Optum 360 – 440

Language: English

Language: English

▪ Official naming: • Range name: Optum • Model name: Optum 440

Key selling points

▪ Multi-Purpose Tractor Concept

▪ Designed for heavy-duty fieldwork, transport, and front/rear implement versatility.

▪ Wide range of configurable options for PTO, linkage, hydraulics, and trailer systems.

▪ High-Performance Cursor 9 Engine

▪ Up to 435 hp and 1851 Nm torque, optimized for extreme load applications.

▪ Flat power curve and low idle strategy for fuel efficiency and smooth CVT operation.

▪ Industry-Leading Engine Brake System

▪ Decompression Brake delivers up to 700 Nm braking force for safe deceleration.

▪ Reduces wear on service brakes and supports cost-effective transport.

▪ Advanced Transmission & Hydraulics

▪ CVXDrive with 4 forward/2 reverse ranges and Active Hold Control for slope safety.

▪ Up to 360 l/min hydraulic flow, Power Beyond, and remote valve customization.

▪ Comfort & Technology Integration

▪ Premium 68 dba cab, Advanced Suspension, Pro 1200 monitor for operator comfort.

▪ Full ISOBUS, AccuGuide, AccuSync, and FieldOps for precision farming.

▪ CTIS – Central Tyre Inflation System

▪ Fully integrated, high-capacity twin-cylinder compressor for fast inflation.

▪ Reduces soil compaction, fuel consumption, and tyre wear for field and road use.

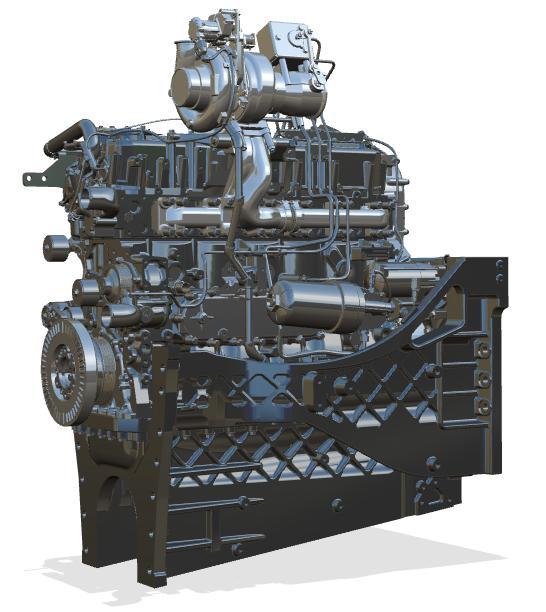

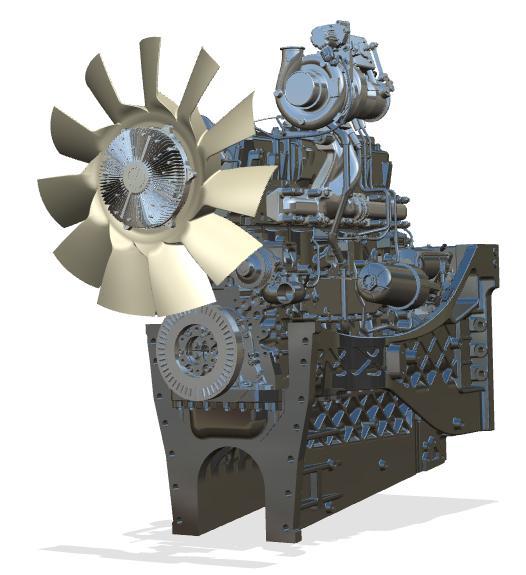

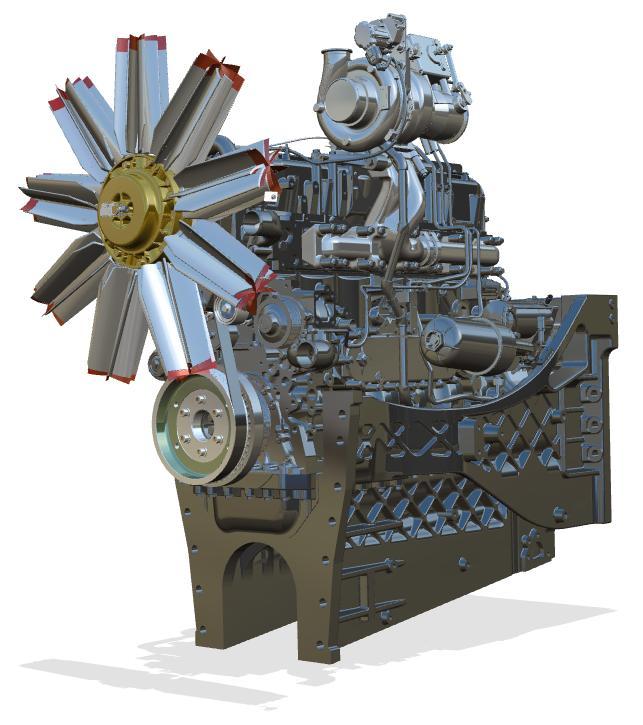

▪ Specific Cursor 9 engine developed for Optum 360 – 440, manufactured in Bourbon-Lancy in France.

▪ In-line 6 Cylinder.

▪ 4 valves per cylinder for better gas exchange.

▪ Common Rail injection.

▪ Cross Flow cylinder head design helps to keep the intake side cool. The cylinder is charged with cooler air for better burn, more torque and lower fuel consumption.

▪ Flat power curve, optimises CVT performance.

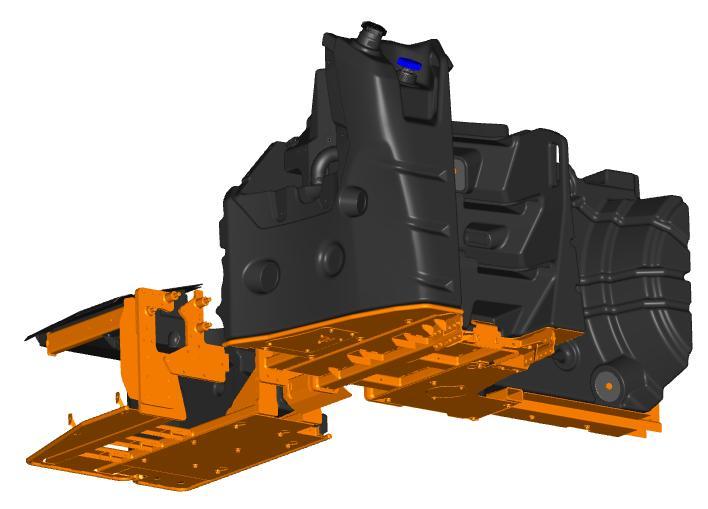

▪ Structural oil sump to minimize weight and maximize turn angle.

▪ Low idle strategy at 650 rpm

▪ Engine service interval of 750 hours, easiest maintanance.

▪ Stage V compliant FPT Cursor 9

▪ Cursor 9 engine specially produced and tuned for Optum 360 – 440.

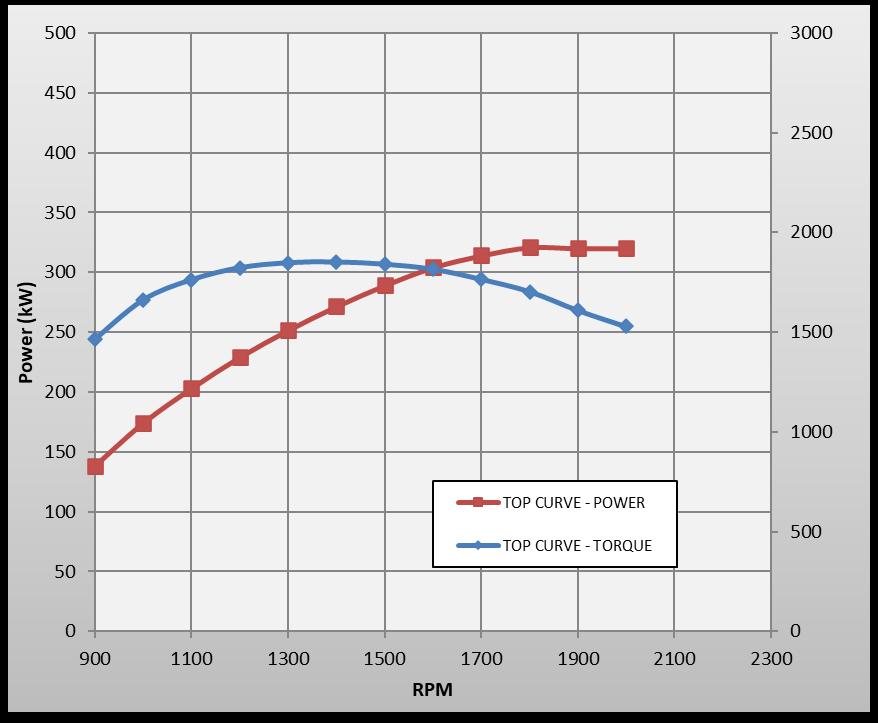

▪ Constant high torque in the wide range of 1100 – 1700 engine rpm.

▪ Maximum Power available from 1700 rpm until rated engine speed of 2000 rpm.

▪ Engine characteristics designed for extreme load applications.

▪ Power reserves due to torque rise.

+ Great engine characteristics

+ eVGT turbocharger for superior torque

+ Wide range of maximum power

▪ Constant engine speed + Eco Drive (dual hand throttle)

Two different engine speeds can be stored. Dual hand throttle allows quick and easy adjustment of the maximum / minimum engine speed as well as engine droop.

▪ APM Engine Transmission Management

Helps cutting fuel consumption by coordinating the engine speed and transmission ratio with the Multicontroller or drive pedal.

▪ Idle Speed Management

Low idle strategy at 650 rpm to further reduce fuel consumption.

▪ Vistronic Fan 762300

Engagement is electronically controlled via engine control unit, minimises power loss.

▪ Air filter and dust ejector

Air filter with spin tube pre cleaner and dust ejector to prevent the entrance of dirt into the engine.

▪ Battery isolator

An electronic battery isolator switch is standard to disconnect the electric power to the tractor.

▪ eVG Turbocharger

Electronically controlled variable geometry turbocharger for quicker engine response and higher torque at low engine speed.

▪ 250 Ampere Alternator

Powerful Alternator to supply several consumers with energy.

▪ Fuel tank

680 liter fuel tank + 93 liter AdBlue tank

Integrated, illuminated shallow steps with adjustable lower step. Power socket for fuel bowser pump, above top step. Left hand toolbox.

▪ Variable Pitch Fan with reverse function – 762302

Hydraulically constantly adjustment of fan blades for best cooling.

Reversible fan blades reverse the airflow to powerfully clean the cooling package.

→ for operation with a lot of plant residue or dusty conditions!

→ increases performance & lowers fuel consumption.

▪ Engine/Decompression Brake 762310

Unique feature, most powerful engine retardation.

For further details, please see the next page.

→ for efficient and cost-saving transport!

▪ Fuel Tank & Protective Guarding 762308

To protect the 680 liter fuel tank and the 93 liter AdBlue/DEF tank

→ for special operations on uneven terrain!

▪ Grid Heater 762312

Intake air heating device that ensures best engine starting.

→ for operation in cold environments

▪ Grid Heater + 240 V engine/transmission heater 762314

To pre-heat the engine and transmission for immediate full operational readiness when starting at very cold environments.

→ for operation in very cold environments.

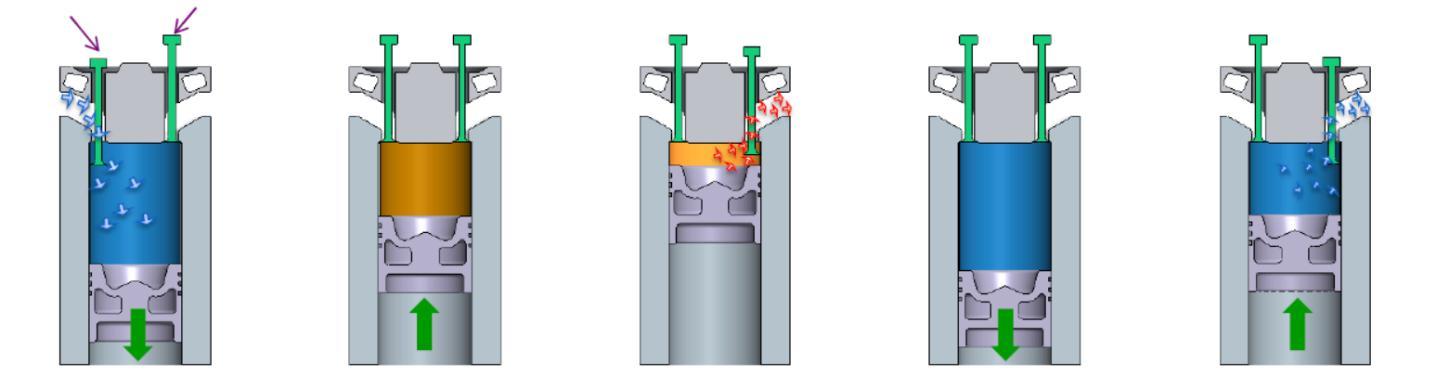

Unique feature, the most powerful engine retardation!

▪ Multiple components contribute to achieving the highest engine braking force in the whole tractor segment:

▪ eVGT – Turbocharger

▪ Exhaust Flap Brake

▪ Engine Fan (Vistronic or Variable Pitch Fan)

▪ Decompression Brake

▪ It releases all cylinder pressure during non combustion cycles. Energy is absorbed by compressing the air at the upstroke, then this pressure is released before the piston gets to the downstroke, removing the air spring effect usually present.

▪ Two Aggressivity settings:

▪ Low: without Decompresssion Brake (200 Nm brake force + fan)

▪ High: with Decompression Brake (700 Nm brake force + fan)

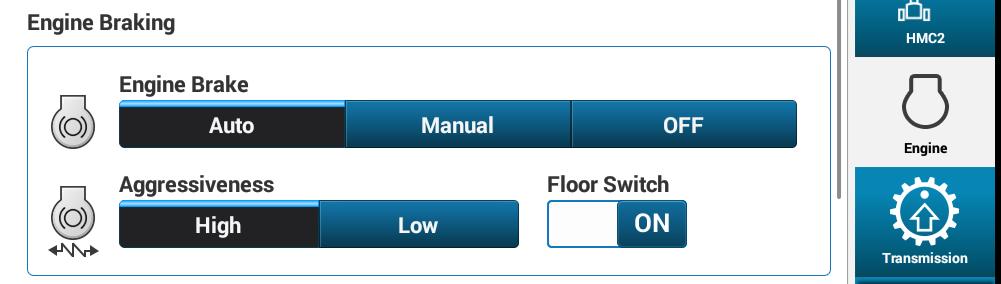

▪ Engine Brake modes:

▪ Auto: automatic activation to reduce/maintain speed when actual vehicle speed is higher than target speed.

▪ Manual: commanded by the operator either with exhaust grake floor button or via a configurable button.

▪ OFF: permanent OFF

▪ If the tractor is expected to perform frequently low-noise operations, the engine fan can be excluded from the engine brake system via EST, to avoid noise emissions.

+ Significantly reduces wear and tear on service brakes.

+ Highest operator comfort.

+ Efficient and cost saving transport!

Unique feature, the most powerful engine retardation!

