GREEN September 2023 In this issue... Using A Multimeter Deere Logos The 4040 Magazine®

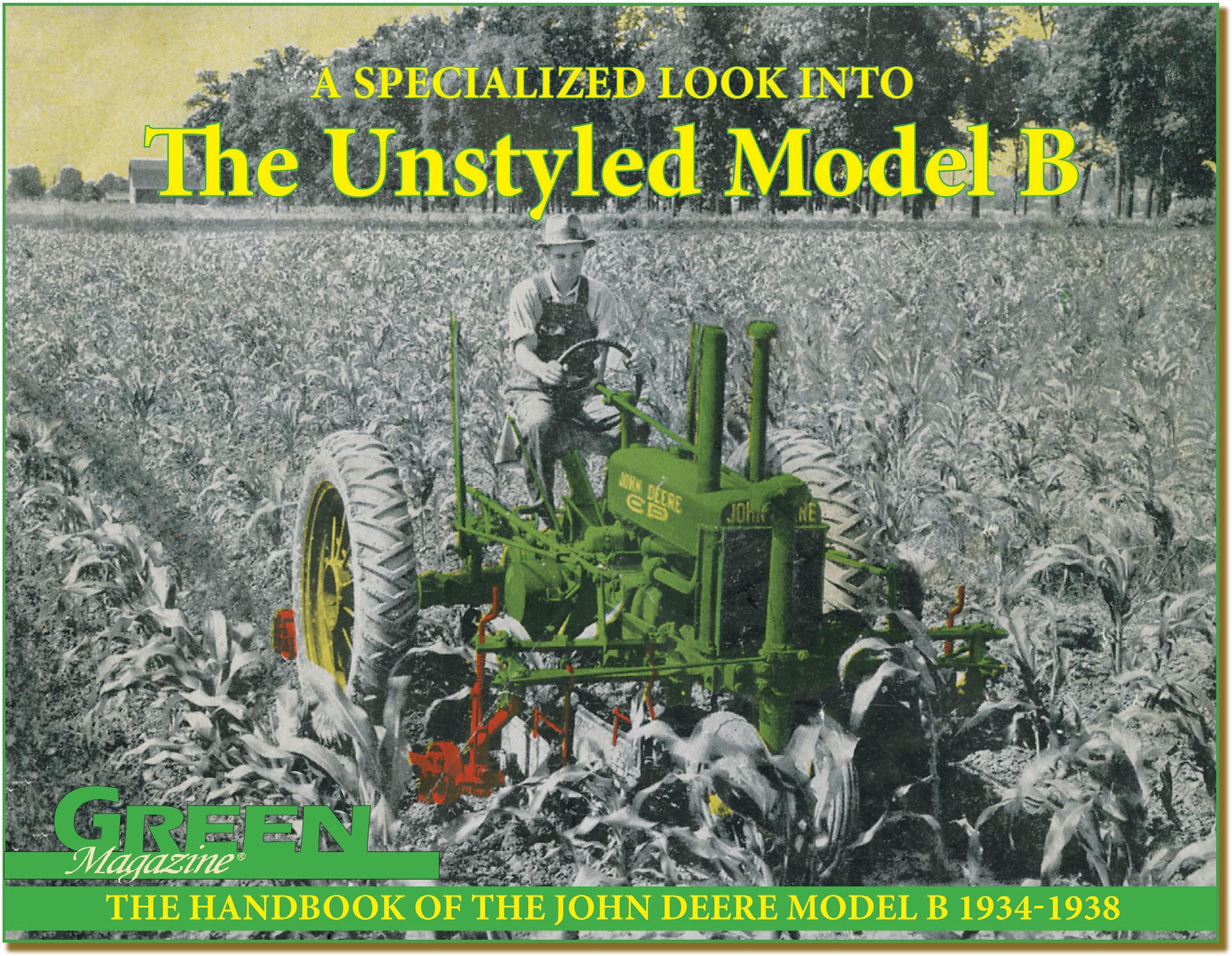

IT’S FINALLY HERE! A Specialized Look Into The Unstyled Model B The Handbook of the John Deere Model B 1934-1938 For years now, thousands of you have relied on the Specialized Look into the Model A book written by Wes Malcolm and published by Green Magazine. Now we offer the same types of information, except about the model “B,” written and compiled by a panel of experts who have spent decades collecting and restoring the unstyled version of Deere’s most popular tractor. This book shows nearly every change made in the parts that make up the unstyled “B.” It also has history, specifications, serial numbers, original prices and much, much more. 84 pages, 11”x8 ½”, soft cover, over 200 photos - most of them in color Order GM8B: $39.95 US • $47.95 Canada (US funds) • $52.95 Foreign (US funds) Call 402-643-6269 • Email info@greenmagazine.com Online www.GreenMagazine.com Mail Green Magazine® • PO Box 95, Bee, NE 68314-0095 Visa, Mastercard, Discover, American Express accepted • Nebraska residents add 5.5% sales tax • Price includes S/H These books are selling fast! Place your order TODAYonline, by phone or check by mail

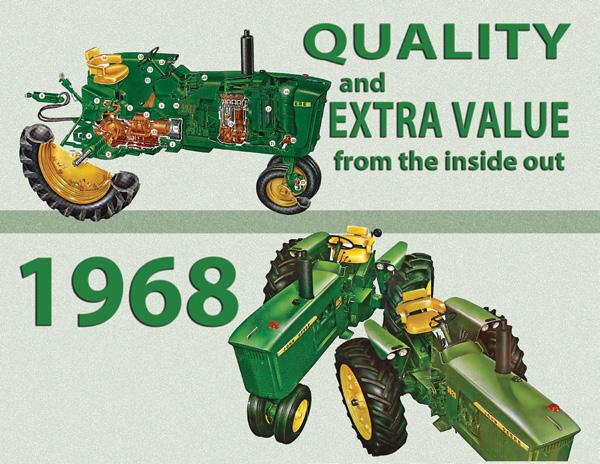

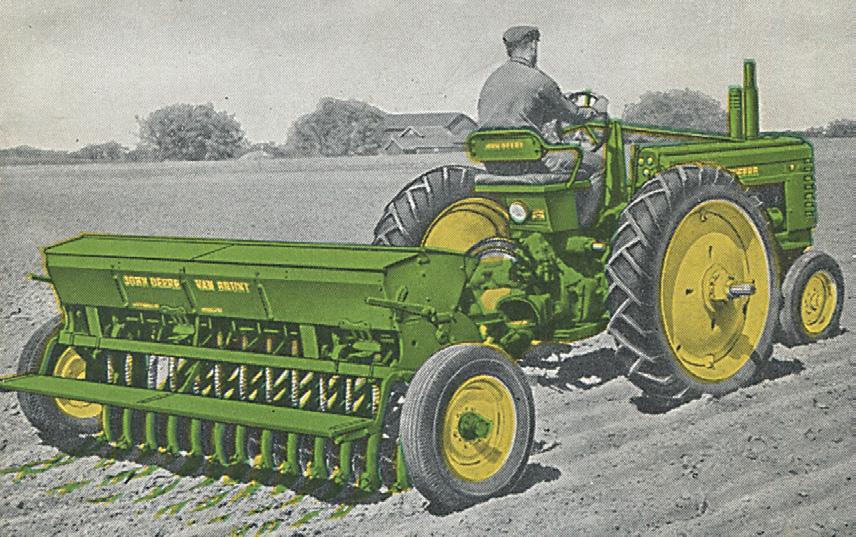

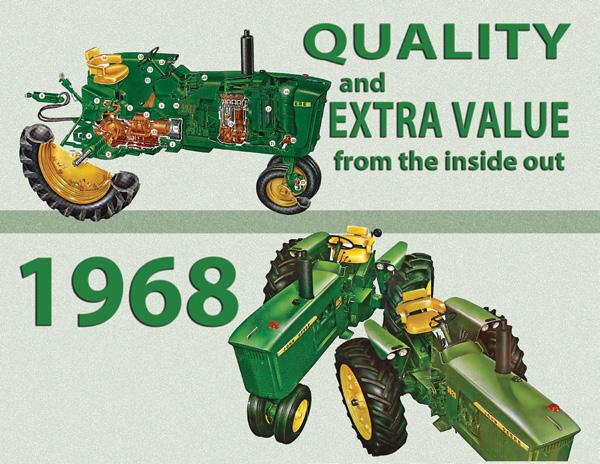

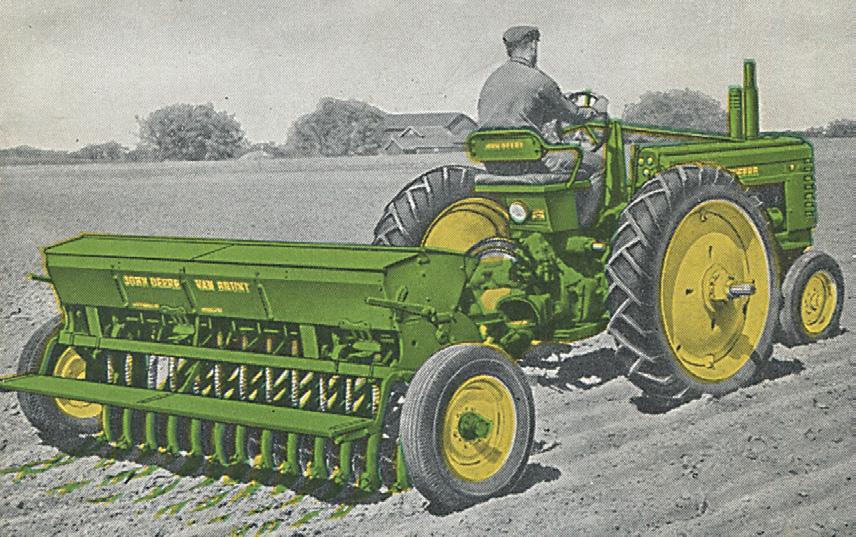

Tractors pictured in Green Magazine’s 2024 calendar are from 1968 — the whole calendar is designed to resemble one from that era. The days in 1968 match up with those in 2024 so the calendar works for next year.

• Only a limited number of calendars are produced so ORDER EARLY before they are gone!

• 12 high quality, professional photos on each calendar

• Photo size is 11” wide x 8-1/2” deep

• Calendar when fully displayed is 11” wide by 18” deep

• Price includes shipping

• Proudly printed in the USA

• Call, go online or send a check to place your order

Green Magazine’s calendar is a customer favorite— order now before they are gone

ORDER CODE: 24CA

U.S. PRICES :

1 calendar: $14.00

2 calendars: $28.00

3 calendars: $36.00

3 or more: $12.00 each

Canada PRICES :

1: $29.00

2: $36.00

3: $45.00

3 or more: $15.00 each

Foreign PRICES :

1: $40.00

2: $50.00

3: $60.00

3 or more: $20.00 each

• Prices include shipping • U.S. funds ONLY, please!

• Multiple calendars must be sent to the SAME ADDRESS to receive the discounted price

Visa, Mastercard, Discover, and American Express accepted Nebraska residents add 5.5% sales tax

PO Box 95 •

68314-0095

www.GreenMagazine.com Email: info@greenmagazine.com

Phone: 402-643-6269 Mail: Green Magazine

Bee, NE

Web:

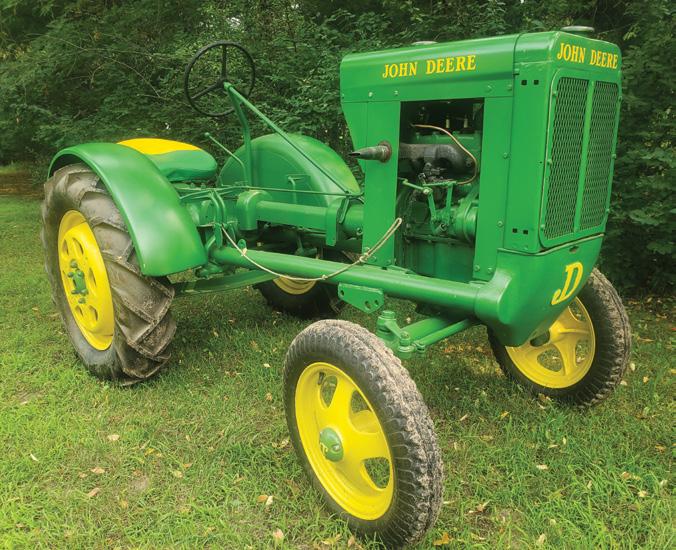

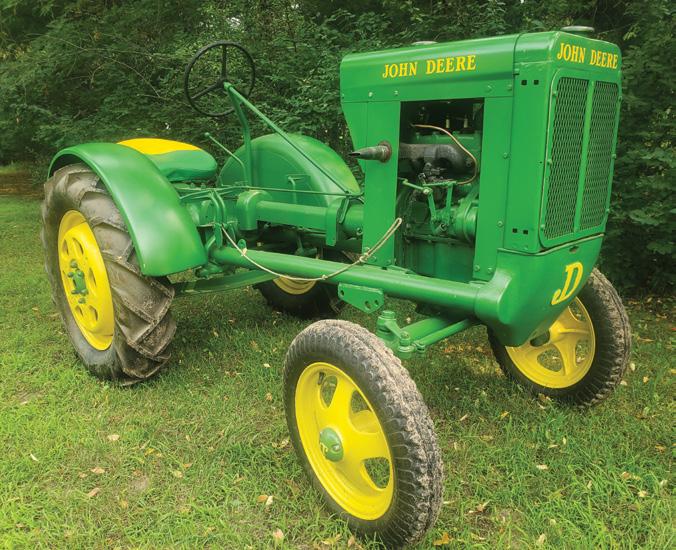

Front cover

This is one of the 12 photos that will appear in the 2024 Green Magazine calendar.

