CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Hatton-Brown Publishers, Inc.

Street Address: 225 Hanrick Street

Montgomery, AL 36104-3317

Mailing Address: P.O. Box 2268

Montgomery, AL 36102-2268

Telephone: 334.834.1170

FAX: 334.834.4525

Publisher: David H. Ramsey

Chief Operating Officer: Dianne C. Sullivan

Editor-in-Chief: Rich Donnell

Senior Editor: Dan Shell

Senior Editor: David Abbott

Senior Editor: Jessica Johnson

Publisher/Editor Emeritus: David (DK) Knight

Art Director/Prod. Manager: Cindy Segrest

Ad Production Coordinator: Patti Campbell

Circulation Director: Rhonda Thomas

Online Content/Marketing: Jacqlyn Kirkland

Classified Advertising:

Bridget DeVane • 334.699.7837

800.669.5613 • bdevane7@hotmail.com

Advertising Sales Representatives:

Southern USA

Randy Reagor

P.O. Box 2268

Montgomery, AL 36102-2268

904.393.7968 • FAX: 334.834.4525

E-mail: reagor@bellsouth.net

Midwest USA, Eastern Canada

John Simmons

29 Bugelli Drive

Whitby, Ontario, Canada L1R 3B7

905.666.0258

E-mail: jsimmons@idirect.com

Western USA, Western Canada

Tim Shaddick

4056 West 10th Avenue

Vancouver BC Canada V6L 1Z1

604.910.1826

E-mail: twshaddick@gmail.com

Kevin Cook

604.619.1777

E-mail: lordkevincook@gmail.com

International

Murray Brett

58 Aldea de las Cuevas, Buzon 60

03759 Benidoleig (Alicante), Spain

Tel: +34 96 640 4165 • Mobile +34 66 931 5837

E-mail: murray.brett@abasol.net

VISIT

Timber Processing (ISSN 0885-906X, USPS 395-850) is published 11 times annually (monthly except Jan./Feb.) by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—TP is free to qualified owners, operators, managers, purchasing agents, supervisors, foremen and other key personnel at sawmills, pallet plants, chip mills, treating plants, specialty plants, lumber finishing

distributors in the U.S. All non-qualified

$55 annually: $65 in Canada; $95 (Airmail) in all other countries (U.S. Funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription

TOLL-FREE: 800-6695613; Fax 888-611-4525. Go to www.timberprocessing.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Timber Processing magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorse nor makes any representation or guarantee as to the quality of goods and services advertised in Timber Processing. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed in U.S.A.

Postmaster: Please send address changes to Timber Processing, P.O. Box 2419, Montgomery, Alabama 36102-2419

Other Hatton-Brown publications: Timber Harvesting • Southern Loggin’ Times Wood Bioenergy • Panel World • Power Equipment Trade

Volume 48 • Number 9 • October 2023 Founded in 1976 • Our 500th Consecutive Issue NEWSFEED Canfor “Renews” BC Commitment COVER: Besse Forest Products Group, one of the largest privately owned lumber, hardwood veneer and specialty plywood producers in North America, has rebuilt its sawmill operation in Goodman, Wis. Story begins on PAGE 18. (Jessica Johnson photo) 6 BESSE FOREST PRODUCTS More Improvements And Growth 18 SFPA EXPO IN PHOTOS One Last Look At Nashville 38 GLOBAL MACHINERY Doing Business Home And Abroad 24 MESA VERDE PELLETS All About Fiber Optimization 42 WOOD DEMAND Putting The Real Numbers To It 52 MACHINERY ROW New CLT Plant In Austria 56 Renew or subscribe on the web: www.timberprocessing.com A Hatton-Brown Publication

OUR WEBSITE:www.timberprocessing.com

operations, corporate industrial woodlands officials and machinery manufacturers and

U.S. Subscriptions are

Inquiries—

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Rich Donnell Editor-in-Chief

THE PORTLAND SHOW KEEPS ON KEEPIN’ ON

The conclusion of the SFPA Expo held in Nashville in August can only mean one thing. It’s time to move on to the next major sawmill machinery show: the Timber Processing & Energy Expo (TP&EE) to be held September 25-27, 2024 at the Portland Exposition Center in Portland, Ore.

Our affiliate, Hatton-Brown Expositions, produces the event, while Timber Processing serves as the primary media host. If you’ll recall the 2022 version of TP&EE, more than 110 wood producer companies, representing several hundred mill operations, sent their personnel; in fact, more than 1,200 (non-exhibitor) attendees from 35 states and 15 countries registered for the event. They combed the aisles of 170 exhibitor companies, who were represented by more than 900 exhibitor personnel.

The 2024 TP&EE will be the sixth one that we have produced, starting in 2012, and keeping in mind we had to skip 2020 due to the pandemic. We started it in 2012 frankly at the request of many exhibitor companies who felt that the previous long-running Portland show had veered off track and its downtown location was too congested. That’s why we moved it out of downtown and to the Portland Expo Center.

Given all of the negative developments in downtown Portland in the past couple of years, it’s probably a good thing we did. It’s no secret that homeless people are an “issue” in Portland, and they were visible in small numbers near my hotel during the last show. But from the Expo Center itself, I saw nary a homeless person. Then again, I can look from our parking lot here in Montgomery, Ala. and see three homeless people right now asking for money on the interstate ramp. It’s a bigger problem than Portland’s alone.

The issue with the Portland show, going way back, is that the city has a liberal mindset and our show has a conservative one. I remember years ago when the environmentalists shut down the interstate leading into downtown. I remember when environmentalists picketed outside the old Portland show. I also remember years ago when downtown Portland was flooded with tramps.

Obviously we still believe there’s a need for a sawmill show in the Northwest. We’ve looked at some other sites as suggested by a few people, but either they weren’t large enough, the move-in logistics were too cramped, or their location was too far off the beaten path.

So we’ve stayed in Portland. The reason the Portland show has always been in Portland is because it’s the most reasonable location to be accessed by the region’s sawmillers. That hasn’t changed.

What has changed of course is the downsizing of the Northwest sawmill industry. I always chuckle when somebody at the show is surprised that there aren’t as many people at the show as there used to be. I always reply well there’s 80% less sawmill industry than there used to be, thanks to the northern spotted owl and other environmental encroachments.

But the industry is still significant in the Northwest. Most recently Canfor announced it is building a new sawmill in British Columbia. Earlier this year Sierra Pacific Industries announced it is building the largest sawmill production operation in the U.S. (if not the world) at Eugene (about two hours south of Portland), replacing its existing sawmilling facilities there. And Oregon-based Roseburg announced a massive investment program for several of its panel facilities in Oregon—not sawmills, but significant nonetheless.

18 24 38 42 THEISSUES

TP Contact Rich Donnell, ph: 334-834-1170; fax 334-834-4525; e-mail: rich@hattonbrown.com TIMBER PROCESSING ■ SEPTEMBER 2023 ■ 5 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NEWSFEED

CANFOR COMMITS TO NEW BC MILL

Vancouver, BC-based Canfor Corp. is investing $200 million to build a new stateof-the-art manufacturing facility in Houston, British Columbia, which will have an annual production capacity of 350MMBF.

“I’m very pleased to be making this announcement in British Columbia, where Canfor has been proudly headquartered for 85 years,” comments, Don Kayne, President and CEO. “This decision comes following a comprehensive evaluation of customer requirements and a careful evaluation of the availability of economic fiber in the region to support a successful investment. We believe we have the plan, the people and the know-how to

build a best-in-class facility that showcases BC workers, suppliers and technology.”

Work will begin immediately on detailed project engineering and permitting requirements. Vendor and equipment selection will be finalized in early 2024 with demolition and site preparation scheduled for the spring. Planning, construction and commissioning of the new facility is expected to take between 28 and 32 months depending on contractor availability and equipment lead times.

Bruce Ralston, Minister of Forests, adds, “For generations communities throughout BC have benefited from good, family-supporting jobs provided by forestry. This announcement demonstrates that this continues, and ensures that long-term jobs will remain in the region. It also

encourages young people in BC to see the opportunities available to them in this vitally important industry. Forestry is and will remain a foundation of the BC economy, and our government is committed to ensuring that forestry remains a strong and sustainable industry in BC.”