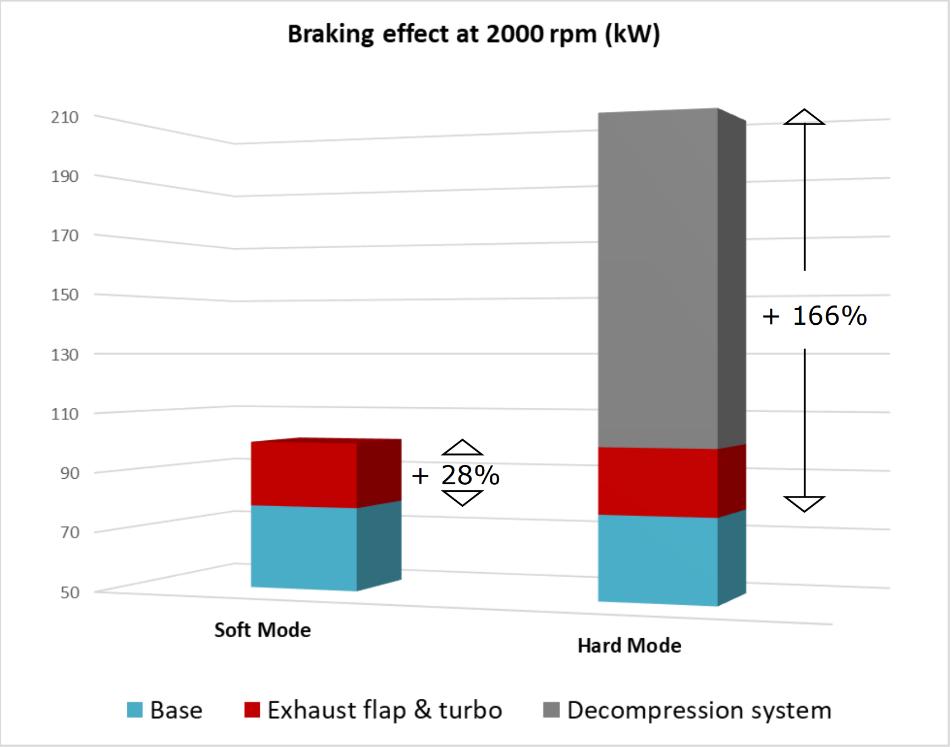

▪ The blue pillar represents the normal engine braking effect that every engine achieves.

▪ Activating the engine brake in the low aggressiveness level increases the standard engine braking effect by 28 percent.

The exhaust flap and the turbocharger are used in this setting.

This feature is common in the market.

▪ At the higher aggressiveness level of the engine brake, the braking effect increases by 166 percent!

In this setting the decompression brake is used additionally.

Variable Pitch Fan can increase the braking effect even further.

This feature is unique to the Cursor 9 engine!

+ Highest engine braking effect on the market.

+ Perfect for smooth and cost-effective transport.

▪ All models meet the Stage V emission standards with HI-eSCR2 technology.

▪ Components:

▪ Exhaust flap and DOC; to ensure highest SCR efficiency.

▪ SCR catalyst; NOx reduction, particulate trapping and oxidation.

▪ CUC; break down the remaining ammonia.

▪ HI-eSCR2, the exclusive, patented and maintenance free after-treatment system.

▪ No exhaust gas recirculation needed:

▪ Pure, oxygen-rich charge air increases efficiency.

▪ Reduces complexity, improving reliability and no maintenance needed.

▪ fewer combustion byproducts (like soot and acids) enter the engine → higher engine oil quality.

+ Ensures emission level Stage V with a highly efficient aftertreatment system.

+ Lower fuel consumption.

+ Higher engine oil quality reduces total cost of ownership.

The engine delivers powerful torque, great fuel efficiency and a flat power curve optimized for CVT performance. Up to 435 hp and 1851 Nm.

2. Efficiency

Optimized engine design, smart management systems, and a maintenance-free aftertreatment solution combine to deliver maximum fuel efficiency, reduced operating costs, and extended service life.

The Decompression Brake offers more than 700 Nm braking force, making it the most powerful engine retardation system in the tractor market. It reduces wear on service brakes and supports safe, cost-effective transport.

The patented HI-eSCR2 system meets Stage V emission standards without EGR, improving engine efficiency, reducing fuel consumption, and lowering total cost of ownership through better oil quality and zero maintenance.

Optional features like the Variable Pitch Fan with reverse function, fuel tank protection, and engine/transmission pre-heating systems ensure reliable performance difficult conditions.

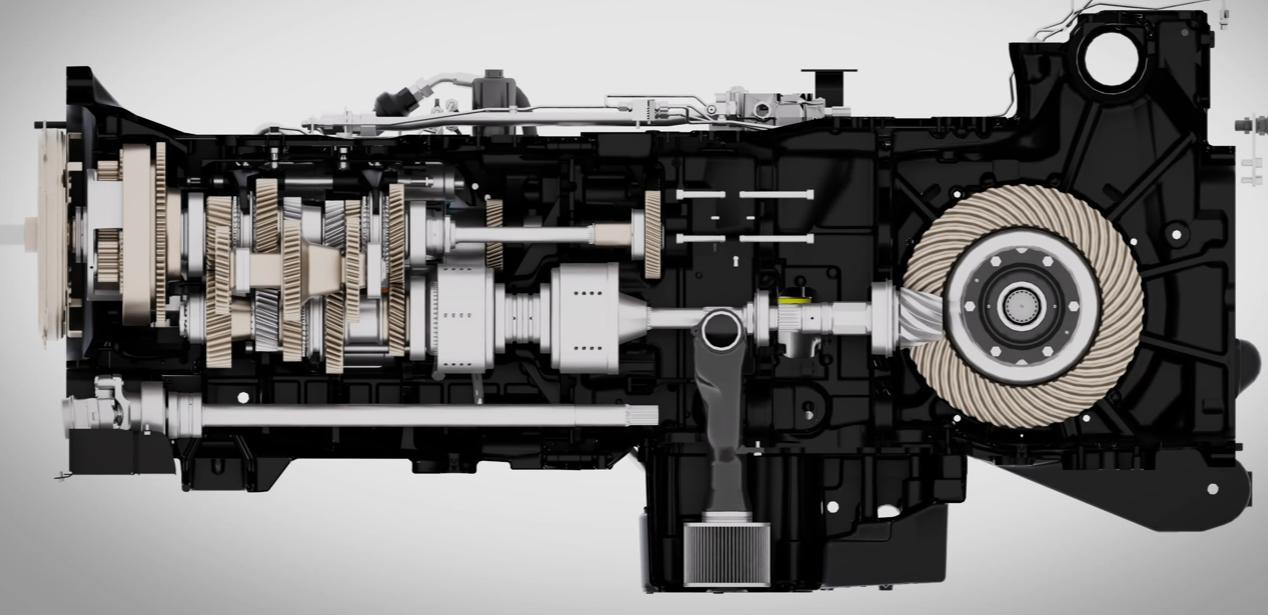

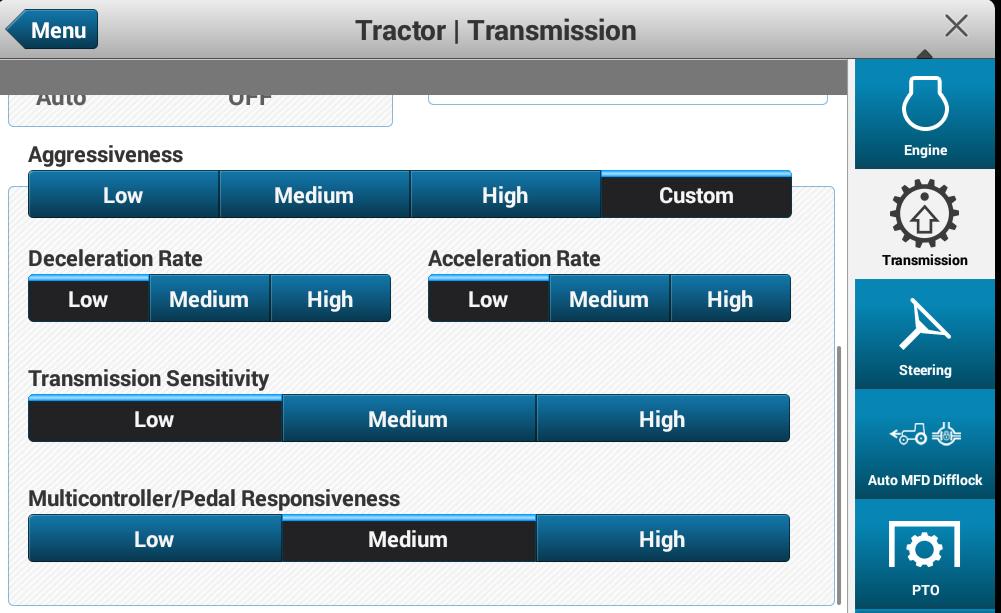

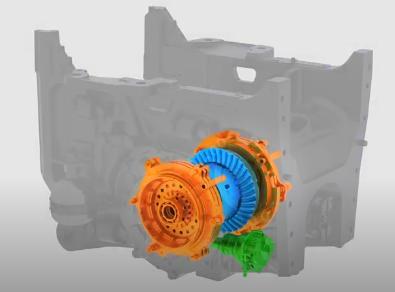

All Optum 360 – 440 are CVXDrive equipped.

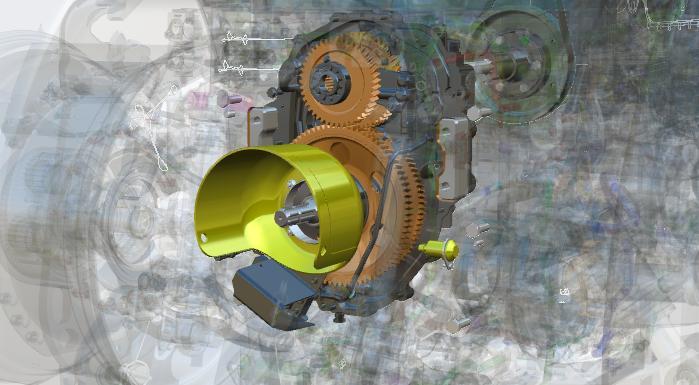

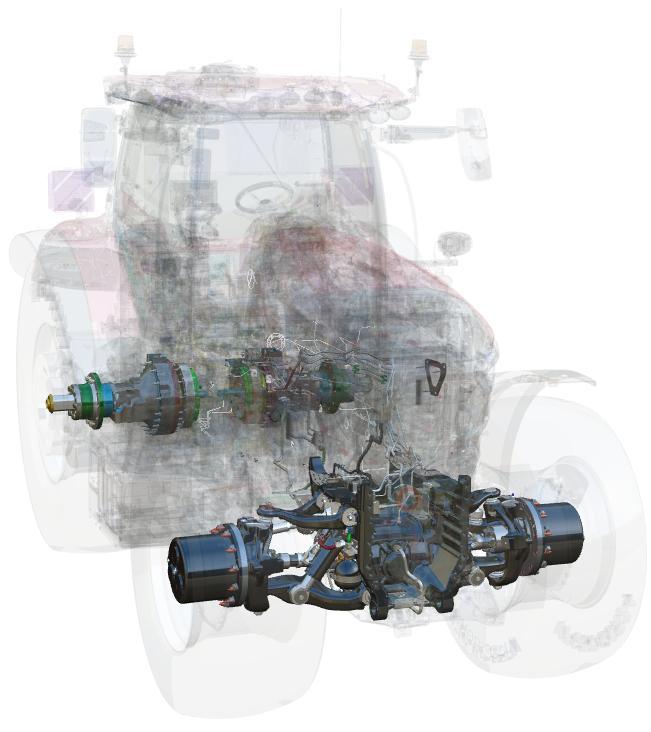

▪ The reinforced driveline of the Optum 360 –440 tractors is an evolution of the proven 4x2 concept.

▪ New, tougher transmission using the same logic as the proven Optum 270 – 340 gearbox.

▪ 4 ranges forward and 2 reverse maximize the mechanical drive to deliver excellent efficiency for transport and field work.

▪ Only 1 wet double clutch shifts the whole gearbox to minimise losses.

▪ 3 different speed options are available:

▪ 40 kph @ 1195 rpm

▪ 50 kph @ 1495 rpm

60 kph @ 1790 rpm

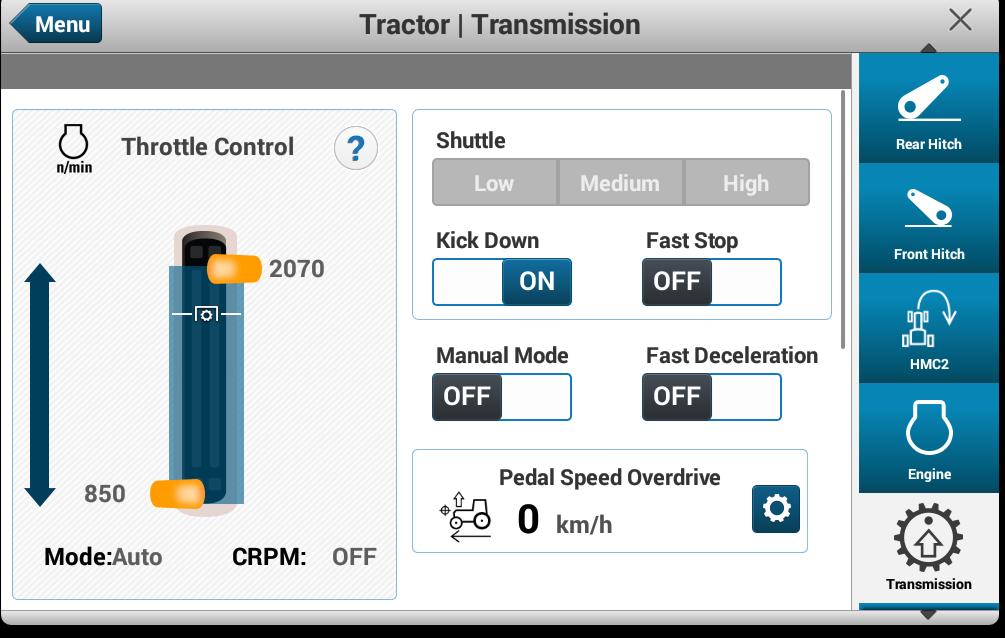

▪ Eco Drive (dual hand throttle) visual indication.

Orange shuttle levers are active, grey shuttle leversindicates inactiveness when used with CRPM or manualmode.

▪ Power shuttle sensitivity

Quick or smooth shuttle behaviour.

▪ Kick down.

Allows the engine to quickly accelerate to peak power.

▪ Fast stop.

Recommended for applications where the tractor needsto stop as fast as possible.

▪ Manual Mode (APM deactivation).

The engine transmission management can be switched off. In Manuel Mode, the transmission is controlled via Multicontroller, the engine speed via foot pedal or hand throttle.

▪ Fast Deceleration

The engine braking is used to decelerate as fast as possible.

▪ Pedal Speed override

Adds selected speed to target speed.

▪ Custom Mode

Allows operators to adjust, save and recall vehicle behavior based on personal preferences and application requirements.

▪ Some transport situations require the use of the service brake for the trailer only, i.e., when crossing a side slope with aheavy trailer attached.

▪ Press and hold the Power Shuttle button on the Multicontroller.

▪ Now you can use brake and drive pedal (or Multicontroller) simultaneously.

▪ The tractor keeps pulling under power, thereby keeping the vehicle train stretched.

+ Great feature for safe trailer braking, standard on all CVXDrive models.

+ Safety and comfortable transport.

CVXDrive key selling points

1. Efficiency

4 mechanical ranges forward and 2 reverse with automatic range change for superior efficiency.

100% mechanic power transfer for common work and transport speeds.

