Helena Bradley F033884

5

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.2

4.3

4.3.3

4.3.4

4.4

5.1

5.2

7.1

7.4

The initial project brief was to promote and support sustainable habits in order to reduce the consumption of single use products

This was then focused in to design a product which assists with and promotes the use of reusable cups in a university environment to increase uptake in reusable cup schemes and in turn reduce disposable cup waste.

1.1. STAGE 1 KEY FINDINGS SUMMARY

1.1.1 Reusable Cups

A study by Keep Cup showed reusable cups carbon footprint is 88% lower than compostable cups and overtakes a disposable cup after only 10 days.

The three most common brands are: KeepCup, Ecoffee Cup and Rcup.

1.1.2 Universities

Majority of universities have reusable cup schemes with incentives and are also increasing supply of drinking water to reduce plastic waste.

About 60 000 drinks are sold in reusable cups in a university each year with the number of drinks bought in reusable cups increasing each year.

1.1.3 Pain Points

Carrying and transporting the cup once it is dirty or contains some liquid.

Cleaning the cup between uses during the day.

Forgetting to clean the cup and dirt/stains getting worse and building up.

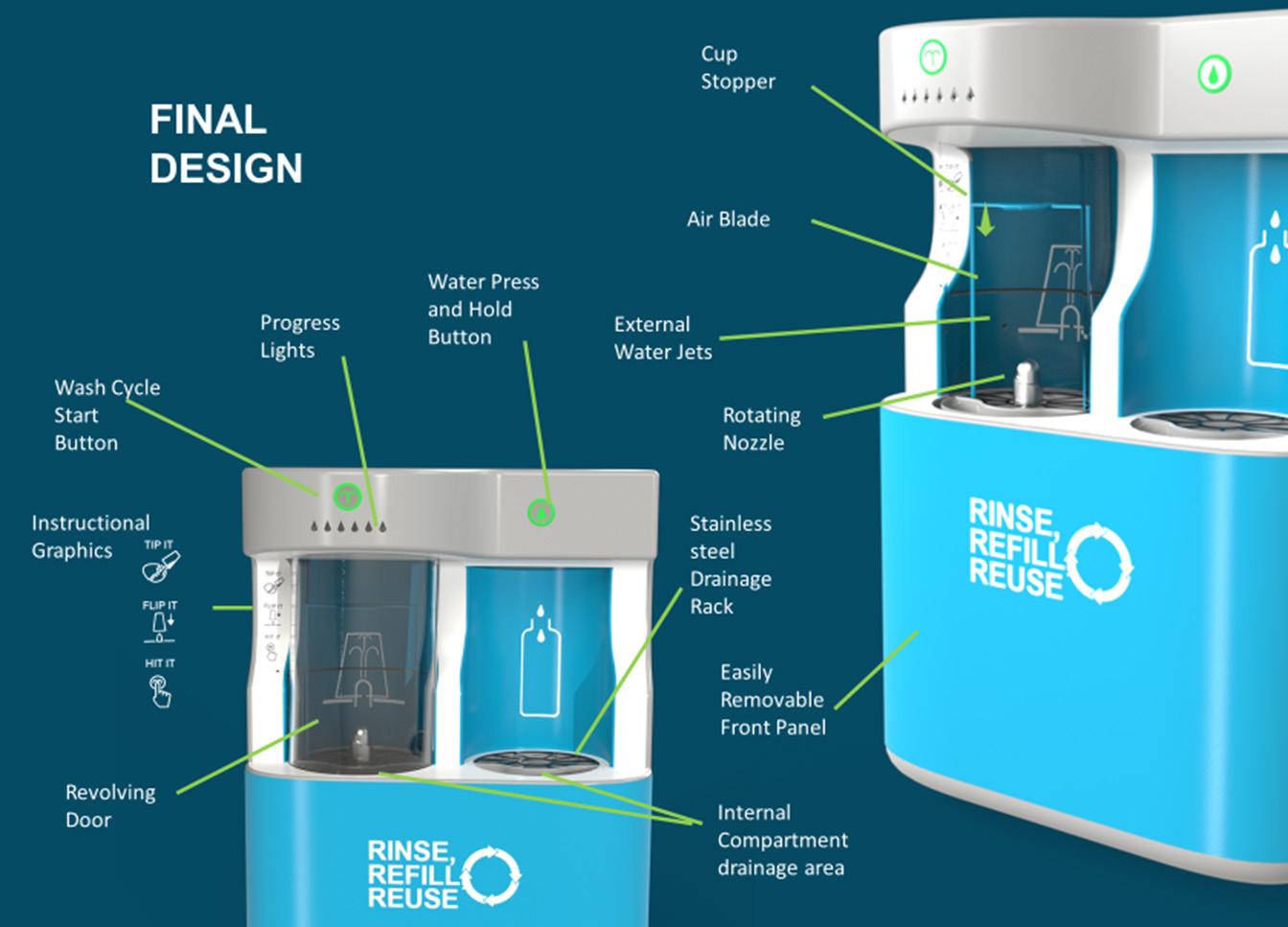

The final design, the eco wash and hydrate station, is a combined reusable cup washer and bottle refill fountain making managing and using your reusable items on-the-go simple. The stations will be wall mounted within universities in key locations for students and staff to use as they go about their day-to-day activities.

