PMM

ENTER THE CPD ZONE!

YOU COULD EARN ONE CPD CREDIT THIS MONTH

interviews with THE IMI, VLS & MOTOR OMBUDSMAN

100-YEAR-OLD GARAGE

PMM YOUTUBE CHANNEL LAUNCHED

BEN JOINS MECHANEX-PMM LIVE SEMINAR LINE-UP

Let’s get technical

INSTALLATION TIPS ON CLUTCHES & TIMING BELTTENSIONERS

BEST PRACTICE ON OIL CHANGES, SHOCK ABSORBERS & TURBOS

COMMON FAULTS: STOP-START DRIVING INCREASING SLUDGE IN OIL

IN THE WORKSHOP: ALL THINGS TOOLRELATED COVERED

MOT BAY TIPS CONVERT CLASSIC CARS TO EVS

FREE TOTHE TRADE

SEPTEMBER 2023 PROFESSIONAL M

M ECHANIC

OTOR

TROUBLESHOOTING A BMW E61 LOSING POWER

Exclusive

Editor’s Picks

26 COMING IN CLUTCH

In the CPD Zone this month, Shaeffler’s REPXPERT Alistair Mason is replacing the clutch and dual mass flywheel in a 2012 Ford Focus 1.6 Ecoboost.

37

KNOWLEDGE IS POWER

With technology and coding now seeping into every aspect of the workshop, Delphi’s training solutions are aiming to take the pressure off and help train and retain your staff.

38 CLASSICS MADE MODERN

If you’ve ever considered converting a classic car into an EV then make sure to catch the first part of our articles on Fellten, a company that provides kits and assistance to workshops tackling conversion.

60 LIGHTING UP THE MOT

With the MOT season looming, lighting and accessories supplier Ring is advising technicians to consider upselling opportunities to help customers tackle shorter days and darker evenings.

69-73 BATTERIES & IGNITION

Contents VOLUME 24 ISSUE 8 SEPTEMBER 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM SEPTEMBER 2023 5 47-56 ENGINES & TRANSMISSION 59-66 MOT Regulars 8-11 NEWS & VIEWS 15-31 CPD ZONE 32-37 BUSINESS & TRAINING 38-45 SPECIAL REPORTS 76 PIT STOP

IN THE WORKSHOP

78

Editor KIERAN NEE

Editor KIERAN NEE

News and Products Editor

News and Products Editor

FREYA COLEMAN

Digital

Manager

KELLY NEWSTEAD

Group

Manager

ROBERT GILHAM

Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

1 year (11 issues) £50

Air mail 1 year (11 issues) £65

Printed by PCP Telford

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk

Website: www.pmmonline.co.uk

Facebook: /ProfessionalMotorMechanic

Twitter: @pmmmagazine Copyright © 2023

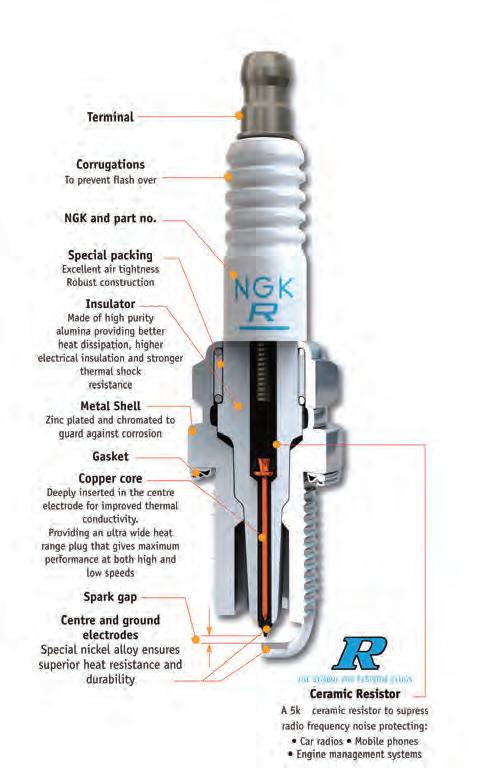

Video killed the magazine star?

The Buggles’ famous earworm would have it that Video killed the Radio Star all the way back in 1979. The logic goes that new, more technologically advanced modes of communication will inevitably see off older forms. Video will kill radio, websites will kill magazines, e-books will kill books, VHS ceded to DVD which ceded to streaming and so on… Soon, we will be downloading binary code directly to our cerebral cortex, bypassing the ineffective and unreliable receivers of the old days, namely our ears and eyes. One can dream, but looking around you would suggest that a post-analogue word remains a dream. OK, so CDs and DVDs are well and truly relics of the past, it’s true. But other pretenders haven’t been as successful at claiming the throne as streaming services. The launch of the Kindle, in fact, had the opposite effect, making readers fall back in love with paper books; LPs are now to be found in Sainsburys across the land (for the low, low price of £20); and indeed radio continues to power on, filling the background gaps in people’s lives, creating a community of listeners with little more than a microphone in a studio. The truth is, we have a great capacity to add new technologies into our lives alongside the old ones. What’s more, whilst we are ruthless in dropping a technology which holds no value in and of itself (CDs will never, ever, make a comeback), we are also resistant to dropping those formats that still hold value despite being told they’re “outdated”.

If you haven’t guessed by now, I am talking about this very publication you are holding in your hand. You may have noticed the papery nature of PMM, or at least PMMClassic. The magazine format continues to be our number one focus, because not only is it the most popular format in our stable, it’s also the most popular publication in the sector. Our ABC-audited circulation of 54,319 copies means that 54,318 other workshop owners and employees are currently reading this magazine (well, maybe not all at the same time). Given that estimates of the numbers of people employed in the aftermarket are around 200,000, I would say that reaching a quarter of the industry directly each month (and that’s to say nothing of shared copies) would suggest that good old, old school, papery magazines are alive and well in the aftermarket.

Now, that’s not to say there isn’t room for innovation and, indeed, that’s what we’ve been doing. Our website has been an extremely popular and useful resource for technicians for years now, as has our e-newsletter which brings articles directly to your inbox. You will have noticed that we launched a podcast, the PMMPodcast, last year, which you can listen to on all the big podcast platforms. The numbers we’ve received have far surpassed our expectations – it really seems the industry was crying out for a dedicated monthly podcast!

But we didn’t stop there. Our (rebooted) YouTube channel has just gone live, bringing you reviews and installation guides from our team of tool reviewers. As that begins to grow, does that mean the magazine will become less relevant? Absolutely not. It means that PMM now is a brand which brings you information, entertainment and opinion in every relevant format. More PMM for all to enjoy!

VIEWPOINT

Kieran Nee Editor

The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available:

M E EACH M ONTH

THE

MM

JOIN

ON

P

PODCAST

PMM NEWS

NEWSIN BRIEF

■ REPXPERT ROAD TRIP

CONTINUES Schaeffler’s digital marketing team have visited workshops across Gloucestershire, Oxfordshire Birmingham and Milton Keynes, discussing its latest developments with members and non-members.

■ EV COMPLAINTS ON THE RISE

The Motor Ombudsman has recorded a rise in EV complaints, the latest increase could be down to the cost-of-living crisis driving more individuals to recoup financial losses.

■ INCREASING INCLUSIVITY

Recent research from Castrol looking at people’s perceptions and experiences of independent workshops, has found there is significant opportunity to make workshops more inclusive.

■ MOTORISTS SKIPPING MOT

18 per cent of UK drivers admitted to having driven without a valid MOT, an increase from 11 per cent in the same study conducted a year ago, according to data from Compare the Market.

■ CAR SALES GROW 177,266 cars were registered during June, marking the 11th consecutive month of growth according to the SMMT. Battery electric vehicle registrations were up 39.4 per cent.

with Freya Coleman

Independent access to vehicle repair information secured by the IGA

The Independent Garage Association has safeguarded the future of the UK independent garage sector by working with the Government, vehicle manufacturers and aftermarket associations – to ensure that garages will have access to security-related repair and maintenance information (SERMI) to the same level as European garages.

IGA will oversee the UK scheme on a not-for-profit basis, ensuring that access is affordable for all garage businesses. The SERMI scheme is embedded in EU law and will launch on a rolling basis, country by country beginning on the 1st of October. The RMI’s ISO company, RMI standards and certification (RMISC) is also planning to launch the scheme in the UK on that date.

The solution is based around mirroring the system being delivered across europe and its claimed all operational delivery will adhere to the same rules.

The association reports that garages are already getting in touch in large numbers to register their interest in the scheme, responding enthusiastically to the announcement.

MOT delayed decision “unacceptable”

The IAAF is calling on the government to make its decision on the MOT test frequency, calling the delay “unacceptable”.

The Department for Transport launched the public consultation on the future of MOTs in February. The consultation looked at the frequency of the test and sought to justify the government’s preference for the first test to be taken at year four.

The IAAF, along with UK AFCAR and multiple trade associations, has opposed such plans to extend the first test frequency. Many in the aftermarket point to the increasing number of new electric vehicles on UK roads

and the fact that these are just as likely to fail the first MOT test. This, it is argued, underlines the importance of safeguarding the current test regime. DVSA data shows that the failure rate on tyres at first MOT of three years is higher on BEVs than on diesel vehicles. Fifty-seven percent of all electric vehicles that fail their first MOT test, fail on tyres, compared with 35 percent of diesel vehicles and 37 per cent of petrol vehicles tested.

Therefore, the IAAF is writing to the Government, calling on them to at least give an indication of their proposals following the MOT consultation.

8 SEPTEMBER 2023 PMM

“The IGA has broken through the barriers to secure access to the SERMI scheme in a postBrexit Britain.”

Stuart James, IGA chief executive

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

Tackling automotive vacancies

With the automotive sector facing a 20year high in vacancies, the Institute of the Motor Industry is embarking on a campaign to debunk the outdated perceptions that are at the heart of the recruitment challenges.

Central to the campaign will be real voices telling real stories about their positive career experiences. The IMI is now on a recruitment drive to find those real voices. There is an urgent need to encourage more people to think about a career in automotive, with the company’s data suggesting 111,400 roles need to be filled in the next decade.

Industry insights

In this episode of the Professional Motor Mechanic Podcast, gain key insights into the current problems facing the industry.

Come along with the presenters Freya Coleman and Kieran Nee, to chat with Steve Nash of the IMI, Mike Bewsey from the VLS

There are currently 218 occupations across the sector, with technological advances –from ADAS and electric to connected motoring and online sales – creating opportunities that go far beyond traditional perceptions of working in automotive.

NEWSIN NUMBERS

£ 70

The amount the average labour rate has now reached according to Garage Industry Trends.

39 %

The percentage of motorists who would try to deal with a roadside puncture, according to a survey by Apollo Tyres. 41 per cent would seek the support of a vehicle breakdown serivice.

and Bill Fennell of the Motor Ombudsman to find out what challenges the sector is facing and how the organisations that stand up for you are dealing with key issues. One impact being that of the cost-of-living crisis. Bill Fennel said “I think what we are seeing is more cases, so we're getting more contact from private individuals regarding concerns they’ve got when they've had their car repaired or when they bought a new or a used car and I think a lot of that is driven by people wanting even more value from what they see.”

To listen, scan the QR code

50 %

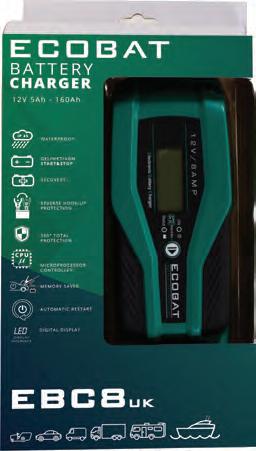

The number of vehicles that are coming into garages with discharged batteries, research from CTEK has suggested.