2. Acitve Hold Control

Tractor has the ability to stop on a hill without applying the brake or clutch, offering comfort & safety on hilly slopes.

3. APM – Automatic Productivity Management

Engine and transmission management system which controls the drive speed independently from the engine rpm. Highest comfort for all operations and maximum fuel savings.

4. Continuous Power Delivery

Optimal traction, continuous pulling performance even under varying loads.

5. Operator-Friendly

The simplest transmission control. Suitable for every worker.

6. Various speed options

40, 50 and 60 kph options

▪ The Optum 360 – 440 comes in standard configuration with an electrically shift able 2 speed PTO.

▪ Comfortable, electrically actuated, PTO speed change via Pro 1200 monitor.

▪ PTO standard features:

▪ Auto PTO

▪ PTO brake

▪ External Control

▪ Adjustable engagement

▪ Drop out speed

▪ 2 different speed configurations are available:

▪ 540Eco / 1000 rear PTO, 6 spline and 21 spline shaft (both 1 3/8”)

▪ 1000 / 1000Eco rear PTO, 21 spline shaft (1 3/8”)

▪ PTO speeds are reached at ~ 1850 engine rpm (Eco: ~ 1580 rpm)

▪ Additional 20 Spline 1 3/4” shaft available as option.

▪ All PTO shafts are bolt on for best durability.

▪ Heavy Duty 2 speed front PTO.

▪ Comfortable, electrically actuated, PTO speed change via Pro 1200 monitor.

▪ PTO standard features:

▪ Auto PTO

▪ PTO brake

▪ External Control

▪ Drop out speed

▪ Speed configuration:

▪ 1000 / 1000 Eco front PTO,

▪ PTO speed is reached at ~ 1850 engine rpm (Eco: ~ 1580 rpm)

▪ Counterclockwise Direction, 6 spline - 1 3/8” shaft.

▪ Additional 21 spline 1 3/8” shaft available as option.

▪ Max power: 186 kW / 253 hp

+ Unique Selling Point: Industry exclusive ECO Front PTO.

+ Reduced engine speed in low load conditions, even with front implements, for reduced fuel consumption.

▪ PTO speed change:

▪ Front and rear PTO come standard with an electrically shiftable gearbox.

▪ Comfortable speed change via Pro 1200 monitor.

▪ Engagement rate can be set for heavy implements with a high flywheel mass.

▪ Auto PTO:

▪ Auto PTO uses the three-point-linkage position to engage and disengage the PTO. It allows easy and comfortable operation on the headland an no PTO shaft damage. The engage / disengage points can be adjusted and stored for an implement.

▪ PTO Brake:

▪ PTO brake can be shut off by pressing a dedicated button on right hand side of the Multicontroller armrest.

▪ Drop out speed:

▪ Automatic PTO disengagement below a certain PTO speed prevents the engine from stalling.

▪ PTO intention switch:

▪ To carry out stationary PTO work while no operator is in the cab, the intention switched must be pressed before leaving the seat.

Operators benefit from comfortable, electrically actuated PTO speed changes and full control over engagement rate settings. This allows a smoother and safer PTO activation tailored to the task.

The Auto PTO feature uses the three-point linkage position to automatically engage/disengage the PTO, minimizing wear and tear on the shaft and simplifying headland turns.

Features like the PTO brake, drop-out speed, and intention switch ensure safe operation during stationary work and protect the engine from stalling under load, enhancing reliability and operator confidence.

Case IH offers the industry-leading ECO Front PTO, allowing efficient operation of front-mounted implements at reduced engine speeds cutting fuel costs without compromising performance.

2-speed rear and front PTOs, including ECO modes that reduce engine RPM for lower fuel consumption. Multiple shaft options (6, 21, and 20 spline) ensure compatibility with a wide range of implements.

▪ All Optum 360 – 440 are equipped with bar axle.

▪ 2 different bar axles are available:

▪ Bar Axle – 98 Inches

▪ Bar Axle – 119 Inches

▪ Large rear tyres with diameter up to 220 cm for highest traction.

▪ Steering Brake as standard feature.

▪ 100% differential lock

▪ Auto mode and permanent mode

▪ Full integration of air lines for tyre inflation system available as an option.

▪ Max. rear axle load:

▪ Unrestricted: 11.500 kg

▪ Restricted: 12.500 kg

8300000 LESS REAR TIRES AND RIMS

8950801 710/75R 42 R1W

8931901 VF 800/70R42 DW27BX42

8971501 VF710/75R42 DW25Bx42

8941101 VF710/75R42 DW25Bx42 EVOBIB

8330701 VF750/70R44

8942201 VF650/85R42 FIX

8951801 900/60R 42 R1W

8960103 VF900/60R42

8452501 480/95R 50 R1W DUAL

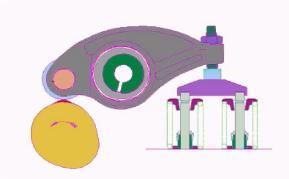

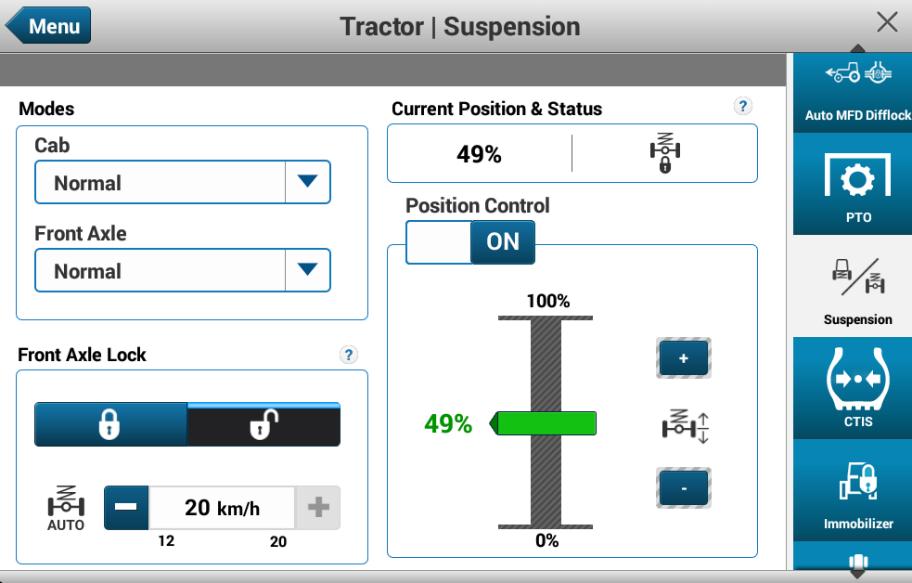

▪ New CNH developed Independent Front Axle Suspension (IFS) as standard configuration.

▪ Hydropneumatic independent wheel suspension.

▪ 250mm overall suspension travel distance.

▪ Wheels always vertical for great manoeuvrability.

▪ Software for anti roll and anti pitch functionalities in addition to self centering behavior.

▪ Full integration of air lines for tyre inflation system available as an option.

▪ Low maintenance, long durability.

▪ Suspension position sensors are inside the rams.

▪ Just 4 grease points on damping rams.

▪ Double wishbone design for comfort and high carrying capacity.

▪ 8.500 kg unrestricted

▪ 10.500 kg restricted

+ Greatest comfort compared with high carrying capacity.

+ Low maintance, long durability.

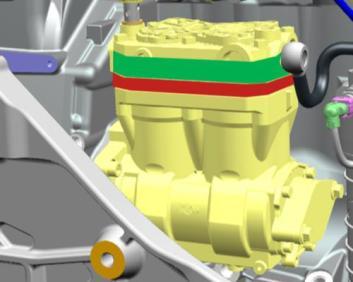

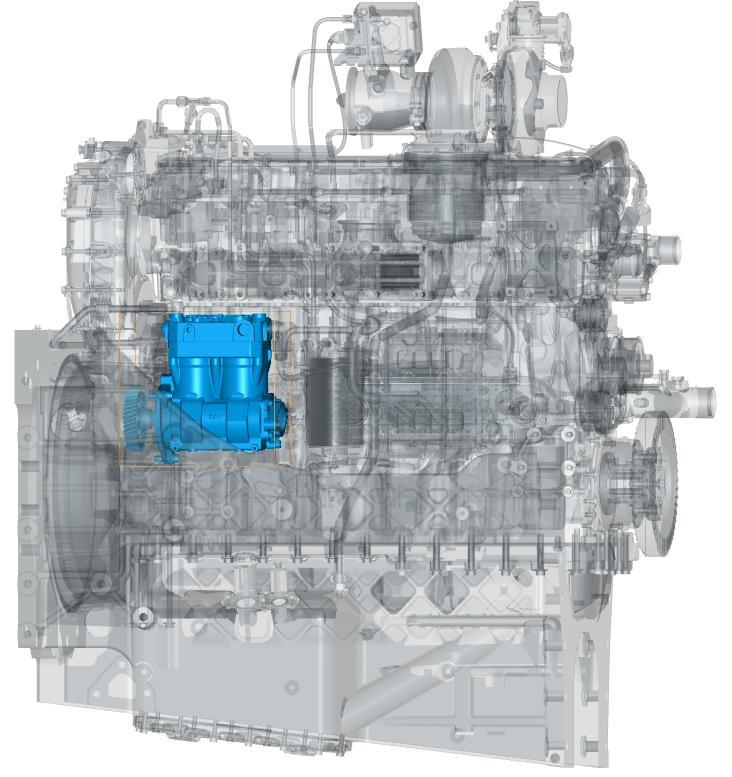

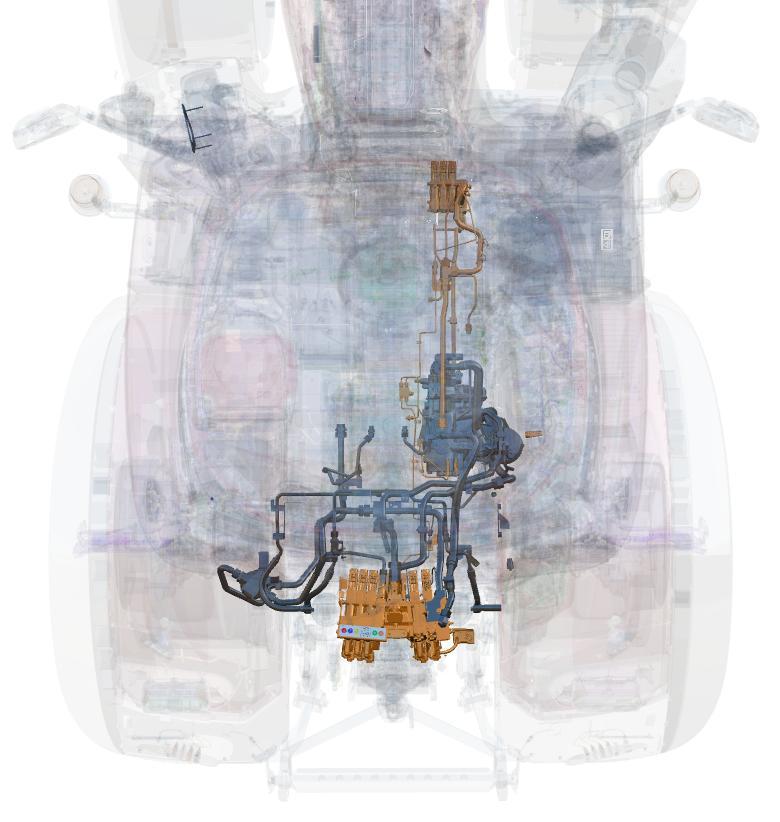

Fully Integrated Tyre Inflation System

▪ Fully Integrated CTIS for Smooth Operation.

− The CTIS features a factory-integrated design with a user-friendly control interface.

▪ High-Capacity, Fast Inflation System.

Twin-cylinder 630cc gear-driven compressor

Increasing pressure by +1 bar in under 5 minutes for standard tyre size, minimizing downtime and maximizing productivity.

▪ Smart, Efficient Air Management.

Single-line supply per hub simplifies the system. No pressure is held in the line when not inflating.

Reduced wear on rotary seals and extending system life.

▪ Proven Performance Benefits:

Reduced rolling resistance on the road

Reduced soil compaction in the field

− Reduced tyre wear and damage

− Increased traction

Reduced fuel consumption

+ Fully integrated, high capacity tyre inflation system.

+ User friendly, low maintance approach

The CNH-developed Independent Front Axle Suspension (IFS) features hydropneumatic wheel suspension with 250 mm travel and a double wishbone design, delivering highest comfort and load capacity.

2. Maximum Traction

The rear axle supports large tyres (up to 220 cm diameter) and includes a 100% differential lock with auto and permanent modes, ensuring maximum traction and stability in all conditions.

3.

Integrated software on the front axle provides anti-roll, anti-pitch, and self-centering functionalities, improving driving dynamics and safety. The rear axle offers adjustable bar axle options allowing flexible configurations to meet various needs.

Both axles are engineered for minimal maintenance: internal sensors, few grease points, and robust components contribute to long service life and reduced downtime. Both axles are built for highest capacity and strength.

Full integration of air lines for a high-capacity tyre inflation system is available on both axles, boosting adaptability and efficiency across various terrains.

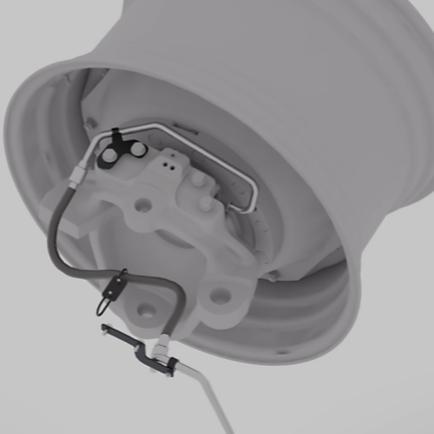

▪ Advanced Pressurized Braking System

− Fully pressurized, hydraulic brake circuit—delivering instant, powerful braking far beyond conventional systems.

▪ Exceptional Pedal Feel & Control

With an integrated accumulator, operators enjoy smooth, responsive pedal action, reduced travel, and confident braking precision.

▪ Dynamic Brake Steering

Independent left/right brake pedals, as a standard feature, enable Dynamic Brake Steering, giving operators enhanced maneuverability and control in tight or challenging terrain.

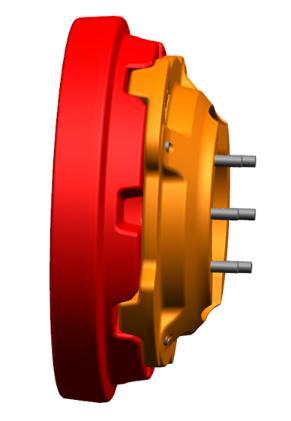

▪ Customizable Brake Disc Options

standard or heavy-duty dual brake discs, built for lasting durability and performance in the toughest applications.

▪ Front Axle Brakes as option:

▪ Significant change to the front brake design compared to existing CNH axles. Increased brake capacity.

▪ Wet Double Disc Brakes.

▪ Oil – cooled system for long term durability.

▪ Electrical scavenge pump circulates oil to rear axle.

