3 minute read

Basics Of Circuit Operation

F-code Section C-code

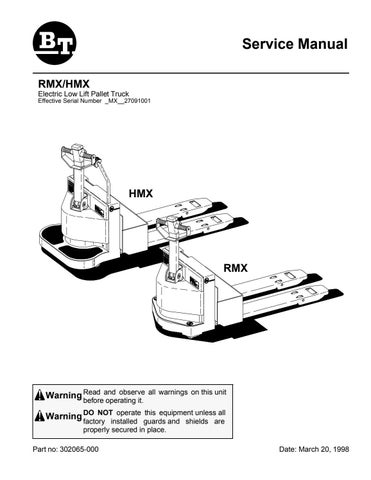

PS S5.10 5460 24 Volt, 300 Amp Transistor Controller

Version no T-code 000 RMX

The First Steps of Any Troubleshooting Procedure are to:

1.Inspect the truck for physical damage or mechanical malfunction. Contactors must be free to move and the tips must not be welded or burnt. 2.Check for ground faults from the electrical system to the frame with an ohmmeter. A minimum of 20,000 ohms resistance from the frame to any and all wiring is acceptable. 3.Check that the battery is fully charged and connected. 4.Operate the truck in all modes to determine the exact symptoms. DO NOT forget that these systems are equipped with safety circuits that prevent operation in the event of improper operating procedures.

2. Basics Of Circuit Operation

The Curtis© PMC SepEx™ model 1242 is a microprocessor based, programmable motor controller designed for separately excited motors. It is a true MultiMode™ controller capable of four distinct operating modes, or personalities, and is programmable with a Curtis© 1307 Programmer. In addition to programming the controller, the 1307 has Diagnostic and Test modes to display error codes and display the status of the controller's inputs and outputs. The 1242 controller includes an armature controller and a field controller. Both of which regulate the voltage and current applied to the motor according to a preprogrammed motor control algorithm. This motor control algorithm allows the user to select programmable speed and torque profiles that can be tailored to almost any material handling vehicle traction system. The polarity and magnitude of the field current is also controlled to provide solid state, contactor-less direction control and plug braking. The 1242 is energized by applying power to the key switch input, pin number 16. At that time the controller is powered up and performs an internal self test. The controller becomes active by applying power to the brake input, pin number 15. At that time, the following start-up checks are performed:

F-code Section C-code

PS S5.10 5460 24 Volt, 300 Amp Transistor Controller

Version no T-code 000 RMX

1.Checks to see if there is a short between M- and

Ground. This insures that the M- output or power

MOSFETs are not shorted. 2.Checks to see if there is continuity in the field coil. This also occurs each time forward or reverse is selected. 3.Checks to see if the main contactor coil has actually closed, when commanded, by checking for battery voltage at the B+ terminal. 4.Checks to see if the throttle is below 25 percent. 5.Checks to see if there is continuity in the emergency reverse wiring. The controller applies a brief pulse from the emergency reverse check output, pin number 10.

This pulse is read by the emergency reverse input, pin number 13. If the pulse is not present, there is an open circuit and the controller is disabled. This check first occurs during power up and runs continuously whenever the controller is powered. Selecting either forward or reverse will apply battery voltage to the respective input pin and select the direction of current flow in the field. Increasing throttle increases the voltage and current in the armature circuit. The field current will then follow a predetermined current map to match the armature current. In this manner, the motor is kept in its commutation range and arcing on the commutator is minimized. As the throttle is increased, and the motor speeds up the armature voltage will approach the battery maximum. If further increases in speed are commanded, the field will weaken automatically as directed by the field current map to provide the desired speed. Top speed is limited by limiting the minimum allowable field current, Further top speed limiting can be obtained by limiting the maximum armature voltage through the MAX. SPEED Parameter. Plug braking is initiated by selecting the opposite direction and applying throttle. The amount of plug braking is regulated by controlling the field and, consequently, the armature current, based on the amount of throttle applied. In this manner, smooth controlled braking force is controlled by the operator. A feature called “neutral braking” provides automatic plug braking in neutral. Whenever neutral is selected (releasing the throttle ever), a programmable amount of plug braking is automatically applied to bring the