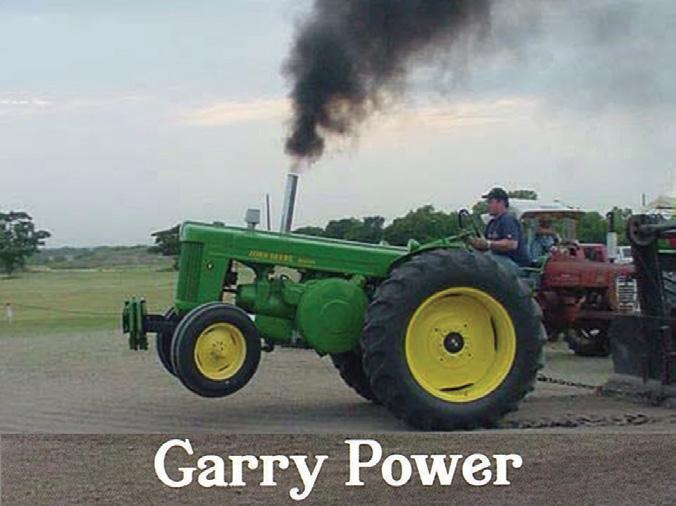

1949 “G” returns home

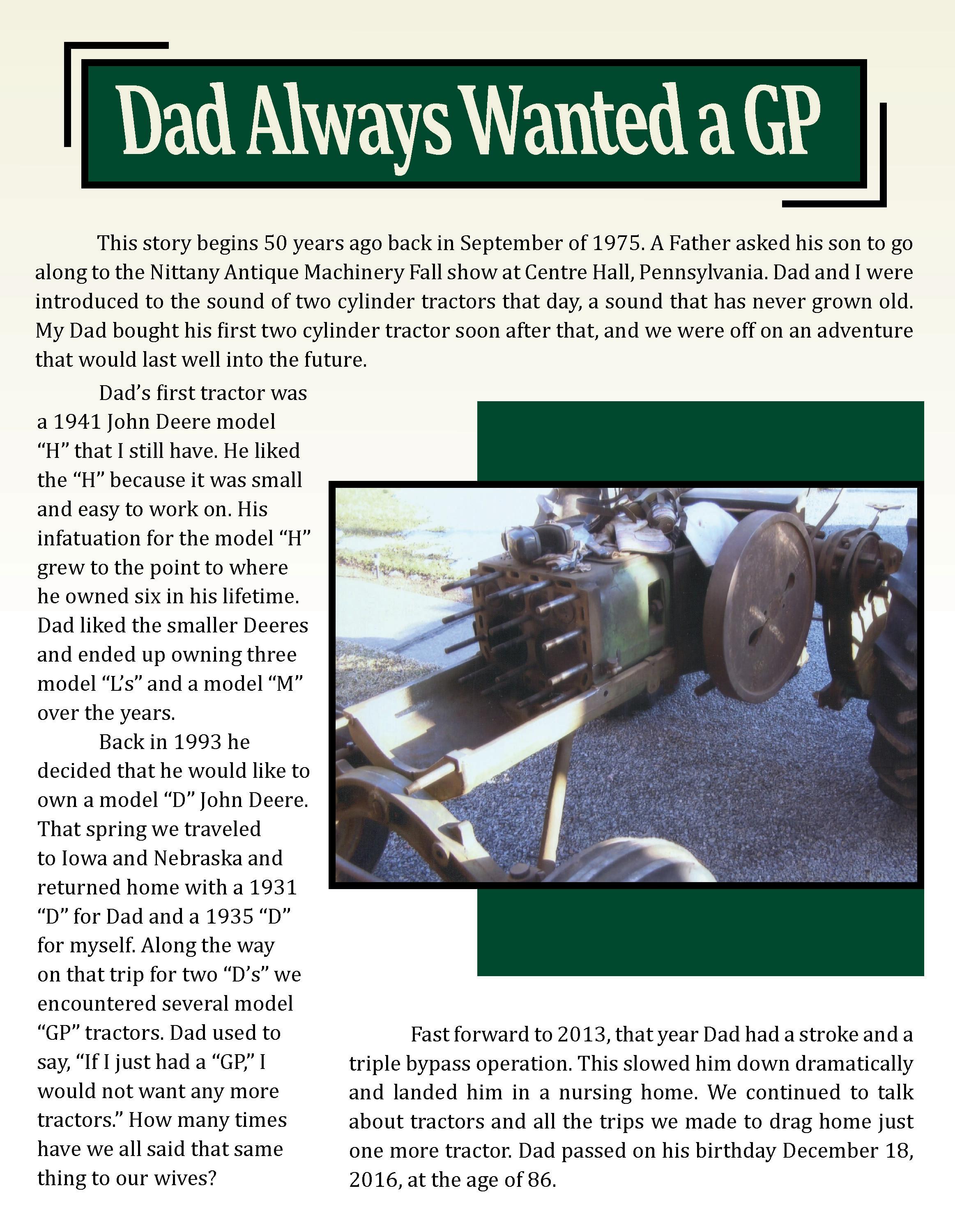

In 1980, I purchased a 1949 “G” with an 801 hitch from my uncle. It also came with a three bottom 810 plow. Grandpa had purchased it in the late ’50s or early ’60s. It had been parked outside for the last 14 years before I purchased it. It had been parked due to its always overheating when using it. My uncle had a NOS lower radiator tank and water pump and a NOS flat head and a gas manifold for it.

Surprisingly it was not stuck as he had kept the exhaust and air stacks covered.

I installed the water pump kit and the new head and manifold and got it running and used it a little on a bush hog. Then in 1981, a guy made me an offer on it and, like a typical 20 year old, I just saw the dollar signs. So I sold him the tractor and sold the plows to another guy.

In 1997, I thought it would be nice to have Grandpa’s tractor back. Luck-

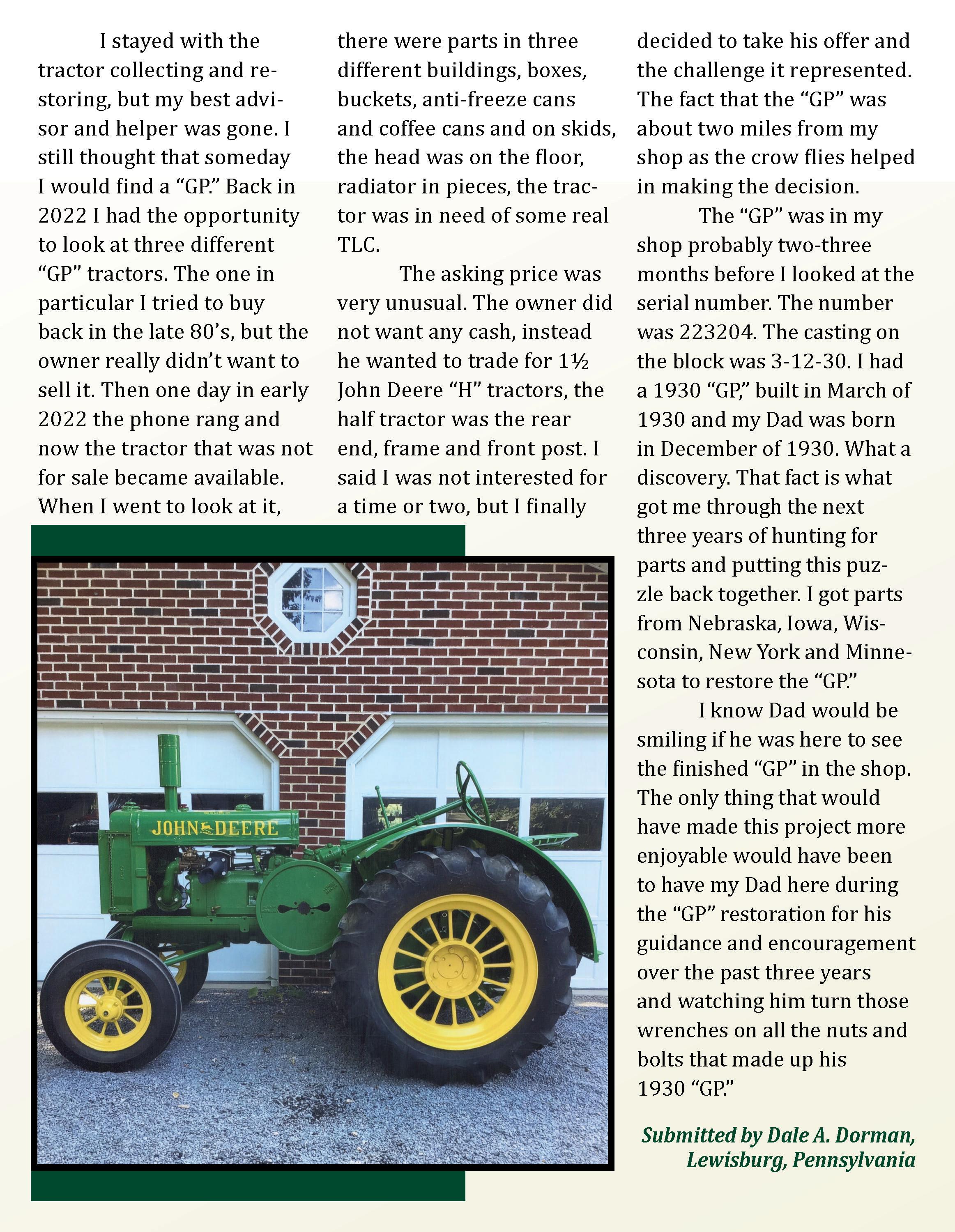

ily, the person I had sold it to still had it, but did not want to sell it. I would see him about once a year and question him about selling it and the answer was always the same. Then in 2012, he approached me at our local tractor show and said he was ready to sell it. I went and looked at it a few days later. It had not run in several years but was intact and it had been repainted shortly after he bought it from me.

We made a deal and in the meantime, I had been trying to buy back the plows. They had gone through three different owners over the years. The original guy had sold the plows to another neighbor, then he sold them to the local LP gas driver. So I had approached him about them when he brought us gas. But again, he did not want to sell. He contacted me a couple of weeks after I bought the tractor and was ready to sell them.

So in two weeks’ time, they were

back together. The “G” took a good carburetor cleaning and a mag rebuild to get it running. Then on to the gas tank. It was three-quarters full of nasty gas and had several large holes in it. I sent it off to be cleaned and patched. I did a little body work on the grills and while pressure washing it, before going to the “G” Reunion in Greenville, the old incorrect hood decal came off. I happened to have some other decals and while not the best quality, they were better than the ones that had been on it.

It will not get painted again as it is good enough for me. I take it to a few shows, but I have never plowed with it.

It will be here until I am gone, then it will be up to my son as to what happens to it.

Submitted by, James (Bob) Wheelock Bloomfield, IN

Complete clutch rebuild kits and clutch lining kits

& light parts

cores, water pumps, bolt kits

PARTS TRACTORS

720D, 2010G, late A, 530, 720D pony start, 50, 1020G, LA ES, 50 w/801 hitch, G, uns A, 730G, 5020, uns G, 430T, 2510G, 730 LP, 2010D, 530, late 520, ’39 B, BN, 40U, ’53 AO, ’41 H, ‘46 A, late A’s, ‘46 B, late Bs, slant dash B, uns B, sty D, G, uns L, M, MT, R, 40T, 40U, 40W, 70D std., 70G, 420U, 420W, 440 w/reverser and PS, 440 gas, early & late 50s, early 60, 60 w/power block, 620, 620 LP, 630, 70G, 720G, 720 LP, 720D pony, 730D, 730G, 820, 1010, 2010, 2010D, 2010RU, 2020, 3010D, 3020, 4020D. Most of these tractors are parted out & on the shelf—ready for quick shipment!

Oversize pistons available again for many two cylinder tractors

Wabi-sabi is a traditional Japanese philosophy centered on finding beauty in imperfection, impermanence, and simplicity. It is an aesthetic concept rooted in Zen Buddhism that encourages the acceptance of life’s transient nature and flaws, rather than striving for unattainable perfection. The philosophy celebrates the natural cycles of growth and decay, and can be seen in art forms like the tea ceremony, where its influence is evident in the use of modest, unique, and weathered objects.

I don’t usually read or quote Japanese philosophy. Still, I came across this idea in a book by celebrity chef and author Alton Brown, and I thought the last line was particularly pertinent to what we are doing here.

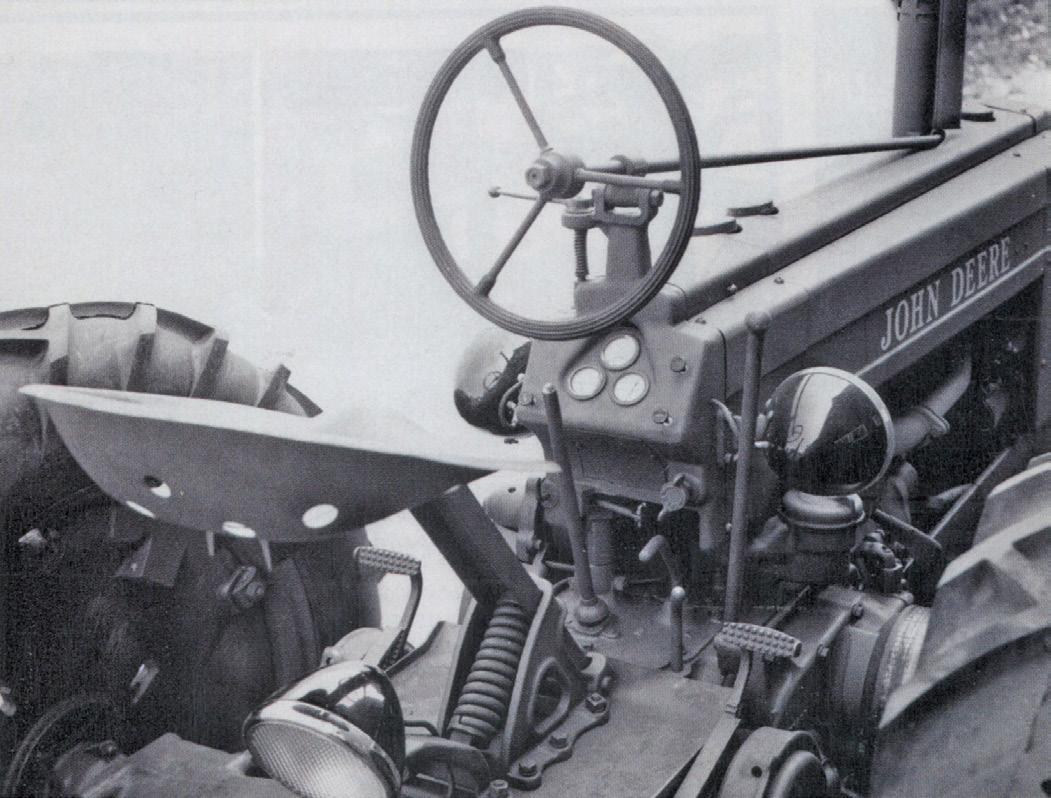

When Deere engineers were designing their early tractors, stopping them didn’t seem to be a major priority. While most of them had a differential brake, you couldn’t reach the handle from the seat. Since almost all of the early tractors were on steel, it was probably figured that they weren’t going to coast much when the clutch was disengaged, and the brake was meant mostly to keep the tractor planted when doing belt work.