“GREEN MAGAZINE®” (ISSN 0883-5462) is published monthly and released 12 times a year on or about the first of each month for $39.95 per year or $76.95 for 2 years (foreign: $56.95 per year - U.S. funds) by Hain Publishing, Inc., 2652 Davey Road, Bee, NE 68314-9132. Periodicals postage paid at Bee, NE and additional mailing offices. POSTMASTER: Send address changes to “GREEN MAGAZINE®, PO Box 95, NE 68314-0095.” GREEN MAGAZINE® reserves all rights regarding reprints of this publication. Our phone number is (402) 643-6269. GMagazine® reen Copyright © 2023 Hain Publishing, Inc. All rights reserved. The monthly publication for John Deere enthusiasts 10 A sleigh and an “A”— Marvin Huber’s connection to JD Cindy Ladage 12 Classic Green and the Great “G” Giveaway Jackie Bell 22 John Deere model 4040 Benjamin Hain 28 The front cover: Grandpa’s “B” Doug Anderson • Paxton, IL

2023

Departments 5 Richard’s Column 6 Deere John 16 The Young Timer Visitors from Germany Tyler Buchheit 30 Saw it online Tape measure: $1,797 Adam Smith and Benjamin Hain 34 How our hobby started Events of 1986-1987 Richard Hain Each March issue of Green Magazine includes an index of major articles from past issues. The March 2023 issue featured the newest index. 36 Auction highlight Summertime sales Eric W. Mickelson 42 Deere & There 44 The tractor doctor Little green monster rides again Ron O’Neill 48 What’s new—and old? Logos through the years, Part 2 Greg Stephen 52 Scale models 50th anniversary 7520 Bill Proft 55 Do you have one? 56 Tip of the month Multimeter basics, Part 1 Dan Brotzman 60 Aussie Ken Training courses Ken Nicklas 77 Advertiser index 80 Mr. Thinker ON THE COVER: For more information about this 1936 “B,” owned by Doug Anderson of Paxton, Illinois, see page 28. Photo by Warne Riker Photography. Editor Richard Hain Managing Editor Carol Hain Circulation Assistant Vivian Beckler Layout/Design Debbie Behne Green Magazine® PO Box 95 Bee, NE 68314-0095 Hours: 8:30 AM to 4 PM M-F Phone: 402-643-6269 email: info@greenmagazine.com web: www.greenmagazine.com Check out the sample articles, catalog, ads and other features! NOTE: VISITS TO OUR OFFICE BY APPOINTMENT ONLY! Please call prior to visiting so we can be here to talk with you. At that time we can also give you our location. Thank you! Rates: U.S.: $39.95 / 1 year - 12 issues or $76.95 / 2 years - 24 issues Nebraska residents, add 5.5% sales tax ($42.15 or $81.18) Foreign: $56.95 per year First Class/Airmail delivery now available: See page 5 Visa/Mastercard/Discover/AmExpress accepted Page 4 September 2023 • Green Magazine®

September

• Volume 39 Number 9

In this issue, you will see the first ad for our 2024 calendar. The calendar features models from 1968, and includes a model that will cause a few of you who are either new to the hobby or haven’t been paying attention to say, “They didn’t build those in 1968!” Oh, but they did, they very much did. I won’t spoil the fun and I’ll let you figure it out when you get the calendar.

I know that I have a history of writing about how the simplest of tasks always seem to take me much longer and prove much more difficult than I had anticipated, so I must tell you about one that turned out surprisingly easy. Almost two years ago now, I bought an HA-92 engine with the thought of possibly using it to power my next speedster. The thing looked to be in decent shape, and even had good looking coolant and oil in it. Its biggest problem was that the magneto would not turn; the shaft that runs up through it was hopelessly stuck. I ran a wanted ad in this magazine looking for a working one and ended up with two—maybe I’ll get into that story later. I bolted the mag on, following the vague timing instructions in the manual, cleaned the carb and installed a couple of new gaskets, without even bothering to check if I had screwed the needle valve in anywhere near spec. I attached a battery and a temporary fuel tank, hit the starter, having no idea what would happen, and to my shock, it instantly began running. Not only did it purr

like a kitten at all speeds, but the valve cover and sediment bowl gaskets that I cut from a sheet of cork material with a giant pair of scissors also didn’t even leak. I guess that my motto of “Why can’t anything ever be easy?” will need revision to “Why are things so rarely easy?”

In the “How Our Hobby Started” in the August issue, I briefly mentioned one of the controversies concerning a show many years ago that was not allowing tractor owners to put up ropes around their tractors. I got to thinking about this, and it seems like it’s something I rarely see at shows any more, other than in obviously dangerous situations where something is operating. Case in point—at this year’s Classic Green Reunion, you could have driven several rare and valuable tractors. This is great news for the hobby, and I hope shows a new inclusivity that was perhaps lacking at times in the past.

We didn’t make it to as many shows this summer as we would have liked, but the ones we did make it to were great. Thanks to everyone who stopped to say hello—it’s always nice to finally meet someone in person that you’ve talked to on the phone many times before. With the Classic Green Reunion being farther south than most of the shows we’ve attended in the past, it gave us a chance to meet quite a few new people.

See you next month.

Missing an issue? We mail every issue by the first of the month. Please contact your post office if you suspect a problem with delivery. We will not replace missed issues three or more months past original mail date (four or more months for foreign subscribers) free of charge.

U.S. subscribers: If it is on or after the 20th of the month and you haven’t received your issue, call us for a replacement.

Canadian subscribers: Due to postage costs, we are forced to ask for a $2 postage fee (U.S. funds, please) for re-sending issues that do not arrive by the end of the published month OR we can add an issue onto your subscription for the missed issue.

First Class/Airmail delivery: First Class delivery is now available at an additional cost of $2.50 per issue in the U.S. (plus the base rate) and Airmail to Canada ($87.95 per year, U.S. rates). Call for rates for Airmail delivery to other countries.

Foreign subscribers: We will add an issue onto your subscription OR for a $7 airmail postage fee (U.S. funds), we will resend the missed issue two months after publication date.

Notice: If your address label shows an expiration date of “9/23” above your name, this is your last issue. Renew immediately for continuous service. If your address label reads “10/23,” you have one more issue on your subscription.

Renewal notice: We send postcards to let you know your subscription is about to expire (or has expired). We NEVER call to ask if you would like to renew your subscription. If you

receive such a call, it is most likely from another publication—NOT Green Magazine® for John Deere enthusiasts.

Address Changes: Please send or call with notification of an address change as soon as you know what your new address will be. Periodical mail cannot be forwarded. Green Magazine will not replace issues missed due to late notice of address change. Those missed issues will have to be bought at back issue price. See the back issue listing and prices elsewhere in this issue.

Looking for your photos and stories! Accepted material is subject to such revision as to meet the requirements of this publication. Payment will be made at our current rate within 90 days of publication. Submission of manuscript implies that the material is original and in no way an infringement upon the rights of others. Please send good, clear photographs. If you would like these returned, send us a stamped return envelope to help us get them back to you.

Free Issue Offer: It seems you, our subscribers, are our best form of advertising! More people find out about this publication by “word of mouth” than other forms of advertising. So if you're enjoying Green Magazine®, why not spread the word? Telling others about it can pay benefits. When you tell a friend about Green Magazine® and they subscribe, make sure they tell us who let them know about it. When they do, you will get an issue added to your subscription. These must be new subscribers, not renewals.

MOVING? Whether your move is SEASONAL or PERMANENT, contact Green Magazine® with your address change AT LEAST FOUR WEEKS in advance of the move. Missed issues WILL NOT be resent free if your address has not been changed with us due to a move. Ph. 402-643-6269 • info@greenmagazine.com Green Magazine® • September 2023 Page 5

Ray Mak from St. Joseph, Michigan, graciously allowed us to use his 1938 “G” to pull the City of St. Joseph’s float in the annual Blossom Parade. Sadly, Ray passed away the day before the parade. Rest in peace, Ray. Thanks for your generosity.

Robert Basselman, MI

Robert Basselman, MI

This is my 1969 front wheel assist 4020, serial number T213P221323R diesel, which was shipped to Mountain Home, Idaho on July 7, 1969. The tractor is a daily user. Power Shift was ideal for this moving job—we are making a place for grandkids to stay overnight.

Lee Baker, owner, MO

Lee Baker, owner, MO

Page 6 September 2023 • Green Magazine®

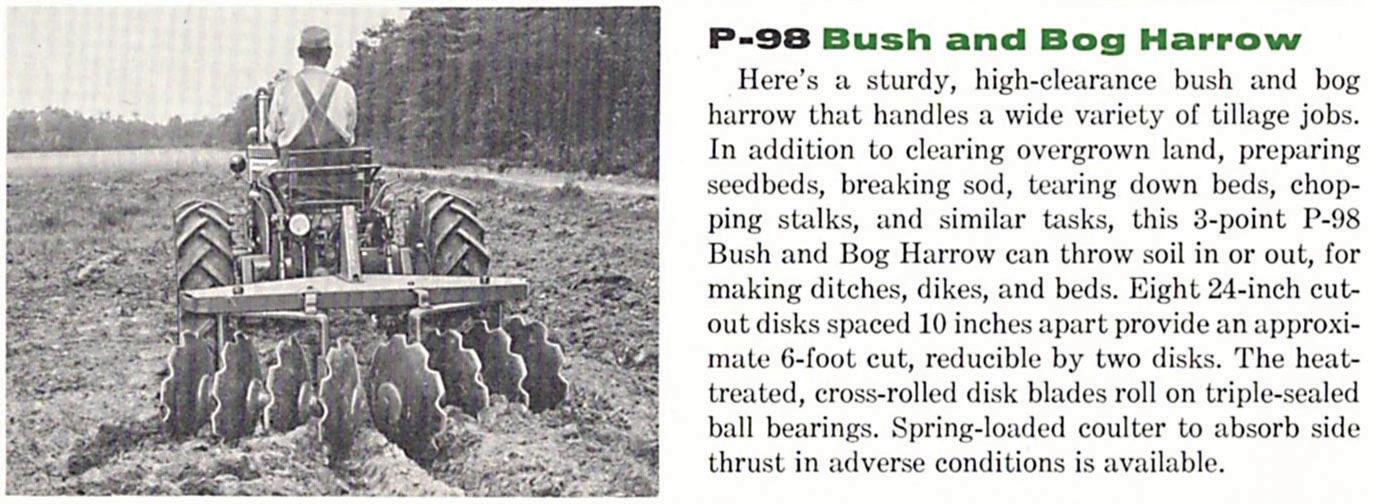

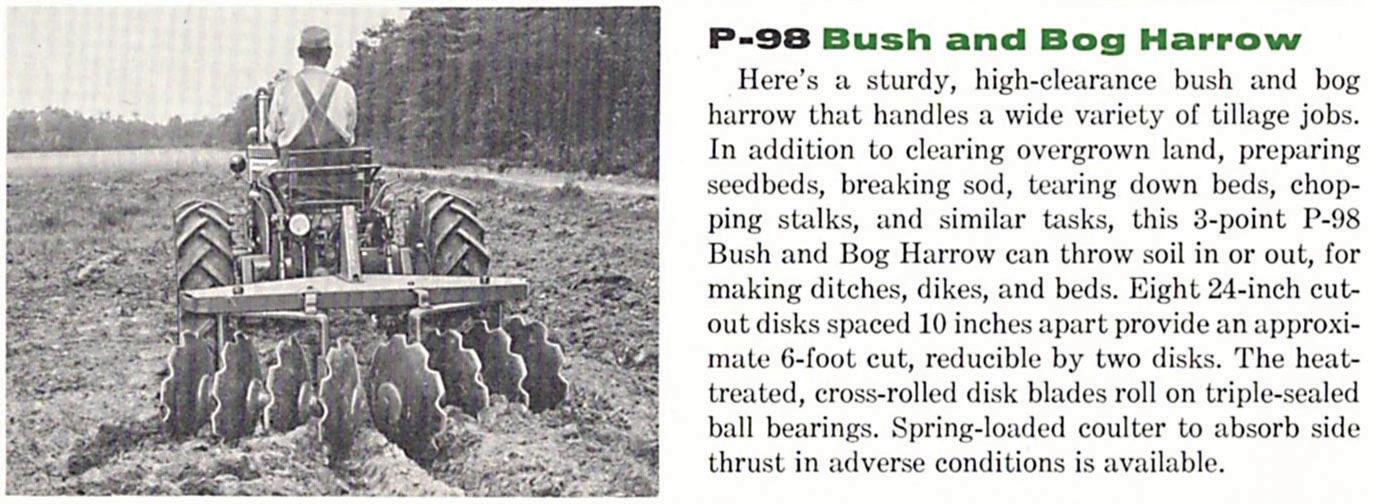

The inquiry to Mr. Thinker from V.W. of PA in the August 2023 issue of Green Magazine piqued my Dubuqueinterest to go and research it. The disk in the picture is a P-98 bush and bog harrow, built from approximately 1955 to 1958. They are illustrated in the April 1957 “Integral Equipment” brochure for the 320 and 420 series tractors, but do not show in the 1958 issue for the 330 and 430 series tractors. It is described as a “sturdy, highclearance” unit. I am not sure which factory produced these, as the part number prefixes are predominantly “ADT” and “DT,” which I have never seen before. The part numbers that the reader is looking for are: DT30W - front

end washer, or possibly the DT31Wbumper washer. The disk blade part number is DT2174W, while the part catalog reference number is PC-383. Above is an image of the unit. I would be interested in getting

some measurements from the reader, if he makes the purchase. That would be a nice 1/16th scale scratch built project to tackle.

