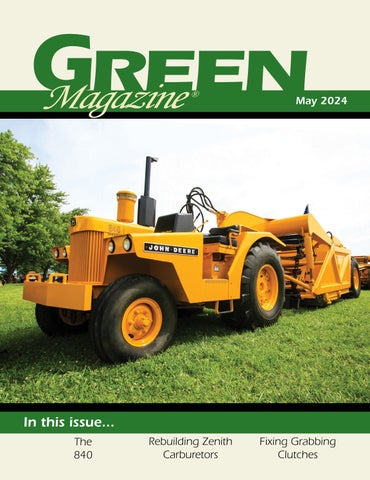

The 840 Fixing Grabbing Clutches Rebuilding Zenith Carburetors May 2024 GREEN Magazine® In this issue...

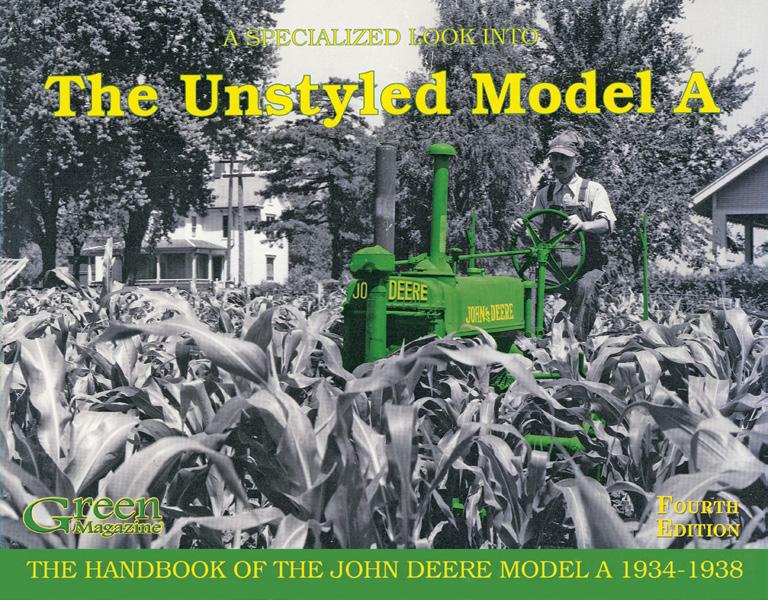

The Handbook of the John Deere Model A 1934-1938

Fourth Edition

• By Wes Malcolm

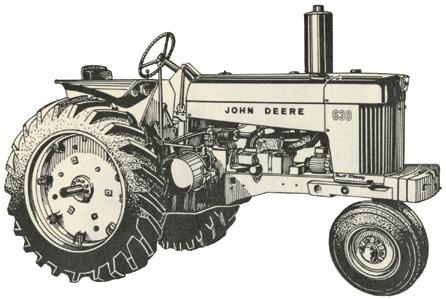

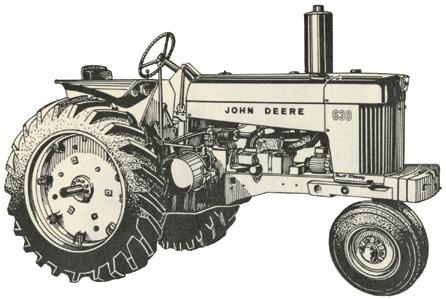

Now in its fourth printing with 15 more pages, this is the handbook of the John Deere model “A,” 1934-1938. A book that should be on the “must read” list of any unstyled “A” owner. There is probably no other book on the market that goes into so much detail on a single model of tractor. Shows illustrations of nearly every change made in the parts that make up the unstyled “A.” 95 pages, 11x8-1/2 inches, soft cover.

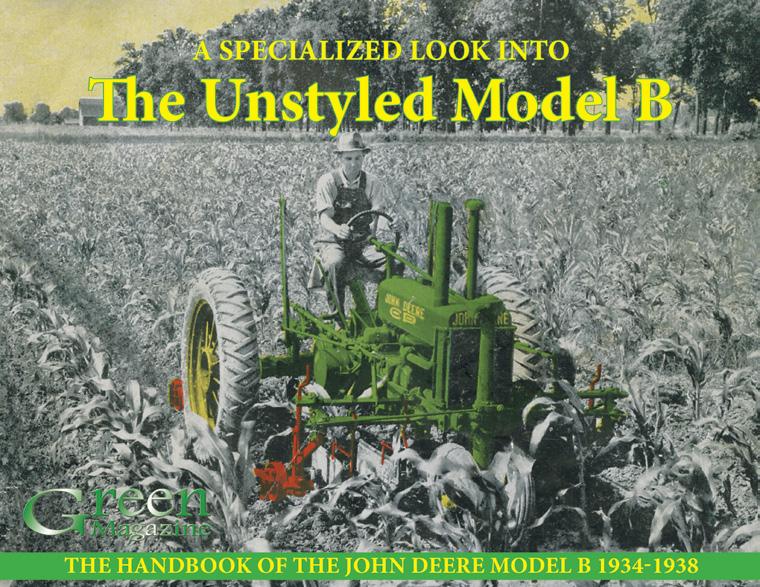

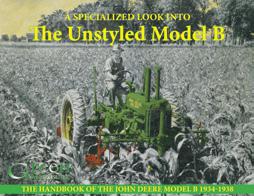

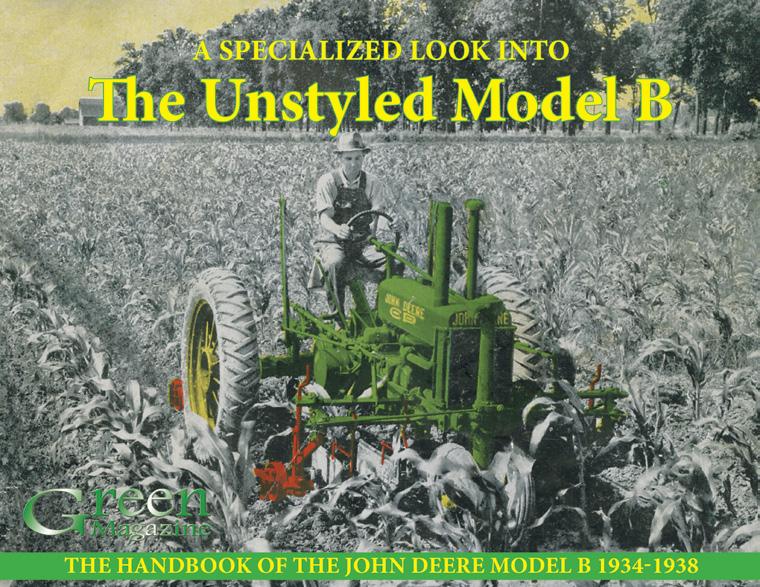

Both books include history, specifications, serial numbers, original prices and much more A Specialized Look Into

The Handbook of the John Deere Model B 1934-1938

The same types of information as available in the book above, except now about the model “B,” written and compiled by a panel of experts who have spent decades collecting and restoring the unstyled version of Deere’s most popular tractor. This book shows nearly every change made in the parts that make up the unstyled “B.” 84 pages, 11”x8 ½”, soft cover, over 200 photos - most in color.