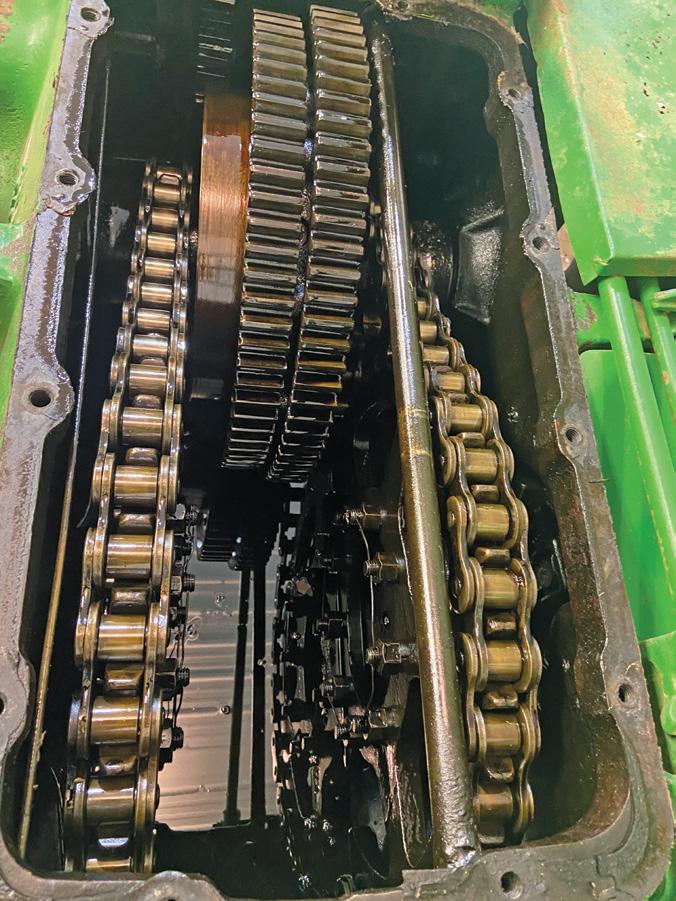

I prefer tractors with brakes, especially if they will occasionally be driven onto a trailer. The brake lever on my “D” flopped around as if it weren’t attached to anything, and upon removing the cover from the transmission case, I found that to be exactly true. Not only was the lever not connected to anything, but the brake band to which it should have been connected

Apparently “easily” meant something different to whoever wrote their manuals than it does to us today.

Right: The used brake band, newly relined.

was nowhere to be seen. I drained the transmission oil, which was in surprisingly decent condition, to see if the band had been chewed up by

The brassy looking drum to the left of the two gears should have a brake band around it. I was asked what a 1933 “D” would have cost new, and what I thought the chains would cost today. The tractor was about $1,200 new. I found #240 chain online, which I believe is about the right size. The price is $1,700 for 10 feet.

the gears and was still lying at the bottom of the case somewhere. No trace of it. Apparently, it had been completely removed at some point. So, I sought out and found a new band, which was sent to Bob Dillner for relining. After getting it back, I began the job of installing it. Someone quipped, “You’re going to have grease up to your armpit.” To which I stated, “Maybe I’ll have to go to the farm store and get some of the long OB gloves used on cattle.” Another veteran restorer spoke up and said

An OB glove, available at most farm stores, is one way to get a little less messy when working in the bowels of a tractor. A nitrile glove over it aids in dexterity.

that he uses them all the time when having to reach deep within the guts of a tractor. Wish I had thought of this decades ago.

The seemingly simple task of getting the band around the differential and the threaded end up through the hole in the main case took much longer than I would have ever imagined. While I was warned that it wasn’t as easy as it looks, I hadn’t imagined that it was going to be this bad. I did get it done, though, only to find that the band was too short and that the loop end fell about two inches short of where it was supposed to connect to the lever shaft. It is apparently one from a later “D,” where things were rearranged to make room for a third gear.

Since I had already spent money on the band and relining it, and blood, sweat, and tears installing it, I wasn’t about to take it out again, so I decided to do a little metalworking and make an extension.

Let’s go from the mechanical to the cosmetic for a while. I’ve been removing the green paint a piece or two at a time and either sandblasting or using paint stripper. The sandblaster is much faster and easier, but there are certain areas I don’t want to use it on for fear of getting grit in the mechanical works. I’m still learning as I go, but my process is to remove most of the paint, then use a process to rust the bare metal,

followed by a coating to keep it from rusting further.

While I could just leave the bare metal pieces outside to rust naturally, I prefer to move things along considerably faster by spraying them with a mixture, the formula for which I found on the Internet. The mixture is one cup of hydrogen peroxide, onehalf cup of white vinegar, and about a tablespoon of salt. Mix well, brush or spray on, and you will see rust almost immediately. Since I usually work on this project in the late afternoon after

I’ve left the office, I leave it overnight and hose it off the next morning. If you delve into researching this topic on the internet, you will find many different ratios and methods, such as spraying the vinegar first. However, I have found this method to be effective and am sticking with it. If you are a real science nerd, you can also read about the chemical reaction taking place, oxygen atoms exchanging places and how and why this works.

That’s enough wabi-sabi for this month.

I was told by a “D” aficionado that the 1934 models (still a two-speed) had a different sized starting tank than the later three-speed models. Sure enough, the tank on John Nikodym’s 1934 is nine inches across. The tank from a three-speed that was on my tractor when I got it is seven inches across.

Above, left: Here’s the main case cover sand blasted. Middle: After 30 minutes of brushing with the hydrogen peroxide, vinegar salt mixture, and (right): rinsed, dried and sprayed with Fluid Film.

Lind Bros Tractor and Parts, LLC

• New aftermarket, rebuilt and used parts for JD A, B , D, G, H, M, R, 320, 330, 40, 420, 430, 50, 520, 530, 60, 620, 630, 70, 720, 730, 80, 820, 830, 3010 3020, 4010, 4020.

• Used parts include: weights, 3-pts., toplinks, dual hydraulics, float ride seats, clutch parts, hubs, transmission gears, sheet metal, tires and rims, 720-730 ES parts, all-fuel manifolds, brake parts, square and round tube WFEs, heads, blocks and PTO parts.

• New parts include: manifolds, battery boxes, carburetor kits, air stacks, mufflers, grill screens, radiator cores, lights and overhaul kits.

• Rebuilt parts include: Taper-Loc flywheels, electric start conversion kits, float ride seats, starters, carburetors, cleaned and lined gas tanks. Also have crack checked heads and blocks.

Wiring Harnesses - Cables - Switches

We build restoration quality wiring harnesses to fit these John Deere models and their variations:

AG Models: A, B, D, G, GM, L, LA, M, R, 40, 50, 60, 70,80, 320, 420, 430, 435, 440, 520, 530, 620, 630, 720, 730, 820 2 cyl, 820 3 cyl, 830 2 cyl, 830 3 cyl, 920, 1010, 1020, 1520, 1830, 2010, 2020, 2030, 2040, 2040, 2130, 2240, 2350, 2355, 2440, 2520, 2550, 2555, 2630, 2640, 2840, 2855, 2950, 2955, 3010, 3020, 3150, 3255, 4000, 4010, 4020, 4030, 4040, 4050, 4250, 4230, 4240, 4430, 4440, 4455 Mexico, 4630, 4640, 4840, 5010, 5020, 6030, 7020, 7520, 8010, 8020, 8430, 8630, 8440, 8640, 8560, 8760, 8960, 8770

Harnesses available for other models & brands

See website for complete listing Due to numerous variations, call to order Shipping/handling not included Visa, MC & Discover accepted Prices subject to change without notice

Circuit protection kits for Diesel tractors

From $35 (2 cylinder)

From $60 (New Gen)

Industrial Models: Al, Bl, DI, 300, 301, 302, 302A, 310A, 350, 350B, 350C, 380, 400, 400 Scraper, 400B, 400C, 401, 410, 410C, 410D, 440I, 450, 4508, 450C, 450E, 455E, 480B, 500, 500A, 500C, 510D, 540E, 544A, 548E, 600, 7E Scraper, 700, 700A, 710D, 750, 755, 840, 1010C, 1010W, 2010C, 2010W, 3010I, 4010I

AG Machinery: 45, 55, 4710, 5730, 5830 Lawn and Garden: Commercial mowers: 38”, 48”, 54”, GX1320, 727

Z-Trak, 60, 70, 110, 112, 120, 140, 200, 208, 210, 212, 216, 245, 300, 312, 314, 316, 318, 285, 320, 322, 330, 332, 420

Compact Tractor: 790, 850 Snowmobiles: 340 Cyclone

We also carry: Starters, Regulators, Generators, Alternators, Relays, Coils, Lights, Alternator Brackets, Pulleys