Thanks!

Dave McEachren, ON, Canada

1) Call 402-643-6269 with credit card in hand 2) Go online: www.greenmagazine.com 3) Send a check by mail with the subscriber’s name and address to Green Magazine, PO Box 95, Bee, NE 68314 For more info on subscription rates, see page 4. Questions? Call 402-643-6269 for great customer service! It’seasy! We like to hear from our subscribers — send a letter by mail or email Green Magazine, PO Box 95, Bee, NE 68314 • info@greenmagazine.com Green Magazine® • September 2023 Page 7

4020 diesel, SyncroPARTING

5020, SN 018699

Call for more information on these tractors

Gary & Cheryl Titsworth Online Only Tractor Collection Auction

Sale

Load

After many years of collecting tractors, Gary & Cheryl have decided to liquidate their collection so that other people can enjoy them as much as they have. This line up will be as clean and pristine as any you will ever find!

Auctioneers:

Please visit “hanoldauctioneering.com” for more information and complete sale bill or call Hayden Geisler, 217-248-4045; or Cody Hanold, 618-781-9810

OUT!

PARTING OUT!

Soft-Close • Auction

Oct. 15, 1-4

Closing Date: Oct. 16, 6 PM

Preview:

PM

•

RT

out: Oct. 17, 4-8 PM

Location: 16332

111, Chesterfield, IL 62630

Geisler Auctioneering & Hanold Auctioneering

JOHN DEERE TRACTORS: 1970 4020, diesel, SN 214704R Engine #236881R • 1969 5020, diesel, SN 024055R Engine #M33R0024778R • 1974 6030, canopy, fully restored, SN 034342R Engine #285176R • 1974 6030 original condition, SN 034301R, Engine #285142R • 1958 420T, gas, SN 1366160 • 1954 70, SN 011705R • 1970 2520, diesel, SN 021331R Engine#166033T • 1959 730, diesel, SN 7319809 • 1949 M, gas, SN 32965 • 1956 60, gas, SN 6055629 • B, late model but serial number is unreadable • 4020, pre-1970, gas, original condition, SN unclear. See website for complete listing, including other brands. JOHN DEERE IMPLEMENTS: 613 2 bottom plow w/coulters • 613 2 bottom plow, no coults • 623 2 bottom plow w/ oulters • 3 bottom plow •2 bottom disk plow • Single bottom horse drawn • Sickle mower • 6 ft. rotary cutter • 8 ft. cultivator • See website for complete listing, including other brands. Page 8 September 2023 • Green Magazine®

ONLINE ONLY JOHN DEERE TRACTOR AUCTION

Selling for W.H. MACSWEYN COLLECTABLES, who is downsizing his collection

On location: #19812 Concession #6

North Glengarry, Ontario, Canada KOC 1A0

•• STARTS CLOSING SEPTEMBER 27TH AT 7 PM

JOHN DEERE TRACTORS:

2555 2WD with loader, only 375 hrs; 1971 4320 diesel with cab;

2-1971 4020 diesels, one Power Shift;

2-1971 4000 diesels, one Power Shift; 1972 4000 gas, less than 300 built;

2-1972 3020 diesels; 1969 3020 diesel, Power Shift;

3-2520s, one diesel; 2-50 gas, one with JD 227 mounted corn picker.

TRUCK: 1985 Peterbilt 379 tandem highway tractor, rare Corvette dash.

OTHER: JD 216 forage wagon; JD front mount fuel tank; JD rear wheel weights; 4000 series grill and frame.

VIEWING: September 22, 8 AM to 3 PM or by appointment with Wayne at 613-330-8773

TERMS: Ten percent internet fee – maximum $1,000 per item.

PAYMENT OPTIONS: Onsite #19812 Concession #6

North Glengarry, Ontario, Canada KOC 1A0 on September 28th from 9 AM to 3 PM by cash, debit or proper check. Credit card with 3% user fee. Payment also accepted by wire or E transfer to: lesley@shackeltonauctions.com All payments to be made before pick up.

PICK UP: September 28th 9 AM to 3 PM. Or by appointment with Wayne – loading available.

FOR INFO: Call Wayne Macsweyn, 613-330-8773

••

JOHN, LES & CAM SHACKELTON – AUCTIONEERS Shackelton Auctions Inc • 519-765-4450 www.shackeltonauctions.com Call or go to website for more information

MIKE,

This past June 15-17, 2023, collectors swarmed to the Wilson County Fair Grounds for a little John Deere time at the Classic Green Reunion 2023. John Deere exhibits were in the buildings and filled the historic Fiddler’s Grove, which was a beautiful area with historic cabins that have been relocated there. This made for picture perfect photos.

In one of the buildings, one of the Classic Green members, Marvin Huber, brought a Deere Webber sleigh from the 1930s’ Ag Museum in Quincy, Illinois. The museum is owned by Marvin and his 95-year-old father-in-law, Don McKinley. Don is a John Deere historian who worked in academia. The museum is open by appointment only. To set up a visit, call Marvin at 217-430-9250.

The 1930s’ museum features John Deere implements manufactured during the transition from horsepower to tractor power. “This sleigh came out of the Minneapolis Branch; they had them made and sold,” Marvin shared about this beautiful piece of John Deere history.

There are a few things that make this sleigh special. “The leaf spring suspension makes the sleigh ride like a Cadillac,” Marvin said. “Most sleighs are just cut out and don’t have a door.”

The doors that Marvin Huber is referring to are located on both sides of the sleigh. “These would have been used in snow country like Michigan,” Marvin said. “The sleigh was built between 1895 and 1910.”

On loan at the show from the museum, it also appeared at one of the Gathering of the Green events but doesn’t get out much because of its age and fragility. “Jaimie and Jackie Bell,

the show chair couple, said let’s put up a Christmas exhibit in June,” Marvin said.

The sleigh was set up next to a beautiful Christmas tree hanging with John Deere ornaments. “Jamie is the Christmas guy,” Marvin added.

The Deere Webber story, like many in the John Deere history books, involves family. Here’s a little abbreviated history based on information written by author Sam Moore in Farm Collector. Charles Deere is thought to have brought in his brother-in-law, Christopher Columbus Webber. Webber joined the family when he married Charles Deere’s sister, Ellen

Page 10 September 2023 • Green Magazine®

Sarah. Dying young, Webber left Sarah with five children and one of them was Charles C. Webber, who joined Deere at an early age. Later Charles C. Webber joined the Minneapolis Moline Branch House, eventually taking over as the manager. In 1893, the branch house became the Deere and Webber Company.

Marvin said the sleigh is rare, but after it came to the museum, they did get it out one winter after a deep snow and hooked it up to one of his wife Cathy’s beautiful Morgan horses and took it for a spin: “Cathy said it rides smooth.”

These days, the sleigh just sits and looks pretty. “We took great care loading it up; it is at least 135 years old,” Marvin added.

Besides the sleigh, Marvin also brought his 1940 John Deere “A” to the show. Marvin said he obtained the “A” from a customer at the John Deere dealership where he was working as service manager at the time. “He came in and said, ‘You mess with John Deere tractors and I have an ‘A.’ Would you be interested in it?” It didn’t run and had bad tires, but my kids went to school with his, and they kept six to eight foster kids.”

Marvin said he didn’t really need it, but it seemed like the right thing to do at the time. He thought it was the right idea, especially when his son, Mike, came in and said that he wanted to restore a tractor. Marvin had just the right one! “I told him if you want to restore it, you must

take every nut and bolt out of it. I want you to know what’s happening with the tractor.”

Mike agreed and, during the next two months, tore it down and started to clean up parts. “I got the needed items ordered, then Mike said the girl he was dating was moving to Chicago and he was going to move, too. He would work on it from time to time.”

The girlfriend worked out and they married. Today they have two boys and a girl! The tractor, however, didn’t work out; it sat for years in Marvin’s shop. “For 25 years, it laid on my floor. Then after we sold the horse business, Cathy came in and said, ‘What are you going to restore? You should restore the ‘A’ so I started in.”

It all went well in the beginning. “I started to assemble the frame, getting ready for the crank shaft, then I found out that the splines for the clutch drive were bad.”

A good friend, Mike Williams, recommended to Marvin that he needed to find a good, used crankshaft because it would cost as much to repair the damaged one. When talking to a friend named Gary Foster from Missouri, Marvin learned that he had a used crank shaft that was in perfect condition. He bought it and it worked out perfectly, solving the crank shaft dilemma.

The next question Marvin had was what to name the pretty little “A.” He said he had bought the tractor from a guy with foster kids, and he received the needed part from Gary Foster, “So I named it Foster!”

This tractor also has a sentimental tug because Marvin’s dad had an “A.” Marvin even has a picture of himself at two years old on that John Deere “A,” so the tractor is right at home, fitting into the Huber John Deere history. Besides the “A,” Marvin said that his great grandfather bought the first John Deere “G” that came into the county back in 1938. “He needed it for 360 acres. We are now seven generations involved with John Deere farming.”

After Marvin finished up his “A,” he said his friend, Ed Veith, needed a tractor for a display. “I finished it up just weeks before Gathering of the Green in 2022.”

The “A” was a hit at the Gathering and seemed perfect to bring to the Classic Green Reunion as well. The Hubers are interwoven with John Deere history and visitors at Lebanon were grateful to Marvin and his family for sharing their equipment and history!

Green Magazine® • September 2023 Page 11

Marvin at two on his father’s John Deere “A.”

About three years ago, a member of Classic Green reached out to us stating he wanted to donate a “G” to Classic Green. He told us to use it to benefit Classic Green in any way we wanted. The Classic Green board wanted to use the “G” to benefit Classic Green but also someone else, so we partnered with Liberty Union FFA in Ohio to refurbish it.

The tractor made its first appearance at CGR21 in Columbus, Ohio where ticket sales began. During the CGR21 parade, an eight year old boy named Emmett drove with Jamie. Classic Green then started showing the “G” at shows and selling more raffle tickets.

Jamie Bell put a step on the back of the “G,” which made it much easier to share and teach people to drive a hand clutch. One of these teaching times was in the vendor area at Gathering of the Green in 2022. Leslie Zunk had purchased a ticket to win the “G” and Jamie asked him if he had ever driven a “G”? Leslie said “no” and Jamie said, “We can fix that right now. Hop on.” Jamie then proceeded to show Leslie how to put the tractor in gear and what the clutch does and they proceeded to drive.

Not to be outdone, Leslie’s five-year-old cousin, Anne, took a turn driving the “G” with

Jamie’s guidance. At the Gathering banquet, we shared photos. Afterward, back at the vendor area, our group of people had grown. Everyone was visiting with each other and many were driving the “G,” several driving a hand clutch tractor for the first time. It was magical! I remember little Anne asking, “Is it my turn again?” over and over.

Several hours later, the young man who was to close the building asked Dan Meisner how much longer this was going to last because he should have locked the doors an hour ago. Dan told him, “You will be our last driver of the night” and he drove the “G” with Jamie. He said his granddad would have been so proud of him.

Classic Green shared this tractor at shows and other events from Iowa to Georgia, Oklahoma, Mississippi, Ohio, Alabama, Arkansas, Illinois, Indiana, Kentucky and all over Tennessee. And at the Wooster, Ohio show, Emmett was there to drive the “G” again. Photos were taken of it with a Blue Angel at Discovery Park of America and crossing the finish line at the Nashville Super Speedway. The “G” was hauled between 17,000 to 20,000 miles before CGR23 and shared with everyone it met along the way.

Friday night after a fun Trivia night at CGR23, it was time to draw a winner. A special thank you to Mark Ostrander for the use of his John Deere handy farm mixer to tumble the tickets. During the last minutes before tumbling, Travis Wibben and Dan Meisner sold all the tickets Classic Green had remaining.

Jamie then found a young man to draw the ticket. The ticket was drawn and Dan and Jackie called Bill Hanehan from New York, but there was no answer so they left a

Page 12 September 2023 • Green Magazine®

Sweet Anne, age 5, at Gathering of the Green beside Jamie Bell on the “G.”

message telling him, “This is Classic Green calling. Congratulations! You have won the Great ‘G’ Giveaway tractor.”

The next day, Bill called Dan and Jackie back and asked: “Is this a joke? Are you pulling my leg?”

The reply: “No sir, you are the winner.”

Bill asked if he could have a few days to think about this and comprehend it. He was told, “Sure, you can let us know.”

Bill reached back out to Jackie, asking for dates she and Jamie would be home to pick up the tractor. The date of Saturday, July 1, worked for everyone and at about 9:45 CDT, Bill arrived in White Bluff to pick up his “G.”

He was still a little shocked but happy and wanting to hear all about it, so stories were shared about the “G.” Jamie asked Bill, “Do you have any tractors?”

