2 minute read

Services to be Performed Annually

F-code Section C-code

PS P2.0 Service Schedule

Version no T-code

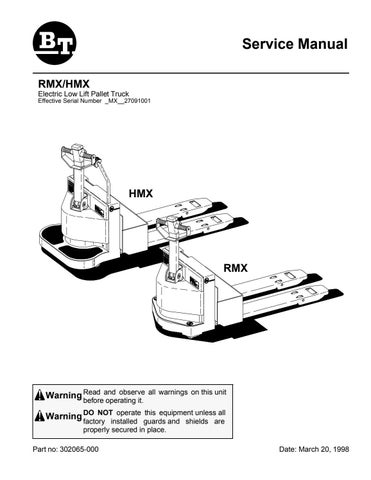

000 HMX,RMX

2.3. Services to be Performed Annually

The annual planned maintenance service will take a longer period of time to complete than does the monthly service. This would be a good time to arrange other repairs that have been noted on the monthly service.

2.3.1. Inspection

All of the services and inspections listed for the daily and monthly inspection should be performed at this time. The inspection procedure should be more thorough, and minor deficiencies should be corrected.

2.3.2. Transmission

The transmission fluid should be drained. The drain port is the lower left hand bolt holding the side cover in place. 1.Remove the bolt to drain the transmission fluid. 2.Flush the transmission case with safety solvent. 3.Pour clean solution into the level check plug in the side cover. 4.With drive tire off the floor, allow solution to run out of drain port while transmission is running. Stop flushing when the solution run clean. Allow the solvent to drain well before replacing the drain plug bolt. 5.Replace the drain plug bolt. 6.Refill the transmission with the proper clean oil before operating truck.

2.3.3. Battery

At approximately 1500 hours, contact an authorized battery dealer to determine the overall condition of the battery. Determine if the battery needs to be washed down. This can only be done by properly equipped and trained personnel.

2.3.4. Hydraulic System

The hydraulic system should be drained, flushed and refilled, and the pressure relief valve setting should be checked and adjusted.

F-code Section C-code

PS P2.0 Service Schedule

Version no T-code

000 HMX,RMX

WARNING

Before siphoning oil from reservoir, make certain siphon is clean.

To drain reservoir, disconnect and remove the hydraulic pump assembly. 1.Remove hydraulic reservoir from assembly. 2.Drain the oil and clean the inside of the reservoir. 3.Drain oil from hydraulic hose and lift cylinder. 4.Assemble hydraulic pump assembly and install on truck. 5.Fill reservoir with proper clean oil. 6.Operate raise and lower function several times to purge air from system. 7.Check oil level, fill to line. 8.Put rated truck capacity load on forks and adjust pressure relief valve, if necessary, so that truck will lift rated load.

2.3.5. Brakes

1.Remove brake drum, and inspect brake shoe linings and brake drum for wear. If the brake drum is damaged or worn, a new drum should be fitted. 2.The brake shoes should be replaced if the linings have worn down so much that the brakes will not meet stopping and holding specifications. 3.See the procedures for adjusting brakes before replacing the brake shoes.