We make alternator conversion harnesses

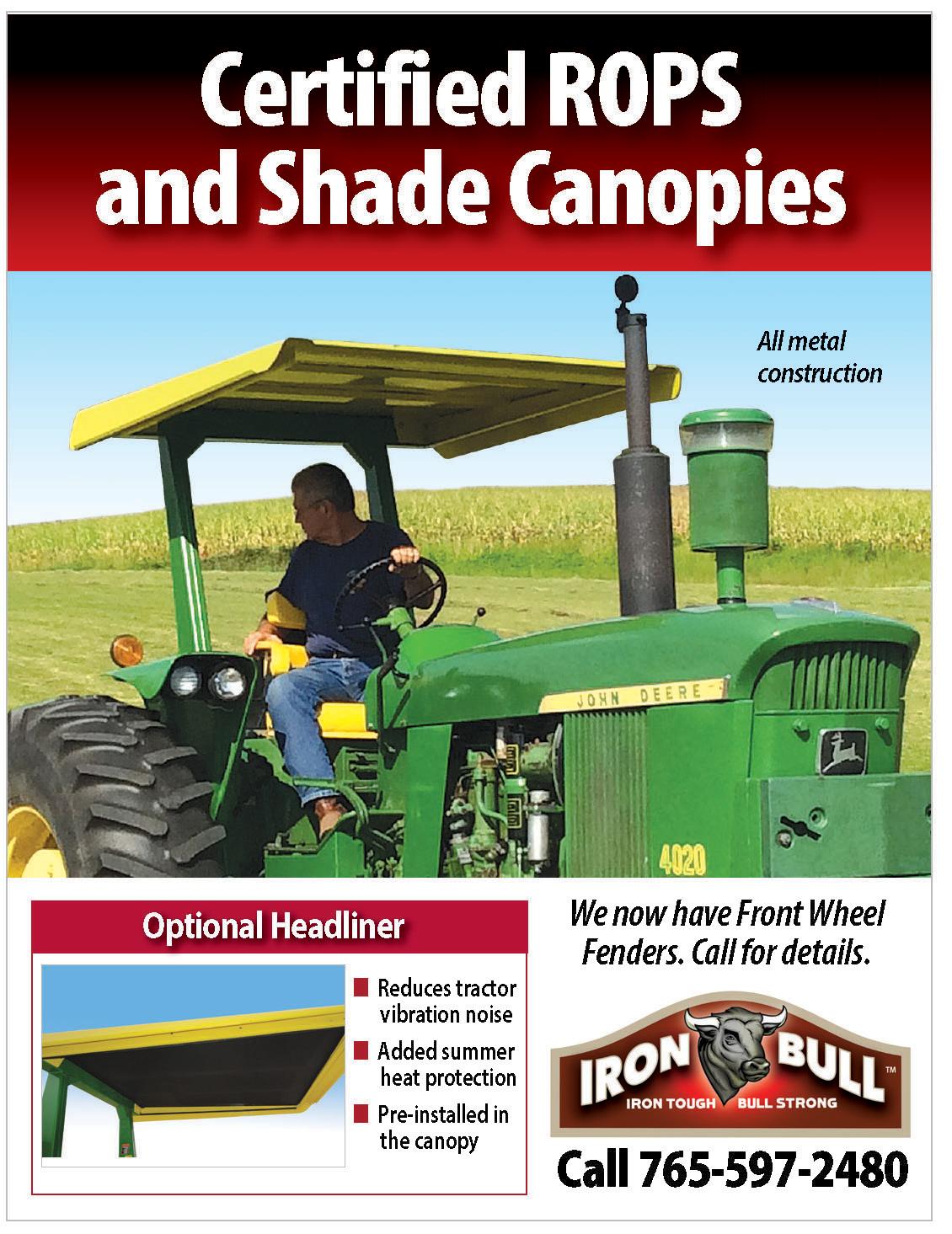

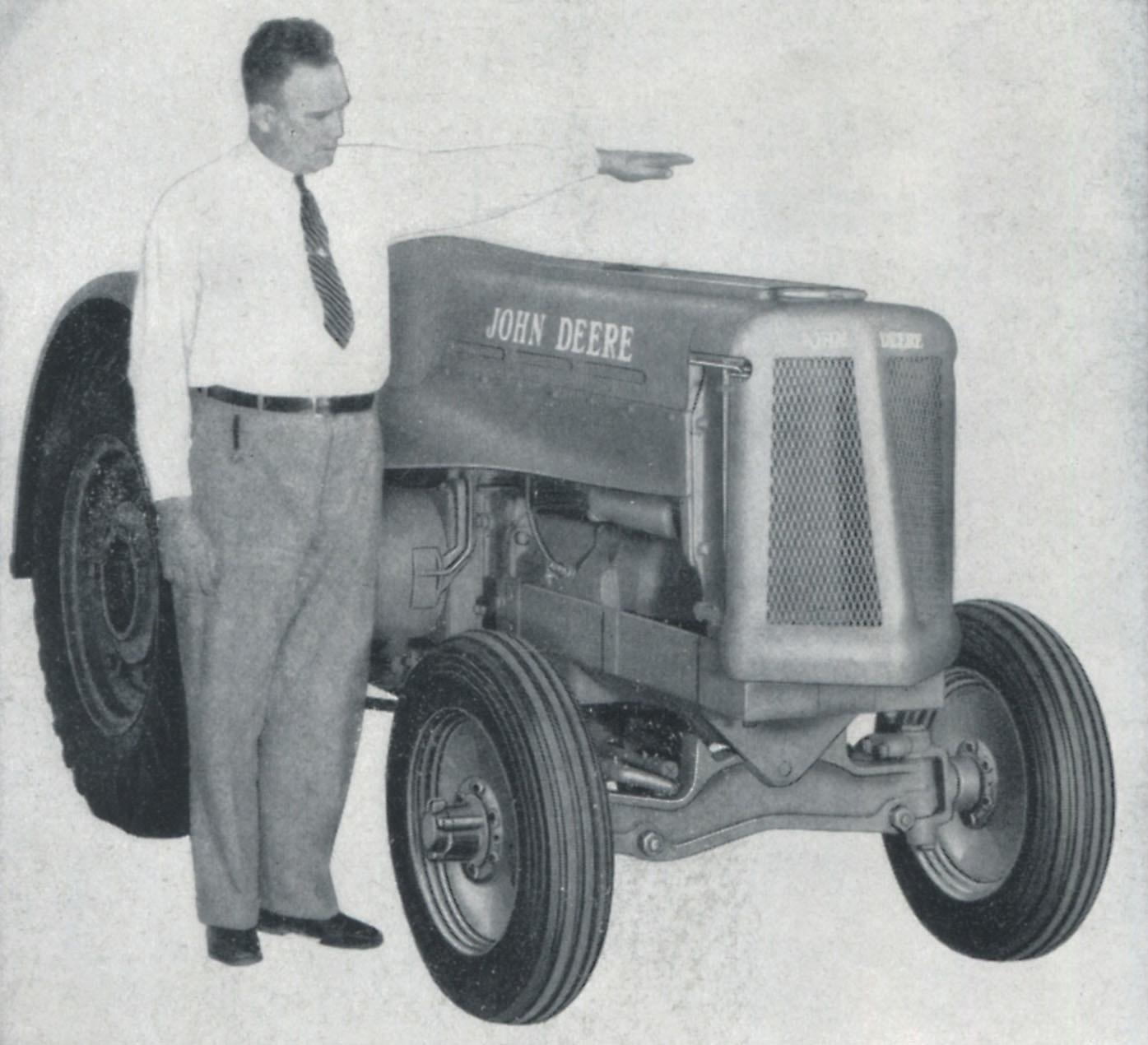

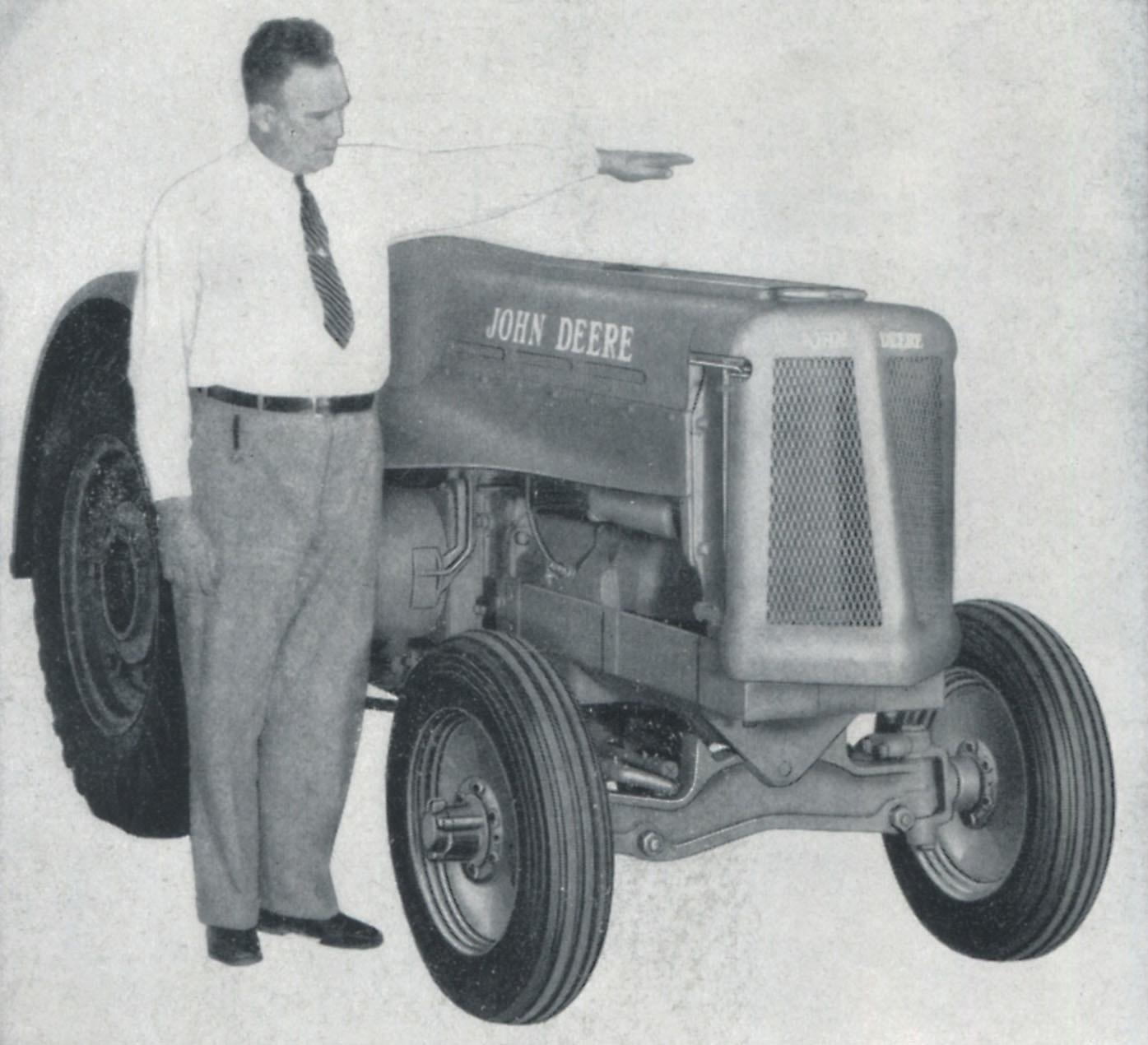

A tractor in full orchard dress pulls an “OR” offset disc.

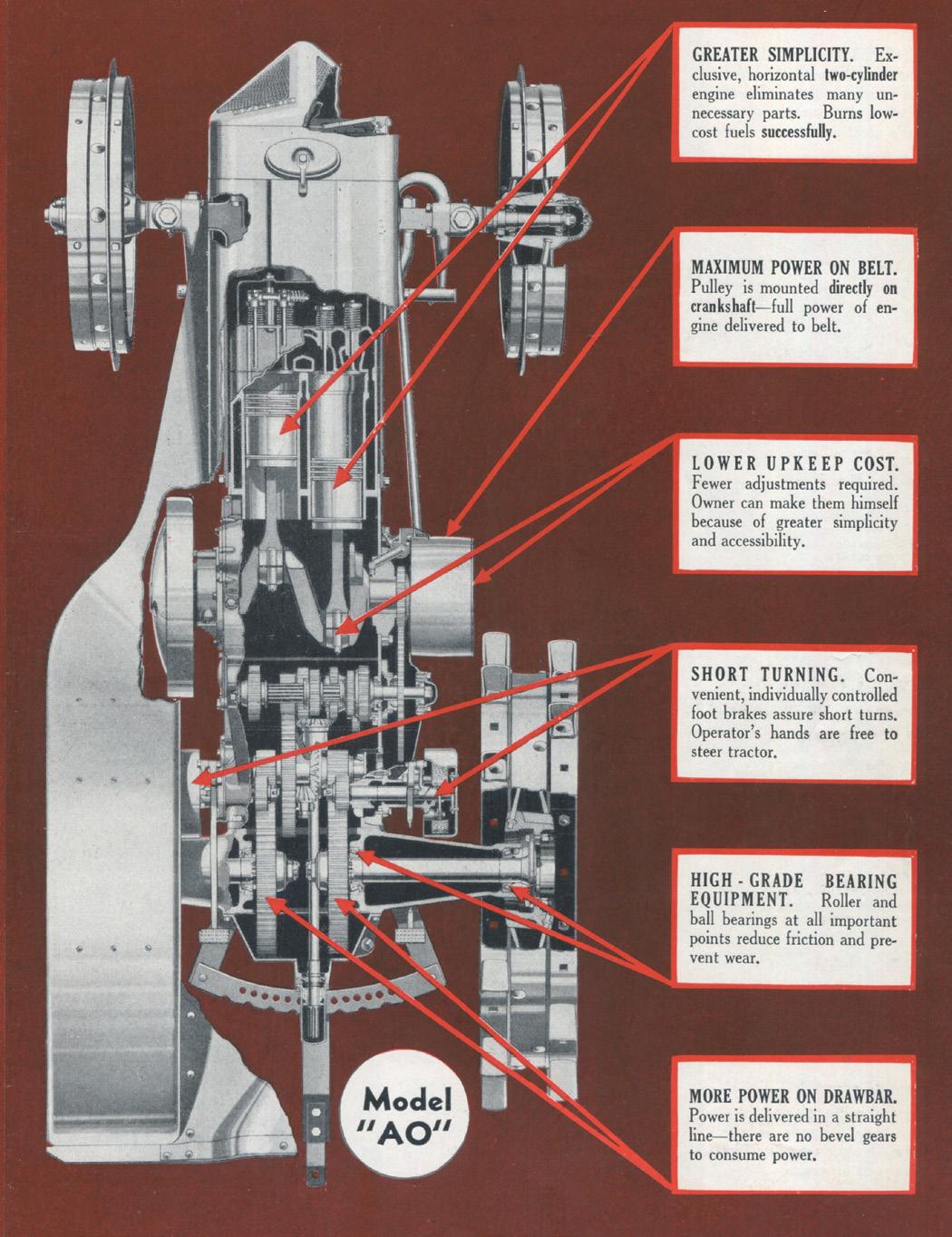

The progenitor of Deere and Company’s tractors, the Waterloo Gasoline Engine Company, was one of the first tractor manufacturers to recognize and attempt to cater to the needs of grove and orchard farmers. The company built a “California Special” version of their model “R” tractor, which featured a single front wheel for a shorter turning radius. Later in production, Waterloo shortened the wheelbase of the tractor to improve its maneuverability further. When Deere purchased Waterloo, the company was still building special tractors for orchard use, and a “California Clearifier” version of the model “N” was built. Approximately 27 of these tractors were produced, with the main changes being made to help the tractor work near apple trees while “clearing” the branches.

Deere’s model “D” was a comparatively effective tractor in orchard and grove work. It was low to the ground and more maneuverable than many tractors of the day. In fact, a number of the first 50 early production model “D” tractors were sent to California and tested in orchards there. Deere did not produce a special version of the tractor specifically for orchard service, but the company did offer special grove fenders, a “California” drawbar, and special lugs and wheels as options for the “D.”

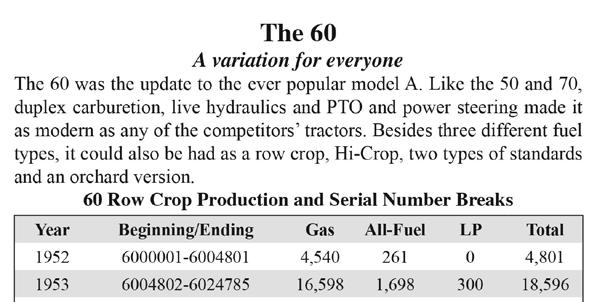

Deere did not put much thought into modifying the “GP” for orchard service, but the Lindeman Brothers, owners of a Yakima, Washington dealership, did. They had a new front axle cast and rotated the final drives toward the rear. This put the tractor eight inches lower. A lowered operator’s seat gave even more room under the trees. Personnel from Deere and Company were invited to Yakima to have a look at

This man is demonstrating how low the tractor sits, enabling it to get under branches.

the tractor that they were modifying there, and Deere was impressed. Using the Lindemans’ ideas, Deere created the “GP” orchard tractor, or “GPO.” Deere estimated that 300 of these would be sold the next year, and 600 each year afterward, but the first tractor was built in April of 1931, and the Great Depression severely limited demand for any tractors. A total of 718 “GPO” tractors were sold over four years.

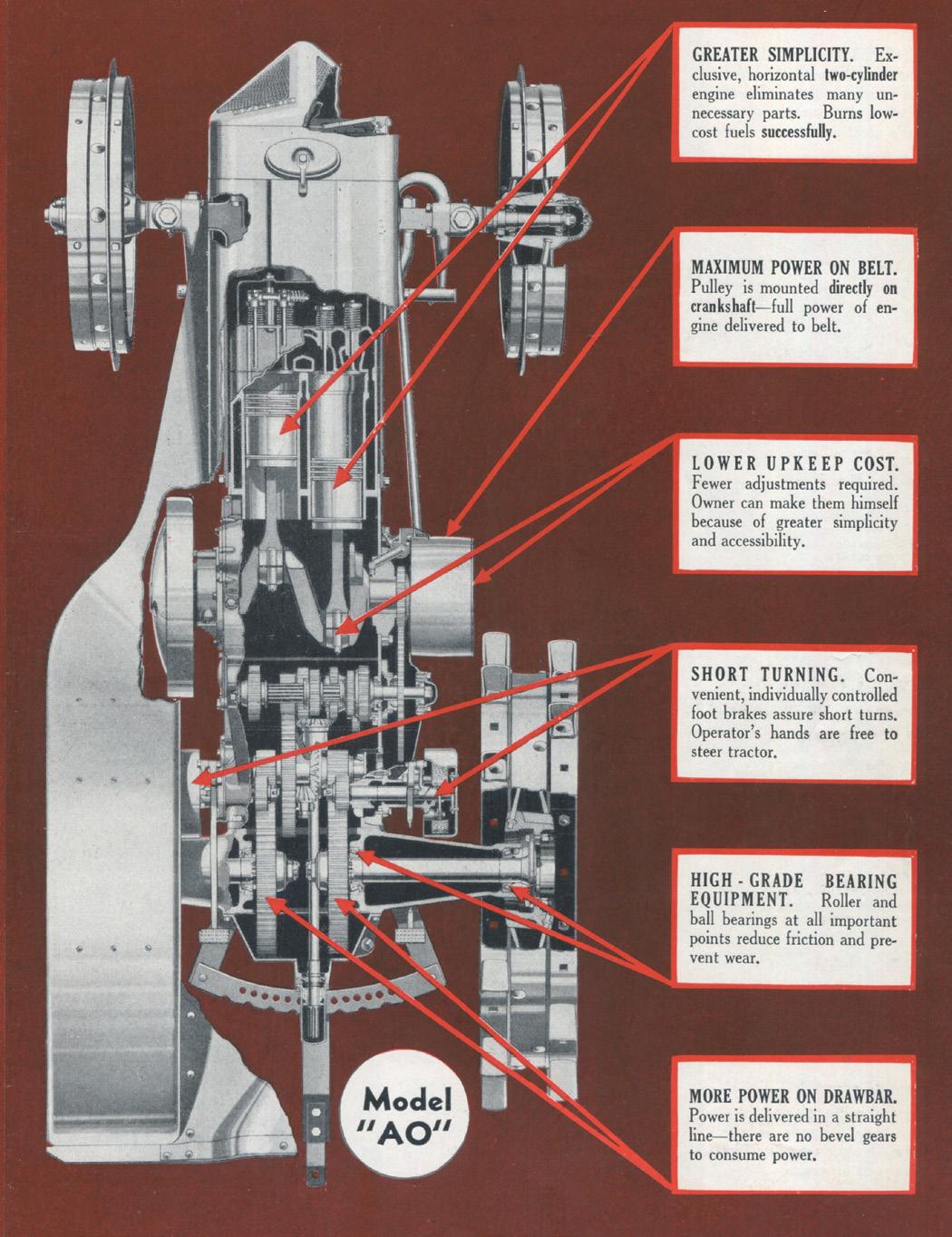

The model “A” that replaced the “GP” led to the standard tread model “AR,” released in April of 1935. A grove and orchard version of this tractor, the “AO,” was released shortly afterward. The “AO” was changed only

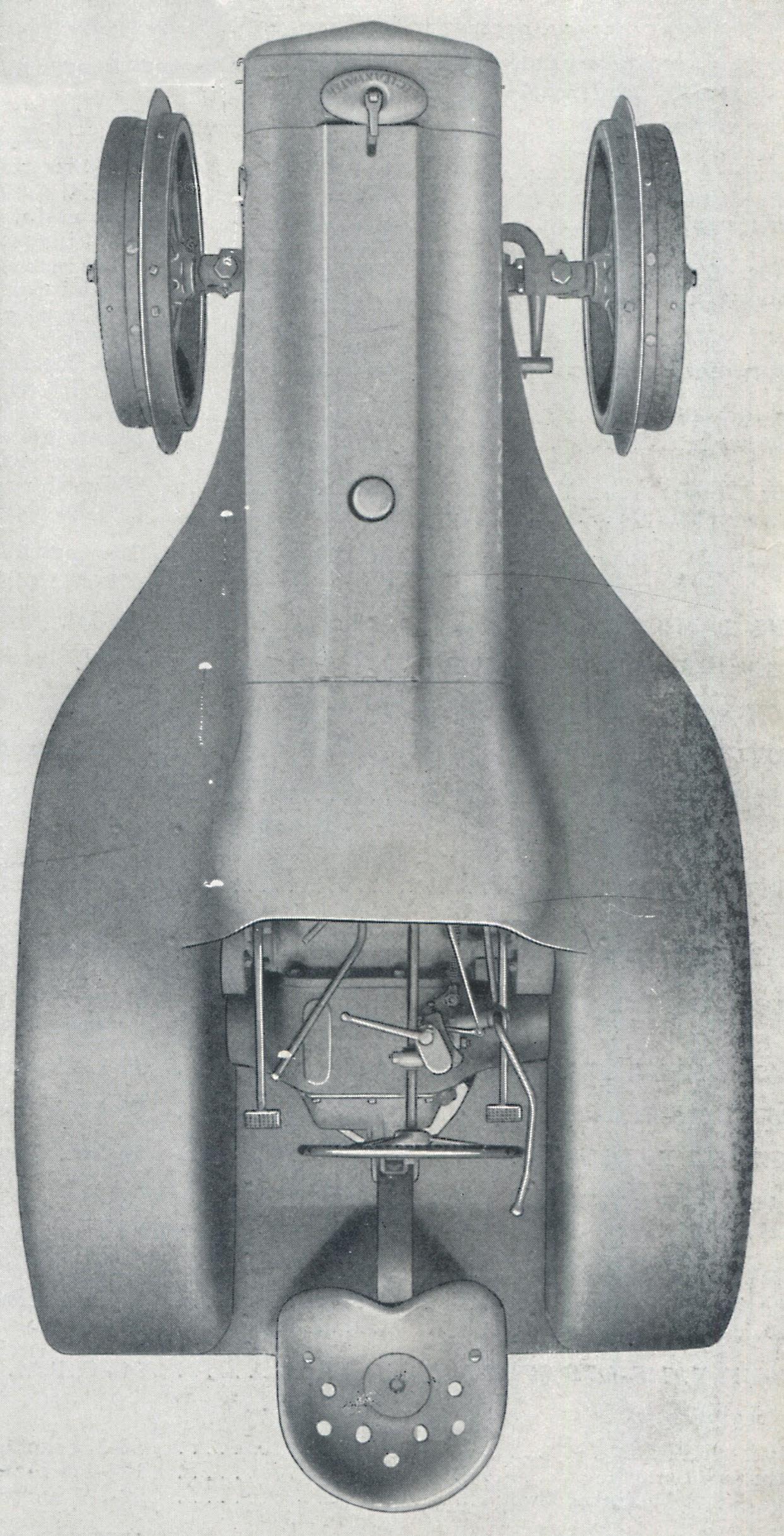

Overhead view of an “AOS.”

slightly from the “AR.” It featured low intake and exhaust, special shields to protect the operator from trees and the trees from the tractor, and differential brakes to allow for short turns between the trees. The tractor was a clear improvement over the “GPO.” The economy had also rebounded. These two facts allowed the “AO” to sell much better than the “GPO” could.