Bill said he was 70 years young and had a “B,” 330 and 5020 along with a few others. Bill said he was a mechanic by trade and had a family that milked cows. He stated he had wanted a “G” for several years.

The tractor was loaded and tied down ready to head home to New York. After hand shakes, well wishes and more congratulations, Bill headed out for the 1,020 mile trip from White Bluff, Tennessee.

Jamie said it was like watching a child leave home.

Classic Green Reunion thanks everyone who purchased a ticket and sends congratulations to Bill Hanehan of New York!

Classic Green currently has two more projects—one with Dickson County Tennessee High School FFA on a 110 and one with Elkmont FFA on a “BN.” Both will be raffled off at CGR25 in Wisconsin. Please purchase your tickets to support more projects like these.

Green Magazine® • September 2023 Page 13

All smiles before the “G” left with Bill Hanehan, headed to New York.

Martin Parts & Repair Martin Parts & Repair Oversize pistons available again for many two cylinder tractors Radiator cores, water pumps, bolt kits Emblems Chrome stacks Ignition parts Lights & light parts Battery boxes Fuel sediment bowls Valve train parts & kits Manifolds & exhaust pipes Gasket kits Seats and seat parts Grill screens PARTS TRACTORS 430T, 2510 gas, 730 LP, 2010D, 530, Late 520, ’39 B, BN, 40U, ’53 AO, ’41 H, ‘46 A, late A’s, ‘46 B, late Bs, slant dash B, unstyled B, G, unstyled L, M, MT, 40T, 40U, 40W, 70D std., 70G, 420U, 420W, 440 w/reverser and power steering, 440 gas, early & late 50s, early 60, 620, 620 LP, 630, 4 Gs, 70G, 720G, 720 LP, 720D pony, 730D, 730G, 820, 1010, 2010, 2010D, 2010RU, 2020, 2520D, 3010D, 3020, 4020D. Most of these tractors are parted out & on the shelf—ready for quick shipment! Electric start kits Tachometers and cables Complete clutch rebuild kits and clutch lining kits Brake rebuild parts SUPPLYING PARTS for your CLASSIC JOHN DEERE NEW & USED • IN STOCK • READY TO SHIP Call or e-mail with all your parts & restoration needs or for a FREE CATALOG PTO clutch kits & parts Full round main bearings for 2 cylinder tractors Sheet metal bolt kits Wide front parts Complete carburetors, kits and parts 7487 E. 450 N. • Rochester, IN 46975 574-598-6083 • 844-720-2510 Email: sales@martinparts.net Now stocking USA MADE GAUGES LOTS OF NOS PARTS Email for a price list 60 with 801 HITCH STYLED D

Summer of 2023 has gone by in what seems like a short afternoon nap. To be more specific, like a nap where the window air conditioner is humming away with a stream of air that blows over you like a cool blanket. Your mind slips off into the subconscious where the sense of time is forgotten. When the dreaming thoughts have almost pulled you into a deeper sleep; all at once, with a

snorting sound, you wake up—three hours later.

Our growing season began with a drought in my part of southeast Missouri. Winter wheat was a real highlight for us with record yields in the region. After baling several thousand small square bales of wheat straw, I planted soybeans into the dry hard soil. The beans laid in the ground waiting for moisture to germinate. Droughty conditions persisted in the area about eight weeks without any meaningful rainfall, which led to our crops looking tough. I was about to give up on the corn when along came the rains once again. To date in late July, there

is sufficient moisture now to make the corn crop and push the soybeans ever closer to making something.

Zachary and I had big plans of working on the 1941 “H” to not only get closer to the goal he has of plowing with it this fall but to bring the story of our tractor adventure to all GM readers right here. As life goes, we have not made tremendous progress on the ”H”—rather, life and other priorities got in the way. Several times I offered to work on the “H” with Zachary but he

Zachary could not wait to show Marcus the 630 and ask him about his 630 back in Germany.

Below: Marcus’ first time driving a John Deere Dubuque 420W. Zachary is wearing a Lütt Buur hat that he received as a gift. This translates to “good little boy” in Platt Deutsch (low German). We are driving the 630 in front of Marcus.

Marcus found the spark plug covers for the “H” while inspecting the 1941 “H” project in my shop. He calls them “duck hats” since they would be about the right size for a duck.

Below: Marcus asked Zachary to explain his 4-H tractor project poster to him that he won a best of show ribbon on at the 4-H fair.

Eleanor, Zachary and Marcus on the Avery steam engine in the American Tractor Museum.

Eleanor, Zachary and Marcus on the Avery steam engine in the American Tractor Museum.

Page 16 September 2023 • Green Magazine®

was not interested. As a father, I want to encourage him, but do not want to force him and risk turning his interest away from the project. There was a bit of progress on the project with new engine parts having arrived since the last update in the July issue. However, given the lack of accomplishment on our project in general, I am saving it for the next installment of Youngtimer. You might recall that last year, I had a work trip to northern Germany where I was able to spend a whole day with my friend, Marcus Wiege, from Wilstedt. It had been nearly 18 years before that when we had last seen one another. At that time, I suggested that Marcus and his family come to visit us at my house in Missouri—not in another 18 years, but soon. Earlier in 2023, I learned that Marcus was planning the trip back to the USA with his family. After discussing dates and our schedules, we finally had a plan that worked.

Marcus, Ina, and their daughter, Luisa, arrived in Charlotte, North Carolina in mid-July. They traveled to Charleston, South Carolina in their Honda SUV rental vehicle before heading west across Georgia, Alabama, Mississippi, and Louisiana. They visited some old colleagues and friends from when Marcus worked in east Tennessee about 20 years ago. New Orleans, Louisiana and Natchez, Mississippi were a few cities they visited along the way. Ina planned various stays near plantation attractions, even getting to stay in an actual original plantation house. She was fascinated with antebellum charm and their stops did not disappoint.

The southern USA in July is, as Marcus and his family learned, not a comfortable place to be, especially for folks who come from part of the world where air conditioning is scarce. Southern USA heat and humidity proved difficult for Marcus and his family to endure. Worse yet was the shock to the system when going from outside into air conditioning. The temperature differential was a lot for them to handle, since back home in Germany, high temperatures were rarely above 90 degrees Fahrenheit. While cars in Germany have A/C, they typically only use it cool down 10 to 12 degrees Fahrenheit so the temperature differential is not such a shock to the body.

Marcus and family arrived late in the afternoon with much excitement from my family. While waiting on their

arrival and to pass time, Zachary and I decided to take a little joy ride on a two-cylinder tractor. I had my grandfather’s 1951 “A” running but Zachary wanted to drive a tractor as well so he got out my 1952 “B.” We were just cruising around the farm lane as they pulled into the drive.

Originally when planning the visit, Marcus asked about going to St. Louis, Missouri to see the Gateway Arch and other attractions in the city. By the time Marcus and family arrived at our place, they were quite tired of driving (having traveled nearly 2,000 miles since arriving in the USA) and it was no surprise that they wanted to relax and stay close in the area. We spent the first evening on tour of our house and my newly complete shed, where most of the tractors are stored. Marcus took special interest in my 630, since he too has one just like it back in Germany.

On the first full day of their visit, Teresa made a typical American breakfast with bacon, sausage, biscuits with gravy and an egg frittata. In fact, Teresa cooked up a storm as her goal was to wow our guests with her fromscratch cooking; of course, she nailed it! Marcus, Zachary, and I spent the morning touring the farm and driving around on vintage JD tractors.

Later in the day, we set out for a tour of the American Tractor Museum in Perryville. This local museum has been open since 2021 and has some very unusual tractors and even a steam engine. Kenny Buchheit, a distant cousin of mine, started the museum as a local attraction and to showcase some of his large tractor collection. Eleanor (my youngest), Zachary, Marcus, and I spent nearly two hours on a self-guided tour of the museum and spent a lot of time talking about local history.

After lunch, Eleanor joined the ladies on a grocery shopping experience to see the many differences between German and American supermarkets while Zach, Marcus,

Zachary, Tom Ziegler, and I looking at a 620 while a very rusty “H” sits in the foreground.

Green Magazine® • September 2023 Page 17

Below from left: None of us have ever seen a tractor axle so badly corroded/ rusted. The splines are literally rusted away. The left-hand wheel looks like it sat in a pile of fertilizer for many years.

Since he is a mechanical engineer by trade, Marcus was intrigued at the complicated design of the 202H plow that Tom has for sale.

Below: Zachary and Marcus on the 630 while tedding alfalfa hay. Zachary has the bigger smile but I assure you, Marcus was smiling just as much.

Marcus taking the 4450 around the block.

Below: While it’s not an antique, Marcus asked to drive our 333G track loader as they are not sold in Germany. Marcus has a side business with an articulated wheel loader and a mini-excavator so construction equipment is quite interesting for him.

Ina, Marcus, and Luisa with a neat vintage pickup truck in Tennessee. We were so busy having fun during their visit that we forgot to get a group photo of all of us.

Below: Posing for a photo at the antique mall, Luisa snapped a good photo next to the giant penguin. Ina found a pair of JD suspenders for Marcus that he was not too keen on.

and I headed north to French Village, Missouri. My friend, Tom Ziegler, has a large tractor collection as well as a lot of parts tractors. He showed us around as we looked for treasures. Marcus spotted a late model John Deere “H” that caught his fancy. Tom had just gotten it in and was trying to decide if it should be parted out or stay complete. Marcus was tempted but of course it is best to import a complete running tractor to Germany as any spare parts would have to be shipped in since there are basically no two-cylinder salvage yards in Europe.

Zachary was naturally curious as we checked over the “H,” seeing how it was similar or different from the 1941 project tractor in our shed at home. He spotted an interesting looking bracket mounted on the rear axle and we talked about that it was a cylinder mount/lift bracket for an H-1 plow. It just so happens that we have been looking for this exact part for over a year now. Our “H” came with the H-1 plow but did not include the mounting bracket. Tom was glad

to part with the bracket as he did not have the plow for this tractor. Zachary was thrilled to know we can use the hydraulic cylinder to lift the H-1 plow once we get the tractor running. Perhaps our visit to Tom’s will help get him motivated to work on the “H” after all.

Our visit to Tom’s lasted several hours and we saw a lot of parts and whole tractors. Marcus noted several times that he had not seen so many Dubuque built two-cylinder John Deere tractors before. When we got back to the farm, Marcus spent some time on my Uncle Dwayne’s 420W (which resides at my place as I keep it in good working order for him), getting a feel for the tractor. Perhaps the Dubuque design is growing on Marcus, but I think for now he is sticking to a model “H” as his next American built two-cylinder John Deere tractor.

The next morning, Zachary woke up on his own about 6:15 a.m. He was excited that we were going to be run-

ning the hay tedder on a 10 acre alfalfa patch which my dad mowed the day prior. The hay was the third cutting and was quite a thick crop, considering the lack of rain for most of its growing time. Marcus joined Zachary on the Gator and me on the 630 and tedder and we headed for the field. I adjusted the tedder and made the first few passes. Once it was adjusted, Marcus got behind the wheel while I showed him the field and a few spots to be careful of (gullies and a steep hillside along the creek). I hopped off the tractor and let Marcus go on his own. As is typical for most folks in the antique tractor hobby, he was quite happy to be doing something productive with the tractor. For us, he was helping to bring in a hay crop, but to him, it was pure joy. Back home near Wilstedt, Germany, the terrain is very flat so

Page 18 September 2023 • Green Magazine®

our rolling hills were a learning experience for Marcus. He completed the most difficult parts of the field while we let Zachary drive in the smoothest areas. In a little over an hour, the job was done and once again Teresa fed us with an excellent breakfast.

After breakfast, we set out for the farm once again. I gave a small tour of my workshop area and we looked over the “H” project. With parts and pieces everywhere, it was not much to look at but Marcus understood as he too has covered his garage with tractor parts during a teardown and rebuild. After looking through my shop, we checked out the other farm equipment. Marcus spied the 4450 two-wheel drive tractor in the shed and stepped in to have a look. He, too, owns a 50 series John Deere (European model 2850) and wanted to see how the Waterloo, Iowa built version compares. I suggested he take it for a drive and he fired it up for a spin. He really liked how high it sits (42 inch rear tires sure make it feel tall) and that it has dual rear wheels. In Europe, dual rear tractor tires are almost never seen as traffic laws make wide vehicles difficult, if not impossible, to transport on roadways.

For the afternoon on day two, we drove to visit my brother, Alex, at his house. Alex had visited Marcus in Germany 10-plus years ago while he was traveling to that area for a work trip. They were delighted to see each other again after such a long time.

From Alex’s house, Marcus, Ina, Luisa, Eleanor, Zachary and I headed over to Sainte Genevieve, Missouri to see check out this historic French/German town. Aside from looking at various

Luisa and Adeline working on 13 dozen homemade doughnuts, which was quite a job for them. They were able to connect since they were the only teenagers in the house. In only three days, there was a lot of culture and language exchanged between the two.

Below: Headed out from our house onto the next leg of their journey across the USA—we were sad to see them go. Auf wiedersehen!

from Luisa, Ina, and my wife, Teresa. Marcus asked to drive our 333G John Deere track loader as he never drove one before. In Germany, excavation work is done with either wheel loaders (articulated) or with excavators. I had a pile of dirt behind my new shed that I told him to go and try it out. After getting acquainted with the machine, Marcus asked if I had a job for him. He took 2-1/2 hours and smoothed down and graded my dirt pile for me. He was happy to get the experience and I was happy that he made the job look easy.

