5 minute read

Drag Rope Replacement '" , "

injury, or serious damage to the dragline could result should a rope become uncontrolled.

/). CAUTION: The condition of the ropes ft may make it necessary to modify the procedure outlined here, especially if the rope is broken or severely damaged. Be sure to always follow safety precautions when burning or climbing. Always keep the ropes under complete control.

1. Move the machine to an area sufficient to perform the repair and set the bucket on the ground about halfway between the base and the boom point. Allow enough slack in the hoist rope so that the hoist socket is laying on the ground.

3. Position a signal man in the machinery house in a position to observe the hoist drum and ropes. Activate the hoist drum slowly in the lowering mode to spool the ropes from the drum. At the same time, pull the hoist ropes from the boom with the ground vehicle. Stop the hoist machinery and ground vehicle as the last winding or rope starts to spool from the drum. Then very slowly rotate the drum until the left hoist rope is completely off the drum and only secured to the drum with the rope clamps. The right hoist rope will have one half wrap on the drum.

/). CAUTION: Throughout this operation, a signal man is necessary to communicate drum or rope positions to the operator. Make sure that a system ofsignals is worked out in advance and that the line ofcommunication is unbroken.

4. Run the left deck winch line under the drag drum and securely attach it to the left hoist rope, then remove the left hoist rope drum clamps.

5. Slowly rotate the drum so that the right hoist rope is completely off the drum and only secured to the drum with the rope clamps. Run the right deck winch line under drag drum and securely attach it to the right hoist rope, then remove the right hoist rope drum clamps.

6. Using the deck winches to control the hoist ropes, pull the hoist ropes from the boom with the ground vehicle.

BI005574 7. Pull the hoist ropes and attached deck winch line over the boom point sheaves and down to the ground.

8. Separate the deck winch lines from the old hoistropes and remove the old hoistropes from the area.

9. Check the condition ofthe drum rope grooves, rope clamps, deflection and boom point sheaves.

10. Position the reels of new hoist ropes in front of the machine beyond the boom point. Attach the deck winch lines to the new hoist ropes.

Remove the staples securing the new rope to the reel.

/). CAUTION: When removingthe staples, ... be sure to stand to the side as the rope will snap downward when the staples are removed.

12. Rotate the hoist drum 180 0 to put the left hoist rope drum sockets in position for installing the rope.

14. Take up on the hoistmachinery to reel the hoist rope onto the drum. Make sure the rope seats properly in the drum rope grooves. Stop the hoist machinery when the ropes are off the reels. Disconnect the ropes from the reels and remove the reels from the area.