The “AO” was a good tractor, and was beginning to show grove and orchard farmers what a tractor built for them could be, but as more man-hours were spent in the seats of these tractors, more tweaks and adjustments were asked for. Primarily, the farmers wanted a tractor that was even more maneuverable, narrower, and more protective of both the operator and the trees that it worked around.

Six “AR” tractors were pulled from the production line and used as experimental machines for a new version of the orchard tractor. The engineers began by installing the front end support from an “AI” on these tractors. This support set the front axle farther back seven inches, which reduced the turning radius of the tractor by almost a foot. The axle supported there was six inches narrower than the “AR” axle, measuring

41-7/8 inches. The rear axle housing was shortened, as well. It was 2-7/16 inches shorter on the left side and 2-13/16 inches shorter on the right. The rear tread width was now just 453/8 inches.

The tread width had been narrowed so much that the tractor itself had to be narrowed to fit inside the wheels. On the flywheel side, Deere’s engineers simply installed a different flywheel to give a half-inch of clearance to the wheel on that side. The first reduction gears were changed, and a narrower clutch pulley was installed on the clutch side. The crankshaft was shortened, and Deere added a counterweight. The right-hand main bearing was narrowed, but the diameter was increased so that the surface area of the bearing would remain the same.

After harvest the “AOS” provided efficient power for processing equipment.

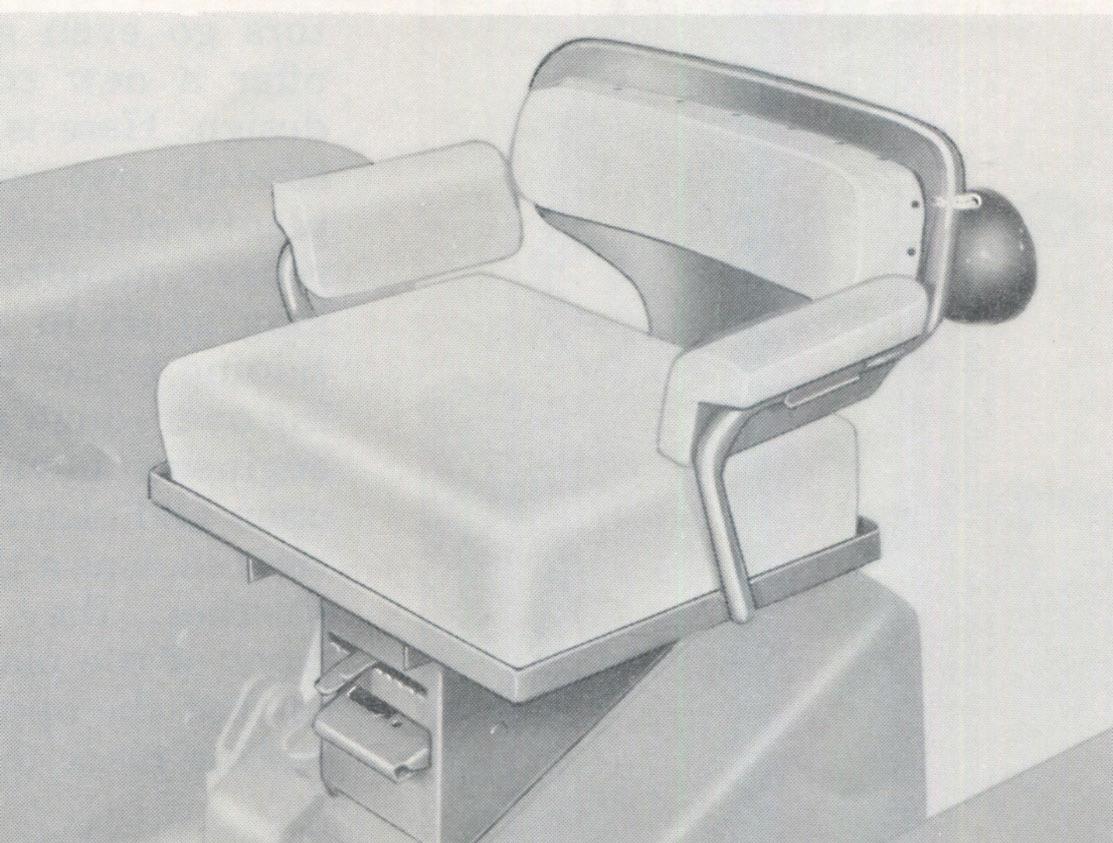

Now that the tractor was as maneuverable as Deere could make it, Deere focused on lowering the tractor as much as they could. A new radiator, hood, fuel tank, and fenders were all created and installed on the tractor. These made the tractor more than five inches shorter in overall height compared to the “AO.” They also provided a streamlined look for the tractor and assisted in making the tractor less likely to snag tree branches. Deere also put the seat from the model “D” on the tractor, which made the ride more comfortable with the seating position lowered by three inches.

All “AOS” tractors used a Marvel Schebler DLTX-19 carburetor. Tractors 1000 to 1524 used a Fairbanks Morse RV2B magneto. Tractors 1525 to 1891, an Edison Splitdorf CD.”

Deere tried a few features during the tractor’s experimental phase that did not make it to production. This was typical, of course, but one thing that did not make production on this tractor is surprising. During testing, Deere had an engine oil dipstick installed on the tractor on the main case just in front of the flywheel. For whatever reason, Deere decided not to put these on the production machines. It would be years before they were added.

The first experimental tractors were shipped to various places across the country in June of 1936. There,

they could be tested in real world conditions to see if there was anything else for the engineers to address before full production. By August, a proposal was made to the board to begin production of the new tractor, and in October, that proposal was accepted. Production of the “AO” ended almost immediately, retooling was done, and production of the new streamlined “AO,” or “AOS” tractor, began in November. The first of these was sent to Grand Rapids, Michigan.

The “AOS” was a specialty tractor and, therefore, did not have many options available to it. The place where the buyer had the most agency was in the wheel equipment on the tractor. Standard equipment was a

foursome of steel wheels. Rubber tires were available in 11.25x24 or 12.75x24 inch sizes. Another option for the “AOS” was special “citrus” fenders. These included skirts that covered the sides of the rear wheels and valances that extended to the front of the tractor. These provided maximum protection for the plants that the tractor worked around, but were a rare option with a $35 cost. Finally, Deere offered both a slowspeed and high-speed gear assembly for the tractor, to help you personalize the four-speed transmission on the tractor.

The “AOS” was a hit from the start. It had the features that grove and orchard farmers had been asking for. The 512 tractors that Deere built in the first year exceeded all expectations.

That would be the highlight of the tractor’s production. A recession began and brought sales of the “AOS” down to 158 tractors in 1938. Things only got worse after that, and yearly sales of the tractor never again broke out of the double digits. Even a $25 discount on the machine failed to breathe any life into its sales numbers. The last “AOS” was built in October of 1940. The 1941 model year of the “AR” brought a multitude of improvements to the tractor—improvements that had been made to the model “A” a bit prior, and which brought more horsepower to the tractor. Seeing the “AOS” (and its cousin, the “AI”) languishing in sales, and now having the updated “AR” to work with, Deere brought back the model “AO” that was based on the “AR,” ending

the run of the “AOS.”

Only 820 model “AOS” tractors were built, making them one of the rarest of Deere’s tractors. If simple scarcity isn’t enough to draw attention to a tractor, unique looks certainly are, and the “AOS” has some of the most unique looks of any tractor that Deere has built. An “AOS” would be a head-turner anywhere, with more sheet metal and curves than some of the world’s most popular sports cars. Restoration of one of these tractors would be difficult. Even if you are an artist skilled at smoothing out sheet steel, you’ll also have to contend with a machine that incorporates many parts that are unique to it. If you venture forth and succeed, though, you’ll have one of the showiest John Deere tractors that ever existed.

question may be chosen for publication

2-Cylinder Plus Tractor Salvage

2-Cylinder Plus Tractor Salvage

A’s, Bs, 420s, 430 thru 4010, Hs & Ms Hay Equipment, Balers, Disk Binders & Hay Bines David and Robin Marlin

417-589-2634 • 417-589-3337

322 Marlin Prairie Dr • Conway, MO 65632

Only 70 miles northeast of Branson, Missouri

Need a Green Magazine back issue?

Buy them by the SET

There are three sets available—buy one or all! Back issues can also be purchased individually. See the ad on page 71, call 402-643-6269 or go online to www.GreenMagazine.com for more information about back issues. Availability changes, depending upon supply. Green Magazine back issues—packed with good reading!

Tractor Parts We Fabricate

Weight Bracket

5010, 5020, 6030: AR58358, Pr $460

Rear Engine Panels

4620 Right, AR43290, $155

4620 Left, AR51804, $255 2510 Right, AR38206, $300 2510 Left, AR38207, $220

2520 Right, AR38838, AR38202, $300

2520 Left, AR38839, AR38203, $220

5010, 5020 R, AR35023, $300 L, AR35024 OR AR36796 $300 6030 Right, AR53645, $350 6030 Left, AR53646, $350

Dust Shields

5010 Right, AR35334, $320 5010 Left, AR35335, $320 5020, 6030 RC Right, AR40930, $350 5020, 6030 RC Left, AR40931, $350 5020, 6030 Whd R, AR36772, $350 5020, 6030 Whd L, AR36773, $350

Rock Shaft Cover

5010, 5020 Right, R36420, $295 5010,5020 Left, R36422, $160 5010, 5020, 6030 Center, AR55756, $70 6030 Right, AR55755, $295 6030 Left, R51485, $160

Toolbox Cover

5010, 5020, 6030 - AR35050, $65

Hood Air Cleaner Cover

4050, 4520, 7020 - AR43256, $165

Hydraulic Dipstick Cover 5010, 5020, 6030 - R36421, $80

Step w/Pads

5010, 5020, 6030 - AR40914, $165

Step U Bolts $18

Seat Base Cover for Tractor w/o

Rock Shaft - AR26846, $295

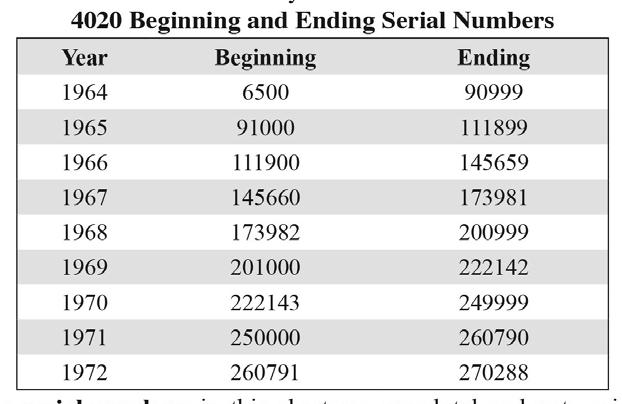

4000 & 4020 Std SN 201,000 & Above

AR40773 LH Rear Eng Panel = $80

AR40774 RH Rear Eng Panel = $80

AR40871 Platform (can modify AR48727) = $155

AR41097 Platform Support = $84

AR41098 Platform Support = $84

AR41137 Dust Shield RH = $315

AR41138 Dust Shield LH = $315

AR41174 Support To Dust Shield=$27

R41253 Ext Front Right = $156

AR41451 Ext. (RH) = $74

AR42594 Step Bracket

3020 Standard Tractor

In the heart of a sun-baked southeast Missouri field, where dust swirled like memories, ran an old John Deere model “H” tractor pulling a small disk harrow, its green paint weathered but proud. Zachary, a farm boy with calloused hands, pondered a question that had been bugging him. His tractor, a 1941 model “H” he had completely overhauled with help from his Paw, needed a name. His tractor was not just any machine—it had plowed through droughts, floods, and the dreams of several generations. Naming it felt like naming a piece of his soul, and it

was not an easy decision.

Having been an avid reader for GM, Zachary noticed a long time ago that many readers who have written letters to the editor and submitted articles would often reference names for their tractors. Names for tractors often were references to old acquaintances or perhaps the name borrowed from a favorite comic. Zachary asked me for ideas and we discussed names that began with the letter H. After discussing names for over few months, he chose HANK for the name of his tractor. Hank, which is usually short

Hank being operated by Zachary with the six foot disc harrow.

Belted up to the dynamometer for the first time was quite a thrill.

Below: The first attempt on the dynamometer resulted in right at 15 horsepower, but the belt came off, requiring a repositioning of the tractor for another attempt.

for Henry, represented a little yet powerful spirit that encapsulated the tractor that would never give up, no matter how hard the work.

Finally having a tractor with a name was special, you see. On the Buchheit Farm, we do not have any special names for equipment or tractors and simply refer to them by their model number. My parents each have their own JD gators; “Dad’s Gator” is a well-worn 825 XUV while “Mom’s Gator” is the newer 835M that is hardly broken in. While there are not any exceptions for naming equipment on our family farm, there are special names given to certain livestock and pets. My mother has named all her breeding stock of beef cattle since before I was born. I believe for her naming each animal builds the personal connection more than just a numbered ear tag.

Seventeen horsepower was smaller than the others but it was the most of any “H” tested at the show.

Below: Plowing behind the 1973 Chevy pulling a 66H 4-14 inch moldboard plow that I once owned. Zachary said he had a real good furrow to follow.

Of course, using proper names for animals makes it even more difficult when the time arrives to say goodbye.

