THE DIG PUTS HYUNDAI HX360L THROUGH ITS PACES

@CPN_mag cpnonline.co.uk

cpn@hamerville.co.uk e

Construction Plant News, Regal House, Regal Way, Watford, Herts, WD24 4YF.

16 DEVELON ups the ante in its demolition range with the introduction of the DX140RDM-7.

10 CPN takes a tour of Vertikal Days and reports on some highlights.

19 Increased functionality is the name of the game when it comes to telematics and Bobcat is bringing just that to its Machine IQ platform

Finning explains why understanding the difference between reman and rebuild is important for customers.

Net zero –aspiration or reality? Well, if one is to believe Nigel Topping, the recently appointed chair of the climate change committee (CCC), the UK could reduce carbon dioxide emissions to net zero as early as 2045. Topping sees a strong mandate for climate action among the UK public, saying that “the evidence we see is that people recognise that bold strong action needs to be taken.”

Thankfully the construction equipment industry, which has come under scrutiny as a carbon contributor, approximately 2% of the country’s total emissions, is taking positive action to rectify this and reduce and/or remove CO2 emissions. A recent study entitled Decarbonising construction equipment: management practices and strategies for net zero in UK infrastructure projects bears this out

Its findings recognisedvarious decarbonisation measuresalready in place, including adopting alternative biofuels, introducing electric and hydrogen-based equipment, establishing construction equipment-specific requirements and standards, integrating telematics and machine control technologies, and setting project and organisation-specific net-zero targets.

The study also identified challenges related to alternative fuels, supply chain coordination, technology adoption, and data management which all require attention to fully realise the potential of decarbonisation efforts. Addressing these challenges presents opportunities for industry-wide collaboration and innovation to achieve net zero emissions.

The Construction Equipment Associationcontinues to advance its own position as to how to reach net zero. Speaking at the recent Trade Association Forum’s (TAF) Best Practice Exchange, which was discussingWhat’s the Future for Net Zero?,CEO Viki Bell underlinedthe CEA’s position on technology neutrality and the need for supportive policy frameworksas the way forward.

She said: “The CEA remains technology-neutral. We do not advocate for one solution over another, as many technologies will be needed to meet the carbon agenda. We are also calling for recognition that developing these technologies is expensive, often requiring much higher research and development budgets, which should be supported. Technologyneutral outcomes are needed, not a mandated route pushing one tech area over another. The UK will also need a solid infrastructure to support these various technologies, from battery and charging to hydrogen production and storage.”

While these are admirable sentiments there remains lurking in the background the spectre of uncertainty and even watering down of net zero policies. According to Nigel Topping in an interview with the Guardian “the business community want strong, stable policy signals, and flip-flopping is not good for investment. We see it right now in the US with a huge brain drain and capital drain, as whole sectors are being de-invested or even attacked.”

“It’s been a real strength of the UK. That’s one of the main reasons to be concerned about the fragmenting political consensus, is if we start to signal to the world that we’re going to flip-flop, like the US.”

For construction equipment manufacturers, buyers, owners and operators, some degree of certainty though would be a valuable commodity.

Happy reading The CPN Team

Editor JOHNNY DOBBYN JOHN LEVICK

cpn@hamerville.co.uk

Advertising Manager PAUL FITZGERALD pfitzgerald@cpnonline.co.uk

Magazine Designer DONNA BOOTH

Production Assistant CLAIRE PICTON

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF.

Tel: Watford (01923) 237799 Fax: (01923) 246901

Copyright © 2025

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

LIAM LAMBERT, DIRECTOR OF LIAM LAMBERT CONSTRUCTION, HAS BEEN CROWNED CHAMPION AT THIS YEAR’S UK PLANT OPERATOR OF THE YEAR, WHICH TOOK PLACE AT CITB’S NATIONAL CONSTRUCTION COLLEGE (NCC) IN BIRCHAM NEWTON, NORFOLK, IN SEPTEMBER.

Construction, while Lewis Jarman from Breheny Civil Engineering picked up third place.

Gary Cumiskey, head of CITB’s NCC said: “This year’s competition didn’t disappoint – it was a hotly contested event! And it is such a wonderful reminder of the wide array of talent we have in the industry.

“On behalf of CITB I would like to congratulate this year’s winner, Liam Lambert, director of Liam Lambert Construction, and all the finalists for setting such high standards within the industry. Events like this are vital in highlighting the crucial role plant operators play in building the UK’s infrastructure safely and

HENRY BOOT HAS SUCCESSFULLY COMPLETED A TRIAL OF HYDROGENATED VEGETABLE OIL (HVO) FUEL AT ITS PLANT HIRE BUSINESS, BANNER PLANT, AS PART OF ITS COMMITMENT TO IMPROVE FUEL RESILIENCE AND REACH NET ZERO CARBON BY 2030. AS A RESULT, THE GROUP IS NOW PREPARING FOR A WIDER ROLLOUT OF HVO FUEL ACROSS ITS OPERATIONS.

The trial saw Banner Plant operate a selection of its fleet using HVO provided by Certas –a renewable, drop-in alternative to diesel that can reduce greenhouse gas emissions by up to 90% compared with traditional fuels.

According to Henry Boot, the pilot scheme demonstrated strong operational performance and carbon savings of 95 tonnes.

Serena Lang, non-executive director, said: “The success of our HVO trials will see it become a vital element of our journey towards decarbonisation. The cost efficiency, fast implementation potential,

efficiently.”

Jeff Schofield, director of UK Plant Operators magazine added: “UK Plant Operator of the Year gets bigger and better every year. This year we had record applications to compete and over 2,000 people registered to attend. We trust that we were able to inspire a next generation to consider a career in construction by training to be a plant operator at CITB’s National Construction College in Bircham Newton.”

WWW.RDR.LINK/CBE001 i

and immediate carbon savings make it a practical solution that we can deploy and scale now, while also continuing to explore and evaluate a broad range of decarbonisation strategies.

WWW.RDR.LINK/CBE002 i

division manager for parts. “This is particularly useful for those who are working away from base, as it can save a lot of time while also contributing to a reduction in downtime.”

For more information

WWW.RDR.LINK/CBE003 i

SMART CONSTRUCTION, THE DIGITAL ARM OF KOMATSU, SAYS IT IS ENHANCING THE MANUFACTURING PROCESS OF THE EXCAVATOR RANGE TO OFFER THE FIRST ‘BESPOKE’ MACHINE FROM THE FACTORY.

Its European team claims the new ‘fitted at the factory’ process, is set to revolutionise the manufacturing of Komatsu’s PC240 and PC228 crawler excavator models.

Smart Construction 3D machine guidance, which was previously retrofitted locally or in the field, will now be fitted during the machine assembly at the factory - offering a fully bespoke, digital-first machine.

Bart Vingerhoets, senior commercial manager, commented: “With installation now taking place at the factory, Komatsu Smart Construction is proud to expand the capabilities of its technology-fitted excavators, which is set to support the digitalisation of the construction industry, both for today’s jobsites and those of the future.

IPAF IS WARNING THAT CERTAIN CONSTRUCTION HOIST MANUFACTURERS ARE MARKETING EQUIPMENT, DESCRIBED AS ‘TRANSPORT SYSTEMS’ OR OTHER SIMILAR TERMINOLOGY, THAT LOOK LIKE TRANSPORT PLATFORMS, BUT WITH OPERATING SPEEDS AND PASSENGER CAPACITIES THAT EXCEED THE LIMITS SET FOR A TRANSPORT PLATFORM IN THE EUROPEAN STANDARD EN 16719.

Suppliers of the aforementioned machines, which do not comply with the EN 16719 standard for transport, claim that these products have been ‘approved’ and certified by a third party. IPAF considers this to be a dangerous and unacceptable practice, warning all relevant stakeholders across the industry that safety is being compromised, there are possible legal consequences, and it is damaging to the industry.

Brian Parker, head of safety & technical, said: “These improperly labelled ‘transport platforms’ are operating outside the safety limits defined by EN 16719 and EN 12159, putting users at unjustified risk. These standards exist for a reason – to ensure that equipment is used safely and appropriately. Any attempt to circumvent them, even using third-party certification as justification, is both dangerous and misleading. Industry stakeholders must refuse unsafe practices and stay committed to equipment compliance to protect operators and maintain trust in the sector.”

For more information

WWW.RDR.LINK/CBE004 i

WWW.RDR.LINK/CBE005 i

THE PROPERTY CARE ASSOCIATION (PCA) IS URGING THE PRIORITISATION OF WASTE DISPOSAL PRACTICES THAT HELP PREVENT THE SPREAD OF INVASIVE NON-NATIVE PLANTS (INNPS).

