CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vol. 52 No.9

Kenneth Henry Green (right, with his daughter Dillan, left), the third generation owner of K.P. Green Logging in Bristol, Fla., is a simple, straightforward man with roots planted firmly in his family’s logging tradition: he’s honest, direct, plain-spoken and to the point. He fields two crews in the panhandle region, running Barko and Tigercat

Michael-damaged timber

Abbott photo)

September 2023

A Hatton-Brown Publication

Phone: 334-834-1170

Fax: 334-834-4525

www.southernloggintimes.com

Publisher David H. Ramsey

Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Senior Editor Dan Shell

Managing Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director Cindy Segrest

Ad Production Coordinator Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING CONTACTS

DISPLAY SALES

Eastern U.S. Kathy Sternenberg

Tel: 251-928-4962 • Fax: 334-834-4525

219 Royal Lane Fairhope, AL 36532

E-mail: ksternenberg@bellsouth.net

Midwest USA, Eastern Canada

John Simmons

Tel: 905-666-0258

29 Bugelli Dr.

Whitby, Ontario, Canada L1R 3B7

E-mail: jsimmons@idirect.com

Western Canada, Western USA

Tim Shaddick

Tel: 604-910-1826

4056 West 10th Ave.

Vancouver, BC V6L 1Z1

E-mail: twshaddick@gmail.com

Kevin Cook

Tel: 604-619-1777

E-mail: lordkevincook@gmail.com

International Murray Brett

Tel: +34 96 640 4165

Mobile: +34 66 931 5837

58 Aldea de las Cuevas • Buzon 60 03759 Benidoleig (Alicante), Spain

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane

Tel: 1-800-669-5613 • Tel: 334-699-7837

Email: bdevane7@hotmail.com

Southern Loggin’ Times (ISSN 0744-2106) is published monthly by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—SLT is sent free to logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel in the U.S. South. See form elsewhere in this issue. All non-qualified U.S. subscriptions are $65 annually; $75 in Canada; $120 (Airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.southernloggintimes.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Southern Loggin’ Times magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Southern Loggin’ Times. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or in part without written

(Founded in 1972—Our 612th Consecutive Issue)

permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed In USA. POSTMASTER: Send address changes to: Southern Loggin’ Times, P.O. Box 2419, Montgomery, AL 36102-2419 FEATURES 4 ● SEPTEMBER 2023 ● Southern Loggin’ Times Other Hatton-Brown publications: ★ Timber Processing ★ Timber Harvesting ★ Panel World ★ Power Equipment Trade ★ Wood Bioenergy Southern Stumpin’. . . . . . . . . . . . . . 6 Bulletin Board. . . . . . . . . . . . . . . . . 22 From The Backwoods Pew. . . . . . 26 Industry News Roundup. . . . . . . . 28 Iron Works. . . . . . . . . . . . . . . . . . . . 41 Safety Focus. . . . . . . . . . . . . . . . . . . 45 Coming Events/Ad Index. . . . . . . . 46

machines, working

and hauling to mills in Florida, Georgia and Alabama.

begins on

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

on Hurricane

Story

Page 8. (David

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

By David Abbott

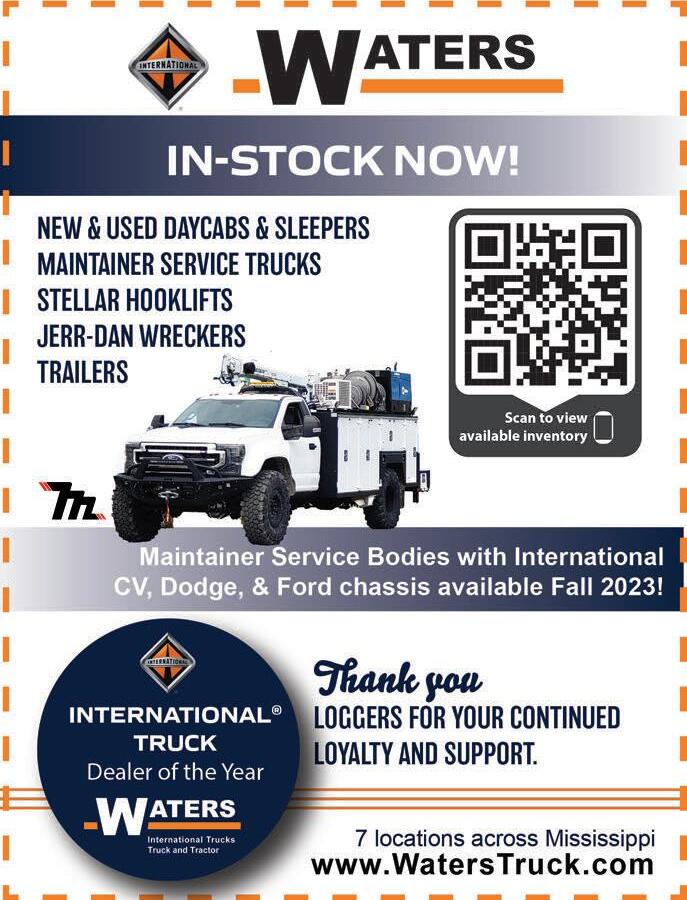

Mississippi Bound SOUTHERN STUMPIN’

bragging rights; food trucks for lunch, and a kids’ play area. It’s always a family-friendly environment.

Mid-South will host presentations both days at which attendees will have the opportunity to earn continuing education credits. In fact, according to the show’s web site, loggers receive three hours of Category II credit just for attending the show. Show admission gains you access to all events at the show, but CE classes are first-come, first serve as far as seating availability, from what I understand.

Mississippi Forestry Assn. communications coordinator Lauren Hawkins and show manager John Auel say they anticipate a similar turnout to last time (estimated around 4,000) and around 70 exhibitors, a slight increase over the 2021 show (which of course took place on the tail end of the pandemic and all its related delays).

“We’re excited about it,” Auel says. “It’s the same layout as last time, compact and easy to walk. Hopefully there won’t be too much rain and not too much heat.” Late September is usually at least a little less brutal than August in that regard.

As usual, the Mississippi Loggers Assn. will host its annual meeting at a nearby site (same one as last time) on the Friday night of the show weekend.

On-site registration will be different this year; show staff will check everyone in at the gate with iPads. Most people tend to register in person onsite, but you can save yourself a little money if you pre-register online ($30 to pre-register vs. $40 to do it on the day of the show). Spouses and children under 17 get in with you for free. Visit www. midsouthforestry.org to find out more.

I’ll be there both days, mostly walking around taking photos, visiting the various exhibitors and maybe occasionally checking in at our HattonBrown/Southern Loggin’ Times booth. If you’re so inclined and you can find me, feel free to say hi. In the meantime, here are some shots I took at the last Mid-South in 2021. See you there! SLT

•

Editor • Ph. 334-834-1170 • Fax: 334-834-4525 • E-mail: david@hattonbrown.com 6 l SEPTEMBER 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Managing

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Straight Shooter

■ K.P. Green Logging owner Henry Green always calls it like he sees it.

BRISTOL, Fla.

Even though he was born in a U.S. Army base hospital in Heidelberg, Germany while his father was stationed there during his time in the service, there was never any doubt in Henry Green’s mind that his place in this world was in the woods of Florida. He’s been working out here since he was a boy in the ’60s; now he’s a man in his 60s, and there’s still nowhere else he’d rather be.

Green, 64, owns K.P. Green Logging, a family business he inherited upon his father’s death seven years ago. The company takes its name from his dad, Kenneth Paul Green,

name, Kenneth Henry Green, from both his dad and his granddad, John Henry Green, who was an early feature subject for Southern Loggin’ Times in the early ’70s. A cousin and a third Kenneth, Kenneth Alan Green, also named for Henry’s dad, works on the crew with Henry.

The Greens trace their family heritage of logging and farming in this area back several generations. “My great-great granddad owned 70% of Calhoun County,” Green says. “It was all timber back then. That’s where we were raised up in that river swamp; that’s where my granddaddy loved to log. If he wasn’t logging down there

8 l SEPTEMBER 2023 l Southern Loggin’ Times ★ CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

he’d just as soon go to the house. I grew up helping my dad and my grandpa. We farmed and had cattle, too, but mostly, I’ve just logged.”

Equipment

Between his two crews, Green has a 2023 Barko 595B loader and an older 595; a 2018 Barko 830B feller-buncher and a 2019 Tigercat 720G feller-buncher; and a pair of Tigercat 620E skidders (’14 and ’19 models). He hauls with several Kenworth trucks pulling Pitts trailers. His dealers are Knight Forestry (Barko) in Whigham, Ga., Tidewater Equipment in Thomasville, Ga., and Ring Power Truck Centers in Florida.

Green also keeps some older machines in reserve. He loves his ’95 Timberjack 450C, and still uses it some. “It was built on my birthday, May 5,” he says. Like many loggers of his generation, he was a fan of the brand. “We had about every Timberjack they ever made,” he figures. In fact, his CB handle is “Timberjack.” He also still has an old Logger’s Dream at the shop, one his dad bought. “When I was a little boy I used to pull cables and hook the logs for it.”

On his newer skidder, Green runs 35.5 size tires, but 30.5 on everything else. “I think the 30.5s do just as good as any of them,” he says. For insurance he looks to John Chancy Insurance, Inc. in Tallahassee, with BITCO General Insurance Corp. covering his equipment and general liability. The crew conducts safety training on the spot in real time in the woods.

Markets

Southern Loggin’ Times l SEPTEMBER 2023 l 9 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Green buys Barko machines from Knight Forestry in Georgia.

wood bought, and hauled to mills only to be turned away and told to come back another day, wasting their time and the fuel on the trip.

Despite those frustrations, the crews remain productive, as long as weather and quotas allow them to work. The Friday when SLT visited in July, one crew hauled more than 70 loads for the week. Primary destinations include Rex Lumber in Bristol for pine logs and Spanish Trail Lumber in Marianna for smaller wood. Occasionally they

haul further out: Cross City Lumber in Cross City, 130 miles from Bristol, or International Paper Cantonment near Panama City, 170 miles away.

Instead of buying his own stumpage, Green works with timber procurement man Jeff Russell through Panhandle Forestry Services and D&S Logging in Chipley, Fla. As its name would indicate, that outfit, just like K.P. Green Logging, is based right on the Florida panhandle, not too far south of the Ala-

bama line and not too far west of the Georgia line. From that convenient location, it’s no surprise Green has hauled to mills located nearby in all three states, like GeorgiaPacific’s paper mill in Cedar Springs, Ga. and Tri-County Poles & Piling in Slocomb, Ala.

Products sorted include mainly chip-n-saw, grade logs and pulpwood. “When we get in some patches with some decent hardwood, we’ll get some hardwood,” Green says. “And precut logs if it’s

bigger,” his cousin Alan adds.