Readers might recall that a few months back, it was shared that Zachary had found a small IHC disc harrow to match up to Hank, the JD “H.” He was itching to find an opportunity to get it out and work a shine on the blades once again. In early July, a neighbor of ours decided to disc under the weeds growing in a field in preparation to planting soybeans. I passed the field several times as is located right off US 61 Highway (runs from just south of Duluth, Minnesota to New Orleans, Louisiana) and decided to ask him if we might bring Hank and the disc harrow to play. He agreed so we took a couple hours before a family reunion one Sunday. Hank pulled the disc well in second gear. I even hopped onto the back of the disc for some added weight and to allow the blades to dig in deeper for a greater load and to shine up more of the blade surfaces. Everything worked perfectly, but we had to leave sooner than Zachary wanted to make it to the family reunion in time for some potluck lunch and some homemade coffee cake for dessert.

Hank went to his first tractor show of the 2025 season in Pinckneyville, Illinois in mid-August. We

hooked up the H-1, one-bottom 16 inch plow for the field demonstration. Plowing went well as it had rained an inch just prior to the show, making the sun-baked soil workable once again in time for the plowing demonstrations. Zachary was thrilled to be up to plowing on his own (last year we took it but he was not keen on operating it solo).

Arguably, the best part of the Thresherman’s Show was finally officially testing the horsepower of Hank’s overhauled and souped-up engine. Zachary and I both guessed what the maximum horsepower would be. He guessed 15 horsepower and I said 17 horsepower. There were several dynamometers set up at the show grounds but we decided to use the engine belt pulley since the mounted plow would have to be removed for a PTO shaft hookup test.

There were some serious Farmall tractor guys in charge of the testing so they gave us a hard time being the green guys. Since we took the engine up several points in compression and bored the block to 1/8th inch overbore, it was assumed that Hank would best the original Nebraska Test results of 14.84 horsepower on the belt. A 10 percent increase in power would be 16.32 horsepower. After several tests of load, it ended up right at 17 horsepower! Hank showed us the number

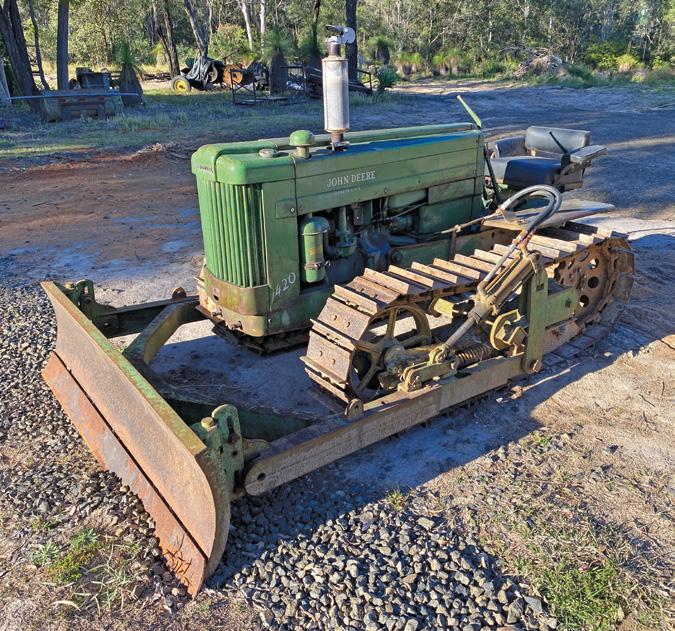

At the 50 Years of Progress show in Rantoul, Illinois, Zachary wanted his picture taken with Marvin Finfrock’s “D” on tracks.

and it was a good one. Zachary was pleased to finally know his tractor was more powerful than when it left the factory in 1941.

Zachary and I headed up to 50 Years of Progress in Rantoul for a week of peddling plow parts and checking out the cool stuff at the event. The weather was beautiful and the crowds were bigger than ever. We did not take anything along to the show to play as it was a work event for us. We did get some time in to check out the plowing and corn picking demonstrations. The IH collectors put on a good display of 1206 tractors with well over 300 in total (from what we heard). I expected to see at least one 1206 painted green and yellow as it seems to be tradition

After hitting a hard spot, the 4D disconnected to the dismay of a 10-year-old boy.

Below: Eleanor trying her hand at driving the 1951 “A” pulling the 4D plow. She decided that matching overalls were just right for our little plowing demonstration.

for the JD and IH collectors to pick on each other and that there was a red 4020 on display.

Back at home after all the summer shows for us, Zachary and I were working on a model 4D plow that he wanted to fix up and try to sell. We got the plow bottoms fixed up and rebuilt the clutch along with new tires. Summer rains had been scarce and after two months without any significant rainfall, it would be a real test of a plow to see if it would go in the ground. We hooked up the 2-16 inch model 4D to Grandpa Buchheit’s 1951 “A” and went to the spot where we feed round hay bales to our cattle in the winter. I have plowed there before and figured it was worth an attempt. We managed to get it working and both Zachary and his younger sister Eleanor took their hand at plowing.

I also managed to get the F120 plow with JD factory chisel plow “mulch” bottoms to see how hard it would pull. I can attest that the 720D would bark in fourth gear even with only three twisted chisels. I have an extra chisel bottom “frog” and I may end up building a four-chisel plow to allow for completely covering my 720D tractor wheel tracks.

Rounding out the fun with Hank this summer was a project that Zachary had been bugging me with for

After a couple rounds, the plow was pulling much straighter.

well over a year. When he has extra energy or needs a break from the home school routine at our place, he often takes Hank for a drive around our farm and in doing so, he likes to hook up a piece of equipment from a hay rake to a wagon. My 630 and 720 both have front hitches and he would like one for Hank. The reason he never had one before is that one of the lower threaded bosses in the front steering pedestal had the thread stripped out. Zachary kept on reminding me that I told him we would eventually fix this a make a front hitch for Hank.

First, we found a 5/8 HELICOIL repair kit after it was misplaced for several years. Once I found it, then I realized that I did not have the proper size drill bit. Another week later, my eBay purchase of a 21/32 inch drill bit arrived. I drilled out the hole and got the rest of the broken stud out as well. Zachary took charge on the special tap and then I showed him how to install the HELICOIL insert.

With the thread fixed, creating the hitch came next. I searched all through the scrap iron pile for something that might work, but found nothing just right. The hole spacing on the “H” implement stud mounting is narrower than other models such as the “A,” “B,” “G” series tractor. I

HELICOIL was just what was needed to repair the stripped-out hole on the “H” front pedestal.

One-turn in and one-half turn back out keeps the tap turning smoothly.

Below: Zachary was surprised that the thread insert only required a flimsy plastic installation tool.

ground with Hank.

months

Below: He declined waiting to install the hitch after painting.

settled on a couple pieces of steel from a JD plow that I had dismantled. We measured, sliced, cut, ground, drilled, and finally welded up a proper hitch. I even made sure that the hitch plate had a slight downward angle on it to ensure it would be less likely to bind for low hitch pivot points (Zachary observed the front hitches on my 630 and 720 are sometimes in a bind on the pin due to being flat and level).

Zachary spent a couple hours hooking up and practicing backing an empty gravity wagon around the barn yard with Hank. He will require more practice, but with school starting up again this fall, Zachary will likely have more time to hone his front hitch driving skills between math and English lessons from his mother.

Contact Tyler Buchheit by email at tyler@mrbtractors.com. His website is www.mrbtractors.com.

With help from AI and some time on my hands, I found the perfect hood decal for Zachary’s tractor.

The 720D with the three-chisel plow conversion. Left: Smoothing out the plowed

After

of bugging dad, the front hitch is installed.

Josh Salm of Kiel, Wisconsin was at the Half Century of Progress Show with his half scale model 8020 John Deere tractor. “I started this around 1996 and built the tractor portion. My dad (Bob) had just gotten an 8020 and, being a farm boy, I had to have something to do.”

For the engine, Josh used a Ford Escort diesel engine. “I scoured and salvaged parts. I was trying to be a resourceful 16 year old.”

Graduating in 1999, he bought a place and, in time, started working on the model again. “I got better tools and had shop equipment. I started finishing the back half during the early 2000s.” It was around 2006 that he finished the ongoing project. “I got a three-point hitch as a design project. It was the last project in 2010.”

After that, Josh came to the Historic Farm Days at Pen-

field, Illinois and saw collectors like Darrell Fischer plowing with his 8020. At Penfield, he took measurements of the plow and built it for his father as well as his son, Grant. “I got the hitch done and built the plow. It is all custom, even the bottoms. I modeled it as best I could.”

Josh was contemplating whether to take it out at the Half Century. He added, “We plowed with it twice. We are going to play with it in the future. Really, I am prouder of the plow than the tractor; I has a tripping bottom raising it to a higher level.”

Over time, Josh decided that he wasn’t as pleased with the front end that he had created early on in his teens and he decided to redo it. “I redid it this spring. Now it has a Kubota four cycle engine.”

The half scale designation, he said, is more of a match in the back. “I started going over it from front to back, getting it more accurate, then I went back to the front now that I have more ability, and it is more accurate.”

The half scale 8020 hasn’t made too many debuts. “It was briefly at Classic Green but otherwise, it hasn’t been out in 10 years,” he said, except for the appearance at the Half Cen-

tury of Progress. This is the largest vintage tractor show in the U.S. that takes place every two years in Rantoul, Illinois on the former Chanute Air Force Base. The location is now Rantoul Airport.

These days, it’s more about what his son, Grant, wants than his wishes. “I want to see what my son dreams up and play around with it more. At some point, I would like to get a small engine built in the future.”

In the early 1930s, petroleum companies began using a new method called “catalytic cracking” to produce gasoline, which, compared to earlier methods, such as distillation and thermal cracking, was less expensive and more efficient. The result was less of a price difference between gasoline and heavier fuels like distillate and kerosene. This, in turn, led to more and more farmers converting their all-fuel tractors to run on gasoline only.

Many aftermarket companies introduced so called “cold” manifolds for these engines. These manifolds separated the exhaust and intake chambers so that the gasoline was not heated, which could cause a new set of problems.

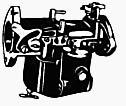

One of these companies was the Robinson Engineering and Development Company, then located in Calgary, Alberta. The company produced grain augers, loaders, and various other implements, many under the trade name Robeco.

Called the “Robin” manifolds, they were available for many different tractors that were popular during the day, including the John Deere model “D,” and were fairly popular in western Canada. The manifolds used a Schebler model “TR” carburetor commonly used

on certain Moline and Massey Harris tractors. The system was said to provide easier starting, more power, and better fuel efficiency, hard to believe when you consider all of the 90 and 180 degree turns the air and fuel traveled through, but then, have you ever seen something advertised

as making your engine weaker, less efficient, and harder to start?

If anyone has any experience with these manifolds, we would love to hear about it.

Thanks to Darcy Meyer for the photos and Herb Bartel, who owns the tractor.

If you have a John Deere Hay Cuber, you almost have to have a 75 or 76 dump wagon. Reg Gurney and Henry Deter from Ontario, Canada have a 76 to use along with their 425 Cuber. Since the two of them own it, this month we are going to split the pot and add six months to each man’s subscription.

fewer problems going through the combine. A quick side note—with improved varieties of grain and chemical termination, windrowers are not used nearly as much today.

In the 1960s, Deere offered the model 190 windrower, a 16-foot machine that had the unique optional feature of being able to reconfigure for heavy or light crops. In good years, the crop left the machine through the hole in the back, but in years where the crop was light on the return trip, the material could all be sent to the left to drop the windrow on or next to the previous windrow. The price for the base machine was about $1,900. The optional two-swath attachment added another $450. Do you have a 190 windrower? If so, be the first to send a photo of it and yourself to us, and we will add one year to your subscription.

In certain environments, especially in the north, small grain crops will not dry to a harvestable moisture before they are infested with weeds. The answer is to cut the crop and move it into windrows, where it will dry in the sun, and it can then be harvested with a combine equipped with a pick-up head. Any weeds in the crop are also dried so that they will cause

Right: Henry Weber sent us this photo of his 50. Below: Michaela Stinson sent us this photo of Deere tractors put away for winter.

Right: Paul Roback of Inland, Nebraska brought his nice “BR” to the Old Trusty Show.

Here’s a 1953 model 60 owned by

Below: You don’t often see a 4010 with a split manifold, but James Lampmann of Grant, Nebraska, owns one.

John Ralston sent us this photo of his daughter, Aidan, after the two finished putting up hay. She claims a 4020 as her tractor.

Left:

Left:

Jeff Dau.

If you are reading this, you are more than likely what is referred to as a “collector.” Collector is described as “one who collects” and “a person who makes a collection.” I would say that is a fairly accurate definition. But boy, oh boy, do some people take it to an extreme!

I have often said that if something has been made, there is someone who collects it. We are all familiar with the Beanie Baby craze (and don’t tell me about this one as my wife was head over heels into it and I lived it), Pokemon cards, vintage sneaker collectors, car collectors and, of course, vintage farm machinery collectors. The list goes on and on. The feeling that a collector gets when he finds a wanted item is what most collectors chase—that momentary “high.” Think back to the last tractor you found and brought home; that was the best feeling ever, right? As I have told you before, my collecting started when I found a brass compression petcock in the yard of my grandfather’s old home place. I picked it up, took it home and polished it on my father’s wire wheel. I LIKED it! I was probably 10 years old. Fast forward to after we had bought the dealership. By this time, I was into Fords and had a 1971 Mach One, three Falcons, and five Galaxies. I also had a 1970 Cobra Torino. All of this changed the day I stayed after work and went outside to take a look at a steel wheeled model “D” we had sitting outside for display. I was lucky that it was not stuck and, as this was

long ago, no one had come by and stolen anything off of it. I started messing with it and I got it to pop. I will never, ever forget the overwhelming sense of excitement that big engine gave me when it started. After that, I was hooked. I mostly never worked on my cars again and began chasing tractors. What I find interesting about collecting, and most of you can agree with me on this I think, is the many side trails and rabbit holes collecting will lead us down. I know very few people who collect one thing and one thing only. Most have other side collections that have come along as we concentrate on our hobby. One example I have heard time and again is that a collector is chasing a tractor but finds a really nice implement, so he buys it. At the next sale, he finds another implement that is slightly different than the one he has at home, so he buys it, too. Surprise, he is now also an implement collector.

