1 minute read

COUPLING GUARD 18. GEARCASE BREATHER CAP 25. MOTOR ROD BOLT

CHAPTER! MECHANICAL MAINTENANCE

SECTION 2 - LOWER WORKS

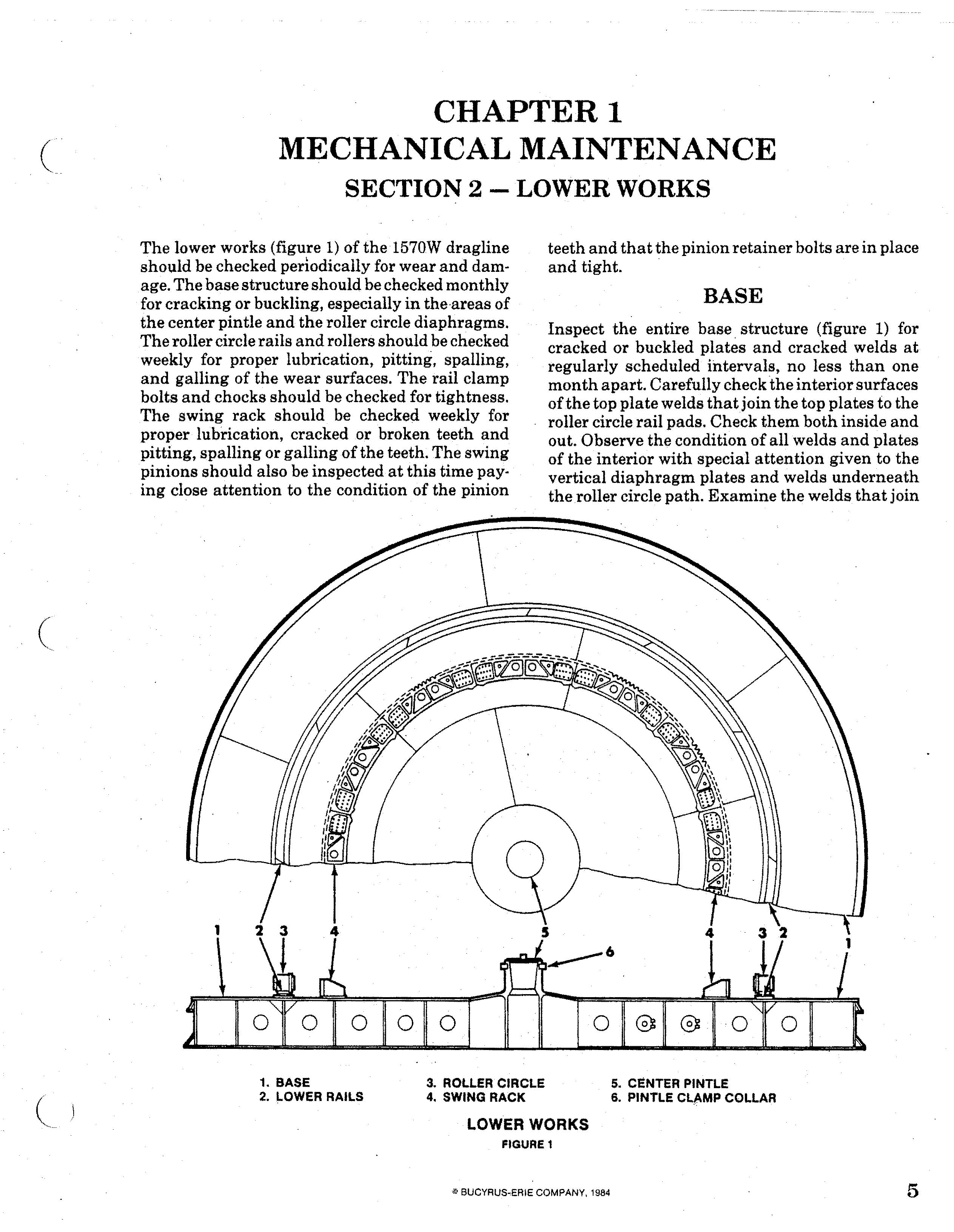

The lower works (figure 1) of the 1570W dragline should be checked periodically for wear and damage. The base structure should be checked monthly for cracking or buckling, especially in the-areas of the center pintle and the roller circle diaphragms. The roller circle rails and rollers should be checked weekly for proper lubrication, pitting, spalling, and galling of the wear surfaces. The rail clamp bolts and chocks should be checked for tightness. The swing rack should be checked weekly for proper lubrication, cracked or broken teeth and pitting, spalling or galling of the teeth. The swing pinions should also be inspected at this time paying close attention to the condition of the pinion teeth and that the pinion retainer bolts are in place and tight.

BASE

Inspect the entire base _ structure (figure 1) for cracked or buckled plates and cracked welds at regularly scheduled intervals, no less than one month apart. Carefully check the interior surfaces of the top plate welds that join the top plates to the roller circle rail pads. Check them both inside and out. Observe the condition of all welds and plates of the interior with special attention given to the vertical diaphragm plates and welds underneath the roller circle path. Examine the welds that join

o o 0

o @ @

1. BASE 3. ROLLER CIRCLE 5. CENTER PINTLE 2. LOWER RAILS 4. SWING RACK 6. PINTLE CLAMP COLLAR

LOWER WORKS