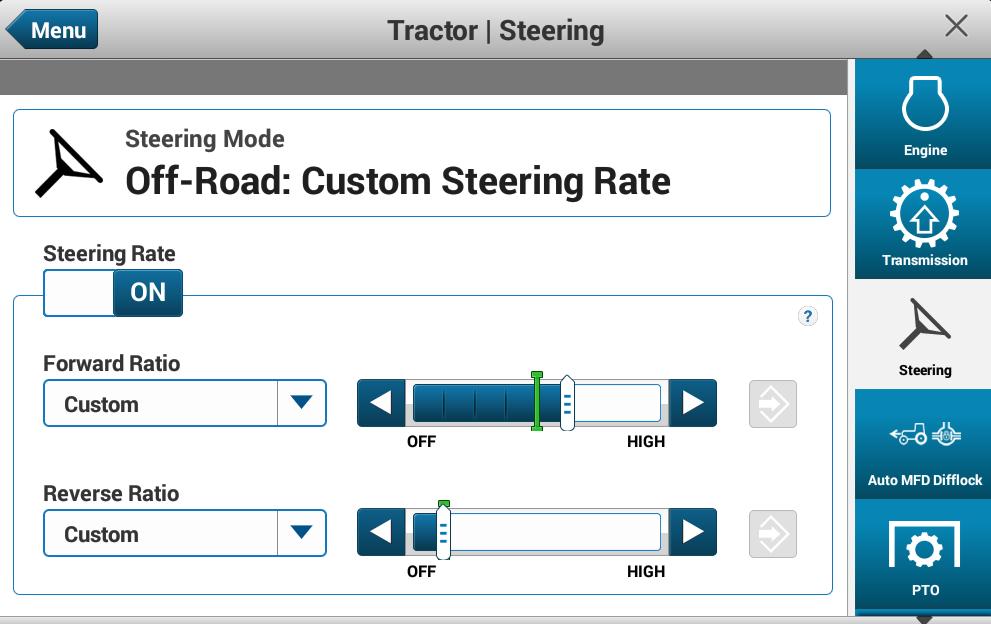

Comfortable and safe steering.

▪ Reactive Steering

− The steering system features a self centering characteristic that allows the steering system to operate in a reactive mode. This means that the wheels return to straight forward position after driving around a curve.

Note: The AccuGuide master switch needs to be in road mode (off).

Standard feature.

▪ Adaptive Steering Control (ASC):

This variable rate steering system features an electronically controlled steering orbitrol unit. Allows the operator to choose a steering ratio independently for forward and reverse drive direction:

▪ Guidance ready options needed for AccuGuide operation.

+ Fully integrated, high capacity tyre inflation system.

+ User friendly, low maintance approach

▪ Optum models can be equipped with various trailer brake options, depending on different needs and local market requirements.

▪ EU markets: The hydraulic trailer brakes require to have the same fail safe features as pneumatic brakes. This requires a dual line, proportionally controlled hydraulic system with an added safety valve like pneumatic brakes.

▪ Pneumatic trailer brake always designed as a dual line variant.

3 differint couplers available:

▪ UK type couplers

▪ Italian type couplers

▪ Universal couplers for all other markets

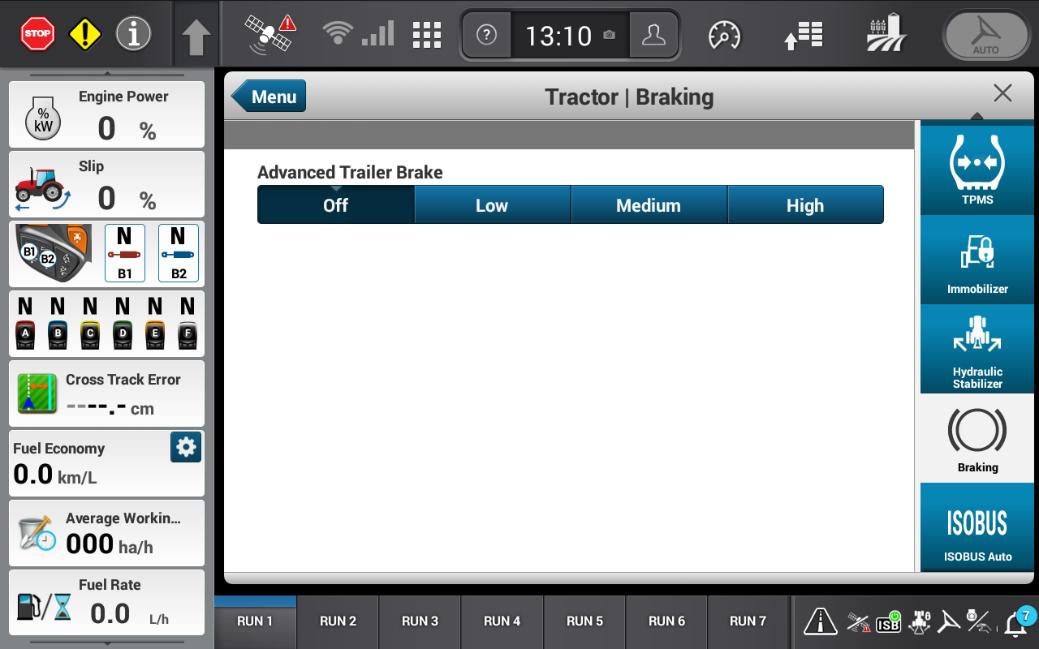

▪ This unique feature improves the tractor and trailer stability during braking and speed reduction via engine and transmission for increased safety and comfort.

▪ The system adjusts the trailer brake force applied with a measurement of transmission input torque, based on the flywheel torque sensor and Engine Control Unit data.

▪ The trailer brake is intelligently controlled and activated in intervals to prevent the trailer wheels blocking and the brakes overheating.

▪ If the system automatically applies the trailer brakes, the brake lights are illuminated.

▪ This feature is available ex factory or as a DIA kit (unlock code):

+ Unique and intelligent feature to increase vehicle train safety and driver´s comfort.

+ Anti jack-knife effect.

+ Comfortable and safe deceleration in combination with engine/decompression brake.

▪ The excellent, patented system actively recognizes the current driving situation and stabilizes the tractor using the trailer brakes.

▪ To increase the tractor and trailer stability the Advanced Trailer Brake Rate should be aligned.

▪ Low: Lower reactiveness.

▪ ▪

▪ High capacity compressor option, capable to power the central tyre inflation system (CTIS), air brake system and external airline.

▪ Two cylinder design with 633 cm² displacement.

▪ Highest efficiency due to gear driven design, no rubber belt losses or slip. No risk of belt wear/damage.

▪ To further boost efficiency, the system features idle management that cuts power use by up to 60% when no air is needed. A pneumatic signal increases the compressor’s dead volume, reducing energy consumption during idle periods.

▪ The air compressor option is mandatory for CTIS and for pneumatic trailer brake option.

▪ External airline underneath the cab door.

Increased Idle Dead Zone

Standard Dead Volume + Efficient, high-capacity two-cylinder compressor, an all-inone solution – gear-driven for maximum reliability.

Brakes key selling points

1. Outstanding Braking Performance & Control

Fully pressurized hydraulic brake system with exceptional pedal feel and Dynamic Brake Steering for superior maneuverability and precision braking.

2. Maximum Safety in Trailer Operation

Advanced Trailer Brake automatically adjusts trailer brake force without wheel lock or overheating and protects against the dangerous “jack-knife” effect.

3. Flexibility for All Markets & Requirements

Multiple trailer brake options (hydraulic, pneumatic, or combined) with UK, Italian, and universal couplers ensure full compatibility.

4. Efficiency & Durability Built-In

Oil-cooled wet dual disc brakes with electric circulation pump and intelligent trailer brake control deliver long-lasting durability and smooth deceleration.

5. More Power & Reliability with High-Capacity Compressor

Gear-driven two-cylinder 633 cm³ compressor powers CTIS, pneumatic brakes, and external airlines, with idle management reducing energy use by up to 60%.

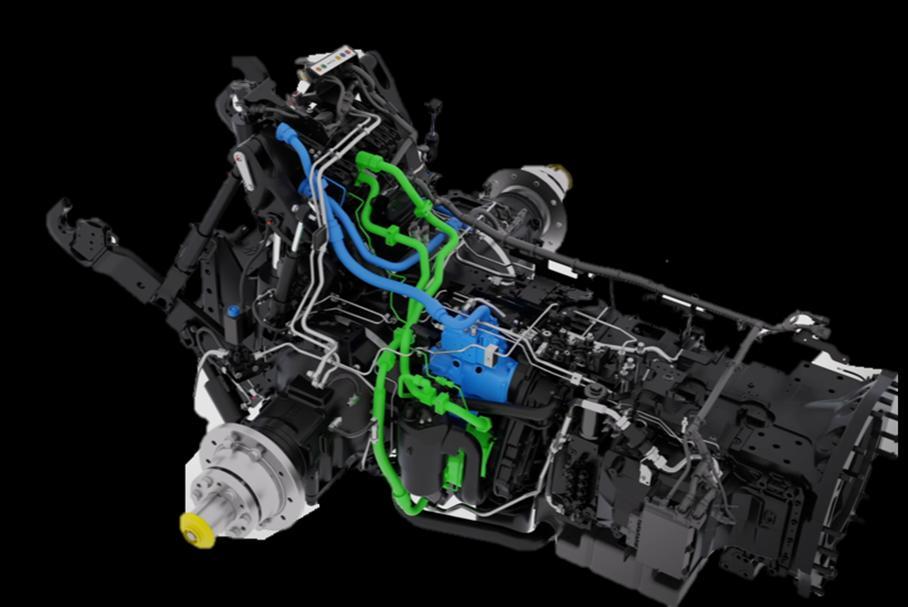

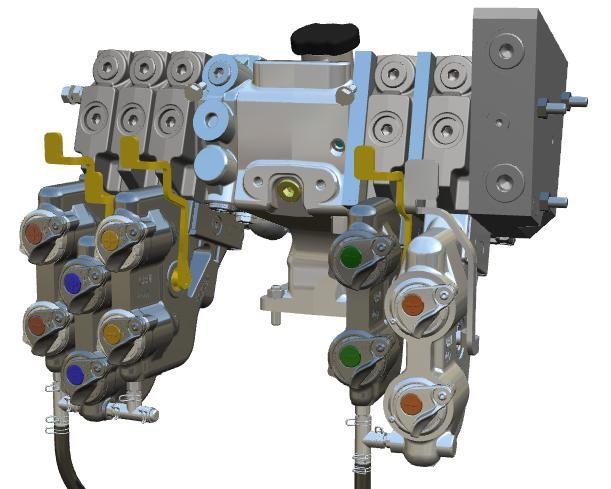

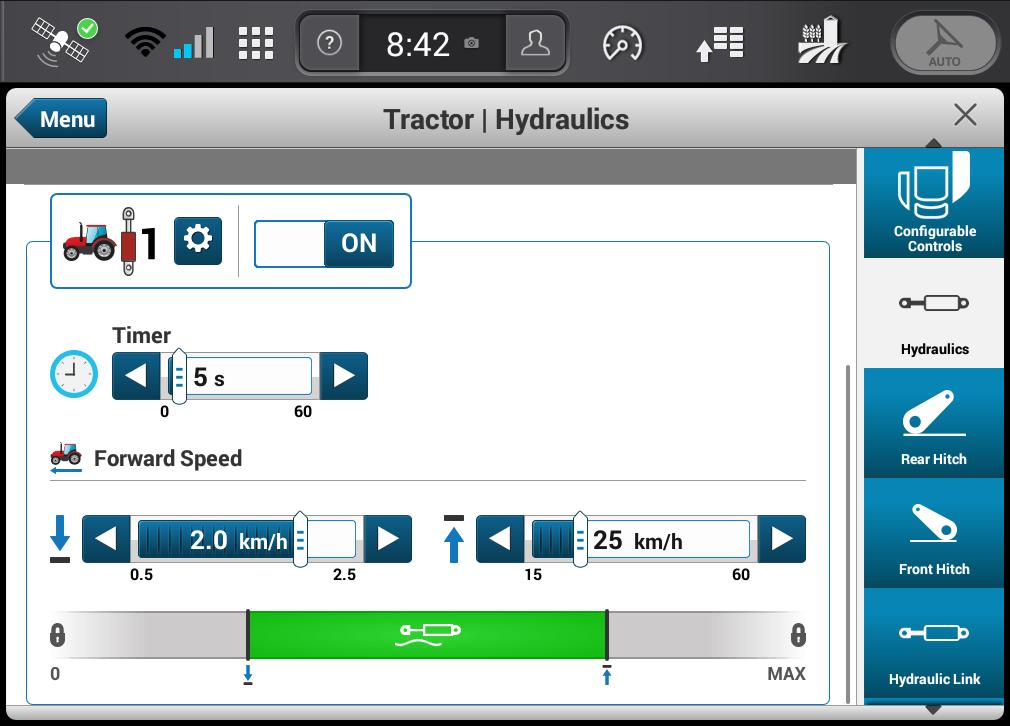

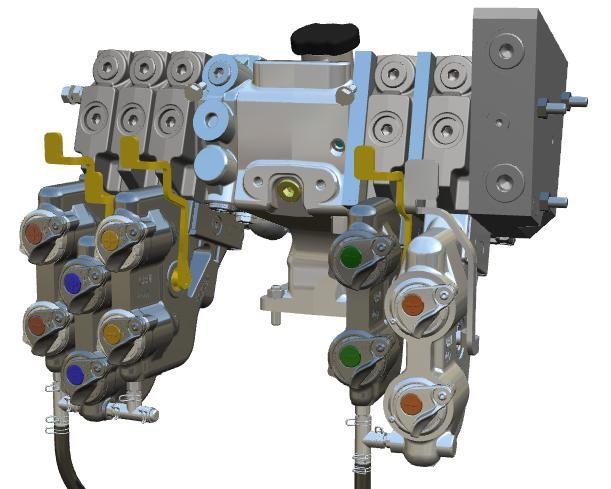

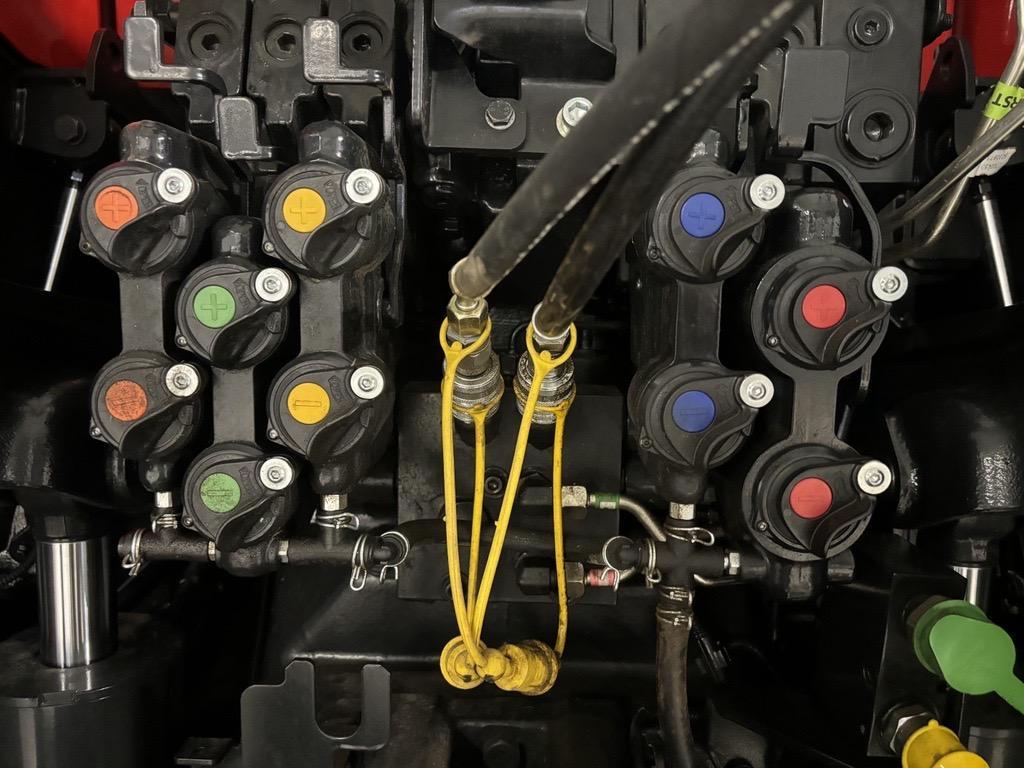

▪ There are two different hydraulic pump options available:

▪ 220 l/min high flow, single CCLS pump option

▪ same component as Optum 270 -340 high flow pump.