WHAT A DEAL! SPECIAL BUNDLE PRICE on these TWO books published by Green Magazine A

The

A

Specialized Look Into

Unstyled Model

The Unstyled Model B

Order GMAB: $63.95 U.S. (Nebraska residents add 5.5% state tax) $76.95 Canada (US funds) • $89.95 Foreign (US funds) The prices shown here are for BOTH books shown above - the first time for this BUNDLE DEAL. •• Prices in this BUNDLE DEAL are up to 20% OFF the regular price •• Visa, Mastercard, Discover, American Express accepted • Nebraska residents add 5.5% sales tax • Price includes S/H Call 402-643-6269 • Email info@greenmagazine.com Online www.GreenMagazine.com Mail Green Magazine® • PO Box 95, Bee, NE 68314-0095

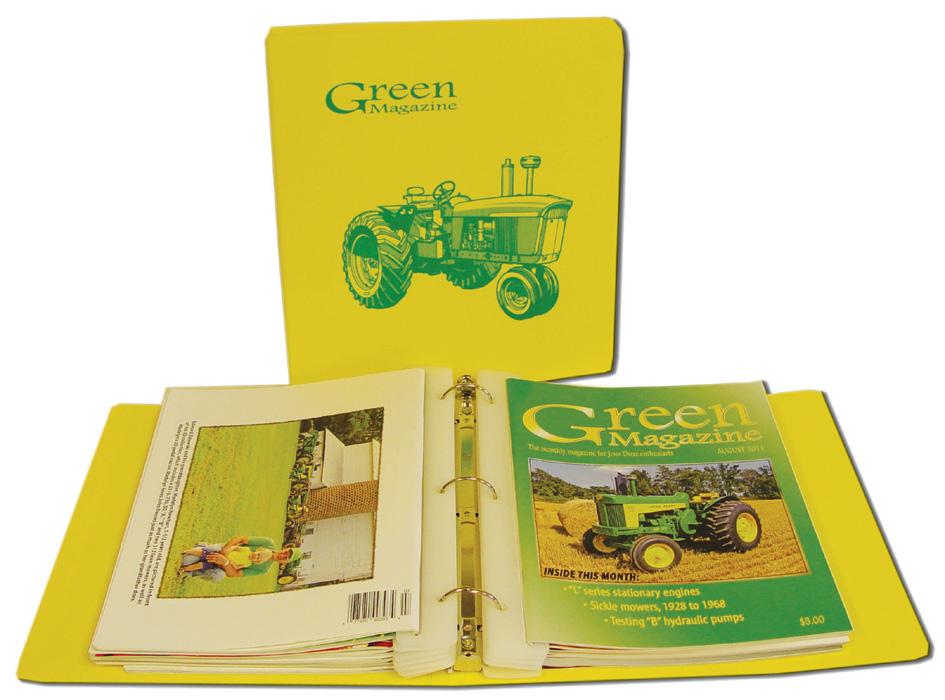

The monthly publication for John Deere enthusiasts

Managing

Layout/Design

Historic Farm Days celebrates model “D” Cindy Ladage

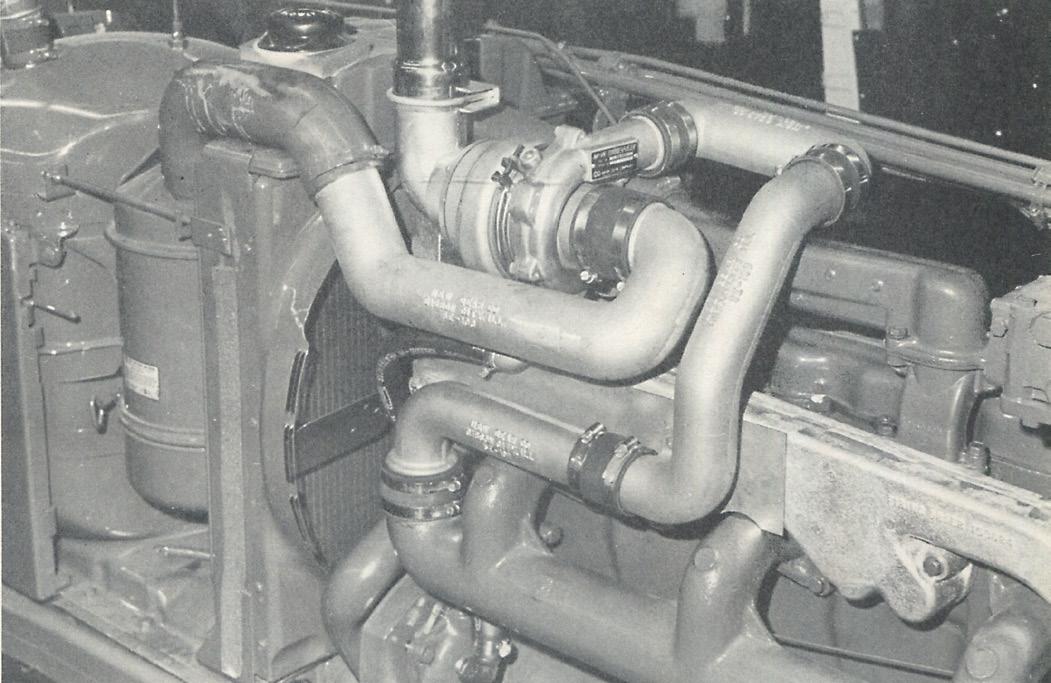

John Deere model 840 Benjamin Hain

The story of a “GP” standard Eric Sherman

The Young Timer The Alaska connection Tyler Buchheit

How our hobby started A new catalog and a new show Richard Hain

Tip of the month Jumpy clutches on two cylinders Dan Brotzman

“GREEN MAGAZINE®” (ISSN 0883-5462) is published monthly and released 12 times a year on or about the first of each month for $39.95 per year (Canada: $59.95 per year; Foreign: $69.95 per year) by Hain Publishing, Inc., 2652 Davey Road, Bee, NE 68314-9132. Periodicals postage paid at Bee, NE and additional mailing offices.

