2 minute read

Service Training

from Bomag BW 145 D-3 DH-3 PDH-3 Single Drum Rollers Service Training Manual 00809955 - PDF DOWNLOAD

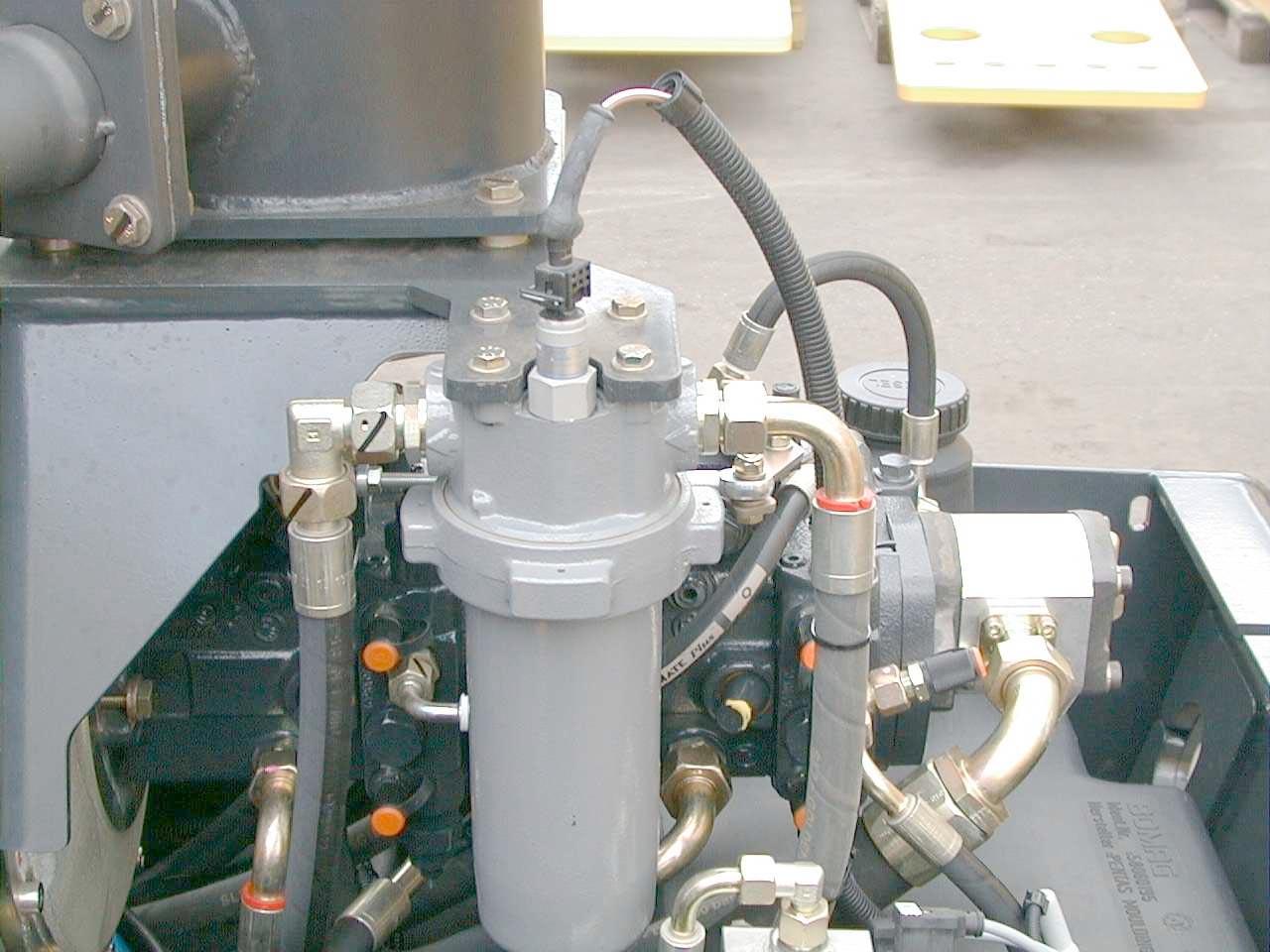

A flushing valve integrated in the travel motor permanently flushes oil out of the low pressure side into the motor housing, in order to supply the circuit permanently with cooled and filtered oil. The flushed out oil leaves the motor together with the leak oil and flows to the tank thermostat.