▪ theoretical hydraulic power output: max. 80 kW

▪ 360 l/min twin flow, dual CCLS pump option

▪ 220 l/min high flow pump + additional 140 l/min twin pump.

▪ theoretical hydraulic power output: max. 129 kW

▪ lower engine speed required to reach the output of the single pump option.

▪ For both pump options an additional oil reservoir of 35 litres is available.

▪ Beneficial for applications with high oil circulation or for additional efficiency at high road speeds. This option is mandatory for 60 kph option.

▪ Maximum draw off capacity / removeable oil of 86 litres.

▪ Robust oil filtration, 3 fine filters plus an additional magnetic filter before the hydro unit.

+ Twin-flow option delivers maximum oil flow while ensuring a perfectly consistent output for applications requiring constant flow.

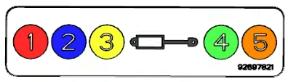

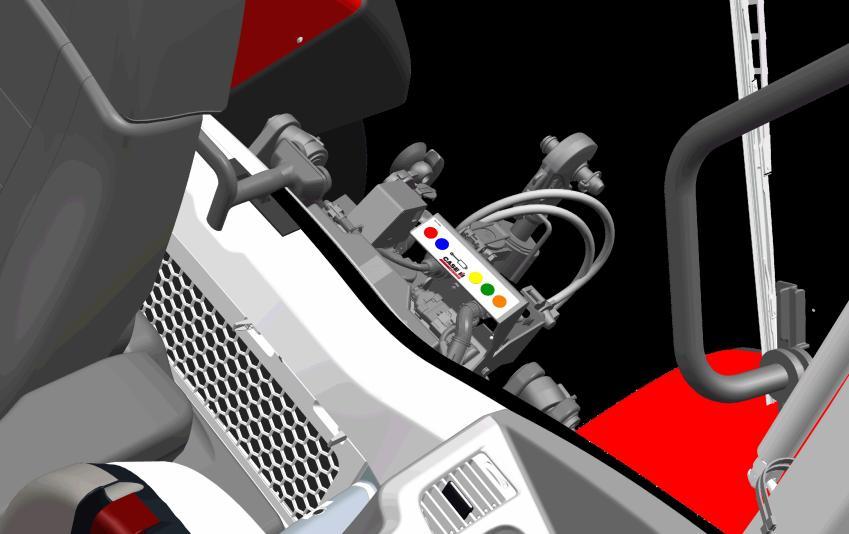

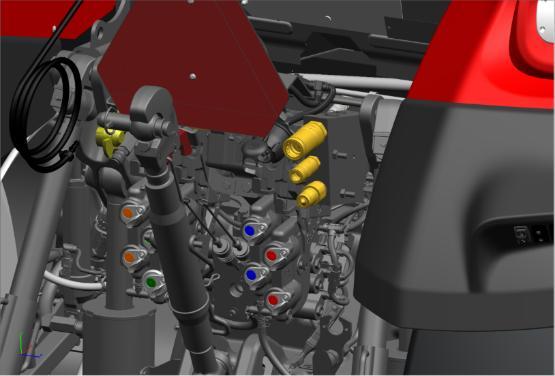

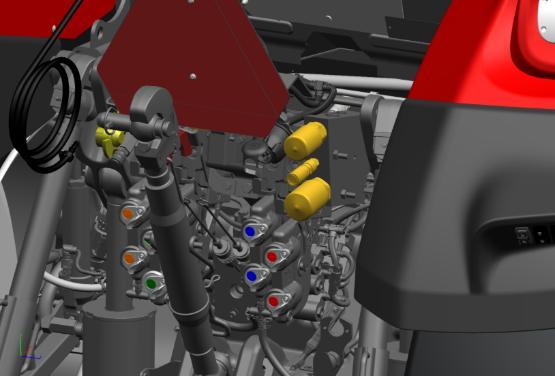

▪ Up to 5 remote valves can be installed at the rear.

▪ The mid mounted remote valve options allow up to 3 additional valves for the front.

▪ All rear remote valves are sourced from BOSCH and all Couplers are sources from FASTER equipped with features which make the operation easier:

▪ Lever-assisted ejection couplers for an easy uncoupling of hydraulic hoses.

▪ The dual active lever allows coupling and uncoupling of hydraulic hoses under pressure.

▪ Colour coded self closing coupler doors.

▪ Dirt can not reach the hydraulic couplers.

▪ Corresponding decals with colour code for each valve.

▪ Allows a clear identification from inside and outside the cab.

▪ Both channels (extend and retract) are equipped with a non leaking valve.

▪ All rear remotes are angled outward by 5°, creating more space for easier, quicker hose connections.

▪ 360 l/min Twin Flow Option:

▪ 220 l/min pump powers: rear remotes 4 and 5, power beyond, mid mount valves.

▪ 140 l/min pump powers: rear remotes 1, 2 and 3 and the rear three-point linkage

▪ Maximum oil flow at one single remote valve:

▪ 1/2" couplers: 140 l/min.

▪ 3/4" couplers: 170 l/min

▪ Easy and ergonomically remote valve control. The controls are arranged within the radius of the arm. No elbow movement necessary.

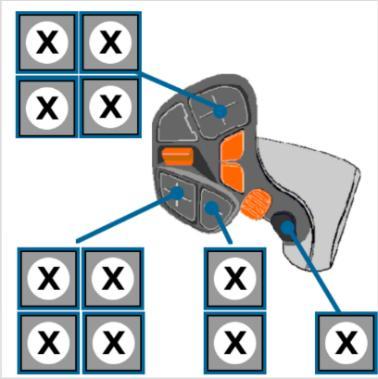

▪ 4 paddle levers, the configurable buttons and the optional joystick can be used to control all remote valves.

▪ Without Joystick:

▪ 4 paddle levers.

▪ 2 dedicated button pairs on the Multicontroller.

▪ Configurable buttons.

▪ With Advanced Joystick:

▪ same like without joystick + additional advanced joystick

▪ Advanced Joystick:

▪ Proportional control of 3 remote valves in level A and 3 in level B.

▪ Fully configurable to control remote valves or three-point linkage.

▪ Power Shuttle and range shift.

▪ 2 additional free configurable buttons for all tractor functions.

▪ The tractor can be equipped with an automatic trailer steering axle control. This feature is available with Advanced Trailer Brake option:

▪ The operator can select one of the rear remote valves and activate the automatic function. The selected remote valve needs to be in float control, this will engage the auto lock feature.

▪ When driving below a selectable speed between 0,5 and 2,5 kph or reverse, the float control will be deactivated, and the system automatically applies pressure to the trailer’s steerable axle to straighten and lock it for smooth, controlled reversing.

▪ In transport any speed between 15 and 60 kph can be set. Above this speed the system will automatically lock the trailer steering axle for highest safety.

▪ The timer function is used to define the required duration of pressure application to straighten the steering axle.

Power Beyond

▪ The Power Beyond has a load sensing device which activates flow and pressure as required to supply implements directly with hydraulic oil.

▪ Power Beyond Plate with caped ports (no couplers). Coupler sets are available as DIA kit:

▪ Normal couplers kit number: 731317014

▪ Flat face couplers kit number: 731316014

▪ Direct connection to the main hydraulic circuit.

▪ Automatic oil flow compensating reduces fuel consumption.

▪ Forward inclined coupler plate allows ergonomic coupling and uncoupling of the hydraulic hoses.

▪ Additional case drain is standard on all tractors.

▪ Zero pressure return for hydraulic motors.

▪ ½ “ female coupler.

Pressure: oil flow and pressure acc. to demand (max. 220L/min, 215 bar)

Load Sensing: signal from implement to supply oil. Return: free flow, low pressure return to the sump.

Normal couplers kit number: 731317014 Flat face couplers kit number: 731316014

Hydraulics key selling points

Choice of 220 l/min single pump or 360 l/min twin-flow dual pump with high draw-off capacity, delivering full hydraulic flow at low engine speed for maximum efficiency and power output.

Up to 5 rear and 3 mid-mount valves with color-coded couplers, angled design, and high flow capacity (up to 170 l/min) for fast, easy, and reliable operation.

Ergonomic paddle levers, configurable buttons, and optional advanced joystick allow proportional, fully configurable valve operation with seamless integration into tractor functions.

Automatic axle straightening and locking at set speeds improves reversing, transport safety, and operator comfort, working in perfect combination with Advanced Trailer Brake.

Load-sensing Power Beyond supplies oil directly to implements on demand, reducing fuel consumption and ensuring maximum hydraulic performance.