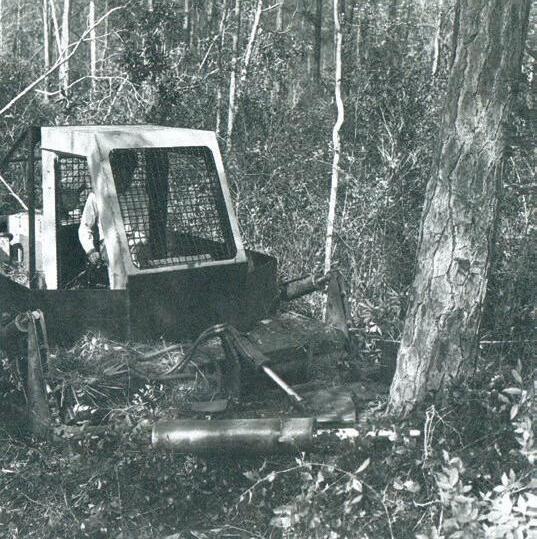

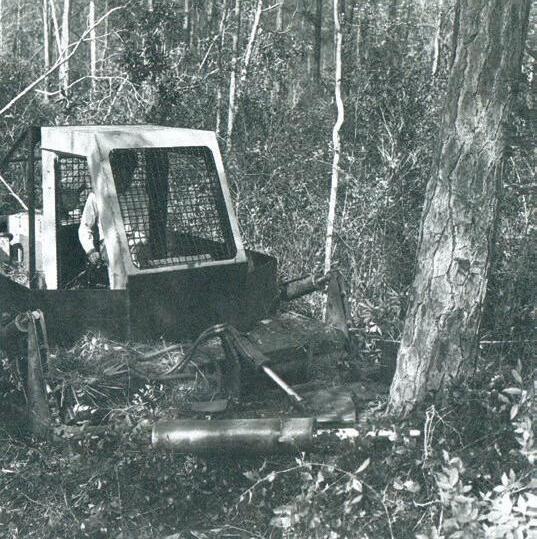

Michael Aftermath

This summer, Green was lamenting that his crews were “working in a bunch of blown down crap.” Like most loggers in the area, his business felt heavily the impact of Hurricane Michael in 2018; nearly five years later, they still feel the effects. “All the timber was damaged from the Apalachicola River Basin and Sepulga River right on up to Col-

10 l SEPTEMBER 2023 l Southern Loggin’ Times

From his central location in the panhandle,Green hauls to mills in Florida,Georgia and Alabama.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Green's crews have been working in a lot of storm-damaged timber still from Hurricane Michael five years ago.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

umbus, Ga.,” Green says. “Most places you work in, all the big wood is laying on the ground, like here. They are trying to clean this up where they can replant it.” Green won’t take all of what remains on the ground, though. “They can send a chip crew in here to get that,” Alan suggests. “That’s all it’s worth,” Green nods sourly.

On top of all that damaged or ruined timberland that won’t recover for another decade or so, storm cleanup was followed by a number

of mill closures that hurt every logger in the region.

Crew

Alan Green runs the Tigercat feller-buncher, while Shane Tolley mans the Barko cutter; Joe Lambeth and Donald Jourdan drive the skidders; Mark McGill and Green himself operate the loaders. Truck driver Billy Foxworth has been with Green for 20 years, but he’s been driving a truck a lot longer than that; Foxworth is 80, but that number hasn’t slowed him down a bit. “He is able bodied, and he goes and comes just fine,” Green says.

What worries keep this logger awake at night? “Keeping these boys a job,” he confesses. He’s concerned about the whole industry going down or even the whole economy.

Another Green family member somewhat involved in the business is Green’s younger daughter Dillan, who sometimes climbs in a skidder cab when she needs to help out. Older daughter Ashley and wife Brenda Green are both schoolteachers, and Brenda also takes care of K.P. Green Logging’s payroll books.

For his part, Green is not eyeing retirement anytime soon. “I like to make the trucks roll,” he says. He likes what he does, and when you like what you do, it’s not work, or it’s not bad at least. “As long as my legs hold up, I’ll still be out here,” he predicts. “They are getting bad.” He says he ruined his knees and ankles playing high school sports (football and baseball, where his team went to the state championships).

As far as advice for younger loggers, Green has some pretty wise words. “Try to keep the trucks rolling; that is the main thing. If the trucks ain’t rolling, you ain’t making no money.” Beyond that, he suggests: carpe diem, seize the day. “You got to do what you can do when you can do it, because you’re gonna have weeks when everything you got is tore up, or it’s raining. So get it while you can.” SLT

12 l SEPTEMBER 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Green,right,with daughter,Dillan,left

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Rhoad Crew

■ All roads led to logging for the Rhoad family, which recently added chipping to the mix.

By David Abbott MCBEE, SC

By David Abbott MCBEE, SC

If you’ve followed the Fast and Furious film franchise over the last 20+ years and counting—or even if you’ve only seen the memes on social media—then you know it’s all about family for Vin Diesel’s car enthusiast character. But that focus on la familia is not exclusive to the fictional Toretto clan. It’s always been about family for a lot of southern logging companies, too, and Rhoad Timber, LLC is no exception. “The family part of it is really important for me,” says Daniel Rhoad, 44, the current head of the family business.

Daniel’s dad, Danny Rhoad, 73, is still here, too. He started the whole thing; he’s been in logging since his own high school days in the mid 1960s. He started his own crew in the ’70s. Even back then at the beginning, it was mostly family on the crew: Danny worked with his brothers and cousins. Some of them had

different last names, but they were all members of the Rhoad family.

It was in that environment that the current generation of Rhoads was raised. “When I was young I always came to the woods, and started working on equipment as soon as I was old enough to be able to do it,” Daniel recalls. He followed his dad’s footsteps into the woods, as the only son to Danny and his wife Jenny. One of Daniel’s two older sisters, Toni Allison, is also heavily involved in the family business as the company secretary/bookkeeper. “If it wasn’t for what she does, I couldn’t do what I do,” Daniel acknowledges. She handles about everything in the office, from insurance to payroll. The only paperwork he spends much time on is counting tickets and checking numbers at the end of the week to ensure it all matches the load sheet. His sister takes care of the rest, sending load counts to the timber buyer so everyone can get paid.

Daniel has no sons of his own, but Toni’s sons, Austin, 26, and Jacob, 24, work in the woods with their uncle Daniel and grandfather Danny.

Looking ahead to the next generation, Daniel figures his two nephews may be the ones to carry on the family legacy when that time comes. For his part, Daniel has two daughters: Emily, 14, and Dana, 9. He says it won’t bother him at all if they do end up deciding they want to be involved in logging, but he won’t push it on them; it’s entirely their choice to be whatever they want to be.

For now, the nephews, Austin and Jacob, can both run every piece of equipment on the crew. Their versatile proficiency and flexibility is critical to the company’s success. “That is what I really strive for is being able to diversify,” Daniel

says. “If you have someone who can only run one piece of equipment, they are not as valuable to the operation. They may be the best on that one piece but if they can’t run some of the other stuff they’re not as valuable. Sometimes you’ll need to run two skidders to keep up, if you’re on a long pull, and the fellerbuncher can run at a more relaxed pace. But sometimes it’s the other way around and one skidder can overrun the loader with the cutter man cutting as hard as he can. So you need to be able to move a guy from one piece of equipment to another as needed.”

Also working on the crew part-

★

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Left to right:Dana Rhoad,Daniel Rhoad,Emily Rhoad,Danny Rhoad,Jenny Rhoad,Toni Allison,AustinAllison,JacobAllison

who is the son of one of the truck drivers, Bryan Horton. “Bryan worked with (us) previously before leaving for another opportunity,” Toni says. “He recently rejoined the RTC family and brought his son with him.” Other truck drivers are Carlton Gainey and Gregory Peterson.

Operations

The Rhoad Timber crew shoots for hauling 40-50 loads of roundwood weekly. Unfortunately, since the end of 2022 and into much of 2023 so far, that hasn’t often been possible due to mill restrictions and shutdowns, not to mention weather. It had been unusually wet in spots, though other spots of the state were still considered drought conditions earlier this year. In early April the crew was on an especially sandy tract. “It fought us with some wet areas, and not just in the bottoms,” Rhoad says. “Some of the flat areas on top of the hills still have issues with bogging up, like the ground is saturated. I don’t have dual tires on anything so we’re not set up for it.”

For many years Rhoad and crew did almost nothing but first thinning. Daniel believes, “If you start a tract of wood and thin it right the first time, take out the crooked and diseased trees and leave good quality stuff, the final result of the timber

would rather thin than clear-cut, because that’s what I know how to do best, but the market determines what products you have to haul, what’s in demand.”

In the past they used to cut on a lot of state forest and federal wildlife refuge land, but in the last few years have done more private and corporate work for groups like American Forest Management. The job they were on during the Southern Loggin’ Times visit in April was a clear-cut of a 120-acre private tract. Majority of this was planted pine, outside some natural growth hardwood bottoms. “When we get it wrapped up, they will replant it back mostly in pine, and let those bottoms grow back natural,” Daniel says.

The cost of fuel has been their biggest problem since last year. “It jumped so high so quick, almost to $6 a gallon for on road fuel in some places,” he says. “In most places it was around $5.69, and now it’s back down around $4. That’s still higher than it was before, but not near as bad as it briefly got. It’s not as big a problem, but it still is a problem.” It takes almost $1,000 to fill up one truck, he notes, not to mention off road fuel. All together his crew burns around 1,200 gallons, around $5,000, a week. Some mills offered a slight fuel surcharge last year, Daniel says, but many

have since considered canceling it; the mill giveth and the mill taketh away, it seems.

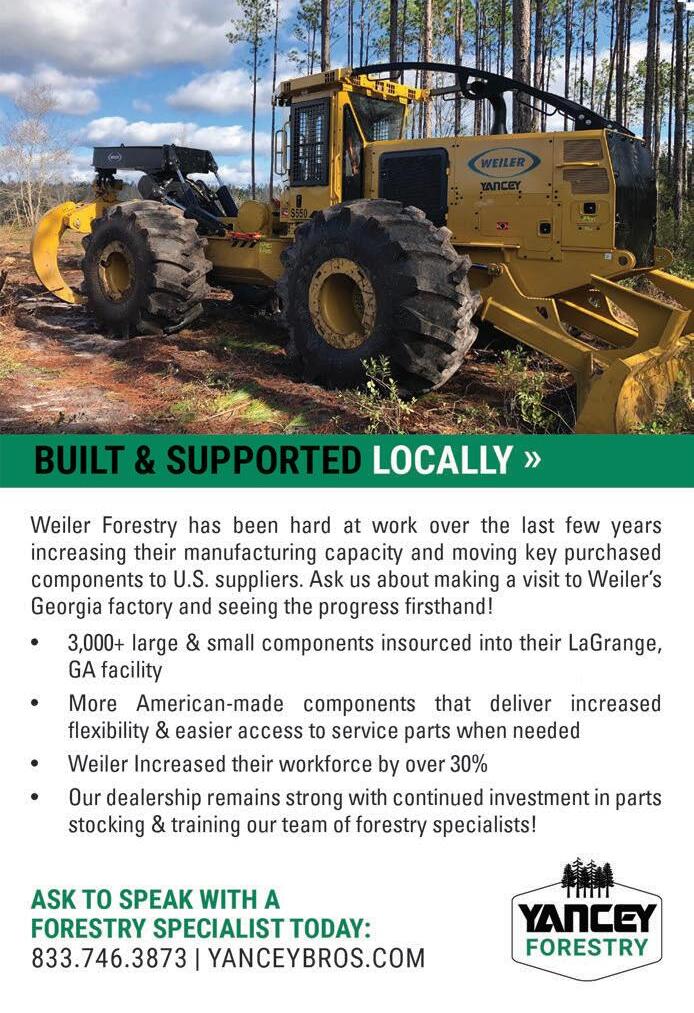

Equipment

Rhoad Timber’s main dealer is Blanchard Machinery of Florence. “They are great people and they are mainly why I run Weiler and Cat,” Daniel says. “The people at Blanchard, the sales, parts and mechanics, all the way down the line, are just top notch. Any issues we’ve had come up with the machines, they are right on it and they are steady in contact with me making sure everything is fine. That is the main thing that has gotten me where most of my equipment is yellow and it is because of Blanchard.”