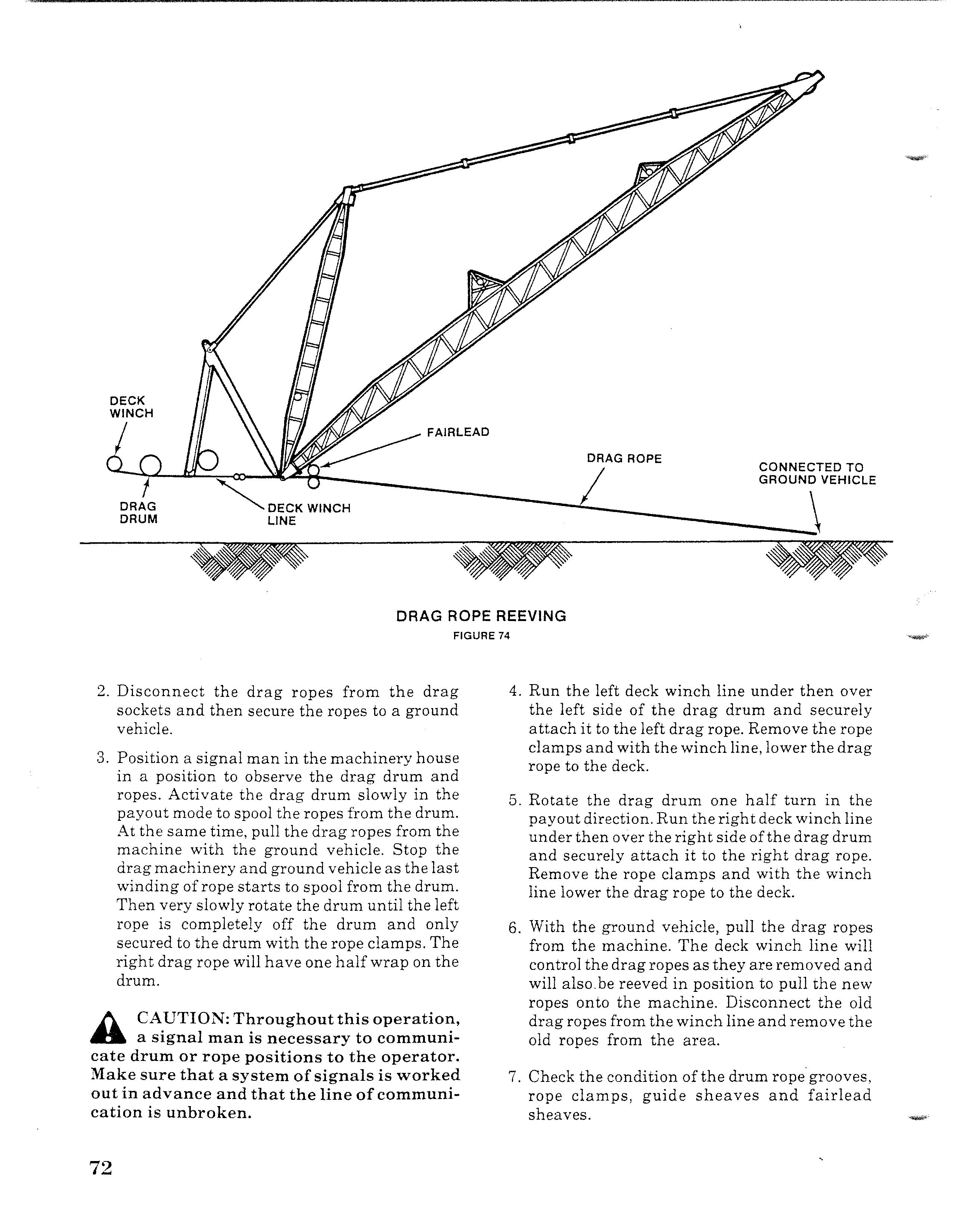

DRAG ROPE REPLACEMENT (Figure 74) Refer to cautions at the beginning of the topic HOIST ROPE REPLACEMENT.

1. Move the machine to an area sufficient to perform the repair and set the bucket on the ground under the boom point. Allow enough slack in the drag ropes so that the drag sockets are on the ground.

DRAG DRUM

DRAG ROPE ..l.C

CONNECTED TO

DRAG ROPE REEVING

FIGURE 74

2. Disconnect the drag ropes from the drag sockets and then secure the ropes to a ground vehicle.

3. Position a signal man in the machinery house in a position to observe the drag drum and ropes. Activate the drag drum slowly in the payout mode to spool the ropes from the drum.

At the same time, pull the drag ropes from the machine with the ground vehicle. Stop the drag machinery and ground vehicle as the last winding ofrope starts to spool from the drum.

Then very slowly rotate the drum until the left rope is completely off the drum and only secured to the drum with the rope clamps. The right drag rope will have one half wrap on the drum.

h CAUTION: Throughoutthis operation, .. a signal man is necessary to communicate drum or rope positions to the operator. Make sure that a system ofsignals is worked out in advance and that the line ofcommunication is unbroken.

4. Run the left deck winch line under then over the left side of the drag drum and securely attach it to the left drag rope. Remove the rope clamps and with the winch line, lower the drag rope to the deck.

5. Rotate the drag drum one half turn in the payout direction. Run the right deck winch line under then over the right side ofthe drag drum and securely attach it to the right drag rope.

Remove the rope clamps and with the winch line lower the drag rope to the deck.

6. With the ground vehicle, pull the drag ropes from the machine. The deck winch line will control the drag ropes as they are removed and will also.be reeved in position to pull the new ropes onto the machine. Disconnect the old drag ropes from the winch line and remove the old ropes from the area.

7. Check the condition ofthe drum rope grooves, rope clamps, guide sheaves and fairlead sheaves.