Increasingly, evidence indicates that waste soil containing invasive plant material is being diverted to quarry infill or land reclamation schemes rather than landfill.

PCA chief executive Sarah Garry said: “We’re calling on the Government to reward or enhance incentives for low environmental impact remediation methods that avoid landfill and urging professionals in the waste recycling sector to understand the key role they can play in preventing the environmental and economic harms caused by the spread of INNPs.”

Soil contaminated with fragments, seeds or rhizomes of non-native invasive species such as Japanese Knotweed has limited options for reuse or recycling and its removal is a fundamental step towards restoring land with a view to achieving Biodiversity Net Gain.

For more information

WWW.RDR.LINK/CBE006 i

EURO AUCTIONS HAS ANNOUNCED THE LAUNCH OF ITS LATEST PERMANENT SALE SITE IN MOUNTRATH, COUNTY LAOIS, IRELAND.

The new site is located in the heart of Ireland, positioned on the R445 between Dublin and Limerick, with excellent transport links, including the nearby M7 motorway. The facility will serve contractors, farmers, dealers, and fleet operators across Ireland, providing a powerful new platform for buying and selling machinery through live, on-site public auctions, says Euro Auctions. Cathal Doherty, Euro Auctions’ territory manager for Ireland, said: “We’ve long wanted a permanent sales site here in Ireland, and we’re genuinely excited. Euro Auctions has run numerous off-site auctions here over the years, and the sheer volume and variety of machinery available is staggering. You never quite know what’s going to come through the gates.”

WWW.RDR.LINK/CBE007 i

QUATTRO PLANT, ALONGSIDE INETIC AND EV PARTS, HAS WON THE PRESTIGIOUS 2025 NICK CARPENTER INNOVATION AWARD AT CENEX EXPO FOR ITS BATTERY-ELECTRIC CONVERSION OF A 4WD MEWP OFF-HIGHWAY CONSTRUCTION VEHICLE. WITH ONE TONNE OF CO2 SAVED PER VEHICLE, PER YEAR, THIS IS ANOTHER SOLUTION ON QUATTRO’S PATHWAY TO NET-ZERO.

John Murphy, Quattro MD, said: “I’m delighted to receive the Nick Carpenter award for innovation on behalf of our team at Quattro Plant and our consortium partners, iNetic and EV Parts. The funding offered by the Niche Vehicle Network has been invaluable. The collaboration will go beyond the scope of the project as we look to implement the system into future vehicles. This is our road to net zero.”

The NVN Nick Carpenter Innovation Award was created in memory of pioneering technical director and co-founder of Delta Motorsport, Nick Carpenter, a key figure within the EV industry and NVN advocate. It celebrates the visionaries behind the latest cutting-edge niche vehicle design and sustainable technology.

WWW.RDR.LINK/CBE008 i

pedestrian access.

WWW.RDR.LINK/CBE009 i

ERNEST DOE CONSTRUCTION IS THE LATEST AUTHORISED MERLO CONSTRUCTION DEALER TO BE APPOINTED BY THE MANUFACTURER. WITH A NETWORK OF BRANCHES SERVING EAST ANGLIA, THE EAST MIDLANDS, AND SOUTH-EAST ENGLAND, THE BUSINESS HAS BUILT A REPUTATION FOR DELIVERING HIGHQUALITY EQUIPMENT, EXPERT ADVICE, AND FIRST-CLASS CUSTOMER SUPPORT.

Merlo telehandlers will now join Ernest Doe Construction’s line-up of leading brands, reflecting the dealer’s recognition of the growing demand for versatile, high-performance materials handling equipment that can operate efficiently on sites where space is limited.

Graham Parker, sales director at Ernest Doe Construction, commented: “Merlo’s innovative telehandlers are a natural addition to our construction offering. We pride ourselves on supplying machines that deliver exceptional performance and reliability, and Merlo’s reputation for quality fits perfectly with our approach. We’re excited to introduce this innovative range to our customers and provide them with even greater choice and capability.”

The Merlo range will be available from five dedicated construction branches: Albourne, Benington, Dartford, Ulting, and Wymondham.

WWW.RDR.LINK/CBE010 i

buckets for 3-tonne machines; type 2 buckets for 5- and 8-tonne machines; and type 3 buckets for 14-tonne machines

“Lynch’s strong focus on safety, digital innovation and productivity aligns with RodRadar’s breakthrough and easy-to-use technology. Our customers have identified that utility strikes are a significant concern, and we believe that the LDR bucket is the answer”, said Chris Gill, director at Lynch.

For more information

WWW.RDR.LINK/CBE011 i

CPN braves the elements at Vertikal Days to bring you a flavour of what was on offer from the world of cranes and access.

The British love talking about the weather and the recent Vertikal Days exhibition was a case in point. How two days could follow exactly the same weather pattern – bright but blowy in the morning, torrential rain and thunder in the afternoon – only a meteorologist could say. To call the weather after lunch inclement would be an understatement as visitors sheltered in the various marquees, nursing a free coffee and a slice of cake, listening to the rain drumming insistently overhead.

While people looked towards the heavens, there was still plenty to see on the ground when conditions permitted. Newark showground’s kilometre long Vulcan runway featured stands from many of the leading brands and distributors, a diverse mix of machinery dedicated to the lifting and working at height industries. Boom lifts, tower cranes, spider cranes telehandlers and hoists don’t even cover it. No surprise then that the organisers claim that the event is the leading specialist cranes, access and telehandler exhibition in Europe.

Tracked access and spider lifts seem to appeal to our readers and there was no shortage of these versatile machines on display. Access Platform Sales had several

Hinowa models, most notably the 40m 40.18 tracked spider and smaller sibling the 26.14. Next door Promax Access featured the brand-new Platform Spider 54T. With a 54m working height and 20m outreach, it features a four person, 400kg cage capacity, an OEM 125kg cage winch and optional 1000kg hoist attachment for heavy-duty lifting. At the other end of the scale the new, nifty and slimline Spider 18.95 has a working height of 19.6m, a maximum outreach of 9.6m and a safe working load of 230kg. With radio control and a hybrid option, the model should lend itself to many applications.

Italian manufacturer CMC was exhibiting its LC Series of tracked aerial platforms which are recognised for their reducedweight and maximum compactness. The three different models featuredouble pantograph and telescopic arm plus jib andare designed and built to give the maximum in terms of operational efficiency, versatility of use and transportability. The small S15is ideal for working inside large buildings, the new S20 is characterized by a 10.4moutreach, andthe allpurpose S23, is itslatest-generation platform.

As is the norm these days at any construction machinery show, there were plenty of Chinese OEMs in evidence. Dingli showed two articulated boom lifts; the 138ft BA44HRT uses a three section lower boom, three section top boom and an articulated jib to achieve a 44m working range. The hybrid 54ft BA16MRT2 has a 16.27m working height, 320kg platform capacity, four-wheel drive and twowheel steering.

The green liveries of Liugong machinery stood out as the Chinese OEM displayed a raft of kit from its aerial work platform range including the 11.2m LM09JE mast boom, making its UK debut. It offers 3m of outreach and 200kg platform capacity. Alongside was parked another new model, the 19ft LS0608E that comes with a 7.8m working height.

In contrast to the green of Liugong was the vibrant red paintwork of the LCMG machinery. The company’s stand was packed with new launches including its next generation electric scissor and boom lifts. These feature magnetic drive motors for smoother performance, greater energy efficiency and reduced maintenance. Another new introduction was its new generation boom lifts that come equipped with an all-new single drive motor that is

designed to improve fuel efficiency, lower overall weight and a more compact chassis. Other equipment on show included the 2500kg/5.94m H625E compact electric telehandler and the recently introduced T14J-2 telescopic boom, the S0607E-2 slab scissor and AR18J-2 articulated boom lift.

Hered might be a name that’s unfamiliar, but this Chinese OEM was making its debut, showcasing several new models including its 42ft HA12CEA electric articulated boom lift that features 14.6m working height, 200kg platform capacity and 6.82m of outreach at an up and over height of 6.79m. It weighs in at 5250kg. It also had two new 39ft scissor lifts on the stand, the HC1216E-R tracked lift and the HS1218ERT rough terrain.

Dutch spider and mini pick + carry crane OEM, Hoeflon, showed four models of varying sizes; the 550kg capacity C1e Compact, the 3000kg/16m electric C6e, the 400kg/19.8m electric C10e and its most powerful option, the 9-tonne capacity C30e. These bits of kit are made even more versatile with the Hoeflon Multitool crane attachment for placing beams, pipes, sheets of glass and pallets, very handy around site.