And, he adds, now that Weiler has bought out the forestry side of Cat, people from Weiler also come to check in on him regularly. “They have shown me that they are real

For years, another important member of the RTC family has been Tick the dog. In the summer of 2006, the crew discovered a little dog living in the woods where they were working. “The men fed her, loved on her, and took off the many ticks that covered her body,” Toni recalls. “That is how she got her name.” Tick was there with them on that job site every day from that summer until early December. When they were finished with that tract and ready to move on, Danny’s brother David Rhoad decided to adopt her. Seven years later, when David died in October 2013, Tick came to live with Danny and Jenny, and has remained a part of the larger Rhoad Timber family all that time. Sadly, Tick died in July, just a few months after Southern Loggin’ Times visited the crew. “She was a big part of RTC and will be missed,” Toni says.

concerned about customer satisfaction. That means a lot when you know they are concerned about changing what they need to change to make things better. ”

The crew uses a 2022 Weiler S350 skidder, 2020 Weiler B570 cutter, 2015 Cat 529C loader with CSI buck saw and CTR delimber, and a rebuilt 2006 John Deere 648G-III skidder.

“We bought it used but sent it to River Ridge in Arkansas to do a complete rebuild on it,” Daniel says of the Deere skidder. “It was a complete strip down to the bare frame. They went through it all to check the frame for cracks, to redo all pins and bushings, reman the motor, reman the transmission, reman the rear end, the hydraulic pumps and valve banks, repack cylinders, replace seals. When you get it back, you practically have a brand new machine. We did it in 2012 and it has worked good. I love that style of machine; it’s got some of the electronics but not near the new where everything is computerized. It is getting to the point that you can’t work on a piece of machinery anymore without a computer in your hand.”

On first thinning and some second thinning jobs they use a Chambers Delimbinator. “It has really helped out with wood that size,” Daniel says.

They also still have in reserve two three-wheel cutters: a Franklin 3600 shear and Morbark Wolverine

The Deere skidder was bought used in 2012 and rebuilt completely by River Ridge Equipment inArkansas.

Rhoad got into chipping earlier this year.

Tick Southern Loggin’ Times ● SEPTEMBER 2023 ● 15 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

with saw head. “When I started, that was all we used, and I loved running them because of the maneuverability,” the logger recalls. Both machines are still in running condition, though with considerable age on them, but available if needed.

Rhoad runs Primex 32.5 size tires on skidders and 28s on the cutter, bought from Blacks Tire in Monroe. “Primex tires have gotten better,” Rhoad says. “We had some issues with beads on tires tearing up because new skidders are heavier and pull a heavier load and that puts more stress on the tires. We run the

32.5s because we do a lot of thinning and you need a narrower tire to get down some of the roads. A wider tire is made to carry heavier loads, but wider won’t fit on some rows. We only have a 12-14 ft. corridor in first thinning sometimes.”

Chipping

In March this year, Daniel decided to try out chipping for the wood pellet market in his region with a borrowed 2014 Morbark 3036 chipper. “The machine is not new, but I am new to the chipping game,” he says.

He had been discussing this for a while with his timber buyer, Timothy Griggs of Carolina Timber Brokers, especially for tracts full of non-merchantable wood, like the one he was working in early April. Griggs loaned him the chipper until Rhoad could decide if he would keep it on the job more permanently. Using borrowed chip vans, the crew has been delivering 15-20 chip loads a week for the last six months. So far they have only hauled to Enviva Pellets in Hamlet, NC, and Sonoco in Hartsville, which uses wood residuals to generate electricity.

Chipping is not a big focus of Rhoad’s business, but it serves a purpose. “When you get on clear-cuts like this, the landowner wants it gone anyway, and if you take the time to cut it, you need to merchandize it some kind of way and get paid for it,” he reasons. “A lot of the hardwood tops have so many limbs that it’s not merchantable for pulpwood. Plus, debris piles are an eyesore and make it hard to replant. So (chipping) is a service to the landowner and is a way to merchandize material that you have to handle anyway.”

By late June, Rhoad was pleased

16 ● SEPTEMBER 2023 ● Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

From left:CoreyWayne,Danny Rhoad,Daniel Rhoad,Carlton Gainey,JacobAllison,AustinAllison Rhoad buysWeiler because of good service from Blanchard Equipment.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

enough with the chipping that he committed to keeping it as part of his operation going forward, and is now in the process of securing financing to buy the Morbark from Griggs, as well as to acquire some chip vans of his own.

Hauling

Rhoad Timber runs its own trucks, Western Stars and Peterbilt, 2015-17 models, purchased from Triple T truck center in Florence, pulling Evans plantation trailers. All have GPS and dash cam systems. Unfortunately, in late July the company suffered the total loss of one truck in a fire; it had only been back from the repair shop for three months when the fire occurred. “Thankfully the driver and the load being hauled were unharmed,” Toni says.

Their main mill destinations include Domtar Paper in Bennettsville, Canfor Southern Pine in Darlington and Camden, and across the state line to Edwards Wood Products in Marshville and Peachland, NC.

Safety is a top focus for the Rhoad family. Daniel frequently advises his drivers to make their hauls as fast as is safely possible...with emphasis on safe. He conducts monthly safety meetings and addresses concerns on the spot as they arise. “The guys on the logging crew are majority of the time in the cab of a machine, but we do have the chain saw type hardhats with ear muffs and face guard and gloves for occasional chain saw work, cleaning up or trimming ends on loads.” They buy from Stihl dealer Darlington Chain Saw.

“Our insurance rep has a logging background but now works for Hawkins & Rawlinson,” the logger says. “They understand this side of the business and the challenges we are faced with.”

Daniel is a very dedicated member of Whispering Pines Baptist Church in Hartsville, SC. “I accepted the Lord at age 21,” he says. “When Dale Earnhardt got killed, the week after, the preacher preached on the fact that it’s that quick when you leave this world and heaven or hell is your home for eternity. The Lord really dealt with my heart to show me that I was not saved, so I went to the altar and asked the Lord to save me and I don’t doubt a bit that if I was to go right now, heaven is my home for eternity. It is not following religion, it is just trying to live the way the Lord wants and walking by faith.”

Rhoad has also found ways to integrate logging with his faith. “Years ago, in the ‘80s, our church planted some pines on the church property,” he relates. A decade ago, the small church undertook building a new fellowship hall and needed to pay off a remaining balance of $24,000 for the project. Daniel offered to thin a few acres of the church’s planted pine as a donation. After a timber dealer took his cut to sell to a mill, what was left came up to the exact amount the church needed.

“This is how the Lord works miracles,” Daniel believes. “All I did was thin the wood; the church still has the rest, another few acres of good quality longleaf. They’ll have that timber one day plus in a few years they’ll have revenue from pine straw. Being able to be in this business and help my church through the timber side has been a blessing to me. I take no credit; the Lord laid it on my heart to do that. To be involved and see a miracle the Lord worked was a real blessing to my heart.”

A version of this story appeared previously in the August issue of Wood Bioenergy magazine from Hatton-Brown Publishers.

SiblingsToniAllison,left,and Daniel Rhoad,right

A version of this story appeared previously in the August issue of Wood Bioenergy magazine from Hatton-Brown Publishers.

SiblingsToniAllison,left,and Daniel Rhoad,right

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Chipping isn't the main focus but it is useful to the business.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Thoughts On Leadership

l A leader is like a shepherd. He/she stays behind the flow, letting the most nimble go out ahead, whereupon the others follow, not realizing that all along they are being directed from behind.

—Nelson Mandela

l If your actions create a legacy that inspires others to dream more, learn more, do more and become more, then you are an excellent leader. —Dolly

Parton

l The very essence of leadership is that you have a vision. It’s got to be a vision you articulate clearly and forcefully on every occasion. You can’t blow an uncertain trumpet. —Rev. Theodore Hesburgh, former president of the University of Notre Dame

l A good leader inspires people to have confidence in the leader. A great leader inspires people to have confidence in themselves. —Eleanor

Roosevelt

l The supreme quality for leadership is unquestionably integrity. Without it, no real success is possible, no matter whether it is on a section gang, a football field, in an army, or in an office. —Dwight D. Eisenhower

l A leader takes people where they want to go. A great leader takes people where they don’t necessarily want to go but ought to be.

—Rosalynn Carter

l Ultimately, a genuine leader is not a searcher for consensus but a molder of consensus. —Martin Luther King, Jr.

The Winners Are…

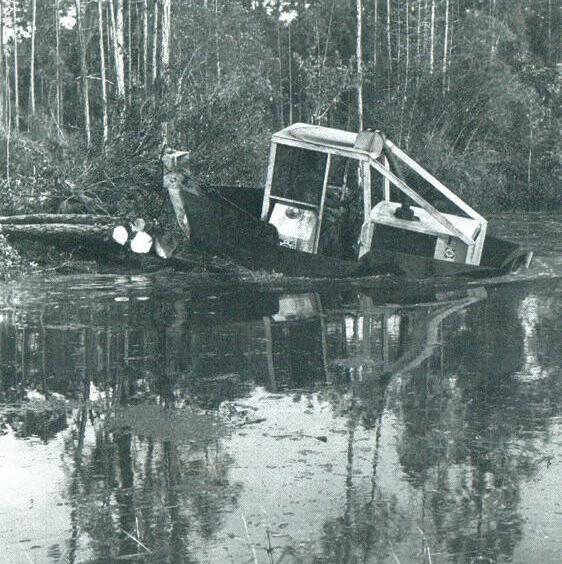

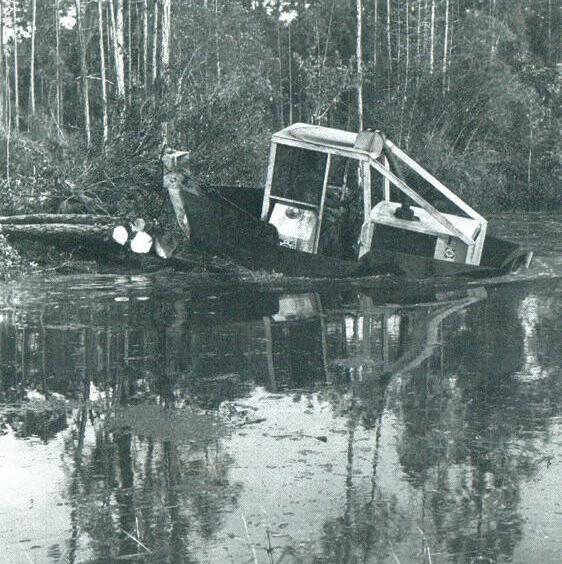

Florida,experimented with Bombardier tracked vehicles,which featured low ground pressure,to fell (fold-up I.B.White shear) and/or skid timber in the treacherous sog terrain that dominated thousands of acres in the area.