With the awareness of sustainability and the requirements of businesses to reduce their impact growing, many universities are currently taking steps to reduce their environmental impact. A key movement is the push to eliminate single use plastic bottles and disposable coffee cups. By doing so they both meet the needs of their customers of which a growing number now use reusable products and increase their marketability to new students. Whilst carrying and refilling a bottle is becoming standard practice the use of reusable coffee cups is still on the rise. There is now a clear gap in the market to provide the facilities needed to support their use as a water fountain does for a bottle.

The wash half features a cylindrical compartment with automated revolving door and wash cycle featuring hot wash, cold rinse and air dry supplied as jets through a revolving nozzle central nozzle and wall nozzles. It also features an automated stopper that holds the cup down during the cycle. The wash cycle is activated by the user pressing a start button and a series of lights act as a progress bar to indicate wash cycle progress.

The bottle refill side provides chilled water and is activated by a push and hold button. Both sides feature an internal drainage area at the front of either compartment.

To wash a cup the user will walk up to the station, pour away any excess fluid at the front of the compartment and then place the cup upside down over the nozzle on the drainage plate. Once the cup is in place the user presses the start button which activates the cycle. The door automatically closes, and the stopper moves down until it senses the top of the cup and stops. The door then locks and the wash cycle commences. LED lights at the top indicate the process completing. Once complete the door unlocks, automatically opens again and the user removes their cup. The progression of use is displayed within the storyboard:

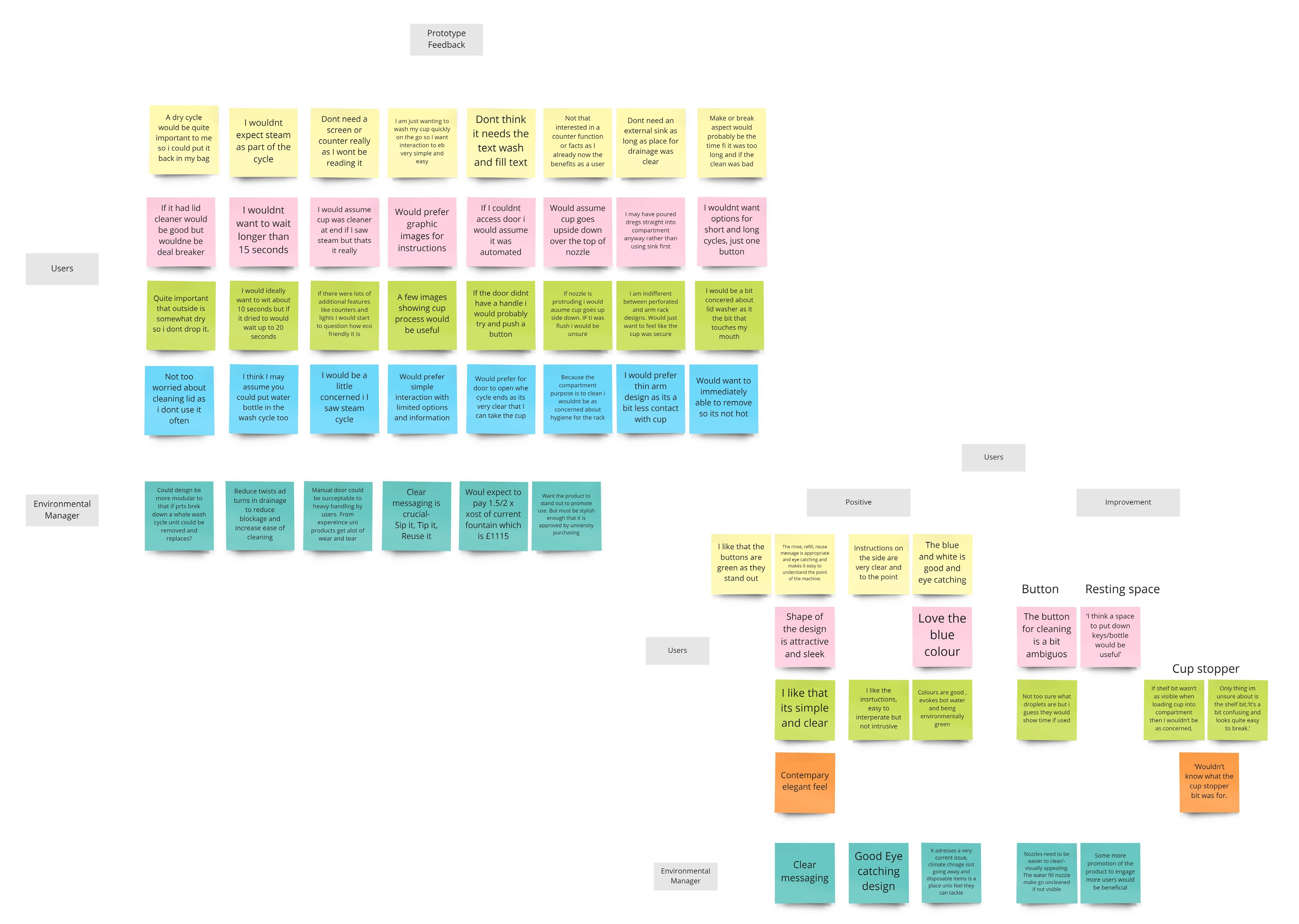

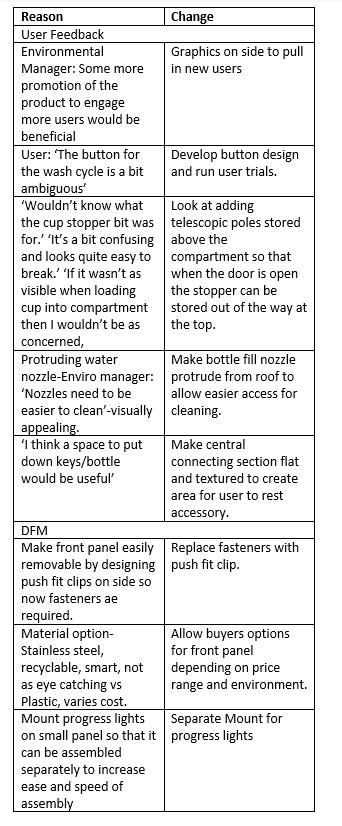

The table and annoated images highlight the key design changes that were made as a result of prototyping and development in stage 2. Most decisions were made as a result of multiple tests combined with user feedback. The majority of user feedback was collected during a series of overall prototyping feedback interviews with users which are expanded on within the evaluation section. User evaluation of the final resulting design was then carried out and further design changes suggested. For more information on the development of the rotating nozzle and air blade see portfolio pages 34,35 and 66,67.

Aesthetic & Interaction

A Sink, Tapered base and double circle top

B Cup stopper attached only on one side and also holds lid

C External sink

Simplified streamlined modern shape

Attached at two points from underneath

Drainage areas combined with each compartment

D Small holes drainage rack design

Larger gaps start drainage rack design

In keeping with products on market popular among users and universities.

Stronger design that allows door to rotate within compartment rather than within body of product.

Reduce risk of dripping drink between sink and compartment

Make action one fluid movement

Reduce material consumption to produce product

Less contact surface area with cu. More space for water to flow out of cup.

Space for thicker fluids, food to pass through.

E Aesthetics- Neutral Colours Colour Accents added To suit university environment often featuring bright accents

To draw attention to product to encourage engagement.

F Single Nozzle Rotating Nozzle By rotating the nozzle, it allows more surface area of the cup to be covered by water jets with less jets.

G No Instructions Instructional Graphics

Was established some guidance was needed to reassure users and that graphics were preferred to words

H Sensor Activation Button Activation Less opportunity for system failure & less parts.

User feedback showed people found button initiation more intuitive and reassuring.

Functional

I User manually opens door Door automatically closes and shuts once cycle is activated.

J Station sits with door closed Station sits with door open-

Reduced user interaction and therefore reduces risk or users damaging mechanisms.

Reduces cross contamination of germs. Increases ease and intuition of process. Users find it more intuitive to find device in state It will be left. Can’t rely on people to manually reset door.

Allows compartment to dry and if people walk up to open door, they are less likely to try and shut it before starting cycle

4.1 NOZZLE AND WASH CYCLE TESTS: FUNCTIONAL PROTOTYPES

4.1.1 Purpose

• What nozzle exit size it the most effective? 1mm,2mm,3mm?

• What is the most effective nozzle design to target dirty coffee cups?

• Is hot water required in the wash cycle to remove dirt?

• If yes what temperature water is required?

• If yes it confirms the need of a door to the compartment for safety

• What timings for the wash cycle get the best results?

• How long are users willing to wait?

• Does steam improve the wash process?

• Is it enough to validate the additional energy and wash cycle time?

4.1.2 Prototypes used

• FDM Plastic Additive Manufactured 1mm/2mm/3mm Single jet and Quadruple Jet nozzle

• SLA Resin Additive manufactures Dual Direction jet nozzles 1mm & 2mm.

• Nozzle and hose pipe Rig. 3D printed holder attached to connected containers

• Low fidelity to allow low cost and quick set up.

• Steam Cleaner adapted to test steam application

4.1.3 Test Process & Prototype Development

1. Cup dirt Analysis

2. Manufacture Single Jet nozzles and rig set up

3. Single Jet Nozzle Tests

a. Does set up Work

b. How effective are single jet nozzles?

c. 1mm, 2mm o4 3mm jets more effective?

4. Manufacture quadruple jet nozzle

5. Manufacture Dual direction nozzle

6. Nozzle Test round 2

a. Comparing the effectiveness of different design

b. How long does the cycle need to be?

7. Hot Water Test

a. Does hot water improve the wash process?

b. What is lower temperature which is still effective?

8. Steam Cleaning Test

a. Does steam improve cleaning results?

b. Steam applied to variety of cups for different time lengths.

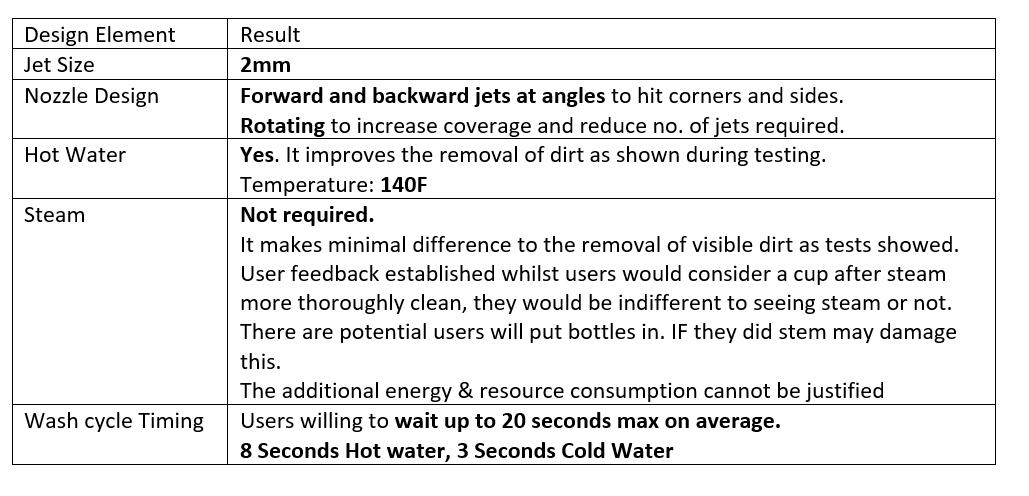

4.1.4 Key Results

4.2.1 Purpose

• Should door be closed automatically or manually?

