5 minute read

Superbolts ....................................................................5

BI016912-04 (EN-US)

Advertisement

Superbolt installation and specifications

Read all these instructions completely before you begin.

This procedure is typical for the majority of Superbolt products. Specific installation procedures that are shipped with all products may supersede this general procedure. Use the appropriate instructions shipped with the product you are installing. Contact Superbolt, Inc. at (412) 2791149 with any questions.

general tightening procedure

IMPORTANT! Air or electric power wrenches of the appropriate size may be used for running up jackbolts. Attempt to tighten as consistently as possible and remove the power wrench frequently; do not tighten all at once. Use a standard torque wrench to verify final torque values.

1. Superbolt products are designed for use with hardened surface washers. Slide the washer onto the bolt or stud first.

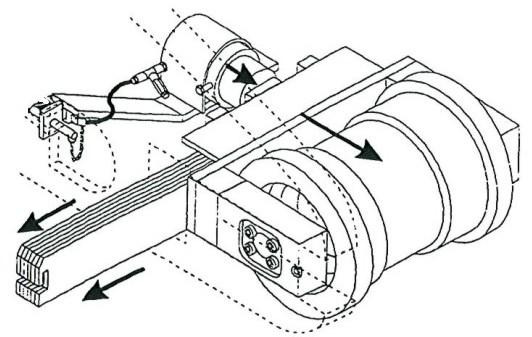

2. Check the base of the tensioner (s) and verify that all jack bolts are flush with the bottom of the tensioner body. (Fig. 227, View A).

3. Clear any dirt or chips from the threads of the bolt or stud and from the main internal thread of the tensioner. (Fig. 227, View A)

4. Spin the tensioner body down on the main thread of the bolt or stud by hand. The tensioner body should be in light contact with the hardened washer. (Fig. 227, View A)

5. Determine the target jackbolt torque value for the desired preload, either from the installation sheets shipped with the product or the catalog tables, or by calling Superbolt, Inc. The jackbolt torque value stamped on the tensioner is a standard value for that part, and may not be appropriate for your specific application. Since jackbolt torque is directly proportional to the tension load, you can easily figure other values as required (e.g., 1/2 preload = 1/2 jackbolt torque).

6. Start by snugging the jackbolts to 10% of the target jackbolt torque value from step 5. This seats the main thread and eliminates clearances. The star pattern shown in View B should be used for this initial tightening sequence.

7. Tighten the jackbolts in the star pattern to 50% of the target jackbolt torque value. (Fig. 227, View B)

8. Change to a circular pattern and torque the jack bolts to 75% of the target jackbolt value. (Fig. 227, View C)

9. Continue one more pass in the above circular pattern with 10% more torque than that of the target jackbolt torque value. (Fig. 227, View C)

10. Long bolts will stretch, so by the time you get back to the first jackbolt, it will be loose again. (Fig. 227, View C)

11. Set the torque wrench for the final torque value and continue to repeat the circular pattern until all jackbolts are torqued to the same value. do not exceed the torque value stamped on the tensioner without specific approval from Superbolt, Inc. (Fig. 2272, View C).

Fig. 227: Superbolt tightening sequence

View A View B View C

BI016912-04 (EN-US)

general loosening procedure

Superbolt lubricants

Jackbolts should be loosened with care. For longer bolts and studs, this procedure is even more important. Loosening can be accomplished quickly, but do not rush to completely loosen individual jackbolts. Remember that the intent is to slowly release the preload force. All jackbolts should be loosened uniformly, and usually there is no need to remove any jackbolt from the tensioner body during loosening.

1. Turn the first jackbolt counter-clockwise until it feels loose (no more than one half turn). The idea is just to unload each jackbolt, not to completely loosen it.

2. Move in a circular pattern to the next jackbolt and repeat Step 1.

3. Continue repeating until all jackbolts have been unloaded.

4. By the time you get back to the first jackbolt, it will be tight again. Repeat the process moving in a circular pattern.

5. Usually after two or three passes, the tensioner can be spun off the bolt or stud by hand. Long bolts or studs that stretch more may require extra passes.

6. Before reusing any tensioner, the jackbolts should be removed in the appropriate manner. The body and jackbolts should be cleaned and re-lubricated with SUPERBOLT approved lubricant to ensure proper jackbolt torque verses preload performance upon reinstallation.

The torque-preload relationship of Superbolt tensioners depends on the tension body and jackbolt materials, heat treatment, plating, lubricants and many other factors. Superbolt engineers have performed extensive tests to determine the best lubricants for the various materials utilized by Superbolt, Inc. Two custom lubricants, JL-G and JL-M, are offered by Superbolt, Inc.

■ JL-G is a lubricant paste made from selected flaky graphite and prime mineral oil. It has a relatively uniform friction factor of 0.130 under widely varying conditions. JL-G is used in the assembly of most SUPERBOLT products.

■ A number of commercially available graphite - or nickel - based lubricant compounds such as Fel-Pro C102 or Fel-Pro N5000 can be used for re-lubrication in the field. Copper bearing com pounds have not performed well as jackbolt lubricants.

JL-M is a lubricant paste made from molybdenum-disulfide powder and pure mineral oil. It has a friction factor of 0.045 to 0.070.

Tests have shown that when jackbolts are tightened the first time, the friction of JL-M is approximately 0.070. Each subsequent tightening reduces the friction factor lower until at the fourth tightening it levels out at approximately 0.050.

Superbolt, Inc. uses an average friction factor of 0.055 for torque calculations. It must be emphasized that the tensioners must be tightened several times to stabilize at the low values. After many repeat tightenings, the friction factor can be as low as 0.045. Due to these variations in friction factor, moly-based lubricants are used instead of graphitebased lubricants only in the following cases.

■ On very large jackbolts when the torque required for a specific preload would be too high; or,

■ Where space restrictions prohibit the use of sufficiently large torque wrenches.

In some cases, Superbolt tensioners are “broken in” at the factory to lower the friction factor for field installation.

Fel-Pro C-870 molybdenum-disulfide paste has performed similarly to JL-M. Other molybdenum pastes and greases tested had much high friction factors. Testing for friction factor is recommended for all critical installations where lubricant and/or bolt and nut materials are unknown.