Canfor operates 55 facilities across its diversified wood products manufacturing platform in Canada, the United States and Europe. The company has a 70% stake in Vida AB, Sweden’s largest privately owned sawmill company and also owns a 54.8% interest in Canfor Pulp Products Inc.

LABOR DEPT. SLAPS SAWMILL OPERATOR

U.S. Dept. of Labor obtained a federal consent order

and judgment against a sawmill operator in Wisconsin following the death of a child due to an “industrial accident.” The order requires the company to place labels and signage to prevent children under age 18 from using dangerous equipment and entering the company’s sawmill and planer buildings. The company has agreed not to hire anyone under the age of 16 and if the company hires anyone between the ages of 16 and 18 in the future, the company must strictly comply with the requirements for apprentices or student learners and inform the department before hiring them.

The action follows an investigation by the department’s Wage and Hour Division into a 16-year-old worker’s death at the Wisconsin sawmill, which led to the department invoking the “hot

6 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

goods” provision of the Fair Labor Standards Act. The division opened the investigation after the teenager suffered severe injuries in June and died two days later.

In September, in a U.S. District Court for the Eastern District of Wisconsin, the company agreed to, and was ordered by the court to comply with, federal child labor regulations now and in the future.

“This tragic case illustrates just how vital and urgent it is that the Department of Labor uses every tool at our disposal to combat child labor,” says Acting Secretary of Labor Julie Su. “Any death of a child is too many. That’s why our Wage and Hour Division and Solicitor’s Office took immediate steps to prevent the sale of ‘hot goods’ and to hold the company accountable for allowing children to perform hazardous and, in

this case, deadly jobs. Illegal child labor is a stain on this country and will not be tolerated by this administration or this department.”

In February the department announced the creation of an Interagency Task Force to Combat Child Labor Exploitation to better align federal efforts to protect children from exploitative situations in the workplace. Led by the department, the task force includes the departments of Agriculture, Commerce, Education, Health and Human Services, Homeland Security, Justice and State to improve crosstraining, outreach, education and health outcomes of children that could be subject to child labor. The administration is using a whole-of-government approach to tackle the issue of child labor abuse and root it out of the country.

In addition to learning of

the 16-year-old worker’s death, the division’s investigation found the following:

—Three children, ages 15 to 16, suffered injuries in November 2021, July 2022 and March 2023. One child suffered injuries on two separate occasions.

—The mill company employed nine children, ages 14 to 17, to illegally operate machinery, such as a chop saw, rip saw and other automated machines, which federal law considers hazardous occupations for workers under 18.

—The company employed seven children, ages 14 and 15 years old, to work outside legally permitted hours.

“(The company) risked the life of a child by allowing him to operate dangerous equipment in violation of federal child labor laws, and now family, friends and co-workers are left to grieve,” says

Solicitor of Labor Seema

Nanda. “The Solicitor’s office will use all legal tools available to combat child labor, including placing pressure on supply chains to hold their suppliers accountable.

“This case underscores the importance and urgency of the administration’s interagency work to combat child labor exploitation. The department’s use of legal tactics in this and other cases like invoking hot goods is one important piece of the puzzle when it comes to rooting out child labor.”

The Fair Labor Standards Act forbids any producer, manufacturer or dealer from shipping or delivering for shipment in interstate commerce hot goods removed from the producing establishment in the 30 days after a child labor violation. Prohibition on shipping hot goods is

8 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NEWSFEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

not limited to employers who initially produce products with child labor. It also applies to any producer, manufacturer or dealer who later receives them.

During its investigation, the division also alerted two of the sawmill’s customers that they possessed goods subject to the hot goods provision. Both customers agreed voluntarily to refrain from shipping or delivering for shipment in interstate commerce the hot goods they received until the legal matter was resolved.

The day after the teen’s death, the mill company terminated all employees under age 18 at its facility, and later verified to the court that no one under the age of 18 is now employed by the company. After the company agreed to pay $190,696 in civil money penalties to resolve its

child labor violations and the court executed the order and judgment, the department lifted its objection to shipment of the goods.

In accepting the court’s judgment, the mill company also agreed to the following conditions to prevent future violations of the FLSA’s child labor provisions:

—Placing signage to warn children not to enter the sawmill and planer buildings at its locations.

—Using the division’s Youth Employment Compliance Assistance Toolkit to identify materials for use in training employees, provided in a language understood by workers, and maintaining training logs.

—Auditing machinery and labeling machines with stickers warning that workers must be 18 years of age or older to operate legally.

—Providing employees with fact sheets on child labor.

In fiscal year 2022, division investigators identified child labor violations in 835 cases and assessed employers with more than $4.3 million in penalties.

EQUITY FIRM BUYS BUSE TIMBER

Lynx Equity Ltd. announced the acquisition of Buse Timber & Sales Inc., a sawmill founded in 1946 by brothers Norm and Delmer Buse, and located in Everett, Wash. The company predominantly serves the West Coast and operates in niche commercial markets that demand beams, trusses and crossarms. Buse is one of the few sawmills that can process large logs to its clients’ specifica-

tions while carrying a significant amount of inventory, thereby allowing the company to fulfill multiple orders on short notice.

The acquisition of Buse will bolster Lynx’s presence in the wood manufacturing market, a space already occupied by sister companies, Winfield Wood & Lath and Yellowhead Wood Products Inc.

Andrea Natarelli, Lynx’s Senior M&A Associate, comments, “Buse has been a local landmark within the community of Everett for the past five decades. Lynx is extremely excited to preserve the company’s legacy while partnering with its existing management led by Tom and Diana, Buse’s President and CFO, respectively, who’ve each played a key role in the company’s success.”

“Buse Timber & Sales is

10 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NEWSFEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

one of two remaining lumber sawmill manufactures in Everett,” adds Tom Parks. “In selling to Lynx, Buse Timber will keep the historic landmark and its employees in operation as a sawmill for years ahead. As president, I am extremely grateful and proud that Lynx will keep the Buse name which has been a symbol along I-5 since the freeway was constructed in 1965.”

Lynx continues to pursue acquisition opportunities throughout North America, Europe and the United Kingdom.

WEST FRASER WILL BUY SPRAY LAKE

West Fraser Timber Co. Ltd. has entered into an agreement to acquire Spray Lake Sawmills in Cochrane, Alberta. The transaction is anticipat-

ed to close later this year.

Spray Lake Sawmills produces treated wood products, dimensional lumber and a variety of wood residuals and byproducts. It has an annual lumber capacity of 155MMBF and holds two Forest Management Agreements granted by the Government of Alberta with a total Annual Allowable Cut of approximately 500,000 m3.

“We are excited to welcome Spray Lake Sawmills to the West Fraser family,” says Ray Ferris, President & CEO of West Fraser. “Spray Lake Sawmills has an experienced, dedicated group of employees. With its solid safety performance, and focus on sustainability and community, the mill is an ideal fit for West Fraser.”

The CDN$140 million acquisition enables West Fraser to grow its footprint in south-

ern Alberta and expand its Canadian treated wood business, while providing access to a high-quality timber supply.

GP PLANS CLOSURE OF FOLEY FACILITY

Georgia-Pacific reported that it informed employees at its Foley Cellulose mill in Perry, Fla. in mid-September that it plans to permanently close the facility.

“Various factors influenced this difficult decision. Ultimately, GP does not believe that the mill can competitively serve its customers in the long term despite the significant investments and commitment by GP Cellulose since the site was acquired in 2013,” GP states. “This is a strategic decision that was made prior to Hurricane Idalia and is not a reflection

of the hard work and effort of the Foley team.”

All of the approximately 525 jobs at the mill will be impacted by the closure. Production was expected to continue for a limited time as the site worked to fulfill as many customer commitments as possible. The closure will have a ripple effect on the wood supply chain in the region.