One their last evening of their time with us, we all headed out to the 4-H fair. I can think of literally no better way to show our international guests true rural American culture than at a 4-H fair. We chowed down on a fried chicken dinner and afterward visited and looked through the project exhibits. It was hard to explain beforehand to them all about 4-H and what sort of event this was. We were glad to share a bit of our lifestyle and culture with Marcus and his family during their visit.

18th century French style buildings, and to the delight of Ina and Luisa, we visited the local antique mall. We spent the next few hours looking at all the interesting offerings of the mall and they even found a few souvenirs to take back to Germany.

For the last day of their visit with us, we all pitched in with getting ready for the local 4-H fair/dinner. Adeline made 13 dozen homemade doughnuts to sell at the fair with help

It was hard, but on the last morning, we said our goodbyes. Time had simply raced by us all during their visit. From our place, they were headed to Chattanooga, Tennessee for a few nights before heading to the Smoky Mountains for a cabin stay until returning to Germany. Before parting ways, we vowed to come as a family to Germany soon so my family can experience their culture and see what it is all about in a different continent.

Contact Tyler Buchheit by email at tyler@mrbtractors.com. His website is www.mrbtractors.com

Email your question to Mr. Thinker: info@greenmagazine.com or mail to: Mr. Thinker / Green Magazine PO Box 95 • Bee, NE 68314 Green Magazine® • September 2023 Page 19

• An easy leak-free ISO conversion kit for John Deere tractors from 1964-1982 • Push-pull design eliminates levers • Breakaway action includes all seals and dust covers

$315

NO MORE DRIPS!

DELUXE CONVERSION KIT

Remanufactured stepper motor

models: 6000 SRS tractors ‘00, ‘05, ‘10, ‘15 & ‘20 SRS OEM part #AL181805

core value

315-536-3737

Products LLC Rebuilt in our facility Page 20 September 2023 • Green Magazine®

Fits

$450.00 exchange $200.00

Ph.

GreenLight

John

John Deere Unstyled A, #472222

John Deere 3020, Propane, #114478R

John Deere B, square seat, with

John Deere 4010

John Deere 60, #6016691

John Deere B, #27933

John Deere M, #53376

John Deere A, #641606

John Deere 520, #5207352

John Deere long hood A

John Deere AO, #269661

John Deere 3010, D, WF

John Deere G, #268804

John Deere R, D, #18533

John Deere 3020, #13R003980R

John Deere G, #33338

John Deere 50, #5009781

John Deere 5020

John Deere G, #39073

John Deere 2010, Gas, tricycle front, #2010R68244

John Deere 4010, D, #2T13312

John Deere 4020, #6599

4 – John Deere 4020

AUCTION October 6 and 7, 2023 • Lyerly, Georgia • Start time: 9:00 AM Selling

Braden

ESTATE

the estate of Jerry

Hwy.

October 6 address: 5595

114, Lyerly, GA

GA Visit our website for complete listing & photos: www.rjoauctions.com • Email: rjayop@aol.com

Deere AO, #27616 • John Deere 40 Standard, w/cultivators, #6976202L

Deere AR, #275868 •

Deere

Deere 2510, D • 4 -

2 -

Deere

•

October 7 address: 4340 Holland Chattoogaville Rd, Lyerly,

John

John

John

D John

John Deere L

John

LA

John Deere 720 Std, D, pony start

hood •

Deere B, long

2 row cultivator John Deere AR, #275707

•

•

•

•

•

•

•

RJO Auction Co For info, call Ronnie Odom: 770-846-3225 Viewing dates: Sept. 30 - Oct. 5, 2023 8:00 AM to 4:00 PM Live onsite and online bidding Terms: 10% Buyers premium Online bidding with Green Magazine® • September 2023 Page 21

Page 22 September 2023 • Green Magazine®

Andrew Baldner's 1982 4040 Syncro.

Are you looking for a tractor that has all of the benefits of the venerable John Deere 4020 but with the added convenience of a Sound-Gard cab? Look no further than the model 4040. The 4040 shared much in common with the 4020, but modernized that old machine by a couple of series, making it predictably more comfortable and convenient and sacrificing almost nothing.

The 4040 was powered by Deere’s six-cylinder 404 engine. This engine was born of Deere’s 380 cubic inch engine from the 4010 tractor. When the 4020 came about, the engine was bored out from 4-1/8 inches to 4-1/4 inches, giving it its 404 cubes. In the 4020, the engine made over 95 horsepower, up 15 from its output in the smaller size. The 4020, with this 404 cubic inch engine, has long been hailed as one of the greatest agricultural tractors that has ever been produced.

The success of the 4020 and the proven power and durability of the power plant that was in it inspired Deere to put the 404 engine in more machines. The engine was used in the 4000 tractor. With the addition of a turbocharger, the 404 was installed in the 4520, now making 135 horsepower. The 4320 tractor used another turbocharged 404, this one rated at 115 horsepower. When the 4020 was retired and the Generation II series came along, the 404 continued in each of the three larger tractors. It made 100 horsepower in a naturally aspirated setup in the 4230 and with a turbocharger and intercooler, 125 horsepower in the 4430, and 150 in the 4630. Deere also put the 404 to work in the 105, 6600, and 7700 combines and even more pieces of equipment.

With the new 4040 tractor, the 404 engine proved to be more resilient than disco and survived into the 1980s.

Deere was kind to the esteemed old engine and tuned it down to 2,200 RPM and just 90 horsepower. The engine made its power easily at this rating. For a tractor of its size and power, the displacement and torque were quite high. This was planned, as one of Deere’s goals for the 40 series

“New Iron Horses” was a focus on improving both of these areas in their entire lineup.

Taming the engine down to 90 horsepower had a soothing effect on the 404. As Deere’s advertising said, “The 4040 features the same engine that powered the 100 horsepower 4230. Now, it is required to develop just 90 horsepower…and predictably it will last longer.” The 404 was already known for durability; in the 4040, it was set up to last nearly forever.

At 90 horsepower, the 4040 was

a 10 horsepower improvement over the 4030. It felt like more, though. The added torque of the 404 made the tractor a much better tugger than its predecessor, and that became obvious when you put the machine to work.

Deere called the 4040, “A plowing tractor, a planting professional, an agile artist with a loader, a heads-up haying expert…the 4040 is an ‘everything’ tractor.” It really could do everything necessary on a small farm.

While Deere liked to compare the 4040 to the 4030 to show how many

Green Magazine® • September 2023 Page 23

Here's a rare narrow front model. It is a 1982 owned by Steve Plambeck of Kenesaw, Nebraska.

improvements and increases the new tractor had over the old, the connection between the two tractors was tenuous. The 4030 was, in terms of size and power, a descendant of the 3020. The 4040 was much closer to the 4020. Still, the 4040 was the new tractor that replaced the 4030, and Deere’s advertising team could point to all of the ways that the company had improved the machine, so the comparisons were made to the benefit of the salespeople.

Deere had several transmissions available for the 4040. The Quad-Range was installed as standard equipment. This transmission had been introduced with the release of the Generation II tractors and had already proven its reliability and versatility. This was a 16 speed transmission with four speeds in each of four ranges. Power shifts were available between first and second gears and third and fourth gears in each range. Eight of the gears were clustered in the most common field working speeds, giving several options to the farmer to match the tractor to the job at hand. The Power Shift and Syncro-Range transmissions were also available, as well as a creeper version of the SyncroRange. The creeper added five speeds in an extra-low range from .43 to 1.45 miles per hour. Jobs requiring extreme precision or heavy PTO work benefitted from this specialized gearbox.

In addition to the bigger, more powerful engine, the 4040 was simply…bigger. It weighed 1,400 pounds more than the 4030 thanks to a strengthening or expanding of parts throughout the tractor. The 4040’s wheelbase was three inches longer than the 4030. It had more hydraulic capacity and more hydraulic cooling capacity. The engine had more cooling capacity as well, and the three-point could lift 14 percent more. The fuel tank and drawbar were also each a bit larger. The tractor took to heart the slogan of the New Iron Horses, “More horses; more iron.”

Customers were very happy to

see what Deere had done with the 4040 and the New Iron Horses in general. The Generation II tractors were fantastic machines, and the SoundGard body was a revolutionary step forward in agricultural tractors, but customers did sometimes complain that the machines lacked hydraulic capacity and low-end torque. This was a fair assessment. Much of what was in the Generation II tractors had been brought forward from the New Generation, and Deere was pushing small engines to do big work. The turbocharged engines required spooling up to speed to make the power they needed, so they did not have that low-end torque. As far as hydraulic capacity, even the top-end 4630 had less three-point lift capacity than the big members of the previous generation. The chassis on many of these tractors were holdovers from previous years, as well. Customers’ arguments had some teeth, but with the 40 series, Deere had made things right.

Deere also made changes inside the cab. The Sound-Gard body may have been less than a decade old, but that didn’t mean there were not any

improvements that could be made to it. The new “HydraCushioned” seat was the beginning of the improvements. This seat, Deere said, “floats the operator on a cushion of air.” The seat had a pneumatic shock absorber and a hydraulically controlled height adjustment and a spring-loaded horizontal shock absorber. With all of these parts at work, the seat did all that it could to completely isolate the operator from the movements of the tractor. The cab had even more upholstery and sound-deadening material than it did before, and as a result, was quieter than before. It didn’t hurt the noise level that the engine in the 4040 ran at a couple-hundred fewer horsepower than the 4030, either. Deere also added a lot of light to the tractor, putting about a third more light to the front and nearly tripling the amount of light that was aimed at the rear.

The 4040 was an easy and obvious replacement for the 4030 on farms that needed an upgrade. For farms still running older equipment such as a 4020, the 4040 might have been just a bit lacking in horsepower. Those farmers had the option of add-

Page 24 September 2023 • Green Magazine®

David Ferrell, Apex, North Carolina owns this 1982 Power Shift that he displayed at this year's Classic Green Reunion.

ing aftermarket parts, like the M&W turbo kit that had been so popular on the 4020, to the 4040, as they would fit and work just as well. With one of these, the 4040 was capable of putting plenty of power down. If you ever find yourself shopping for a 4040 and happen upon a tractor with an aftermarket turbocharger or other upgrades, you might wonder if such a change would harm the engine. Possibly, though, consider the fact that the 404 had been used in other official applications with the output turned up as high as 150

was satisfied with what they were seeing from it.

The 4040 came with 15.5-38 inch rear tires and 9.5L-15 front tires installed as standard equipment. Many other tire sizes were available, as well. Duals were also available in the back, and several weight packages could be ordered and installed. If you still couldn’t get enough grip out of your 4040, you could order Power Front-Wheel Drive. This system worked on hydraulic

justify. For farmers who wanted the lowest possible profile or the lowest possible price, there was the open station option. Power steering was standard equipment along with a Category 2 three-point, hydraulic differential lock, and independent 540/1000 RPM PTO. A single hydraulic outlet was also standard, but the owner could order up to three on the tractor. Ether starting aid and a full light package were also standard equipment.

horsepower, and most of those tractors are still among us. Furthermore, the 4040 shared many of its drivetrain parts with the 4240 and 4440, so it is not like it is hurting for iron in its spinny parts. In short, it might lose a few hours between overhauls, but it will likely be just fine.

Deere released the 4040 in 1978. The little tractor sold about 2,200 tractors in its first year, which was the slowest sales of the New Iron Horses, but faster than the 4030 was selling the year before. Sales picked up over the next couple of years, and through four years of production, a little over 10,000 tractors were built. The machine might have been the slowest seller, but it was more of a specialty tractor at this point in time, and I’m sure Deere

power, turning off and on at the flip of a switch. High and low torque settings were ready to go on the switch. The higher torque for pulling through tough ground and the low torque for improved steering, sidehill operation, and for lighter loads. The bigger tires and bulkier system gave the tractor a wider turning radius and a bit lower crop clearance at the front axle but could make a big difference at times, saving a farmer from a bad situation or an impossible task.

Standard equipment on a 4040 was a four-post Roll-Gard ROPS. Most of the tractors that left the factory had a Sound-Gard body, however. The quiet and comfort of the cab were far too attractive to ignore, and the cost was cheap enough for most farmers to

The 4040 is now more than 40 years old. Farmers who owned one, or still do, almost unanimously review the tractor in a positive light. It seems that the marketing by Deere was correct on this one. It really was a tractor that was ready to do whatever job you had waiting for it. As for the comparisons between it and a 4020? Well, the responses are mixed. The 4040 had the advantages of the more comfortable operator’s station (at least if they had a cab) and a heavier frame. The stronger front axle on the 4040 is especially important for those who made them a loader tractor. The extra transmission options were also better for the 4040. The 4020 had the obvious benefit of more power, though many say a 4040 can easily be turned up or tuned to match. Others say that their 4040 was a lot thirstier for fuel than their 4020. It seems the tractors run pretty neck and neck. I guess, if you have to choose, take them both.

