Thisinformation,includingdesignandconstructiondetailsandspecifications,isdocumentedhereto serveasaguideonly.Project-specificcertifieddocumentationanddetailsmustbeobtainedbyrelevant professionalsforallprojectsinanylocation.Healthabitatacceptsnoresponsibilityforanyinformation providedinthisdocument.

Healthabitat would like to thank all of the donors, trade supporters and students who have partnered with us throughout our work in Nepal. Most importantly we would like to thank Bishnu Ji Shrestha and all of the communities we have worked with in Nepal.

We would like to thank all of the volunteers who have assisted in compiling this resource, including former Sanitation Studio students, tradespeople, and general Healthabitat supporters.

In particular: Deb & Russel Brown, Georgia Browning, Hannah Byrne, Emma Gaal, Sahibajot Kaur, Jake Kellow, Steph Palmer, Emerson Sims, Hayley Skelton, Kalyna Sparks, Tom Studholme, Courtney White, Jye Whyte and Sam Wigman.

Special thanks to Dave Donald, Heleana Genaus, Owen Kelly, Justine Playle, Karin Richards, Maria Roberts, Grant Stewart and Bobbie Bayley for their time and knowledge, and for sharing their global experiences.

We acknowledge the legacy that the late Paul Pholeros AM carries globally and, crucially, the role Australian Aboriginal and Torres Strait Islander communities have played in the development of Healthabitat and its work.

Produced by Healthabitat Sydney | Australia www.healthabitat.com | info@healthabitat.com | (02) 9973 1316

Compiled by Bobbie Bayley

Edited by Maria Roberts

This work is copyright. It may be reproduced in whole or in part for study, education, training purposes and to guide projects. It may not be reproduced for commercial usage or sale. Reproduction for purposes other than those indicated above requires permission from Healthabitat.

© Healthabitat 2022

ISBN: 978-0-6455190-0-6 (paperback)

ISBN: 978-0-6455190-2-0 (Digital version)

For further copies, please contact Healthabitat. Further e-copies can be downloaded from the Healthabitat website September 2022

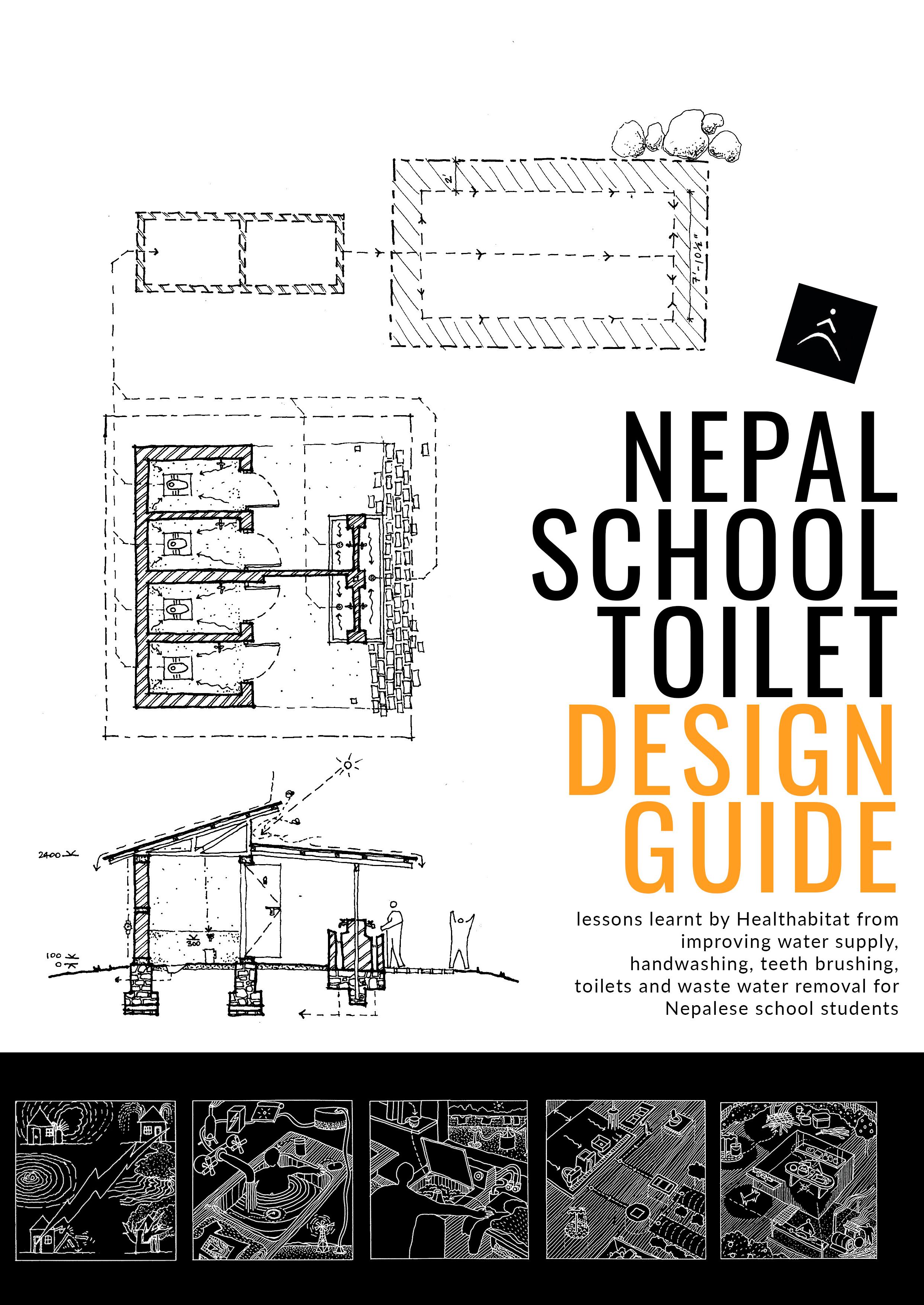

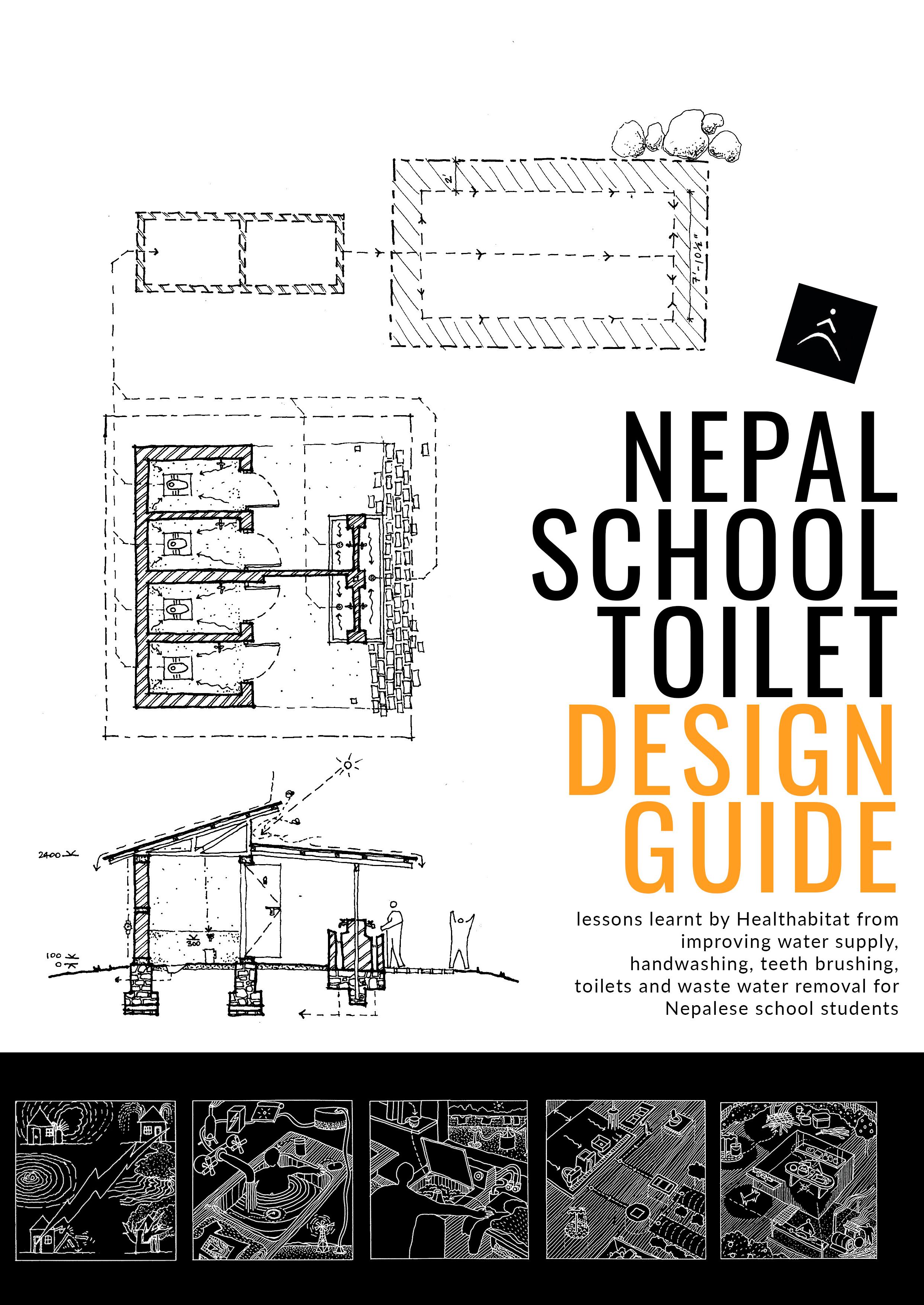

INTRODUCTION

Healthabitat works with local communities to improve the health of people living in poverty by improving their living environments.