“Georgia-Pacific’s focus in the coming weeks and months is to continue to safely operate while supporting our employees during the transition,” the company states. “Georgia-Pacific thanks its employees at Foley for their hard work and commitment and will work with them to provide access to local support agencies and job placement resources, including available opportunities within Georgia-Pacific or other Koch companies.”

GP will reportedly offer

NEWS

12 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FEED

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NEWSFEED

severance packages for eligible salaried employees. As for hourly employees, GP is bargaining with the United Steel Workers to discuss benefits, including severance.

“Georgia-Pacific’s decision to close Foley Cellulose will be felt throughout the supply chain,” comments Mike Beardsley, executive director of the Southeastern Wood Producers Assn. “2023 has been tough—this is the third permanent closure in the region this year. Certainly, our loggers and log truck drivers will be on the front lines of coping with the closure, not just financially but also logistically figuring where to move the wood profitably. The roughly 525 mill jobs from this closure are just the tip of the iceberg. The closure impacts jobs throughout the supply chain including loggers and log truckers, equip-

ment and parts suppliers, forest landowners, and throughout the local economy at gas stations, restaurants, and convenience stores. The ripple effect of this closure goes beyond our industry to the economies of Perry and surrounding communities.”

Florida Commissioner of Agriculture Wilton Simpson states, “I spoke with top executives at Georgia-Pacific to discuss the devastating decision to close the Foley Cellulose Facility in Taylor County. While there is never a good time to lose a major employer, particularly in a rural county, this news could not come at a worse time for families devastated by Hurricane Idalia.

“The decision is final and cannot be reversed. According to their leadership, the macroeconomic conditions resulted in another business casualty.”

Simpson says that GeorgiaPacific “are willing sellers. I would welcome another investor or company to come in and take over operations. There are many economic incentives available, and Florida has an excellent climate for business. I challenge anyone to find harder working people than those in Taylor and surrounding counties.”

Simpson asked GeorgiaPacific to do all it can to assist with finding jobs for the hundreds that are displaced. “This will not only impact the direct employees, but the many industries that are a part of the complex network supporting the operation such as loggers, truckers and other essential workers.”

Congressman Neal Dunn (Florida-02) offered a list of “demands” to GP, which he said were based on community feedback:

—Extend health benefits, pay, and severance for at least six months.

—Organize food banks for at least six months.

—Provide paid leave for employees to access job fairs.

—Provide and pay for access to job training resources.

—Donate the building to the county after the closure.

Prior to the announcement, GP referred to the Perry operation as one of four worldclass wood pulp mills in the Georgia-Pacific Cellulose business. Foley Cellulose has produced specialty and fluff pulp, primarily from slash pine, that is delivered worldwide to customers for a variety of high-end uses and converting technologies and in products such as clothing, tires, shampoo, diapers, filters and towels.

Constructed by Procter & Gamble in 1954, the facility

14 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NEWSFEED

was acquired by a private business partnership in 1993 when P&G sold its Cellulose and Specialties Div. The partnership evolved into a publicly traded company, Buckeye Technologies, Inc., in November 1995, before being acquired by Georgia-Pacific in summer 2013.

In 2018 the mill completed an $84 million investment to make the mill more energy efficient and to reduce groundwater usage through the installation of new Black Liquor Evaporators (BLE). BLEs evaporate water vapor from byproducts of the pulping process, resulting in improvement in steam economy and reduction in mill emissions.

In 2017, members from the United Steel Workers union voted to accept a new contract from Foley Cellulose, following a year-long bargaining between the union and GP.

WEYCO GOES AFTER CARBON CREDITS

Weyerhaeuser Co. announced it has received approval from the American Carbon Registry for its Improved Forest Management (IFM) carbon credit project in Maine. Covering approximately 50,000 acres and verified through a thirdparty auditor, the Kibby Skinner IFM Project is the first issuance of credits for Weyerhaeuser through the voluntary carbon market. The project has an estimated initial credit issuance of nearly 32,000 mtCO2e, with one credit equal to one metric ton of carbon dioxide equivalent. Over the lifetime of the project, it is expected to generate 475,000 credits.

“Forests represent one of the largest and most readily available opportunities to remove

carbon dioxide from the atmosphere and help address the impacts of climate change,” says Russell Hagen, senior vice president and chief development officer for Weyerhaeuser. “Since launching our Natural Climate Solutions business, we have been working to develop forest carbon projects that can generate meaningful carbon additionality with measurable climate benefits. This initial project is an important milestone for Weyerhaeuser and demonstrates our commitment to offering only the highestquality credits to the market.”

Weyerhaeuser is currently in the early stages of developing several IFM projects on select areas within its 11 million acre land base in the U.S., including two in the South slated for completion in late 2023 or early 2024. As it develops these projects, the company is working with experts at Carbon Di-

rect to ensure that all credits offered will generate real, additional carbon absorbed and stored in project areas. Carbon Direct will provide advisory and marketing services and evaluate Weyerhaeuser projects against the Criteria for High-Quality Carbon Dioxide Removal, which provides science-based benchmarks to drive effective, equitable climate action at scale.

“As the demand for carbon removal projects increases, it is important to recognize that these projects will only be effective if they represent real and additional carbon removal,” adds Jonathan Goldberg, CEO of Carbon Direct. “Our team, including leading experts on Improved Forest Management and other naturebased removals, worked closely with Weyerhaeuser to ensure the credits meet the most stringent quality standards.”

16 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FO CUS A NEW

By Jessica Johnson

Group brings the sawmill at Goodman Veneer & Lumber into the 21st century.

Besse Forest Products

Besse Forest Products

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GOODMAN, Wis.

In the years immediately after Besse Forest Products Group’s purchase of the old Goodman Veneer & Lumber operation in 2000, the company upgraded its kilns to better dry the hardwoods common to the region, added a lumber handling system, did some sawmill modifications and certified under FSC, but owner Greg Besse knew it had a long way to go to take the sawmill and truly bring it up to date, while also expanding the company’s product offering.

Based in Gladstone, Michigan, where John Besse founded Northern Michigan Veneers in 1966, Besse Forest Products Group is one of the largest privately owned producers of hardwood lumber, veneer and specialty plywood in North

Northern hardwoods dominate the Goodman landscape.

Northern hardwoods dominate the Goodman landscape.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Left to right, Greg Besse, Cain Besse, and Tyson Stuck, GM of GVL

dysmith and Mattoon, Wis. in addition to the Goodman sawmill, as well as four veneer mills, plywood mills, export log yards and concentration yards.

The Goodman sawmill was the fourth sawmill to be added to the roster but the first with kiln drying capabilities, enabling Besse to truck in green lumber from its affiliated facilities. That the purchase also included a veneer mill was typical for the Besse way of doing business, operating complementary veneer and sawmills at the

“You either improve or you continue to make Model-T Fords, and soon you will be out of business. So, we’re always looking to continue to improve,”

Greg Besse says.

Today the site operates 12 package kilns, including two new American Wood Dryers units, two rebuilt Hildebrand units and eight SII kilns. This lets the site scale up its production to an efficient level, with an estimated 15MMBF annual drying capacity.

The existing sawmill building was 110

sawmill town in 1908, and the Goodmans were known for their logging and lumber operations well before then, including as pioneers in selective cutting and sustainable yield management). Besse decided to relocate the sawmill equipment into a new building, with a capital investment of $5.5 million. Some of the equipment was sent to its original manufacturers for rebuilding and parts replacement, so in addition to moving into the new building, the equipment was now in almost-new condition.

From start to finish Besse estimates the move and rebuild took about eight months, and about three months to work out the bugs. “It took a good portion of a year from start to end, to be back up to full capacity. And it’s been going pretty well ever since,” Greg says.

Besse counts the kiln project separately, and admits that he doesn’t view it as completely finished. “It would be another logical project to add capacity at the kilns to drive more production and recovery.

GOOD GEAR

Besse says he stayed with manufacturers he previously worked with on the rebuild because he’s never been disappointed by their machine quality or service after the sale. Major supplier Cleereman is just 20 miles from Goodman. McDonough is also a Wisconsin-based company.