Green Magazine® • September 2023 Page 25

Tractor Parts We Fabricate

Weight Bracket

5010, 5020, 6030: AR58358, Pr $490

Rear Engine Panels

4620 Right, AR43290, $155

4620 Left, AR51804, $255

2510 Right, AR38206, $300

2510 Left, AR38207, $220

2520 Right, AR38838, AR38202, $300

Step w/Pads

5010, 5020, 6030 - AR40914, $165

Step U Bolts $18

Seat Base Cover for Tractor w/o

Rock Shaft - AR26846, $295 4000 & 4020 Std SN 201,000 & Above

Fabricated tractor parts - Dave Haala

AR40773 LH Rear Eng Panel = $80

AR40774 RH Rear Eng Panel = $80

2520 Left, AR38839, AR38203, $220

5010, 5020 R, AR35023, $300

L, AR35024 OR AR36796 $300

6030 Right, AR53645, $350

6030 Left, AR53646, $350

Dust Shields

5010 Right, AR35334, $320

5010 Left, AR35335, $320

5020, 6030 RC Right, AR40930, $350

5020, 6030 RC Left, AR40931, $350

5020, 6030 Whd R, AR36772, $350

5020, 6030 Whd L, AR36773, $350

Rock Shaft Cover

5010, 5020 Right, R36420, $295

5010,5020 Left, R36422, $160

5010, 5020, 6030 Center, AR55756, $70

6030 Right, AR55755, $295

6030 Left, R51485, $160

Toolbox Cover

5010, 5020, 6030 - AR35050, $65

Hood Air Cleaner Cover

4050, 4520, 7020 - AR43256, $165

Hydraulic Dipstick Cover

5010, 5020, 6030 - R36421, $80

Dave

AR40871 Platform (can modify AR48727) = $155

AR41097 Platform Support = $84

AR41098 Platform Support = $84

AR41137 Dust Shield RH = $315

AR41138 Dust Shield LH = $315

AR41174 Support To Dust Shield=$27

R41253 Ext Front Right = $156

AR41451 Ext. (RH) = $74

AR42594 Step Bracket w/2 pads = $215

F3195R Step Pad = $30

AR42989 Cover Battery Box = $80

AR45129 Battery Box Support = $75

AR45130 Battery Box Support = $75

AR45131 Ext L Ft AR48964 = $184

AR45207 Battery Box = $340

AR46289 Weight Bracket = $102

AR48964 Ext L Ft AR45131 = $176

3020 Standard Tractor

R34944 Floor Panel 3020 Std PS

R34943 Floor Panel 3020 Std PS

AR34801L Dust Shield = $325

AR34801R Dust Shield = $325

R42893 Fastener Pin for Battery Box = $36

Haala: dave@haala.com or 507-920-9181

Page 26 September 2023 • Green Magazine®

Green Magazine® • September 2023 Page 27

More about the front cover

’30s. In the spring of 1935, his mother purchased a farm near Coleta, Illinois for him and his wife to operate and raise their family. My father was born in the farmhouse that fall, the eighth of eventually 11 children.

The following spring, my grandfather purchased his first tractor, a 1936 John Deere “B,” from Wagner Implement in Milledgeville, Illinois. He had only farmed with horses prior to this. My father often shares that his Dad ended up selling his horses at least three times because he couldn’t bear to let them go. With the tractor, my grandfather bought a two-row cultivator, a two bottom plow, and a 10 foot single disk. The cultivator was a hand lift, but the power take-off driven power lift was added a few years later. Dad and Grandpa milked cows and raised hogs and farmed about 180 acres.

Dad’s oldest brother also farmed in the area and the “B” often went back and forth between farms, depending on who needed to use it. In my uncle’s younger years, he also used the “B” to do some custom work for a couple of farmers in the area.

In the 1950s, Dad joined my grandpa in the farm operation. They only ever farmed with two cylinders. As a young child, I was often on Dad’s lap, helping steer a tractor whether we were moving hay from one barn to another or hauling manure or just about any other job where I could be there. I was even allowed to drive the tractor myself baling hay while Dad was on the hayrack stacking bales. The hand clutch allowed me to be able to operate the tractor in slow gear knowing that Dad could get to the tractor to

stop it if something broke down. One of my favorite memories was riding with Dad moldboard plowing with his John Deere “R.” I can still remember the orange glow coming out of the muffler as we went up and down the clay hills after dark.

Dad and Grandpa farmed together until the fall of 1971 when Dad decided it was time to change occupations. Grandpa didn’t want the first tractor he ever bought to be sold on the farm sale so he gave the tractor to me. I was in the fifth grade at the time. Our family moved 50 miles south to Walnut, Illinois, where my father was employed by PAG Seed Company and the tractor moved with us. We ended up living in the country just a mile and a half from Dad’s work. Our new location consisted of a

house, barn, crib, and old tin machine shed where the tractor was stored. The year Dad quit farming was the first year he had allowed me to do a

Doug Anderson’s father drives the “B” in a parade and, at 88, still starts the tractor, right.

Page 28 September 2023 • Green Magazine®

few farm jobs on my own with the tractors. I enjoyed the many different farm tasks immensely.

As I was preparing to go to high school, the guidance counselor came out to sign me up for classes. As he went through the choices, one of the classes I wanted to take was vo-ag. Dad was quick to remind all of us that he had quit farming and I couldn’t be in ag class because I would need a farm project. The counselor refuted this and said I didn’t need a farm project, but could do farm beautification or gardening or any host of other nonfarm projects so Dad consented to let me enroll in vo-ag.

During the fall semester of my freshman year, the ag teacher and a local farmer organized an opportunity for FFA members to buy two feeder calves each and enter a rate of gain contest. They also prearranged financing at the local back to buy the calves and finance the feed until they would be sold the following summer. I couldn’t wait to get home to ask my parents if I could participate. With just a little persuasion, I was good to go. After all, I had the “B” to use on a burr mill grinder and could pull a manure spreader to haul manure. Thankfully, the farmer who owned and farmed the land where we lived allowed me to borrow some of his equipment and haul the manure on his ground.

In the spring of my freshman year, an ag classmate of mine informed our class that his dad had three bred

gilts that he needed to sell because they were due to have their litters a month later than all the rest of his sows and gilts. Again, I asked and was granted permission to purchase those as well. Fortunately, I had access to cracked corn and other waste corn products from Dad’s work, which allowed me to have cheap feed in addition to what I had to purchase commercially. My livestock operation grew and the “B” wasn’t up to the task of all the work I needed to do so my senior year, I attended a farm sale with my ag teacher and bought my first tractor, a 1953 John Deere 50. A year or two later, I discovered the 50 wasn’t really big enough either and bought a 1953 John Deere 70. I could accomplish everything I needed to do with those tractors.

Having farming in my blood and no way to really farm, I decided to attend the University of Illinois and study agricultural education. By the time I was finished with college (with Mom and Dad’s help), I was raising about 50 head of feeder cattle and farrowing 20 sows and gilts and selling feeder pigs. The love of the

putt putt and operating the tractors never diminished. During my 33 years of teaching agriculture, I was on the lookout for tractors. I taught 150 miles from where I grew up and where most of my tractors still reside. Eventually, I collected all of the first numbered series of John Deere two cylinders and then my brother and I worked to collect some of the smallest tractors from many of the other brands of tractors. My brother has also collected the Patio

series of John Deere lawn mowers, acquiring all four colors of the 110s and a 112, 120, and 140, all in orange. The front cover photo was done by Warne Riker several years ago using a technique called light painting. Warne operates Warne Riker Photography out of Nashville, Tennessee. Dad, almost 88 years old, still starts the “B” by hand. The cultivator makes that a little more challenging, but the tractor has always been an easy starter. We all enjoy getting the tractors out two to three times a year just to run them around a little bit and drive several of them in the Walnut Days Parade around the 4th of July. I retired from teaching a few years ago, which affords me the opportunity to spend more time with the tractors. I will have to say that my most valued possession is the 1936 John Deere “B.” I will follow Grandpa’s lead and will not be selling the 1936 John Deere “B.” My hope will be to keep it in the family.

Submitted by,

Doug Anderson Paxton, Illinois

Green Magazine® • September 2023 Page 29

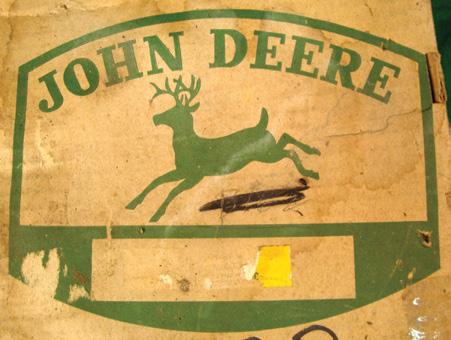

John Deere part AR21282R. Can you name what part that is? If so, you’re probably either way too into this hobby or you just bought one. That part happens to be our first item in What Brought More? this month. That part number is for an exhaust rain cap for a 60 through 730 John Deere tractor. This piece is new old stock and was in the box until the seller took a picture of it for the eBay listing.

in an irregular four-sided shape. It is black with yellow and white writing, advertising the quality of Deere parts. The most impressive aspect of this sign is the fact that it is still in decent condition after so long. Being made of painted pressboard, it wouldn’t have taken much to severely damage the thing over the last several decades. Somehow, it’s still here, with only light wear around the edges, ready to be your second contender in this month’s What Brought More?

California dealership that still sold machines from both companies. The trademark on it dates this thermometer to the late 1950s or early 1960s. It’s in great shape with no dents or rust. It brought $174.50.

Yet another John Deere fertilizer item brought a huge price this month. This little pocket tape measure is also from sometime around 1960. It’s silver with green and yellow enamel and was given out by a dealership in Walsh, Colorado. Somehow, it is now worth

The second item in What Brought More? does not have a part number. Instead, it existed to try to get you to buy more John Deere parts. This is a simple old sign. Based just on the look of it, I would guess that it dates from the 1940s. It is a slab of pressboard

The Deere and Caterpillar union was a mutually beneficial situation for quite a while. The two companies would sell each other’s products in their dealerships and share a bit of information. Since the companies generally kept to different markets with their machines, there was only a little overlap and little competition. That said, neither company’s salesmen had any real drive to sell the other company’s products, and so the relationship wore away over time. Eventually, Deere started building larger industrial equipment and moving into Caterpillar’s space, and the companies were in more direct competition. A thermometer that sold on eBay this month must be from the tail end of Deere and Caterpillar’s relationship, from a northern

$1,797, or about $180 per foot of tape. Sometimes I wonder where these prices come from. This is a neat tape measure, definitely, but there was only one photo of the piece and almost no description. How were so many people bidding on it with such blind confidence? They must know more about the value of some of these things than I do…which isn’t exactly surprising.

Keeping on the topic of high prices, we get a couple of examples

Page 30 September 2023 • Green Magazine®

of the Deere Christmas ornament number one. These have commanded a high price for many years now and the prices have gone up over time. Two sold this month. Both were in good condition and came with their

had some scratches and paint loss and maybe a small dent here or there, but it looked like they were complete and not missing any parts. The set sold for $203.50.

Two more toys sold, in separate lots, on eBay this month. These two toys were also a bit worn but mostly

this hat would really make you the big man around town. It looks to have been only lightly used and in good shape. It sold for $129.99

At just six inches wide and six inches deep, this little rack and sign is one of the smallest that we’ve featured in this article. Advertising Deere belts,

velvet bag. The first sold for $1,400. The second for $2,000. I can’t help but think that something was up with these, though. The second sold four days after the first. The title and description were identical, though the pictures and sellers were different. However, the one that sold for $2,000 sold to the one and only bidder. Are these being used for money laundering or something? Maybe they’re just that desirable.

All right. Let’s calm things down a bit with a piece of literature. This time we have Deere’s vehicle catalog from 1919. Inside you can find information and drawings of all of the wagons and buggies that Deere sold that year, as well as an order sheet to mail in your purchase of a Deere vehicle. The seller

in better shape than the previous toys. Both also came with a (somewhat beaten up) box. The first was a 630 tractor. This tractor was missing its exhaust pipe. It brought $212.50. The second toy was a model 12A combine. It had just a tinge of rust but was in quite good condition. It doubled the tractor, selling at $426.01.

this 1960-era sign is in pretty good shape, with just some wear on the background. The rack looks good and would make a great display for more other small collectibles. See if you can find some John Deere belts (the kind that keep your pants up) and start an ironic display. This rack would’ve cost you just $268 to get started on that joke.

says that there are a few creases and some pencil marks in the book, but that it’s in good condition overall. The book is 11 pages long. It brought $39. A small set of well loved toy tractors from the 1940s to the 1970s sold on eBay this month. Overall the machines were in pretty good shape for their age and apparent use. They

Tired of looking like a nobody when you’re out on the town? This hat will fix that. Look like somebody special with a vintage green John Deere cowboy hat. This hat includes a band with an embroidered leaping Deere on it. The seller did not state the age of the hat but it’s from somewhere between 1968 and 2000…which is admittedly quite a wide range. In size extra large,

Getting back to What Brought More?, we get to find out whether the Deere part or the sign advertising Deere parts brought a higher price. The muffler cap was in perfect condition, ready to crown any tractor in the 60 to 730 range. One fun part is that the box looks like it has a price of $3 written on it, but what do you think it brought at auction in 2023? The price of $280 is the correct answer. Nice investment! The sign is old and really looks pretty good for its age and the material that it is made of. Is it interesting or unique enough to beat $280? This time, it was. It brought $309 after a week on auction—giving it the win.