Healthabitat is an Australian-based not-for-profit company that started in 1989 working to improve the health of Aboriginal people by improving housing in Australia. As time went on it became clear that environmental health issues affect many nations and so the methodology has been applied and successfully practised worldwide, including in Nepal.

Safety and the 9 Healthy Living Practices form the framework that Healthabitat projects follow globally to create measurable improvements to health through targeted improvements in people’s living environments.

AIM OF THE GUIDE

The purpose of this guide is to put in one place all the work, lessons and thinking accumulated by Healthabitat in Nepal since 2007.

Over this period of time, the work, ideas and expertise of dozens of students, plumbers, other trades and local communities have helped to create a successful and robust toilet design. This includes aspects such as the sizing of septic systems, local adaptations for soakage trenches and the modular sizing of toilet cubicles.

WHO IS THIS GUIDE FOR?

This guide is open source and intended for:

• Healthabitat to use as a comprehensive reference document in future projects

• Nepalese or international NGOs working in schools and communities in Nepal

• International NGOs working in other countries to learn about the Healthabitat process

• Students and volunteers to understand the complex parts that make up a ‘simple’ design to improve health.

3

TABLE OF CONTENTS

INTRODUCTION 3

AIM OF THE GUIDE 3

WHO IS THIS GUIDE FOR? 3

TABLE OF CONTENTS 4

TIMELINE 6

01 Healthabitat & Projects Overview 9

WHO ARE HEALTHABITAT ? 11

HOW DOES THE LIVING ENVIRONMENT IMPACT HEALTH? 11 What is health hardWare & Why is it important? 11

WHAT ARE ‘HEALTHY LIVING PRACTICES’ (HLPs) ? 12

HEALTHABITAT’S METHODOLOGY 13

HEALTHABITAT PROJECTS 14

PROJECT OVERVIEW 15

02 Nepal, School Sanitation & The HLPs 17

PROJECT OVERVIEW 19

SCHOOL SANITATION & THE TARGETED HLPs 20 safety 20

hlp 1 - Washing people 20 hlp 3 - removing Waste Water 21 hlp 6 - reducing negative effects of animals, insects, and vermin 21 hlp 9 - reducing hazards that cause trauma 21

SCHOOL SANITATION - THE HEALTH STORY 22

03 Nepal Projects: Method & Process 25

KEY PEOPLE 26

PROCESS OVERVIEW 28

STAGE 1: PROJECT INITIATION 29

STAGE 2: PROJECT FEASIBILITY 30 2.1 project suitability overvieW 30

STAGE 3: DESIGN 32 3.1 design process overvieW 32 3.2 project brief 33

site analysis 34

design criteria 36

further design considerations 36

design presentations 38

tools & student involvement 39

STAGE 4: CONSTRUCTION 40 4.1 milestones 40

STAGE 5: MAINTENANCE 41

STAGE 6: REPORTING 42 6.1 milestones 42

PROJECT CASE STUDIES 43 a project story - the soakage trench saga... 43

3.3

3.4

3.5

3.6

3.7

4 NSTDG

04 Design & Construction 47 THE OVERALL TOILET DESIGN 50 THE KEY DESIGN FEATURES 51 TOILET NUMBERS, SIZES & CONFIGURATIONS 52 1. STONE FOUNDATIONS, DOUBLE BRICK CONSTRUCTION & EARTHQUAKE BANDING 54 2. STEEL FRAMED ROOF CONSTRUCTION & STEEL ROOF SHEETING 59 3. SECURE & RELIABLE WATER SUPPLY (TO TOILET BLOCK) 61 4. PLUMBING DESIGN 63 5. TOOTH, HAND & FACE WASHING 66 6. WASTE DISPOSAL SYSTEM 67 7. STONE & BRICK FOOTPATH 71 8. CUBICLE DESIGN & HARDWARE 72 9. VENTILATION & INSECT SCREENING 77

Maintenance

WHY IS MAINTENANCE IMPORTANT? 80 HOW IS MAINTENANCE CARRIED OUT? 81 1. training a maintenance manager 81 2. maintenance checklist 82 3. toolkit & restocking checklist 83 4. cleaning checklist 84

DEFINITIONS, ACRONYMS & EXPLANATIONS 88 RELEVANT RESOURCES 88 Website links 88 articles & guides 88 specifications 88 feasibility document 89 feasibility document - additional reference

project process checklists

Water process

septic tanks/ Water tank sizes

toilet footprint

maintenance checklists

toolkit & restocking checklist

cleaning checklist

5

05

79

06 Appendix 87

92

93

96

97

98

99

104

105

TIMELINE of HEALTHABITAT WORKING IN NEPAL

Itbeginswith2toilets Healthabitat starts work in a small village building toilets with the community identifying key design criteria and testing these in real life with careful monitoring.

TIMELINE

Fromsinglevillage toilets to school toilet blocks

“Sanitation Studios” commence with university students, plumbers, local trades and community members collaborating on refining the design of toilets and waste systems. Here, a siting kit is rolled out at 1:1 scale.

After the careful evaluation of the first 30 or so toilets, 58 toilets and waste disposal systems are completed in one village.

‘How a Septic Tank Works’ YouTube animation story created

The Sanitation Studio produces a maintenance checklist for toilets based on community knowledge and careful monitoring.

2007 2008 2009 2010 2011 2012 2013 2014

6 NSTDG

After the earthquake in 2015, an earthquake banding system was developed to aid in the rebuilding of houses in communities to make them safer in the future. This system was adapted and used within school toilets.

School toilets continue to be constructed as part of sanitation projects, leading to over 2500 people getting access to functioning toilets, handwashing and waste disposal. A maintenance manual, toolkit and training package is developed and delivered to schools, with training, to ensure ongoing function for sanitation facilities in Nepal.

Devastating earthquake and aftershocks - All toilets survive

Sanitation Studios continue, leading to the design and construction of several more sanitation facilities for Nepalese schools.

2015

2016 2017 2018 2019 2020 2021 2022

The first school Sanitation Studio, leading to the design and construction of a new water supply and handwashing facilities, toilets and waste disposal system.

7

Diarrhoeal and respiratory diseases, in particular, are the major causes of illness among Indigenous children and also play a major role in malnutrition in the first three years of life.

Skin infection is one of the most common problems of Indigenous children...persistent skin infection is known to increase the risk of developing kidney disease and rheumatic fever.

All these illnesses are commonly linked to poverty.

- Housng for Health:The Guide

“ “ 8 NSTDG - 01 Healthabitat and Projects Overview

chapter 01

An overview of Healthabitat, their worldwide projects and the focus of improving health through the HLPs

01 Healthabitat & Projects Overview 9

• Health Hardware: Image from ‘AP Design Guide’ explaining what ‘health hardware’ is

10 NSTDG - 01 Healthabitat and Projects Overview

Healthabitat is an Australian-based not-for-profit company governed by a board of directors who draw upon the experience of a dedicated team who have worked on Healthabitat projects over many years. It is a multidisciplinary team of architects, environmental health officers, plumbers and other professionals.

They work with local communities to improve the health of people living in poverty around the world by improving the living environment.

Healthabitat has a clear methodology: Safety and the 9 Healthy Living Practices. Healthabitat projects follow this methodology globally to create measurable improvements to health through targeted improvements in the living environment.

HOW DOES THE LIVING ENVIRONMENT IMPACT HEALTH?

More buildings or toilet blocks in communities will not guarantee better health outcomes.

Poor housing conditions in places of poverty are associated with a wide range of health conditions. For example:

• Persistent scabies infections can lead to an increased risk of infection by bacteria (especially Group A streptococcus). These infections are most effectively treated by frequent washing and this will also help to reduce the consequent high rates of renal disease, rheumatic fever and rheumatic heart disease.

• In many regions, Indigenous children have high rates of trachoma and bacterial eye infections. Studies have shown regular face washing can reduce the amount of eye infection.

• Washing hands after using the toilet can significantly reduce the transmission of hepatitis.

• Waste water in the living environment can make people sick. If people come into direct contact with waste water, or if their water supply is contaminated with waste water, there is a greater risk of transmitting bacteria and viruses that cause disease. These risks are also increased if animals, vermin or insects have been in direct contact with waste water, which can pass bacteria on to people.

‘health hardware’ is the term used to describe the physical equipment needed to give people access to the healthgiving services in a house, including items such as a:

• toilet

• waste drain

• sewage system

• tap

• spout

• shower rose.

Research has shown that improving essential health hardware (electrical repairs, fixing a leaking toilet and having properly functioning sewage systems and waste treatment, sufficient hot water, and a place to wash hands and face and somewhere to wash a baby or child, etc.) can lead to improvements in health status and reduce the risk of disease and injury.

What is Health Hardware & Why is it Important?

HEALTHABITAT ? 11

WHO ARE

WHAT ARE ‘HEALTHY LIVING PRACTICES’ (HLPs) ?

Safety and the 9 Healthy Living Practices (HLPs) are based on bestpractice public health knowledge and apply globally.

They identify elements of the living environment that can compromise safety and/or health. The HLPs are a series of practical considerations to better inform the design and maintenance process.

Life-threatening issues have the highest priority, followed by washing people, especially children 0-5 years old.

Safety and the 9 HLPs were developed in 1989 to “stop people getting sick”. They are the key focus of every Healthabitat project, in the order shown in the diagrams on this page.

• Safety and life-threatening issues.

• HLP 1. Washing people.

• HLP 2. Washing clothes and bedding.

• HLP 3. Removing waste water safely.

• HLP 4. Improving nutrition, the ability to store, prepare and cook food.

• HLP 5. Reducing the negative impacts of over-crowding.

• HLP 6. Reducing the negative effects of animals, insects and vermin.

• HLP 7. Reducing the health impacts of dust.

• HLP 8. Controlling the temperature of the living environment.

• HLP 9. Reducing hazards that cause trauma.