He says when comparing the cost of new versus rebuild, both McDonough and Cleereman were honest and specific with him about what could be done—that further earned them Besse’s respect. Besse is looking at replacing the Cleereman carriage and scanning system with a brand

Big band saws are prepped to take on a mix of hardwood species.

20 ■ OCTOBER 2023 ■ TIMBER PROCESSING CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Goodman sawmill brought lumber drying into the Besse Group.

new system also from Cleereman.

Aside from the new kilns, Besse also made the choice to buy a new Precision chipper for the sawmill, a second planer line, McDonough band saw, linebar resaw, and circle saw.

MILL FLOW

Goodman processes a mixture of gatewood and stumpage purchased by Besse. Loads are unloaded either by the truck driver or a member of the yard staff using a Ponsse machine or Timber Pro. Gatewood is unloaded and laid out for scaling by log buyers before being decked into inventory. From the deck, the sawmill production is planned based on market conditions and available logs.

Logs are debarked by a Nicholson ring debarker, then pass a doublehead saw log kicker from Cleereman. The decision on which side to put logs depends on size but also line speed. The right side is a bandmill headrig; the left is a circle saw.

The headrig cuts logs down to 16x16 or less. After the carriage, wood moves to a roundabout with a preturner and goes to the McDonough linebar resaw. Then the decision is made if the cant will stay a cant (and taken to 3x6 size) or be

cut for railroad ties. Goodman intentionally leaves these pieces oversized so they can drop down and go to a two-head Brewer resaw, which functions like a gang saw. The Brewer takes the oversized cants and either cuts double cants or a cant and a board.

From the Brewer, an edger takes off any wane before pieces flow to the trim saw where any flaws (affectionately called beaver tails around Goodman staff) are cut off. Lumber then moves to the grading line for inspection by two graders and four pilers prepare graded lumber for the air drying yard. When ties are cut at the resaw, they come down to a tie bridge, before dropping to the tie deck for piling.

Lumber is tallied and bundles are sorted in the air yard by grade, with lower grades in one section, cants in another, and grade lum-

TIMBER PROCESSING ■ OCTOBER 2023 ■ 21 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Goodman sawmill is one of four in the Group.

ber in preparation for the kilns in another. Lumber designated for the kilns is stacked, end sealed and put on sticks. Once there is enough of a given sort for a kiln charge, bundles are pulled out of the yard and put into one of the kilns.

The mill dries its whiter woods, mainly the maples and birch species, in the American Wood Dryer units or SII kilns as Besse feels they give a very nice, bright and crisp white color. Besse’s son, Cain, Vice President of Lumber Operations, says that another benefit to the AWD and SII kilns is their controls. Cain explains,

“We can adjust them to do what we need them to do. They have better venting capacity, and better fans, than others we looked at.”

After drying, lumber is pulled into the cool down shed ahead of the Newman 24 in. planer. A three strand deck functions as the planer infeed, flowing into the tilt hoist, dropping into the Newman, surfaced and then to the four-strand, double sided, piling deck where Goodman does as many as nine sorts. Finished lumber is hand banded and then put into dry storage in preparation for shipping.

The mill does have a second, 18 in. planer line, with the same nine sort capacity as the 24 in.

Goodman ships lumber predominately by truck, though there is a rail spur on site. Goodman is mainly cutting hard maple, red maple and red oak, with a good mix of the rest of the Northern hardwood species (ash, birch, aspen, basswood).

POINTS OF PRIDE

The company is incredibly proud of the attention and investment to the Goodman mill site—and how it complements the entire Besse FP portfolio. The addition of the new concentration yard, with the expanded kiln capacity is something Besse himself admits is one of his favorite aspects of the facility. “Unlike some of our competitors buying from many different vendors, we control 100% of the quality of the wood from logs to lumber. It has really been a selling point for us.”

Taking a site that is more than 100 years old and modernizing it is no small feat either. Besse says, “If you don’t upgrade, if you don’t invest, you’re going to eventually be out of business. We’ve transformed this site into an up-to-date hardwood manufacturing site. If you want to be here tomorrow, you have to improve.”

The original veneer mill here has also undergone improvements toward plywood manufacturing, including the recent installation of a 15-opening plywood press and Timesaver sander. T

P 22 ■ OCTOBER 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Besse has also expanded plywood operations at Goodman Veneer & Lumber.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GLOBALMACHINERY

EDITOR’S NOTE: The following companies submitted these editorial profiles and images to complement their advertisements placed elsewhere in this issue. Please refer to those advertisements for web site and contact information. All statements and claims are attributable to the companies.

BID GROUP

BID Group is a key player in the wood processing industry, not only leading the North American market but also leaving its mark on the international stage. Our commitment to innovation, excellence, and cutting-edge technology has allowed us to undertake and successfully complete various projects across the globe, solidifying our position as a global leader.

One of BID’s standout achievements includes collaborating with Berneck in Brazil, where we’ve played a pivotal role in the establishment of three state-of-the-art sawmills. These projects exemplify BID’s dedication to providing top-notch equipment and support from start to finish.

BID Group embarked on the journey with Berneck in 2007, supplying innovative equipment for their log infeed system and sawline. The installation was a success, reflecting our unwavering commitment to delivering top-tier solutions.

Building on this success, in 2013, we took on the challenge of providing Berneck with sawmill equipment for their new sawmill in Curitibanos. BID provided a comprehensive range of equipment to optimize their sawing processes. Our partnership continued to thrive, and our contributions were met with appreciation and recognition.

Fast forward to 2022, BID Group completed the delivery of equipment for a complete state-of-the-art sawmill. This marked the culmination of our journey with Berneck, as we transformed their vision into a reality.

But our reach extends far beyond the shores of Brazil. We have ventured into various international markets, including Chile, New Zealand, Australia and Europe. These diverse projects reflect our adaptability, technical prowess, and the experience required to succeed in different geographical and operational contexts.

Our international endeavors have provided us with invaluable insights and experience, equipping us with the knowledge and expertise to tackle even the most complex wood processing projects worldwide.

At BID Group, we are not just leaders in North America, we are global leaders in the wood processing industry. Our journey is characterized by a commitment to excellence, a dedication to innovation, and a relentless pursuit of delivering the best solutions to our partners.

BRUNNER HILDEBRAND

Brunner Hildebrand Lumber Dry Kiln Co. (BHL) is a leading kiln manufacturer based in Nashville, Tenn. and has served the North American lumber industry for many decades. BHL is part of the German Brunner Group and in cooperation with its global partner companies manufactures high quality dry kilns.

Dry kilns from Brunner Hildebrand are known around the world for their reliability, efficiency and innovation. For decades BHL has introduced innovations including global advancements in kiln drying technologies to the North American market. The combined up to date global experience and innovations package mixed with German ingenuity makes BHL a leading supplier for the North American market.

After a long and positive cooperation and exciting projects, Brunner Hildebrand recently put eight large HTR 100 kilns into operation for Lewis Lumber at their new location in Clarion, Pa. Maple, red oak and white oak are now dried there to high quality standards. After the drying procedure, Lewis Lumber further processes lumber on site into hardwood floors, furniture strips and door frames for kitchen cabinets.

Four latest generation continuous kilns for spruce and pine drying were delivered to Latvia, which have unique Brunner Hildebrand features such as the GreenKilns system and Hildebrand Turbo technology. In contrast to the older development stages of the continuous kilns, the lumber packages in the HCK series are transported lengthways through different drying zones. This enables separate and independent drying zones that can be individually designed and equipped. Powerful booster coils in combination with Hildebrand Turbo Technology ensure fast drying times with very good final moisture distribution and deliver high quality lumber.

With the ground breaking GreenKilns technology, the individual drying zones of the HCK work together in a thermal compound system. Excess heat from one drying zone is removed and directed to another drying zone that actually requires additional heat. In addi-

24 ■ OCTOBER 2023 ■ TIMBER PROCESSING

BID assisted Brazil’s Berneck with three sawmills.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Brunner Hildebrand offers dry kiln solutions across North America and worldwide.

GLOBALMACHINERY

tion, the system will integrate and optimally utilize heat recovery with intelligent software. In this way, up to 30% of heat consumption can be saved and reused for drying wood in an environmentally friendly way.