See something interesting online? Forward it to sawitonebay@ yahoo.com

Green Magazine® • September 2023 Page 31

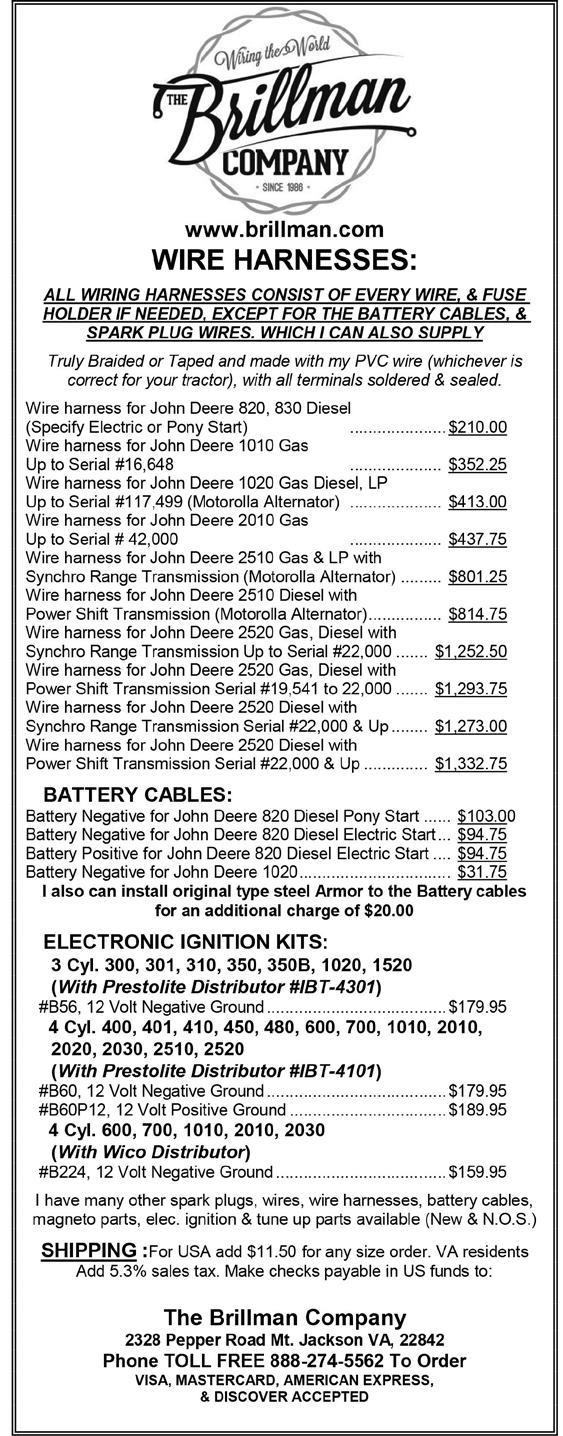

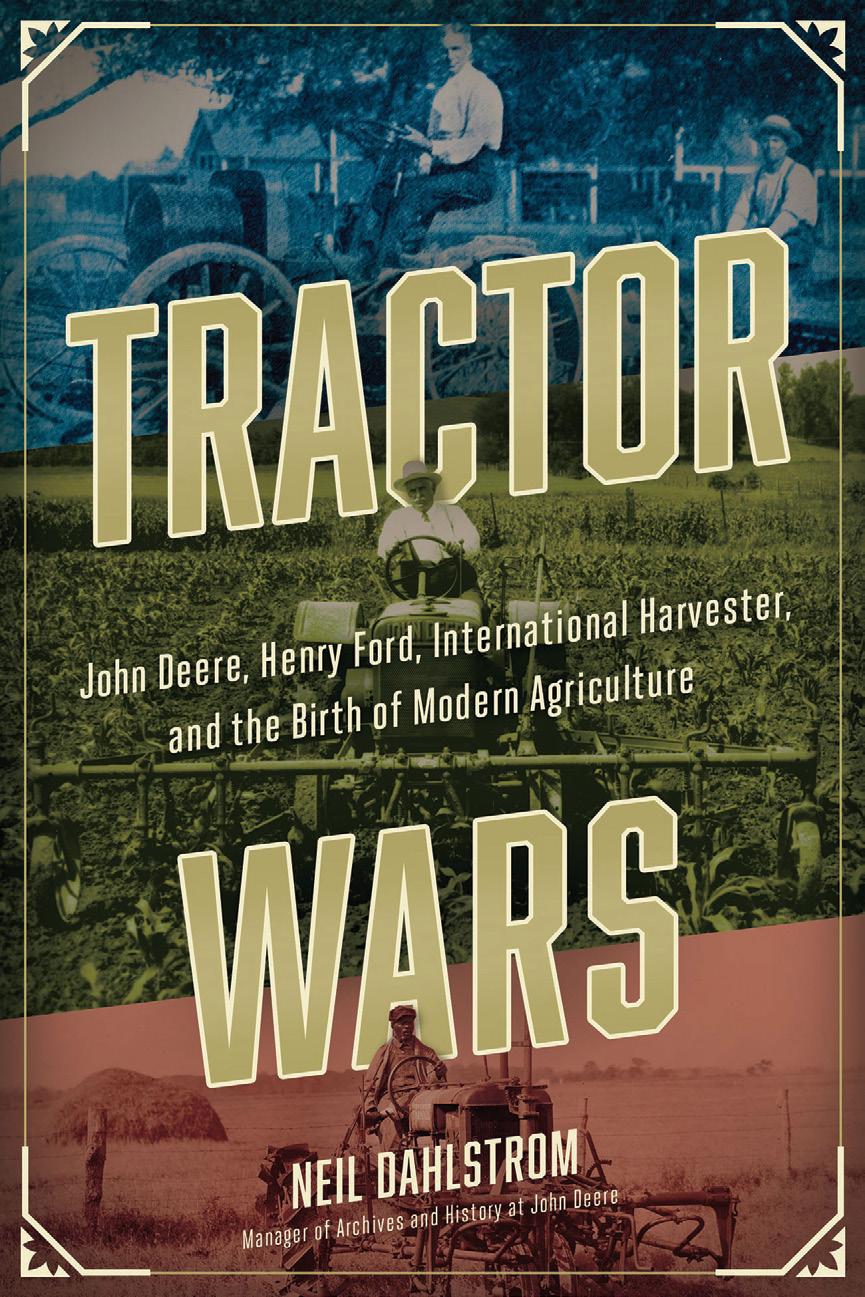

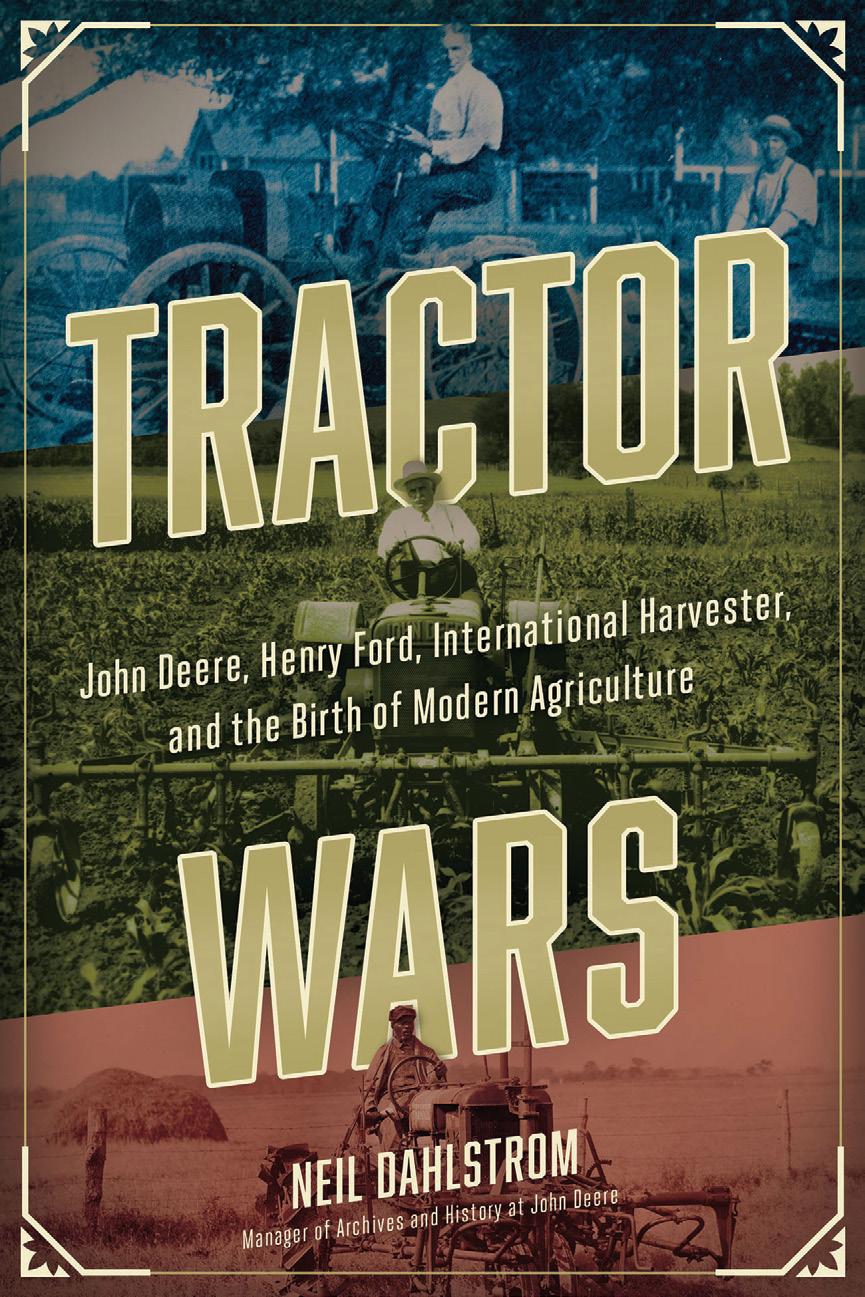

Tractor Wars: John Deere, Henry Ford, International Harvester, and the Birth of Modern Agriculture This book explores the origins of the farm tractor in the early 20th century, centered on the fierce competition of companies and entrepreneurs to out-innovate and invent modern agriculture Written by Deere Archivist Neil Dahlstrom 288 pages • 6” by 9” • Hardcover Order GMTW: $33.95 U.S. $43.95 Canada (U.S. funds only) $53.95 All Others (U.S. funds only) Call us, go to our website or send us a check Green Magazine • P.O. Box 95 • Bee, NE 68314-0095 Phone 402-643-6269 Email: info@greenmagazine.com Website: www.GreenMagazine.com Visa, Mastercard, Discover, and American Express accepted • Nebraska residents add 5.5% sales tax David and Robin Marlin • 322 Marlin Prairie Drive • Conway, MO 65632 Ph. 417-589-DEER (3337) or 417-589-2634 • Email: rpm@2cylplus.com • Website: 2cylplus.com Mastercard/Visa/Discover accepted • Ship UPS and truck lines daily We are located just 70 miles northeast of Branson, Missouri Check us out on Facebook Hundreds of salvage 2-cylinder tractors: A and B through 830 Some of the services/parts available at 2-Cylinder Plus: New piston kits, new taper-loc hubs, diesel injection service & more! Page 32 September 2023 • Green Magazine®

•

aftermarket, rebuilt and used parts for

• Used parts include: weights, 3-pts., toplinks, dual hydraulics, float ride seats, clutch parts, hubs, transmission gears, sheet metal, tires and rims, 720-730 ES parts, all-fuel manifolds, brake parts, square and round tube WFEs, heads, blocks and PTO parts.

• New parts include: manifolds, battery boxes, carburetor kits, air stacks, mufflers, grill screens, radiator cores, lights and overhaul kits.

• Rebuilt parts include: float ride seats, starters, carburetors, cleaned and lined gas tanks. Also have crack checked heads and blocks.

SMV emblem support bracket - K&K Antique Tractors K & K Antique Tractors Kent Kaster • 5995 N. 100 W, Shelbyville, IN 46176 Phone 317-398-9883 Website: www.kkantiquetractors.com • Email: info@kkantiquetractors.com A v A il A ble P A rts in s tock * Complete battery tray assembly Headlights Fenders * Step kit * Gauges Radiator core * Safety plate * Front & rear side panels Hydraulic outlet plugs * Raincap for late side console * Nameplates $225 per set * Decals Hood ornament Pre-cleaner bowl * 3-piece seat kit * Battery boxes * Rockshaft covers Fuel cap & radiator cap Steering wheels & centers * Side & front grille screens Order today! NEW ITEM * SMV Emblem Support * Original part number AR46282 * Selling bracket ONLY * Made in USA Lind Bros Tractor and Parts, LLC

JD A, B , D, G, H, M, R, 320, 330, 40, 420, 430, 50, 520, 530, 60, 620, 630, 70, 720, 730, 80, 820, 830, 3010 3020, 4010, 4020.