The Washington Post has published the winning submissions to its annual neologism contest, in which readers are asked to supply alternate meanings for common words. The winners included:

—Coffee (noun), the person upon whom one coughs.

—Flabbergasted (adjective), appalled over how much weight you have gained.

—Abdicate (verb), to give up all hope of ever having a flat stomach.

—Esplanade (verb), to attempt an explanation while drunk.

—Willy-nilly (adjective), impotent.

Remember When You Could Refer To Your Knees As Right & Left Instead Of Good & Bad?

—Negligent (adjective), describes a condition in which you absentmindedly answer the door in your nightgown.

—Lymph (verb), to walk with a lisp.

—Gargoyle (noun), gross olive-flavored mouthwash.

—Balderdash (noun), a rapidly receding hairline.

—Rectitude (noun), the formal, dignified bearing adopted by proctologists.

—Circumvent (noun), an opening in the front of boxer shorts worn by Jewish men.

Heavenly Encounter

A minister and a lawyer arrived at the pearly gates. Saint Peter greeted both of them and gave them their room assignments. “Pastor, here are the keys to one of our nicest efficiency units. And for you, sir, the keys to our finest penthouse suite.”

“This is unfair!” cried the minister.

“Listen,” Saint Peter said, “ministers are a dime a dozen up here, but lawyers are scarce.”

Father’s Figures

“Tell me, Johnnie,” said his teacher, “if your father borrowed $100 and promises to pay $10 a week, how much will he owe in 7 weeks?”

“One hundred dollars,” said Johnnie.

“I’m afraid you don’t know your lesson very well,” remarked the teacher.

“I may not know my lesson,” said Johnnie, “but I know my father.”

Presbyterian vs Baptist

A Baptist minister and a Presbyterian minister are sitting next to each other on a long flight. The Presbyterian leans over to the Baptist and asks if he would like to play a fun game. The Baptist just wants to take a nap, so he politely declines and turns towards the window to catch a few winks.

The Presbyterian persists and explains that the game is real easy and a lot of fun. He explains, “I ask you a question, and if you don’t know the answer, you pay me $5. Then you ask me a question, and if I don’t know the answer, I’ll pay you $5.”

Again, the Baptist politely declines and tries to sleep. The Presbyterian, now somewhat agitated, says, “Okay, if you don’t know the answer you pay me $5, and if I don’t know the answer, I’ll pay you $50!”

This catches the Baptist’s attention, and he sees no end to this torment unless he plays, so he agrees to the game. The Presbyterian asks the first question. “What’s the distance from the earth to the moon?” The Baptist doesn’t say a word, but reaches into his wallet, pulls out $5 and hands it to the Presbyterian.

Now, it’s the Baptist’s turn. He asks the Presbyterian “What goes up a hill with three legs, and comes down on four?”

The Presbyterian stares up at him with a puzzled look. He takes out his laptop computer and searches all of his references. He taps into the phone and searches the net and the Library of Congress. Frustrated, he sends e-mail to his church, all to no avail. After about an hour, he wakes the Baptist and hands him $50. The Baptist politely takes the $50 and turns away to try to get back to sleep.

The Presbyterian, more than a little miffed, shakes the Baptist and asks “Well, so what’s the answer?”

Without a word, the Baptist reaches into his wallet, hands the Presbyterian $5, and turns away to get back to sleep.

Catchy Construction Slogans

Call Us…Or Screw It Up Yourself

This is Not A Drill

Hard As Concrete, Flexible As Steel

The Rest Don’t Measure Up

Roof With The Best, Or Leak Like The Rest

If You Find Yourself Lost, Start Shouting About Politics. Someone Will Soon Start Arguing With You.

We’ll Leave No Stone Unturned

No Loose Screw Here

You Dream It, We Dig It

We Are Nailing It

Concrete Is Our Language

We Cover All Dimensions

22 l SEPTEMBER 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FROM THE BACKWOODS PEW Ribbons

If you spend much time in the southern woods, you may carry a field guide. The field guide is all about answering the questions that arise while being out and about in the great outdoors. For example, you have just

been stung. Looking in your field guide, you find that the little terror that stung you is called a yellow jacket, being yellow in color with black stripes on its body. This information then can be shared with others, like the

EMS squad, who respond to your call, as you are having an allergic reaction and thus trouble breathing. While the EMS is looking in their toolbox for an EpiPen, you can even share with them the scientific name, “Hurt-us Maximus.”

Suppose you are bitten by a snake. Open your trusty field guide, and see what options are available to be listed as the “cause of death.”

This will be very helpful to the funeral home should they have to supply an obituary. It won’t do, however, if you are simply scared to death, and not actually bitten. However, if you feel yourself going into cardiac arrest after seeing a corn snake on your path, just simply turn to “coral snake” as you are going down. By the time they find your body, they will not know the difference. In fact, I recommend carrying a picture of a poisonous snake with you, and go ahead and scribble “this is what got me!” in the margin. EMS are usually good to relay this information on to the coroner.

Perhaps it’s lunch time, and feeling a bit clem (that’s hungry for those of you who did not grow up watching TheAndy Griffith Show), you decide to snack on some mushrooms. If you ate first then checked your guide, leave some notes for the EMS; after all, if they come out and they too are a bit clem, you don’t want them eating what you had for your last meal.

Now there is always some sort of vine or flower that grows in the southern woods, that seems to be everywhere. You find it in the woods, growing around trees and hanging from branches. You see it wrapping around road signs also. It has many different hues, but it usually can be found in orange, pink, or blue. Sometimes you will find it growing in clusters, with branches as long as three feet, and then in some cases it can barely wrap around a slender branch. The scientific name for this colorful vine is “Plasticus Rib-onis.”

Finding it in your field guide, complete with colorful pictures, you learn that it is a pioneer species, and seems to propagate in advance of timber harvesting operations. The colorful foliage is what often limits the logger, usually stopping them from cutting any further in a block of timber. Even a burly logger likes to see the pretty colors. In some states, it is actually considered dangerous to harvest trees that support the ribbon-like-vine, especially if the vines are growing on trees claimed by an adjoining landowner. Log-truck drivers have been known to get carried away while driving down a county road, and upon seeing the vines wrapped around a road sign, will often just turn on that road in order to follow the beautiful wrappings.

But upon further research, the colorful vines known as “Plasticus Rib-onis” are not natural in their origin, nor will they show up

26 l SEPTEMBER 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Antill

in any field guide. They are the result of man’s activity. They actually declare that someone has walked through the woods, or has been down a given road. When the forester marks off a stand of timber to be harvested, he leaves in his wake the “vines.” He uses them to mark the sale boundaries, the place where the logger has to stop cutting. The “vines” also serve to direct the truck drivers, so they can find the logger and thus the log deck. “Go south on County Road 712 until you cross the bridge, and you will see pink ribbons on the left, turn on that dirt road.”

Wouldn’t it be great if life was like that? If a colorful ribbon, a marker, declared to us where to turn, where to stop. On a logging job, bright blue ribbons tied along a stream might represent a protective area to be left undisturbed. Maybe God could put up some ribbon that said, “Don’t go to that party,” or “Don’t take that drink.” While a forester might use orange ribbons to declare a change in land ownership, maybe God could wrap up the secretary with orange ribbon to keep the infatuated fellow employee from throwing away his marriage. The purpose of the “Plas-

ticus Rib-onis” vine is to declare a change is happening here.

Yet God has done this same thing, and his list of declarations are found in the Bible. They are called the Ten Commandments, recorded in Exodus 20:1-17, and they are just as valid today, and just as critical to your relationship with God, as they were when they were given to Moses.

You shall have no other gods before Me.

You shall not make for yourself a carved image.

You shall not take the name of the Lord your God in vain.

Remember the Sabbath day, to keep it holy.

Honor your father and your mother.

You shall not murder.

You shall not commit adultery.

You shall not steal.

You shall not bear false witness against your neighbor.

You shall not covet.

Let God wrap up your life with his ribbons; you will find it will keep you and your family from wandering out of the woods into the wasteland.

“For this is the covenant that I will make with the house of Israel after those days, says the Lord: I will put My laws in their mind and write them on their hearts; and I will be their

God, and they shall be My people.”

Hebrews 8:10

Excerpted from Woods, Worship, and Wasteland, Bradley Antill author. See more at www.onatreeforestry.com

Southern Loggin’ Times l SEPTEMBER 2023 l 27

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

As We See It: Can’t See The Forest For The Trees

By Scott Dane

Originally the phrase was “Can’t See the Wood for the Trees.” Either way it is apropos for the timber industry. Sometimes even loggers have a hard time seeing the forest for the trees.

“From him who sees no wood for trees and yet is busy as the bees.”

The expression refers to someone so consumed by the details of a problem (situation) that they are blind to the big picture. Looking at the situation from a 30,000-foot perspective can bring the big picture into focus and shed some light on the challenge instead of having tunnel vision or blinders on.

Rarely have the economic challenges of the timber industry been so daunting and challenging: mill closures, quotas, price cuts, workforce shortages, inflation, costs, etc.

Pulling back and playing into the doom and gloom scenario of all the negative economic news would be tempting. But there is a lesson about a hotdog salesman that is a good example worth considering:

There was a man who lived by the side of the road and sold hot dogs.He was hard of hearing, so he had no radio.He had trouble with his eyes, so he read no newspapers.

But he sold good hot dogs.He put up signs on the highway telling how good they were.He stood on the

side of the road and cried, “Buy a hot dog, mister.”And people bought.

So, he increased his meat and bun orders.He bought a bigger stove to take care of his trade.He finally got his son home from college to help him out.

Then something happened.

His son said, “Father, haven’t you been listening to the radio? Haven’t you been reading the newspapers? There’s a big depression. The European situation is terrible. The domestic situation is worse.”

Whereupon the father thought:

“Well, my son’s been to college.He read the papers and listened to the radio and ought to know.”So, the father cut back on his meat and bun orders, took down his advertising signs, and no longer bothered to stand out on the highway to promote his hot dogs.His hot dog sales fell almost overnight.

“You are certainly right, son,” the father said to the boy, “we are certainly in the middle of a depression.”

It is all a mindset, but it can be a self-fulfilling prophecy. Scale back, less income, more contraction, less income, more contraction…

It is an induced downward spiral.

The economy is cyclical; it always has been and always will be. Look at the Great Recession and the housing industry collapse of 2008. Even the stock market tanked. But we recovered from that. The economics of the timber industry will improve (if it doesn’t, then the entire economy is in bigger trouble, and it won’t matter). The only question is: will you be weaker, like the hotdog vendor, and have to recover and play catch up, or will you maintain your strength and be positioned to take advantage of the recovery?