DATES FORTHE DIARY

■ Mechanex, the UK’s longest-running trade show dedicated solely to the independent aftermarket will once again be held at Sandown Park on Tuesday 7th and Wednesday 8th November. This year’s show is sponsored by filters specialists Mann+Hummel. Go to page 34 to read our interview with the latest addition to the PMM Live seminar programme, Ben’s Rachel Clift.

■ Garage management software Garage Hive has announced the Blend is back on the 7th of October 2023 at the Eastside Rooms in Birmingham, with tickets now on sale. It is a two-in-one event featuring a conference during the day where you can hear from industry speakers on how to run your business more efficiently.

■ The BIG Awards are back this year on Friday the 22nd of September at Leicester City Football Club. Categories include the business improvement award, the diversity equality and inclusion award and the training and development award among many others.

Meeting oil standards

The Verification of Lubricants Specifications has recently brought several cases concerning low temperatureproperties to a conclusion, resulting in affirmative action from the companies involved.

One of the instances concerned a complaint regarding Westway Lubricants 75W-90 synthetic gear oil and the product’s compliance with SAE J306 regarding low temperature properties and its claim to meet MB 235.8. VLS independently procured a sample of the product within the UK and

tested it for low temperature properties against ASTM D2983. The test results demonstrated that the product did not comply with the SAE 75W specification detailed in the SAE J306 standard, as it turned solid before reaching -40˚C.

In response to the investigation, Westway Lubricants quarantined all stock and arranged an uplift of products from the warehouse with the supplier. They also changed supplier and removed reference to the MB 235.8 specification from the productlabel.

PMM hits the small screen

The Professional Motor Mechanic YouTube channel is now up and running, bringing the magazine to life!

Current videos include putting Milwakee’s power tools to the test and a look at how to install and use the Rozone parts washer.

The man at Hamerville behind the move, the very same who launched PMM magazine all those years ago, Oliver Shannon commented: “We’re very excited to bring the content from PMM to life in video form. We will be working with key brands and leading

garages to bring our audience the most engaging technical content possible.”

To visit the channel, scan the QR code

Many of you have responded to our call for the next video sensation, but we are still on the hunt for technicians to get in front of the camera. If you are interested in having your five minutes of fame (and then some) just drop us a quick email at PMM@hamerville.co.uk

10 SEPTEMBER 2023 PMM

PMM NEWS with Freya Coleman

EV driving tax a non-starter

More than half of motorists are against a new proposal to make EV drivers pay six pence per mile to counter a tax shortfall compared to petrol and diesel cars.

July’s Startline Used Car Tracker shows 55 per cent believe such a move would not be fair while 40 per cent say that EV tax should be kept low by the government in

order to encourage take-up. The six penceper-mile rate proposal was part of a document created last month by the Resolution Foundation think tank on the future of road pricing, which addressed an expected £10 billion shortfall in fuel and road tax receipts by 2030 caused by car electrification.

NEWSIN QUOTES

“ Any failure to add these roles to the shortage occupation list would be directly damaging to the government’s own zero emissions targets. We have already seen a flattening of demand for EV training which we attribute directly to the record high vacancies in the sector not allowing employers to be able to spare technicians to go on training courses. A shortage of people to service and repair electrified vehicles is potentially as much of a barrier as insufficient charging points.”

Steve Nash, CEO of the IMI, on the failure so far from the Government to add vehicle technicians to the shortage occupation list.

Raising mental health awareness

Ben, the charity dedicated to supporting the people of the automotive industry, has invited the automotive community to raise vital funds and support those who are struggling or in crisis.

Ben’s Big Breakfast is in its third year and will run from 9th to the 15th October, inviting automotive industry companies to host a breakfast to fundraise for Ben. Breakfast brings together employees, customers and families to share the most

important meal of the day, aiming to connect with each other and check in, supporting each other’s mental health.

“ In July it's already sitting at 70 pound and 30 pence. Now, we've been measuring labour rate since August 2022. So, it's about a 9 per cent increase in less than a year in the average labour rate. It is worth noting that this is for Garage Hive customers that are opted in. So, it may not be indicative of the overall industry labour rate, but it’s certainly very indicative of the trends of the labour rate, which seems to be really nicely tracking inflation, as it should be. So, I do consider it to be, to be great news that we've finally reached the £70 milestone.”

Alex Lindley, Garage Hive’s director, commenting on the average labour rate of Garage Hive customers opting into Garage Industry Trends officially reaching £70.

PMM SEPTEMBER 2023 11 MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: Mechanex, the hands-on show for hands-on techs is more committed than ever to bringing PMM to life with new opportunities to debate the future of independent workshops. Returning to Sandown Park in Surrey on the 7th and 8th November.

A look inside:

Video

Your favourite trade magazine is now on YouTube, bringing you reviews and video guides on the best tools and workshop solutions. Find us at @professionalmotormechanic. Recently, our tool reviewer Darren Quinn from Mechanic Mindset got his hands on some tools from Milwaukee. Let’s take a look.

Milwaukee, the American power tool brand, has made a name for itself in the building industry in recent years. Its distinctive red livery and lightning motif bring a bit of stateside excitement to the workshop – sure to stand out among the usual greens and blues.

Charging up: The rapid charger puts a decent amount of charge in the battery over the 25 minutes it takes Darren to go for a cuppa. It’s a long time for a cup of tea, but a short time to get to 50 per cent charge on the M12 6Ah battery.

Power tools vs air tools: Darren found that using the battery powered tools offered him extra flexibility and more comfort as the handle remained warm. Plus they’re more quiet!

The video, which can be seen on PMM’s YouTube channel (@professionalmotormechanic) showcases a range of tools, including a ratchet and an impact wrench, with battery charger, alongside a set of spanners and deep impact sockets. Darren uses the ratched to remove a Mini’s rocker cover, preferring its lower torque setting and its ability to reach into tight spaces. Later, Darren puts the impact wrench to good use removing wheel nuts in seconds flat.

Talk the Torque: Although the impact wrench offers a huge 800 Nm of torque, Darren was most impressed by both tools’ ability to modulate the torque settings. All technicians will know the importance of a light touch when dealing with sensitive parts…

The verdict?

“I am particularly impressed with how quickly the impact wrench with the M18 battery removes the wheel bolts and the retorque feature is really nice so we don’t overtighten the wheels”

TO WATCH THIS VIDEO AND THE OTHERS ON THE PMM YOUTUBE CHANNEL, SIMPLY SCAN THE QR CODE

12 SEPTEMBER 2023 PMM

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS –ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS –ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

PMM SEPTEMBER 2023 15

CPDZONE READ ME TO COLLECT YOUR CPD POINT

TROUBLESHOOTER

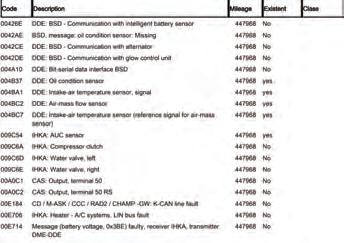

Why is the BMW E61 M-Sport losing power?

Ben Johnson investigates an (extremely) high mileage vehicle which left its driver stranded after losing power and discovers that faults, like good things, come in threes…

It has been quite a while since I’ve come across a car riddled with so many quirks that it turned me into more of a police detective than a mere fault finder. But let me tell you, last week, a nice looking E61 in M-sport trim rolled in on a flatbed truck, flaunting its seemingly flawless exterior and boasting an impressive set of wheels. Little did I know, this fine-looking car was about to take me on a wild ride.

The unhappy owner claimed that his prized possession had abruptly lost its power, leaving him stranded on the side of the road. Intrigued, I decided to dig deeper into the mystery lurking beneath the hood of this 447,968 Km driven E61 530d. Was it a sinister electrical glitch? Or perhaps something else?

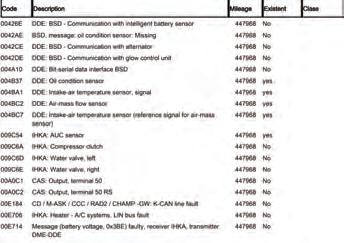

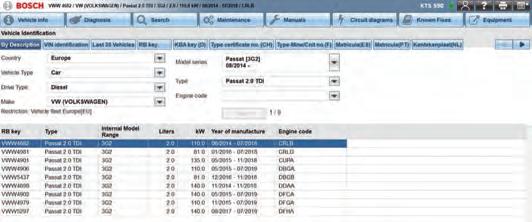

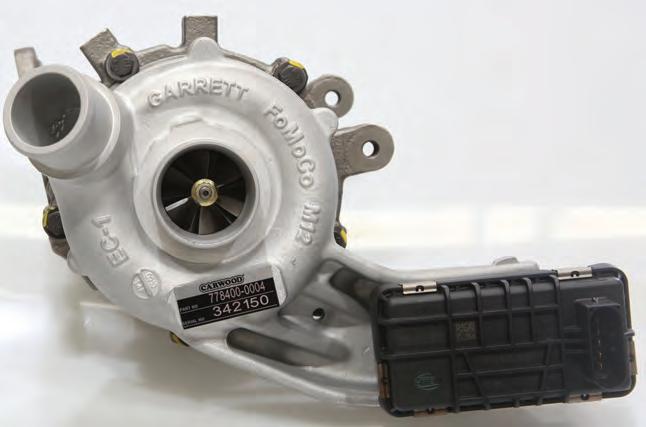

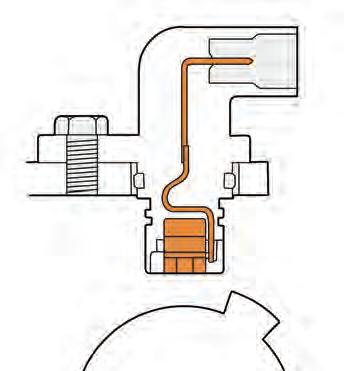

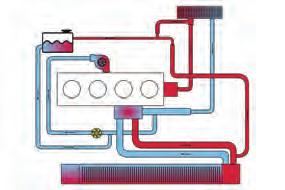

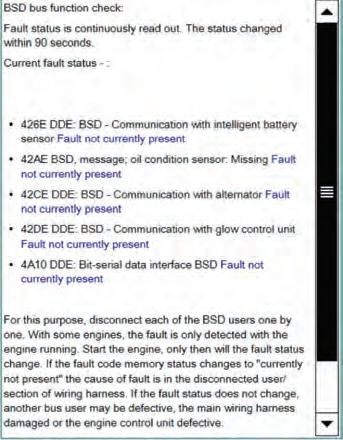

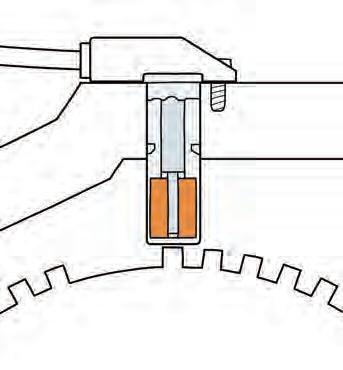

The engine was the trusty M57 featuring a single turbocharger which is usually a strong and capable platform even at high mileages except in this case, which upon driving the vehicle on our car park, I found would not accelerate at all. I should also mention, for the reader’s benefit, that in Finland such high Km readings on passenger vehicles are perfectly commonplace. As with all of my fault finds I decided to interrogate the fault memory which can be seen in Fig.1.