POSTMASTER: Send address changes to “GREEN MAGAZINE®, PO Box 95, NE 68314-0095.”

GREEN MAGAZINE® reserves all rights regarding reprints of this publication. Our phone number is (402) 643-6269.

Copyright © 2024 Hain Publishing, Inc. All rights reserved.

10

18

32

May 2024 • Volume 40 Number 5

5

6 Deere

14

24

30

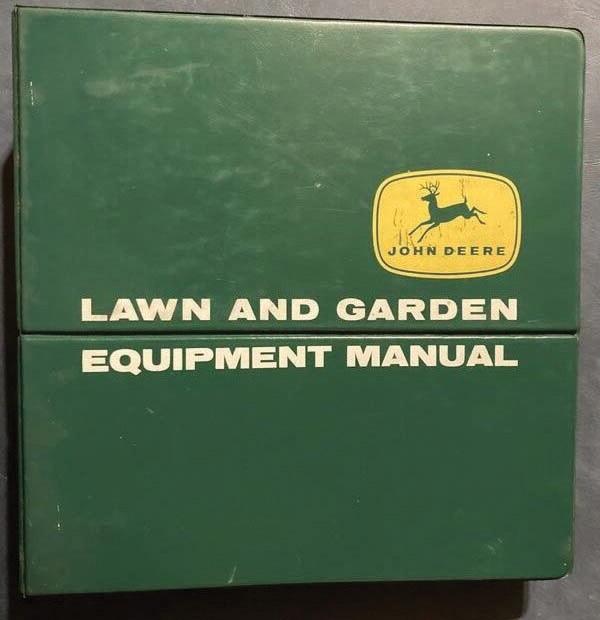

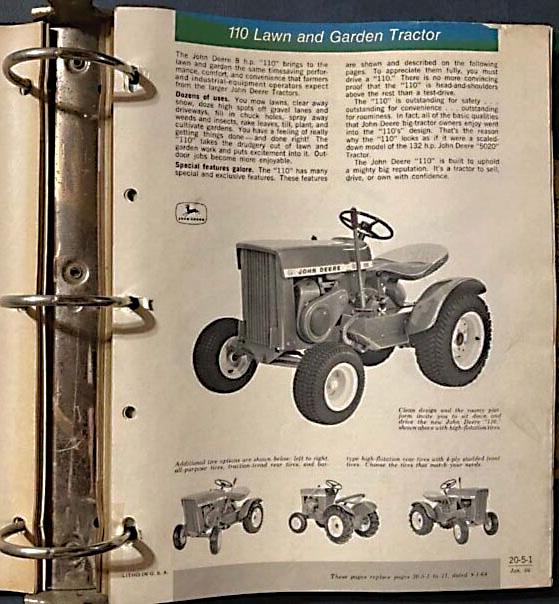

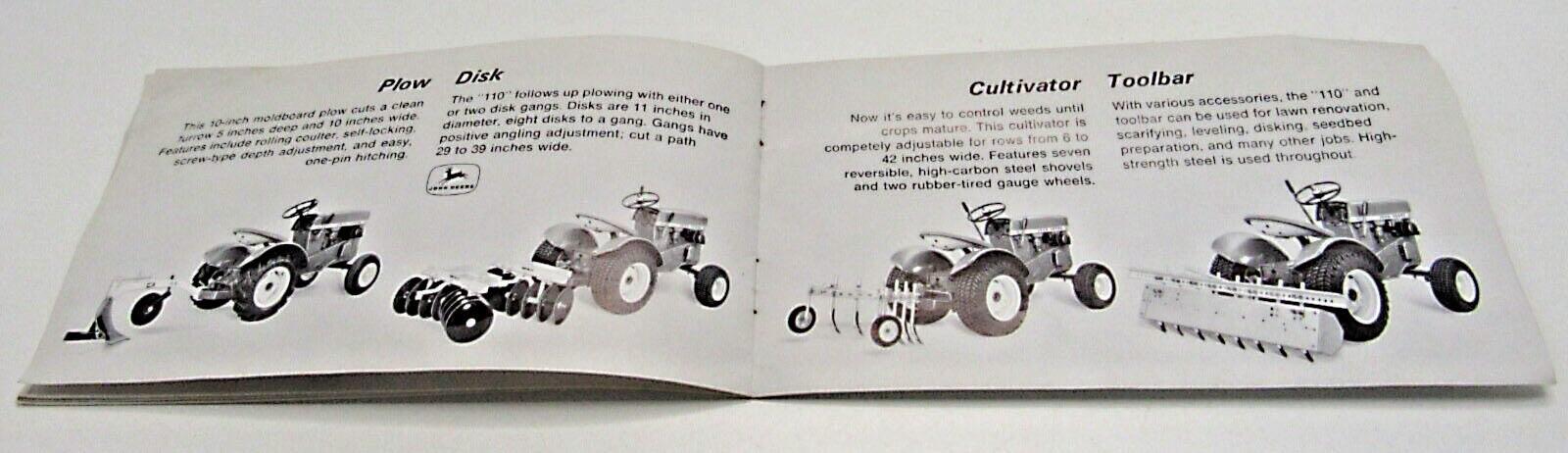

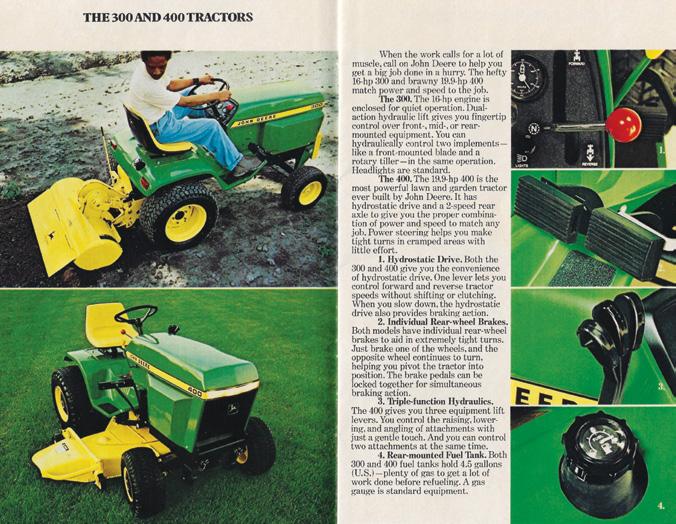

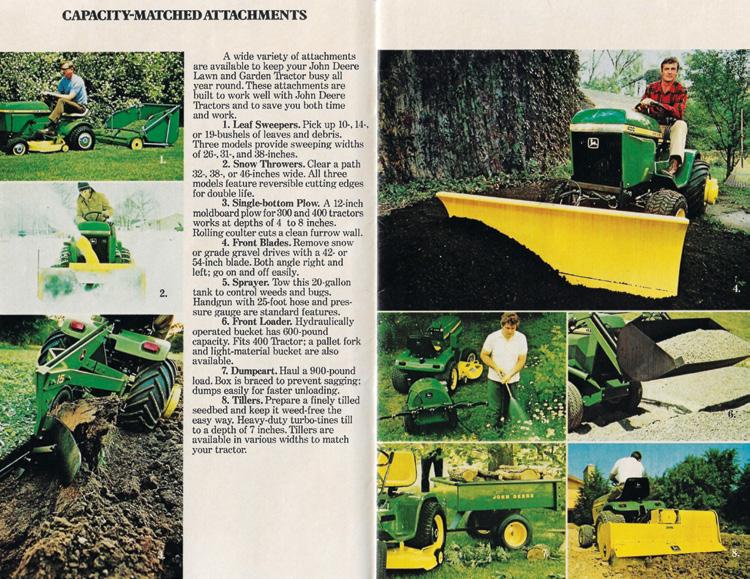

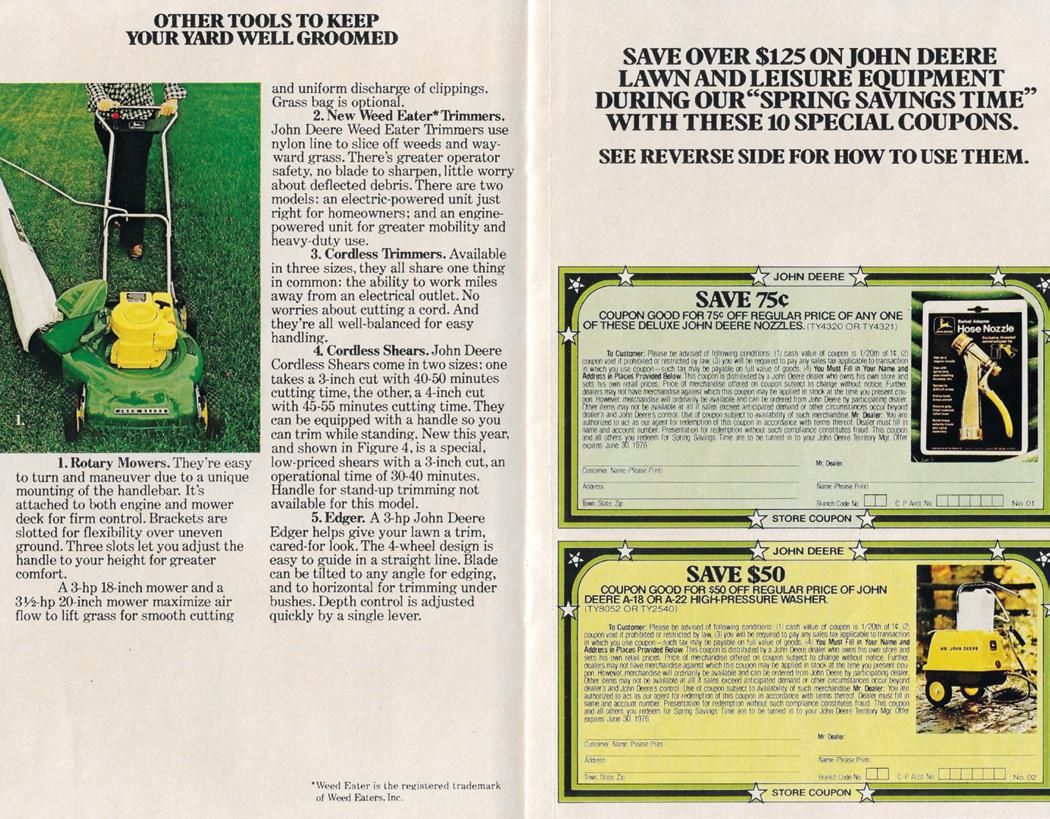