S

4 7

5 9 8

6 3 2 1

12 NSTDG - 01 Healthabitat and Projects Overview

Healthabitat’s main program of work is called ‘Housing for Health’. The program has a clear 7 stage methodology that is followed for each project which begins and ends with the community.

Alongside the 7 stage methodology, Healthabitat uses the HLPs and certain priorities as a clear framework for every project to ensure health is being improved. These priorities include:

Local Teams & Community Engagement

• The project has to come from community groups or organisations already working with the community, as they have the greatest vested interest in improving their communities and know what the local people want and need.

• Local people bring important local expertise to a project, whilst also remaining within the community to maintain the environment when other project team members have left.

• Local people are engaged in active roles in all aspects of the work, providing training and skill sharing to train local teams.

• Local teams undertake much of the on-the-ground work.

• Image: Community team members review completed work

Partnerships with Professional Trades

• Bring highly trained people with skills and expertise to all projects

• Ensure projects are carried out to industry standards

• Play a large role in providing training and facilitating skill sharing with local community members.

• Image: A trade professional teaching skills to community members

• The late eye surgeon Professor Fred Hollows coined the phrase ‘no survey without service’, insisting that his teams make a tangible difference on day one of any project.

• Skilled local teams and professional trades are engaged to deliver a project and are integral to the success of the ‘no survey without service’ methodology, making a difference from the very beginning of each project.

• Image: Professor Fred Hollows in action

• Data is recognised as an important resource and is used to measure and compare the function rates of homes before and after the work.

• Analysis of water usage data can be a useful way to inform the size and design of systems and health hardware.

• Image: Community team member filling out Housing for Health survey sheets

HEALTHABITAT’S METHODOLOGY

‘No Survey Without Service’ Data Collection & Reports 13

HEALTHABITAT PROJECTS

Heathabitat has engaged with communities globally by applying the HLPs to improve health outcomes.

Nepal-Sanitation

Bangladesh-WaterandSanitation India - Water & Sanitation

South Africa - Sanitation

Ethiopia-ReducingTrachoma

NavajoNation-HousingforHealth NewYork-HousingforHealth Alabama-HousingforHealth

Australia-HousingforHealth

Indonesia-CommunityPlumbingChallenge PNG - Sanitation with SAGO Network

14 NSTDG - 01 Healthabitat and Projects Overview

PROJECT OVERVIEW AUSTRALIA | HOUSING FOR HEALTH

• Map: Project locations in Aboriginal & Torres Strait Islander communities across Australia

Location

Housing for Health projects are located largely in indigenous communities in regional and remote areas of Australia.

Beneficiaries

• Over 59,000 people living in these houses

• Local teams trained and employed to work on project teams

Aim

The aim of the Housing for Health projects is to work with local communities to provide a healthy living environment and better health outcomes.

Partners and Donors

• Federal and state government departments

• The Fred Hollows Foundation

• Industry partners

• Individual Indigenous communities

• Volunteers working on projects

Detail

The Housing for Health program has conducted surveyfix work, research and development and maintenance on over 9,600 existing houses in 252 communities as of February 2022.

Impact

• Over 305,000 items fixed or inspected in houses

• Over 2,500 local staff trained and employed

• 40% reduction in hospitalisations from illnesses associated with the living environment

• Targeted Healthy Living Practices: The Australian projects target Safety and all 9 HLPs

15

TARGETED HEALTHY LIVING PRACTICES

S 1 2 3 4 5 6 7 8 9

16 NSTDG - 02

The

Nepal, School Sanitation &

HLPs

• Image: Tap heights are tested on school children of all ages during construction to ensure they are suitable

chapter02

An overview of school sanitation Healthabitat projects in Nepal and improving health through targeted HLPs

02 Nepal, School Sanitation & The HLPs 17

PROJECT OVERVIEW

NEPAL | SCHOOL SANITATION

• Map: Project locations in communities across Nepal

Location

School sanitation projects have been located at five participating schools in the Bagmati Zone of central Nepal.

Aims

The aim of the projects is to improve sanitation to reduce gut infections, respiratory illness and improve dental health, as well as improve the structural integrity of buildings against future earthquakes to improve safety.

Better toilet facilities are also known to improve school attendance, especially for girls experiencing menstruation.

Details

The projects involve the design and building of toilet facilities with handwashing facilities, waste water treatment and water storage facilities.

Beneficiaries

• Over 1500 school students and teachers

Partners and Donors

• WorldSkills Australia

• The International Association of Plumbing and Mechanical Officials (IAPMO)

• Reece Plumbing

Impact

• Functioning toilets, waste water treatment systems and handwashing facilities

• Safer buildings for future earthquakes

• Local staff trained and employed

• Targeted Healthy Living Practices: The Nepal school sanitation projects target S, HLP1, HLP3, HLP6 & HLP9.

19

TARGETED HEALTHY LIVING PRACTICES S 1 3 6 9

SCHOOL SANITATION & THE TARGETED HLPs

Healthabitat’s work in Nepal targets Safety, HLP1, HLP3, HLP6 and HLP9.

The health research that underpins the 9 HLPs tells us that a toilet is not as effective at improving health unless there is also handwashing available. Therefore, handwashing is a critical part of the toilet design.

Safety

When designing, upgrading or maintaining sanitation structures, immediate and life-threatening dangers are given the highest priority.

The design of sanitation structures in Nepal should provide earthquake-resilient walls and roofs. While it is common in Nepal to see roof sheeting held down with rocks, these structures are susceptible to collapse during high wind or earthquakes. Falling rocks can also be a danger to people.

HLP 1 - Washing People

In Nepal, many schools lack basic or well-maintained washing and toilet facilities.

Being able to use functioning washing facilities reduces the spread of diseases, including diarrhoea, respiratory disease, hepatitis and infections. These diseases can have lifelong negative effects on people.

Handwashing facilities can assist in improving dental hygiene, tooth brushing and reducing dental diseases.

20 NSTDG -

02

Nepal, School Sanitation & The HLPs

• Images: Devastation caused by the 2015 earthquake shows the importance of structural safety

S 1

• Images: Examples of existing poor water supply, washing facilities and waste water removal at project sites

Waste water in the living environment can make people sick.

If people come into direct contact with human waste, or if their water supply is contaminated with waste, there is a greater risk of transmitting bacteria and viruses that cause diseases, specifically gut and bowel problems.

The lack of toilet facilities within schools and communities means that human waste and waste water is commonly found on the ground, which increases the risk of foot and skin infections.

Removing the waste safely requires toilet facilities that are adequately built and maintained.

HLP 6 - Reducing Negative Effects of Animals, Insects, and Vermin

People’s health can be affected by contact with animals, vermin and insects in the living environment, as they can carry a variety of diseases.

Mosquitoes and flies transmit diseases such as trachoma, malaria, Japanese encephalitis, and dengue fever.

These risks are also increased if animals, vermin or insects have been in direct contact with waste or waste water, which can pass bacteria on to people.

HLP 9 - Reducing Hazards that Cause Trauma

If sanitation facilities are poorly designed and constructed, or not well maintained, there is an increased risk that people may be injured.

Hazardous or broken materials causing cuts and abrasions, trips or falls are typical hazards and should be prevented.

Personal security is also an issue, especially for women, due to a lack of privacy within the toilet facilities, or lack of toilet facilities.

HLP 3

- Removing Waste water

21 3 6 9

3. 2.

The Health Issue

1. Human waste and contaminated waste water create a greater risk of transmitting bacteria and viruses that cause disease.

2. Having nowhere to wash hands after using the toilet increases the transmission of hepatitis and diarrhoea.

3. Personal security is also an issue, especially for women, due to a lack of privacy within the toilet facilities, or lack of toilet facilities.

SCHOOL SANITATION - THE HEALTH STORY

1. 22 NSTDG - 02 Nepal, School Sanitation & The HLPs

7.

The Environmental Solution

4. A secure, well-built toilet, made by local trades with a place for handwashing and teeth cleaning, can address these issues.

5. Safe collection and treatment of human waste and water takes faeces off the ground, reducing the risk of transmitting bacteria and viruses that cause disease.

The Health Outcome

6. Less faeces on the ground will lead to better gut health, less diarrhoea especially in children, and improved dental health.

7. Young women are also more empowered, leading to better, more confident and safe school attendance.

S 1 3 6 9

5. 4. 6. 23

24 NSTDG - 03 Nepal Projects: Method & Process

• Image: 2019 University of Newcastle Architecture Sanitation Studio with two Australian and North American IAPMO funded project plumbers - a thank you ceremony from the school before leaving

chapter03

03 Nepal Projects: Method & Process

An overview of the established method and process used for all Nepal-based school sanitation projects. A method that can be replicated in any part of the world, yet must be tailored to suit the community needs, context and site location

25

The key people in the project team during the design and construction phases include both local Nepali and international contributors. Each group plays a specific role in the project development, drawing on their expertise and experiences, which include:

Client

The local school that requires the project for improved healthy living practices is the client.

The client is responsible for guiding the project brief, location, requirements and ongoing maintenance. Local staff can speak the local language and liaise between the community and work teams employed.

Designers & Engineers

Designers, such as architects, collate the information collected from the project brief, client discussions and site analysis to find the best design solution.

Their goal is to problem-solve and provide a design relevant to available local materials, local techniques of construction and local building standards.

The engineer reviews the design and specifies requirements, such as size of structural members, tie down details and earthquake banding requirements.

The designer and engineer collaborate to produce a finished documentation package of the design and specifications ready for construction.

The engineer should continue to be engaged, providing site inspections throughout the project construction, similar to the role of a ‘building certifier’ in Australia.

Project Manager

Project managers are of Nepali origin and come from the local communities or central towns. They are accredited and contracted by Healthabitat to run Nepal sanitation projects.

They are responsible for all stages of the project and report at regular, specified intervals to Healthabitat on project progress.