• How should cycle by started?

• Should station sit with door open or closed?

• What labelling & graphics is required?

• Casing form development

• What height should the station be mounted at for accessibility?

• Sizing: Compartment, button

• Refine size and placement of sink for drainage?

• Drainage rack design?

• Is it intuitive to use?

4.2.2 Prototypes Used:

• Main Cardboard Model with Iterations:

o External Sink

o Thin compartment roof

o Thick sweeping compartment roof

o Metal drainage rack- Perforated

o Star design arms drainage rack

o Cup stopper- Cardboard/Plastic/Metal perforated

o Compartment Light

o Labelling & Graphics

4.2.3 Test Process & Prototype Development

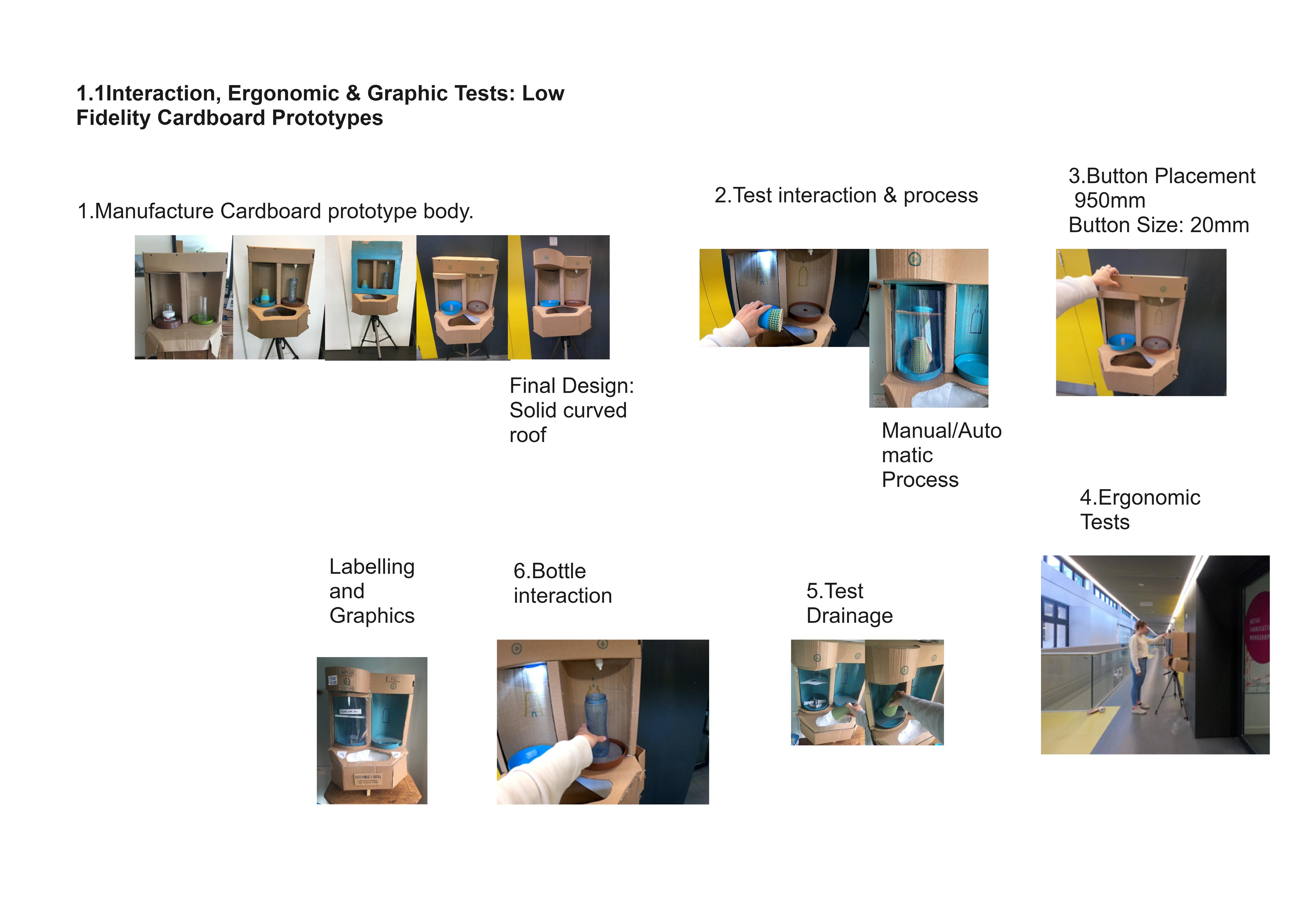

1. Manufacture Cardboard prototype body.

a. Using cardboard sheets, Stanley knife to score card to produced rounded shapes, hot glue to assemble.