The air mass sensor (fault code 004BC2) caught my attention the most due to the significant limitation in engine power. Instead of examining live data, I found it more convenient to visit the parts department, retrieve a sensor from the available stock, and give it a try. This approach proved to be quicker; however, in this particular case, the replacement air mass sensor had no real effect. The car continued to exhibit a lack of power, and to make matters worse, random warning messages regarding the oil level sensor started to appear. At that point, I made the decision to remove the air mass sensor and analyse the original values using the original

air mass sensor. Unsurprisingly, they were similar to the readings that I had witnessed as provided by the new sensor. Recognising that resolving the substantial power loss required further investigation, I planned to revisit this component once I had identified the root cause because one thing was sure – it sure as heck wasn’t the air mass sensor at fault.

Digging deeper into this troublesome vehicle whilst starting the engine, a noticeable increase in exhaust back pressure was evident, suggesting a potential issue. During the evidence-gathering stage, it became apparent that this vehicle had

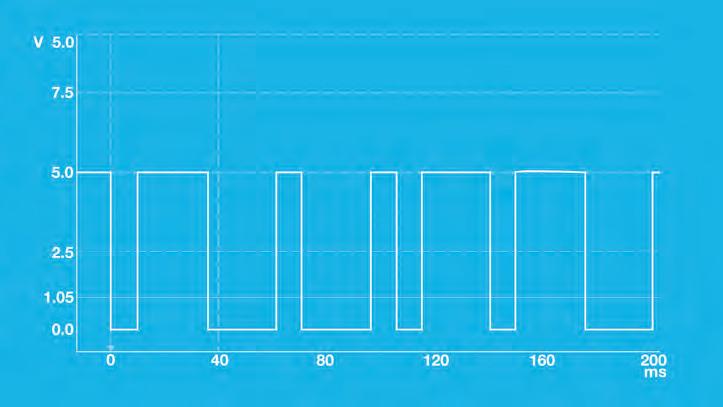

possibly undergone a chip tuning modification, as the diesel particulate filter had been cut open and subsequently welded back together. Undeterred by this finding, I resolved to measure the back pressure, even if the internal components of the DPF may have been removed. Removing the Lambda sensor revealed a monolith in good condition – the oxidising catalytic converter. With time, as ever, at a premium, a back pressure reading at 4,000 RPM was taken which resulted in a value of around 230 millibars – way too high. Never one to take live data at face value (think implausible sensor values) a general specification compound meter was hooked up to the back pressure sensor hose tube bore and the same test was repeated. The results were very close to the live data value that I had observed from the Autologic tester so I was very sure that there was a high soot loading within the particulate filter.

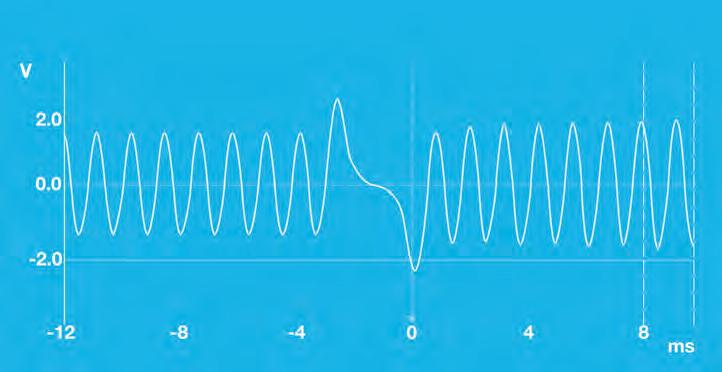

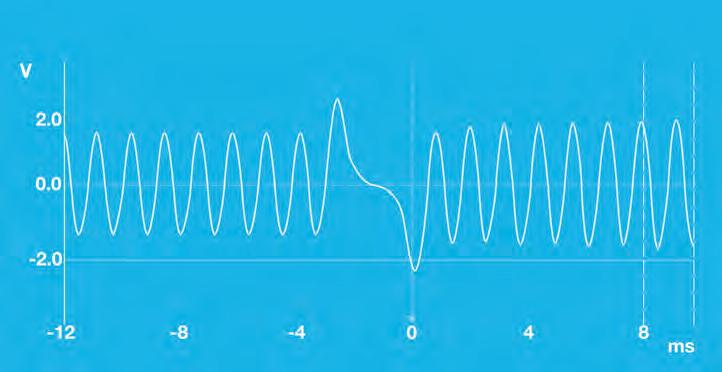

The pressure is on

The initial stage of evidence gathering posed a potential risk of misdiagnosis due to the fluctuating back pressure, which pulsated in waves, occasionally dropping to significantly lower values. These fluctuations could have been easily overlooked, as they caused unusual readings both in the live data and on the manual compound meter. For instance, the initial idle reading of 49 Millibars would randomly decrease to 11 Millibars. At 4,000 RPM cutoff speed the pressure would decrease to 170 Millibars – very strange indeed. It was important to note that I observed this change on the gauge, which, once again, ruled out the possibility of a faulty exhaust backpressure sensor (Fig.2).

The decision to unblock the DPF with JLM fluid was made and carried out. This subsequently dropped the cut off speed pressure from 230 down to 70 Millibars.

16 SEPTEMBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

Initial fault codes

Extremely high exhaust backpressure at 4000 rpm

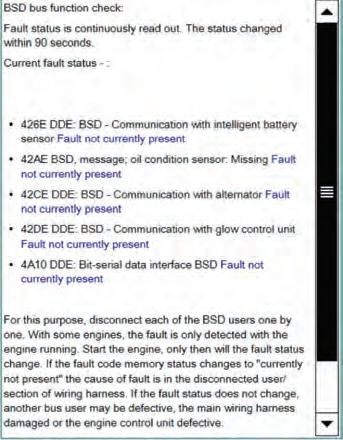

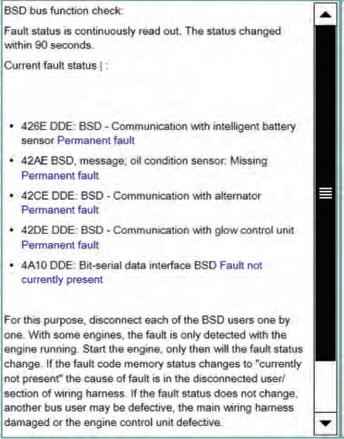

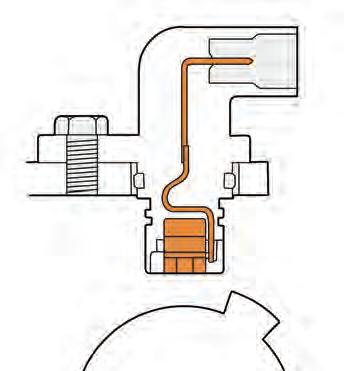

With the blocked DPF issue seemingly resolved, it was time to address the second problem: the lack of power. During a road test, it was evident that the car now drove smoothly, but only once the engine reached over 2,000 RPM did it exhibit reasonable pulling power. In the E series BMW vehicles, the BSD bus system was employed, although it has since been discontinued due to its limited fault tolerance and susceptibility to expensive repairs. For instance, if the BSD bus crashes due to a faulty or missing ground or a fault that causes a dominant signal, the DDE (Digital Diesel Electronics) is unable to control the glow plugs, read battery IBS (Intelligent Battery Sensor) data, or regulate the alternator. Additionally, the oil sensor, which is connected to the same bus, triggers a warning lamp. Thus, it is evident that this bus plays a vital role and when it goes wrong it causes no end of problems. I had encountered lots of BSD faults in the past which usually involve removing and thus isolating one bus user at a time then checking the signal on the bus to see if it is restored or not. In this way, as long as one bus user is connected at the minimum, faults can be found quickly. I had a strong belief that this fault would turn out to be something entirely different, perhaps you could call it a fault finder's intuition.

The glow plugs are responsible for heating up the combustion chamber during DPF regeneration if the cylinder temperature is not sufficiently high. Non-functioning glow plugs could certainly contribute to multiple failed DPF events. However, it was perplexing that no DPF fault codes were present, despite the high

back pressure that should typically trigger them. Nonetheless, with chip tuned cars, such functionalities can be disabled, so encountering poorly written remaps at Schmiedmann is not uncommon. Our approach is to work around these issues as best as we can. Undeterred I cracked on working out what was flagging up the bus issues (Fig.3).

Going for the triple

At times, a seemingly simple issue with a component can have a profound impact on other parts, while unexpected events can surprisingly provide assistance. After investing considerable time into starting the engine, it became evident that the oil warning light would appear during engine cranking and while driving the car under load. Based

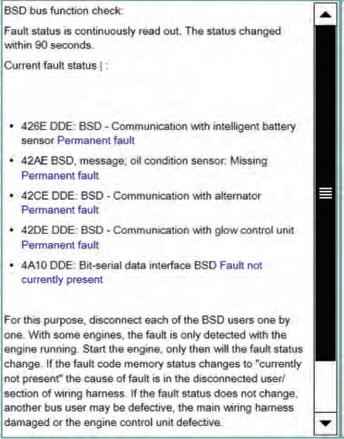

on this observation and further road tests, I made the decision to establish an additional ground connection for the engine, suspecting that the BSD bus faults were caused by a weak engine ground. By adding a thick jump cable from the jump post to the engine, the previously persistent BSD faults disappeared. However, in order to eliminate any uncertainties, I removed the temporary supplemental ground while the engine was running, only to witness an immediate failure of the BSD. This test was repeated multiple times, consistently yielding the same outcome. In this case, conducting a voltage drop test to verify the ground was unnecessary; a visual examination sufficed. I identified a heavily corroded ground, which was promptly rectified. Subsequent road tests revealed that the BSD faults did not resurface—thus, a successful resolution. However, my satisfaction was short-lived, as the issue of lacking power at low RPM reemerged. At this point, I found myself asking, "how many faults can one car possibly have?"

The BSD bus usually has a ground yet the wiring diagrams never show where this magical and highly mysterious ground point is located. Somewhere in the main harness the BSD bus will ground on the cylinder head. In the petrol engines this point is a brass washer moulded into the main engine harness conduit and it is bolted to ground in this way. It was clear that the lack of a decent ground due to massive resistance and draw from the starter motor was causing the BSD to fail under load, especially when cranking

PMM SEPTEMBER 2023 17

The BSD bus faults disappeared when a better engine ground was added

Permanent fault on the BSD bus with no supplemental ground attached

BSD faults rectified by adding a supplemental ground cable –success!

Voltage drop testing not necessary here!

the starter motor continuously. In fact, the main ground cable was so worn that it eventually failed to provide enough ground path that the starter motor failed to operate.

With things looking somewhat better, the only remaining issue to address was the lack of power at low RPM. Unfortunately, this led eventually to a complete loss of power, with the car struggling to rev at all. I had been working on this problem for half a day by now and was becoming increasingly frustrated since the problem was getting worse.

Upon examining the live data for air mass, it became evident that under load, the desired air mass value should be 1,000 Mg of air, yet the actual air mass reading was barely 370 Mg – a significantly low air mass.