Project managers are the most experienced members of the Healthabitat team and bring decades of knowledge to each project.

KEY PEOPLE

• A local school group in their new toilet block

• University architecture students collating ideas

• Nepali Project Manager and dentist, Bishnu, addresses the local community about a project

26 NSTDG - 03 Nepal Projects: Method & Process

Trade Experts

International trade volunteers are supported by organisations that have a broad charter aimed at using trade skills to improve living conditions and assist the training of people in developing countries.

Trade experts range from plumbers, carpenters, engineers and architects to environmental health officers.

The organisations that have supported Healthabitat projects include IAPMO (International Association of Plumbing and Mechanical Officials), World Skills and Reece Plumbing.

Environmental Health Workers

International health workers assist with solutions for a sanitary environment. The outcome should meet the standard list of the healthy living practices and be easily maintained in this condition.

Alongside this are dental camps that are part of the Teeth and Toilets (TT) program, providing critical dental care for villages in addition to teaching young people about the importance of oral health.

Local Teams

The local team are responsible for building all elements. Throughout this process they work in collaboration with the project manager and international trade experts, learning new skills and techniques.

The local team carries out all the site works and builds the required structures to the required design and specifications.

They may also be responsible for maintaining the structures at project completion, working on other projects nearby and educating others.

• Trained builders constructing the roof for a project and local labourers excavating the soakage trenches for septic tanks

• IAPMO Australia plumber Grant teaches local plumber and workers new methods

• IAPMO Australia plumber Grant teaches local plumber and workers new methods

27

• A young school child washes their hands in the finished handwashing station

Healthabitat utilises a staged methodology, inspired by their Housing for Health projects in Australia. Beginning and ending with direct community involvement, the process follows these 6 stages:

PROCESS OVERVIEW

1: PROJECT INITIATION STAGE

PROJECT FEASIBILITY STAGE 3: DESIGN STAGE 4: CONSTRUCTION STAGE 5: MAINTENANCE STAGE 6: COMMUNITY FEEDBACK 28 NSTDG - 03 Nepal Projects: Method & Process

STAGE

2:

Projects are initiated when organisations already working on the ground or community leaders, groups or members seek help from Healthabitat to assist with building projects, health issues, workshops or other initiatives. Projects can be instigated through word-of-mouth or through community contacts where other projects have already taken place.

STAGE 1: PROJECT INITIATION

• Example of a letter of Invitation from a community in 2018 for a school sanitation project

01 - PROJECT INITIATION CHECKLIST :

Obtainofficialrecordofinitiationinwriting

Begintodiscussexpectations,roleofengagement,timeframes,accessconcerns,seasonsandweather

What are the details of the brief? 29

STAGE 2: PROJECT FEASIBILITY

After accepting the school’s invitation, the second step in the project’s development is establishing its drivers, needs and requirements. The careful planning of each project is fundamental to its success.

The school and local community are involved throughout the process to help negotiate with different groups and improve access to the preferred project site. Engaging locals from the start of the project ensures that local knowledge of place, infrastructure services (power, water and waste), construction methods and final users are a crucial part of the project’s development.

2.1 Project Suitability Overview

Although a community group or organisation may want a project delivered in a certain way or expect a certain outcome, the project or process may not always be suitable or feasible.

The early consultation period will determine which aspects of the project are suitable or unsuitable. This stage must determine the following:

02 - PROJECT FEASIBILITY/ PROJECT SUITABILITY CHECKLIST

Project Initiation/Feasibility:

What are the key project expectations and do these align with the HLPs?

Whatdoestheschoolexpecttobeapart/notapartoftheproject?

e.g.Doestheschoolwantyoutobuildatoiletwithnosecurewatersupply?Ordoestheschoolwantthe toilet to have no roof?

Where is the project funding coming from?

Whatistheexpectedcostofalltheprojectstagesandcontractor? Whatisthesourceoffunding?

Isthefundingalreadysecuredwithnostringsortimeframesattached?

Iffundingiscomingfromoutsideofthecommunity,whatwilltheschoolcontribute?Theremustbelocal investment,whichcouldbein-kindsupportsuchaslabour,materials,maintenancefunding.

Are there travel requirements or access restrictions?

Isthereanairfarecostassociatedwithreachingthecommunity?Ifso,howmuchisit?

Isit4WDroadaccessonlyforpeopleandmaterials?

Are there seasonal access restrictions such as the monsoon season?

What are the private vs. community needs and benefits?

Althoughthisisaschooltoilet,willthecommunityuseitalso?

Do the government, NGOs or the school have future development plans or are they already doing work?

AreotherNGOsdoingsimilarorthesameprojectintheareaalready?Ifso,whatistheirprojectdifference andsimilarities-canyoucollaborateorjoinresources?

Design & Construction:

Who is the project management team and the licence or insurance holder?

Whowillbetheon-the-groundprojectmanagementteamforallphasesincludingconstructioninspections and defects?

Whatifsomebodygetshurtduringtheproject?Aretheyinsured?

Who will be the construction team?

Are there local workers/labour available?

Aretherelocaltradestodothework-plumbers,electricians,engineers,inspectors?

Ifnotlocal,whoaretheyandwheredotheyhavetotravelfrom?

After the Project is Over:

Who will pay for and carry out the maintenance?

Whowillbetrainedasthededicatedmaintenancemanagerandcarryoutmaintenanceregularly?

Whowillrestockandsupervisethetoolkitsandtraining?

Who will carry out a defects inspection at project completion?

Istheremoneyinthebudgettofixanydefectsorpoorlyconstructedaspects?

NOTE: SeeFeasibilitydocumentsintheAppendixforreference/use

30 NSTDG - 03 Nepal Projects: Method & Process

Sample page from the ‘Water supply and sanitation feasibility study’ document

See Appendix for Feasibility resources 31

•

STAGE 3: DESIGN

After official project initiation and feasibility studies, the project team commences detailed planning and design with stakeholders, students and staff. The process overview below explains the common path of design development. This section provides information and resources that show how to carry out this process effectively.

3.1 Design Process Overview

03 - DESIGN CHECKLIST:

Project Brief - Finalised and agreed on by all stakeholders

Havetherebeendiscussionswiththeclient,schoolcommittee,parents,studentsandstaff?

Areinclusions,exclusionsandexpectationsnotedintheprojectbrief?

Projecttimelineandalldesignandconstructionphasesaredocumentedincludinginspections

Site Analysis - Completed and documented

Siteobservations,futureplansandsitequalitiesareunderstoodandcaptured

Prosandconsofthelocationandpossiblesiteshavebeenunderstoodandcaptured

Thesehavebeenreviewedwithstakeholdersforconfirmationsandinput

Sketch Design - Options are developed by understanding the brief and site

Minimumoftwoplanninganddesignoptionsaredevelopedusinghandsketches,siteplans,building plans,elevationsandsectionsandscalemodelstocommunicateideas

Presentedtostakeholdersforapprovalandselectionofmostappropriatesolution

Design Development and Detailed Design

Theselecteddesignisdevelopedanddetailedtoapointwhereitissufficienttoengageexternal consultantsandcompleteconstructiondocumentation

Presentedtostakeholdersforfinalapproval

Construction Documentation, External Consultants Engaged and Planning Approval

Externalconsultantsareengaged,suchasanengineer,toconfirmdesignanddetailspecifications

Constructionpackageisdevelopedwithconsultantcollaboration

Submittedtoauthoritiesforplanningorconstructionpermissionandapproval

Projectisbegunandcarriedoutaccordingtoprojecttimeline

NOTE: Theprojectmanagermustbeavailableatallstagesoftheprojecttotroubleshootanyunforeseenissues orquestionsandengageanyconsultantsasrequired,especiallythroughouttheconstructionphase.

32 NSTDG - 03 Nepal Projects:

& Process

Method

3.2 Project Brief

The project brief outlines the project requirements, inclusions and exclusions. There is often a lengthy process involving the client and stakeholders to clarify and document what their wants and expectations for the project are. • Example of stakeholder discussions informing project brief development

33

Site Analysis

‘Site analysis’ is carried out before any design commences. It is a focused study of the site’s characteristics and local context as it exists now. It also considers any other future plans or development proposals in the area.

All findings, observations, pros and cons must be documented in one place, in the form of sketches, diagrams, site plans, models and photographs, to inform the next design stage.

How a site analysis is executed and captured varies between professionals; there is no wrong or right way, yet a thorough site analysis is critical for ensuring a successful project with a long future.

The dot points below outline basic questions that will inform any site analysis.

The Location (Zoomed out)

• What is the climate? Does it snow or have hot summers? Do you need to capture or block cooling breezes?

• What is the seasonal weather? Are there monsoon downpours restricting access/travel? Does the rain come from the west in the summer? Is there a possibility of earthquakes or landslips?

• In the local culture are there gender requirements or restrictions?

• Are there local traditions that must be considered throughout design and construction?

• What are the local or state building requirements and available materials?

The Site (Zoomed in)

• What are the favourable and unfavourable orientations?

• Is the site made of fill or unstable ground?

• What is the proximity to the main school area? What other buildings are close to it?

• Is the site located to allow passive supervision from teachers?

• Where does water come from and drain to, on and around the site?

• Where are the people, car and machinery site access, exit and travel routes?

• Is there enough space for water storage, a toilet and handwashing block, soakage trenches and septic tank away from play areas?

The Future

• Does the school or community have plans for any future construction or student number expansion?

• Does the government have development plans?

• Do any other local or international NGOs have plans or projects proposed?

•

3.3

See Appendix for Site Analysis resources 34 NSTDG - 03 Nepal Projects: Method & Process

Architecture students carrying out site analysis: tracking path of water supply, interviewing female students, documenting what local materials are available, siting drawing from the ‘Draft Construction Manual’

• Example of plans made for a site analysis

3.4 Design Criteria

With every project, Healthabitat aims to maximise their health impact and so the target HLPs are always the key design criteria.