2. Test interaction & process

a. Put plastic tray in prototype to allow for real water to be used

b. Film to allow for user review

3. Test different body shapes and button placement.

a. Attach variations of front panel form/

4. Ergonomic Tests

a. Height

b. Reach

c. Size

5. Test Drainage

a. Bottle and cup

b. Ease of movement

c. External vs within compartment

6. Bottle Interaction

a. Sizing

b. Process

4.2.4 Key Results

Here is a table summarising the results of the various stages of testing. Summary of user feedback is included in some sections to explain decision. The overview of the user interviews is given at the end of the prototyping section of the report

4.3 INTERACTION AND FUNCTIONAL TESTING: FUNCTIONING PROTOTYPE

4.3.1 Purpose

• Give more realistic interaction to allow for better visualisation of product and user feedback

• Allow for interaction with liquid

• Aid development of internal components and electronics

• Test drainage

4.3.2 Prototypes Used:

• Functioning prototype made of plastic components to allow for functioning interaction with water and liquids

o Electronics controlled water supply to each side, lights and switches.

o Main body is a plastic container. Compartments made of heat formed HIPS

o 3D printed guides to assemble compartments.

o Perforated metal drainage plate from cardboard prototype

o 3D printed nozzles from nozzle prototyping.

o Laser Cut front panel to mount lights and switches.

o Rate of water flow for bottle filling?

4.3.3 Test Process & Prototype Development

1. Visible wash cycle

a. Filmed to give better visualisation for user feedback on product

2. Bottle fill interaction

a. What water flow rate is ideal?

3. Drainage

a. Test perforated metal drainage alongside compartment drainage.

b. Drainage: Tests showed that the compartment tray was not draining quickly enough through the 8mm tube and would overflow at the end of longer cycles.

c. Tests perforated rack with thicker, lumpy fluids (hot chocolate)

4. Light Use

a. Do lights help indicate use of product and invite users?

5. Wash Cycle

a. Water nozzle jet, external nozzle jet, steam

b. Visualise process

4.3.4 Key Results

The main feedback for the design elements across the prototypes was collected in a series of interviews with users online in which videos and pictures of the nozzle, cardboard and functioning prototype were shown. This feedback was collected within one interview following completion of all prototypes to allow for in depth review, and a range of sources to provide visualisation of the product for the user. These results have been included within the results tables of the previous prototyping sections as they were used to feedback into the devlopment process. An overall summary of feedback can be seen on the next page. Videos used within evalutation and prototype testing can be seen here: https://www.youtube.com/channel/ UCeTnj08_s9_WZ1hNqIVL5kw.

When selecting particpants it was atempted to get a range of users, however due to the time delays cuase by covid isolations and the overlal covid restrictions this was also somewhat a conveneinve sample.

1.

Gender:Female

Age:24

Occupation: PHD Student

2.

Gender: Female

Age:22

Occupation: Graduate Scheme-Sales

3.

Gender: Female

Age:25

Occupation: Graduate Maufacturing Engineer & masters student

4.

Gender: Male

Age:27

Occupation:Software Analyst

A online evaluation of the prototypes was also carried out with the environmental manager of a university, an expert in sustainability and a customer.

The final user evaluation was conducted online using CAD renders of the developed design alongside storyboards and functioning protoypye videos to aid visualisation of the product and process. Key comments can be seen summarised ont he next page.

Participants:

1.

Gender: Male

Age:27

Occupation:Software Analyst

2.

Gender: Female

Age:22

Occupation: Graduate Scheme-Sales

3.

Gender: Female

Age:56

Occupation: Medical Phycisist

4.

Gender Male:

Occupation: Univeristy Environmental manager

The diagram and table summarises the design chnages to be made as a result of final design evaluation. Overall the feedback was positive with some minor changes identified. In addition to these chnages identified if this productdevelopment was to be continued to manufacture and sale, due to its complexity further safety testing, user feedback with a market ready prototype and furher manufacturing development would be required. These were not completed in this project due to the time scale and input of only one person as well as delays caused by covid isolations.

The product is made up of a large number of varying components and units. A large majority of these would be purchased as off the shelf items and then assembled on site. Some units such as the water cooling unit would be developed with a subcontractor to fit the product requirements and then delivered as a unit for final assembly.

In addition many of the custom plastic parts such as the casing and internal funnel from the fan to compartment air blade would require mould design and set up with subcontracotrs and add to the start up costs. To increase the sustaianability of the product companies who can guarantee renewable energy consumption only, waste recycling and reduced shipping would be chosen. Further more the parts would be designed to reduce the number of materials and componeets, particulalry fastners to reduce consumption, make it easily repairable and designed for dissasebly at end of life. Furthermore a lifecycle assessment of the whole process would be completed.

Buyer: UK university product purchasing & environmental teams

User: Attendees of the university. Mainly students and staff.

Market size:

Initial Market:

• 106 UK Universities. ~60000 drinks per year per uni sold in reusable cups.

Expanding market:

• 25892 coffee shops In the UK.

• All UK customers

Delivery: Retail. Online Sales.

Volume: A university is likely to tart with a purchase of 3 to try before investing in more.