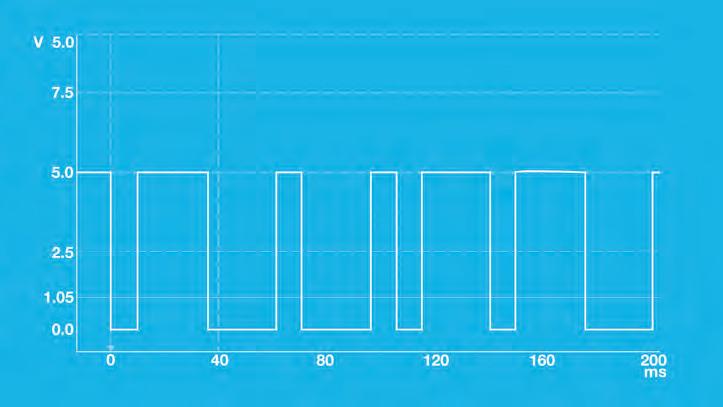

To identify the root cause, I focussed on the M57 engine's air mass measurement and the operation of the EGR valve. The air mass is digitally measured using a square wave signal that widens as the air mass increases. When the turbocharger draws in more air, the air mass reading should rise accordingly. On the other hand, the EGR valve is controlled by a solenoid valve, which supplies pulsed vacuum at a high frequency to open the EGR feed into the throttle body.

Considering the possibility that excessive, unmeasured EGR feed-in was contributing to the power loss, I decided to remove the intercooler boost hose with the engine idling. However, to my disappointment, the EGR feed-

appeared to be closed. Nevertheless, when examining the duty cycle data on Autologic, it indicated that there should have been some slight EGR feed-in. Surprisingly, upon removing the vacuum pipe from the EGR valve, I discovered a lack of vacuum. Subsequent road tests with the disconnected line yielded the best driving experience so far, clearly indicating an improvement compared to previous tests. This led me to suspect that the EGR solenoid, located under the intake manifold, might be intermittently shorting or getting stuck in the open position, allowing full vacuum to pull the EGR feed-in wide open. It was frustrating that no fault codes were recorded.

A return to normality

Before deciding to order a new solenoid, I conducted a road test using a handheld vacuum pump and a length of vacuum pipe (Fig.8). While driving without vacuum, the power delivery was excellent. However, when applying a significant amount of negative pressure, I was able to replicate the same conditions, experiencing a lack of power and poor engine response. Analysing the live data revealed an interesting observation: unlike more modern BMW diesels that calculate excess air mass based on unmetered EGR feed-in through the temperature sensor after the EGR cooler, this particular car exhibited the opposite behaviour, with the air mass decreasing as more EGR was fed in. In a more modern vehicle, an excess amount of exhaust air might result in a higher air mass reading. Fault finding can be frustrating, particularly when faults are not present during testing.

However, that's the nature of the task. If it were easy, everyone would be a fault finder. The final job for this vehicle was the fitting of a new EGR solenoid followed by a long roadtest. This resulted in normal air mass values and a smooth and enjoyable ride – finally! Indeed, this challenging triple whammy of faults really made me pause and contemplate the situation as a whole, prompting me to reflect on what was happening and why. As fault finders, we often have to rely on traditional evidence gathering methods, carefully evaluating data and conducting practical simulations to effectively diagnose and resolve issues. In cases like this one, relying solely on fault codes and computerised test plans is not enough. It is through the process of thorough evidence gathering that we uncover the root causes and through knowledge of how things work we implement successful solutions. This knowledge is useful and even essential especially when faced with such badly “modified” vehicles. So, until the next edition, let us continue our commitment to diligent evidence gathering, eagerly anticipating what challenges the upcoming month will bring.

18 SEPTEMBER 2023 PMM

in

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABA001 READ ME TO COLLECT YOUR CPD POINT CPDZONE New versus old

Using a hand operated vacuum pump to recreate the sporadic egr feed-in problem

The mystery solved! Sporadic full vacuum bypassing the EGR solenoid caused full EGR feed-in and subsequent power loss

KNOW YOUR PARTS

OE vsaftermarket shock absorbers

Suspension specialist KYB provides some helpful pointers on the differences between OE and aftermarket shock absorbers.

When removing an old shock absorber from a vehicle and comparing it alongside its replacement, you may have found yourself asking yourself “why is this KYB Shock Absorber shorter than the OE one?”

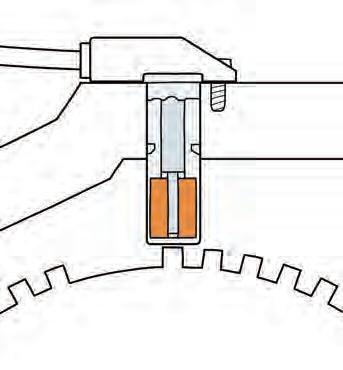

It’s certainly a question the KYB technical team have been asked numerous times as the piston rod on the replacement unit can sometimes appear to be much shorter, leading many mechanics to believe that there is something wrong with the unit. However, the piston rod is in fact the same size – the only difference is the amount visible. The reason for this lies within the body of the shock absorber, caused by the presence of a component known as a “rebound spring”.

Damage prevention

A rebound spring is a component that sits around the base of a piston rod, acting as an extra layer of internal cushioning that stops the bottom of the piston rod from hitting the top of the shock absorber cylinder when fully extended. This prevents any damage to the internal piston rod guide and the oil seal, as well as improving smoothness and stability when cornering.

When a brand-new vehicle is launched to the market, it is common that the shock absorbers originally fitted to the vehicle will have rebound springs. When the model eventually reaches maturity, the vehicle manufacturer will go through cost cutting measures, often leading to the rebound springs being removed entirely. However, at this point, KYB aftermarket shock absorbers have

been released, matching the initial designthis means that the KYB replacement unit will have a rebound spring included.

Sometimes the difference between an extended piston rod with and without a rebound spring can be as much as 50mm. This difference often leads to confusion.

Why is it so hard to fit?

Due to the extra cushioning offered by a rebound spring, this often means that the piston rod is incredibly hard to pull out to its full length when trying to attach a strut mount as the rebound spring is simply in the way, preventing the piston rod from extending further.

Whilst it may be tempting to try and pull the piston rod out to its full-length using pliers or mole grips, KYB strongly warns against doing this as it can cause damage to the oil seal on the piston rod and cause leakage, leading to premature failure of the shock absorber.

Instead, KYB suggests that a good coil spring compressor should be able to compress the spring that extra amount required to allow the top nut to be screwed securely onto the piston rod.

There are also tools available on the market to assist with any fitting difficulties, such as a strut controller, that will safely attach to the piston rod and extend it by the required distance to easily attach to the mounting kit.

HOW TO USE A STRUT CONTROLLER

Place the protective clamp over the piston rod. Do not tighten.

WWW.RDR.LINK/ABA002

Place the strut controller on top. Place the top nut provided with the shock absorber on top and tighten.

Turn the handles on the strut controller – this will pull the piston rod out further, compressing the internal rebound spring.

Use the key wrench to tighten the protective clamp. This will prevent the piston rod from retreating back into the body of the shock absorber once the strut controller is removed.

Unscrew the handle and remove the piston nut.

Assemble the unit and remove the protective clamp once the strut mount has been safely secured.

Please note, the above illustration is for demonstrative purposes only – please consult the manufacturer’s manual before use as designs of strut controller may vary.

PMM SEPTEMBER 2023 21 READ ME TO COLLECT YOUR CPD POINT CPDZONE

FOR MORE INFORMATION

WANT TO KNOW MORE?

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

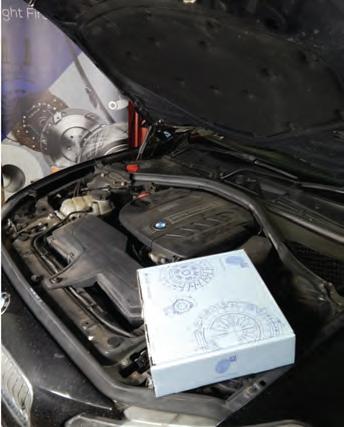

HOW TO Replace the clutch on a BMW 1-Series

Vehicle Information

Manufacturer: BMW

Model: 1-Series F20 116d

Year: 2011

The BMW 1-Series was introduced to the market in 2004, adding a new dimension to the established BMW 3, 5 and 7Series models. This new range of vehicles offered an alternative to front-wheel drive competition such as the Volkswagen Golf, with the first and second generations using the traditional BMW powertrain set-up of rear-wheel drive. The third generation 1Series is now based on a larger version of the primarily front-wheel drive MINI platform –marking a change in BMW’s philosophy.

The example featured in this article is a second-generation 1-Series F20 116d equipped with the N47 2.0 diesel engine, which had covered 116,000 miles (187,000

Engine 2.0 Diesel N47 Mileage: 116,000

In this instance, the tailgate would not be able to open, making the battery difficult to access for reconnection. All other operationsto remove the transmission to gain access to the clutch assembly are from underneath the vehicle.

With the vehicle fully raised, the engine and transmission undertrays can be removed, followed by the right-rear exhaust silencer mounting, which allows for the exhaust system to be lowered. Once lowered, there is enough clearance to remove the exhaust heat shields to expose all the fixings to remove the propshaft (Fig.2).

km) and was showing all the signs of requiring a new clutch.

Before the clutch replacement process can begin, the vehicle must be raised onto the ramp in order to lift up the vehicle’s tailgate and locate the battery. Remove the negative terminal and set it to one side before lowering the tailgate and setting the latch into the ‘shut’ position to stop the tailgate from closing completely. This is because, with the battery disconnected, the tailgate latch would remain in the ‘shut’ position if closed, due to the latch requiring battery power to operate (Fig.1).

Unbolt the front and rear propshaft couplings (also known as flexible discs), along with the centre support, and remove the complete propshaft from the vehicle. This is a perfect opportunity to inspect the propshaft universal joint for any ‘stiffness’ or excess play, along with the centre bearing and condition of the propshaft rubber couplings, and to replace any worn parts - if necessary –before reassembly (Fig.3).

PMM SEPTEMBER 2023 23

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Blue Print’s Charles Figgins guides readers through a clutch replacement on a BMW 1-Series.

“The third generation 1-Series is now based on a larger version of the primarily front-wheel drive MINI platform – marking a change in BMW’s philosophy.”

Next, detach the gear linkage. There are two pins fixing the linkage to the transmission and one to the gear selector; simply remove them and the linkage becomes separated from the transmission (Fig.4).

Other items requiring removal include the clutch-slave cylinder, located on the left-side of the transmission. This can be unbolted from the transmission with the hydraulic hose attached but – In the case of the vehicle featured in this article - the hose was clamped, then disconnected, before the slave cylinder was unbolted, because a new slave cylinder was going to be part of this repair anyway.

The starter motor wiring harness can now be removed – then, unbolt the starter from the engine, being aware of the hidden bolt that goes through the deep rubber grommet attaching it to the engine.

Other wiring harness components that require unclipping and removing are the reverse lamp switch on the left side, the neutral switch on the top of the transmission, and an earth cable on the right side.

Remove bell housing bolts

Next, put a transmission jack in place to take the weight from the transmission, then unbolt the rear transmission mounting from the vehicle’s body. Remove all the bell housing bolts and the bracket that was attached to the DPF –however, the transmission must be lowered to gain access to the bolts at the top of the transmission using a long extension and socket. Once all

bolts are removed, the transmission can be guided away from the engine and lowered to the workshop floor for inspection.

With the transmission removed, the flywheel can be ‘locked’ in place to stop the engine from turning. Unbolt the original clutch and dual-mass flywheel and remove them for inspection. Check the flywheel – in the case of the vehicle featured here, some ‘blueing’ on the friction surface was discovered, this being due to the excess heat created by the worn clutch. A rock test should also be carried out on the flywheel –in this vehicle’s case, it failed the rock test, so the flywheel did require replacement.