TARGETED HEALTHY LIVING PRACTICES

S 1 3 6 9

Footprints and

Hand Basin (2 taps) Hand Basin (3 taps)

Hand Basin (2 taps) Hand Basin (3 taps)

• Targeted Healthy Living Practices: The Nepal school sanitation projects target S, HLP1, HLP3, HLP6 & HLP9.

Hand Basin (2 taps) Hand Basin (3 taps)

Hand Basin (2 taps) Hand Basin (3 taps)

3.5 Further Design

Hand Basin (2 taps) Hand Basin (3 taps)

Hand Basin (2 taps) Hand Basin (3 taps)

Considerations

Modular Design

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys 1200

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

Without Urinal Girls / Teacher

Without Urinal Girls / Teacher

Low Maintenance

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys 1200 2100 3650 450

/ Teacher / Boys

/ Teacher / Boys

Toilet Footprints and Sizes

Hand Basin (2 taps) Hand Basin (3 taps)

Further to Safety, HLP1, HLP3, HLP6 and HLP9, other important considerations must be made in the design and placement of the toilet and handwashing block. These are focused on the local context, the site and future plans and are critical for ensuring a successful project for the place with a long future.

Hand Basin (2 taps) Hand Basin (3 taps)

Hand Basin (2 taps) Hand Basin (3 taps)

Hand Basin (2 taps) Hand Basin (3 taps)

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

Hand Basin (2 taps) Hand Basin (3 taps)

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

An understanding of modular design is important to aid the design process when considering toilet configurations for different-sized spaces and for different numbers of students and teachers.

Hand Basin (2 taps) Hand Basin (3 taps)

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys 1200 2100 3650 450 850 1400

• Modules have been well thought through and tested to determine the best sized toilet and handwashing. Site-specific considerations are still encouraged.

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

4.8m/16’ 2m/6’6” 2m/6’6” 3.8m/12’8” 8.4m/28’

• Modules provide an easy understanding of space requirements when considering siting, layout and design.

6m/20’

• If the school expands they could simply add another toilet or handwashing module.

3.3m/11’ 2.6m/8’8” 3.5m/11’8”

The facilities endure very high use, often becoming the only working public toilet and handwashing service in town. Resources are often not available to consistently fix or repair items. Low maintenance design ensures long-term, high-intensity use.

• Low maintenance toilets are fitted with durable health hardware which can easily be cleaned.

• All tools and materials specified are durable and low maintenance.

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys 1200 2100 3650 450 850 1400 2100

CLIFF FACE

2100 3650 450 850

1200

1400

1200 4’ 16m²/172ft²

6m²/65ft² 22m²/237ft² 10m²/108ft² 16m²/172ft² 22m²/237ft²

1’10” 7’ 1’6” 12’2” 3.3m/11’ 3m/10’ 3m/10’ 6.2m/20’8” 6.2m/20’8” 3.3m/11’ The following are diagrams of possible toilet configurations and their areas

12m²/129ft²

20m²/215ft² 4’8”

1200 2100 3650 450 850

1400

2100 3650 450 850

6m/20’ CLIFF FACE

1200

1400 4.8m/16’ 2.6m/8’8” 3.5m/11’8” 6m/20’

450 850

1200 2100 3650

1400

6m²/65ft²

10m²/108ft²

3m/10’ 3m/10’

The following are diagrams of possible toilet configurations and their areas

Toilet

Sizes 4’ 16m²/172ft² 12m²/129ft²

22m²/237ft²

16m²/172ft² 22m²/237ft² 20m²/215ft² 4’8” 1’10” 7’ 1’6” 12’2” 3.3m/11’

2.6m/8’8” 6.2m/20’8” 6.2m/20’8” 3.3m/11’

1200 2100 3650 450 850 1400 CLIFF FACE

Options:

Girls

1200 2100 3650 450 850 1400 2100 4.8m/16’ 2m/6’6” 2m/6’6” 3.8m/12’8” 8.4m/28’ 3.3m/11’ 2.6m/8’8” 3.5m/11’8” 6m/20’

6m²

²

10m²

²

1’10” 7’

12’2”

3m/10’ 3m/10’

following are diagrams of possible toilet configurations and their areas

850 1400 Toilet Footprints and Sizes 1200 4’ 16m²/172ft² 12m²/129ft²

/65ft

22m²/237ft²

/108ft

16m²/172ft² 22m²/237ft² 20m²/215ft² 4’8”

1’6”

3.3m/11’

2.6m/8’8” 6.2m/20’8” 6.2m/20’8” 3.3m/11’ The

CLIFF FACE

1200 2100 3650 450 850 1400

6m/20’

Options:

Girls

1200 2100 3650 450 850 1400 2100 4.8m/16’ 2m/6’6” 2m/6’6” 3.8m/12’8” 8.4m/28’ 3.3m/11’ 2.6m/8’8” 3.5m/11’8” 6m/20’

CLIFF FACE

2100 3650 450 850 1400

Toilet Footprints and Sizes 1200 4’ 16m²/172ft² 12m²/129ft² 6m²/65ft² 22m²/237ft² 10m²/108ft² 16m²/172ft² 22m²/237ft² 20m²/215ft² 4’8” 1’10” 7’ 1’6” 12’2” 3.3m/11’ 3m/10’ 3m/10’ 2.6m/8’8” 6.2m/20’8” 6.2m/20’8” 3.3m/11’ The following are diagrams of possible toilet configurations and their areas

See Chapter 04 & Appendix for Modular Design 36 NSTDG - 03 Nepal Projects Method & Process

Replaceable & Easily Repairable Materials & Fittings

When items do fail, it is important that they can be easily repaired or replaced to ensure the toilet and handwashing facilities can continue to be used. They must be able to be sourced locally, quickly and easily.

• All items are installed to ensure they can be unscrewed or opened to allow replacement.

• All tools and materials specified are durable and locally available.

• All replaceable items such as taps are locally available, with spares stocked in the maintenance toolbox.

• Healthabitat’s illustrated Maintenance Checklist (see Appendix) encourages the community to ensure all plumbing is maintained and repair jobs are identified and documented.

37

3.6 Design Presentations

Presenting design ideas and development at every stage to the client and stakeholders is crucial for project confidence and success.

This gives an opportunity for design feedback and input from the people who use and will use the proposal most and who know the location and site the best. Such presentations are always most effective when done in person to enable design troubleshooting and resolutions to be brainstormed as the discussions are occurring.

38 NSTDG - 03 Nepal Projects Method & Process

• Design documents from a sketch design presentation by architecture students with Healthabitat

3.7 Tools & Student Involvement

‘Tools’ are the outcome of designers, healthworkers and trade experts working together to produce a series of clear simplified methods over the many years of the projects.

These are processes that have been developed to solve common problems that occur in projects and can be used for the project at hand and for all future projects.

The examples listed below were produced by Australian university students in architecture, engineering, construction management, psychology, ecology and design as part of an ongoing Healthabitat Sanitation Studio since 2013. They are examples of how students can be involved in such projects.

This opportunity has exposed students to the challenges of their industry in foreign contexts and has allowed many Nepalese communities to benefit from the energy, innovation and inspiring design thinking and problem-solving qualities that students possess.

Septic Tank Siting Kit (2013)

This kit consists of three (3) items, to be used in conjunction with each other to assist with communication amongst the villagers:

• Part 1 - Flip charts: Diagrams on pocket-sized cards to discuss the key siting issues.

• Part 2 - Model: A scaled prototype as a small portable model to show the location of all the parts, above and below ground.

• Part 3 - Template: Full-scale shapes to place on the ground and set out each item in preparation for construction.

Mud Test (2015)

Dust and mud being tracked into the toilet areas will mask harmful human waste. Over time, as mud washes down toilet pans and into the septic tank, it reduces the capacity of the system.

Students carried out tests with different ground surfaces (brick and rocks of different sizes) to see which removed mud and dirt from shoes the most effectively.

Results were documented and now inform the design and placement of the path and entry to the toilet block.

Earthquake Banding (2016)

A construction manual was produced which graphically communicates the steps of construction through the stages of design, foundations, earthquake banding, walls and roof.

It provides engineered details and relevant easy-to-check points to ensure that each item is addressed.

Overall, the document is collated in a way that sums up previous tested methods and allows for easy reproduction.

•

•

Document extract: Start of wall construction

• Septic Tank Kit: Template positioned for discussion

Mud Test: Circulation across surfaces

39

After the design phase is complete, it’s time to start on site. Using the site-specific design, developed ‘tools’ and lessons from the expert trades, the key milestones below are followed.

Essential trades, with the support of trained and untrained community members, complete the construction of the project.

4.1 Milestones

Key construction milestones include:

• sourcing materials: ordering and delivery of materials for building the structure and fittings

• preparing the site: marking out the site, excavation and earthworks

• services: installation of services below and above ground as required

• foundations: construction of footings to support the building as designed and specified

• structure: construction of walls, roof and doors as designed and specified

• fixtures, fittings & finishes: installation of health hardware, hooks, shelves and surface finishes as specified.

• Overview of a construction site for a new toilet block (left), and an example of a completed toilet block (right)

• Examples of Stage 4: Construction project milestones

STAGE 4: CONSTRUCTION

40 NSTDG - 03 Nepal Projects Method & Process

5: MAINTENANCE

Without maintenance at all stages of the health hardware ‘chain’ (as discussed in Chapter 01), things will fail.

Maintenance plans, checklists and ongoing funding for the life of the project are essential tools that provide information on taking care of the essential design features. These improve the chances of the project’s long-term success and also ensure the best possible chance of improving the health of its users.