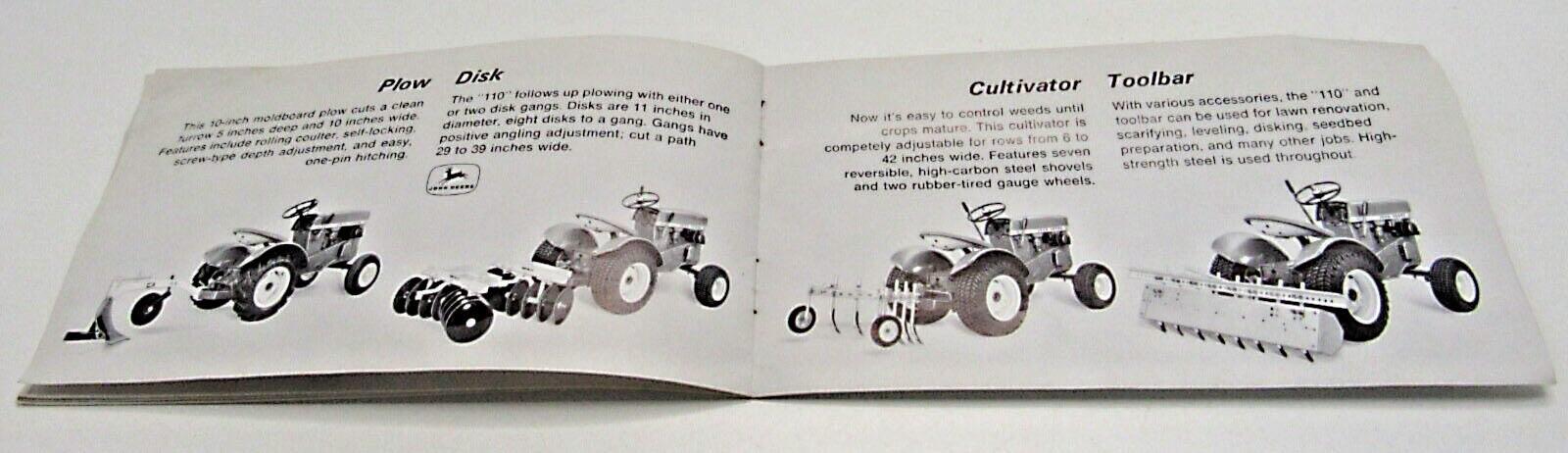

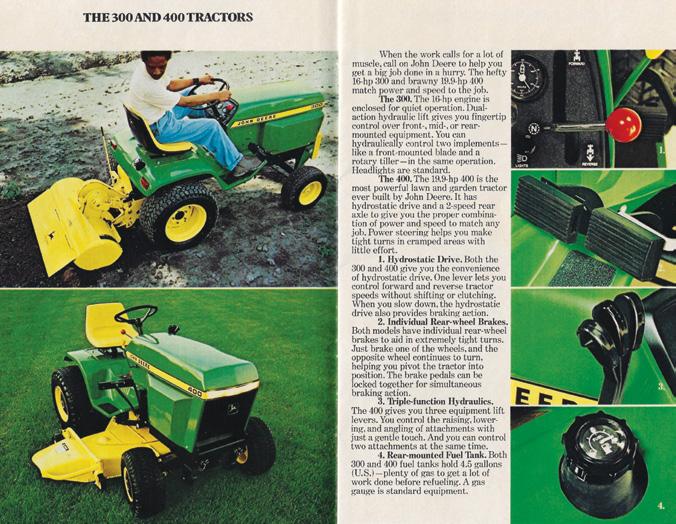

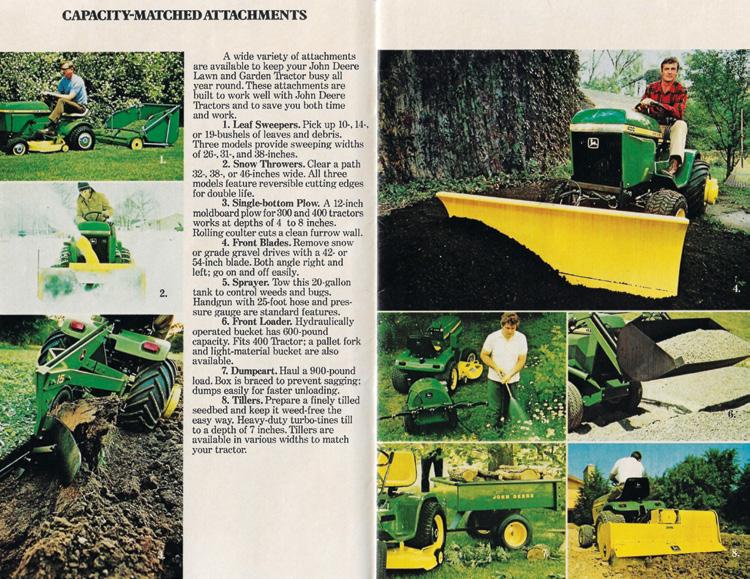

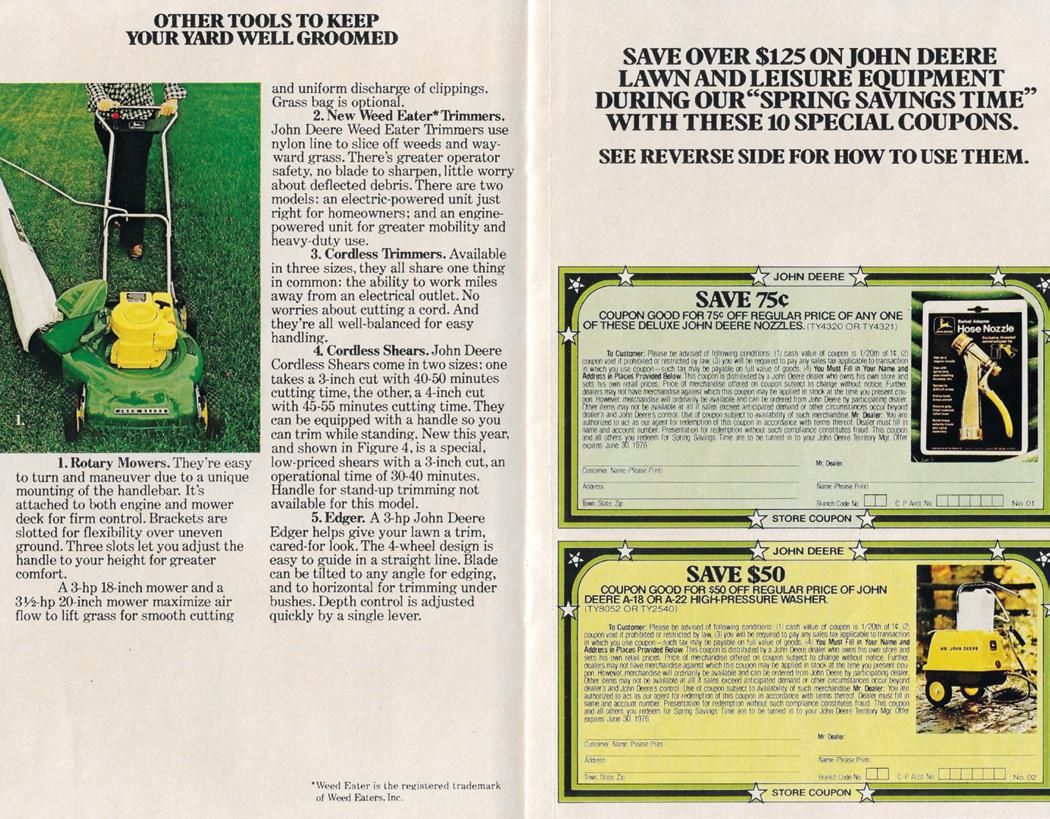

Each March issue of Green Magazine includes an index of major articles from past issues. The March 2024 issue features the newest index. 38 Deere & There 40 What’s new—and old? JD Lawn and Leisure line, Part 1 Greg Stephen 44 Do you have one? 46 The tractor doctor Headaches

1 Ron O’Neill 49 Scale

70 diesel standard Bill Proft 52 Auction highlight Unique 420s Eric W. Mickelson 54 Aussie Ken Sea container arrives in Australia Ken Nicklas 57 Saw it online Box versus button Adam Smith and Benjamin Hain 69 Advertiser index 72 Mr. Thinker ON THE COVER: John Craig of Mentone, Indiana owns this late style 840. Editor Richard Hain

Departments

Richard’s Column

John

and carbs, Part

models

Editor Carol

Hain

Debbie

Green Magazine® PO Box 95 Bee, NE

8:30 AM to 4 PM M-TH Closed Fridays through Labor Day Phone: 402-643-6269 email: info@greenmagazine.com web: www.greenmagazine.com

out

sample articles, catalog, ads and other features! NOTE: VISITS TO OUR OFFICE

APPOINTMENT ONLY!