Furthermore, loggers are in far more control of the situation than they realize. You are the most important segment of the timber supply chain and you are indispensable, irreplaceable, and essential.

The timber and forest products industry is a lot like the human body. Each part is vital to survival and has a distinct function. The following analogy is an example of the vital function that the logging sector plays in the overall forest products industry:

One day the different parts of the body were having an argument to see which should be in charge. The brain (foresters) said: “I do all the thinking, so I’m the most important, and I should be the boss.” The eyes (landowner) said: “I see everything and let the rest of you know where we are, so I’m

28 l SEPTEMBER 2023 l Southern Loggin’ Times

INDUSTRY NEWS ROUNDUP

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Dane

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

the most important, and I should be in charge.”The hands (equipment vendors) said: “Without us, we wouldn’t be able to pick anything up or move anything. So, we’re the most important and should be in charge.”The stomach (mills) said: ‘I turn the food we eat into energy for the rest of you. Without me, we’d starve. So, I’m the most important and should be the boss.” The legs (truckers) said: “Without me, we wouldn’t be able to move anywhere. So, I’m the most impor-

tant and should be in charge.”

Then the rectum (loggers) spoke and insisted it should be in charge. All the rest of the parts laughed and derided the very notion. The rectum wasn’t necessary. How could it possibly be in charge?

So, the rectum closed. After a few days, the legs were all wobbly, the stomach was queasy, the hands were shaky, the eyes were watery, and the brain couldn’t think straight. The other body parts soon agreed that they couldn’t take it

anymore and that the rectum should be in charge.

This all goes to show that you don’t have to be the most important; you just need to show others that you do matter, and without you, the rest cannot exist or function. Although some people say the story’s moral is that it demonstrates that to be in charge, you just must be an…

In conclusion, step back and gain a 30,000-foot perspective. See the forest, not just the trees. Don’t cre-

ate a self-fulfilling prophecy of decline. Position yourself to weather the economic storm but from a position of strength, not weakness. All storms pass. Having spent 15 years sailing the seven seas, I have encountered many storms, some life-threatening. When young sailors expressed concern, I would tell them, “Three days from now, we will have calm seas again,” and we did. Yesterday’s storms you faced have passed, last month’s storms are history, last year’s storm is a distant memory, and today’s storms will be, too.

You are far more important than the brain, eyes, hands, stomach, and legs want you to believe. You might be taken for granted, not given rightful respect, neglected, and abused, but if you weren’t functioning, they wouldn’t be either. Don’t be afraid to speak up or stand up for yourselves.

MS Operator School Gets Deere Simulators

This summer, the Logging Equipment Operator Academy at Hinds Community College in Raymond, Miss., received several training simulators from John Deere. Deere provided three fullsize standalone simulators, which offer a more immersive experience, and four desktop simulators, which include joysticks and pedals that connect to a computer. These simulators can be used to train students in the controls of tracked or rubber-tired feller-bunchers and skidders.

Administered as a partnership of Hinds with the Mississippi Loggers Assn. (MLA) and Mississippi Forestry Commission, the 8 to 16week Logging Academy program is designed to train students with little or no prior experience in logging how to operate equipment, with safety certifications and Professional Logging Manager (PLM) status upon completion of the course.

David Livingston, Executive Director at MLA, says these simulators are for the time being the only ones of their kind anywhere. “We have the original prototype as well as the only ones that have been built so far,” he says. “The three standalone units are identical to the same controls you would find in a machine cab, so it’s just like sitting in the real machine.”

The simulators arrived in late July, and were paid for by a grant to get the school started.

Justin McDermott, John Deere’s Forestry Sales and Tactical Marketing Manager for U.S. and Canada, says this all started when MLA reached out to inquire about

30 l SEPTEMBER 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

a prototype training simulator that John Deere had developed and exhibited at an event a few years ago. “We went to our engineering group and said there is a need for this in the market, so can we make this available?” McDermott says. Deere relied on its software design team in Finland to develop the training tool.

“It was not a smooth process,” McDermott reveals, noting that they were working on the project in the middle of the COVID pandemic, so there were major delays in manufacturing and shipping components. “It was challenging, and Hinds was incredibly patient.”

David Creel, Associate Vice President of Workforce Development at Hinds, worked with local Deere dealer Stribling Equipment to complete the transaction and set up the units, which will soon be available to train the next class of students to go through the program.

Livingston says one of the simulators will be on display at the Stribling/John Deere tent at the MidSouth Forestry Equipment Show in Starkville, Miss. on Friday and Saturday, September 22-23, 2023.

Weyco Buys 22,000 Acres in Mississippi

In July, Weyerhaeuser acquired 22,000 acres of timberland in Mississippi for $60 million. The company states that the highly productive timberlands are strategically located to deliver immediate synergies with existing Weyerhaeuser operations and offer incremental real estate and natural climate solutions opportunities.

Employment Trends Are Major Concern

Logging companies nationwide are losing employees, according to a report by Shawn Baker, Vice President of Research at Forisk Consulting, who contributed the following to the Forisk Research Quarterly Q3 2023 edition:

“An old Ray Charles song uses one of the many iterations of the phrase, ‘If it wasn’t for bad luck, I’d have no luck at all.’ The saying feels regrettably fitting for the logging sector of late. Over the last two years, inflation stressed contractors with higher logging costs. A recent cooling of lumber markets amid continued slow paper demand forced production quotas on many loggers, as well.

“Low margins and constrained production are a financially damaging mix. Historically, logging employment declines in response to reduced wood demand. Data from

the Bureau of Labor Statistics shows that a four-quarter moving average of U.S. South logging employment declined 13 consecutive quarters through the end of 2022. Despite the recent slowdown in lumber, Southern wood demand did not decline over the last 13 quarters. Harvest levels in 2022 exceeded those in 2005, prior to the Great Recession. Western logging employment fell 3% year-over-year in 2022, but the decline has not been as consistent as in the South.

“Looking beyond national trends, there are 23 states in the U.S. with at least 100 logging businesses headquartered in them. Out of those 23 states, only two increased logging employment between 2018 and 2022, Pennsylvania (+4%) and Texas (+6%). Of the remaining 21, nine recorded logging employment declines greater than 10%. Montana and Idaho are two of the top three, each losing more than 14% of their logging force as wood demand fell in the region. Louisiana recorded the second greatest drop in logging employment (15%), likely influenced by the closure of GeorgiaPacific’s Port Hudson pulp mill. Oregon also recorded a 14% decline.

“Total employment increased in seven of the nine states, indicating logging employment fell while the workforce in most states rose. Louisiana again stands out as an exception, highlighting general labor concerns there. With substantial investments in sawmill and bioenergy capacity over the last three years, Louisiana wood demand could increase as much as 30% over the next decade. Shrinking harvesting capacity should be a concern.”

ALC-Idaho Launches Health Ins. Plan

Responding to concerns from its members, officials with Associated

Logging Contractors-Idaho rolled out the organization’s medical insurance plan with special discounts and coverages designed for ALCIdaho members, says ALC-Idaho Executive Director Shawn Keough. The plan is open to ALC Regular members and is tailored for small businesses like logging and log truck driving. For example, groups as small as two are eligible, as long as both work at least 20 hours a week in the business. Employers can offer one to three different plans.

“The prices are competitive and the coverage is great,” Keough says. “The more people we get enrolled, the stronger the plan will be.”

Since she began working with ALC-Idaho in 2000, Keough says that obtaining affordable health insurance for association members has always been an issue. The group tried a self-funded plan 40 years ago but wasn’t able to sustain it. She adds that ALC-Idaho members have always wanted some sort of health plan but their voices have

32 l SEPTEMBER 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

become louder more recently as costs have risen.

The association was able to put the plan together by working with its long-time affiliated insurance company Associated Insurance Service, which in turn has coordinated with PacificSource Health Plans.

Emily Koleno, director of operations for Associated Insurance, notes that the ALC-Idaho board has been tremendously supportive of the formal process as the plan was developed over roughly 16 months. She adds that officials with the Idaho Dept. of Insurance were very responsive and ALC-Idaho’s experienced staff were a big help. PacificSource also has some of its business roots in the forest products industry and their people were excited about helping make the plan work, she says.

The issue of health insurance being offered—or not—by logging contractors is increasingly being raised as a big obstacle to both recruiting employees and retaining the ones already on the payroll. This is pertinent, as data indicates logging employment nationwide is declining.

In addition to Idaho, several other groups are also working on health

plans. The North Carolina Forestry Assn. (NCFA) is putting together a health care plan that the group hopes to begin offering the first of 2024, pending a board vote in September. “We hope to bring value to our members, and especially a health care option for smaller groups,” says NCFA Executive Director John Hatcher.

Kirby-Smith Is New Morbark Dealer

Morbark, LLC, has selected Kirby-Smith Machinery Inc. as an authorized dealer for all Morbark, Rayco, Denis Cimaf, and Boxer equipment product lines in Oklahoma, Kansas, Missouri, and Western Illinois. This collaboration brings together two industry leaders committed to providing exceptional customer service and top-of-the-line equipment solutions to the market.

Kirby-Smith has served the construction, mining, and industrial markets since 1983 as a full-service dealer. Its branch locations in Oklahoma City, Tulsa, McAlester, St. Louis, and Kansas City, will provide customers in the region with greater accessibility to all Morbark

product lines, as well as top-of-theline service and support from Kirby-Smith’s team of experienced sales and service professionals.

New EU Regs For Hardwood Exports

According to a release from the National Hardwood Lumber Assn., exporters of U.S. hardwood products should expect their business to be impacted by the European Union Deforestation-free Regulation (EUDR). The NHLA release states that the new regulations will require GPS coordinates that tie hardwood products back to an individual real estate holding where they were grown, and require that land to not be subject to land use conversion or “forest degradation.” The EUDR will affect not just the European market but also all of markets that export finished products into Europe, meaning this regulation will tremendously impact international markets.

ROM Employees Better Themselves

The RoyOMartin University (ROM-U) program identifies emerging leaders and develops their potential to ensure that the company maintains a pipeline of leaders prepared to take the next step in their careers.

Recently, Louisana-based RoyOMartin recognized Luke Briley, dry end manager, RoyOMartin-Plywood; Brett Danzy, mechanical maintenance superintendent, RoyOMartinPlywood; Jermaine Davis, corporate purchasing coordinator, corporate

office) and; Kelly Matthews, senior sales representative, corporate office, for completing RoyOMartin University-Management. This program is designed for leaders already in place with the company at a supervisor, team leader, superintendent, or manager level.

The program utilizes four key components to develop the participants: experiential learning, formalized training, mentorship programs, and cross-departmental assignments.

“RoyOMartin is successful because of our people,” the company states. “We believe that growing people is essential to the future of the organization. Effective leadership is built on a solid foundation consisting of a clear mission, a vision for the future, strategy, and a learning culture.”

l The company also recognized a group of team members, who since January 2020 have participated in the Corporate College program at Central Louisiana Technical Community College (CLTCC), and have recently completed their Associate of Applied Science degrees, with concentrations in general office and accounting.

