3 minute read

Services to be Performed Monthly

F-code Section C-code

PS P2.0 Service Schedule

Version no T-code

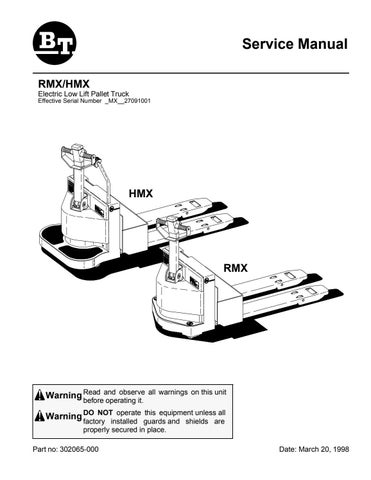

000 HMX,RMX

2.2. Services to be Performed Monthly

The monthly planned maintenance service should be performed by a qualified technician.

2.2.1. Inspection

All of the services and inspections listed above for the daily inspection should be performed at this time. The inspection procedure should be more thorough, and minor deficiencies should be corrected.

2.2.2. Transmission

Check the transmission fluid level. The level check point is a plug on the side cover of the transmission about 4 in. [100 mm] above the bottom of the transmission case. Remove the plug and inspect the level of the fluid inside the transmission case. The fluid level should come to about 3/8 in. [10 mm] below the plug and should never be above the level of the plug.

2.2.3. Brakes

The brakes should stop a fully loaded truck at full speed in approximately one truck length. The brakes should fully release when the control handle is moved down 12 degree from the fully raised position and should apply at 28 degree above the fully lowered position. Adjust the brake linkage as required.

2.2.4. Battery

Contact your battery dealer for specific instructions on care and maintenance of the battery. An average battery will have a specific gravity of 1.170 at the 80 percent discharged level. However, there are many different batteries on the market. Only the battery manufacturer can accurately determine the fully charged and 80 percent charged levels. Contact the battery manufacturer for this information.

2.2.5. Electrical Connections

1.All electrical connections should be checked that they are clean and tight. Plug-in connectors should be unplugged and plugged back in to clean the terminals.

F-code Section C-code

PS P2.0 Service Schedule

Version no T-code

000 HMX,RMX

2.If the truck is equipped with any of the cold-storage, freezer use, or corrosive environment application packages, the di-electric compound in the plug-in connectors should be renewed. This compound is available through the parts department of your authorized dealer.

2.2.6. Contactor Tips (NOT Sealed) Inspect contactor tips for arcing, pitting, or burning. Minor pitting of the tips is not a problem. However, if the tips are pitted through the tip to the copper bar, the tips should be replaced. DO NOT file tips. Replace tips only in complete sets. Some contactors have concealed tips or are fully sealed so that tips cannot be replaced.

2.2.7. Motor Brushes

Inspect the drive and pump motors for brush wear and condition of the commutator. Minimum brush lengths are given in the specifications section of this manual. As a rule of thumb, the brushes should be replaced if the brush spring is within 1/16 in. of touching the brush holder.

2.2.8. Drive Motor

1.Blow out the drive motor fan and vents. 2.Check for any signs of oil on the drive motor fan and air vents. 3.Check for any damage to the fan or air vents.

WARNING

Compressed air used for cleaning MUST be reduced to less than 30 psi., and then only with effective chip-guarding and personal protective equipment worn.

2.2.9. Hydraulic Reservoir

Check the fluid level in the hydraulic reservoir. The level check point is the line on the side of the reservoir.

2.2.10. Frame Lube (“Lubrication Chart” on page57)

The pressure type grease fittings (zerk fittings) should be lubricated with Texas Refineries #880 Crown and Chassis lubricating grease. The total number of grease fittings depends on the truck options when built. Cold-storage,

F-code Section C-code

PS P2.0 Service Schedule

Version no T-code

000 HMX,RMX

freezer use, or corrosive environment application package will have more grease fittings than a standard truck. Look for flush-type grease fittings on the load wheel axles. Regular grease fittings are found on the transmission pivet bearings.

2.2.11. Pivot Points

There are some pivot points and other items that need to be lubricated but do not have grease fittings. These include, but are not limited to, the control handle mounting shaft and the cylinder mounting pins. Lubricate these non-greasable wear points with a drip oil can using 10 wt. machine oil.