Rates:

$39.95

year - 12 issues Nebraska residents, add 5.5% sales tax ($42.15) Canada: $59.95

1 year - 12 issues Foreign:

1 year - 12 issues

accepted Page 4 May 2024 • Green Magazine

Behne

68314-0095 Hours:

Check

the

BY

Please call prior to visiting so we can be here to talk with you. At that time we can also give you our location. Thank you!

U.S.:

/ 1

/

$69.95 /

First Class/Airmail delivery available: See page 5 Visa/Mastercard/Discover/AmExpress

As of this writing, I am still working on prepping my “A” for painting, though I am gaining on it. As is likely not a surprise to any of you, the worst part is trying to clean the fossilized dirt and grease from beneath the transmission and rear axle housings. One day, while lying on my back trying to remove some of this gunk, I began dreaming about how much easier it would be if one could flip the tractor over, or even point its nose toward the sky. I could probably do the latter with my 158 loader and 4440, but it seems like there would be a real possibility of damage to either of the tractors, the loader or myself. Possible advantages would be that it would make cleaning easier and Carol would be able to retire and live off my life insurance money.

Speaking of restorations, Dan Brotzman—who we read in the March issue is now semi-retired from writing articles—suggested that we rerun some of his older articles. Not a bad idea since some of you weren’t yet born when he began writing for us, so in this issue

on page 30, you will see an article that he wrote back in 2002 on a problem that has bothered many of us—jumpy clutches on two cylinders.

In other “what was gone is back” news, we stopped publishing Little Green, the Tractor Magazine for Kids last fall, but it is back, but no longer being published by us. So keep the hobby going by buying a subscription for your kids, grandkids or any other random kids to get them interested in old tractors and the history of agriculture. You will find an ad for the new Little Green on page 12. So give them a call.

One last thing, since it will be May by the time most of you read this, remember that from now until Labor Day, we will be observing our summer hours. That just means that we are closed on Fridays. The phone rings a little less during the summer and it gives us more freedom to take off and head for tractor shows.

See you next month.

Those who want to call to place orders for magazine subscriptions or renewals, gift items or ads, please note this schedule. Our website, www.greenmagazine.com, is always open for orders and ads. Email info@greenmagazine.com with questions, if needed.

Missing an issue? We mail every issue by the first of the month. Please contact your post office if you suspect a problem with delivery. We will not replace missed issues three or more months past original mail date (four or more months for foreign subscribers) free of charge.

U.S. subscribers: If it is on or after the 20th of the month and you haven’t received your issue, call us for a replacement.

Canadian subscribers: Due to postage costs, we are forced to ask for a $2 postage fee (U.S. funds, please) for re-sending issues that do not arrive by the end of the published month OR we can add an issue onto your subscription for the missed issue.

First Class/Airmail delivery: Call for rates for First Class in the U.S. or Airmail to foreign countries.

Foreign subscribers: We will add an issue onto your subscription OR for a $7 airmail postage fee (U.S. funds), we will resend the missed issue two months after publication date.

Notice: If your address label shows an expiration date of “5/24” above your name, this is your last issue. Renew immediately for continuous service. If your address label reads “6/24,” you have one more issue on your subscription.

Renewal notice: We send postcards to let you know your subscription is about to expire (or has expired). We NEVER call to ask if you would like to renew your subscription. If you

receive such a call, it is most likely from another publication—NOT Green Magazine® for John Deere enthusiasts.

Address Changes: Please send or call with notification of an address change as soon as you know what your new address will be. Periodical mail cannot be forwarded. Green Magazine will not replace issues missed due to late notice of address change. Those missed issues will have to be bought at back issue price. See the back issue listing and prices elsewhere in this issue.

Looking for your photos and stories! Accepted material is subject to such revision as to meet the requirements of this publication. Payment will be made at our current rate within 90 days of publication. Submission of manuscript implies that the material is original and in no way an infringement upon the rights of others. Please send good, clear photographs. If you would like these returned, send us a stamped return envelope to help us get them back to you.

Free Issue Offer: It seems you, our subscribers, are our best form of advertising! More people find out about this publication by “word of mouth” than other forms of advertising. So if you're enjoying Green Magazine®, why not spread the word? Telling others about it can pay benefits. When you tell a friend about Green Magazine® and they subscribe, make sure they tell us who let them know about it. When they do, you will get an issue added to your subscription. These must be new subscribers, not renewals.

Green Magazine announces its spring/summer hours, in effect now through Labor Day : Monday through Thursday 8:30 AM - 4 PM • Friday: CLOSED

Green Magazine® • May 2024 Page 5

Thank you!

At right is a portion of my John Deere collection, from right: 730 standard came from Saskatchewan, Canada. I purchased it at Polk’s Auction in 1992.

The 730 diesel/pony start is a local tractor. It was a basket case I purchased in 1987.

The 730 LP was purchased in Marianna, Arkansas in 2008.

The next—a 730 diesel, electric start—was also a basket case I purchased locally in 2017.

The 730 gas came from Louisiana, Missouri and I then purchased it from “High Dollar” Harold of Greencastle, Indiana in 2003.

Phil Doughty, IN

I enjoy Mr. Thinker’s column every month in Green Magazine. In the December 2023 issue, you discussed which baler is better—John Deere or New Holland. You are right saying that the flywheel on a John Deere baler is on the same plane as the crankshaft, but there is still a set of bevel gears in the gear box from the PTO shaft that

drives the crankshaft. These bevel gears in a John Deere baler have a tendency to fail. Referring to the New Holland baler, the flywheel is driven by a Hypoid gear, not by bevel gears. They are just like a ring gear and pinion shaft in a tractor differential. They are very durable.