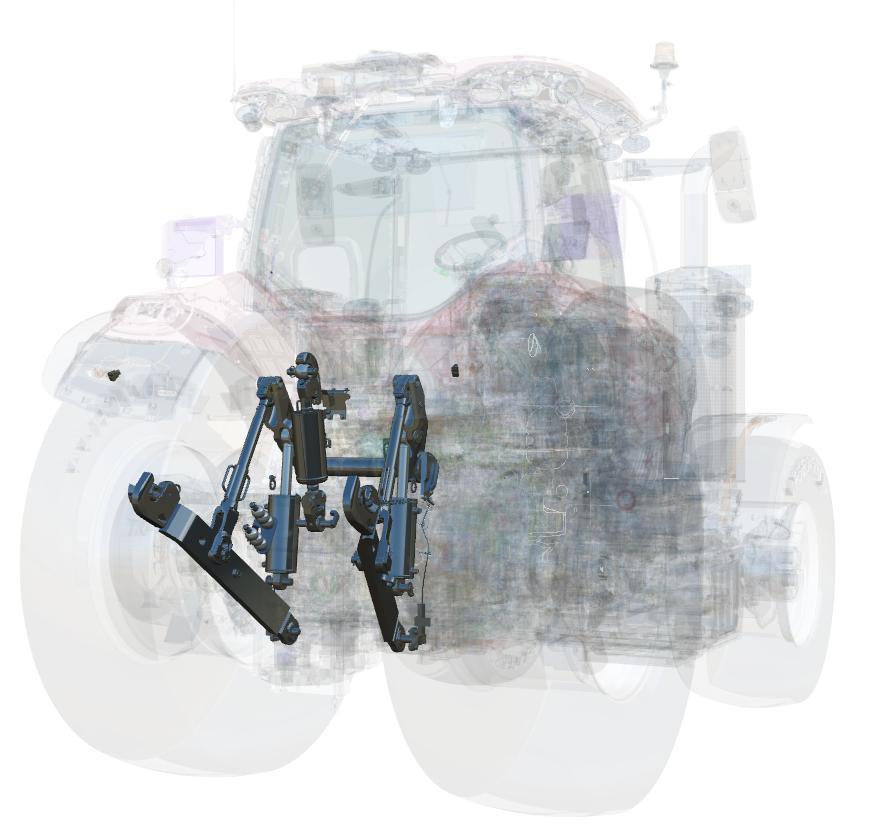

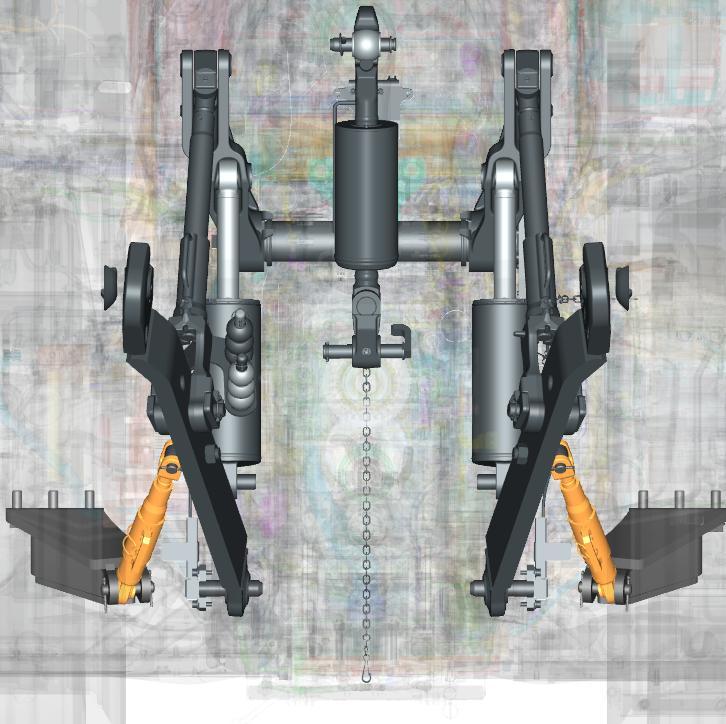

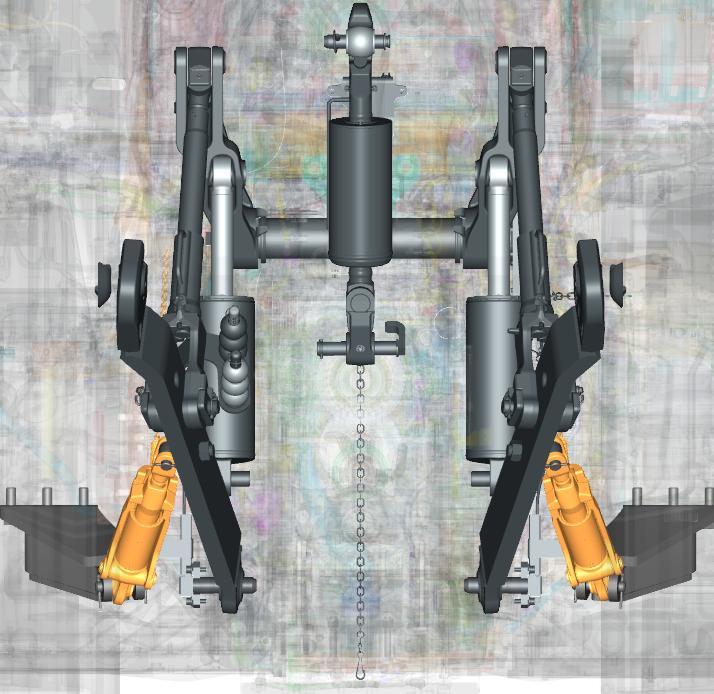

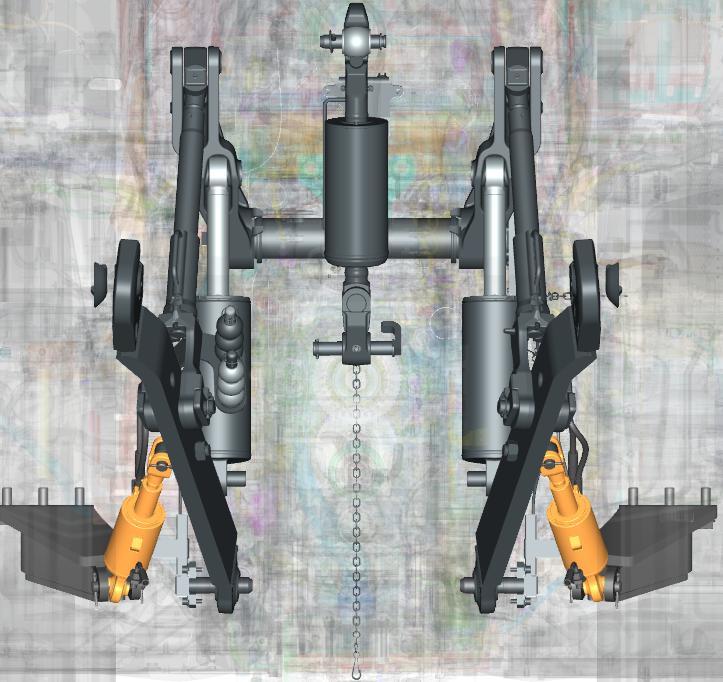

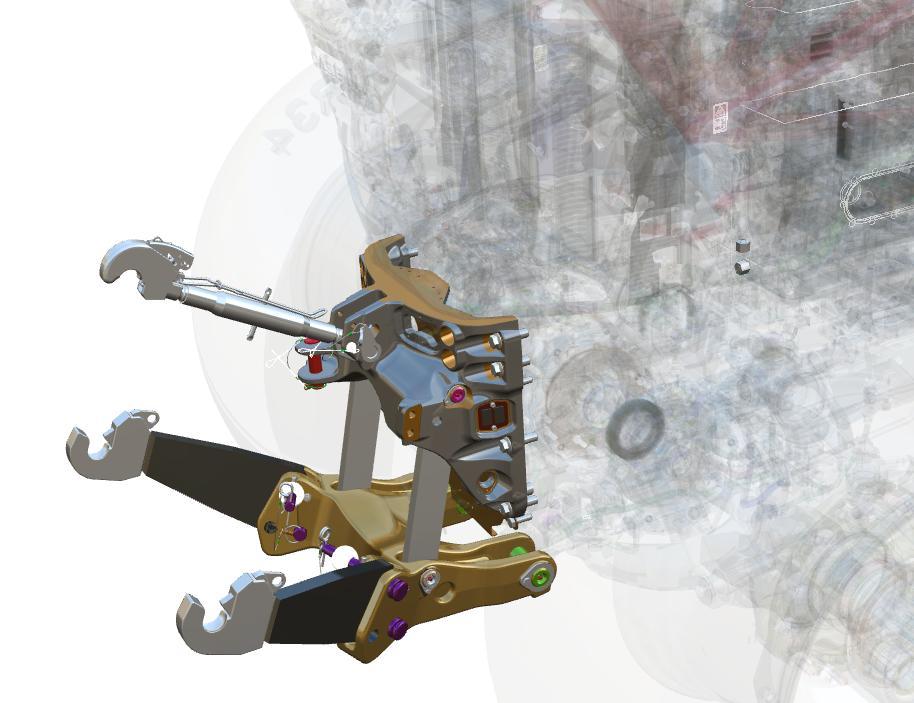

▪ New, fully reinforced, rear linkage built for highest horsepower with an improved geometry.

▪ Electronic Draft Control (EDC) and slip control is standard on all models.

▪The draft control system as well as the slip control system helps to bring the power to the ground. More area power, less fuel consumption.

▪ Maximum lift capacity: 11.760 kg at the full range at 610 mm distance: 10.500 kg

▪ External left- and right-hand-side control is standard.

▪ Storage area for six rear linkage balls.

▪ Optional hydraulic diverter block for top link, hydraulic lift rod and pick-up hitch.

▪ The tractor can be equipped with different versions of three-point linkage stabilizers.

▪ 1 – Manual stabilizers

▪ Manual, screw type stabilizers.

▪ Adjustable to Cat 3 and 4.

▪ 2 – Automatic stabilizers

▪ Automatic lower link stabilizers, lock the linkage into a fixed position when raised, but also allow the implement to move when lowered.

▪ 3 – Sway block stabilizers

▪ Sway blocks can be used to control the amount of side sway of the three-point linkage.

▪ Only available in combination with North American quick attach frame.

▪ 4 – Hydraulic stabilizers

▪ With the hydraulically controlled stabilizer the three-point linkage can automatically be centred and stabilised at any height of lift.

▪ Lock and unlock values can be stored for any implement configuration.

▪ Hydraulic diverter block is able to operate different functions:

▪ Hydraulic top link

Within this option the hydraulic top link is connected to the diverter block. No remote valve is blocked for the top link.

▪ Hydraulic right-hand lift rod

▪ Pick-up hitch

▪ This dedicated hydraulic valve does not block a proportional rear remote valve.

▪ Control:

▪ Paddle levers

▪ Joystick (if equipped)

▪ Configurable buttons

▪ Pro 1200 monitor

▪ External fender control buttons

▪ All important three-point linkage controls are located on the armrest for easy and quick access.

▪ Three-point linkage can be controlled via:

▪ Multicontroller

▪ Paddles

▪ Joystick (if equipped)

▪ Position control potentiometer

▪ manual raise and lower (grey buttons for implement connection)

▪ external fender control

▪ Linkage position is shown in the A-pillar display and Pro 1200 monitor.

▪ Three-point linkage settings can be set via:

▪ Armrest potentiometer

▪ Pro 1200 monitor

▪ Encoder

▪ Armrest encoders with new layout for easier adaptions on the go.

Rear three-point linkage key selling points

Fully reinforced rear linkage with improved geometry and a maximum lift capacity of up to 11,760 kg, ensuring top performance.

2. Versatile Stabilizer Options

Choice of manual, automatic, sway block, or hydraulic stabilizers, allowing operators to match stability and flexibility to every implement and working condition.

3.

The optional hydraulic diverter block adds functions such as top link, right-hand lift rod, and pick-up hitch without using up any rear remote valves, keeping all remote valves available for implements.

4. Easy and Ergonomic Operation

All functions are ergonomically placed on the armrest and on the Pro 1200 monitor, with intuitive control via Multicontroller, paddles, joystick, buttons or external fender buttons for maximum comfort.

5. Smart Draft and Slip Control

Electronic Draft Control (EDC) and slip control optimize traction, reduce fuel consumption, and maximize power transfer to the ground.

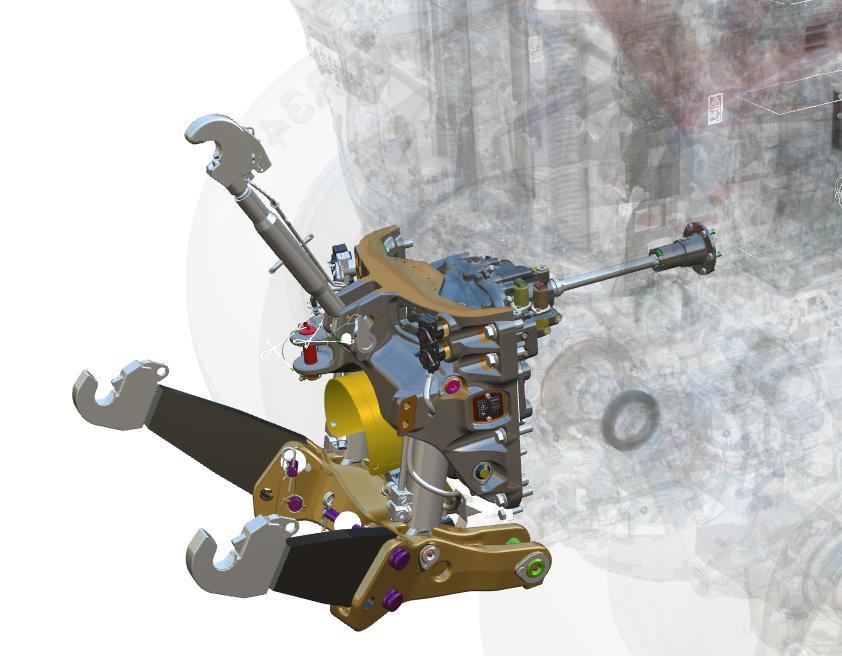

▪ Rigid three-point weight carrier as cost effective solution for farmers without front implements.

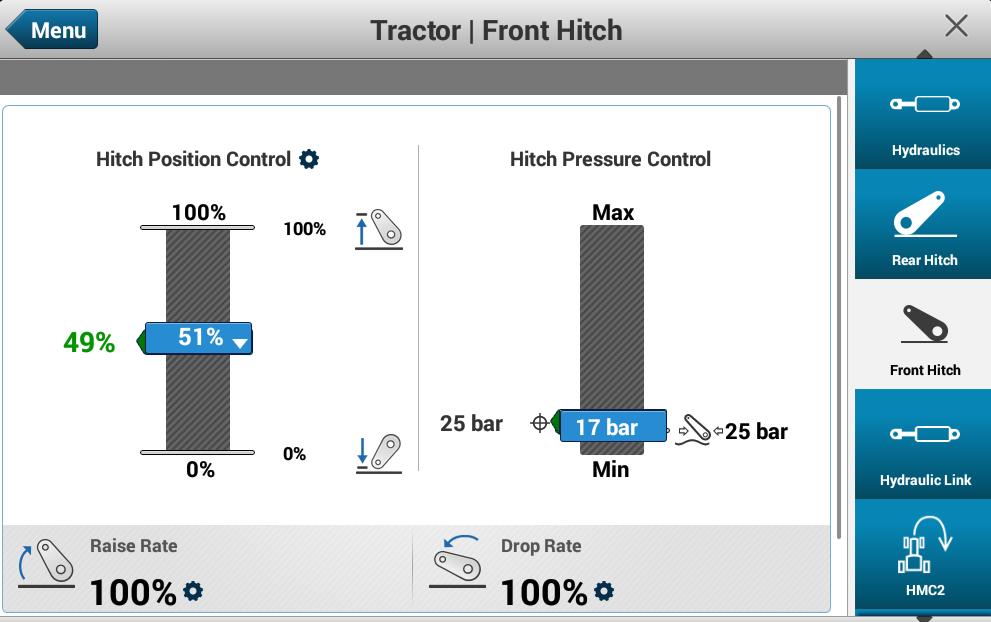

▪ Fully integrated front linkage with high lift capacity of 5.800 kg.

▪ EFH – electronic load relief control, no need to install or adjust relief springs.

▪ Front hitch management, position control + electronic front sockets

Weight carrier

▪ Easy and quick weight attachment without hydraulic front linkage.

▪ Cost-effective solution for farms without front implements.

▪ Same load distance as for ballasting with hydraulic front linkage, for same ballasting effect.

▪ All common three-point weights can be used. No need for suitcase weights.

▪ Flexible ballasting possible without hydraulic front linkage.

▪ 250 mm travel distance of independent front axle suspension can be used to attach / detach front weights.

▪ Same Cat 3N lower- and top-link as on hydraulic front linkage option.

▪ Tow hook included.

+ Easy and quick ballasting possible without hydraulic front linkage.

+ Attach / Detach with front suspension travel distance

Front linkage

▪ Fully integrated front linkage, suitable for heaviest implements.

▪ Powered from a mid mounted remote valve.

▪ Ride accumulator for smooth road transport. It acts as a form of suspension and limit shock loads.

▪ Double acting function, activation via Pro 1200 monitor.

▪ Lower links:

▪ Designed for category 3N implements.

▪ Foldable arms for storage when not in use.

▪ Top link:

▪ Cat 3 mechanical top link with integrated parking solution.

▪ Storage area for linkage balls on the left and right side.

▪ Front camera available for easy implement connection.

+ Integrated, double acting design with high lift capacity.

+ External operation and vibration damping.

▪ The front linkage management allows easy control of the front linkage via Multicontroller.

▪ Up / down and automatic float via shift button and three-point linkage buttons.

▪ Position control potentiometer available on the armrest allows precise adjustment of the working position.

▪ Drop/lift rate and upper/lower limit can be set via:

▪ Controls below the armrest

▪ Pro 1200 monitor

▪ Auto float mode:

▪ Lowering the front linkage with the Multicontroller sets the front linkage automatically in float mode as soon working position is reached.

▪ Electronic sockets are linked to the front hitch management option:

▪ 3 pin connector

▪ 7 pin lighting socket

▪ ISOBUS socket

▪ The front implement closely follows ground contours at a consistent height, ensuring gentle operation and reduced fuel consumption.

▪ higher forage quality.

▪ better soil/grassland protection.

▪ no relief springs needed.

▪ Front implements can be used without extra relief springs, while steering remains precise even with a front packer.

▪ Optimal traction and stability: weight transfer to the front axle improves grip and prevents drifting on slopes.

▪ Simple and convenient setting of the relief effect in the Pro 1200 monitor.

+ Perfect for mowing / mulching to ensure highest forage quality and longest machine durability.

+ Higher steerability with front packer use or municipality applications.

764357 FRONT LINKAGE + 1 EXTRA REMOTE VALVE + EFH/ELECTRONIC LOAD RELIEF CONTROL

764358

764359

764360

FRONT LINKAGE + 2 EXTRA REMOTE VALVES + EFH/ELECTRONIC LOAD RELIEF CONTROL + FREE RETURN

FRONT LINKAGE + 2 SPEED FRONT PTO + 1 EXTRA REMOTE VALVE + EFH/ELECTRONIC LOAD RELIEF CONTROL

FRONT LINKAGE + 2 SPEED FRONT PTO + 2 EXTRA REMOTE VALVES + EFH/ELECTRONIC LOAD RELIEF CONTROL + FREE RETURN

Front three-point linkage key selling points

1. Cost-Effective Flexibility with Weight Carrier

Quick and easy ballast attachment without hydraulic linkage, compatible with all standard three-point weights, offering a simple and economical solution for farms without front implements.

Fully integrated front linkage with up to 5,800 kg lift capacity, double-acting function, foldable arms, and ride accumulator for smooth transport and maximum durability.

3. Front Hitch Management

Easy operation via Multicontroller, Pro 1200 monitor, or armrest potentiometer with auto-float mode, adjustable lift/drop rates, and full electronic integration including ISOBUS, power and lighting sockets.

4. Advanced Electronic Load Relief (EFH)

Ensures consistent ground following without mechanical springs, improving forage quality, soil protection, and traction while reducing fuel consumption and steering issues.

5. Operator Comfort and Ease of Use

Intuitive external and in-cab controls, electronic sockets, and camera-assisted implement connection provide maximum convenience and confidence for every task.

▪ Big variety of trailer hitch and drawbar options specifically designed to fit local market and customer requirements.

▪ New fully integrated pick-up hitch without lifting rods, hydraulic operated via diverter block

▪ New HD drawbar Cat 4 with Cat 3 Adapter – Auto Lock Function, increased vertical load.

▪ Common 390 mm ladder frame.

▪ The tractor can be equipped with innovative security solutions.

▪ Immobilizer:

▪ Anti-Theft-System – must be inside the cab.

▪ Central locking system.

▪ Automatic unlocking by touching the door handle (key fob in operators' pocket).

▪ Buttons on the key fob lock or unlock the cab door.

▪ The fob also activate the Egress lighting (follow me home) depending on operator preferences.

▪ Many immobilizers can be assigned to to a machine and one immobilizer can be assigned to many machines. Perfect for contractors!

Engine Start/Stop – button for highest comfort.

▪ Three different Cab Packages to satisfy all customer needs.

steering wheel

steering wheel

DeLuxe fabric seat with Dual Motion headrest –heated & passive ventilation

MSG95AL-DDS-741

DeLuxe leather seat with Dual Motion headrest –heated & passive ventilation

MSG95AL-DDS-741

DeLuxe leather seat with Dual Motion headrest –

& active ventilation

MSG97EL-DDS-741

▪ A new twin panhard rod system increases significantly the roll compensation and the overall suspension performance.

▪ Mechanical cab suspension as standard offering.

▪ Adjustable in five mechanic supension levels.