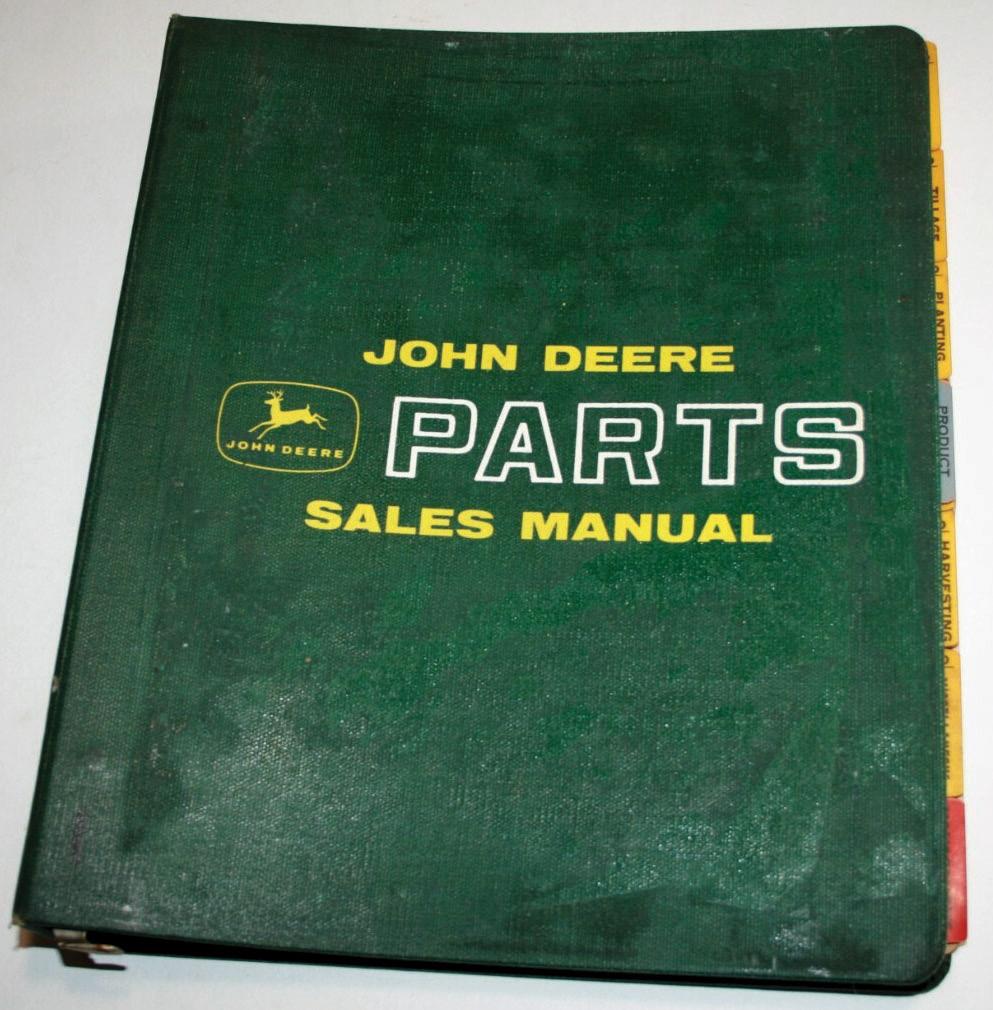

That happened to me as I began my tractor collecting. I started looking for a manual I needed and found it as well as others. I was now a literature collector. I found a few John Deere type “E” engines at the dealership back under a shelf and drug them out. I was now a gas engine collector. I found a few extra carburetors and magnetos, not just John Deere, and really liked them so I looked for others. I was now a carburetor and magneto collector. To me, it was all so very interesting and the more I found, the more I kept looking. After more than 40 years in the

hobby, I am still interested in anything to do with the tractor companies, and it does not have to be just Deere. I like to think that I have studied this more than many people may have because, being a dealer, I was in the industry so what I learned often had real time applications to my job and business.

For all that I think I know, though, I have to say I am constantly surprised at how much other collectors know. That is one of the things that keeps me engaged—there is so much history in this industry that no one can ever know it all and there is constantly something new to discover and learn about. Also, I never begrudge anyone about their hobby of collecting, whatever it is they are interested in. Who am I to say that collecting rusty old tractors is any better than collecting Pillsbury Dough Boys? If it makes you happy, go for it. That is one of the points of living.

What I am leading up to is I thought I would show you a few things I ended up collecting that I had no idea I would ever get into. This is just one or two of the many things I have collected, and I thought it might be interesting for you to look at and maybe even get a few of you started in these areas, too. This is by no means an exhaustive take on this area of collecting; it is more of a fun look at it. Let’s get started.

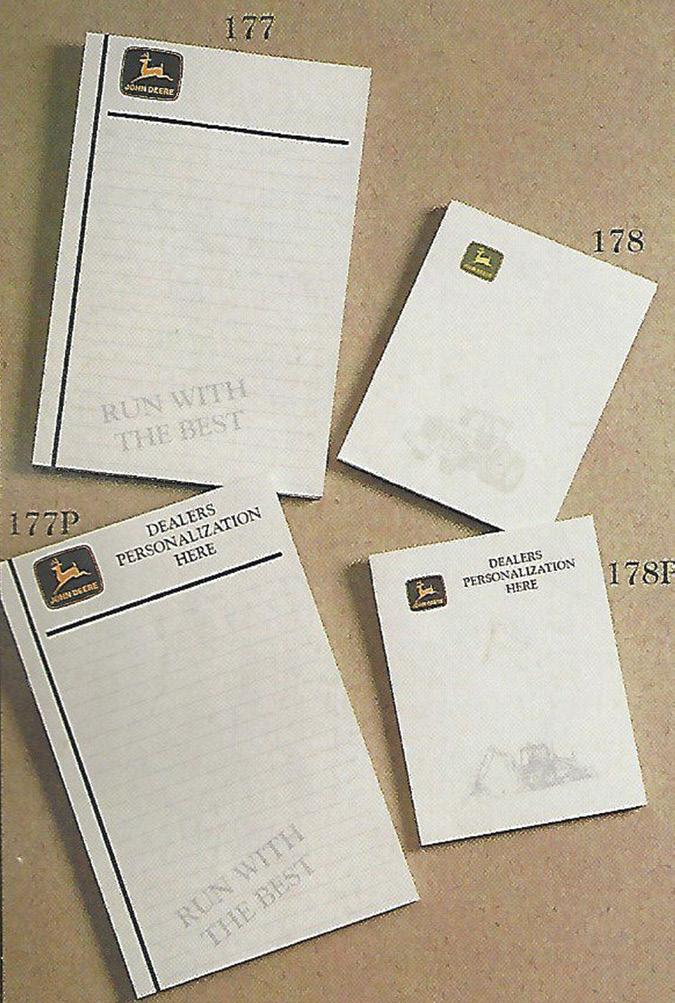

This area of collecting I got into started by keeping a note pad from our dealership. Then I found a note pad from the dealer we bought out. Then I found another one and another

and another and like I said, I was now a note pad collector. This one is from Bondy Implement from Drayton, North Dakota. It is a four legged deer logo note pad and dates from January of 1968. This style of note pad was the standard John Deere dealer note pad supplied by Deere for many years, perhaps even still is—I do not know (Photo 1).

This note pad is from S. Quilci & Sons of Wells, Nevada. This is one of the dealers I bought out and I moved everything from Nevada to Franktown. I was glad to run across this note pad in some of the stuff I got from them. This is an old two legged deer logo note pad and note that the slogans change as the years go by (Photo 2).

Photo 3 is a note pad from Weakly & Sloan, Inc. of Havana, Illinois. It features a grid background and has an old two legged deer logo. This one is from Bader Brothers of Reese, Michigan. From the internet, I found that Bader Brothers began in 1934 and, around 2009, they were facing pressure from Deere to expand or sell, like Deere has done to so many other old-line dealers. Bader Brothers sold their John Deere dealerships in 2010 and when Bader & Sons, a cousin, sold their dealerships in 2021, this marked the first time there was not a Bader family store serving Michigan in the John Deere business since 1934. A sad story I think, but typical of Deere’s policies regarding dealerships in today’s market. This note pad has a four legged deer logo and also is dated January of 1968, like the first one we looked at (Photo 4).

the slogan is different.

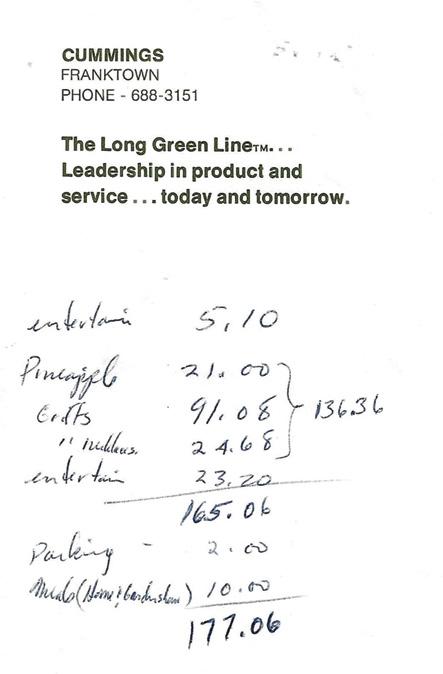

Photo 5 is a bit closer to home, this

being the dealership we bought out in 1976. Cummings Implement dated back to the early 1960s and had two stores at one time. We continued to use the Cummings Implement name for a few years after we bought the dealership and then changed it to Stephen Equipment. What is interesting to me is that this is my father’s handwriting on this note. Looking at it, it would appear he had written down pricing on “entertainment, gifts, necklaces, parking and meals” for a home and garden show. It would appear our company attended this show, but I have no memory of it. It was likely a sales event and we parts people would have been far too busy to concern ourselves with that. LOL. It has an old two legged deer logo and, again,

Photo 6 is our later Stephen Equipment notepad with the old two legged deer logo. It is funny but for all of the note pads we had around the dealership over the years, it was incredibly difficult to come up with one to save.

Photo 7 is a note pad from our friends at the Two Cylinder Club. I do not know the age, but I do know they have not put anything like this out in quite a few years. It has a two-cylinder two piston logo.

I just recently picked up this note pad from Schwitters, Inc. of Cedar Rapids, Iowa. I had not heard of this dealer before so I was glad to get it. It has an old two legged deer logo and the design is a bit different (Photo 8).

I think I may have borrowed this picture (Photo 9) due to the background not looking like anything I have used to take a picture

Photo 1 • 2, below

Photo 3 • 4, below

Photo 5 • 6, below

Photo 7 • Photo 8, below

Photo 9

on. Whatever the origins, it is a note pad for the John Deere Training Center in Wichita, Kansas. I myself have attended a class or two at the Wichita training center, probably back in the early 1990s. I remember wandering around Wichita at night after class trying to find something to do. I was not successful. It has an old two legged logo.

Photo 10 is a smaller note pad and it is a sticky note pad. It is for the Deere Harvester Credit Union.

Another sticky note pad—this one is for John Deere Marketing Services, Inc. in Waterloo, Iowa. It has an old two legged deer logo and a light grid background (Photo 11).

Photo 12 is a sticky note pad for the John Deere Health division; it has an old two legged deer logo.

to the everyday workings of a corporation like Deere. It has brown printing. This note pad is used for checking out tools, I would assume. It says “Tool Check Slip” and is for the John Deere Waterloo Tractor Works. It does not have a logo, but it dates from 1970 (Photo 15).

This is another good one. It is from John Deere Insurance and has an old two legged deer logo. Back in the day, Deere offered life insurance and even car insurance. I had a policy for

I liked this one. It is for the John Deere Foundry Division and has an old two legged logo (Photo 13).

Photo 14 is a message note pad from Deere. It has an old two legged logo and is dated November of 1984. This was long before emails, so documenting phone messages was critical

my car because, as a dealer, it was far cheaper than anything else I could find. Deere also at one point wanted dealer personnel to take training and become insurance agents. We did so and I took the test and actually passed. Deere’s brilliant strategy was for the dealer insurance agents to contact their customer base and sell them insurance. A win for Deere? Maybe. For us? No way. We did not feel right about pushing insurance on customers who looked to us for tractors and equipment, not insurance. I think most other dealers felt the same way as the program was

not in place too long before Deere dropped it. Deere eventually exited this market entirely.

This note once again has my father’s notes on it and this time it appears he was pricing out duals as he had a column for snap-on and also for bolt on. Apparently, it was for someone named Diane and that is all I know about it. I like the silhouettes of the vehicles at the bottom of the note page. I checked and this phone number is no longer associated with Deere (Photo 16).

This time the note pad has the slogan “Opportunity ’93” at the top and a John Deere tractor ghosted in the background (Photo 17). Deere constantly changed and added slogans as their marketing programs were announced to dealers. I do not remember the “Opportunity ’93” program but I would assume it was a sales program as dealers were told they could report their tractor sales by calling the phone number listed at the bottom. This phone number also is no longer associated with Deere. On this note, my father had sketched out a map for a customer, I assume for delivering Judy and Stan’s equipment. Remember hand drawn maps, kids? Pre-GPS? What a monumental change

Photo 11 • Photo 12, below

Photo 18

Photo 16 • 17, below

Photo 13 • 14, below

Photo 15

Photo 10

GPS was. I checked out the address and it appears to still be vacant land, 32 years later. I wonder what ever happened to Judy and Stan?

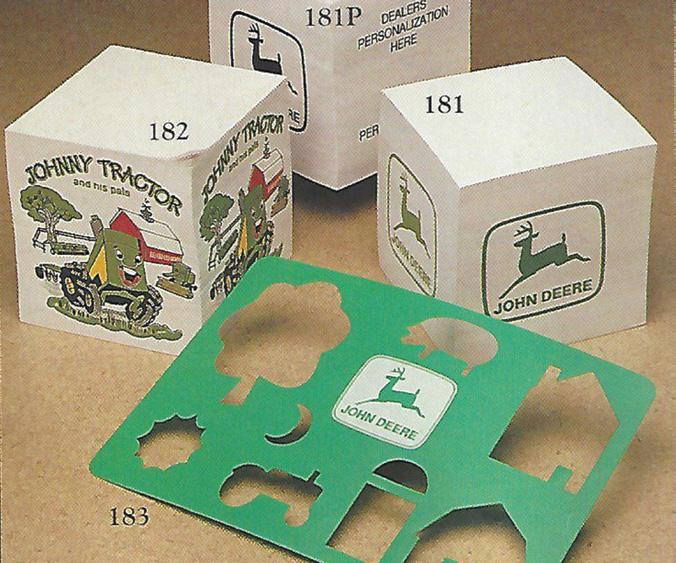

Photo 18 is from a John Deere catalog dealers could order from. Shown here are four different styles of note pads that could be ordered, with the dealer name at the top or no dealer name. These have the old two legged deer industrial logo.

Note cubes were another popular form of note pad. I have several and these were available for dealers to order. Note the Johnny Tractor note pad (Photo 19). In my experience, this is a fairly rare note pad; I know I only ever sold a couple of them but kept one back. Note cubes are great as the graphics are shown on the sides of the cube, in this picture the old two legged deer logo and the Johnny Tractor graphics.

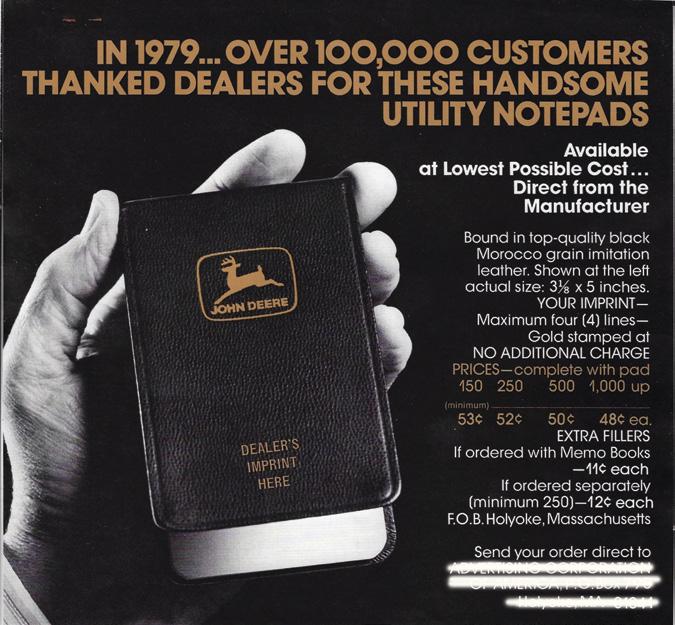

Note pads often took the form of pocket notebooks. I have quite a few different ones similar to this one. This was available for dealers to order, and if 500 were ordered, the dealer cost was 50 cents each. This was in 1980 so today it would be dollars, not cents (Photo 20).

Photo 21 is a note pad for Valley Implement Company of Sterling, Colorado. Valley Implement was far enough away from Franktown that we rarely competed, so we considered them a good neighbor. In local lore, they were legendary as Valley Implement had at least one John Deere snowmobile still new in the crate, never set up. Before you get all worked up, it is long gone—I checked. They sold many snowmobiles back in the day. I like the old-style leaping deer on this note pad. I am not sure if it is the same dealer but today Valley Implement is a Case-IH dealer. Imagine that.

If I had to guess I would say, there are likely hundreds of different note pads and notebooks that Deere has offered over the years. A collector could spend years just concentrating on these.

We are now going to look at an item I was excited to finally get all in one place.