For maintenance to be carried out efficiently and successfully, the following items need to be in place:

05 - MAINTENANCE CHECKLIST:

Ongoing Maintenance Funding - Allocated from day one of feasibility

Fundingforthetrainingandsalaryofadedicatedmaintenancemanager

Fundingfortoolkitrestocking

Fundingforurgentandplannedmaintenancework

Training a Maintenance Manager - Providing the knowledge to carry out maintenance

Theprojectmanagertrainsadedicated,ontheground,maintenancemanagertooverseeregular inspections

Themaintenancemanagermusthavetheknowledge,skillsandtoolstocarryoutrepairsand maintenance

Theymaybeateacherfromtheschool,aparentoratradespersonfromthecommunity

Maintenance Checklist - A system to follow and use to keep records of maintenance work

Anestablishedprocessforinspections,testingandsurveyingitemswithrequiredtimeframes

Ensuresthatfaultsarepreventedordetectedearlyandeffectsoffailurecanbereduced

Isaformaldocumenttoreviewanduseasaresourceforfutureplannedmaintenanceandtoolkit restocking

Hasbeenestablishedasaprioritylist,focusingattentionandfunding

Toolkit & Restocking Checklist - Providing the tools and basic parts (e.g. taps, hooks) to carry out maintenance

Theprojectmanagerattheendofconstructionwilldeliverafullystockedtoolkitandchecklistsand providecompetencytrainingtoundertakemaintenance

Thechecklistincludesallitemsandtoolsrequiredforregularrepairs,maintenanceandreplacementof hardware

Thesemustberestockedregularly

Cleaning Checklist - Cleaning also helps maintain parts of the project

Regularcleaningisimportanttomaintainthetoilet

Forexample,removingdirtbuild-upincubiclesbeforeitgetsflusheddownthetoiletpanreducesdirt build-upinthesepticsystemthatcouldminimiseitscapacity

NOTE: The2019SanitationStudiodevelopedandtestedthesetoolswithexistingprojectcommunities.With feedback,thetoolsareconstantlybeingrevisedtoincreasecommunication,efficiencyandsuccessonthe ground

STAGE

See Chapter 05: Maintenance & Appendix for resources

41

Reporting on project successes, failures and ideas for improvement in all phases is important, and it is also important to document this information. It is then important to feed this information back to the organisation carrying out the works program to help inform future projects.

The project manager on the ground is the point of contact for all community feedback and reporting.

6.1 Milestones

Key reporting milestones include:

• Throughout construction: work progress and photo reports

• End of construction: final report

• After construction: defects reporting, community feedback and maintenance successes and failures.

STAGE 6: REPORTING

42 NSTDG - 03 Nepal Projects: Method & Process

PROJECT CASE STUDIES

Using the details of two past projects in Nepalese schools, the different process stages, as explained in this chapter, can be understood.

These examples show that every project is unique, has unique issues, and that each process stage looks different for every project, yet is based on the same principles.

A Project Story - The soakage trench saga...

The usual way... On projects, Healthabitat had used 100mm polypipe for soakage trenches. They would drill big holes along its length and wrap the pipes in geotech fabric before backfilling with gravel to bury it.

On this particular project an international plumber suggested some changes...

A new way... So, instead of the usual method of drilling holes the plumbers used a thin hack saw to cut thin slits in the polypipe. The pipes were then laid in the trench with geotech fabric laid on top, rather than wrapping the pipes. The trench was backfilled as usual and the toilets and handwashing stations began being used.

The Issue... Some time after its completion, the Project Manager was contacted by the school as the septic tank started backflowing through the toilet block.

The Project Manager visited the school as soon as possible with a plumber, digging up different parts of the system to try to find the source of the issue. There was sewage everywhere!

Digging up the soakage trench, they realised the weight of the dirt on the 100mm polypipe made the pipe compress, closing the sawn slits. This stopped any treated waste water from the septic tank seeping out and soaking into the ground. Instead it filled up the septic tank quickly and backflowed sewage through the toilet block.

The Lessons...

• Every new project changed to specifying and installing rigid 100mm PVC pipes for soakage trenches (rather than softer polypipe), drilling big holes and wrapping in geotech fabric.

• This demonstrated the importance of having a present and contactable project manager on the ground to carry out regular visits, troubleshoot any issues and pass this feedback on for future projects.

• It is important to try new ways of doing things and new products, but start at a small scale, trialling for a specified time and closely monitoring and then approving, before rolling out at large scale across all projects.

43

A higher secondary school which accommodates 600 school students and is located in a mountainous village was severely damaged in the 2015 earthquake. The details of the project stages on this project included:

Stage 3: Design

In February 2015 a 10 day design workshop was undertaken at the school.

The project team included the local project manager, Worldskills Foundation-supported plumbers, a local engineer, local Nepali construction team, local Nepali dental team, Australian university students and staff and Healthabitat staff.

The team’s brief involved many aspects, including:

• Testing methods to reduce mud in the sanitation block due to past project feedback. The team developed the Mud Test tool which informed the specification of the brick and rock path.

• Carrying out a site analysis, site studies and design briefings to design a new toilet and handwashing facility along with upgrading the existing facilities.

• Designing tooth brushing facilities at the school and commencing dental health initiatives.

• Formally developing an Australian university course for the Sanitation Studio.

Stage 4: Construction

All construction work was done by trained locals and members from the school as well as trained international plumbers.

The project was built in 2 stages:

• 1st stage = the girls’ toilet (including toilet cubicles, handwashing, temporary tooth brushing area, waste water treatment and disposal system) and upgrading of the existing boys’ toilet, which had been buried during a mud slide in the wet season. This included remedial works.

• 2nd stage = additional works to the existing boys’ toilet including main drainage line set out, excavation for drainage pipework and effluent line and construction of the septic tank and soakage trench.

Stage 5: Maintenance

The school teachers, management committee and locals were encouraged to be involved in the construction process so they would be familiar with how the building works. These project members were then the dedicated members trained by the project manager in how to carry out maintenance checks and do basic repair work on all the health hardware.

The school was given basic tools and maintenance checklists to assist in the ongoing maintenance.

HIGHER SECONDARY SCHOOL | 2015/16

• Architecture students carried out mud tests and design work and the dental team carried out dental workshops

44 NSTDG - 03 Nepal Projects: Method & Process

SECONDARY SCHOOL | 2017/18

A village near Melamchi was devastated by the 2015 earthquake.

The two toilets that survived at the school were, prior to the earthquake, unsatisfactory for clean handwashing and the safe removal of waste. The situation was exacerbated as the remaining two toilets had to cater to the 627 students enrolled at the school. The Head of School noted that students were suffering from additional obstacles and requested help and support.

Details of the stages on this project included:

Stage 1 & 2: Initiation & Feasibility

In October 2017 Healthabitat completed a feasibility study for the design and construction of new toilet blocks at the school and in January 2018 received a formal invitation from the school to commence the design process.

At the time, Healthabitat was unaware that two other organisations, ‘Mondo’ and ‘HELP,’ had secured funding to rebuild the school, including provision for a set of toilet blocks.

In May 2018, Healthabitat, HELP and Mondo met and agreed on a plan to work together to design and construct new toilet facilities for the staff and students of the secondary school to complement the construction of the school being funded by Mondo.

Stage 5: Maintenance

Specialist teams were brought on site to work and to train local builders/trades in the skills needed to install and maintain the plumbing, fixtures, septic tank and soakage trench.

Staff were trained in the maintenance process, cleaning routines and skills and tools required to carry out the work.

Stage 6: Reporting

Throughout construction the project manager completed work progress and photo reports to detail and report back to Healthabitat, Mondo and HELP on the stage and development of the project.

At the completion of the project, a final report was formulated, with maintenance reporting and community feedback sessions undertaken.

• Architecture students, following in-depth site analysis, produced design and construction documents, including those shown here: a site plan and 3D rendering of the Senior School toilet block

45

46 NSTDG - 04 Design & Construction

• Under construction 2018/19: secondary school sanitation and handwashing project nears completion in February 2019. Note Septic tank in front of the toilet block

04 Design & Construction

DOCUMENTATION&

47

chapter04 An outline of the key design features, specifications and construction details that are utilised to improve health in all Healthabitat’s Nepal school sanitation projects NOTE: THIS INFORMATION IS DOCUMENTED TO SERVE AS A GUIDE ONLY. PROJECT-SPECIFIC, CERTIFIED

DETAILS MUSTBECOMPLETED BYRELEVANT PROFESSIONALS

48 NSTDG - 04 Design & Construction

NOTE: ALL DIMENSIONS AND SPECIFICATIONS NOTED HERE ARE A GUIDE ONLY. REFER TO STRUCTURAL ENGINEER’S DRAWINGS AND NOTES OBTAINED FOR ALL NEW BUILDINGS FOR ACTUAL DIMENSIONS AND SPECIFICATIONS TO FOLLOW.

DESIGN

THE

TOILET

CONFIGURATIONS

1. STONE

2. STEEL

3. SECURE & RELIABLE WATER SUPPLY

4. PLUMBING DESIGN

5. TOOTH, HAND & FACE WASHING

6. WASTE DISPOSAL SYSTEM

7. STONE & BRICK FOOTPATH

8. CUBICLE DESIGN & HARDWARE

9. VENTILATION & INSECT SCREENING

49

04 Design & Construction 47 THE OVERALL TOILET

50

KEY DESIGN FEATURES 51

NUMBERS, SIZES &

52

FOUNDATIONS, DOUBLE BRICK CONSTRUCTION & EARTHQUAKE BANDING 54

FRAMED ROOF CONSTRUCTION & STEEL ROOF SHEETING 59

(TO TOILET BLOCK) 61

63

66

67

71

72

77

2286mm [7'-6"]

THE OVERALL TOILET DESIGN

The Healthabitat sanitation block design utilises key design features in every project. These key features are linked to the priority of the HLPs and are proven to improve the health of its users.