They include John Budnik, Land and Timber; Jenna Foster, RoyOMartin-Plywood; Brandon Granger, Land and Timber; Crystal Hoover, corporate office; Cale Parker, Land and Timber; Raymond Rollins, Land and Timber; and Robyn Smith, corporate office.

Hood Rebuilding Plywood Plant In MS

Hood Industries announced plans to invest more than $200 million to

34 l SEPTEMBER 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

build a plywood manufacturing facility in Beaumont, Miss. and create 265 direct jobs. The announcement was part of a groundbreaking event at Beaumont held May 4, and it comes 40 years after Hood Industries took over operations at Beaumont Plywood in 1983.

The new facility will operate at twice the capacity of the previous facility, which was made inoperable by a tornado on April 17, 2022. Construction will begin this summer, and manufacturing will commence in early 2025. Hood Industries plans to fill the jobs over the next four years.

Hood Industries is a mix of wood manufacturing and distribution operations that also includes a plywood manufacturing plant in Wiggins, Miss. and four sawmills in Waynesboro and Silver Creek, Miss., Bogalusa, La. and Metcalfe, Ga., and 15 wood products distribution operations.

ALC Talks Bird Habitat With ABC

The American Loggers Council (ALC) and American Bird Con-

36 l SEPTEMBER 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

servancy (ABC) toured a site near Natchitoches, Louisiana, to discuss the essential role logging and loggers play in maintaining healthy ecosystems for bird habitats. In attendance were David Cupp, Walsh Timber, and ALC Secretary/Treasurer; Kevin Smith, ALC Communications Director; Jeremy Poirer, International Paper Biologist; Enyart Mitchell and Joe Cooper of Echo Forestry, and EJ Williams of

the American Bird Conservancy.

After the tour, Smith wrote, "When you are in the woods with EJ Williams, her energy and love of wildlife is contagious, almost like the forest is EJ's natural habitat. EJ has dedicated the past 25 years to preventing the decline of native birds, conserving essential bird habitats, reducing top threats to birds, and building an American-wide community of bird conservationists.

In the short time we were there, she identified over 25 different types of bird by ear. She used her vast knowledge to discuss the importance of logging and forest management in maintaining bird habitats.

“Many birds rely on young forests for nesting and raising their young, and logging is the first step in creating healthy young forests. Also, when loggers leave wide forest buffers along streams and rivers, they protect water quality and provide essential bird habitats.

“The group visited Walsh Timber's logging site of a private landowner managed by Echo Forestry. Logging the site was Jason Edwards of J&H Logging Coushatta, Louisiana, who is a 2nd generation logger and avid hunter. Most loggers hunt, fish, hike, camp, and enjoy the woods immensely. For many, they found their way to logging, allowing them to make the woods into their office.”

Big Changes For P-P-C Market

Pulp, paper and containerboard producers are undergoing a shift in infrastructure and product focus that’s resulting in big impacts to fiber demand and currently hitting loggers hard in the procurement areas surrounding such wood consuming facilities. The changes are reflected in the 2023 Timber Harvesting Logger Survey results and also popping up in various news

reports and industry newsletters.

The pulp and paper segment is continuing to adjust to declines in demand for publishing paper and other print media as more people work from home. There’s also been a drop in demand for shipping and packaging paper products, reversing the skyrocketing demand for packaging at the height of the COVID pandemic when traditional retailers were closed, leading to a boom in online shopping.

A comprehensive report in Fastmarkets RISI’s early June North American Woodfiber & Biomass Markets by Chris Lyddan notes that across 30 pulp-paper industry sites since 2020, outright closures and displacement through expansion that’s utilizing mostly recycled fiber have had a huge impact:

“Altogether, an estimated six million tons of finished product, perhaps 20 million tons of chips, has so far shut either permanently or indefinitely across nearly 30 mill sites, large and small, recycled and virgin,” he says.

Closures just announced this year include WestRock at North Charleston, SC; Pactiv Evergreen at Canton, NC; Cascades in Niagra Falls, NY; and Graphic Packaging in Tama, Ia.. And those closures don’t count the unscheduled downtime, reduced operations and indefinite closures such as NP Paper in Rumford and Old Towne, Me. and IP’s three straight quarters marked by unscheduled downtime. PCA’s announcement in May it was closing its Wallula, Wash. paper and corrugated packaging plant until later in the year is also a big hit, as the facility is a large destination market for many Northwest Intermountain chip producers.

In the Lake States region high inventories and lowered demand have mills taking downtime and cutting back on production, some taking away fuel bonuses as diesel prices have eased. Lyddan cites sources such as a Michigan procurement manager who says they haven’t bought open market wood since March, are currently running at about 50% and taking in less than 25% of what they normally buy. There’s also a Wisconsin logger who believes that after the current downturn, combined with inflation hitting almost all operating costs, the region could see “a different world, with a lot of logging capacity gone.”

38 l SEPTEMBER 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

IRONWORKS

TOLL FREE: 1-800-669-5613

CLASSIFIED AD RATES: Classified advertising rates are $55 per inch. Space is available by column inch only, one inch minimum.

DEADLINES: Ad reservation must be received by 10th of month prior to month of publication. Material must be received no later than 12th of month prior to month of publication.

CONTACT: Call Bridget DeVane at 334-699-7837, 800-669-5613, email bdevane7@hotmail.com or visit www.southernloggintimes.com

Southern Loggin’ Times ● SEPTEMBER 2023 ● 41

5078

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

6209

42 ● SEPTEMBER 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2687 6288 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Southern Loggin’ Times ● SEPTEMBER 2023 ● 43 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2891 4433 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

44 ● SEPTEMBER 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2687 13189 7393 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

1300 Morbark Tube Grinder, C&L, 2006, 6000

2004 Barko 495ML Loader, 2018 CAT 559D LOADER, delimber, HYD trailer, 10K, VERY NICE FOR THE HRS, JOB READY!......$10,2500

Also available:

■ 5400 Peterson Grinder, 2000, 3412 CAT, 800HP

■ 5710 Peterson Grinder on Tracks, 2016, C-27, 1050HP

■ 6800 CBI, Tracks, 2016, 4800 hr., 1050HP

EUREKA! EUREKA! EUREKA!

OWNERS HAVE OVER 30 YEARS COMBINED EXPERIENCE!

We can save you money on Saw Teeth. Hundreds of satisfied customers. Rebuilt Exchange or New. We specialize in rebuilding Koehring 2000, Hurricana, Hydro Ax split teeth and all other brands. Call Jimmy or Niel Mitchell. Quantity Discounts!

Steel Shard In Workers’ Eye: A Reminder of the Importance of Protective Eyewear

BACKGROUND:

On a fall day in the Pacific Northwest a bulldozer operator exited his machine to work on a sweep arm pin on the dozer blade.

PERSONAL CHARACTERISTICS:

The operator’s experience and training are unknown.

UNSAFE ACTS AND CONDITIONS/ACCIDENT/INJURY:

The operator was hitting the pin with a hammer when two steel shards broke off from the pin. One missed the operator; however, the other shard lodged in his left eye. The bulldozer operator was not

wearing protective eyewear. He called a co-worker for assistance, who then transported him to the hospital for emergency treatment. His recovery time and return to work are unknown.

RECOMMENDATIONS FOR CORRECTION:

We often take everyday activities for granted. Do a proper assessment of what Personal Protective Equipment (PPE) is needed

prior to performing any work. What are the hazards? What are the risks? Among other tasks, protective eyewear should also be worn anytime you are:

● Cutting

● Welding

● Hammering

● Chiseling

● Spraying

● Working in an environment involving airborne debris Supplied

Southern Loggin’ Times ● SEPTEMBER 2023 ● 45 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM

hrs., 3412 eng.

4710-B Peterson Track Grinder, 2007, All Rebuild, 600HP

Call for details and pricing 1-888-992-9595 13121 2583

EUREKA SAW TOOTH CO., INC. 4275 Moores Ferry Rd. • Skippers, Virginia 23879 PH./FAX (day) 1-434-634-9836 or Night/Weekends • 1-434-634-9185 NOW ACCEPTING CREDIT CARDS 7180

SAWDISK REPAIR

CARVER

ground

252-945-2358 566

or

Zane 334-518-9937 3939 visit us online southernloggingtimes.com

All cracks are hand

Using chemical dye process Tig welding using Alloy rods Air hammer peening provide Lasting repairs. I straighten and balance all makes of Feller buncher saws Washington, NC

FOR SALE

Call

Text

by Forest Resources Assn.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

COMING EVENTS

September

5-8—Tennessee Forestry Assn. annual meeting, Marriott Cool Springs, Franklin, Tenn. Call 615-883-3832; visit tnforestry.com.

7-9—Great Lakes Logging & Heavy Equipment Expo, UP State Fairground, Escanaba, Mich. Call 715-282-5828; visit gltpa.org.

10-12—Alabama Forestry Assn. annual meeting, Perdido Beach Resort, Orange Beach, Ala. Call 334-265-8733; visit alaforestry.org.

15-16—Kentucky Wood Expo, Masterson Station Park, Lexington, Ky. Call 502-695-3979; visit kfia.org.

15-17—Virginia Forest Products Assn. Annual Conference, The Omni Homestead Resort, Homestead, Va. Call 804-737-5625; visit vfpa.net.

22-23—Mid-South Forestry Equipment Show, Starkville, Miss. Call 800-669-5613; visit midsouth forestry.org.

26-28—Arkansas Forestry Assn. annual meeting, Oaklawn Hotel & Spa, Hot Springs, Ark. Call 501374-2441; visit arkforests.org.

27-29—North Carolina Forestry Assn. annual meeting, Biltmore Estate, Asheville, NC. Call 800231-7723; visit ncforestry.org.

October

3-6—American Loggers Council annual meeting, Sunday River Ski Resort, Newry, Maine. Call 409625-0206; visit amloggers.com.

4-6—National Hardwood Lumber Assn. Convention & Exhibit Showcase, Omni Louisville Hotel, Louisville, Ky. Call 901-377-1818; visit nhla.com.

18-20—Texas Forestry Assn. annual meeting, The Fredonia Hotel, Nacogdoches, Tex. Visit texasforestry.org.

28—Alabama Loggers Council annual meeting, Marriott Prattville Hotel and Conference Center, Prattville, Ala. Call 334-265-8733; visit alaforestry.org/events/EventDetails.aspx?id=1745682.

November

8-10—Forestry Assn. of South Carolina annual meeting, Wild Dunes, Isle of Palms, SC. Call 803-7984170; visit scforestry.org.

February 2024

21-25—Appalachian Hardwood Manufacturers annual meeting, Hammock Beach Resort, Palm Coast, Fla. Call 336-885-8315; visit appalachianhardwood.org.

23-25—South Carolina Timber Producers Assn. annual meeting, DoubleTree Resort by Hilton, Myrtle Beach, SC. Call 800-371-2240; visit scloggers.com.

March 2024

12-13—Wood Bioenergy Conference & Expo, Omni Hotel at CNN Center, Atlanta, Ga. Call 334-834-1170; visit bioenergyshow.com.