No wander around Vertikal Days is complete without a visit to Liebherr. The German giant was showcasing three UK debutants: the 130 tonne LRT 1130-2.1 rough terrain, the first two axle RT with a 60m main boom; the 150-tonne electric powered LTM 1150-5.4 E all terrain; and the MK120-5.1 E self-erecting tower crane.

Some say he’s best in a backhoe, others that he excels in an excavator. All we know is that we call him The Dig. This month he explores Hyundai’s all new HX360L

The latest next generation Hyundai hydraulic excavators were presented to the public for the very first time at Bauma last April, with the 36-tonne class HX360L being the focal point of the daily live demonstrations.

That same HX360L, along with other new Hyundai machines, was made available for a ‘first drive’ event at the training school not far from Hyundai Construction Equipment Europe’s European facility in Tessenderlo, Belgium.

Being an excavator man, I was naturally drawn to the HX360L from the start. Walking around the machine and one cannot but fail to be impressed with the new styling, which I would describe as dynamic and bold, but these machines are much more than just a cosmetic makeover, they are a totally new design and brimming with the latest technologies.

Climbing up onto the upper structure you are guided by the standard fitted handrails, enabling three points of contact on the initial climb. This example didn’t have the full wrap around boxing ring (fall from height protection) but one would imagine UK spec ones will be supplied with that set-up.

Out with the old, in with the new Popping the engine bonnet we notice a big change, no longer home to a Cummins power pack, the new machines feature Hyundai’s own DX08 diesel engine, which was recently awarded the prestigious title of Diesel of the Year 2025.

This clean sheet design six-cylinder EU Stage V/Tier 4F emissions compliant engine has a maximum power output rating of 227kW (304hp) @1800rpm, and an impressive and powerful 1,230Nm of torque @1200rpm. It features a two-stage turbocharger, which Hyundai suggests offers a 23% higher power output than previous generation engines. In addition, this engine is said to offer an 8% fuel efficiency gain over the old powerpacks.

These engines have been specifically tailormade to meet the arduous demands of powering a hydraulic excavator. In terms of maintenance, oil filter and oil change intervals have now been increased from the previous generation machines at 500 hours, to 1,000 hours, further reducing downtime and costs overall.

The engines meet the EU emissions regulations without the need for costly exhaust gas recirculation (EGR) and diesel particulate filter (DPF) cleaning intervals are extended up to 8,000 hours.

A massive air pre-cleaner filter was fitted on this example and an auto greasing system which is an optional fitting but, in my opinion, well worth investing in on a production machine like this.

Coming back down to ground level and wandering around to the near side rear, we notice that some things remain the same as ever. Opening up the wide twin rear panel doors, reveals the usual fare, with the cooling packs and air conditioning radiator all easily accessible for cleaning of debris. In addition, the machine is fitted with a reversible fan which also assists with keeping cooling packs clean of debris

Behind the panel closest to the cab, we find the air filter housing, 24-volt batteries, major isolation switch, windscreen washer bottle and other electrical components. There are also plastic covers on the batteries, so you could potentially store some cloth lifting strops in there too if needed.

To the offside rear, no surprise, it’s home to the main hydraulic pump, which is the latest design from Rexroth. Both the HX360L and HX400L are the first Hyundai excavators to feature full electrohydraulic (FEH) control of main pump flow and the individual control valves. This precise control of hydraulic output, through the use of EPOS (electronic pump optimising system) and a virtual bleed-off valve, is said to improve responsiveness for the operator and reduces fuel consumption.

Also, in this area we find the engine oil and fuel filters, all easily accessible from ground level, or for someone of my stature, aided by a small box step, this is also home to the electric refuelling pump which is a standard fitment.

Sometimes it’s the little things that make a big difference, and on the HX360L, even the door opening handles and opening retaining latches have a feel of good quality about them.

On the undercarriage it’s the well proven and strong X-frame design, sitting on standard

600mm track pads, the track length on this model is 4958mm, with a track width of 3280mm. Nine lower track rollers are fitted with two top rollers, with three track guards to prevent de-tracking.

At the business end the HX360L has a boom length of 6500mm and a dipper arm length of 3200mm, and according to Hyundai hydraulic pipework has been re-routed for improved protection against accidental damage, with trees for instance.

Climbing up into the extremely spacious next generation cab and my first impressions immediately were wow! We see a lot of cab interiors in the line of duty, and I often think just how can they can be improved, but it appears that Hyundai has once again taken it to another level.

Starting with the seat, this example was fitted with the optional ‘comfort pack’

“... my first impressions immediately were wow!...”

the right-hand joystick. There is also a digital key option which allows the cabin to be opened and the engine started via a smart phone app, this digital key can be shared by up

On dark mornings operators will be delighted to see the welcome light strip, incorporated into the front console, lighting up the floor area and further improving safe access to the seat. Talking of the floor area, a newly designed mat is fitted which looks like it will be easier to sweep out at the end of a shift.

These machines can be supplied with optional new technology, like the automatic weighing function, that measures the weight of the material inside the bucket, allowing for the precise calculation of truck loads and even volumes of material on site.

Another option is the lift assist feature which offers operators a visual guide on the screen, divided into four visible quadrants, which display the safe zones for lifting a particular load ensuring maximum stability during a lifting operation.

The e-boundary option is another piece of technology that can be used to set a ceiling height, floor or wall boundary, similar to other manufacturers systems we have seen in recent years. This version can be used to stop the machine slewing out into a live traffic lane for

instance, or to prevent accidental collisions with buildings or other structures when set to do so.

Also, as an option is the radar object warning system which features three wideangle radars capable of detecting people, objects or even other items of plant which may be approaching the machine’s working area and offers an audible and visual alarm. The e-stop function, when activated, can even slow down the machine and eventually stop it if it’s a dangerous situation. This is controlled by a fourcorner beacon set up on the roof of the cab.

The machines come as standard with Hyundai’s Hi MATE telematic system and equipment health management (EHM) technology ensures real-time monitoring of the working condition of the machine, ensuring the service department can predict any future problems ahead of a costly breakdown.

Taking to the seat I took a few moments to acquaint myself with my surroundings and to adjust the seat to my requirements. Starting involves pressing the start button and holding it down for a split second then the machine springs to life. I was initially greeted by a loud beeping noise, which was apparently the advanced detection system (ADS) telling me there were people nearby, although a considerable distance away, though it was great to witness the technology at work.

However, I decided to isolate the function via the monitor and was just greeted by the purr of the six pot Hyundai diesel. A quick tweak of the throttle dial to up to the P position and the engine was up to full chat.

Releasing the isolation lever on my lefthand side and with a tug on the right-hand joystick the boom powered up and we were away. Climbing up on a heap of previously excavated material I proceeded to dig out more from the hole. The soil here was extremely sandy and had probably have been dug over 1000 times before, so it presented no challenge to the big 36-tonner even with its biggest bucket on board.

However, this soil was damp and pretty heavy so over the side with a full to the brim bucket, you knew you had it out there, but try a I might to unsettle the machine it largely remained planted.

I would best describe the pace of the HX360L as steady and certainly lively enough, but I still felt it needed a bit more, so I opted to press the HP button. The change in both speed and power was, I felt, quite dramatic and

“...try as I might to unsettle the machine it largely remained planted...”

I quickly warmed to the new performance level. Talking of warmth, by now the early morning sun was piercing the glass so after a bit of navigating I found the airconditioning/blower selection screen, which by then was a welcome relief!

The machine features the company’s new FEH (fully electrohydraulic) which, it says, improves fuel consumption by controlling the flow rate via an EPOS (electric power optimising system).

Hyundai states that FEH controls send an electrical signal to the control valves, delivering faster, more accurate operation of hydraulic functions. There is no back pressure or energy loss, as the exact oil flow and pressure is delivered when required, resulting in a fuel efficiency improvement of up to 8% over hydraulic servo levers.

Personally, I’m not a fan of electrohydraulic controls. They kind of feel numb to me; it’s the

little things like trying to fire some material towards yourself with a quick jerk of the dipper arm lever, it just doesn’t seem as effective with electro hydraulics as it used to with traditional servo controls.

I also found fine grading a little bit tricky as there always seemed to be a dip at the transition point of bringing in the dipper, however, one would get used to it after a day or so of constant operating. In all other aspects the machine was super smooth, had impressive power and performance.

I especially liked the joystick-controlled tracking, with just a click of an index finger on the left-hand control lever, I could travel and steer the tracks with that one lever, a feature that would be very useful on site.

The entry level

DX140RDM-7 might be the smallest in DEVELON’s demolition excavator range but it has some big features.

With the introduction of its new DX140RDM-7 model, DEVELON has increased its offering to the demolition industry and now offers a total of four specialised machines with operating weights up to 71 tonne and a reach of up to 31m. The model line-up in ascending order is as follows - DX140RDM-7, DX245DM-7, DX380DM-7 and the top-of-the-range DX530DM-7.