Each design will vary in shape, size, aspect and details as a response to the specific conditions of each project site. For example, due to the size of a school there might be more toilets and handwashing facilities, or in a school for young children, the tap and sink height might be lowered. 6261mm [20'-612"]

2286mm [7'-6"]

water tank brick paving verandah of new HELP classroom block

SCHOOL scale: 1:100@A4 A02 date: 22.08.18 issue: SK

6261mm [20'-612"]

water tank brick paving verandah of new HELP classroom block

5766mm [18'-11"]

5766mm [18'-11"]

2059mm [6'-9"] CL P P P P septic tank soakage trenches

SCHOOL scale: 1:100@A4 A02 date: 22.08.18 issue: SK

1250mm [4'-1"]

1250mm [4'-1"]

1250mm [4'-1"] 1250mm [4'-1"] 3900mm [12'-9 1 2 "]

1250mm [4'-1"] 1250mm [4'-1"] 3900mm [12'-9 1 2 "]

new HELP classroom block

new HELP classroom block

2059mm [6'-9"] CL P P P P septic tank soakage trenches

1250mm [4'-1"] 4800mm [15'-9"] 2400mm [7'-1012"]

1500mm [4'-11"] 1809mm [5'-11"]

1500mm [4'-11"] 1809mm [5'-11"]

1250mm [4'-1"] 4800mm [15'-9"] 2400mm [7'-1012"]

• Sanitation block design - plan: Due to plans for a new classroom and the location of existing buildings in this project, the toilet block, septic tank and soakage trenches were located around it, as shown

50 NSTDG - 04 Design & Construction

8 7 4 6 6 7 7 3 5

THE KEY DESIGN FEATURES The key design features are listed in order of HLPs as it is always the priority to maximise health benefits. The HLPs are listed in order of importance. STONE & BRICK FOOTPATH CUBICLE DESIGN & HARDWARE STONE FOUNDATIONS, DOUBLE BRICK CONSTRUCTION & EARTHQUAKE BANDING STEEL FRAMED ROOF CONSTRUCTION & STEEL ROOF SHEETING SECURE & RELIABLE WATER SUPPLY (TO TOILET BLOCK) PLUMBING DESIGN TOOTH, HAND & FACE WASHING WASTE DISPOSAL SYSTEM • Sanitation block design - section 1 2 3 4 5 6 8 7 11' 0" (3350) 12'0"(3660) 900mm [2'-11 1 2 "] cement render brickwork (no render) cement render to handwashing walls 102mm [4"] 2097mm [6'-10 1 2 "] 102mm [4"] 2300mm [7'-6 1 2 "] EB EB tap hard render 615mm [2'] 610mm [2'] 254mm [10"] 1108mm [3'-7 1 2 "] 610mm [2'] 610mm [2'] 1065mm [3'-6"] F1: Column footing 1'x1'x2'deep 723mm [2'-4 1 2 "] 50mm [2"] ventilation screen 2164mm [7'-1"] 2" fall EB render 2'x2' stone footing BHOTENAMLANG SECONDARY SCHOOL SECTION A (both toilets) scale: 1:50@A4 A06 date: 22.08.18 issue: SK 11' 0" (3350) 12' 0" (3660) 900mm 1[2'-11"]2 cement render brickwork (no render) 102mm [4"] 2097mm 1[6'-10"]2 102mm [4"] 2300mm 1[7'-6"]2 EB EB tap hard render 615mm [2'] 1108mm 1[3'-7"]2 610mm [2'] 610mm [2'] 1065mm [3'-6"] 50mm [2"] ventilation screen 2" fall EB render 2'x2' stone footing SHREE BHOTENAMLANG SECONDARY SCHOOL END ELEVATION, SECTION A (both toilets) scale: 1:50@A4 A06 date: 22.08.18 issue: SK 100mm tie beam 1 2 1 2 5 8 9 7 51 S 1 3 6 9 S 9 S-Safetyandlifethreateningissues HLP9-Reducinghazardsthat cause trauma. 1 3 HLP1-Washingpeople HLP3-Removingwastewater 1 3 (continued) HLP1-Washingpeople HLP3-Removingwastewater VENTILATION & INSECT SCREENING 9 6 HLP6.Reducingthenegativeeffectsof animals,insectsandvermin.

TOILET NUMBERS, SIZES & CONFIGURATIONS

Area requirements are dependent on the nature of the program: toilets/handwashing only, teeth only, or toilet/ handwashing plus teeth.

Simple tables outlining student-to-toilet ratio and area diagrams have helped Healthabitat in their feasibility studies and initial conversations to calculate facilities, footprint and cost requirements.

Toilet Numbers

School Population

Toilet Sizes and Areas

Toilet Sizes and Areas

How many boys are at the school?: ...............................................

School Population

How many boys are at the school?: ............................................... How many girls are at the school?: ................................................ How many t eachers are at the school?: ..........................................

How many girls are at the school?: ................................................

How many t eachers are at the school?: ..........................................

Number of toilets and handwashing points

Circle appropriate field based on total number of people using the school’s toilets

Number of toilets and handwashing points

Toilets and hand washing points

Circle appropriate field based on total number of people using the school’s toilets

Number of people using facilities

Number of people using facilities

Toilets required for school (1 toilet per 60 people)

Toilets and hand washing points

Girls Boys* Teachers Hand basins 100 3 1 1 1 2 200 3 1 1 1 2 300 5 2 2 1 2 400 7 3 3 1 4 500 8 3 3 2 4 600 10 4 4 2 4 700 12 5 5 2 6 800 14 6 6 2 6 900 15 6 6 3 8 1000 17 7 7 3 8 *1 of the male toilets will be a urinal, unless the total number of male toilets is less than 2

Toilets required for school (1 toilet per 60 people)

of B Divisional breakdown oy vs girl toilets depends on the ratio of boys:girls at the school hool with 600 people and a ratio of boys:girls = 3:1 toilet allocation for student For example, in a sc s = 6:2 (boys:girls)

Note*

Divisional breakdown of boy-girl toilets is dependent on the ratio of boys to girls at school. For example in a school of 600 people;

Girls Boys* Teachers Hand basins 100 3 1 1 1 2 200 3 1 1 1 2 300 5 2 2 1 2 400 7 3 3 1 4 500 8 3 3 2 4 600 10 4 4 2 4 700 12 5 5 2 6 800 14 6 6 2 6 900 15 6 6 3 8 1000 17 7 7 3 8 *1 of the male toilets will be a urinal, unless the total number of male toilets is less than 2

Ratio of boy: girl = 3:1 Toilet allocation for students would be = 6:2 (boy: girl) Areas

Note* Divisional breakdown of boy-girl toilets is dependent on the ratio of boys to girls at school. For example in a school of 600 people; Ratio of boy: girl = 3:1 Toilet allocation for students would be = 6:2 (boy: girl) Areas

of B Divisional breakdown oy vs girl toilets depends on the ratio of boys:girls at the school hool with 600 people and a ratio of boys:girls = 3:1 toilet allocation for student For example, in a sc s = 6:2 (boys:girls)

Toilet Sizes & Footprint

Notes:

• Excerpt from feasibility study document • Excerpt from feasibility study document

Notes:

The average size of a toilet cubicle, including slab and handwashing points, is 5.2m²

The average size of a toilet cubicle, including slab and handwashing points, is 5.2m²

To calculate approximate area of new toilet blocks, multiply number of toilets (found above) by 5.2m²

To calculate approximate area of new toilet blocks, multiply number of toilets (found above) by 5.2m²

For example, a school with 800 students will need 14 toilets. These will occupy an approximate area of 72.8m² including slab and handwashing points

For example, a school with 800 students will need 14 toilets. These will occupy an approximate area of 72.8m² including slab and handwashing points

See Appendix for Feasibility & Toilet Configuration and Area resources

52 NSTDG - 04 Design & Construction

Hand Basin (2 taps) Hand Basin (3 taps)

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

Hand Basin (2 taps) Hand Basin (3 taps)

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

Hand Basin (2 taps) Hand Basin (3 taps)

Options: Without Urinal Girls / Teacher Girls / Teacher / Boys

CLIFF FACE

1200 2100 3650 450 850 1400 2100

1200 4’ 16m²/172ft² 12m

6m²/65ft² 12m²/129ft² 23m²/247ft² 22m²/237ft² 10m²/108ft² 16m

² 22m

1’10” 7’ 1’6” 12’2” 3.3m/11’ 3m/10’ 3m/10’

The following are diagrams of possible toilet configurations and their areas

Toilet Footprints and Sizes

²/129ft²

²/172ft

²/237ft² 20m²/215ft² 4’8”

2.6m/8’8” 6.2m/20’8” 6.2m/20’8” 3.3m/11’

CLIFF FACE

1200 2100 3650 450 850

2100

1400

CLIFF FACE

1200 2100 3650 450 850

2100

2m/6’6” 3.8m/12’8”

6m/20’

1400

4.8m/16’ 2m/6’6”

8.4m/28’ 3.3m/11’ 2.6m/8’8” 3.5m/11’8” 6m/20’

Excerpt from feasibility study document 53

Toilet Configurations •

1. STONE FOUNDATIONS, DOUBLE BRICK CONSTRUCTION & EARTHQUAKE BANDING

Earthquake banding was introduced into Healthabitat’s sanitation projects as a result of the Nepal earthquake in April 2015. The earthquake killed 9,000, injured nearly 22,000 and made hundreds of thousands homeless due to building loss and damage.

PROBLEM - Many buildings failed in the earthquake due to:

• landslips as a result of the earthquake which damaged buildings that were sited on fill on a sloping site

• no steel reinforcing or structural components for tensile stability in walls and foundations

• stone wall gable ends, unreinforced and not tied into the roof or wall structure - in many cases these fell into the building causing injury and death

• placing the roof on top of the walls without tying this into the structure

• little to no use of traditional timber construction due to material shortage and excessive cost. Traditional building techniques often withstood earthquakes due to construction techniques.