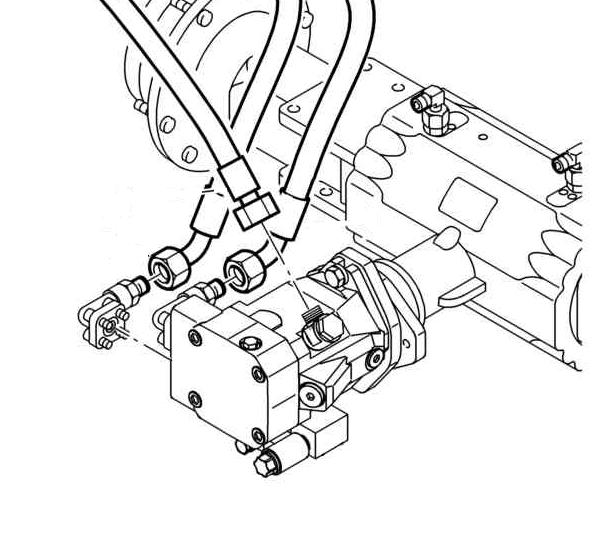

Test and adjustment points, travel system

Measuringvalues 1Chargeandsteeringpump09 2SteeringpressuretestportMB170+/-15bar

Pos.DesignationPos.inwiringdiagramPos.inhydraulic diagram

Measuringvalues pressure,2.5

Pos.DesignationPos.inwiringdiagramPos.inhydraulic diagram

1Highpressureportreverse12,R

2Highpressureportforward12,L

3Brakereleasingline12

4Crossflushinginlet12

5Crossflushingoutlet12,1

Measuringvalues

Pos.DesignationPos.inwiringdiagramPos.inhydraulic diagram

Measuringvalues

Pos.DesignationPos.inwiringdiagramPos.inhydraulic diagram

Measuringvalues

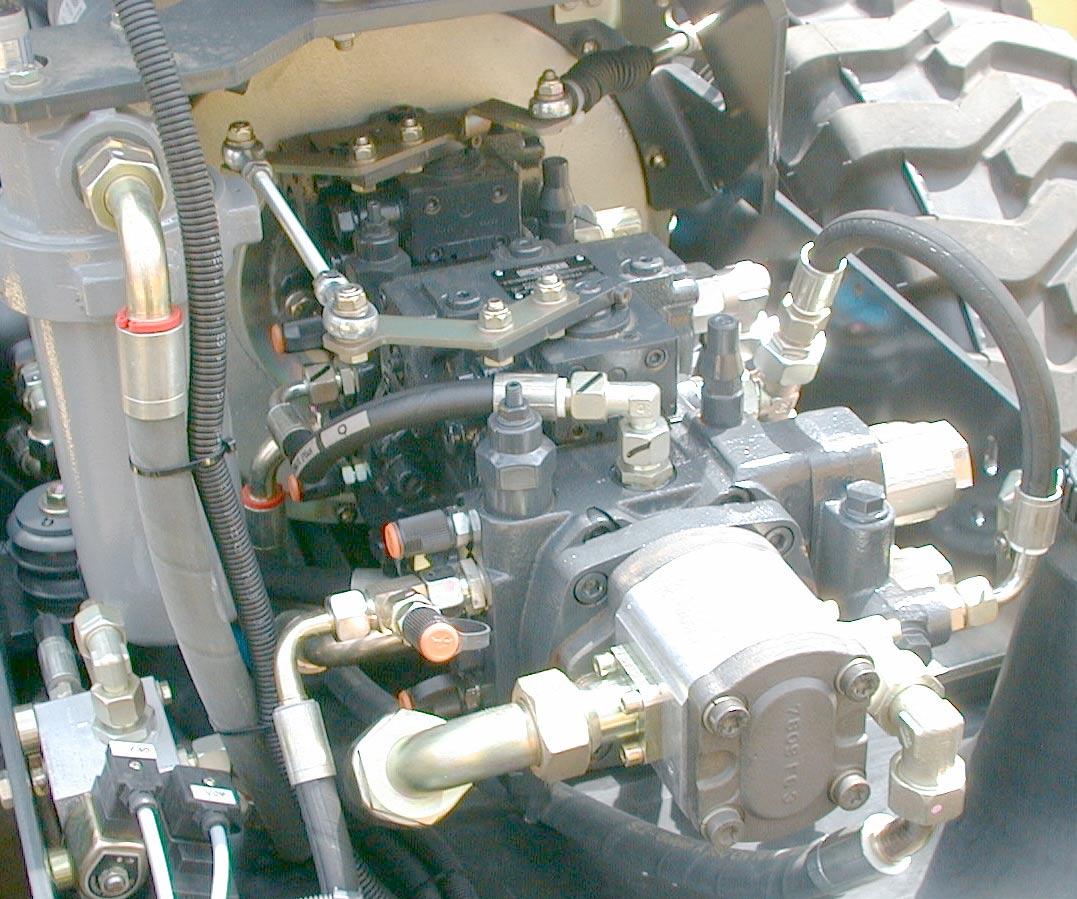

Adjustment / inspection of the double pump actuation kinematics

The two pumps of the tandem travel pump unit (only BW 145 DH / PDH-3) must deliver absolutely identical flow rates for drum and axle drives. If this is not true the travel system will lock up, the system will overheat and the machine does not reach the full travel power.

For this reason the mechanical control kinematics must be exactly adjusted. The adjustment / inspection of the adjustment must be performed as follows:

• Detach the travel cable (front pump)

• make sure that the fastening screws of the actuating levers are tightened on the pump lever and that the actuating levers are not damaged / bent.

• Slacken the pump lever clamp screws, so that the levers can rotate freely on the shafts. This is necessary, so that the pump control shaft stays in neutral position during the following adjustment.

• Measure dimension X 1 between the centres of the control shafts.