All the models in the demolition excavator range meet the Stage V emission standard and are powered by engines with outputs up to 294kW (394hp). All four machines are said to offer great flexibility thanks to their modular boom design and hydraulic locking mechanism and boast a maximum payload capacity of up to three tonnes at the boom.

The DX140RDM-7 can be supplied with either a monolithic or interchangeable boom on request. The DX245DM-7, DX380DM-7 and DX530DM-7 always have an interchangeable boom, which not only increases the machines’ availability but also significantly simplifies transport. This is also facilitated by the low

transport width of the machines from 2.5 m thanks to the extendable chassis.

Like the three larger models from 31 to 61 tonne, the 22.5-tonne DX140RDM-7 demolition excavator offers multiple configurations to choose from, providing the operator with a range of solutions depending on the project to be completed, including a multi-purpose version that can be used for other applications on site as well as demolition.

In terms of choices the DX140RDM-7 offers lots of options, starting with a monolithic variant unique to this model that features only a demolition arm without any possibility of interchangeability. Alternatively, like the larger machines, the DX140RDM-7 is also available in a

dual format utilising a modular boom design and hydraulic lock mechanism, allowing the user to change between different arms for demolition and digging using the same machine.

In the fixed monolithic version of the new DX140RDM-7, the machine can work with a demolition attachment to a maximum height of 16m. The recommended maximum tool weight in this mode is 1450kg. In common with the other models in the demolition excavator range, the DX140RDM-7 offers high visibility and a 30o tiltable cab, particularly suited to high reach demolition applications.

In the dual purpose version of the new model, the pin height and maximum tool weight are 14m and 1450kg respectively (with a 2m extension as an option). All the components such as the undercarriage, the tilting cab and the

“...the 22.5 tonne DX140RDM-7 offers multiple configurations...”

shoes remain the same as in the fixed version, only the modular boom design and hydraulic lock mechanism are different, allowing the user to swap between demolition and digging arms.

The clever design ensures it is a simple process to change between a demolition boom and an earthmoving boom to accomplish different types of work on the same project. A special stand is provided to facilitate the boom changing operation, which is based on quickchange hydraulic and mechanical coupler connections. A cylinder-based system is used to push the locking pins into place to help complete the procedure.

The multi-boom design also allows the earthmoving boom to be mounted in two different ways, which with the demolition boom, provides further flexibility with a total of three different configurations for the dual-purpose base machine.

The DX140RDM-7 has a hydraulically adjustable undercarriage, which extends to a maximum width of 3.7m to provide optimum stability when working on demolition sites. The width of the undercarriage can be retracted hydraulically to 2.5m in the narrow width position, which is ideal for transporting the machine. The mechanism is based on a permanently lubricated, internal cylinder design which minimises resistance during the movement and helps to prevent damage to the components.

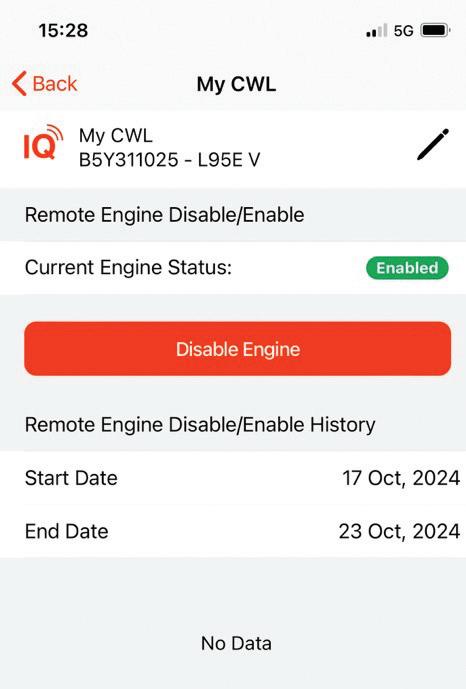

Bobcat has added a remote engine disable/enable feature on the company’s Machine IQ telematics platform. This feature allows customers in Europe to remotely enable or disable their machine’s engine through the owner portal or Machine IQ app. With remote engine disable/enable, operators and owners can shut down their machine with a few clicks, deterring theft and aiding in quick machine recovery.

Machine IQ, launched in 2023 in Europe, allows connected-machine owners to monitor the health of their Bobcat machine and remotely track information that enhances maintenance, security and performance. The remote engine disable/enable feature represents the first two-way update for the telematics system, allowing operators to both send commands to and receive data from the machine. Remote engine disable/enable via Machine IQ can be activated in Bobcat skid-steer and compact track loaders, mini excavators and compact wheel loaders connected to the system.

“Enabling advanced theft deterrence provides critical peace of mind for our Machine IQ users, and remote engine disable/enable allows our European customers to protect their equipment and allow only authorised usage. This feature also demonstrates our ability to interact with machines via two-way communication using telematics. It marks another major milestone for

what Bobcat continues to do - to empower our customers to accomplish more,” said Tomas Plechaty, Machine IQ senior program manager at Bobcat EMEA.

Available with premium Machine IQ subscriptions, this innovative solution lets customers remotely prevent theft and unauthorized use in just a few clicks. If unauthorized use is suspected, customers can log into their Bobcat owner portal or Machine

IQ app to select the asset, and click ‘Remote Engine Disable/Enable’ in the sidebar. Only administrative users can access this feature, and all remote engine disable/enable activity is tracked in the asset’s history table. Upon executing the disable command, any attempt to start an engine in an off state will fail. If the machine is in operation, the engine will shift into de-rate mode.

The company claims that the new functionality brings multiple benefits including: deterring theft, and potentially recovering stolen machines. By remotely disabling engines, unauthorized use can be stopped, and recovery efforts aided. It can also lower insurance rates by demonstrating a proactive commitment to investment protection that potentially can make customers eligible for lower theft-related premiums.

More benefits accrue for premium subscribers as the remote engine disable/enable extends functionality for premium subscribers, creating more value for customers.

Bobcat also believes it boosts resale value by locking in future-proof security and making resale a more attractive, and potentially highervalue, investment for discerning buyers. In addition, there’s the possibility to improve payment compliance for rentals, where remote engine disable/enable can be used for delinquent rental accounts, encouraging prompt payment and reducing revenue loss.

Finally it can help enforce safe operating procedures and prevent potential damage;

“...we are confident that the packages will meet the needs of customers...”

engine operation can be temporarily disabled in response to unauthorized use, unsafe behaviour or potential machine misuse.

With Machine IQ, customers have 24/7 access to crucial machine information on their smartphones or computers. Equipped with this information, customers can optimize machine use and plan jobs for maximum profitability by keeping idle times to a minimum and tracking fuel consumption. Service planning is made easy with maintenance notifications, saving operators time and money by allowing them to efficiently schedule machine maintenance and manage job sites during planned downtime.

Dealers and customers can choose from two options: a standard package with basic telematics and a premium package with additional advanced features. According to Tomas Plechaty, the subscription options let users tailor their experiences and access the level of connectivity and insights that best suit their needs. “With a focus on simplicity for the user, we are confident that the packages will meet the needs of customers and dealers across the globe, and help them grow their businesses,” he said.

Machine IQ comes factory-installed with many equipment models and can easily be installed on compatible Bobcat machines in the field. Customers should contact their local dealer to check compatibility. Bobcat customers can access Machine IQ by visiting my.bobcat.com, creating an account and logging in. Alternatively, the mobile app for Machine IQ can be downloaded from Google Play/Apple Store.

The terms ‘reman’ and ‘rebuild’ are often used interchangeably, leading to ambiguity about which best serves a customer’s needs.

According to Mark Tudball, product manager aftermarket at Finning UK & Ireland, the terms have distinct meanings and distinguishing between them is crucial.

The differences between reman and rebuild have significant implications for customers. Understanding the difference helps customers find the right repair option and, in the process, extends the life cycle of the machine and ensures the maximum return on investment.

With rising costs and sluggish growth, cost effective maintenance is more important than ever. In addition, as environmental regulations become increasingly stringent, it is at the forefront of most customers’ minds to find sustainable alternatives to buying new. This is where remanufacturing and rebuilding come in.

Finning shares Caterpillar’s definition of remanufacturing, which states that a Cat certified reman is not a repair, neither is it refurbishment, recycling, repairing or reconditioning. It is a rigorous engineering process that restores parts to a ‘like-new’ state.

The remanufacturing process restores parts at the end of their lives to ‘like-new’ condition by following a cycle that lasts approximately three to eight weeks. At the end-of-life stage, parts are disassembled, cleaned and inspected. Then the parts are either reused or replaced –all replaced parts are remanufactured or recycled –before being reassembled and tested to ensure their performance is comparable to new.