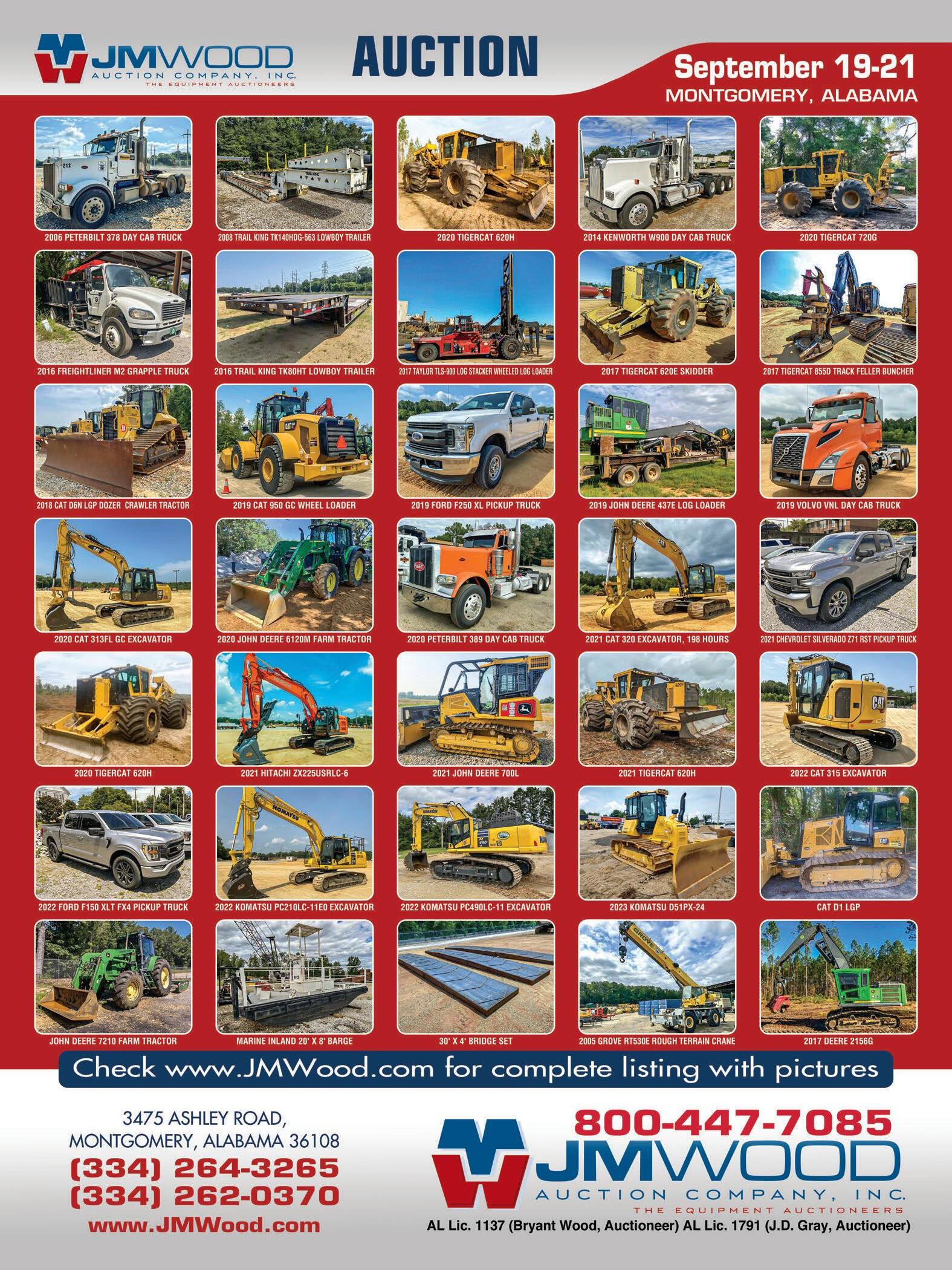

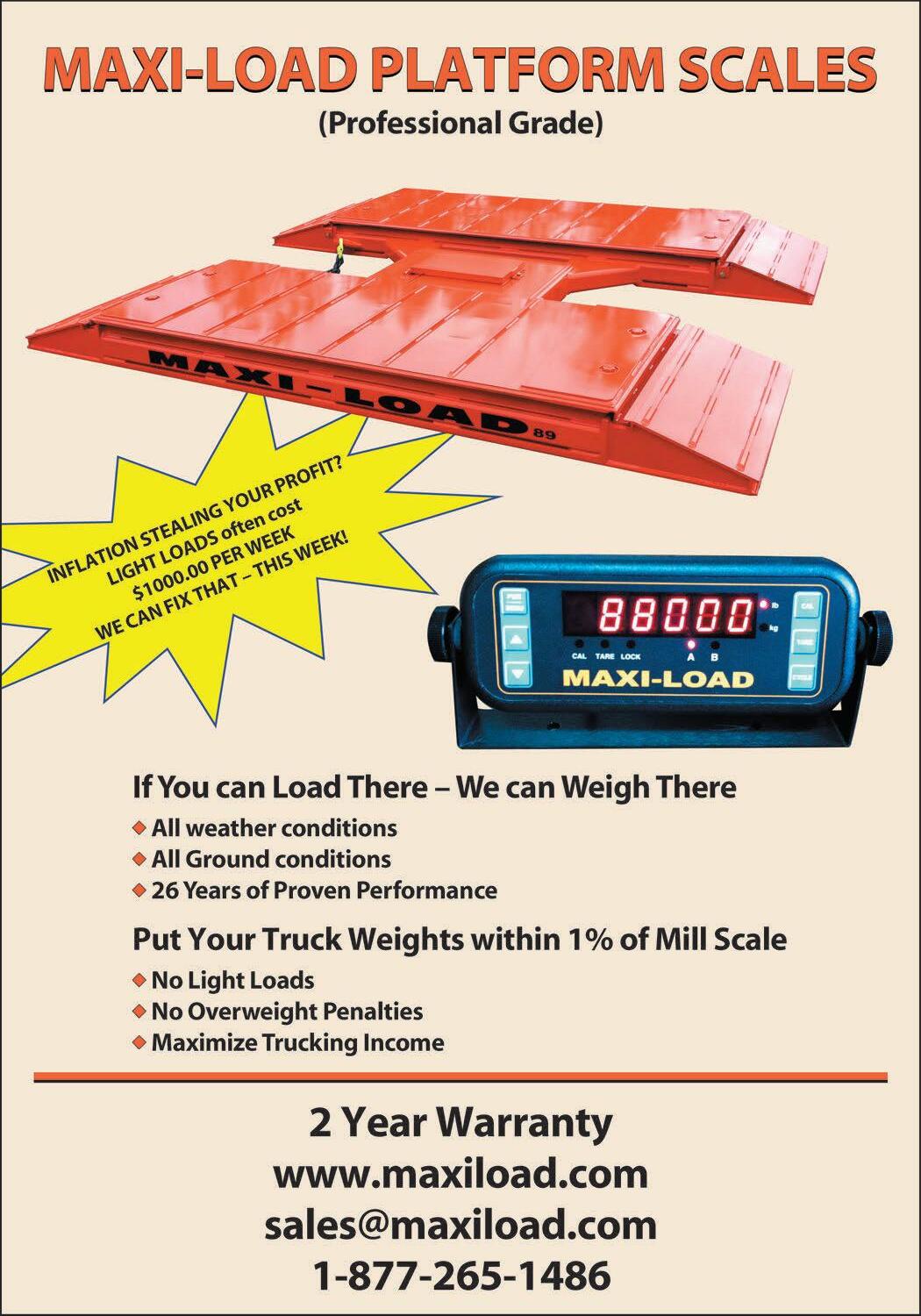

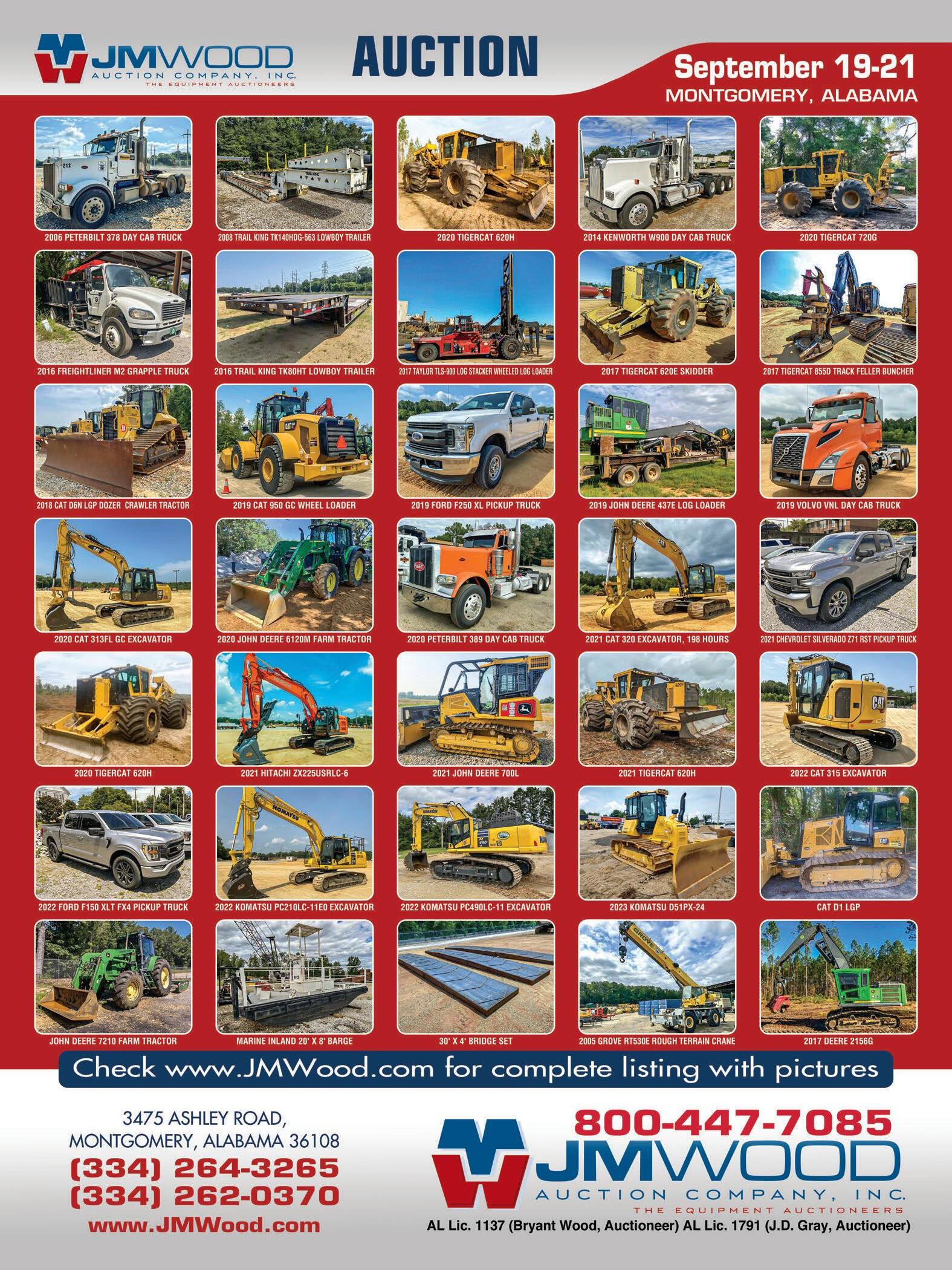

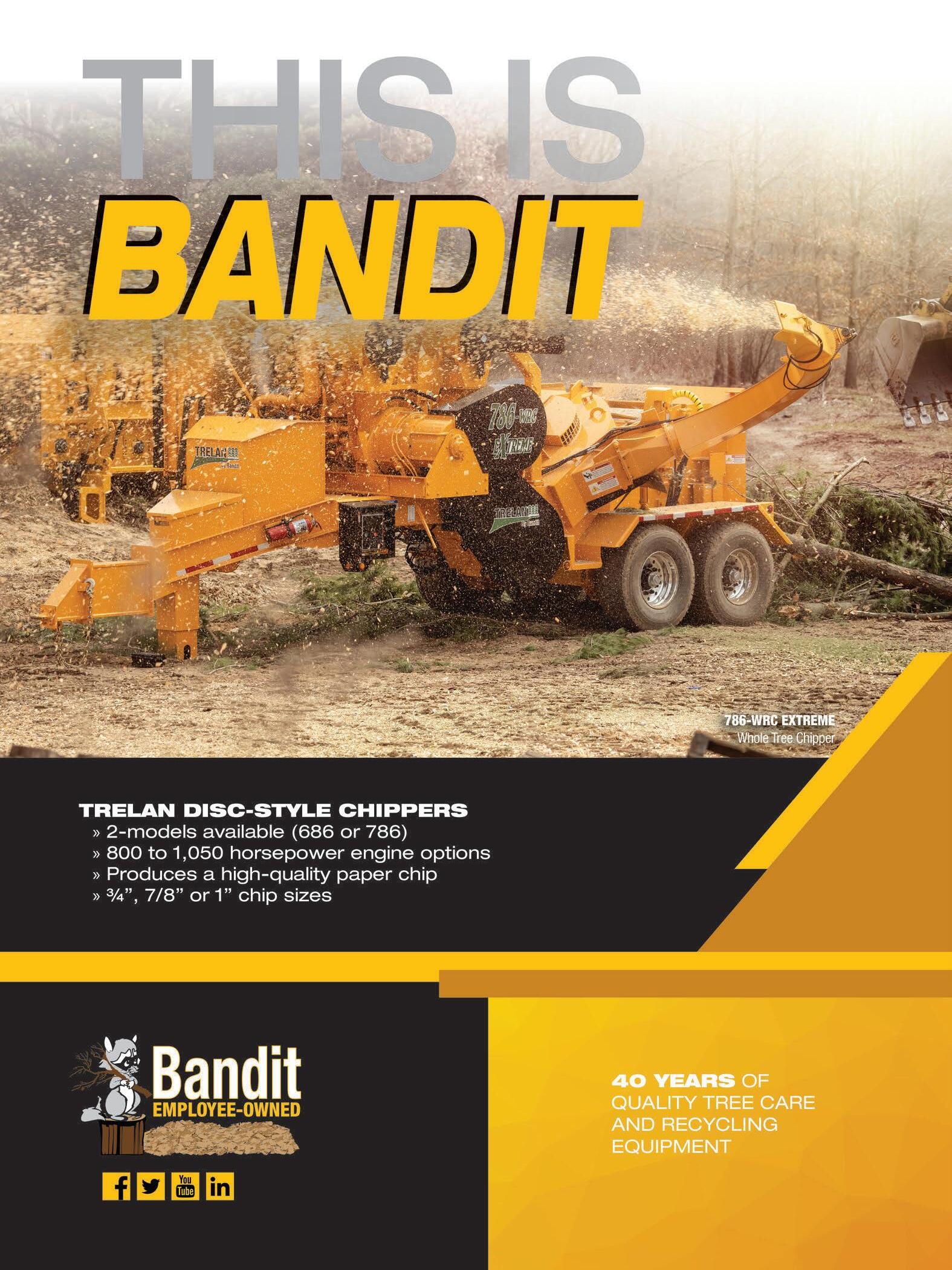

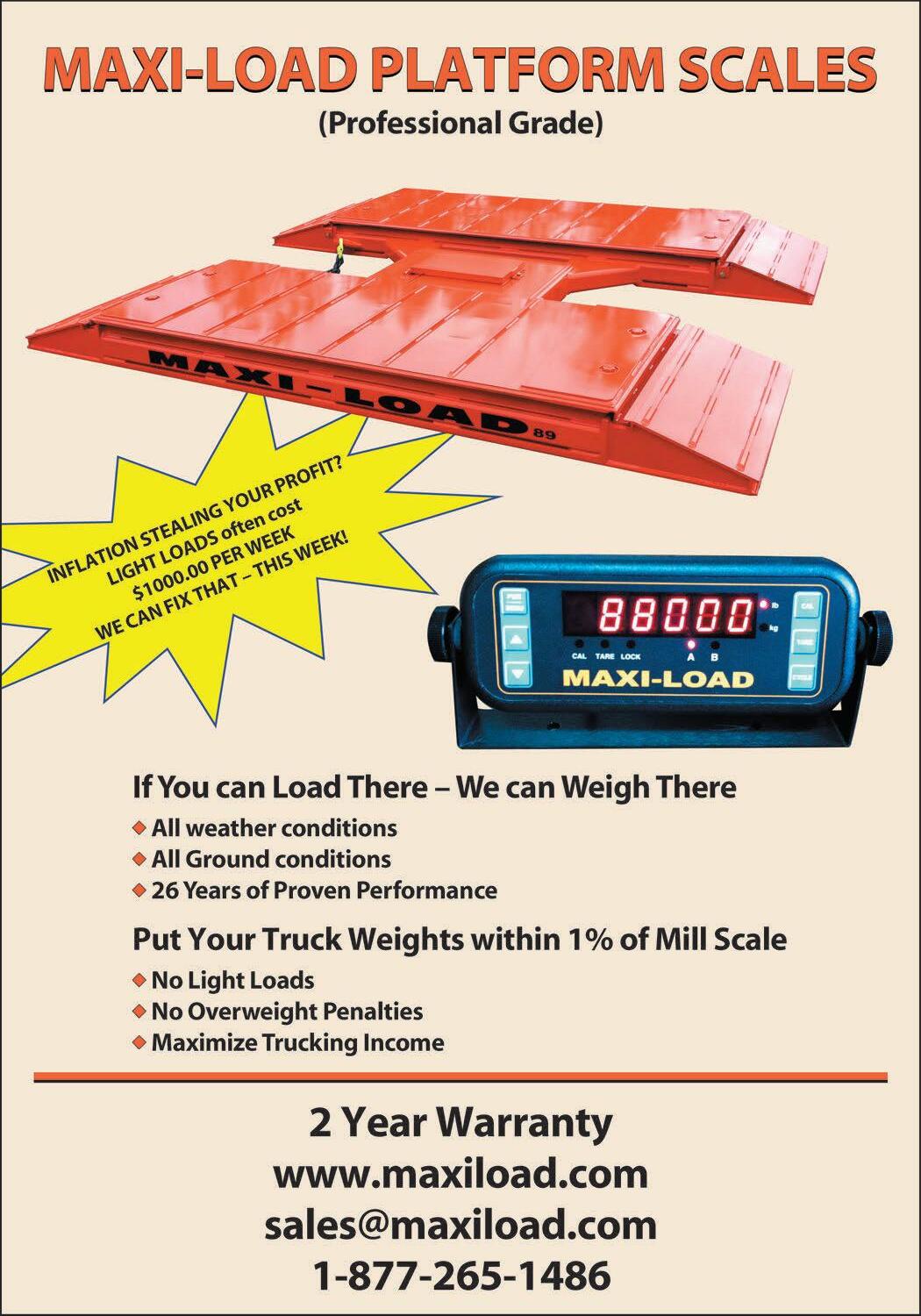

46 ● SEPTEMBER 2023 ● Southern Loggin’ Times American Truck Parts 27 888.383.8884 Around The World Salvage 41 936.634.7210 Bandit Industries 47 800.952.0178 Barko Hydraulics 32,33 715.395.6700 BITCO Insurance 10 800.475.4477 BKT USA 18 888.660.0662 Caterpillar Dealer Promotion 13 919.550.1201 Cleanfix North America 28 855.738.3267 John Deere Forestry 24-25 800.503.3373 Dobbs Equipment 2,21 844.469.3622 Eastern Surplus 27 855.332.0500 FMI Trailers 26 601.508.3333 Forest Chain 34 800.288.0887 Forestry First 42 803.708.0624 Forestry Mutual Insurance 7 800.849.7788 G & W Equipment 38 800.284.9032 Hawkins & Rawlinson 30 888.822.1173 Interstate Tire Service 44 864.947.9208 Kaufman Trailers NC 3 336.790.6807 Mike Ledkins Insurance Agency 35 800.766.8349 LMI-Tennessee 20 800.467.0944 Loadrite Southern Star 36 256.270.8775 Logger Associations 36 Magnolia Trailers 37 800.738.2123 Maxi-Load Scale Systems 12 877.265.1486 Midsouth Forestry Equipment 35 870.226.0000 Moore Logging Supply 38 888.754.5613 Morbark 1,5 800.831.0042 Nordic Traction USA 27 207.487.1984 Olofsfors 17 519.754.2190 Pinnacle Trailer Sales 28 