▪ Advanced Cab Suspension

▪ Semi Active Hydraulic suspension. Adjustable via display: Soft - Normal - Hard.

▪ Self Leveling. Ride compensation based on amplitude and frequency of movement.

▪ Increased damping close to end stops. Damping compensation during braking.

▪ Advanced Vehicle Suspension

▪ Advanced Vehicle Suspension offers additionally full integrated suspension which combines cab suspension and impacts from rear hitch – implement.

▪ AVS uses advanced algorithms and data from accelerometers to further isolate the chassis movement from the cab.

+ Reduced operator fatigue results in higher levels of operator productivity.

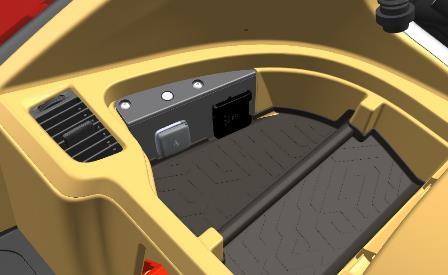

▪ The tractor can be equipped with up to two large cooled storage compartments.

▪ For long days in the cab, the storage below the passage seat is cooled via the air condition. It can contain 2 large bottles and several snack boxes.

▪ A large portable Case IH branded and powered cool box and a mounting bracket is optional available.

▪ The bracket to hold the cooler in place is raised to allow foot clearance when the seat is swiveled.

Up to 4 cameras can be connected to the Pro 1200 display.

▪ No Cameras

▪ No camera cables or cameras of any kind in the cab or on the vehicle. Up to 4 customer supplied cameras can be connected directly to the display via BNC connector.

▪ Camera ready

▪ Additionally, wiring in armrest and to rear of cab. In-cab AEF socket to connect 2 cameras.

▪ Camera Hood

▪ Additionally, fully integrated front camera.

▪ Camera Hood & Rear

▪ Additionally, rear camera on right hand-side cab frame.

▪ Camera Hood & Rear & Wireless

▪ Additionally, one wireless camera (25-meter range) included.

▪ Front windscreen

▪ Laminated, single piece front screen reduces noise for increased operator comfort and allows continuous working with broken glass.

▪ For best visibility, fine, nearly invisible heating elements in the front screen are optional available.

▪ Rear window

▪ The rear window can be opened for ventilation or to mount cables from an implement. The operator’s rearward visibility is very good for easy implement connection.

▪ To improve reverse visibility, a heated rear window is optional available.

▪ High Visibility Roof

▪ Open-able high visibility roof. More daylight in the cab for a pleasant working environment. Improved upwards visibility. Enables the circulation of fresh air.

▪ Sunshades

▪ Pull-down sunshades, made of perforated material, improves visibility towards dusk, when the sun sits low on the horizon. Standard feature.

▪ The lights of the tractor are divided to 4 sections. This provides customers the possibility to select lighting packages depending on the needs.

▪ Up to 22 LED work lights with 55.160 Lumen for best visibility during night operations.

▪ New IH branded rear LED lights

▪ Foldable LED beacons.

LIGHTING 762545 LEFT SIDE BEACON

762546 RIGHT SIDE BEACON

762547 LEFT AND RIGHT SIDE BEACON

762548 MUNICIPALITY LIGHTBAR

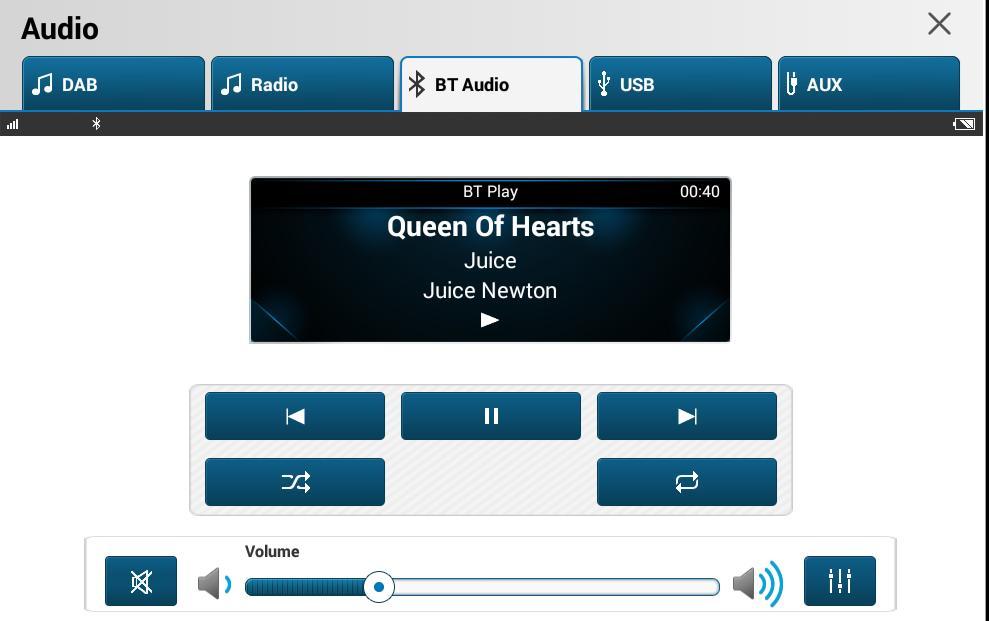

Premium Sound & Smart Connectivity

▪ Versatile audio system

▪ Premium radio with DAB+, Bluetooth, USB/AUX, and control via the Pro 1200 monitor.

▪ Superior sound

▪ Multiple speaker options up to premium sets with subwoofer ensure powerful sound and comfort during long working days.

▪ Hands-free calls

▪ Hands-free function with external microphone, call control via Multicontroller, armrest, encoder, or directly on the display.

▪ Full integration

▪ Phone and audio functions are fully integrated into the Pro 1200 monitor.

▪ Comfort & connectivity

▪ Phone holder, USB charging ports, and clear display of incoming calls enhance usability and everyday operation.

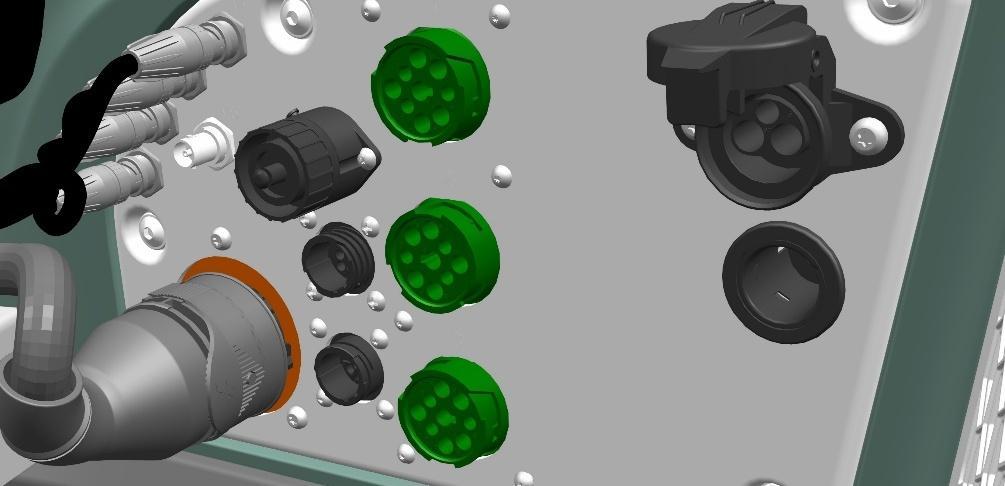

▪ All cabs have several power outlets for monitors, radios, mobile telephones and other related controls needed to make this tractor compatible with current and future implements

▪ Electrical sockets on the right hand cab roof:

▪ 1 x European 3-Pin Power Ports.

▪ Connector to install an additional AFS monitor.

▪ Electrical sockets on the right hand side:

▪ 1 x European 3-Pin Power Ports.

▪ 1 x 12 Volt cigarette lighter capable socket.

▪ 7-pin signal socket (ISO 11786).

▪ 9 pin in-cab IsoBus connector to install an aftermarket monitor or joystick.

▪ 7-pin AEF camera connector, to connect 2 analogue cameras from an implement(optional).

▪ Electrical sockets on the left hand side:

▪ USB 5 Volt charging.

▪ 230V A/C power convertor (150W) (optional).

▪ Electrical socket on the drive pedal:

▪ 1 x 12 Volt cigarette lighter capable socket.

▪ External electrical sockets rear:

▪ IsoBus socket 11783.

▪ ABS socket (optional)

▪ 1 x European 3-Pin Power Port (40 Ampere). Switchable via configurable buttons or HMC.

▪ 7 pin lighting socket for implements (Trailer socket).

▪ External electrical sockets front (optional):

▪ 1 x European 3-Pin Power Port

▪ 7 pin lighting socket for implements (Trailer socket).

▪ ISOBUS 11783 socket.

▪ Modern 12” Multi-Touch Display

▪ Smartphone-like usability with pinch, swipe, and scroll.

▪ High-definition, anti-glare screen readable in direct sunlight.

▪ All-In-One Solution

▪ One Display for all Settings, Guidance, Isobus, Data etc.

▪ Optional secondPro 1200 monitor for parallel operation.

▪ Customizable Run Screens

▪ Each operator can configure up to 7 user-defined windows.

▪ Personalized layouts improve efficiency and comfort.

▪ Integrated Data Management

▪ USB and wireless data transfer.

▪ Seamless export to Case IH FieldOps and desktop software.

▪ User Profiles & Access Levels

▪ Administrator, Basic, and Guest modes.

▪ Secure and tailored access to settings and configurations.

▪ Built-in Help & Manuals

▪ On-screen access to manuals, videos, and dealer contact info.

▪ Reduces training time and improves self-service.

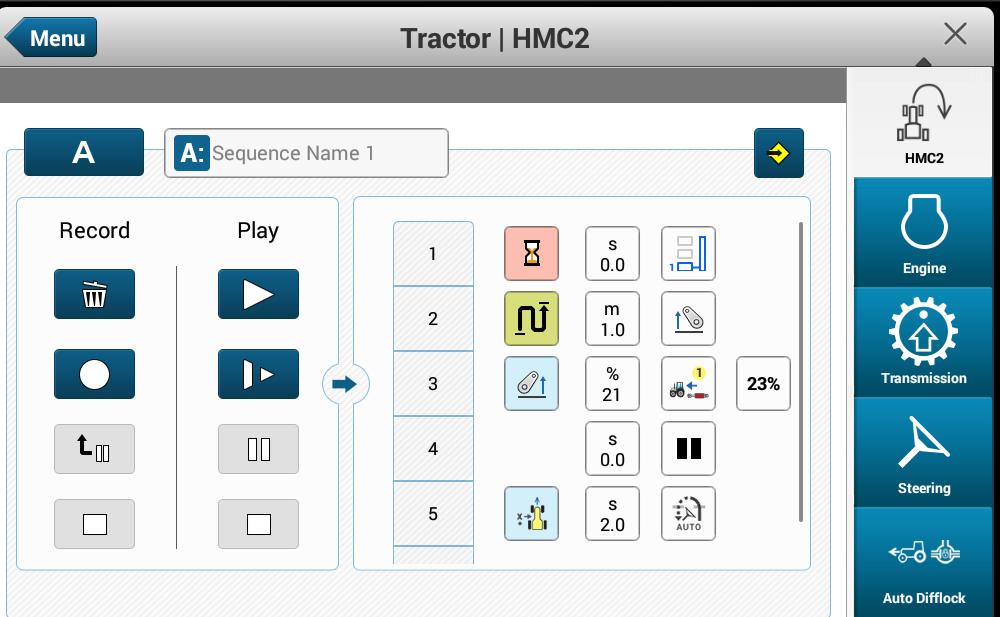

▪ HMC makes tractor operation with repeating working steps on the headland easier, quicker and more precise.

▪ Advanced HMC II:

▪ Recording is possible in real time while working (live HMC sequence) or in parked position, entering commands on the Pro 1200 monitor.

▪ Every single action of recorded sequences can be edited or deleted. Additional actions can easily be recorded by the touch of a button.

▪ Sequence can be stored to allocated implements.

▪ To start a specific action a “trigger“ can be chosen.

▪ 2 different recorded sequences can be activated synchronously and replayed in alternating succession.

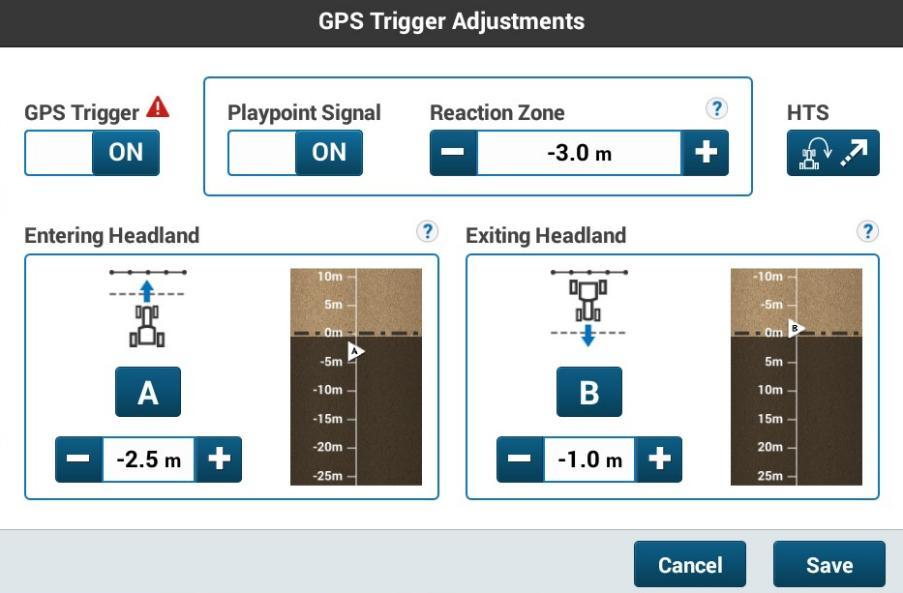

▪ GPS Trigger:

▪ Automatic Playback of the headland sequence

▪ Based on the headland boundary

▪ Independent of AccuTurn

▪ Ensures operator friendly use independent of the field shape

▪ Included in HMCII

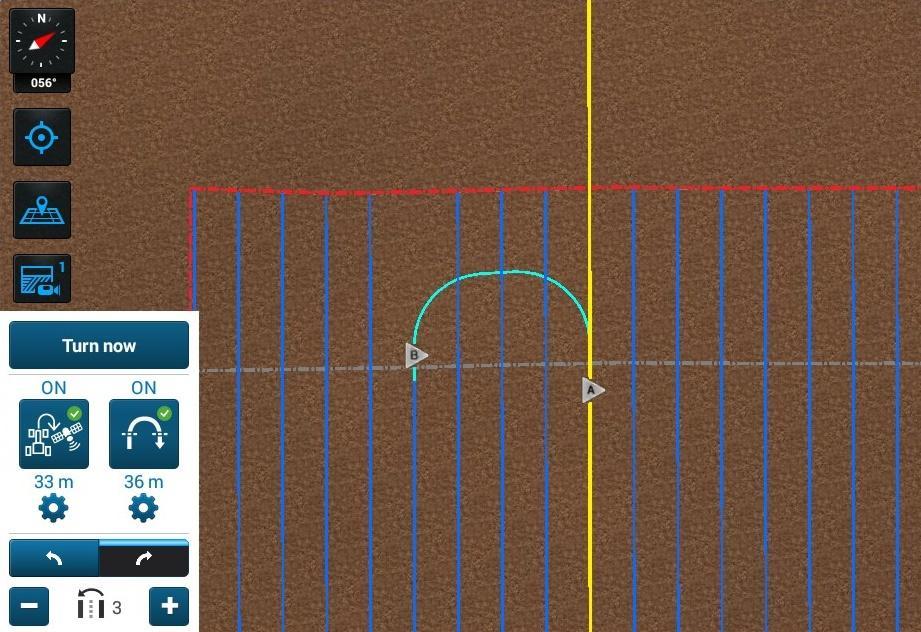

▪ Precise Guidance

▪ Straight, repeatable rows with zero overlap.