SOLUTION - Concrete earthquake banding with the introduction of steel reinforcing is now used, as well as locally available building materials (traditional stone with mud mortar and now double brick). This increases the tensile strength of the building’s walls so that it remains intact in the event of an earthquake, increasing safety for people. There are four key areas of the construction that increase earthquake resilience. Shown through extracts from the ‘Draft Construction Manual’ produced in the 2016 Sanitation Studio, these include:

Excavation and Stone Foundations

Plinth (bottom) Earthquake Band - Steel and Concrete Middle Earthquake Band - Steel and Concrete Roof (Top) Earthquake band - Steel and Concrete

See Appendix under

‘Relevant Resources’ for Nepal Government Earthquake document link

a b c d a b c d 54 NSTDG - 04 Design & Construction

Excavation

•

• accurate set out measurements and footing depths

• types, sizes, cleanliness and quality of stone

• stone laying - staggered joints (common bond pattern).

Typical Footing Plan (nottoscale)

& Stone Foundations When excavating and constructing the stone foundations in preparation for the first concrete band, it is important to consider:

siting and excavation on stable and compacted ground

• Project photos: Strip footing excavation and the beginning of laying stone footings 800 300 6" Thick Plinth Band 265 400 150 150 115 350 115 110 GL GL 580 800 300 6" Thick Plinth Band 265 400 150 150 115 350 115 230 GL GL 580 Stone footing F2 earthquake band / outside double brick wall EB F2 F2 EB EB EB EB F1 F1 F1 650mm F1 F1 650mm 610mm F3 4" PVC form for vertical rod 12mmØ into F1 footing FOOTING PLAN 650mm 569mm 650mm 569mm 650mm 569mm 650mm 569mm 650mm 650mm 1427mm 610mm 1698mm 300mm 1054mm 1219mm 1219mm 1219mm 1219mm 5527mm 2057mm 2687mm 650 x 800 stone footing F1 300 X 600 post footing F2 F3 650 x 600 stone footing a 55

P.C.C (1:3:6) 300mm

Foundations (continued) 230 GL GL 580

Soling Compacted Earth F2 F2 F2 FOOTING PLAN

Stone layouts should have through stones with the placement of vertical steel at corners of the building junctions and at window and door openings. 150 150 115 350 115

TYPICAL FOOTING SECTION (Outer Wall)

TYPICAL FOOTING SECTION (Inner Wall) Stone footing 650 650

ENTRASPACE TECHNICAL CONSULTANT ANAMNAGAR, KATHMANDU Tel: 977-1-4252094 Email:etcconsultation@gmail.com SUBMITTED BY: SUBMITTED TO: PROJECT NAME: SHREE BHOTENAMLANG SECONDARY SCHOOL DESIGN OF TOILET BLOCK

OK? THROUGH STONES - TO TIE THE WALL TOGETHER Typical Footing Section (Outer Wall) (nottoscale) Typical Footing Section (Inner Wall) (nottoscale) • At corners + junctions Install 4” Ø PVC pipe into stone foundation formwork, 1’6” deep with 3/8” steel Remove PVC pipe, infill with concrete to correct ratio as shown 400

• Project photos: Stone and brick wall building with earthquake bands 56 NSTDG - 04 Design & Construction

2 4 FOUNDATIONS

• Project photos: Stone foundations completed and PVC corner pipe with steel; Horizontal steel ladder and vertical rod detail with concrete band Excavation & Stone

a 1 Lyr Flat Brick Soling Compacted Earth 3" Thick P.C.C (1:3:6) 800 300

6" Thick Plinth Band 60 75 265 400 150 150 115 350 115 110 GL GL 580 1 Lyr Flat Brick

3" Thick

4 1/2" PVC PIPE INSTALLED 3/8" STELL INSTALLED 800

OK? OK? OK? 300

REMOVE PVC CONCRETE RATIO 6" Thick Plinth Band 60 75 265

The first concrete band includes a horizontal steel ladder that sits on top of the stonework, followed by a band of concrete on top.

b Plinth Ring Beam (6” Thick)

Middle Tie Ring Beam

Thick)

230 100 2-10mmØ MIDDLE TIE RING BEAM (4" THICK) 6mmØ @ 150 mm C/C 1055mm 100mm 1055mm 230mm 1054mm 100mm 1053mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm 230 150 4-12mmØ PLINTH RING BEAM (6" THICK) 6mmØ @ 150 mm C/C 990mm 230mm 990mm 230mm 989mm 230mm 988mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm 230 100 2-10mmØ MIDDLE TIE RING BEAM (4" THICK) 6mmØ @ 150 mm C/C 1055mm 100mm 1055mm 230mm 1054mm 100mm 1053mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm 230 150 4-12mmØ PLINTH RING BEAM (6" THICK) 6mmØ @ 150 mm C/C 990mm 230mm 990mm 230mm 989mm 230mm 988mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm outside 230 100 2-10mmØ MIDDLE TIE RING BEAM (4" THICK) 6mmØ @ 150 mm C/C 1055mm 100mm 1055mm 230mm 1054mm 100mm 1053mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm 230 150 4-12mmØ PLINTH RING BEAM

6mmØ @ 150 mm C/C 990mm 230mm 990mm 230mm 989mm 230mm 988mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm DATE: SCALE: S1 DSGN BY: AR. SAJANA

ACAD BY: AR. PRERANA

DWG NO CHKD BY: AR. SAJANA

SHEET TITLE: STRUCTURAL DRAWING STRUCTURAL DETAILS TOILET 2 SIGNATURE: 1:50 2018-08-17 NEC NO.:

57

Plinth (bottom) Earthquake Band - Steel and Concrete

(nottoscale)

(4”

(nottoscale)

(6" THICK)

SHRESTHA

JOSHI

SHRESTHA

It is important to install earthquake banding throughout the entire height of the wall in both stone and brick walls to increase their stability to resist earthquakes. Concrete bands at each 2’ of wall height with embedded steel are used, as in the earlier step. c Middle Earthquake Band - Steel and Concrete

ROOF - STEEL

Bend down vertical steel Bend down all vertical steel, tie into horizontal ladder

Install roof ties Tie steel strapping to horizontal steel ladder along exterior walls Space ties to rafter widths at18” centres Stand vertical, install final capping concrete band around the roof ties to all walls as per previous steps

OK ? OK ? VERTICAL

OK ? CONCRETE RATIO GSPublisherEngine 0.12.100.100 5 3 ROOF - STEEL OK? OK? VERTICAL STEEL BENT ROOF

OK? Connecting the

For a single storey

Use the

that

out

the

every

to connect

DO NOT use stone or brick to infill the roof ends ABOVE the ‘earthquake band’. Use timber or metal sheet. 8

• Project photos: Gable ends should be infilled with timber or steel, not brick or stone; Image of steel ties Roof (Top) Earthquake band - Steel and Concrete d Roof

ROOF

6mmØ @ 150 mm C/C 1055mm 100mm 1055mm 230mm 1054mm 100mm 1053mm 230mm 1219mm 1219mm 1219mm 1219mm 5105mm 230mm 1829mm 230mm 2057mm 2286mm 230mm 230 150 4-12mmØ 364mm 1319mm 1186mm 1169mm 540mm 504mm 1018mm 1039mm SHS50x50X2.5 SHS50x50X2.5 TRUSS SECTION DETAILS SHS50x50X2.5 SHS50x50X2.5 6mm truss downs EB to T1 58 NSTDG - 04 Design & Construction

STEEL BENT ROOF TIES INSTALLED

TIES INSTALLED

roof

house

steel strapping

comes

from

‘earthquake band’

18” (450mm) along the LONG walls

the roof timbers.

Key design features of the top concrete band include steel straps to secure the timber roof rafters to the wall. Ensure gable ends are infilled with lightweight material such as timber or metal sheet and not stone or brickwork. To infill with stone or brickwork is a safety hazard during an earthquake. It is important to:

Ring Beam (6” Thick) (nottoscale)

RING BEAM (6" THICK)

PROBLEM - Historically, roof structures in Nepal were made of local hardwood timber. As timber over time has become scarce and more expensive, roof structures have been made of materials that are less strong, durable and safe, with roof sheeting often held down by heavy objects. This is very dangerous and problematic when earthquakes occur, as the roof collapses, damaging property and injuring people.

SOLUTION - The toilet block design uses a steel roof truss system fabricated and welded on site to design and engineering specifications. Roof sheeting screw fixed to the steel structure provides a strong, durable and safe structure to cover the toilet cubicles and handwashing area to ensure the facilities can be utilised in all weather with less chance of collapse and injury during future earthquakes.

2.1 Steel Framed Roof Construction

2. STEEL FRAMED ROOF CONSTRUCTION & STEEL ROOF SHEETING a

Steel Roof Truss to Toilet Cubicles

• Roof structure is directed away from rain and wind, allowing sun into the structure (i.e. roof slopes down towards wind/rain).

• Generous overhang around all sides allows allweather protection in toilets and handwashing areas.

• All design and fabrication is to engineer’s specifications, with engineer inspection upon completion of frame.

Specifications: Continuous fillet weld to all rectangular ollow sections (RHS) members RHS ends capped Mono roof truss fixed down into top of wall to engineer’s specifications All steel structure is painted

Skillion Roof to Handwashing Area

• Sloping the roof in the opposite direction to high level roof ensures water doesn’t fall off roof in one direction.

Specifications: Weld roof into top plate on top of the toilet wall to connect the roof trusses Structure finishes 4”/100mm before end of roof sheeting

•

Truss structure section. detail drawing (example only)

b

59

• Roof framing detailed plan (by engineer): Showing tie down and structural member requirements

2.2 Steel Roof Sheeting

• LYSAGHT Installation Lap & Screw Specifications

a

Steel Roof Sheeting

• Strong

• Durable & easy to source in Nepalcommon construction material