Drivetrain/Track/Brake Systems This section has been organized into sub-sections for servicing drivetrain, track, and brake systems; however, some components may vary from model to model. The technician should use discretion and sound judgment when removing and installing components.

NOTE: When installing a new drive belt, see After Break-In Checkup/Checklist - Drive Belt Break-In in the General Information/Foreword section. REMOVING

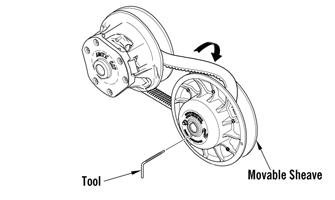

1. Set the brake lever lock; then remove the left-side access panel. Loosen the 1/4 turn on the lower console. 2. Using Drive Belt Deflection Tool, thread the tool clockwise into the driven clutch until the movable sheave opens far enough to remove the drive belt.

NOTE: Whenever a part is worn excessively, cracked, or damaged in any way, replacement is necessary. SPECIAL TOOLS

A number of special tools must be available to the technician when servicing the drivetrain, track, and brake systems. NOTE: When indicated for use, each special tool will be identified by its specific name, as shown in the chart below, and capitalized. Description

p/n

Drive Clutch Bolt Tool

0644-281

Drive Belt Deflection Tool

0644-424

Bearing Removal and Installation Tool

0644-167

Movable Sheave Bearing Tool

0644-594

Clutch Alignment Bar

0744-097

Drive Clutch Puller

0744-062

Drive Clutch Spanner Wrench

0644-136

Driven Clutch Compressor Tool

0644-444

Rear Suspension Spring Tool

0144-311

Brake Caliper Bearing Puller

0744-067

NOTE: Special tools are available from the Arctic Cat Service Parts Department.

CAUTION

743-067B

INSTALLING

1. Place the belt (so the part number can be read) between the sheaves of the drive clutch. 2. With the sheaves fully apart, roll the belt over the stationary sheave. 3. With the drive belt properly positioned in the drive clutch and driven clutch, turn the belt tool counterclockwise, release the brake lever lock, and roll the belt back and forth to allow the driven clutch sheaves to fully close. 4. After the belt is installed properly, secure the left-side lower console and the access panel.

Never attempt to substitute any other drive clutch puller for the recommended puller or severe clutch damage will occur.

Drive Belt If the drive belt is longer than specified, the drive clutch and driven clutch will not achieve full shift ratio. This will result in poor acceleration and a decrease in top speed. If the drive belt is shorter than specified, the starting ratio will be higher causing the belt to slip. A too-short drive belt will cause a bog on engagement and will not allow the engine to reach peak RPM. NOTE: A thinly-worn drive belt may produce the same effect as one that is too long. NOTE: A stiff belt causes a HP loss to the track. As

a belt warms up, it gets more flexible and transmits power with less HP loss.

82

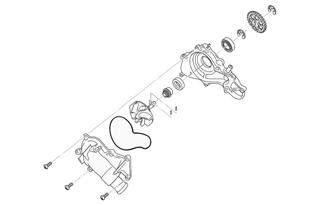

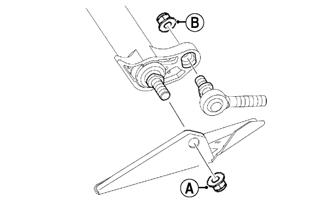

Drive Clutch CHANGING CAM ARMS/SPRINGS Removing

1. Using Drive Clutch Bolt Tool, remove the Torx-head screw and lock washer securing the drive clutch to the crankshaft. NOTE: Before installing the clutch puller, apply oil to the threads of the puller and a small amount of grease to the tip of the puller.

2. Using the Drive Clutch Puller and the Drive Clutch Spanner Wrench, tighten the puller. If the drive clutch will not release, sharply strike the head of the puller. Repeat this step until the clutch releases. 3. Remove the drive clutch from the engine compartment.