2. If measurement is not as specified, use an appropriate spanner wrench to adjust the left and right spring as required.

Suspension The following suspension system components should be inspected periodically to ensure proper operation. A. Shock absorber rods bent, pitted, or damaged. B. Reservoirs damp or leaking. C. Shock absorber body damaged, punctured, or leaking. D. Shock absorber eyelets broken, bent, or cracked. E. Shock absorber eyelet bushings worn, deteriorated, cracked, or missing. F. Shock absorber spring broken or sagging.

WS003A

G. Sway bar mountings tight and bushings secure. H. Proper pre-load and damping for conditions.

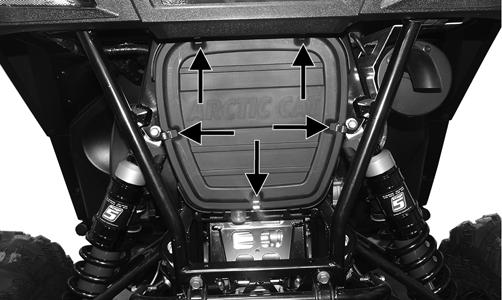

3. Measure from the ground to the bottom of the skid plate along the receiver hitch. Measurement should be 13 inches.

SPECIAL TOOLS A number of special tools must be available to the technician when performing service procedures in this section. Refer to the current Special Tools Catalog for the appropriate tool description. Description

p/n

Shaft Bullet Tool

0644-404

Inflation Needle

0644-604

Piston Location (IFP) Tool

0644-575

Gas Shock Rod/Body Clamping Tool

0644-425

NOTE: Special tools are available from the Arctic Cat Service Department.

WS014B

4. If measurement is not as specified, use an appropriate spanner wrench to adjust the left and right spring as required.

Shock Absorbers CHECKING/ADJUSTING RIDE HEIGHT NOTE: Ensure the vehicle is on level ground, the tires are properly inflated to 12 psi, and there is an average operating load in the vehicle.

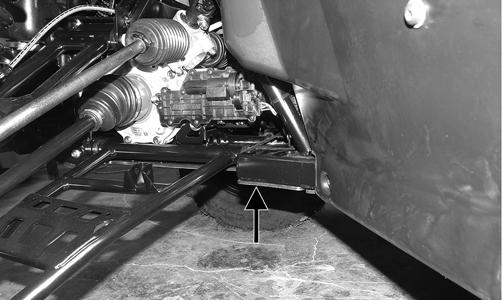

1. Measure from the ground to the bottom of the skid plate behind the lower A-arm. Measurement should be 13 inches.

WS005A

ADJUSTING SHOCK COMPRESSION (Sport/XT) NOTE: The JRI shock absorber comes with a 70position Compression Adjuster for a stiffer or a softer ride. The adjuster dial is located at the bottom of the shock.

Turn the dial towards the + position for more compression (stiffer) or the - position for less compression (softer). WS012A

155