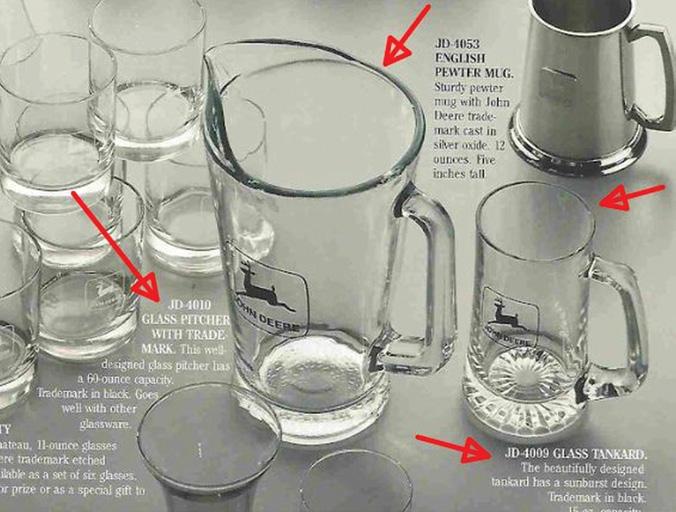

It is a John Deere pitcher and mug set. The pitcher, for some reason, is fairly difficult to find when looking for one. I have only ever seen a couple, and I have one myself I saved back for 30 years probably. I have always really liked this pitcher. Whether I appreciate the design and construction of the pitcher or whether it reminds me of my drinking days in my youth, it is a nice and heavy pitcher. I also always thought the old two legged deer logo

looked great on it. Another unusual thing about this picture is that there are six mugs. I have seen four once in awhile but never a set of six with the pitcher. The glasses are also well made and just feel right in your hands. I finally was able to get them all together in one location so I could take pictures. As with most things these days, they will be moving on to a new home as I have done what I needed to with them (Photo 22).

Photo 23 is a close up of the two legged deer logo mug as well as a different mug with an older deer over a log logo. Both are great mugs.

This is a fun picture. This is the pitcher and mugs from an order catalog I have dating from the late 1980s. JD4009 tankard and JD4010 pitcher are their item numbers. Also take a look at the high ball glasses and the pewter mug. Lots of glassware was available from Deere at this time. Glassware was just an okay seller for us, so I normally did not stock too much of it. Plus, glassware tends to get broken and then you have a pile of nothing (Photo 24).

In 1990, Deere put out a special catalog that listed only items related to the Waterloo Boy tractor. These Waterloo Boy glasses were one of the items. Also shown was a belt buckle

Photo 22

Photo 20 • Photo 21, below

Photo 19

Photo 23 • Photo 24, below

and a key ring as well as the sign in the upper left-hand corner. This was a heavy porcelain sign, not the cheap tin ones you see today for most brands (Photo 25).

Here is a set of Waterloo Boy glasses. The painted graphics really made these glasses stand out and they were bright and vibrant. I have had a few sets of these over the years, and they sold well. Nothing like relaxing after a long day in the shop working on your two-cylinder tractor with a drink in your Waterloo Boy glass (Photo 26).

Our final picture this time is of this set of unstyled model “G” glasses. The glass lists the model “G” as 1937 to 1953 but we all know this is an unstyled “G.” There were many different sets of these glasses produced at one time with different tractors. We will take a look at more glassware in a later article; this article is done for this time (Photo 27).

When you collect something, it

can be a life-changing adventure. You can go to places you never thought you would, and you can meet some of the greatest people with similar interests you will ever know. For me, that is the single best thing about this hobby—the people. Yes, the tractors and the memorabilia and more are all great fun but what I take away from the hobby are the people I have met and the people I have been able to have a discussion with. Collecting can also be a deeply personal activity. Some people collect to remember their past, while others collect for pride of ownership. Still others approach it as a business and, for them, it is about the value and the money and every dollar counts. I think the value part is fun, but I always collected because I liked the item or because I felt there was something to be learned from it. You also have to be very diligent for “mission creep” as John Deere is not the only brand with interesting items. I have veered

off into International a bit as well as Allis-Chalmers, Oliver and others. I appreciate almost anything vintage and, although Deere is my number one focus, I can appreciate other brands, too. As I have said before, I am continually amazed at the sheer volume of items Deere has produced. It is incredible. There is constantly something that pops up that I have never seen before so my interest is continually renewed. At some point I suppose, due to age or death, I will lay my collecting efforts down and take a break. I can always always say, however, it has been more fun than anyone should be allowed to have. I hope you all feel the same way. Don’t forget to look outside the areas you normally collect in, like these note pads and glassware—there are lots of other things that can be collected and enjoyed. This was just a quick glance at two different ones. Until next time. Write Greg Stephen at The Old Tractor Company, Box 89, Franktown, CO 80116; phone 231-846-8243 or email deeredr@hotmail.com

Photo 26 • Photo 27, below

Photo 25

I have mentioned my mom’s youngest brother, my Uncle Kurt, several times over the years in my articles. He farmed (dairy farming) on their home farm near Edgar, Wisconsin his entire life. Uncle Kurt was also one of the founding members of the North Central Wisconsin Steam and Gas Engine Club that hosted their first antique farm equipment show in 1974. That first year it was held at the State Park Speedway near Wausau, Wisconsin, about 20 miles to the east of Edgar. After the first show, Uncle Kurt offered to host the show on his farm. It was centrally located for the members, it was a working farm on which he planted both corn and oats that could be used for demonstration purposes, and there was plenty of room that they didn’t have to pay for. This year on August 22, 23, and 24, the club held their 52nd annual show on the farm. It was very well-attended once again with more than 500 tractors, many small engines, a sawmill, threshing, field demonstrations, and a flea market.

One of my friends, Rick Salber, brought a couple of his beautifully restored machines to the event. Photos 1 and 2 show his model 730 diesel tractor with electric start and mounted 237 corn picker. The tractor is a 1959 model and the picker is from 1965. Photo 3 shows his 1973 6030 tractor. These machines are only a few examples of several John Deere pieces Rick has in his collection. He also farms in the area and was a John Deere mechanic in the 1970s. His talents and capabilities are amazing and it was great to

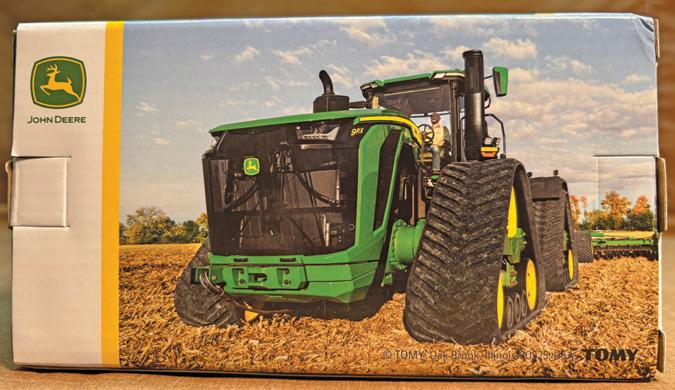

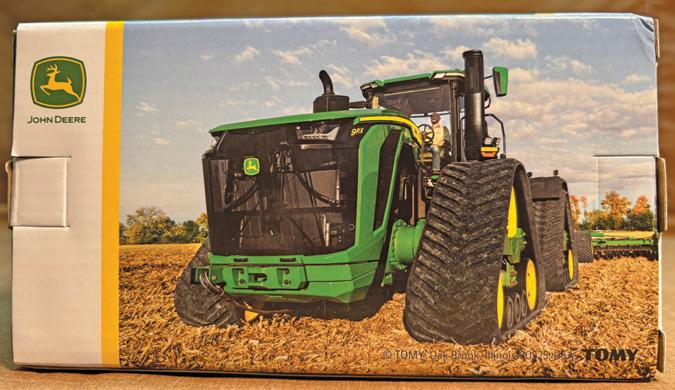

see him, his family, and some of his collection at the show. In case you are wondering, the website for the club is edgarsteamshow.com and next year’s show dates are August 28, 29, and 30. The featured brand will be John Deere. While at the show, I visited with another friend, Mark Vornholt. Mark sells new farm toys of all brands and scales, and attends many farm toy shows and antique tractor shows throughout the year. His website is collectorsshelffarmtoys.com for those looking for another option on where to purchase miniatures. Mark had the new 1/64th scale version of the John Deere 9RX 830 tractor on his table and I decided to purchase one, along with a toy for my oldest grandson (who just turned 4), who went to the show

with me. The Ertl stock number for this tractor is LP86645 and it will be the primary subject for this month. Back on February 28, 2024, John Deere introduced the 9RX 830 as their most powerful tractor to date. This is a massive machine, weighing in at 74,000 pounds and having the capability to add ballast weight to reach 84,000 pounds. It features a John Deere JD18X (18 liter) engine with 830 rated horsepower, 913 maximum horsepower, and 335 PTO horsepower. The engine has a 1,098 cubic inch displacement, carries 18.9 gallons in the crankcase, requires 30.9 gallons of coolant, and has a fuel tank capable of carrying 515 gallons. The overall machine is nearly 12.5 feet tall and 29 feet long. I have seen exactly

Photo 1 • Photo 2, below

Photo 3 • Photo 4, below

one at a dealership about 50 miles from here and I am simply amazed at the size of this tractor.

So, let’s take a look at some of the details on this 9RX 830 toy. The carton is shown in Photo 4. Note that this is a Prestige model, so the expectation is that there will be a higher level of detail on this miniature versus a Replica model. A fully enclosed cardboard carton with clear plastic viewing window was used. The graphics include the standard green, yellow, and white background colors and printing. The

John Deere trademark is on five of the six sides, and the PRESTIGE COLLECTION identifier is on four. Partial photos of the real tractor are on each of the two end panels, and a full-front view of a tractor at work is on the rear (Photo 5). The toy is secured to an inner sleeve that can be slid out of the carton as shown in Photo 6. A clear plastic base is cemented to the bottom of the sleeve in which the tractor sits. Two paper ties were used to fully secure the tractor to the plastic base. I decided to completely remove my tractor from the sleeve so that I could take pictures of all sides.

Photos 7 and 8 provide left and right side views of the tractor. The main frame, or undercarriage, and the axles are made of die-cast metal. The tracks are a rubber material, and the rest of the toy is made up of plastic components. The team at Ertl did a nice job of keeping the fasteners

(screws) hidden by placing them all on the bottom.

The right front corner of the tractor is shown in Photo 9. Note the hood stripe and the model and horsepower designations. These items appear to be printed in place, which is a really nice feature. Also note the black tool box attached to the frame. It includes a tiny green and yellow John Deere trademark. Also visible on the top of the hood are four darker green areas representing the air vents, and the hood ornament highlighted in silver. Photo 10 provides a close-up view of the front of the tractor. Here you can see the headlights, which are silver decals. Unfortunately, since they are the self-adhesive style, they do not stick

and stay in place very well. The John Deere trademark is included near the center of the grille, and you can see the screens and hood ornament on the top a little more clearly. The front weight mounting bracket and “hardware” are provided at the bottom of the frame at the very front of the machine.

The engine and corresponding systems are not visible since the hood does not open and the black side shields for the engine compartment completely block any view of these components. Photo 11 shows the left side of the front “half” of the tractor. Despite the size of the real machine, the 1/64th scale model is still relatively small and it is very difficult to take clear pictures of the small details. So, I will try to point out what I can see that the camera may not pick out very well.

Included are the air intake stack and cover for access to the air filter element. Five green steps are provided for access to the cab. The cab is made of all plastic components and it features a black door handle, rear windshield wiper, and corner posts. The fuel cap is painted green, along with the front surfaces of the two mirrors that are

Photo 5 • Photo 6, below

Photo 7 • Photo 8, below

Photo 9

Photo 10 • Photo 11, below

located on the sides of the cab. The mirrors actually have a reflective surface on the rear side. Also note one of the two steering cylinders located directly below the access platform that is immediately behind the cab.

I tried to capture some of the cab interior in Photo 12, but it is nearly impossible given the size. With a magnifying glass, I could see that the steering wheel actually has a triangular-shaped center medallion with the John Deere trademark. There are some control arms on the sides of the forward console and pedals below it. A foot peg is included on each side of the console. The driver’s seat has a monitor attached to it on the right

side and there is a training seat to the left. All of the interior components are molded in a beige color.

Photo 13 shows the rear of the tractor. Included here are the remote hydraulic outlets highlighted in several colors, the Category 5 drawbar, and some weights attached to both sides of the drawbar. The fenders each have stop and warning lights on the rear surface, and two work lights on top. A slow moving vehicle sign is attached to the inside edge of the left fender. Work lights are also provided in the upper corners of the cab and on the air intake stack and on the muffler.

I added Photos 14 and 15 to provide a better perspective of the size of the 9RX 830. A 1/64th scale X9 1100 combine is to the left and a 6030 tractor to the right. The 9RX tractor is nearly as long as the combine and

almost twice as long as the 6030. The overall assembly, fit, and finish on my model are very good, especially given the small size of some of the components. The track assemblies rotate on the axles, the front and rear of the tractor move in relation to one another to provide “steering” and the tracks rotate on the wheels. There really are many details on this tractor that are simply hard to describe, and they make for a very realistic model. Expect to pay roughly $30 to $35 for one of these toy tractors when purchased from most dealers.

I realize that this is a miniature of one of John Deere’s newest machines, and therefore, is probably not of interest to all collectors. I purchased one since the real tractor intrigues me. It is huge, has tons of technology, and has a very unique, nearly “robot-like” appearance. Ertl is also going to produce a 1/16th scale version of this tractor with their stock number LP86760 as a collector’s edition model. It may already be out when you are reading this. I intend to cover that one in the future. Enjoy.

Contact Bill Proft at N1366 Woodland Dr., Greenville, WI 54942 or email billproft@sbcglobal.net

Photo 12 • Photo 13, below

Photo 14 • Photo 15, below

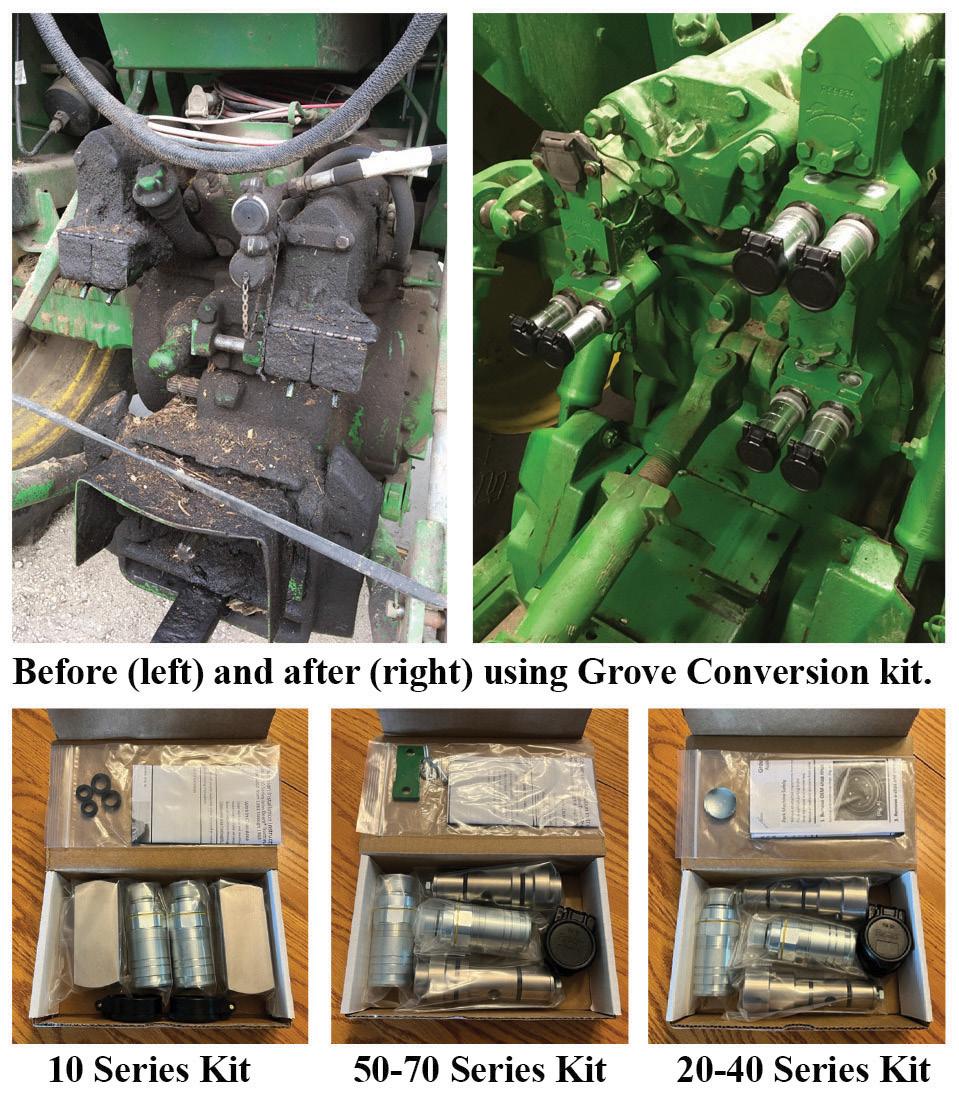

Full disclosure…if you feel as though you have read this article before, you have! We first talked about adding power steering to your heirloom old tractor in the summer of 2018. Since we wrote of this topic, we STILL get many letters and phone calls; therefore, it seems that it remains a big topic of interest. As you read on, please keep in mind that some of the prices mentioned likely have increased. What if I tell you that you can put power steering on your old John Deere for under $100? What if I told you that you won’t need a power steering pump, pulleys, belts, hoses, fluids, and, best of all, you won’t need a $700 torque amplifier? Do I have your attention yet? How about putting 12 volt electric power steering on your tractor? Say what? I say, “Why not?”