The kilns are equipped with Brunner Hildebrand’s control system B-Vector which includes Brunner Hildebrand Weight Precision Technology (HWPT)—a lumber moisture measurement system capable of weighing whole lumber stacks wirelessly. Multi-track HCK kilns are suitable for simultaneous drying of different lumber thicknesses.

CARBOTECH

More than a couple of decades ago, Carbotech and Autolog started to do business abroad. While Autolog was focusing on developing the Scandinavian market by selling many trimmer optimizers to Swedish customers, Carbotech was starting its international journey in South America (Chile), doing majors projects with the big players on this market.

With is long history and expertise in lumber handling of 35 years, Carbotech was requested by the customers in that part of the world to help them with their challenges. At that time, South American mills had trimmer and sorter lines running at 120 boards/minute maximum and they wanted to go faster and they knew that Carbotech had the expertise to go fast.

Then, during the downturn of the industry around the end of 2000 in North America, Carbotech started to explore other markets. Sweden was one of them and the local agent, CGV out of Sweden, helped to sell many projects in their country. Since that time, they have done many projects with most of the big sawmill corporations of Sweden and more recently with some in Finland. Both companies worked many times on the same projects with Carbotech supplying the processing equipment and Autolog providing the PLC/controls of the process and the optimization.

With some footprint in South America, Carbotech started to do business in Brazil as well with their local agent in that country, Mendes Máquinas. While Carbotech was busy with South America, Autolog started to spread their tentacles in other parts of Europe, doing some projects in Ireland with Carbotech, some in France and others in New Zealand. Carbotech also did projects more recently in Spain and many in Australia.

The Carbotech and Autolog teams have always enjoyed providing custom made solutions and when you do projects in such different markets, it requires an ease for adapting your solutions to the needs of your foreign customers and it also brings new ideas that both companies can use for the North American market; it gives them an edge among their competitors to offer more innovative and different solutions.

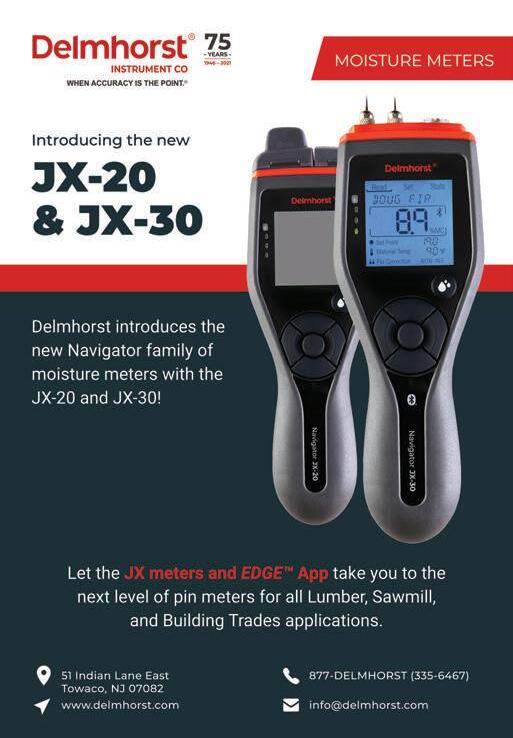

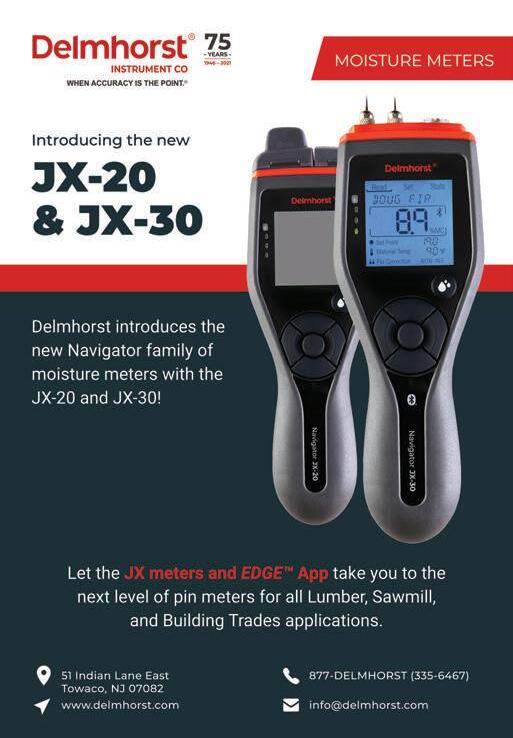

DELMHORST

Delmhorst introduces the Navigator family of moisture meters with release of models JX-20 and JX-30—bringing lumber/woodworking, flooring professionals and inspectors two professional-grade tools to use with complete confidence.

Both meters are packaged in a robust and ergonomically designed ABS case (patent pending) to provide a premium, tactile feel, and intuitive user interface with dashboard-like display. Together with the new Delmhorst EDGE app (JX-30), users can customize meter settings and share MC data quickly and accurately.

The meters carry a two-year limited warranty.

The most valuable tool to use with the new JX meters, or any Delmhorst meter, is the 26-ES hammer electrode. The contact pins that come with the 26-ES penetrate 1 1⁄8 in., have insulated shanks and only the tips are exposed. The pins’ uncoated tips make contact with wood fibers and provide much more accurate readings of moisture content at various levels of penetration. This feature is useful for a variety of different applications:

—Dry kiln operators: Identify shell vs core moisture levels. The moisture gradient is a critical piece of information for a defect-free, high quality lumber product.

—Furniture manufacturers and craftsmen: Easily check the MC of high density hardwood that short pins are unable to penetrate.

—Flooring installers and inspectors: Penetrate through flooring to plywood sub-floor. Moisture meters are easier than ever to use and now with exciting Bluetooth connectivity, moisture meters offer great flexibility and customization. They are fast and accurate, and the information they provide are critical to making good decisions, whether drying lumber, building quality furniture or installing a hardwood floor. You can make best use of your meter by learning its capabilities, following the manufacturers’ procedures and recommendations, and of course supported by your own knowledge and experience.

Delmhorst Instrument has been in the field for more than 75 years. Our products are produced in our New Jersey facility and known worldwide for accuracy, rugged construction and our legendary support.

TIMBER PROCESSING ■ OCTOBER 2023 ■ 25

Carbotech dual fork stacker being assembled in Australia.

Delmhorst JX-20 and JX30 Navigator moisture meters

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GILBERT

Over the past three decades, Gilbert has striven to be a first-class world leader in the planer mill Industry. Since the first installations outside Quebec in 2002, Gilbert has succeeded in installing more than 200 planer projects worldwide.

North America has been Gilbert’s biggest market since 1995. From Western Canada to the Maritimes, and Western USA to the Southeastern USA, Gilbert has installed more than 150 planers in the continent, making us the market leader.

In 2006, Gilbert’s team focused its efforts on developing the European market. In 2007, Gilbert installed four new planers in Europe—two in Sweden and two in Germany.

In 2019, Gilbert’s team installed a Gilbert high-speed planer at Mercer Timber in Deutschland. This planer model is designed to run up to 1200 m per minute, 4000 FPM, and is the fastest planer in the world.

Today, Gilbert has 10 high speed planers running in five European countries

Since 2014, Gilbert has been involved in six important projects in the beautiful countries of Australia and New Zealand.

In 2015, Gilbert had the opportunity to participate in a turnkey solution for a first big planer project at Millpar in Brazil. This project was such a success that a second planer was soon sold to a neighboring sawmill, Lavrama. This year we have recently installed a third and a fourth planer will be installed in Brazil and Argentina.

At Gilbert, understanding our customers’ needs, and adapting our planer accordingly, has always been a priority. From smaller operations to a high speed planer mills, Gilbert presents five different models of planers:

—Gilbert S Series planer for smaller operations and slower speeds from 100 FPM up to 1800 FPM

—Gilbert 6 Roll planer for mid-size operations up to 2800 FPM

—Gilbert high speed planer, the fastest and biggest model up to 4000 FPM

—Gilbert moulder for special patterns and profiles

—Gilbert mass timber planer for big glulam and CLT operations.