This comprehensive process provides a cost-effective alternative solution to buying brand new parts and is fully supported by a warranty, comparable to that which would accompany a new product, but at a lower cost.

“...the remanufacturing process restores parts at the end of their lives to 'like-new' condition...”

Reman reduces waste and emissions, with measurable sustainability benefits. For example, Finning has recycled 3279 tonnes of metal, all of which was diverted from landfill. The process is also responsible for a significant reduction in greenhouse gas (GHG) emissions, producing 6587% less GHG emissions compared to the manufacture of new parts, as well as using fewer raw materials, energy, and water.

Whereas remanufacturing transforms parts to ‘like-new’ conditions, rebuilding is defined by Finning as the renewal of machines approaching the end of their prime, serviceable life. The Cat certified rebuild process means cleaning, inspecting or replacing necessary, worn or broken parts (with new or reman parts) and is used to extend the life cycle of machines.

A full machine rebuild is the most comprehensive offering where the machine is stripped to the bare chassis and up to 7000 parts are replaced with new or reman parts, giving the machine a new lease of life.

Similarly, a powertrain rebuild can mean the replacement of up to 3000 parts with new or remanufactured parts; this can include the engine, transmission and torque converters and will extend the service life of the machine.

Recently, Finning has increased its rebuild offering to include the ‘Rebuilt and Ready to Go’ option. This purchase option is a response to growing industry demand for flexible, lower-cost ownership that doesn’t compromise uptime, safety or performance. Finning identifies suitable machines from its own used stock, rebuilds them to like-new condition, and makes them available to buy with warranty cover, finance options and ongoing support.

Unlike traditional rebuilds, which require customers to take their machine out of service for a period, ‘Rebuilt and Ready to Go’ machines are available immediately. Each unit undergoes a full Cat certified rebuild process, including the powertrain and hydraulics, new undercarriage or tyres, cab upgrades, repainting, updated decals, full welding and bodywork where required, and installation of new ground engaging tools. Machines also come with a five-year warranty and a Customer Value Agreement (CVA) ownership plan that includes parts delivery and maintenance.

All Finning machines that undergo a Cat certified rebuild use Cat reman parts as a core component of the rebuild process to ensure a cost-effective, high-performance and sustainable outcome that is backed by warranties designed to fully protect customer investments.

Only by understanding the differences between reman and rebuild, can customers choose the best for their machines and applications.

Recently, WM Plant Hire made the decision to rebuild its Cat 345C LRE, driven by sustainability, cost and the company’s fondness of the excavator due to its reliability. The factory-built Cat 345C LRE, which features a 20m long-reach configuration with upgraded undercarriage and hydraulics, had over 12,000 hours on the clock. Finning carried out a full inspection before reconditioning the engine at its specialist Component Rebuild Centre in Leeds. The rebuild was delivered within an agreed budget and supplied with a five-year warranty on key components, offering additional peace of mind.

“...a full machine rebuild is the most comprehensive offering where the machine is stripped to the bare chassis and up to 7000 parts are replaced...”

Making the right choice not only supports economic efficiency, but assists customers in meeting environmental objectives, supporting the wider industry’s move towards waste and emissions reduction. Each machine and component has a unique set of requirements, and there is no one size fits all solution. By not taking time to understand the nuances between reman and rebuild there is a risk of missed opportunities, increased downtime and costs.

To ensure customers can make informed decisions, it is vital that customers seek advice from their local Finning representative. By engaging with knowledgeable partners, customers can access the latest strategic advice that will allow them to prolong their machine’s life and receive the biggest ROI.

Finning can advise on the full range of options, allowing for significant customisation to

suit the intricacies of each individual project. When Heidelberg Materials UK was looking into options for its Cat 988XE wheel loader as it began to reach 18,000 hours, the operational team began discussions with Finning to identify the best solution for replacement that fulfilled both the company’s commercial needs and sustainability objectives. Having had a full service and maintenance programme meant the machine was in good condition to be rebuilt.

Finning guided the customer through the process of comparing the benefits of buying a new machine versus a rebuild, and the conclusion was that the rebuild was best for the customer. This not only supported its commitment to sustainability, it enabled it to reduce its carbon footprint. In addition, choosing to have the machine rebuilt also meant the machine could be back operating on-site within 12-weeks. Finning was also able to provide a five-year warranty to add reassurance that the machine will continue to operate effectively during its second life.

In an industry where machine uptime, cost-effectiveness and sustainability are essential, developing an understanding of the difference between remanufacturing and rebuilding is crucial for machine owners.

While the rigorous engineering and testing throughout the reman processes restores machine components to a ‘like-new’ condition, rebuilds provide a tailored solution to give a second life to machines that have passed their prime, utilising reman parts throughout the process. Both options offer substantial financial and environmental benefits compared to buying new. However, the choice between them depends on individual factors such as age, condition, application and the customer’s business objectives.

Making the right investment requires a good understanding of the distinctions between these options, as well as access to expertise and support from dealers. As such, it is vital to partner with experienced, trusted dealers, such as Finning, who can ensure customers receive tailored recommendations that will not only maximise their ROI but enhance machine reliability with the backing of robust warranty and support.

Significantly, recognising the unique value of reman and rebuild solutions, backed by strategic expertise, lets machinery owners access the multiple economic and environmental benefits these options provide, and as a result future-proof their fleet, operations, and businesses in an everevolving industry landscape.

L Lynch Plant Hire is equipping all of its new articulated dump trucks and dozers with the FuelActive clean fuel delivery system, following extensive on-site trials. The company predicts that it will remove 970 tonnes of CO2 from the atmosphere and cut £370,000 in fuel costs from its ADT fleet alone, in a full operating year.

Having been convinced of the uptime benefits on previous installations, the company was keen to verify FuelActive’s fuel economy and sustainability claims, conducting a controlled trial on one of its own earthmoving projects, where five machines were equipped with the FuelActive system and five were not.

“We had 10 identical ADTs, all doing the same route, being loaded by the same machine, at the same weight. That enabled us to be completely fair,” said James Bardon, head of major projects and innovation. “We used OEM telemetry to compare 960 data points over 5,000 operating hours. The machines with the FuelActive system averaged a 3.6% fuel saving. That’s equal to a £9,000 reduction in fuel over a year across the 10 trucks, taking 20 tonnes of CO2 out of the atmosphere.”

The test was so successful, that Lynch has decided to fit FuelActive across a growing number of machines in the fleet. It has already seen 50 units installed, with more to come.

“All new ADTs and dozers will have FuelActive installed before they are sent to site,” said Bardon. “We are also reviewing the installation for excavators and other equipment and expect to install these later this year.”

While fuel savings and a reduction in CO2 emissions are welcomed by both the plant hirer and its customers, Lynch initially opted to fit the FuelActive system as a way to reduce downtime on site.

“We did have a problem at the time, from AdBlue systems and contaminated fuels,” explained Bardon. FuelActive promised to eliminate this problem, by only taking the cleanest fuel from the tank, so we had to investigate it.”

“...the machines with the FuelActive system averaged a 3.6% fuel saving...”

FuelActive’s fuel pick-up pipe can be installed in any fuel tank, across all types of on and off highway machinery. Whereas a conventional OEM pick-up will take fuel from the bottom of the tank, the FuelActive system uses a floating pick-up, that ensures that only the cleanest possible fuel is delivered to the engine’s fuel injection system.

“On some projects, for whatever the reason, the fuel has been contaminated with water and the machines now are so sensitive, especially if they are running SCR (selective catalytic reduction). Any small amount of water can bring that machine to a stop,” said Bardon.

“That leads to downtime for our customer, which is what we are trying to avoid. From the instant that we installed FuelActive, we have never had a case of fuel contamination stopping a machine that is fitted with the system from operating.”

Bobcat has delivered 10 more new T76 compact track loaders to add to the fleet at independent plant hire company, H. E. Services (Plant Hire) Ltd, based in Strood in Kent.

“Since they arrived, we have seen constant demand for the new Bobcat T76 track loaders, which are available to hire from any of the 11 strategically located H. E. Services depots across the UK, for use on construction and agricultural sites throughout the country. The additional 10 loaders will help to ensure that our fleet is ready to provide our customers with the best equipment at all times,” said Malcolm Gough, national hire manager.

He continued: “The T76 machines are a testament to the reputation for innovation and quality that is associated with the whole product range from Bobcat, allowing us to enhance our customers’ productivity and meet the rigorous demands of our clients’ projects. This acquisition

of the latest plant machinery marks the beginning of a sizable expansion and enhancement of H. E. Services’ already extensive machine inventory.”