A long time ago, Mr. Thinker mentioned something about 12 volt steering on an old tractor. The article originated from the Farm Show publication. There wasn’t much said to explain it or how to do it, but it fired my interest. We dug deeper for more information, but came up empty. Turning to another source, we realized that the automotive industry has been using 12 volt electric steering on some models, starting about the year 2002, and increasing to more vehicles as time went on. They favored the electric steering called EPS to eliminate all of the mechanical hydraulic units of the conventional system. The EPS system is far less weight and takes up less space for the automobiles. The EPS

systems operate on 12 volt negative ground and are self-contained except for the control signals that are received from the car’s computer. It seems that us old tractor buffs are a bit slow on the draw on this one, because the hot rod people have been retro fitting these systems into their vehicles for a while now. For myself…I would be interested in a 12 volt steering system for my ’66 Chevelle; it did not come with power steering and when not in motion steers hard. Any old tractor with 12 volts and one foot or less of open steering shaft could be a candidate for one of these systems.

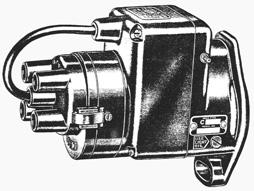

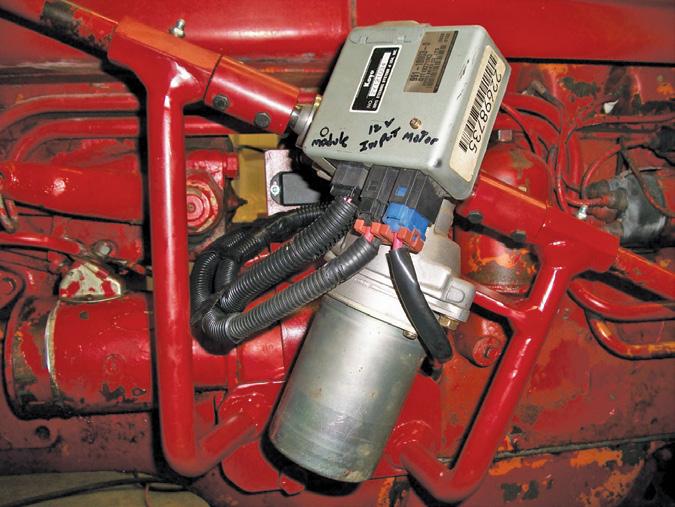

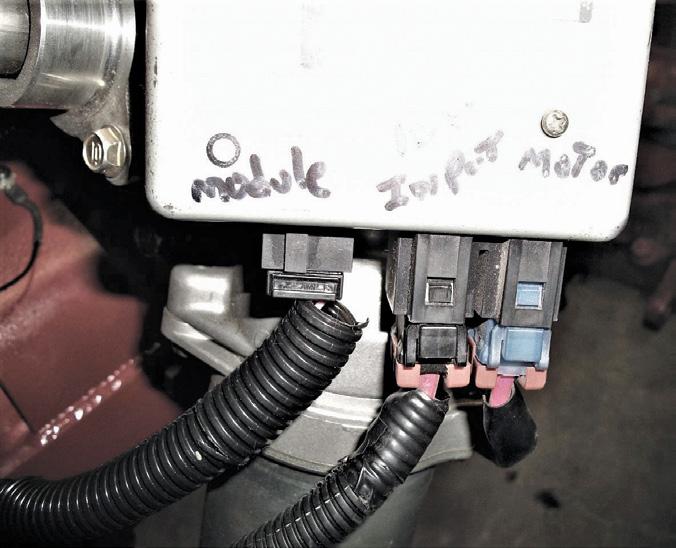

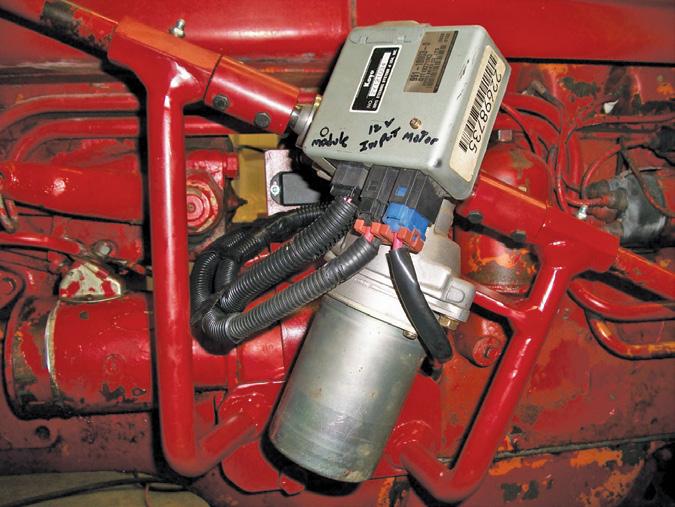

So, I am interested…where do I start? How about a phone call to my local auto salvage yard; ask the parts guy for the electric steering unit from a Saturn Vue. He returned a call and said that he had one from a 2003 model and the price was $45. My reply was, “I will take it. Call me when you have it removed from the vehicle.” I am sure that this price will vary between salvage yards. This is what the 12 volt steering gear looks like (Photo 1). The

units have a through shaft input and output that allows manual steering without the electric assist working. The square box is the unit’s control center, receiving 12 volt battery input and 12 volt output to the steering motor (the round unit). It also (on its third plug terminal) receives signals from the car’s main computer, giving the unit its direction to steer, and how much steering assist is needed. For instance, you would need more steering assistance when the tractor is not in motion than when it is. Again, the idea behind these 12 volt systems is the same as any hydraulic assisted unit. It is meant to reduce the amount of steering wheel effort needed to turn the wheels. These systems use a reversible electric motor to provide assist rather than hydraulic pressure. This system is more efficient because it only needs to provide assist when the wheel is turned, rather than rotating a pump constantly. The square control box on the unit has three plugin terminals, as one can see. One is a 12 volt input, one is a 12 volt to the motor, and one is input signals from the auto’s computer or ECM.

The first two terminals are simple to see and understand, but what about the plug-in terminal from the ECM? What do we do with this one? Obviously, one does not get the car’s ECM with the steering gear, and I am told that even if you did, it would be nearly impossible to get the computer to activate and control just the steering gear. If you were a computer genius of this magnitude, the computer would

Photo 1

just “fail-safe” itself, and shut down for lack of sensor readings from the car. But still…we need computer signals to ACTIVATE this thing. Now what do we do?

Again, before you throw the magazine in your recycle bin, read on a bit farther. It seems that there are electronic folks who have addressed this problem for us. Further research— we found that there are several entities

out there that are making a kit for these units to take the place of what the car’s computer did. Another $48 landed us two little pieces that are supposed to do the job; Photo 2 shows a small black box (smaller than a deck of cards), and a little dial switch called a potentiometer that, when hooked together and activated with 12 volts, then plugged into the control box’s computer terminal is supposed to make the whole thing work. The dial potentiometer is used to manually set how much steering assist the unit will provide by just turning the knob.

Here then (Photo 3) is the unit powered up with 12 volts, and the control unit plugged in. The unit is almost silent in operation and the results were very impressive. Turn-

ing the potentiometer dial up a few clicks, the assist response was greatly increased. It’s a GO! All I had around here right now for old tractors to put this thing on was a Farmall “A” with a belly mower. It has a section of open steering shaft exposed and it was easy to mount the unit in this area (Photo 4).

There are a few more do’s and don’ts that need to be mentioned to complete a successful installation for one of these units. They only weigh about 10 pounds, but how it is mounted is important. I need to mount the unit, its final electrical connections, and make a small simple dash for the control module and the red dial. I am anxious to get this thing on the tractor and working, so some of my other projects are being put on the “backburner.” We have since learned that many models of the GM’s Equinox SUVs also use these steering units. I want to snare me one of those and get IT ready to retro fit in my Chevelle. Anyway, now it’s time to mount the thing to a tractor and hook it up to 12 volts, add the control box and potentiometer, and see if the unit will power steer a tractor. My apologies to all of you “GREEN only” Deere fanatics that I had to use a red tractor for my first project, but that’s all I had around here at the time to work with. However, any tractor with one foot of exposed steering and a 12 volt negative ground electrical system would qualify to be adapted. So, for now, go to your desk drawer and get out those green colored glasses to finish reading our results, and just imagine this being a part of your own green tractor.

The project has been a hotbed of interest to a lot of people who have

spotted the strange looking object pinched in a bench vise in my shop. Many of them have said, “Let me know how this turns out on the tractor.” And so it is with my pal Jeff (I’ve spoken of him many times; I call him the “metal whisperer”). Jeff helped me with the mounting of the power steering unit to the tractor. Jeff always “over builds” and over thinks everything, and then makes the metal works look like they came from the factory that way. What else would one expect from a guy whose motto is, “If man made it, man can duplicate it.”

This project was an “inspiration” for me from Jo Anne, who has long hinted that our little tractor with its belly mower would be much improved if it steered easier. The next step for us…on to digging, research, and reading. The end result of the project and mounting to a tractor is … it works better than I had even hoped it would! The tractor steers effortlessly with one finger, and can be adjusted for the tractor’s steering effort at any time. Photo 5 shows the mounting base plate bolted to the bell housing of the tractor. There are two upright steering shaft supports coming from the base plate. The rear support (Photo 6) pilots the steering shaft into the ESU

Photo 2

Photo 3

Photo 4

Photo 5 • Photo 6, below

(electric steering unit) and is bushed and “greaseable.”

Forward of that is the first coupling that connects the steering shaft to the ESU, and is fastened with “grade 8” bolts (Photo 7). The forward

mount supports the front portion of the tractor’s steering shaft and is bushed and coupled in the same way as the rear mount. The forward mount also includes the bracket for the ESU’s mount. The ESU is mounted from its original bracket with a through bolt as it came from the car. This type of mounting allows the ESU to be free of side thrust and sort of floats in between the two shafts. This is one of a few mounting suggestions that we have come across. Now as you can see on the unit’s input box, there are three electric connections (Photo 8): module input, 12 volt power input, and power to the steering motor. The motor input is part of the unit and comes with it. The center terminal is 12 volt input power, and if you talk nicely to your salvage yard attendant when you purchase one of these units, ask him to cut these wires leaving a length for

you to work with along with the snap connector into the ESU box.

The third item is the module terminal connector from your outsourced control box and potentiometer. This makes the unit come to life. The mount for these pieces is an extension of the bell housing mounting plate. It simply extends up from the lower base plate and allows a neat place for the control box and the dial to be mounted and also grounded (Photo 9). The little black box then needs a 12 volt switched input wire, and then connected to the potentiometer. That’s it! It’s easier to hook up than one would think. If I can do it, so can you.

As for the little red button that turns back and forth, its purpose is to provide the proper amount of steering assistance needed to make YOUR tractor steer as easy as you desire. I have found that for this tractor, the steering effort is best with the dial set about halfway in its range. Turning the dial all the way UP tends to over steer the tractor, and all the way DOWN requires too much steering effort. It’s a fun thing to play with and dial to make the tractor steer just the way you want it to. These two control units are mounted under the tractor’s gas tank and hood for a reason; it is recommended that they not be mounted out in the weather, but also not be put in an enclosed box for fear of their heat build-up.

By the way, what is a variable potentiometer? It is a resistor with a sliding or rotating contact that forms an adjustable voltage divider. Another explanation is…it acts as a variable

resistor or rheostat. I guess what we are doing when we install this thing into the circuit is varying the input voltage to cause more or less steering assist. Again, the unit works like a champ, and when all is said and done, we have a grand total of less than $200 invested in the whole “shebang.”

Regarding the tractor’s 12 volt negative ground charge system needed for these units, there are a few things that must be addressed to power these things and keep them working—one is that they are vulnerable to charge system spikes in the voltage. Our beloved Delco 10-SI alternators set up with one-wire charging tend to do this. Anyone that has these alternators will note that on start-up, they will bury the ammeter in charge rate until the proper voltage is reached. This type of spike voltage will harm the power steering module… we don’t want that, do we? This can be safeguarded easily with restrictor diodes on the module’s input wire, or by using a generator or alternator with a conventional voltage regulator. I have not yet decided which way I will go on this tractor’s charge system to accommodate the ESU. I guess that I will install the recommended input wire diodes for now, and possibly use a 12 volt generator or a compatible alternator as time goes on.

It’s nice to have the tractor on 12 volts now as it turns over and starts so much easier. And the ESU makes the tractor much more “user friendly,” just ask Jo Anne.

**2025 UPDATE: One final note…with our use of this unit over the past years is that they need a voltage operating range low of 11 volts to a high of 14 volts or the unit tends to fail-safe itself and return to manual steering. Whatever charge system you use must provide voltage in that range while the system is in operation.

Until we meet again, God bless you and Happy Thanksgiving. This column is written by Ron and Jo Anne O’Neill.

Photo 7 • Photo 8, below

Photo 9

When I was a kid, my grandmother was a cook at the Arcady Inn restaurant in my hometown of Oklee, Minnesota. They did not just take short orders but also had a buffet line on certain days. They called it “The Smorgasbord”! If you are not familiar, a smorgasbord is a luncheon or supper buffet offering a variety of food and dishes. Well, this month I think we have quite a smorgasbord of auction results Before we get into the auction results, I have to mention what I call a bit of good fortune. I met a neighbor at the gas station in town and he said, “Would you be interested in a few old John Deeres?” He explained his uncle had a few tractors on his place but his uncle passed away. What do you think? So I went over to take a look. The tractors were comprised of a 1937 “A” with a No. 5 mower behind it, a 1942 “A” that was partially restored before the owner passed away, and a 1950 “G,” flatback, with an add on wide front that was made by a machine shop in Grafton, North Dakota. The

“A’s” were loose but the “G” was stuck. He said, “What will you give for them?”