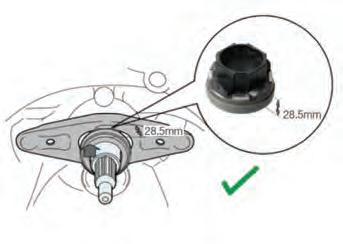

We now turn our attention to the release mechanism: remove the release bearing from the clutch-release lever, which can become dry and noisy with usage and age.

Clean surfaces

Before fitting any new components, thoroughly clean all mating surfaces at the rear of the engine and the transmission bell housing so they are free of all grease, dirt and old friction fibres from the previous clutch. Then, the new dual-mass flywheel and retaining bolts can be fitted to the engine along with the new clutch kit ADB113017.

Tighten all bolts to the manufacturer’s recommended tightening figures, evenly and in sequence, before securing and correctly aligning the components (Fig.5).

Before refitting the transmission to the engine, assemble the new release bearing

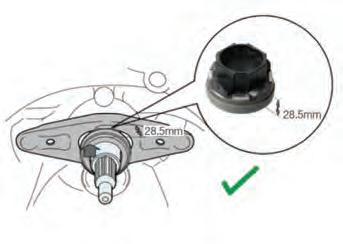

with the new release lever and then fit it to pre-greased pivot points to ease operation. Note: this clutch kit is provided with an information bulletin, because the release bearing can be fitted at two different points: in this case it is in the 28.5 mm position to provide the correct clearance between the pressure plate and the bearing (Fig.6).

With all clutch components replaced, use a transmission jack to support the transmission and lift it into position. Secure all the cables, pipes and the gear-selector linkage so as not to foul the transmission. The transmission can now be refitted to the engine.

Afterwards, refit all components to the transmission and bolt the rear mounting to the body before removing the jack. All other parts previously removed during the process should also be refitted, as well as tightening all bolts and fixings accordingly. The vehicle can now be lowered –once lowered, reconnect the battery and reset the tailgate latch. Top-up the brake/clutch fluid reservoir with fresh fluid, bleed the slave cylinder of any excess air and reset the clock.

Finally, carry out a road test to check the operation of the new clutch and to reset the tyre pressure warning system and steering wheel angle sensor.

24 SEPTEMBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABA003

Check the flywheel – in the case of the vehicle featured here, some ‘blueing’ on the friction surface was discovered, this being due to the excess heat created by the worn clutch.

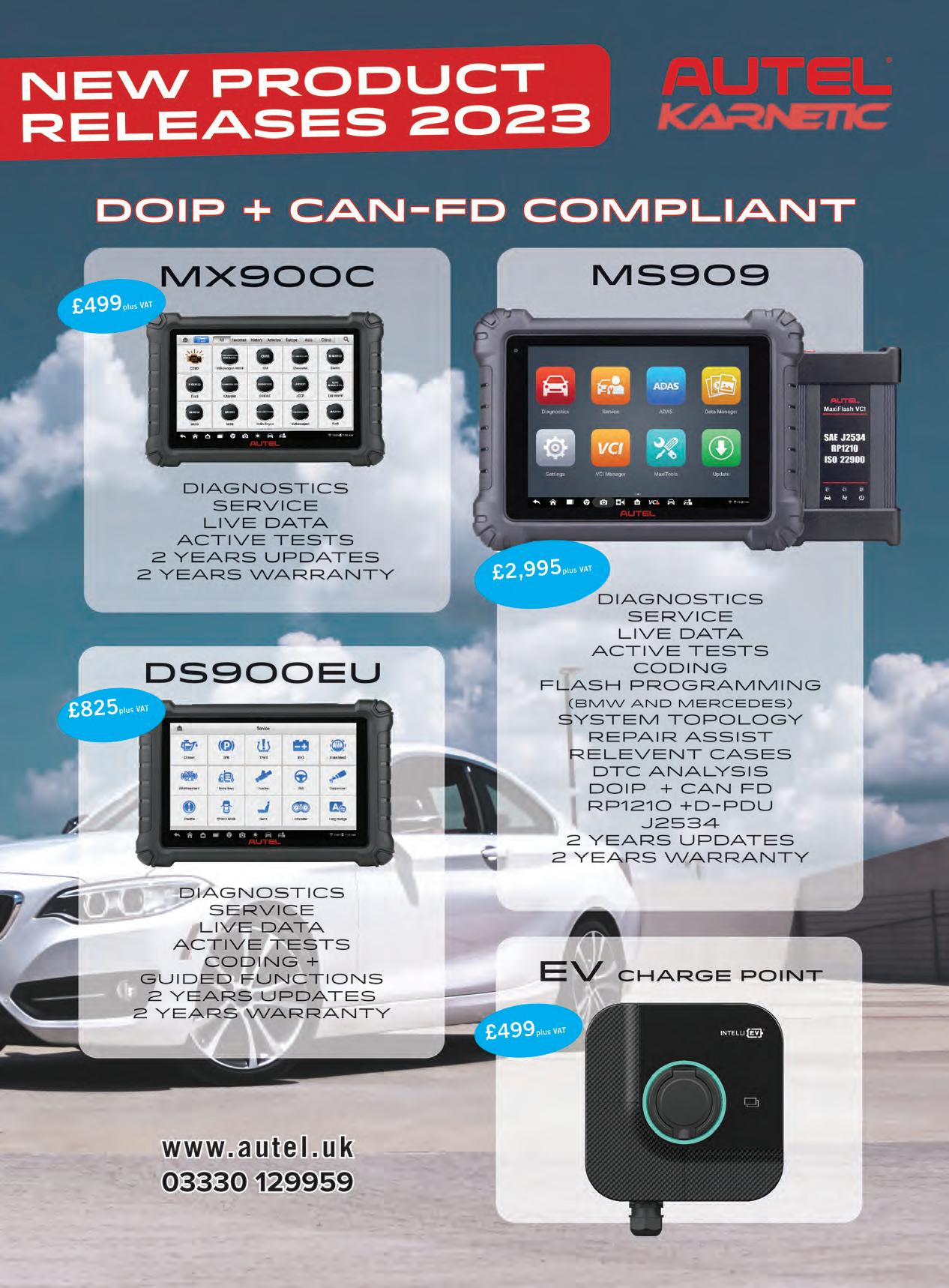

HOW TO

Replace the clutch and DMF on a 2012 Ford Focus 1.6 EcoBoost

In this month’s Schaeffler LuK Clutch Clinic, REPXPERT Alistair Mason is replacing the clutch and dual mass flywheel (DMF) in a 2012 Ford Focus 1.6 EcoBoost that has covered more than 86,000 miles. The customer reported that the vehicle was difficult to get into gear and the initial diagnosis indicated a clutch disengagement problem, so the customer was advised that gearbox removal was required to pinpoint the exact cause and their authorisation was given.

Vehicle Information

Manufacturer: Ford

Model: Focus

Year: 2012

Engine 1.6 EcoBoost

Mileage: 86,000

Schedule time: 4.3 hours

Gearbox removal

If it’s required, after locating the locking wheel bolt key, place the vehicle on the lift, open the bonnet and remove the engine cover and complete air filter assembly, then disconnect and remove the battery, battery tray and carrier (Fig.1), which provides good access to the top of the gearbox. Ease the gear change cables off the selectors, unbolt the cable bracket and stow against the bulkhead. Remove the upper bellhousing bolts, disconnect the hydraulic clutch pipe at the concentric slave cylinder (CSC), but make sure the rubber seal stays on the pipe and blank the pipe to stop the fluid running out (Fig.2).

Raise the lift to waist height and remove the N/S/F wheel and wheel arch liner, raise the lift to gain access to the underside, and remove the engine undertray. Drain the gearbox oil and whilst the oil is draining remove the catalytic converter supporting

bracket (Fig.3) and the lower gearbox pendulum mounting. Remove the N/S bottom ball joint pinch bolt, ease the ball joint out of the hub carrier, push the hub assembly outwards and remove the N/S driveshaft from

READ ME TO COLLECT YOUR CPD POINT CPDZONE 26 SEPTEMBER 2023 PMM

the gearbox, but the O/S driveshaft will stay in place when removing the gearbox. Remove the lower bellhousing bolts and starter motor bolts, leaving two, easily accessible bolts to support the gearbox until the point of removal. Support the engine using either an engine support or a second transmission jack, access the engine bay and remove the top gearbox mounting bolts, then lower the engine slightly and remove the gearbox mounting bolts that are accessed from the N/S wheel arch (Fig.4), then remove the mounting.

Support the gearbox with a transmission jack, remove the final bellhousing bolts, ease the gearbox away from the engine, and when clear, remove the gearbox from the vehicle and stow in a safe area.

Diagnosis and clutch replacement

With the gearbox removed, the fault was clear: a finger of the diaphragm spring had broken off restricting the movement of the clutch (Fig.5). With a clutch replacement required and a new DMF advised, authorisation was

given for the complete repair.

With the clutch and DMF removed from the car, inspect the back of the engine for any leaks that could potentially contaminate the new components, and scan the QR code on the LuK replacement box with the REPXPERT app to obtain the service information and technical bulletins, as well as the fitting instructions and torque settings.

Mount the new DMF onto the crankshaft, install the new bolts and torque to the manufacturer’s specification (Fig.6) and degrease the DMF face with clutch and brake dust cleaner.

Turning to the gearbox, remove the CSC, clean the bellhousing area so that the old clutch dust does not contaminate the new clutch and DMF, and carefully fit the new CSC, ensuring it is located and tightened correctly (Fig.7).

Apply a light smear of high melting point grease onto the gearbox input shaft splines, mount the clutch plate onto the input shaft to evenly distribute the grease and also confirm the correct fitment of the clutch plate, then remove the clutch plate from the input shaft, and wipe off any excess grease.

Mount the new clutch

the DMF using the clutch

tool

make sure the clutch plate is the correct way around, indicated by “Gearbox side” facing the gearbox. Degrease the clutch pressure plate surface using clutch and brake dust cleaner, tighten the bolts in an even and sequential manner, and torque to the manufacturer’s specification.

Before refitting the gearbox, place a drainer under the clutch pipe and flush out the old clutch fluid, before replacing it with new fluid of the correct specification, because old, contaminated fluid, can cause the new seal in the CSC to swell and fail. In this instance, the clutch system was bled using a vacuum bleeder. Check the gearbox alignment dowels are located correctly and that the bellhousing area is clear of cables etc., so not to foul or get caught when installing the gearbox.

Gearbox installation

With the aid of a transmission jack, bring the gearbox close to the engine, take time to align the gearbox correctly. Bring into line the O/S driveshaft, ease the gearbox input shaft into the clutch and then ensure the gearbox locates onto the alignment dowels. Insert two bellhousing bolts and tighten, then fit the upper gearbox mounting and tighten in position. Refit all other bolts and components in reverse order of their removal and refill the gearbox with oil.

After the battery lead has been reconnected, reset all electrical consumers and carry out a full road test to ensure that the repair has been successfully completed. WANT TO

WWW.RDR.LINK/ABA004

PMM SEPTEMBER 2023 27

onto

alignment

(Fig.8), but

MORE INFORMATION

KNOW MORE? FOR

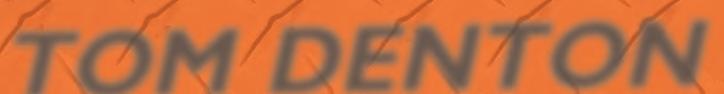

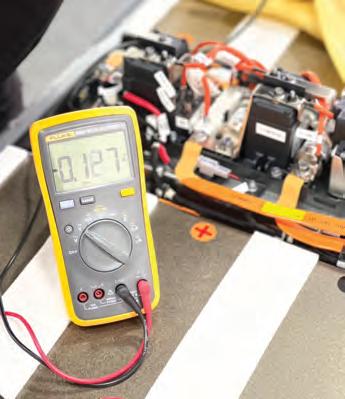

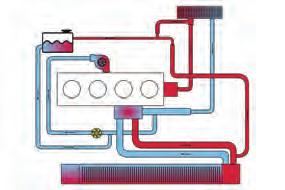

E V

STATE OF CHARGE

State of charge is a measure of the amount of energy left in a battery compared with the energy it had when it was full. It gives the driver an indication of how much longer a battery will continue to work before it needs recharging. It is considered as a measure of the short-term capability of a battery.