Tom Geisler, NE

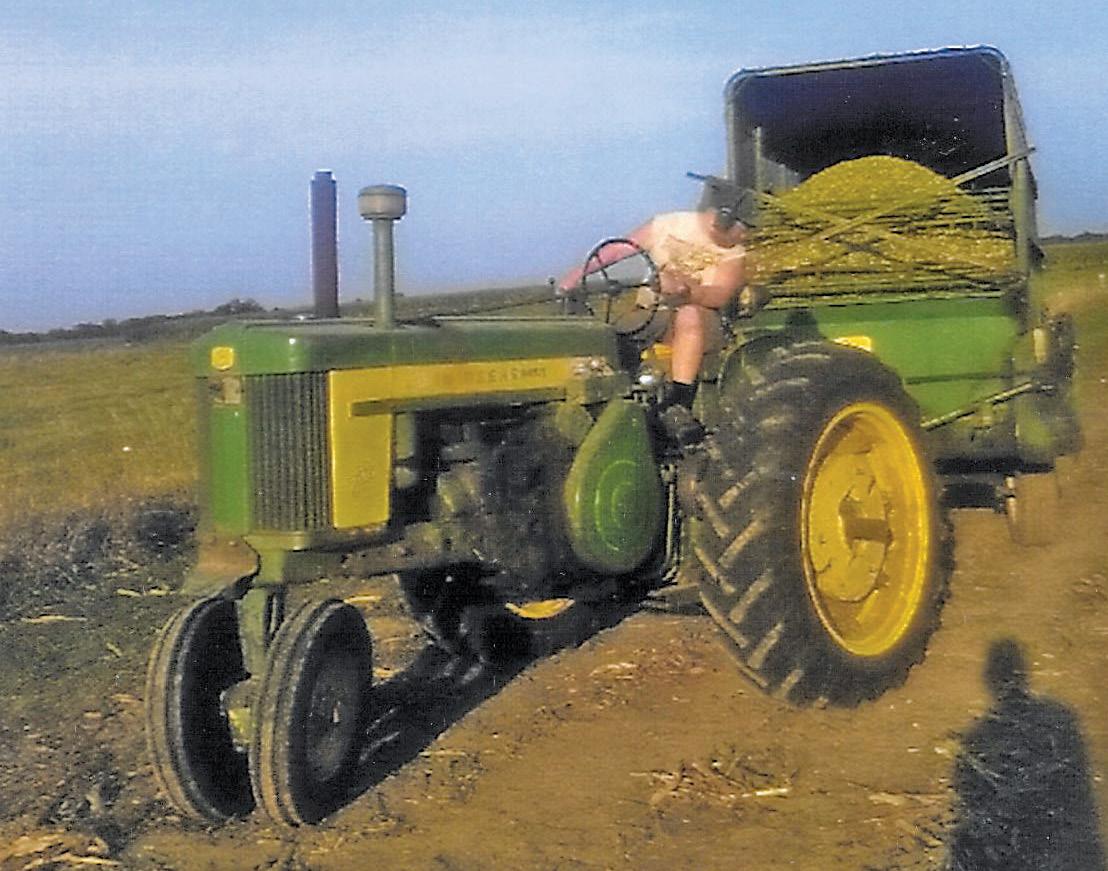

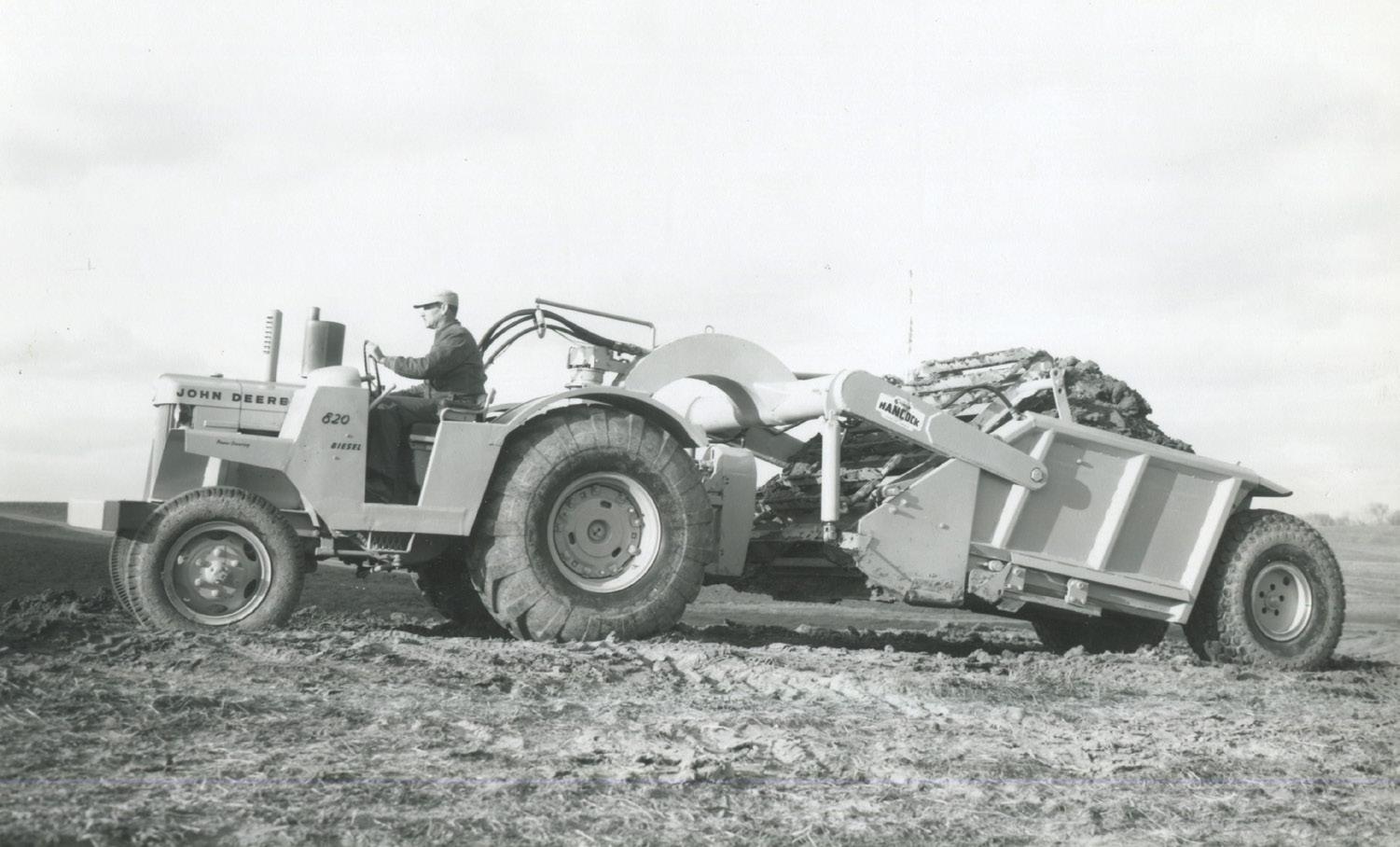