With a team of 140 dedicated professionals, Gilbert is committed to delivering quality planers worldwide. We invite you to explore our line of planers and learn more about us.

JOESCAN

JoeScan 3D laser scanners are made for sawmills. We have more than 5,000 scanners installed in sawmills all over the world, and our very first scanners are still running strong, more than 20 years later. Since 2002 we’ve developed strong partnerships with optimization integrators across the globe, and our scanners can be found in sawmills on six continents. When someone builds a sawmill in Antarctica, we’ll be there too!

JoeScans are simple and reliable. They are built to withstand the harsh conditions of a sawmill environment, including high levels of moisture, dust and vibration. This means our scanners can continue to provide accurate measurements and reliable data even in the toughest conditions. We include a five-year warranty and 10-year support period with every scanner. If you need help, we have the people that designed and built your scan heads answering the phone to get you back up and cutting wood as fast as possible.

Our latest JS-50 models deliver fast and accurate scans throughout the modern optimized sawmill. We design each model to deliver the best results for specific machine centers. From your bucking line, to your carriage, to your gang, end-dogger, edger, and trimmer, JoeScan can help you to improve the recovery, grade and value of every cut you make. Contact us to see a list of our global partners and learn more about sawmill scanning.

26 ■ OCTOBER 2023 ■ TIMBER PROCESSING

GLOBALMACHINERY

Gilbert planer installation in Denmark

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Action at JoeScan exhibit during Ligna 2023 in Hannover, Germany

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GLOBALMACHINERY

LEDINEK

The construction industry is currently undergoing a subtle yet profound transformation that is altering the way we construct buildings while reshaping our approach to sustainability. Leading this movement is Cross-Laminated Timber (CLT), an innovative and environmentally friendly building material that is gaining global momentum. LATAM in Uruguay is now taking center stage as the site for a high-technology mass timber operation, courtesy of the visionary initiative of the Uruguayan sawmill, Arboreal from Tacuarembó.

Arboreal has enhanced its sawmill facilities, which produce 240,000 m3 of kiln-dried timber from FSC-certified pine plantations, through investments in Ledinek’s CLT, GLT, and structural fingerjointed solid timber technology. This investment is also redefining Uruguay’s timber production landscape, positioning the country on the worldwide mass timber market map. They are establishing the largest and most advanced CLT plant in LATAM, boasting an initial production capacity of 50,000 m3 per year.

This step is a significant milestone in the development of sustainable construction practices within the LATAM region. Engineered wood products such as CLT, GLT, and structural fingerjointed solid timber are groundbreaking material composed of strength-graded timber, glued with structural glue according to precise manufacturing procedures. These unique products have highly predictable structural performance, while enabling swift and efficient construction. The utilization of mass timber contributes to the reduction of the carbon footprint associated with construction projects, as wood absorbs CO2 during its growth, aiding in the reduction of greenhouse gas emissions. Furthermore, this project is set to generate numerous employment opportunities and stimulate the local economy.

Investments in Ledinek CLT, GLT, and structural fingerjointed solid timber technology empower the Arboreal sawmill to optimize processes and enhance efficiency. The new plant is equipped with cutting-edge equipment and technology, enabling fingerjointing, precise cutting, planing, gluing, and pressing of wooden panels, ensuring the production of high-quality end products.

In summary, the Ledinek/Arboreal project in Uruguay represents a significant leap forward for sustainable construction practices in LATAM. With the establishment of the largest and most advanced mass timber plant in the region, Uruguay is setting an example for the world. This initiative could serve as an inspiration and growth opportunity for North American sawmills, encouraging them to embrace mass timber technology and play a vital role in the global effort to reduce the environmental impact of construction projects. It’s a promising step toward a greener and more sustainable future for the construction industry, not only in LATAM but potentially across North America as well.

LIMAB

LIMAB was founded 45 years ago and has a long tradition of developing and manufacturing laser-based technology. We supply 2D ProfiCura and 1D PreciCura laser sensors and complete systems for dimensional and profile measurement in sawmills, panel production and steel mills. Headquarters and manufacturing plant is located in Gothenburg, Sweden. LIMAB has regional offices in the USA, UK, and Germany as well as approved distributors and partners in other regions.

BoardProfiler is the system for the wood industry that was developed more than 30 years ago, and it has to date been sold to more than 250 customers. We call our latest version of the system BoardProfiler 3D, which today is available in four versions. The great thing about our system is that the software is almost identical for all versions, which has proved interesting for several customers as they have invested in both an edger and a trimmer in their lines. All versions are also available for transverse and longitudinal processes—block control (optimization for chipper or ripsaw); edger; trimmer; classifier (sorter, dimensional control).

LIMAB BoardProfiler is easy to install, takes up little space in the process, is easy to integrate with sawmill automation systems and has a simple and easy-to-understand software. The sensors we use are our our own 2D sensor, ProfiCura 170, 600, 700 or 800. Each sensor has a high resolution of 640 measuring points across the line. The number in the series indicates the length we have on the laser line that measures the block or board. In that way, we can optimize the measurement and use the sensor that provides the best measurement performance and consequently the highest yield.

LIMAB also produce a length gauge, the LMS 6048, to measure length of boards in transversal process.

28 ■ OCTOBER 2023 ■ TIMBER PROCESSING

Arboreal sawmill and CLT production plant at Tacuarembó, Uruguay

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Limab ProfiCura laser sensors for edger, trimmer and other sawmill applications

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GLOBALMACHINERY

LINCK

Linck, the largest European sawmill machinery company, is also the world’s leader in profiling, having invented and patented the profiling system more than 40 years ago. With 200 years of sawmill machinery experience, Linck develops customized lumber production systems to achieve overall solutions for large production volume mills as well as for small specialty mills. Every biennial world benchmarking study since 2000 has proven that Linck equipped mills have the lowest cost of lumber manufacturing. A majority of the largest lumber producers in Europe have partnered with Linck as their preferred machinery supplier.

Linck equipment is known for highest quality of engineering design and machine manufacturing, and our equipment is valued by customers worldwide for its longevity in continuous operation, having been designed with safety, operations excellence, and ease of maintenance as top priorities. The flexibility of product options and sawing patterns with Linck equipment is unparalleled in the lumber production equipment industry. Linck customers expect high productivity and uptime, excellent product yield, and very accurate sawing quality, and Linck has the long-standing reputation of meeting our customers’ production goals and schedules, as well as their capital project schedules and startup performance.

Regardless of whether you are looking for curved-sawing chipping-canter profiling lines for high production of dimension lumber or reducer technology for producing special lumber products for CLT or other uses, or even long timbers, Linck’s innovative solutions are the answer to your production needs.

Core values of the privately-owned Linck Holzverarbeitungstechnik are reflected in the commitment to excellent solutions for the customer by providing long-lasting, highest quality machinery with high automation resulting in lowest possible manning and high returns on investment for the customer. Despite our leading global market position, a major aspect of our success is never compromised: Linck quality made in Germany.

MEBOR

Mebor has been designing, developing and producing sawmilling machinery since 1982 and has become one of the biggest European sawmilling machinery manufacturers. Today Mebor machines are running in more than 70 countries worldwide. The machines are recognized by their automation, speed and reliability.

Every year, Mebor is constantly investing its earnings in research and development, as well as in increasing its manufacturing capacity—allowing Mebor to be recognized worldwide among companies with the most intense innovation and presentation of new products in the field of sawmilling.

The company supplies complete solutions for sawmills, therefore all machines needed for the sawing of logs, slabs, cants and boards of all shapes and sizes—producing horizontal and vertical band saws, combined board edgers, multi-rip (gang) saws, continuous circular saws (scrags), debarking machines and chipper canter lines. All machinery can be combined together with conveyors to provide complete custom designed sawing lines.

Mebor is the worldwide leader in wide blade horizontal band saws, both in terms of advanced technology and number of units produced per year. Mebor strong and robust band saws are known by their long-life span, lower maintenance costs and precise sawing

High quality of sawing with wide blades is shown through increased yield, precision and high quality of sawn wood. Speed and automation make for more production, time saving and lower operation cost.

