P1-10 to change from all HIGH to one of the fifteen speed patterns explained under Accelerator Control. The logics detects the voltage pattern change at P1-7. P1-8, P1-9 and P1-10, activates the correct direction contactor, regen contactor and starts pulsing the drive power transistors.

With the forward direction selected, current flows from the logics P2-17 through the forward direction and regen contactor coils to logics P2-13 and P210 back to battery negative. The forward and regen contact tips close.

T316 Base Input Signal

NOTE: Shaded lines illustrate current flow in the circuit diagrams. Other circuits can be activated at the same time, but each one is shown separately to illustrate current flow in each individual circuit.

The high amperage current that provides the power and torque necessary to drive the lift truck, flows in this circuit. The speed of the drive motor is controlled separately from the pump motor circuit by the MicroCommand Control System. The logics generates a positive pulsing voltage (approximately 1.5 volts) on P12-5 to the base of transistor T316. This pulse turns ON T316, which turns ON T314 and T315.

A more complete description of this transistor turn on circuit can be found in: Hydraulic Pump Motor Circuit under Power Transistor Pulsing.