However, it is more difficult to define SOC than it would first appear. It is defined as the available capacity expressed as a percentage of a given reference, which could be its:

● rated capacity (as if new)

● latest charge-discharge capacity.

A vehicle that has a range of, say, 100km on a fully charged brand new battery, could reasonably expect a range of 50km if it was 50 per cent charged. However, after ten years or so, the capacity of the battery when fully charged may only be 80 per cent of what it used to be. An indication of 50 per cent charge would now only give a 40km range.

Because electric vehicles use the SOC to determine range, it should ideally be an absolute value based on the capacity of the battery when new. Several methods of

BATTERY HEALTH ASSESSED

Assessing the condition of an EV battery easy. However, there are two main indications we can use: state of charge (SOC), and state of health (SOH).

reduces degradation over time. The voltage changes are therefore even smaller. Nonetheless, taking all factors into account, a voltage measurement under a known load, gives a reasonable estimate of SOC.

It is also possible to calculate state of charge by measuring current and time (in or out). Current multiplied by time gives a suitable value for SOC.

STATE OF HEALTH

performance deteriorates due to physical and chemical changes. Unfortunately, there is no agreed definition of SOH.Cell impedance or cell conductivity is often used as a reasonable estimate of SOH. More complex systems monitor other parameters and involve a range of calculations. Because SOH is a figure relative to the condition of a new battery, the measurement system must collect and save data over time and monitor the change.

estimating the state of charge of a battery have been used.

The easiest way to monitor SOC is a voltage measurement, but this does depend on several factors. An open circuit voltage will be higher than when current is flowing due to cell internal resistance.

Temperature also has a big effect. Lithium-ion batteries also have a cell voltage that doesn’t change that much between fully charged and fully discharged. Most are also actually operated between 80 per cent and 20 per cent as this

The state of health (SOH) of a battery is a measurement that indicates the general condition of a battery and its ability to perform compared with a new battery. It considers charge acceptance, internal resistance, voltage and self-discharge. It is considered as a measure of the long-term capability of a battery.

SOH is an indication not an absolute measurement. During the lifetime of a battery, its

Counting the charge/discharge cycles of the battery is a measure of battery usage and can be used to indicate SOH, if compared to the expected values over time. This is because the capacity of lithium-ion cell deteriorates quite linearly with age or cycle life. The remaining cycle life can therefore be used as a measure of SOH.

There is talk of regulations forcing manufacturers to display their vehicle’s battery SOH.

Sponsored by FOR MORE INFORMATION GO TO WWW.RDR.LINK/ ABA005

READ ME TO COLLECT YOUR CPD POINT

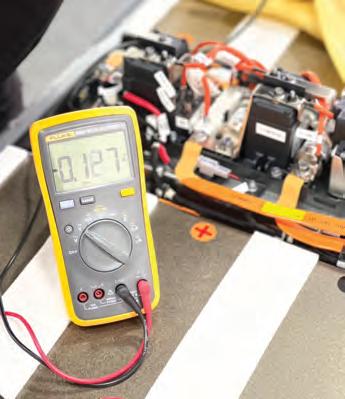

FIG.2 Cell voltages indicating SCO can be displayed on a scanner

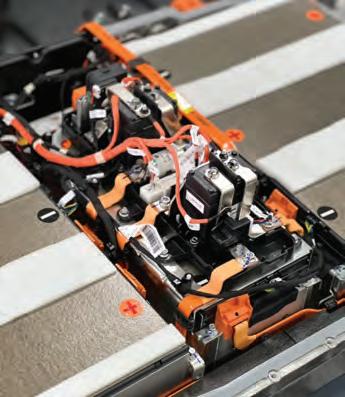

FIG.1 Battery management unit on a Nissan Leaf

FIG.3

Good advice

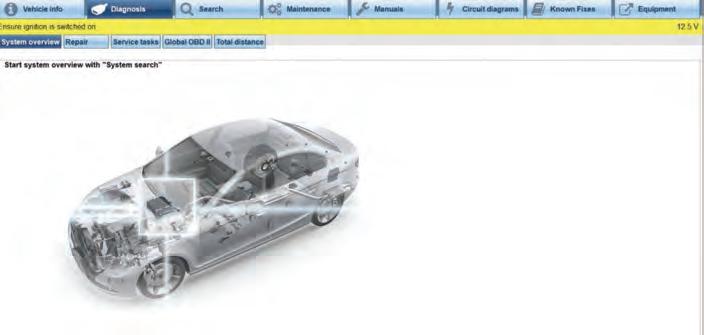

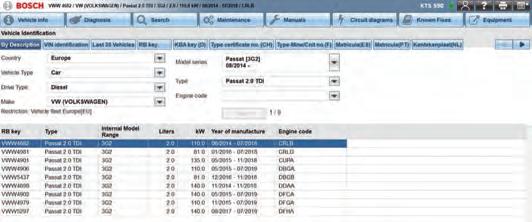

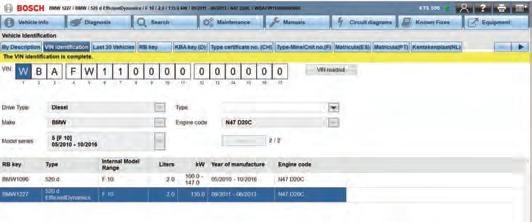

Using Bosch’s ESI[tronic] 2.0

software: a monthly guide

A few years ago, PMM ran a guide from Bosch on its KTS diagnostics software, ESI[tronic] 2.0. We thought it would be a good idea to revisit the guide with Bosch and find out what’s changed. We are beginning this month with selecting the right vehicle.

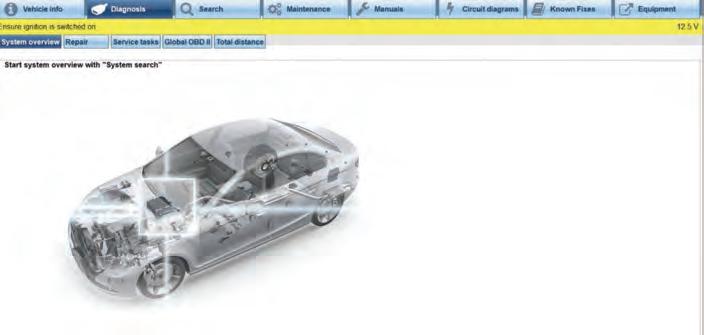

The ESI[tronic] software was designed by Bosch to enhance the potential of your workshop, integrating easily with the KTS 5xx series of VCI (Vehicle Communication Interface) hardware, so you can connect to your workshop PC or laptop and enjoy fast, accurate diagnosis and analysis, across the full range of vehicle types.

Finding the right vehicle

Finding the right vehicle is key to accessing all the tabs you need to get your job done: Vehicle Info, Diagnosis, Maintenance, Manuals, Circuit Diagrams (depending on subscription level), Known Fixes and Equipment (parts). These tabs will guide you through all the relevant functions and data for that specific vehicle, allowing you to carry out your workshop tasks in the most efficient way. Let’s look at two ways to select the right vehicle.

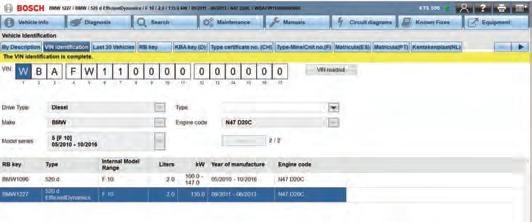

1. Automatic VIN identification

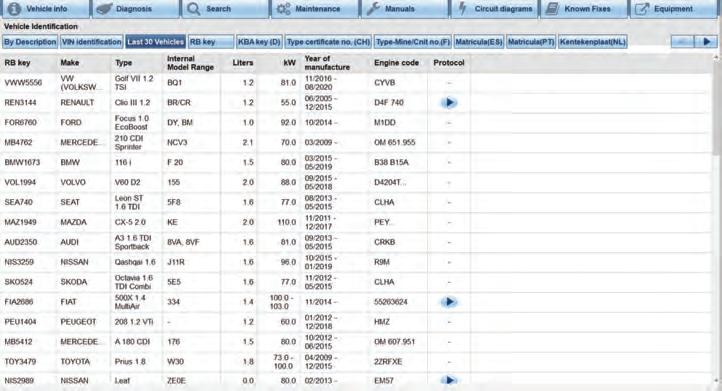

The most intuitive way to identify the correct model. Simply ensure the VCI is already connected to the vehicle and – in most cases – it will automatically retrieve the VIN details by serial diagnosis from the mode 9 of Global OBD II. This will put all the possible vehicle selections associated with this VIN at your fingertips. When identifying a vehicle using the ‘VIN Identification’ tab, the user will generally be presented with a list of 1-3 Robert Bosch (RB) key possibilities, which the user can then select from (Fig.1).

It is also important to point out that some models do not store the VIN in mode 9 of Global OBD II. If this is the case, users can manually type in the VIN and search the database for an RB key this way.

2. Manual search

Unfortunately, with some manufacturers, the VIN associated with some cars does not include model specific details. This means the list of possible vehicles can be quite long. In which case, you would need to narrow your search parameters by adding some additional details in the search ‘By Description’ option for more accurate results. Refining your search through everything from Make, Model and Country to Drive Type and Engine Code.

For example, searching for a Volkswagen

Passat 2.0 TDI (2014) returns nine possible RB key selections. Refining this selection just slightly further by engine code (CRLB) then brings the RB key options down to one. Your desired vehicle will then be highlighted in blue, and you can get on with the job at hand with minimal disruption (Fig.2).

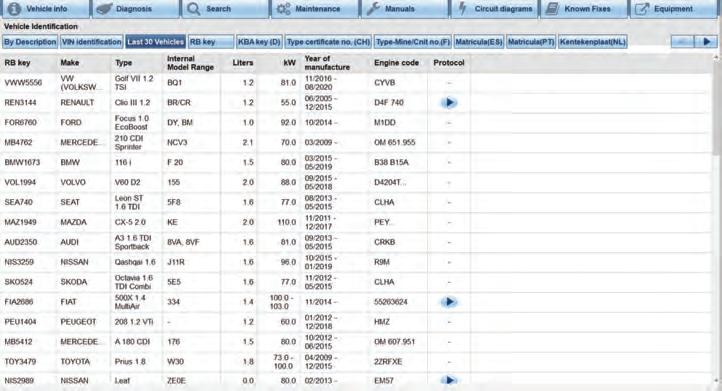

The vehicles you most recently worked on can be recalled at the touch of a button via the ‘Last 30 Vehicles’ tab (Fig.3).

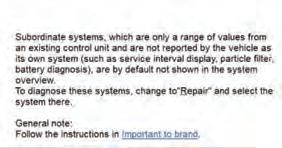

Selected the wrong vehicle?

There may be occasions where you mistakenly select the wrong vehicle, in this case the diagnostic ECU system that you need is not fully identified, and some diagnostic functions may not work properly –but there’s no need to worry.