• Measure dimension X 2 between the centres of the fastening screw heads on the connecting rod. The ´values for X 1 and X 2 must be identical. Furthermore, the 4 points – centres of pump shafts and pivot points of the connecting rod – must form an imaginary rectangle (4 x 90 °, see sketch). If necessary adjust dimension X 2 on the connecting rod. For this purpose slacken the counter nut and turn the rod. After the adjustment tighten the counter nut again and check dimension X2 again.

• Retighten the clamp screws for the pump levers.

• Pull the plug off the brake valve, connect 600 bar pressure gauges to all 4 travel pressure test ports Start the machine and check all pressures in neutral position. All pressure test ports must only show charge pressure. Otherwise the pump adjustment needs to be corrected as described above.

• Set the travel lever on the operator’s platform to neutral position. Then check whether the bore in the travel cable aligns with the bore in the actuating lever. If necessary correct the travel cable adjustment at the guide tube fastening point.

• Attach the travel cable to the actuating lever.

• Check the pressures once again at neutral position.

Trouble shooting

The following trouble shooting chart contains a small selection of possible faults, which may occur during operation of the machine. The fault list is by no means complete, however, the fault table is based on the experience of the central service department, i.e. the list covers almost all faults that have occurred in the past.

Procedure:

The following trouble shooting table contains both electrical as well as mechanical and hydraulic faults. The number specified in the table indicate the probability of the fault cause and thereby the recommended trouble shooting sequence, based on our latest field experience.

