1 minute read

Hoist Rope Replacement

6. Reduction in rope diameter which indicates deterioration ofthe core. This will resultin lack of proper support for load carrying strands.

Excessive rope stretch or elongation may also be an indication of internal deterioration.

7. Evidence of "bird caging" or other distortion which results in some members of the rope structure carrying more load than the others.

8. Noticeable rusting or development of broken wires in the vicinity of attachments.

NOTE: If this condition is localized and the section in question can be eliminated by making a new attachment, do this rather than replacing the entire rope.

Lubricate the hoist and drag ropes at least twice every eight-hour shift with running wire rope lubricant (RWRL) as listed in Appendix. Give special attention to "bright spot" areas. These spots generally appear where the rope travels around a drum or over a sheave. When the use of wire rope is temporarily discontinued, lubricate the rope thoroughly and,if possible, place it on a reel and store it in a dry place. If the wire rope is left on the drum, thoroughly grease that part of the rope remaining on the drum.

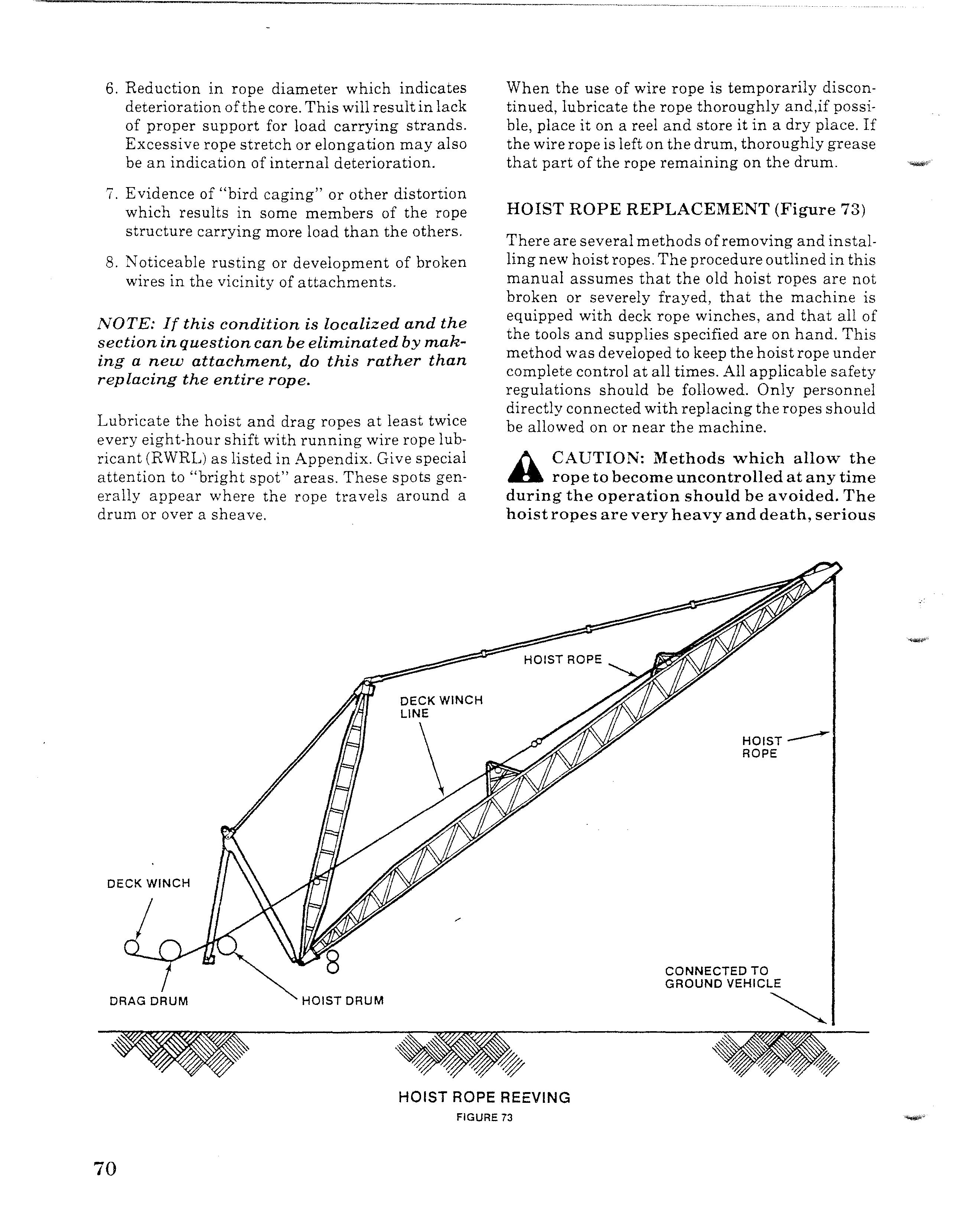

HOIST ROPE REPLACEMENT (Figure 73)

There are several methods ofremoving and installing new hoist ropes. The procedure outlined in this manual assumes that the old hoist ropes are not broken or severely frayed, that the machine is equipped with deck rope winches, and that all of the tools and supplies specified are on hand. This method was developed to keep the hoist rope under complete control at all times. All applicable safety regulations should be followed. Only personnel directly connected with replacing the ropes should be allowed on or near the machine.

ACAUTION: Methods which allow the rope to become uncontrolledatanytime during the operation should be avoided. The hoistropes are veryheavyand death, serious

DECK WINCH

DRAG DRUM HOIST-ROPE

HOIST DRUM

HOIST ROPE REEVING

FIGURE 73 CONNECTED TO GROUND VEHICLE