▪ Saving of fuel, labour, fertilizer and other inputs.

▪ High comfort and productivity even in poor visibility.

▪ Advanced Swath Management

▪ Multiple swath types for in-field and headland.

▪ Swath skipping and tramline setup.

▪ AccuTurn Pro & GPS Trigger

▪ Automated headland turns with zero clicks.

▪ Reduces fatigue and soil compaction.

▪ Customizable Guidance Profiles

▪ Stores diverse guidance settings.

▪ Quick setup for different implements and operators.

▪ Integrated Widgets & Map Views

▪ Real-time monitoring with configurable widgets and views.

▪ Improves situational awareness and ease of use

▪ Field Boundary & Landmark Tools

▪ Create and manage boundaries, headlands, and obstacles.

▪ Enhances safety and precision in complex field layouts.

▪ Multi-Constellation GNSS Tracking

▪ GPS, GLONASS, Galileo, BeiDou, QZSS.

▪ Increased uptime and accuracy in challenging environments.

▪ RTK Fill Technology

▪ Maintains ≤ 5 cm accuracy during signal outages.

▪ Seamless operation without interruptions.

▪ Triple Geostationary Satellite Tracking

▪ Tracks AFS 1, 2, and 3 simultaneously.

▪ Redundant signals improve reliability.

▪ Integrated IMU (Inertial Measurement Unit)

▪ Terrain compensation and guidance continuity under obstructions.

▪ Faster satellite reacquisition.

▪ Flexible Correction Signal Options

▪ Supports EGNOS, AFS 1–3, RTK via modem or radio.

▪ Subscription-based services for tailored accuracy levels.

▪ Robust Field-Ready Design

▪ Built to withstand vibration, dust, water, and extreme temperatures.

▪ Long-lasting performance with minimal maintenance, ideal for demanding environments.

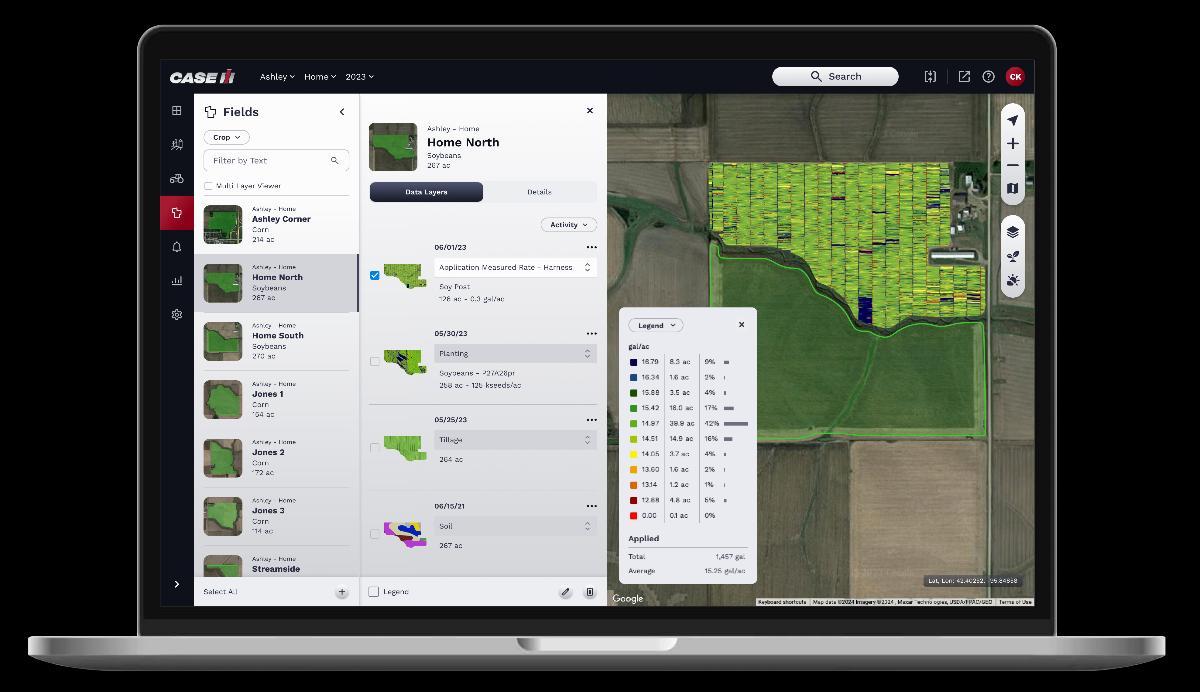

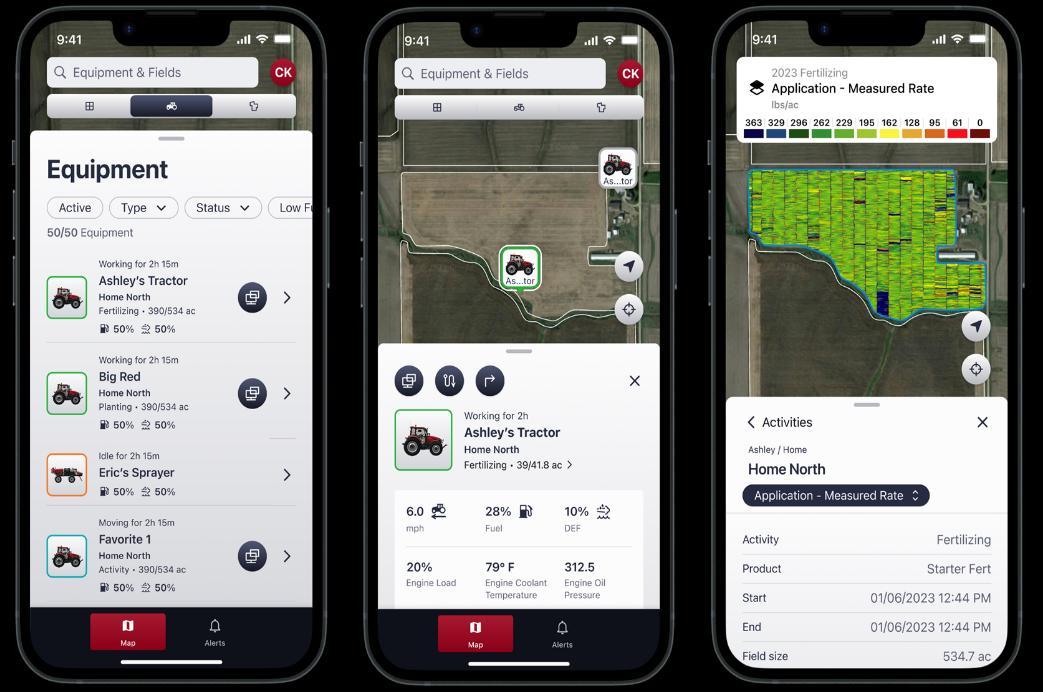

▪ Collect & Create Data

▪ Boundaries & Guidance Lines

▪ Yield Maps

▪ Track different varieties

▪ Create application maps

▪ Transfer Data

▪ “Over-the-Air” Data Transfer

▪ Convert data from/for 3rd Party manufacturers

▪ Keeps an eye on your machines

▪ Position History

▪ Real-Time machine Position & Parameters

▪ Geofence & Curfew

▪ Customizable Notifications for all parameters

▪ Remote Display Access

Also available as mobile app

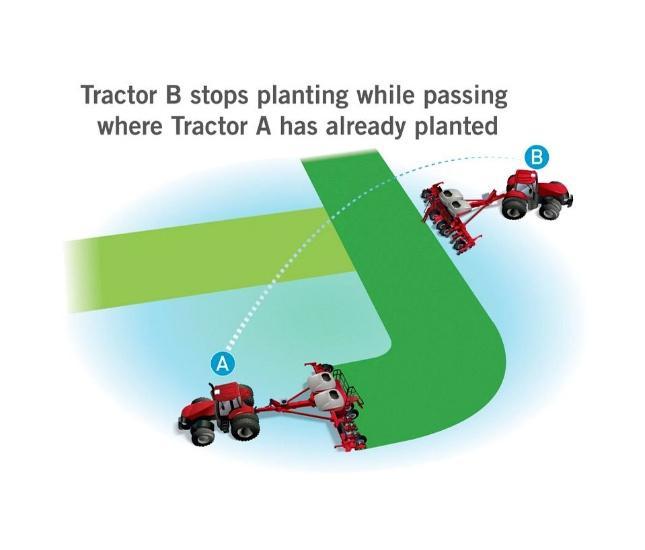

▪ Real-Time Data Sharing

▪ Shares swath lines, boundaries, and coverage maps across up to 6 vehicles in the same field real-time.

▪ Multi-Vehicle Coordination

▪ Enables synchronized operations like planting, spraying, and harvesting with consistent row spacing and efficient field coverage.

▪ Cost Savings

▪ Time Efficiency: Reduces setup time by sharing guidance lines while multiple machines working simultanously in the same field –saving up to € 1,000 per season per fleet.

▪ Cross-Generation Compatibility

▪ Works between all Pro 1200 displays and even with all Pro 700 and Pro 700 Plus displays.

▪ Operational Workflow

▪ Job Creation & Sharing: Lead vehicle creates job, uploads to cloud, others join and sync data.

▪ Boundary & Swath Management: New boundaries and swaths can be added and shared during operation.

▪ Intuitive User Interface

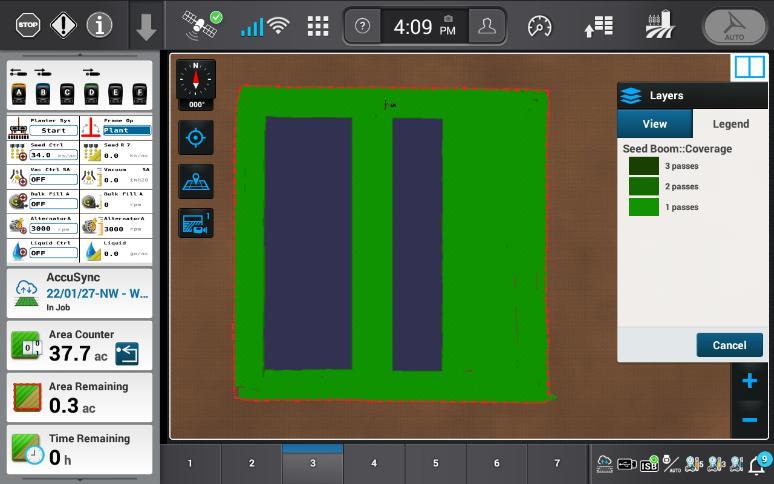

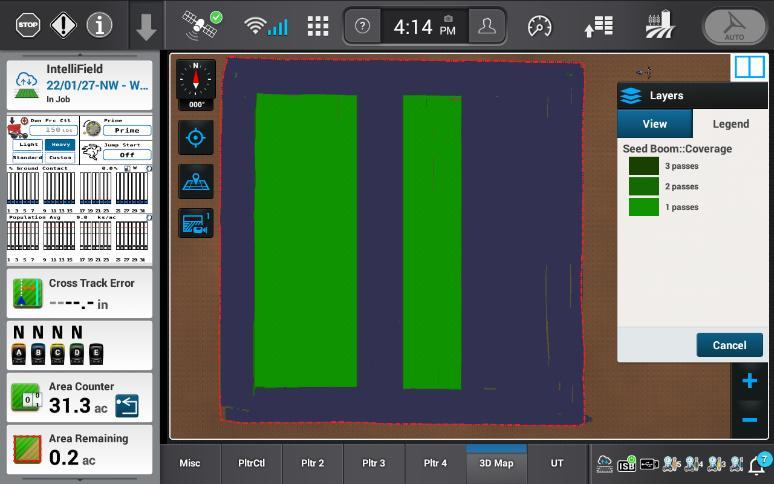

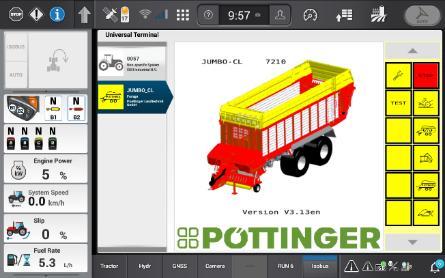

▪ The Virtual Terminal allows operators to control and change settings on an ISOBUS compatible implement through the tractors display.

▪ The Task Controller manages, documents, and optimizes field operations by recording totals, collecting locationspecific data, and automatically controlling implement sections to increase yields while saving inputs.

▪ Isobus Class 2: Operator controls ISOBUS implements via the tractor display. (standard)

▪ Isobus Class 3 + TIM: Implements can additionally control tractor functions like speed, linkage, remote valves, and steering. (optional)

▪ Isobus in-cab connector

▪ 9 pin in-cab Isobus connector is standard to install an aftermarket monitor or joystick.

▪ Isobus AUX-N

▪ Comfortable operation of Isobus implements with known tractor control elements on the armrest.

▪ Wheelbase: 3.190 mm; Total height: 3.490 mm

▪ Tractor weight:

▪ Base weight: 12.450 kg

▪ Full spec weight without ballast: 13.500 kg

▪ Weight distribution: 45% front & 55% rear

▪ Gross Vehicle Weight / max permissible:

▪ European legislation allows a maximum GVW of 18.000 kg

▪ For 40 and 50 kph option CNH provides documents so dealers can request raising the tractor’s GVW to 19.000 kg, but approval depends on local authorities and is not guaranteed.

▪ With 60 kph option GVW is limited to 15.500 kg.

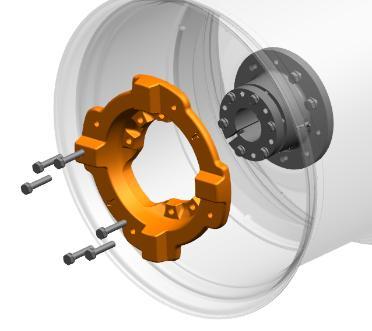

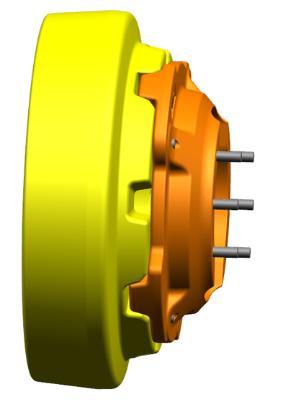

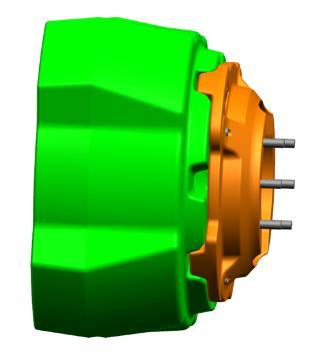

▪ Additional rear axle ballast available

▪ Compatible with tyre inflation system

▪ All components designed for pallet fork handling

▪ Wedge shape design centres the weights for easy mounting

Ballast Support

Directly fixed on the hub, longer dedicated bolts. Remains on the tractor when weights removed

Centering Feature

Angled interface between ballast and ballast support centres the weights. 4 bolts attach the weight

weight configuration CTIS is available