Graham Deacon, national & key accounts sales manager for Doosan Bobcat for the UK and Ireland, stated: “We are delighted that H. E. Services has been impressed with the demand for our latest T76 models. Their commitment to excellence mirrors our own, and we are confident that the latest machines will continue to be in high demand and add to the ongoing success at H. E. Services.”

GOTO

WWW.RDR.LINK/CBE018

West Wales contractor Hywel Griffiths Plant Hire and Groundworks has added an upgraded CASE CX210E-S crawler excavator to its growing fleet, with a bespoke specification to meet the company’s exacting requirements. The machine has been equipped with wider tracks, a Steelwrist tiltrotator, Topcon machine guidance, 360o cameras and an autolube system.

Hywel Griffiths has tailored the excavator further to suit its own use, increasing the track pad width to 800mm, higher than the standard 600 or 700mm pads, to cope with winter use on poor ground conditions. “We do a lot of wet weather work in the winter and the Environment

Agency prefers wider tracks for minimal disturbance of the ground,” explained managing director Hywel Griffiths.

The company is also committed to the benefits of a tiltrotator, with the attachment mountings found on all of its larger machines. In some cases, it has been beneficial to order excavators with a short dipper arm, when equipping them with a heavy tilt-rotator. However, the additional weight in the CX210E-S makes it possible to use the mounting with the standard 2.94m arm.

Operator Evan Griffiths has been particularly impressed by the latest CASE addition to the Griffiths fleet. “It’s amazing, a real game-changer,” he said. “The comfort in the cab is excellent and the cab is massive, even with the seat fully back. The controls are so smooth and responsive and, with the Topcon, it’s fabulous. The new E-Series machines are just a different level to the previous D-Series.”

Collins Earthworks is celebrating 25 years in business with a major investment in its first ever fleet of JCB X Series excavators.

Supplied by dealer TC Harrison JCB, the deal includes eightJCB 220X and fiveJCB 370X models, strengthening the bulk earthworks specialist’s fleet.

Each new machine is decked out in Collins

Nationwide Platforms is expanding its fleet with the addition of two cutting-edge hybrid models from Dingli: the BA44HRT and BT44HRT. These two boom lift models, among the first of their kind to arrive in the UK, mark a significant step forward in the business’ ongoing investment in future-focused, sustainable access technology.

The 44m platforms offer class-leading reach and safety, alongside intelligent hybrid systems that improve energy efficiency and reduce environmental impact on site.

The BA44HRT is an articulating boom lift offering 18.8m of up-and-over clearance, making it ideal for accessing confined or obstructed work zones. The BT44HRT, a telescopic boom lift, delivers a best-in-class horizontal outreach of 25.6m, perfect for infrastructure and large-scale industrial projects.

Dan Smith, chief operating officer at Nationwide, said: “The addition of the BA44HRT and BT44HRT strengthens our position as the UK’s leading provider of specialist working-at-height solutions. These hybrid boom lifts combine exceptional height and reach with the kind of sustainable innovation our customers increasingly demand. Whether working in remote industrial zones or congested infrastructure projects, our clients now have the tools to operate at height more safely and more efficiently than ever before.”

Earthworks’ standout white and blue livery and will be deployed on major earthmoving and infrastructure projects across the UK. They join existing JCB Loadall telescopic handlers, Telemasters, backhoe loaders and compaction models in the Collins Earthworks equipment fleet.

Director, Dave Collins said: “Our heritage is in bulk earthworks, and these new JCB machines will further strengthen our capability in that sector. We’ve chosen to invest in JCB as the X Series range is durable, productive and well supported.”

JCB global excavator sales director, Nick Grills said: “We are delighted that Collins Earthworks has chosen JCB for this latest excavator order. More and more major contractors are recognising the quality of the JCB X Series range. Superb structural reliability, operator experience, serviceability and parts availability are all contributing to increased sales as the reputation of the X Series range continues to grow.”

Based in Ripley, Derbyshire, Collins Earthworks is a family business and has been delivering large-scale earthmoving, civil engineering and infrastructure projects for a quarter of a century, during which time it has expanded into demolition, stabilisation, transport, plant sales, training and vertical builds, as well as quarrying and concrete. WWW.RDR.LINK/CBE020

Bristol-based South West Tool Hire, a supplier of tools and equipment, has invested in a fleet of Trime power generation sets. The order comprised ten 6kVA units and six 10kVA sets.

Commenting on the investment, South West director Lee Edwards said, “Following a review of our power generation range, we decided now was the time to freshen up our fleet, hence this purchase. We chose Trime because of its strong reputation within the hire and rental industry for producing quality products and proven backup services.”

South West Tool Hire Company was incorporated in June 2011 and has been providing tool and plant hire to Bristol and the South West of England. The company has grown to become a trusted supplier to many building, construction and service trades, as well as DIY domestic customers. It currently has branches in Bristol, Bridgwater and Exeter.

WWW.RDR.LINK/CBE022 GOTO

Waterhouse Plant, the East Sussex-based plant hire company, is making a significant first-time investment in a fleet of Wacker Neuson dumpers. The order includes a range of 6-ton and 9-ton Dual View dumpers, chosen for their productivity, ease of maintenance, and suitability for tough site conditions.

Owned and operated by Chris Lavin, Waterhouse specialises in delivering machinery to groundwork and infrastructure services across the Southeast. The company had not previously operated Wacker Neuson dumpers or excavators, but after reviewing the performance, build quality, and dealer support available through GEM Plant Sales, it chose to

place a substantial order for new site dumpers.

“We hadn’t used larger Wacker Neuson machines before, so it was a big decision,” said Lavin. “We’d had years of dealings with GEM Plant Sales for light equipment, particularly purchasing and service of our compaction equipment. However, from the very first dealings, the team at GEM was knowledgeable, honest, and truly focused on understanding our business. Answered every question and gave us

confidence that we’d be properly supported — not just during the sale, but long after.”

“The dumpers themselves are wellengineered, with great visibility and safety features unlike any other. Operators liked them straight away, and the fuel efficiency and reliability we’ve seen so far are encouraging. We see this as the beginning of a long-term relationship.”

WWW.RDR.LINK/CBE023 GOTO

When faced with sourcing a specific bit of machinery for specialist work, contractor

David Allan turned to Kubota for the right excavator, with a few tweaks on the side.

Drymen-based Joe Allan & Sons Plant Hire and Contracting is a specialist in low ground pressure operation, used to accessing remote power infrastructure across Scotland for utility provider SSE. With both wheeled and tracked machinery on the fleet, second generation managing director David Allan was looking for a specific crawler excavator to meet the Glasgow company’s exacting standards.

After consultation with local Kubota dealer HRN Tractors, Allan opted for a KX085-5 midi excavator with a two-piece boom, that provides the additional reach and digging capability that the firm requires. The machine is further enhanced, with the addition of an Engcon tiltrotator.

However, it is below the slew ring that things become more bespoke. Allan called on Stirlingbased low ground pressure specialist JCC Group, to convert the Kubota to meet the company’s specific needs. With standard 450mm wide track pads, that can be taken to 600mm as an option on the KX085-5, the company was looking for lower ground pressure than the standard model could provide. JCC removed the track frames, widened the mountings on the X-frame and equipped each side with an additional two top rollers, to lift the track clear of the frames.

This has allowed the company to fit a 900mm wide track pad, double the standard machine’s track width, resulting in greatly reduced ground pressure on softer terrain. JCC also lifted the slew

“...I'm really pleased with the conversion...”

ring turret by around 150mm, to provide additional ground clearance beneath the upper structure. Finally, the machine’s standard dozer blade has been seamlessly extended on each side, to match the new overall width of the tracks.

“The machine has been designed mainly for utilities and some private work,” said Allan.

“But we have been picking up extra work already, as people know that we have the twopiece boom and the tilt-rotate hitch. It’s still easy to move the machine, especially in tight access, as it’s based on an eight-tonner, just with the wider track frames.”

David’s father Joe Allan started the company almost 50 years ago. With five full-time employees, the business now has nine machines in total, including another Kubota tracked model.

“We’ve known Andy (Wilson, construction sales manager) and the team at HRN for years,” continued Allan. “Service and back-up is always better if you keep it local and we rely on the dealer to look after the Kubota machines. We can cover anywhere up to Perth and across Scotland, and HRN provides the back-up that we need to look after our customers.”

Weighing 8,392kg to 9,097kg, depending on specification, Kubota’s KX085-5 is offered with a monoboom that provides 7,330mm of forward reach, or a two-piece boom that increases that reach to 7,820mm. The machine is powered by a 46.5kW (63.2hp) Stage V turbo-diesel engine. It uses a two-pump load-sensing hydraulic system,

providing smooth multi-function operation and the ability to operate the front attachment while tracking. Two auxiliary circuits are standard for attachment power and an electronicallycontrolled third line return is automatically activated when breaker mode is selected.