Yeah 1 sales target:~30 (UK universities and university associated buildings)

Year 2 Sales target: ~50 (UK universities and other businesses offices)

Year 3 sales target:~60

Marketed online via website adds, youtube & product webiste. Marketed at key shows such as the British Water Cooler Assciation trade show. Become a member of the YHA as well to be promoted as a member on their

website and in workplace and trade publications and wider business press. Membership also gives customers confidence in the service and product due to their demanding food safety standards and UK legislation.

The unit is wall mounts and connected to the buildings water supply, electricity and waste disposal system. This allows for a continuous water supply, power for the refrigeration unit, electronics and interface and disposal of waste water without manual intervention. A stainless steel bracket will be supplied to fix to the wall that the main product is hooked onto.

Hermetically sealed refrigeration system provides chilled water. In hermetically sealed compressor, the compressor and the motor are enclosed in the welded steel casing and the two are connected by a common shaft. This makes the whole compressor and the motor a single compact and portable unit that can be handled easily. They also require less maintenance, have a longer life span and are easier to install. The cooling system works by a compressor which pumps the refrigerant through the condenser which features a fan to assist cooling as the heat it radiated. The refrigerant then reaches an expansion valve at which it is able to suddenly expand into a gas, taking heat out of the surrounding environment. It does this as it passes through the heat exchanger where the water is fed through to cool it.

A direct chill system will be used where within the heat exchanger the water is passed through stainless steel piping coiled alongside copper piping carrying the refrigerant gas. This means the water can be cooled instantly as it travels through the piping and does not need to be stored in a tank. It also means the water never comes into contact with the atmosphere.

The product also features an air supply produced by a fan which is split between the nozzle and the external air blade. The fan unit would be purchased form a subcontractor and them assembled to the air blade funnel and nozzle onsite. The air blade funnel would be cutom deisgned and manufactured using injection moudling.

The water supply is plumbed into the mains at the wall and is attached to a filter.

Total cost of parts per product: £882

Manufacturing costs per product:

Delivery of components: £32

Assembly of components and packaging: 2 hours: £24 labour + £2

Resources +£1 Building= £27

Packaging: £3

Delivery to customer: £12

Total Cost: £74

Total Production cost per unit: £956

Retail Price £2,600

Purpose Section Part £ per product

Water Supply

Connection Y splitter

U-bend- waste water trap

Copper Pipes

Source Manufacturing

£2.59 https://www.bes.co.uk/y-piece-hoseconnector-3-4- -x-3-4-m-bsp-brass23521/?ref=gs&gclid=CjwKCAjw4KyJBhA bEiwAaAQbE5-h-mRNzLZhgLYK-42onWQKJM6NvfuaC8Fkgwaa0GJJxMhtvI jnRoCetAQAvD_BwE

£2.89 P Trap with 76mm Seal 32mm https://www.toolstation.com/p-trapwith-76mm-seal/p16995

£0.83 https://www.screwfix.com/p/wednesbu ry-copper-pipe-15mm-x3m/98683?tc=OT2&ds_kid=9270005528 1954514&ds_rl=1249404&gclid=CjwKCAj w4KyJBhAbEiwAaAQbE20fkSFDrZc9jZWhk1xo4GxE9E5eALtnrtPjfxNylFNKWg7Hr_ qBoC9BgQAvD_BwE&gclsrc=aw.ds £10/12

Off the Shelf Part

Off the Shelf Part

Off the Shelf Part

Flexible tubing

Filter

Fittings

Nozzle Bespoke Rotating water and air nozzle

Control Solenoid *2

Cooling Compresso r & Fan

Condenser Condenser

£1.26 https://www.toolstation.com/washingmachinehose/p71370?store=EF&utm_source=go ogleshopping&utm_medium=feed&utm _campaign=googleshoppingfeed £3.78/3

£42 https://www.watercoolersdirect.com/w cdf4000-1-micron-cold-water-filtertwist-fit

£5

Off the Shelf Part

Off the Shelf Part

Off the Shelf Part

£8 Designed in house, Manufactured by sub-contractor

£15 https://www.amazon.co.uk/gp/product/ B07171LNYR/ref=ppx_od_dt_b_asin_titl e_s00?ie=UTF8&psc=1

Off the Shelf Part

UneMJZVf&terminal_id=397fe375e13e4 b51a37b8664c58a022c

Copper refrigerant coil £18.4 https://www.screwfix.com/p/wednesbu ry-wednesbury-microbore-copper-pipecoil-10mm-x10m/82431?tc=OT2&ds_kid=927000552 81954514&ds_rl=1249404&gclid=CjwKC Ajw4KyJBhAbEiwAaAQbEwlGRZVfB9GHk ttyOFEeKey2WXaf3BEhCSuAa5Jrkv6B3FA8Qk NNxoCv4EQAvD_BwE&gclsrc=aw.ds 0.8* £23

Insulated Casing £3Materials

£100Bespoke design set up

Casing Side panels with vents Injection Moulded £12

Main Body

Wall Mount Stainless Steel Bracket

Motor & Door Track & Reed Switch

£130 https://crwltd.co.uk/embracocompressor-r134a-hbp-2000-p.asp Capillary (control flow)

0.3 https://www.airconspares.com/airconditioning-refrigeration-copper-tube6-4mm-1-4-inch-6-metrecoil?gclid=CjwKCAjw4KyJBhAbEiwAaAQb E5j1iFhP73P4CHUpsFgXD7OcUf6gxussrNHLepGZPI itpZgZWOIWhoCe4IQAvD_BwE Heat Exchanger 10m chilling coilStainless Steel