If you find yourself in this position, a

30 SEPTEMBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

‘Basic Program’ warning message will pop up on the screen. If you continue with this, you may see unknown Diagnostic Trouble Codes (DTCs) or Actual Values that are not accurate or supported. The servicerelated information and technical data could also be wrong, which will not help any user or technician carry out their job and diagnosis efficiently.

You can check the vehicle coverage by scanning the QR code below

Diagnosis

Once you have identified the correct vehicle, all that remains is to follow the process set out across the tabs at the top of your screen. You can use the main tabs across the top row of the screen to navigate through the software to perform the expansive range of diagnostic testing. This allows you as the technician to tick off the diagnostic tests and service-related tasks and functions as you go (Fig.4).

Coverage

The ESI [tronic] software comprises vehicle data for over 90,000 vehicles, from around 150 brands, each with many models. Scan the QR code below to see for yourself.

Next month we will take an overview of the system and explain how to use its reporting function to keep customers informed.

WANT TO KNOW MORE?

WWW.RDR.LINK/ABA006

REDEEM YOUR CPD

Congratulations, you have reached the end of the CPD Zone!To access your CPD credit from The CPD Group, scan the QR Code below or WWW.RDR.LINK/ABA040

CREDIT

CREDIT

A look inside:

PMM THE PODCAST

The PMM team took the podcast studio to Automechanika Birmingham this summer for its Industry Insights episode. Listen to the episode to hear what three of the biggest players in the aftermarket had to say about the future of our sector. Here, podcast host and PMM editor Kieran Nee brings you his favourite parts of the episode.

’ll find us a quiet room to do the podcast in”: the helpful words I’ve heard a million times by now (or more accurately, probably around 14 times, considering that’s how many episodes we’ve done) and each I’ve replied, “no don’t worry about it, a bit of background noise actually sounds good”. So when we decided to make our Automechanika debut this year, the opportunity for some excellently sound-scaped interviews was too good to pass up.

I duly put the feelers out and received a lot of responses – mostly along the lines “I can’t believe it, PMM is coming to Mechanex??”. It was a surprise to many, after all, that we were exhibiting at a show other than our own Mechanex show. Many people, however, jumped at the chance to feature on the aftermarket’s number one podcast: The PMM Podcast. We showcased three of them on our recent Industry Insights episode and we thought we’d share some of their thoughts with you here. Enjoy!

Sometimes we are accused of being a sort of name and shame organisation, but that’s not the number one priority –that’s not what we are here for. Education, for us, is the number one priority. Most of what we do is about advising the blenders or the additive providers or the whole supply chain on how to make the correct claim so that we don’t mislead the distributors or the customer themselves, and do damage to the vehicle.

“We always feel a little bit disappointed if we get to the point where we have to get the manual out and start following

the process to pass on names to trading standards. We see that almost as a failure on our behalf because we haven’t been able to persuade the parties concerned of the purpose of the VLS.”

Are cases on the rise or declining?

“We saw a big drop during the pandemic, which is no surprise because everybody had plenty of other things on their minds. But since then we have seen a resurgence and we’ve seen an uplift.Ithinkthat’sdownto greater complexities in the lubricants industry coming through.”

I think the pandemic must have had an impact, encouraging the growth of mobile mechanics. It's always hard to get exact numbers of mobile mechanics, but I think from a consumer's perspective, it definitely drove the wish to have work done at home. But I think the actual numbers of mobile mechanics and mobile repairers was growing anyway and we could see that even back in 2016. But I think each it's grown higher and higher.”

How is the cost of living affecting the aftermarket?

“Partly, customers are looking for a freebie. Let's be plain, the number of contacts and cases we've had up to May this year is up around 30-40 per cent on the same period last year. What we're also seeing is where before consumers were maybe willing to just have the repair redone or have it done to their satisfaction, we're seeing more now that they want to reject the vehicle or reject the repair and get the repair and full compensation. So, they are being more demanding on what they get and we're seeing more cases.”

32 SEPTEMBER 2023 PMM

Mike Bewsey, chairman, VLS (Verification of Lubrication Specifications)

Bill Fennel, managing director, the Motor Ombudsman

‘‘I

Steve Nash, chief executive, the IMI

Well, I think you'd have to have been under a rock not to realise that in general terms the whole economy is suffering with a shortage of people. There are a lot of reasons for that. I mean, we can't hide from the fact that Brexit had an effect on an awful lot of people who were here working. Post-pandemic, just over 20 per cent of the potential working population decided not to come back to work.

The unfortunate thing is that of all the sectors that you can look at, we are one of only three

sectors where that problem is still getting bigger, despite the cost of living crisis driving people back to work. Right now there are 26,000 vacancies in automotive and I’m talking about that part of automotive that’s outside the factory gates.

Where do we need skilled technicians?

“The engagement with electric vehicle qualifications has been fantastic. We had a skills gap projected for 2026 and that’s moved up to 2029 now. But

we’re still going to need 103,000 roughly people, to be qualified to cope with the job in 2030. However, what we’ve revealed more recently is that there’s a bigger skills gap around ADAS: bear in mind that from the middle of last year, every single

car coming off the production line and sold in this country has ADAS at a minimum level, and that minimum level is around about 11 systems. We are showing a huge skills gap there at the moment.”

TO ALL OF THE EPISODES SO FAR ON THE PLATFORM OF YOUR CHOICE, SIMPLY SCAN THE QR CODE

LISTEN

Industry charity Ben makes MECHANEX seminar debut!

The PMM Live team is delighted to announce its latest partner – industry charity Ben. Here, PMM editor Kieran Nee catches up with Ben’s Rachel Clift to chat about the upcoming show.

2023 sees PMM once again rounding up the most important suppliers in the aftermarket to provide workshop owners and technicians with an engaging, informative day out of the workshop. The UK’s longestrunning trade show dedicated solely to the independent aftermarket will once again be held at Sandown Park on Tuesday 7th and Wednesday 8th November.

Mechanex is well known within the independent aftermarket for offering visitors a hands-on experience, bringing them the latest updates and expertise from across the industry and providing an exciting day away from the workshop. Registration to visit the show is free and so is parking, so why not come and take a look at what the biggest names in the aftermarket have to show you. In such a competitive industry, Mechanex is an opportunity you can’t afford to miss.

If you like PMM, you’ll love Mechanex –it’s simply the magazine in a live format.

What will you be talking to the Mechanex audience about?

I will be providing insights into the health and wellbeing of those who work in the automotive industry, as well as raising awareness of the services and support that Ben (the automotive industry charity) offers.

Have you spoken at trade shows before? What do you like about them?

I have spoken at trade shows before and they are the ideal platform to network and find out about the latest insights and trends of the industry.

What has Ben been up to this year?

We have been very busy supporting those who work, or have worked, in the automotive industry with their health and wellbeing. It’s a tough time for people right now with the costof-living crisis so we’re supporting people in many ways. We have a record number of people coming to us for support, not just

about money worries, but also because of the knock-on effect that the cost-of-living crisis has had on their health and wellbeing, particularly mental health.

Why are events like Mechanex important to mechanics and to Ben?

It’s really important for us to attend events like Mechanex to raise awareness about the services and support that Ben provides. We want everyone in the automotive industry to know that Ben is there for them, providing support with their health and wellbeing through our free and confidential online selfhelp, helpline, support and specialist services. So, if you’re worried about your physical or mental health or concerned about your general wellbeing, we’re here to help.

Are you looking forward to the show?

I’m very much looking forward to the show, it will provide a great platform to share more about the support and services that Ben provides to those who may not already know about us.

34 SEPTEMBER 2023 PMM REGISTER HERE:

TO FIND OUT MORE

THIS YEAR’S MECHANEX AND

GO TO WWW.MECHANEX.INFO ● SANDOWN PARK ● 7-8TH NOVEMBER ● FREE ENTRY

Q&A with Ben’s Rachel Clift, health and wellbeing director

ABOUT

PMM LIVE

TRAIN to RETAIN staff

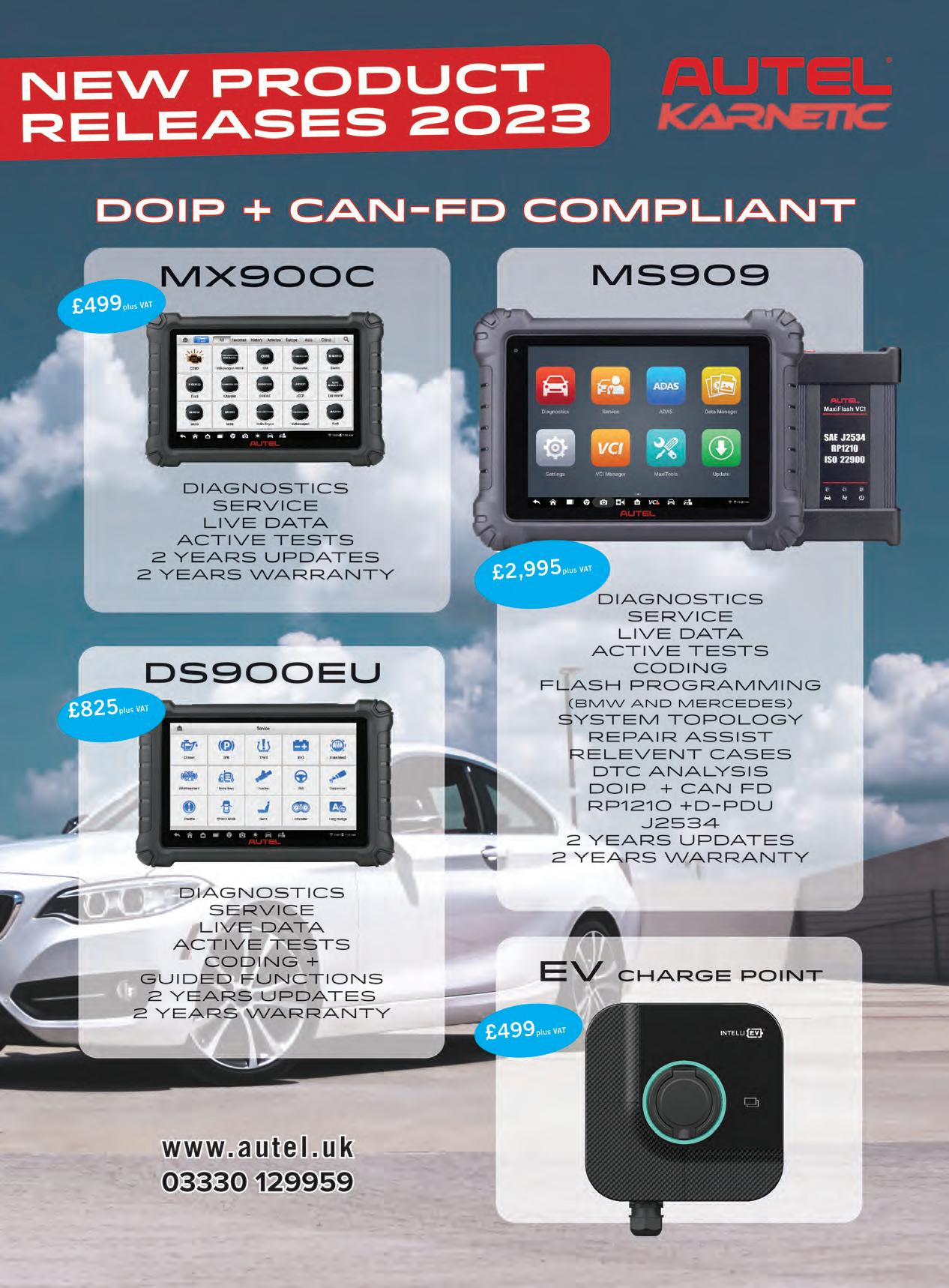

With even simple tasks now requiring skills such as coding, Delphi’s training solutions aim to take the pressure off stretched workshops.