910.629.2824 Pitts Trailers 48 800.321.8073 Ponsse North America 29 715.369.4833 Quadco Equipment 16 800.668.3340 Quality Equipment & Parts 43 386.487.3896 Smith & Turner Equipment 19 770.536.7521 Southern Loggers Cooperative 36 318.445.0750 Stribling Equipment 43 855.781.9408 Tidewater Equipment 42,44 912.638.7726 Timberblade 31 519.532.3283 TraxPlus 39 601.635.5543 VPG Onboard Weighing 39 800.237.0022 W & W Truck & Tractor 40 843.761.8220 Waratah Forestry Attachments 11 770.692.0380 Waters International Trucks 44 601.693.4807 J M Wood Auction 23 334.264.3265 Yancey Brothers 34 800.282.1562

ADLINK is a free service for advertisers and readers. The publisher assumes no liability for errors or omissions. A ● D ● L ● I ● N ● K ADVERTISER PG. NO. PHONE NO. Listings are submitted months in advance.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

southernloggintimes.com

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

By David Abbott MCBEE, SC

By David Abbott MCBEE, SC

A version of this story appeared previously in the August issue of Wood Bioenergy magazine from Hatton-Brown Publishers.

SiblingsToniAllison,left,and Daniel Rhoad,right

A version of this story appeared previously in the August issue of Wood Bioenergy magazine from Hatton-Brown Publishers.

SiblingsToniAllison,left,and Daniel Rhoad,right