£40 https://crwltd.co.uk/embracocondensing-unit r134a hbp-63-p.asp Custom design set up with subcontractor to provide assembly of parts

£20 https://www.aliexpress.com/item/3289 9453455.html?src=google&src=google& albch=shopping&acnt=494-0376276&slnk=&plac=&mtctp=&albbt=Goog le_7_shopping&albagn=888888&isSmbA utoCall=false&needSmbHouyi=false&alb cp=9317296204&albag=99548979972&t rgt=536572975094&crea=en328994534 55&netw=u&device=c&albpg=53657297 5094&albpd=en32899453455&gclid=Cjw KCAjw4KyJBhAbEiwAaAQbE8WSab77z0 HQtMObdgbDP_VMKrzZMoj14nb4Rano 0jD7dF8GibIvHhoCiDsQAvD_BwE&gclsrc =aw.ds&aff_fcid=f4f29f311ea04fa9ac8b 3885f69b54e7-1630244449514-07986UneMJZVf&aff_fsk=UneMJZVf&aff_platf orm=aaf&sk=UneMJZVf&aff_trace_key= f4f29f311ea04fa9ac8b3885f69b54e71630244449514-07986-

£2

£10

Door Polycarbonate £8

Lid Holder, Motor & Injection moulded £4

Electronic s Interface Momentary Switch bottle and Cup wash

£5.60

Counter Screen £4

Custom Madehttps://www.ukpackaging.com/pol ystyrene-mug-boxes-polystyrenemug-box-125x108x128mm

Expanded Polystyrene SuppliesBespoke designs https://expandedpoly.c o.uk/product/packaging /?gclid=CjwKCAjw4KyJB hAbEiwAaAQbE3JXMP9 reMTHlVRPia4FKxMafS XM8pdTwpGKVhu8lrl6R5klaxthoCvssQAvD_B wE

https://www.washroomhub.co.uk/airse nz-commercial-hand-dryer-white-5501800-watts-eco-jet-high-speed Motor https://www.restroomdirect.com/exceldryer-xlerator-part-xl-9.aspx

https://www.restroomdirect.com/xlerat or-noise-reduction-nozzle.aspx Housing

https://www.toolstation.com/redringinstantaneous-manual-electrichandwash/p40656?store=LM&utm_sour ce=googleshopping&utm_medium=feed &utm_campaign=googleshoppingfeed& mkwid=s_dc&pcrid=515847200312&pk w=&pmt=&gclid=CjwKCAjw4KyJBhAbEiw AaAQbE1QZXBstyQE4r7fqTYK9cSmGSbr 4beZSbTI1PiKe35qn16PLxY7nFBoCxiQQA vD_BwE&gclsrc=aw.ds Fittings £4

Assembly on site

https://www.amazon.co.uk/gp/product/ B08K95QG2Q/ref=ppx_od_dt_b_asin_tit le_s00?ie=UTF8&psc=1

https://www.amazon.co.uk/Generic1602-Character-ModuleBacklight/dp/B00N8K2BYM/ref=asc_df_ B00N8K2BYM/?tag=googshopuk21&linkCode=df0&hvadid=21805134143 4&hvpos=&hvnetw=g&hvrand=2303989 030524696124&hvpone=&hvptwo=&hv qmt=&hvdev=c&hvdvcmdl=&hvlocint=& hvlocphy=1006891&hvtargid=pla441236279185&psc=1

Wiring £1

Control Primary Control board

Interval

https://www.amazon.co.uk/gp/product/ B07ZT83R9Y/ref=ppx_od_dt_b_asin_ima ge_s00?ie=UTF8&psc=1

Date: 21/03/21 Version: 1.0

Date: 20/05/21 Version: 2.0

Date: 05/07/21 Version: 3.0

To design a product that supports the use of reusable cups within a university environment to reduce the use of single use cups.

Priority Level:

1.1. Must clean cup in less than 20 seconds.

1.2. Should make minimal noise, ideally below 60dBA, must be below 70dBA.

1.3. Must clearly indicate when task is finished.

1.4. Must be designed to sustain 200 uses a day.

1.5. Should last 5 years minimum. (life-cycle assessment)

1.6. Suitable for a wall mounting.

1.7. If using chemicals should have safety lock and procedure to ensure safe use.

1.8. Powered by mains.

1.9. Work with mains water supply

1.10. Should be able to cool water.

1.11. Designed to be dismantled for recycling at end of life.

1.12. Installation requires max. 2 people and be achievable within max. 1 hour.

1.13. Functional components requiring maintenance should be easily accessible.

1.14. Mounting plate and hardware provided.

1.15. Use less than 0.5L per wash cycle.

1.16. Heat water to 145F.

1.17. Achieve desired performance at standard mains water pressure. (1-3 bar)

1.18. Unable to trap hand or cup in any moving parts.

2.1. Must be suitable for indoor use.

2.2. Must be water resistant allowing it to be cleaned down.

2.3. Should be easily sterilised.

2.4. Must operate at room temperature (18 -26 C)

2.5. Should be able to endure humid conditions.

2.6. Must be able to withstand hot water.

2.7. Should have a IP54 Enclosure rating.

3.1. Selling cost

3.1.1.Should be a maximum of £4000 per unit within the UK.

3.2. Manufacturing cost

3.2.1.Overall, should be maximum of £1000

3.3. Prototyping costs

3.3.1.Should be maximum of £150.