The company intends to keep the Kubota for three to four years and, though anyone can operate it, Allan tends to take control of the widened KX085-5 himself for much of the time.

“I’m really pleased with the conversion,” he said. “It’s exactly what we needed to access our sites, no matter what the ground conditions.”

The new heavy-duty Cat 980 GC wheel loader is claimed to offer low fuel consumption with an on-demand fan, loadsensing hydraulics, intuitive controls and performance series buckets, making it an economical solution for a broad range of applications, according to Caterpillar

The new 980 GC is powered by the Cat C13 engine and comes with a clean emissions module that works in the background without impacting production. The EIMS, auto engine idle shutdown, variable speed fan and load sensing hydraulics combine to offer low fuel consumption and sound levels on the machine.

Its field-proven automatic planetary powershift transmission delivers high reliability and long service life. Four forward/reverse speeds reach a maximum 39.8km/h (24.7mph) to quickly move about the site, and the well-known electronic clutch pressure control (ECPC) shifting system provides smooth, efficient gear changes in all

operating conditions. Available ride control improves operating smoothness over rough terrain while ensuring excellent material retention and increasing efficiency, and the optional limited slip differential axle increases traction in poor underfoot conditions.With a bucket capacity range of 4.3-5.8m3, easy-to-load Cat performance series buckets use a system-based approach to balance bucket shape with the machine’s lift and tilt capacity, weight and linkage. The bucket design improves material retention and reduces dig time with build options that include general purpose, flat floor, heavy duty rock, coal and light material to meet any application.

The Cat Z-bar loader linkage with cast crossmember and tilt-lever provides strong digging efficiency and high breakout forces to enhance production capabilities. Load-sensing hydraulics produce flow and pressure for the implement only when needed, improving machine productivity and resulting in low fuel consumption. The new 980 GC can be equipped with the Cat Fusion quick coupler and controls, and combined with optional third-function hydraulics, the coupler allows use of a wide variety of work tools.

Cat VisionLink, standard for the new 980 GC, allows fleet managers to track critical loader operating parameters like machine location, hours, fuel usage, diagnostic codes and idle time to improve productivity and lower operating costs. Also optionally available, Cat Payload weighs material while moving to the truck and lifting for onthe-go weighing (not legal for trade), so the operator can load to exact specification, load more trucks and avoid over- or under-loading. The Cat Payload for Trade option for Cat Advanced Payload allows the scale data to be uploaded directly into business processes. It is type approved by the International Organization of Legal Metrology, while retaining all the features of the standard version of Cat Advanced Payload.

Providing a comfortable working environment throughout the shift, the 980 GC’s spacious cab design features easy, intuitive controls and excellent visibility. The complete user interface is designed as an intuitive system, allowing the operator to monitor machine health. Pilot-operated hydraulic controls deliver low-effort, comfortable operation and include a remote transmission kick-down switch for operating comfort. FOR MORE INFORMATION WWW.RDR.LINK/CBE025 GOTO

According to Hyundai its newly launched Edition 25 machines take wheeled loader safety to a new level. Available on the HL940A, HL955A, HL970A and the HL975A models, the Edition 25 pack incorporates AAVM+ and Clearview X technology, providing operators with increased visibility all around the machine.

With the new AAVM+ technology, Hyundai has added a rear-mounted radar and a steering angle sensor to the package, working in combination with the cameras. In common with automotive technology, this system provides the operator with coloured arcs overlaid on the monitor, that move as the steering is turned. This demonstrates not only where the loader is standing at that time, but where it will drive to if the operator continues on that reversing trajectory. The system works with both the steering wheel and, if fitted, with the lever steer system.

If objects or other workers come within the sweep of that potential arc, the operator is given an audible and a visual warning, with flashing images on the screen. This allows the operator to slow, or stop if required, or to steer the machine away from the obstacle, reducing the risk of a potential impact.

Clearview X operates at the other end of the machine, providing an improved view to the front of the loader. Using a twin camera system, with one camera mounted on the front axle and the other above the front windscreen, Clearview X combines the two images within the monitor, to create a single picture of what is ahead of the bucket.

As the front arms are lifted, this combined image allows the operator to in effect ‘see through’ the bucket. As with the AAVM+ technology, the system doesn’t just rely on the operator looking at the screen, there are visual warnings, that go from amber to red as the danger increases, along with an audible warning to signal that an object or person has moved into the danger area ahead of the machine.

Together, these two systems greatly increase safety on site, providing the loader operator with increased visibility and warning of any danger ahead of a potential impact. Though initially launched on the four core models in Hyundai’s wheeled loader line-up, additional A-Series models may be added to the Edition 25 range in the future.

Komatsu has unveiled thelatest addition to its electric product range, the PC20E-6mini excavator. Designed to meet the demands of a full working day, the PC20E-6 is said to be ideal for both traditional jobsites and noisesensitive or indoor applications where zero emissions are required.The aim is to provide a machine that fulfils the requirements of a realistic working day on the construction site while being as cost-efficient as possible.

The 11.8 kW battery-powered mini excavator with 23.2 kWh battery capacity and an operating weight of 2110 kg has a drive train specially developed by Komatsu in Europe. Themachine also comes with the Komatsu E-Support customer program. Specially developed for owners of Komatsu electric mini excavators, this program comprises three partsincluding factory scheduled, free maintenance by a Komatsu-trained technician using genuine parts;3 years or 2,000 hours warranty for the machine;and a 5-year or 10,000-hour parts warranty for the high-quality components of the electric driveline.

The company says that numerous data-driven findings have been incorporated into the development of the machine.Using the

XCMG is introducing two new compact excavators, the XE10E (1 tonne) and the XE27E (2.7 tonne), expanding its diesel-powered range of machines. Designed for superior performance in confined spaces, these machines are claimed to combine compact dimensions with robust power, making them ideal for a wide range of applications in tight city environments.

The XE10E, one of the smallest in the series, measures 0.75m (29.5in) in width, enabling access for indoor demolition, backyard utility work, and narrow alley repairs. Despite its

Komatsu fleet management system,Komtrax,40,000 working days of miniexcavators of a comparable sizewere analysed. The findings revealed that 90% of mini excavators work less than 3.5 hours per day. This defined the target for the required, reliable working time with the excavator. This result madeit possible for Komatsu to offer an attractively priced machine with a performance that exactly matches the requirements.

Depending on the operating mode, the PC20E-6 offers capacity for around 3:20 hours (operating mode P), 3:40 hours (operating mode E0) or 4hours (operating mode E1).

Thanks to various charging solutions, the machine can also be recharged flexibly, for example by fast charging during the lunch break. The PC20E-6 operates in the high-voltage range with a system voltage of 77V. An on-board charging option for 230V and 3kW charging power compatible with various plug adapters is offered as standard, as well as the option of an external DC quick charger for 400V and 12kW charging power.

FOR MORE INFORMATION WWW.RDR.LINK/CBE027 GOTO

compact footprint, it delivers reliable digging performance and smooth hydraulic response, powered by a fuel-efficient diesel engine compliant with EU Stage V emissions standards. The larger XE27E offers extended reach and higher breakout force for demanding tasks such as trenching, foundation work, and municipal infrastructure upgrades.

Both machines feature short-tail-swing designs, enabling safe and flexible operation near walls and obstacles in constrained urban areas. Integrated telematics systems allow real-

time monitoring of engine status, machine location, and maintenance alerts—improving fleet management and reducing downtime. Their low noise and reduced vibration make them suitable for residential zones and noisesensitive environments. Ergonomic operator cabins and quick-coupler systems for attachments like breakers, augers, and buckets further enhance comfort, safety, and versatility.

FOR MORE INFORMATION WWW.RDR.LINK/CBE028 GOTO

To celebrate the start of production of its new R2-Series 1-2 tonne mini excavators, Bobcat is releasing a special, limited-edition run of its top models. Only 50 of these exclusive Premiere Launch Edition machines will be produced, making them a rare and highly collectible piece of equipment. The latest generation R2-Series comprises the new E16, E17z, E19 and E20z models, first seen at the Bauma.

The exclusive limited-edition version will be available for the top-ofthe-range models of the 1-2 tonne range: the E19 and the E20z. Only 25 units of each will be produced. Special features offered by the Premiere Launch Edition include: exclusive charcoal grey colour; premium red and black cloth or leather seat cover; individually numbered plate in the cab; aluminium pedals; and four high-value aftermarket kits as standard.