New

Lind Bros Tractors and Parts, LLC 830 Saint Peter’s Church Road SE • Corydon, IN 47112 sales@lindbros.com • www.lindbros.com 812-952-3010 • 833-952-3010 Call or email today! Orders can also be placed online. Green Magazine® • September 2023 Page 33

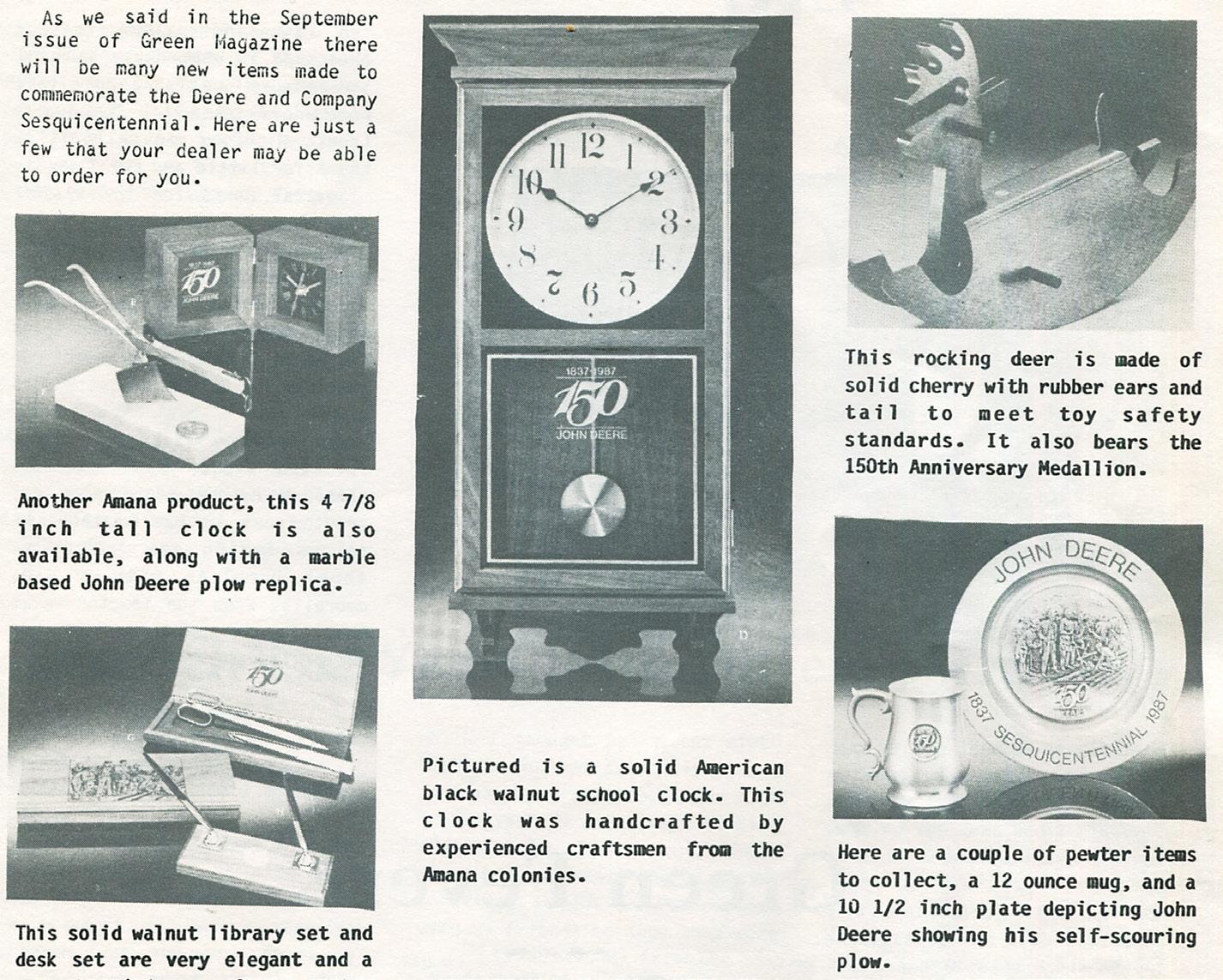

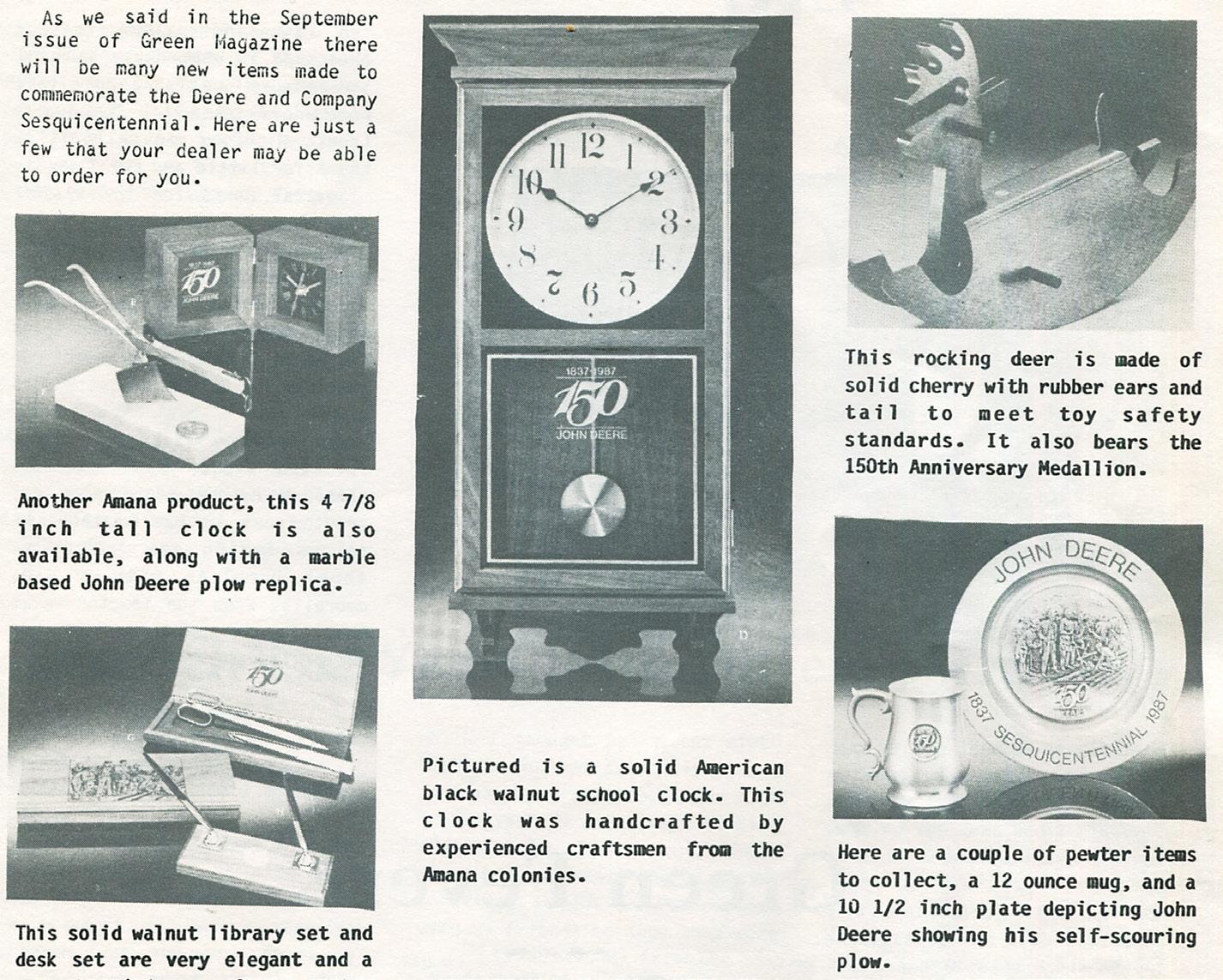

In November of 1986, Deere and Company introduced their new 150th logo in preparation for the upcoming sesquicentennial. For December, a special edition of The Furrow was

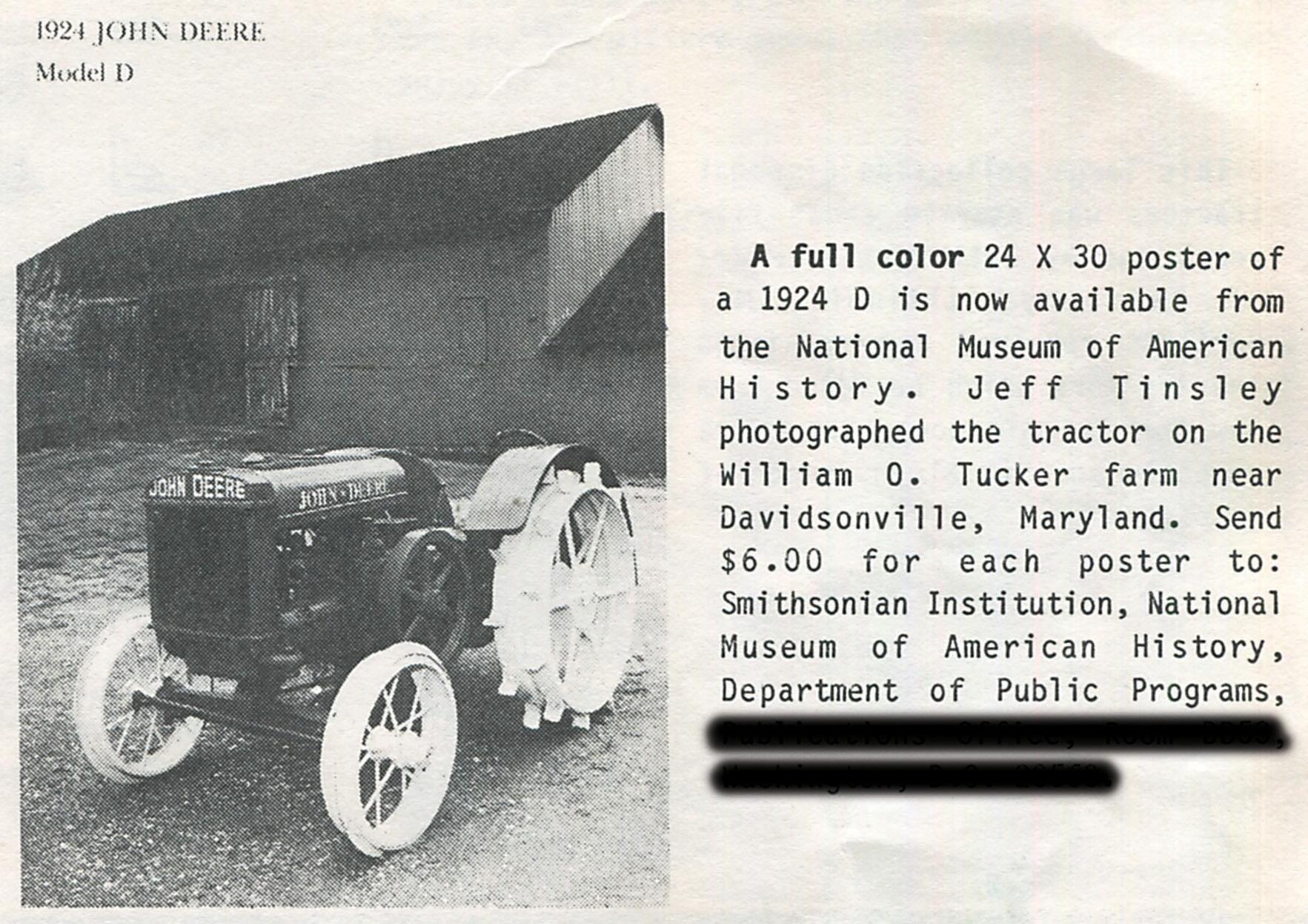

published and a new display celebrating the anniversary was displayed at the company’s administrative center. Farming Frontiers even went back to being called John Deere Day. John Deere’s original blacksmith shop at Grand Detour was being renovated with plans for new audio-visual tours and an actual blacksmith working on weekends. This preceded an upcoming meeting of the Deere and Company board of directors to be held in April 1987. It was also announced that in the fall of 1987, John Deere would be inducted into the Agricultural Hall of Fame in Bonner Springs, Kansas. Shouldn’t he have been the first one? Even the National Museum of American History, more commonly known as The Smithsonian, got in on the act by publishing a poster of a spoker

“D” which anyone could order for $6.

In the September 1986 issue, Green Magazine published the serial numbers of many of the last two-cylinder tractor models, which I had researched at the Deere archives. It may seem strange now, but these numbers were not something otherwise readily available at the time. At that time, we still didn’t have an office number and printed our home number in the magazine. I remember well a phone call from the owner of the last “G” waking me one morning to tell me how excited he was by the information we had published.

In January of 1987, Carol and I

and our two kids decided to take a winter vacation and headed north. Our first stop was at Winner, South Dakota at Grossenburg’s, which was then one of the largest John Deere dealers in the U.S., coincidentally celebrating its 50th anniversary, and then on to Wolf Point, Montana to see Louie Toavs, then the largest collector of Deere tractors. Speaking of big collectors, Tom Teague, who had been running quite a few ads looking for rare tractors, was now running ads for the auction he was having in April of 1987. The rarest of his tractors were an “R” Waterloo Boy, model “C,” model “P” and “GPO” crawler. A few

Page 34 September 2023 • Green Magazine®

months later, we reported that the “R” brought $19,250, the “P” $6,100, the “C” $20,000, and the “GPO” crawler also $20,000.

During this time, Clarence Criswell from Lamar, South Carolina was putting together lists of the serial numbers and owners of some of the rarest and most sought-after models, which at that time would have been Waterloo Boys, spoker “Ds” and other early unstyled tractors. Besides being able to find out the names of others who had the same models as you, in the event you had questions, it also provided a bit of security, letting everyone know that you were the owner of a certain tractor, in case of theft. You could get your own copy of the completed list for $15.

The May 1987 issue of Green Magazine was the first to have fullcolor covers. The inside was still black and white though and you still got only six issues a year.