Mebor’s vertical band saws VTZ PLUS with superfast log carriage are designed for high capacity as well as quality-oriented sawing. The carriage drive is SERVO electric and allows return speeds up to 800 FPM. SMART weight optimize structure with regeneration of energy on the return of the carriage make the VTZ PLUS one of the most energy efficient carriage sawmills.

Mebor also provides solutions with circular saw technology–board edgers, multi-rip saws, chipper canters and continuous circular saws (scrags) for continuous sawing of logs. Mebor’s circular saw machinery is precision made with CNC processed frames. The heavy-duty build ensures vibration free and precise sawing.

Besides band saw and circular saw technology, Mebor offers its debarking machine (rosserhead style) as a heavy-duty, high-capacity machine that features remote control and automatic operation, so constant presence of the operator is not required. As for all machines, Mebor uses exclusively high quality components, providing reliability for the long term.

30 ■ OCTOBER 2023 ■ TIMBER PROCESSING

Linck’s profiler expertise includes the VPM350 profiler.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Mebor is a leader in band saw technology.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

MICROTEC

For more than four decades, MiCROTEC has served the wood products industry, delivering scanning solutions to both hardwood and softwood sectors. From log yards to secondary processing, MiCROTEC remains the sole provider of comprehensive scanning and optimization solutions for the wood product industry, ensuring economical and sustainable wood utilization.

A standout in MiCROTEC’s portfolio, the patented stereoscopic imaging system, Logeye Stereo, offers a complete 360° scan of logs as they enter various processing stages. This technology operates internationally and has recently been installed at Cascade Hardwood’s Chehalis, Wash. mill. Logeye Stereo ensures logs are fully optimized for sawing, considering factors like diameter, length, curvature, taper, and internal quality features.

Logeye Stereo leads to higher throughput speed and improved recovery, capturing the entire log surface without shadows or obstructions. It can detect log rotation at any point in the process, allowing for rotation optimization and turn correction. Moreover, Logeye Stereo empowers operators to adjust cut solutions board by board during the cutting process.

On the 2023 Ligna stage in Hannover, Germany, Mikael Lagerbom, a Sawmill Business Analyst at MiCROTEC, emphasized the company’s ability to pinpoint where value is lost in the sawmilling process. He stated, “A negative insight from the sawmilling industry is that we ‘ruin’ value. But if we know the maximum value in log sorting and trace the value throughout the chain, we can put a number on where we are losing the most money. Is it the debarking, position of log in the sawline, or somewhere else? With MiCROTEC scanners, we have the figures, which makes it easy to decide where to invest, where to put in the maintenance work, etc.”

MiCROTEC’s dedication to the wood industry’s value chain efficiency is apparent through its innovative scanning solutions, such as Logeye Stereo. These advancements drive enhanced productivity, reduced waste, and increased profitability for sawmills worldwide.

MINDA

As a specialist in engineered wood production lines, MINDA has been developing its CLT and Glulam lines for more than 40 years. The last development was the upgrade of the fully automatic curve glulam press. The first one has been running for more than 13 years in Germany. As a result of the experience gained during installation, commissioning and production combined with new needs and requests from other customers, Minda developed the new TimberPress C600 for curved glulam beams.

The advantage of the C600 compared to the semi-automatic C500 beam press is the automatic closing. Manual handling of the heavy pulling rods and pressure plates is no longer needed. The loading can be done with an overhead crane or an integrated automatic system. After this, the press closes on its own and moves itself to the needed curvature. An operator is only needed for observing the process.

A tight segmented top pressure system of approximately 6 ft. ensures the lamellas are aligned well, and less material has to be taken off later at the beam planer. The pressure is applied with a hydraulic system up to 145 psi and monitored during the complete press cycle. To apply the pressing force vertically on the press package, each press segment is adjusted according to the production data.

The beam’s length can be chosen individually. Moreover, it is possible to press two equal beams up to a width of 9 in. at the same time or several short beams behind each other.

Another step is the development of a small-scale CLT plant. The target of this task was not to get bigger and faster. This time Minda wants to offer a small but flexible solution for the entry into the engineered wood market. With some more manual work steps, the production line could be more simplified.

Since the quality of the final product should not be limited, the heartpiece of the line is still the well proven TimberPress X300. To increase the capacity of the line, more automation can be integrated later on. It is also possible to add a TimberPress T200 to the line, when starting with straight glulam.

GLOBALMACHINERY 32 ■ OCTOBER 2023 ■ TIMBER PROCESSING

MiCROTEC Logeye Stereo: Unlocking value in wood processing

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Minda emphasizes pressing technology for the production of CLT and Glulam.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GLOBALMACHINERY

PRINZ

Backed by 75 years of experience. PRINZ is now the leading supplier of crosscut saw systems. It offers efficient solutions for cutting lumber packages, gypsum board, LVL, CLT, paper rolls and plastic products.

PRINZ also produces the saw chains and guide bars itself. This capability makes it unique and the ideal onestop supplier for all businesses keen on cutting with precision and neatness.

The PC120 crosscut package saw stands out for its combination of efficiency and precision. High productivity is only possible with a high degree of automation. The PC120 from PRINZ was therefore designed so that loading, palletizing, strapping and cutting are all executed in a single line and fully automatically. According to the requirements, the packages are moved through roller conveyors, carriage or chain conveyors. Each aspect of the line has been designed for an increased cut capacity; sensors detect package edge and height for an automatic reference cut.

The patented Double Action technology allows the fastest cutting cycles as the cutting process is made alternatively from top to bottom and bottom to the top . Equipped with an app control, the saw can be operated from the forklift, and the remote control guarantees a support at any time.

SIGNODE

Signode is a leading global manufacturer of a broad range of automated packaging equipment, tools, consumables, and automation solutions.

“At Signode, we understand the unique challenges our customers in the forest products industry are facing on a daily basis,” says Jeff Stephens, Construction Segment Manager at Signode. “Our focus is on designing state-of-the-art solutions and support programs that enable our customers to enhance their operations and strengthen their respective positions in the forestry industry.”

Signode boasts a full suite of solutions to help meet the demands of the lumber industry, including its Packaging Plus Reliability Services Team, which boasts more than 500 field service engineers and technicians who help your packaging equipment continue operating at peak performance.

—Signode’s BPX compression strapping system is a userfriendly machine designed to simplify the lumber packaging process and alleviate maintenance burdens. Its streamlined design helps reduce maintenance time, and its intuitive interface enables high efficiency and reliability, ultimately improving production outcomes. This versatile system accommodates quarter-packs, half-packs, and long loads, providing operational flexibility to meet changing production needs. Additionally, the BPX’s side compression mechanism offers enhanced load squaring and coverage, resulting in unparalleled package performance.

—The Lachenmeier stretch hooder helps improve stability of oversized loads and adds efficiency to your end-of-line lumber packaging operation, with wrapping capabilities of up to 200 loads per hour. The fully automatic operation features a film unwinding technology that enhances corner protection, provides added strength and stability, and reduces packaging costs through less film consumption. The electrically operated stretch frame and film handling system and overall smaller footprint means that the machine can also maximize valuable production floor space and be placed closer to a facility’s perimeter.

—The ORA 1650 turntable strap dispenser is another innovative unitizing solution that offers improved productivity and time savings. It requires fewer stops for strap and coil changeovers and relieves workers from the physical strain of lifting and handling heavy coils. With its small footprint design, this coil dispenser is easily integrated into existing strap accumulator towers and offers simplified strap loading. The ORA 1650 reduces stops for strap and coil changeovers, resulting in longer machine uptime. Additionally, this sustainable solution reduces CO2 emissions and carbon footprint by minimizing load handling, deliveries, and shipments within the plant.

–Signode’s wood product solutions also extend to lumber marking for a variety of applications. With the ability to seamlessly integrate into existing operations, these high-speed printing solutions significantly minimize downtime while maintaining printing accuracy with high resolution and precise placement. Signode’s lumber marking solutions accommodate variable printing requirements, including alphanumerics, logos, and barcodes, empowering businesses to efficiently adapt to changing market demands and production requirements.