The E16, E17z, E19 and E20z new generation R2-Series 1-2 tonne mini excavators replace the previous M-Series E17, E17z, E19 and E20z machines, respectively. The new models offer a fresh look, signifying

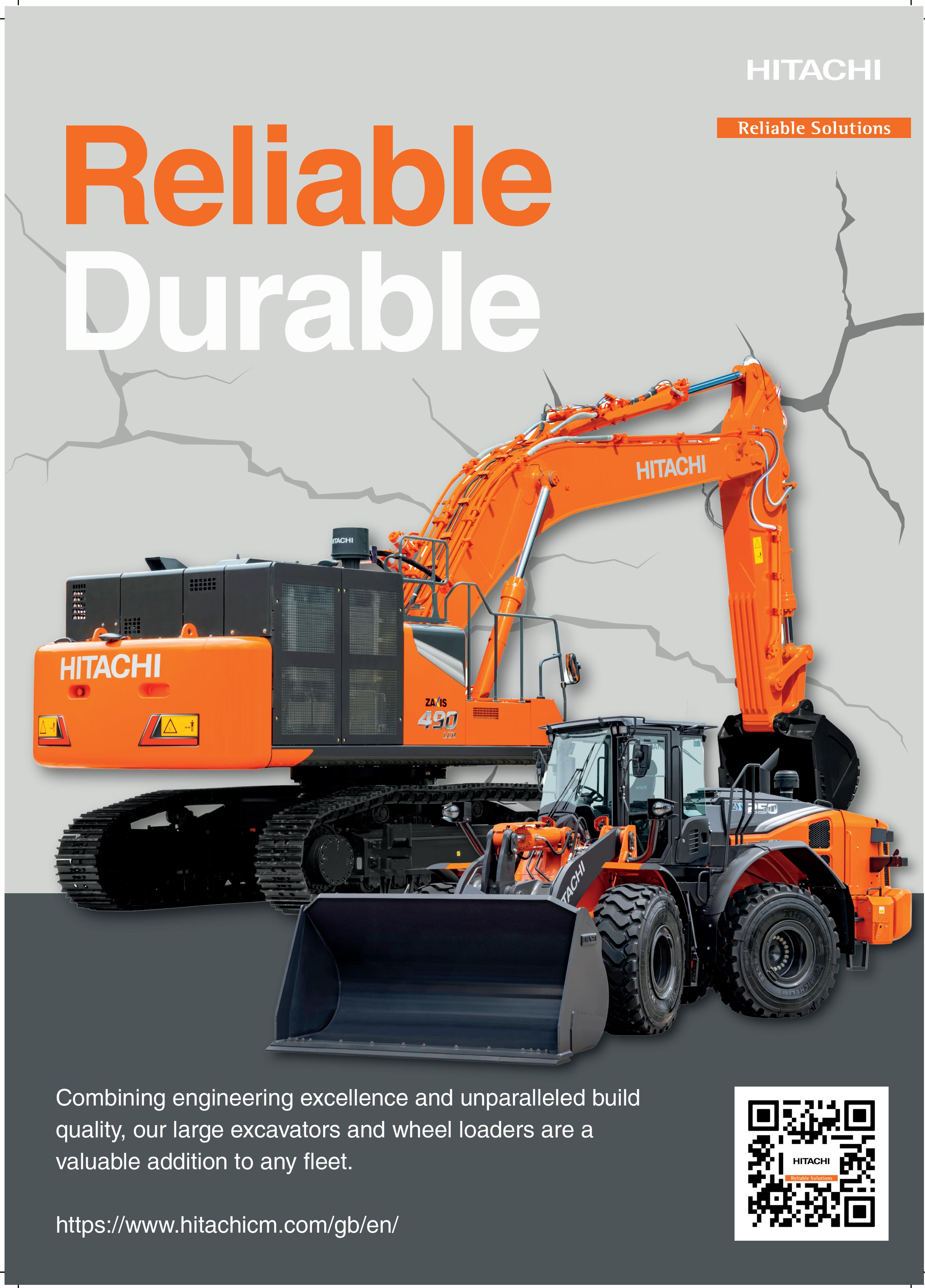

Develon..................................(page 36 outside back cover) www.rdr.link/CBE100

Finning UK Ltd........................................................(page 21) www.rdr.link/CBE101

Hitachi Construction Machinery (Europe)..............(page 26) www.rdr.link/CBE102

new levels of performance and features and are designed to meet all the variations found across the EMEA market.

Among the many new features to be found on the new R2-Series 1-2 tonne mini excavators is the high-performance SmartFlow loadsensing hydraulics system coupled to a closed centre/flow-sharing valve block powered by an upgraded engine, providing a sophisticated engineering set up that is said to be unique in smaller machines like these.

FOR MORE INFORMATION WWW.RDR.LINK/CBE029 GOTO

Liebherr-Great Britain Ltd........................................(page 4) www.rdr.link/CBE103

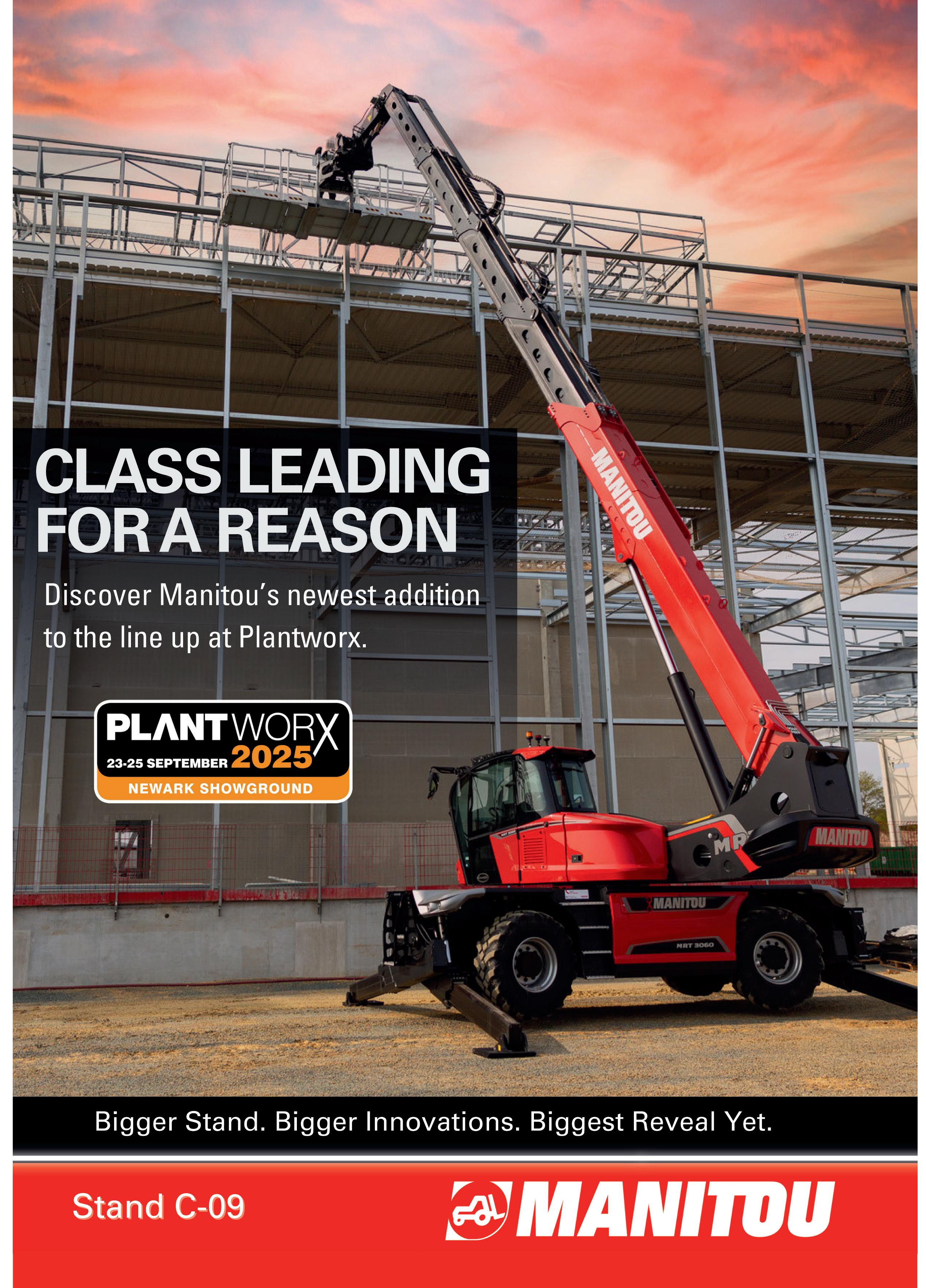

Manitou........................................(page 2 inside front cover) www.rdr.link/CBE104

Plant parts..............................................................(page 18) www.rdr.link/CBE105