Autonomous driving technologies, electrification of the vehicle parc and different diagnostic processes are amongst the key step-changes independents face and are all driving demand for quality technical training.

“Cars are changing,” said Luke Garratt, technical services manager at Delphi. “The drivetrains, the onboard technology and the methods of interacting with the vehicle are all transforming.”

More and more garages are looking to adopt structured training and development programmes to maximise these opportunities.

“Motivation might be getting ahead by winning more work or it can just be about keeping up,” said Luke. “Even doing some of the simplest service jobs now require access to the vehicle’s ECU and coding capability so new skills, new equipment and a commitment to continual learning are absolutely essential.”

Delphi’s comprehensive offering includes diagnostic programmes, face-to-face training in Leamington Spa, online learning through the Delphi Academy and tips, hints, articles and ‘How To’ videos also available at the new Masters of Motion hub. According to the manufacturer, training should be subject to cost-benefit or return on investment scrutiny like any other business decision.

“Garages have to make tough calls on how to allocate their resources,” said Luke.

“We’re finding staff retention is a key driver for training these days.

“Recruiting skilled technicians is difficult and expensive so a modest ongoing investment in training over several years can pay for itself in making it easier to attract new technicians.”

Staff retention is boosted too because technicians who feel they are developing their abilities won’t be as easily tempted to move for a few pounds more in their pay packet, according to Delphi.

“It’s a big ambition but we want to offer the complete training solution,” said Luke. “That means covering lots of scenarios and technologies within a flexible blended framework that provides a clear progression route for the technicians and business owners involved.”

Blended learning

Delphi currently offers face-to-face training from its facility in Leamington Spa.

“We’ve focused on future technology within the centre,” said Luke. “We’ve got vehicles, service equipment and test rigs for technicians to work on – there’s still no substitute for ‘hands on’ learning.”

Delphi’s combined e-learning solution offers a total of over 300 individual modules varying in length from a couple of minutes to nearly an hour each, with most content available in multiple European languages.

The online learning is constantly evolving with new content being added.

Since its inception in 2021, the Delphi Technologies Academy has seen around 1,200 users gaining flexible access to more than 300 courses and modules, all of which have been compiled by Delphi’s in-house trainers.

“The Delphi Academy gives a convenient way to enhance skills and knowledge without the challenges of attending physical training,” said Luke. “There’s a training Needs Assessment which includes a series of questionnaires and online ‘practicals’ before suggesting modules to complete tailored to that user. Hybrid and electric vehicle training is the perfect example of the benefits of a true blended learning experience. For the more advanced EV course we provide six hours of online pre-learning on electrical systems to try and get the foundation knowledge of electrical principle to then build upon in the training centre.”

Delphi’s combined e-learning offering comprises 16 courses on vehicle electrics, hybrid and EV alone. In all, there’s a total of over 100 modules varying in length from a couple of minutes to nearly an hour each.

PMM SEPTEMBER 2023 37 BUSINESS & TRAINING WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABA007

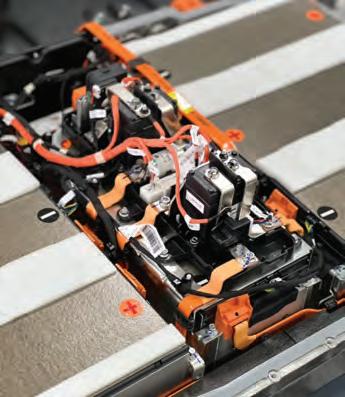

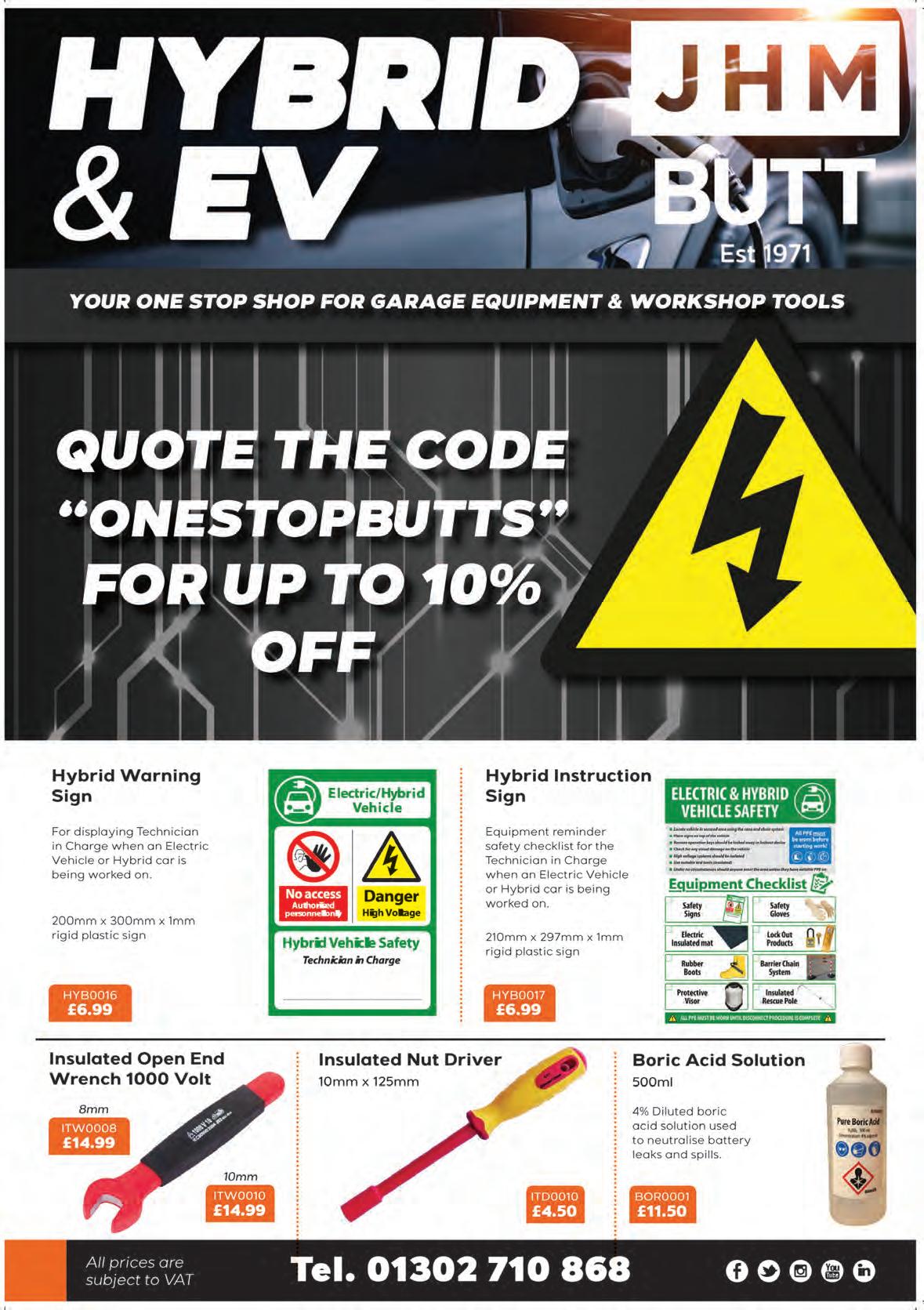

Considering CONVERTING a classic car into an EV?

Read this first (part one)

As featured recently on the PMM Podcast, Fellten provides kits and assistance to workshops taking on classic car-to-EV conversion as an extra offering. Here, the team behindthe kits answers some of the questions you need to be asking before getting started.

High voltage or low voltage?

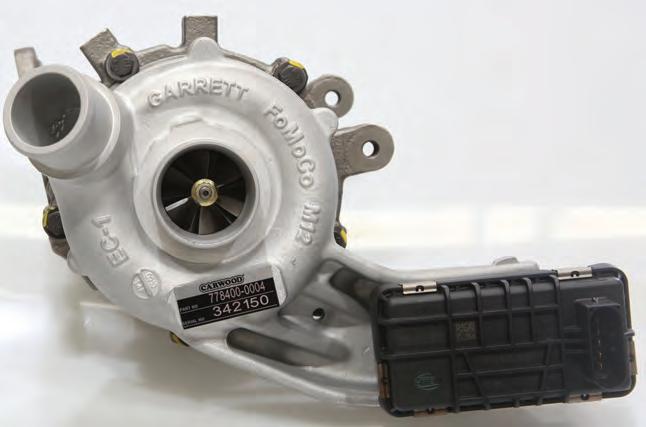

Before you do anything you need to decide what voltage motor you are going to use. Everything else ‘spins’ off that decision. Lower voltage systems (80v to 160v) have been used for years, are generally lower cost and lower power AC motors (Hyper 9 is a good example). Higher voltage systems (300v-800v) are what the OEMs are using and are also typically higher power AC motors/inverters. If you want to use any components from OEM donor vehicles like Tesla, VW, Jaguar Land Rover etc, you will be committing to a high voltage setup. You need to determine the power you require and see what is available/affordable. The inverter obviously needs to be compatible with the system voltage/motor you chose at the beginning. The ZONIC range of motors for example, come with matched inverters, are high voltage and can come with various gearbox options for transverse or longitudinal mounting.

What battery do I need?

A suitable high voltage battery pack will likely be the single largest expense of the conversion. It needs to be sized properly both in total energy capacity as well as instantaneous current capability to support the power you want to make, and not be too big to impact the vehicle’s safe handling. (Aim to stay within or at least very close to the vehicle’s original kerb weight). The BMS (Battery Management System) is the “brain” of a battery pack. It closely monitors the battery condition, voltages and temperatures down to individual cell levels and, working with the charger and Vehicle Control Unit (VCU), it tailors the energy flow in the vehicle to protect the battery cells under a wide range of

operating/charging conditions. It also balances the energy available within the individual cells allowing the most efficient use of a battery’s capacity and identifying problem cells before irreversible damage is done.

A BMS provides individual cell protection by monitoring each cell’s voltage as well as the current flowing into or out of the pack. This is used along with the cell’s characteristics to determine the maximum safe current limits in its present condition which it communicates to the VCU to set limits on available power as well as the allowable regeneration energy from the regenerative braking function, why would you not have re-gen – it’s free electricity? Having a quality BMS allows the maximum power to be safely extracted from/put into a battery module at any given time.

The cell balancing feature of a BMS extends the life of the battery by continuously matching the individual cell’s state of charge with each other whilst on charge. Battery

packs consist of many individual cells that have to work together so to fully utilise the available energy capacity from the battery all the cells in a pack need to be kept at the same state of charge; as the worst cell in a pack determines the current limits for the entire pack, an imbalance in an individual cell’s state of charge results in an overall loss of effective battery capacity. The BMS seeks to mitigate against this.

How big a battery do I need?

While it is impossible to say with any degree of accuracy given the almost limitless options for EV conversions, here are some very rough estimates for how many miles you can expect to travel for each useable kw/h of capacity your battery has.

■ Economy driving = 3.2 mi/kWh

■ Normal driving = 3 mi/kWh

■ Spirited driving = 2.5 mi/kWh

■ Racing = 1-2 mi/kWh

There are so many variables that affect this that you should take these numbers as a very loose guide.

How do I enclose the battery?