3.4. Maintenance

3.4.1.Should be less than £80 per annum to maintain. Including part purchase, delivery and installation.

4. Maintenance

4.1. Antibacterial Clean weekly

4.2. Replacement of filter every 6 months

4.3. Full clean and sanitisation on all water feed pipe work once every 6 months

4.4. Parts required for maintenance should be assessable within 5 minutes.

4.5. All fasteners used should comply with BS6105.

4.6. Spare parts should be available for 10 years following discontinuation of the product model.

4.7. If a key part breaks down or wares out replacements should be purchasable from the supplier and replacement use only standard tools and achievable in under one hour. This is to increase lifespan and reduce environmental impact.

4.8. No special tools should be required for maintenance.

5.1. Existing products includes sink units, cup washers, hot water taps, water fountains.

5.2. Key competitors include water bottle refilling points with drainage and plumbed water supply. Halsey Taylor HydroBoost Bottle Filling Station.

5.3. This product is designed specifically for reusable cups in university environment and therefore meets need of users much closer. Provides a better quality of wash than rinsing out cups with a tap or standard fountain.

5.4. Unit should be compact unit

5.5. Unit is multifunctional

6.1. 106 UK universities (20 units first year)

6.2. 25 892 coffee shops in the UK. Production quantity <1000 Per Year

6.3. Designed for disassembly. Design for recyclability. WEEE Waste.

6.4. WRAS Approved logo on any product or fittings to show they have been tested and meet the appropriate standards

6.5. Manufacture Processes

6.5.1. Reduce components and fastening s for easy, quick assemb ly and disassembly

6.5.2. Reduce and reuse waste from manufacturing processes

6.5.3. Choose more efficient, low energy, low waste manufacturing processes

7.1. Final Manufacture Materials

7.1.1.Final manufactured product materials: Internal components are food safe , Chemical Resistant, Impact resistant,

7.1.2.Scratch resistant, Wipe clean, Durable

7.1.3.corrosion resistant.

7.1.4.Used recycled/recyclable materials where possible.

7.1.5.Minimise material use

7.1.6.Uses 316 grade stainless steel.

7.1.7.Lead free design.

7.2. Modelling Materials

7.2.1.Modelling materials will not be required to meet performance requirements and will be selected for their aesthetic representation and availability on a small scale.

8.1. UV and chemical safety features must not fail within normal use.

8.2. Moving components must be designed for endurance.

8.3. Sanitising of fountain to meet BS EN 1276: 1997 or BS EN 13697: 2001

8.4. Manufacturing must meet quality standards at goods in and good out.

8.5. Testing is to be carried out on 5% of units

8.6. Must pass inspections completed by the WHA (Water Dispenser and Hydration Association)

8.7. Manufacturing will use quality assurance scheme based on BS EN ISO 9001:2000

9.1. The product will comply with relevant EN standards.

9.2. If electrical the product will comply with the requirements of the Low Voltage Directive (LVD) 73/23/EEC or any subsequent update. Manufacturers shall certify that an appliance complies with the LVD and hold a technical file to support their certification. The standards covering the essential requirement of the LVD are BS EN 60335, Specification for safety of household and similar electrical appliances.

9.3. The product should carry a CE mark awarded by an appropriate notified body.

9.4. The product should be designed and installed in accordance with relevant statutory requirements such as the Health and Safety at Work Act and the The Provision and Use of Work Equipment Regulations 1998

9.5. Must comply with The Waste Electric and Electronic Equipment (WEEE) Regulations 2013.

9.6. ADA compliant. Americans with Disabilities Act (ADA) Standards for Accessible Design.

9.7. Water Regulations Advisory Scheme (WRAS) approved fountain.

9.8. The Water Supply (Water Fittings) Regulations, and Byelaws in Scotland, set out the legal requirements for plumbing systems

9.9. Comply with ACOPL8 for the management of Legionella.

10.1. Packaging must be designed to ensure shipment with no damage to the product.

10.2. Packaging should be aesthetically appealing.

10.3. Packaging should be designed for quick removal and installation of the product.

10.4. Packaging should use minimal material, be collapsible and recyclable.

10.5. Packaging must include clear installation instructions.

11.1. The form should assist quick, easy function.

11.2. The form should be attractive, and the style should look appropriate in a university environment.

11.3. Controls should be large enough to allow easy, quick use.

11.4. Main controls should be mounted in an accessible position for range of users.

11.5. One person should be able to safely operate the device without assistance.

12.1. Market Requirements

12.1.1. Food safety Regulations

12.1.2. Meets Electrical Appliance Restrictions

12.1.3. Child proof

12.1.4. One person operation

12.1.5. Requires plumbing and water supply standards

12.1.6. Style requirements between universities and cafes may differ

12.2. Markets

12.2.1.1. United Kingdom

12.2.1.1.1. Universities

12.2.1.1.2. Independent Coffee Shops

12.2.1.1.3. Offices

12.2.1.1.4. Café Chains

12.2.1.1.5. Schools

13.1. Electrical connections shall be via waterproof heavy duty plug and socket.

13.2. General construction and surface finishes shall permit easy cleaning with common materials and equipment. Exposed surfaces of equipment shall be free of rivet heads, screws and bolts. All fastening bolts and screws shall be of the concealed type.

13.3. Safety guard/lock to prevent access to the functional part of the product whilst running.

INTEGRATED INSUSTRIAL DESIGN