34 ■ OCTOBER 2023 ■ TIMBER PROCESSING

PRINZ package saws for industrial use

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Signode BPX user-friendly and versatile strapping system

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

GLOBALMACHINERY

SPRINGER

The ED 3000 Wrapper is Springer’s answer to the great demand for a fully automatic package wrapping machine. This innovative machine design significantly improves the efficiency and automation of lumber package wrapping. Our ED 3000 has a proven track record of success with our customers, establishing itself as a trusted and reliable solution for package auto wrapping.

The ED 3000 makes wrapping a part of the continuous production process. It can wrap a lumber package in less than 60 seconds, positioning it as one of the fastest machines available on the market. This remarkable efficiency translates to increased productivity and improved production.

Automatic centering allows for the wrapping station to adapt to the position of the lumber package as it enters the wrap area. The machine’s built-in sensors and package data alignment guarantee precise wrap placement according to the position of the package.

One of the machine’s unique attributes is its ability to wrap packages tailored to individual sizes. The Wrapper utilizes a package wrap magazine, which holds six rolls of wrap. Gripper arms expertly center the wrap on passing packages while slitter knives cut off any excess wrap. After placing the film over the lumber, the corners are welded or stitched and excess material is removed, all in a single step, leaving no loose wrap edges that require additional fastening. The result is a tightly fitted, waterproof and wind resistant wrap.

To ensure the wrap stays securely on the package, an optional downstream package ribbon staple unit is available. This unit staples a plastic ribbon on the bottom edge of the package, which secures the wrap and prevents the wrap from coming off during transport. The ribbon also helps remove the staples when unwrapping the package.

The Robotic Labeling System is an optional add-on to the wrapping system, which guarantees fully automatic labeling of packages. The robot acquires the package label with the help of vacuum technology and affixes it anywhere on the lumber package with several staples.

The wrapper can come with an automatic wrap reloading option. Once the ED 3000 requires wrap, the reloader will automatically remove the empty wrap roll, grab a new roll, and place it onto the wrap magazine.

The ED 3000 Wrapper is a leap forward in lumber package wrapping technology. Its speed, precision and versatility make it an invaluable asset in the lumber industry, streamlining operations and ensuring consistently high-quality packaging. Manufacturers looking to optimize their production processes need look no further than this innovative solution from Springer.

USNR

When customers buy equipment from USNR they have much more than one product line and process methodology to choose from. Whether it’s North American-style log breakdown or the batch processing of European mills, USNR supplies systems, service, and support for operations around the globe including the United States, Canada, Australia, New Zealand, Sweden, Finland, Norway, Germany, the United Kingdom, Chile, Japan, and many other countries.

Customers can draw from the widest range of design solutions in the world. Whether you produce dimensional lumber, plywood, panels, fingerjointed components, or engineered wood products, USNR has a solution that’s right for you, with 24/7 worldwide support.

We work to combine the latest technology, innovative design, and experience gained through long-standing customer relationships to develop high performance, end-to-end, value-focused solutions. Whether today’s problem is improving yield, expanding production, or entering new markets, we have the tools to help you get the job done.

With USNR’s extensive family of brands, customers can draw from the broadest range of product designs in the global wood processing arena. And with that comes the experience and expertise of our hundreds of talented and dedicated personnel who know their business and understand the needs of wood processors the world over.

Today’s mill managers need suppliers that understand their mills from end to end—the complete process of converting raw material into finished products. That’s why choosing USNR for your next project is your best decision.

From small upgrades to state-of-the-art greenfield mill complexes, USNR delivers complete solutions. We deliver, install, and provide ongoing support for our products 24 hours per day, 365 days each year. Challenging logistics and demanding applications are all in a day’s work at USNR. Our customers have access to the broadest range of locally supported systems that will serve them for decades.

36 ■ OCTOBER 2023 ■ TIMBER PROCESSING

Springer ED 3000 auto wrapper increases lumber packaging production.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

USNR is a global leader in the forest products equipment industry.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

SFPA EXPO REARVIEW MIRROR

Southern Forest Products Assn. hosted its machinery expo in Nashville on August 23-25, and by all accounts there was plenty to sing about. Here are some random photos taken by Timber Processing’s Dan Shell, Jacqlyn Kirkland and Jessica Johnson. The sawmill industry’s next major show will be held September 25-27, 2024 at the Portland Exposition Center in Portland, Ore.

38 ■ OCTOBER 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

TIMBER PROCESSING ■ OCTOBER 2023 ■ 39 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NOT WASTE

MANCOS, Colo.

Operating in remote southwest Colorado, Aspen Wood Products is diversifying its business base while expanding its capacity to handle green material with its new Mesa Verde Pellets operation. The wood pellet mill utilizes residuals from plant operations to produce domestic fuel pellets and is a subsidiary of Aspen Wood Products, which produces ex-

By Dan Shell

Aspen Wood Products continues fiber utilization program with new Mesa Verde Pellets operation.

celsior, a specialty wood fiber. Both businesses operate at the same site in Mancos. An associated business, Aspen Wall Wood, operates an aspen sawmill and paneling plant in nearby Dolores.

Company President David Sitton purchased the excelsior plant in 2018, a year after a catastrophic fire that took it out of operation. Dating to the 1940s and ’50s when it was a

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

match stick company, the mill was converted to excelsior production years ago and for years the mill has provided a key market for short and small diameter timber in the area. When the Indiana-based owners decided not to rebuild the excelsior plant, Aspen Wood Products stepped in, bought the site and rebuilt the specialty fiber operation. The first bale of excelsior from the new facility rolled out in January 2019.

Today, the excelsior plant is a major supplier of the fibrous woody material that goes into the cooler pads for evaporative coolers, and the company has now expanded its services in that market to include cooler pad manufacturing. The facility also produces erosion control products made of excelsior fiber.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Wood Products product line and also fills a key need in utilizing and monetizing the company’s residuals both at the excelsior plant and at the aspen paneling mill. The nature of the forest products in-

cation for residual materials such as chips and sawdust is a key part of building a successful operation. Establishing the pellet mill is one more step toward the company’s goal of creating a zero-

with the more desirable aspen sawtimber. This gives the whole company more flexibility on the ground when procuring raw materials.

In addition to utilizing sawdust and

44 ■ OCTOBER 2023 ■ TIMBER PROCESSING

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Aspen Wood Products operates a major excelsior production facility, rebuilt after a 2018 fire, that’s been a fixture in the local log market for decades and is currently providing most raw materials for the pellet plant.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

able residual material as logs are cut to proper length then fed through specialized shredding machines. Each segment is taken down to roughly a 2 in. core

that’s sold as a firewood product.

“The excelsior residual is significant. We realized we needed to do something, and a pellet mill made sense,” says Plant Manager Corey Stafford.

Construction on the pellet plant began in 2020, with the facility initially

starting with a used pellet machine and then expanding and upgrading capacity with three new Colorado Mill Equipment (CME) pellet machines.

“They’ve been very helpful in the startup,” Stafford says of the in-state machine manufacturer that also supplied material processing and pellet handling equipment.

“We’ve had a learning curve, and now we’re moving on to mill operations and efficiency and how to feed and operate the mill at full capacity,” Stafford adds. One key aspect of the production process and working with aspen in such an arid climate is fine-tuning the injection of needed moisture into the fiber stream

46 ■ OCTOBER 2023 ■ TIMBER PROCESSING

Colorado Mill Equipment provided the pellet mills and much of the new plant’s fiber processing and pellet handling equipment.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Mill personnel are now moving from a startup learning curve into striving for more efficiency and production.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

that is essential to the pelleting process, he says.

Currently operating using only the excelsior residual, the pellet plant operates a Cambio ring debarker on every log. A rotary drum dryer is currently being installed.

PRODUCTION

Excelsior residual raw material is introduced to two hammermills: one is a Williams hog machine that handles rough material and feeds directly to a

new CME hammermill that produces smaller material as it’s sized down.