Troubleshootingtravel System

BW145-FAMILY

Possiblecauses

Bakevalve(electrical/mechanical/hydraulical)1

BremseinFahrmotor/Achse(mechanisch/hydraulisch)323

Travelcableadjustment12 mech.Neutralpositiontravelpump33

Adjustmentofactuationkinematicstravelpump(DH/PDHonly)22

Travelpump(s)defective332

Qmax-AdjustmentAxledrivemotor2

Qmin-AdjustmentAxledrivemotor22

FlushingvalveAxledrivemotorsticks3

TravelMotor(s)defective33

Hydraulicoilcoolerdirty(internally/externally)1

Thermostat(Hydraulic)dirty/sticky/defective2

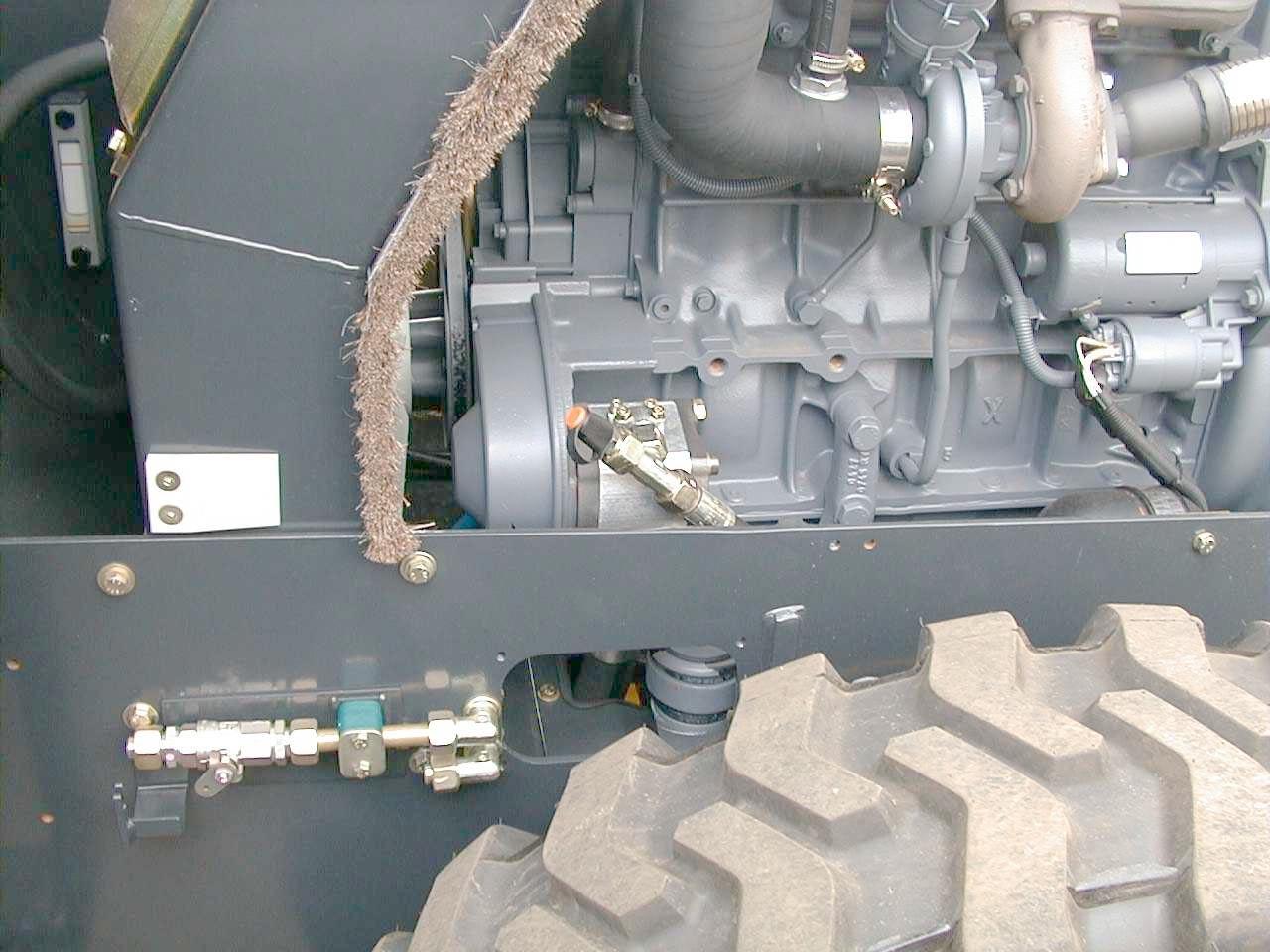

CouplingEngine-Pump2

DieselEngine1