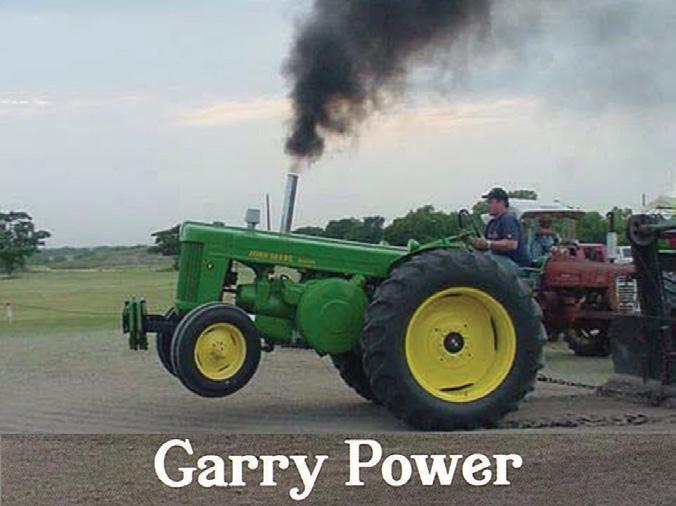

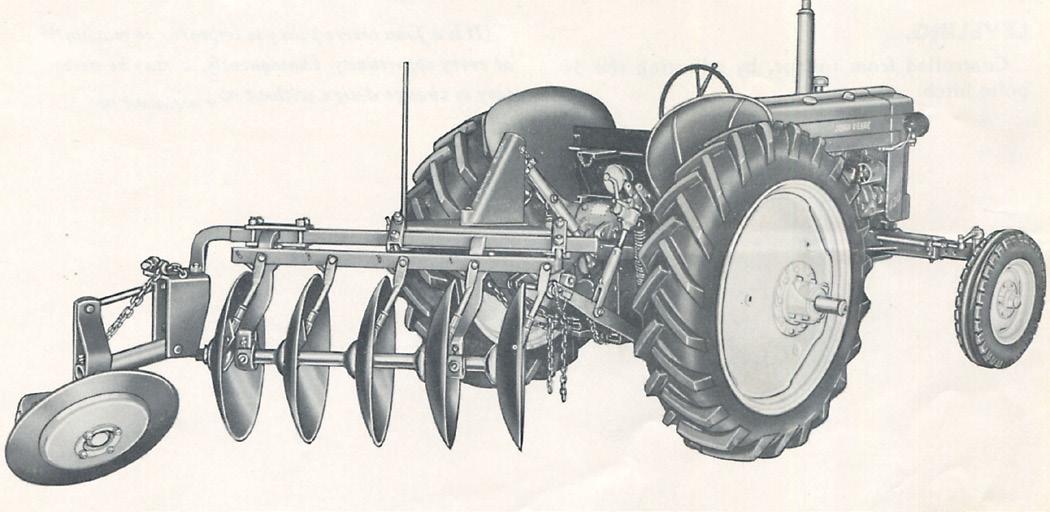

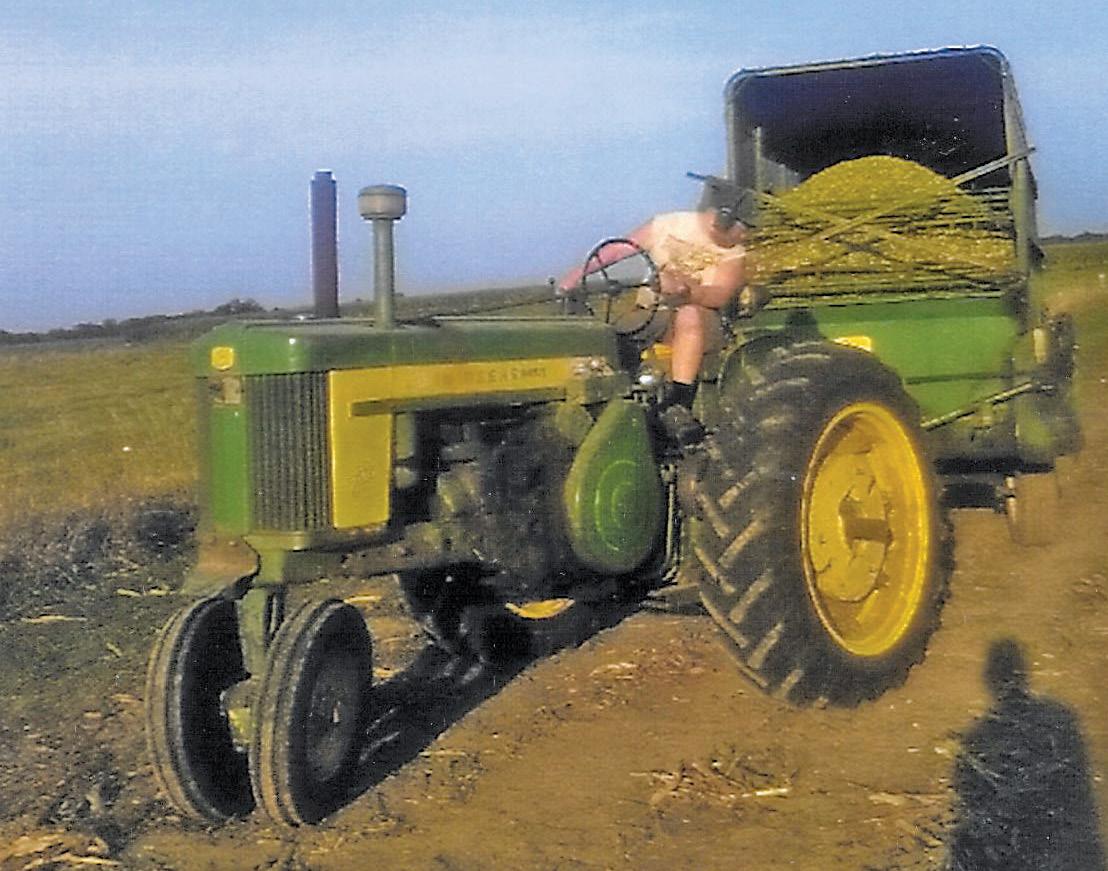

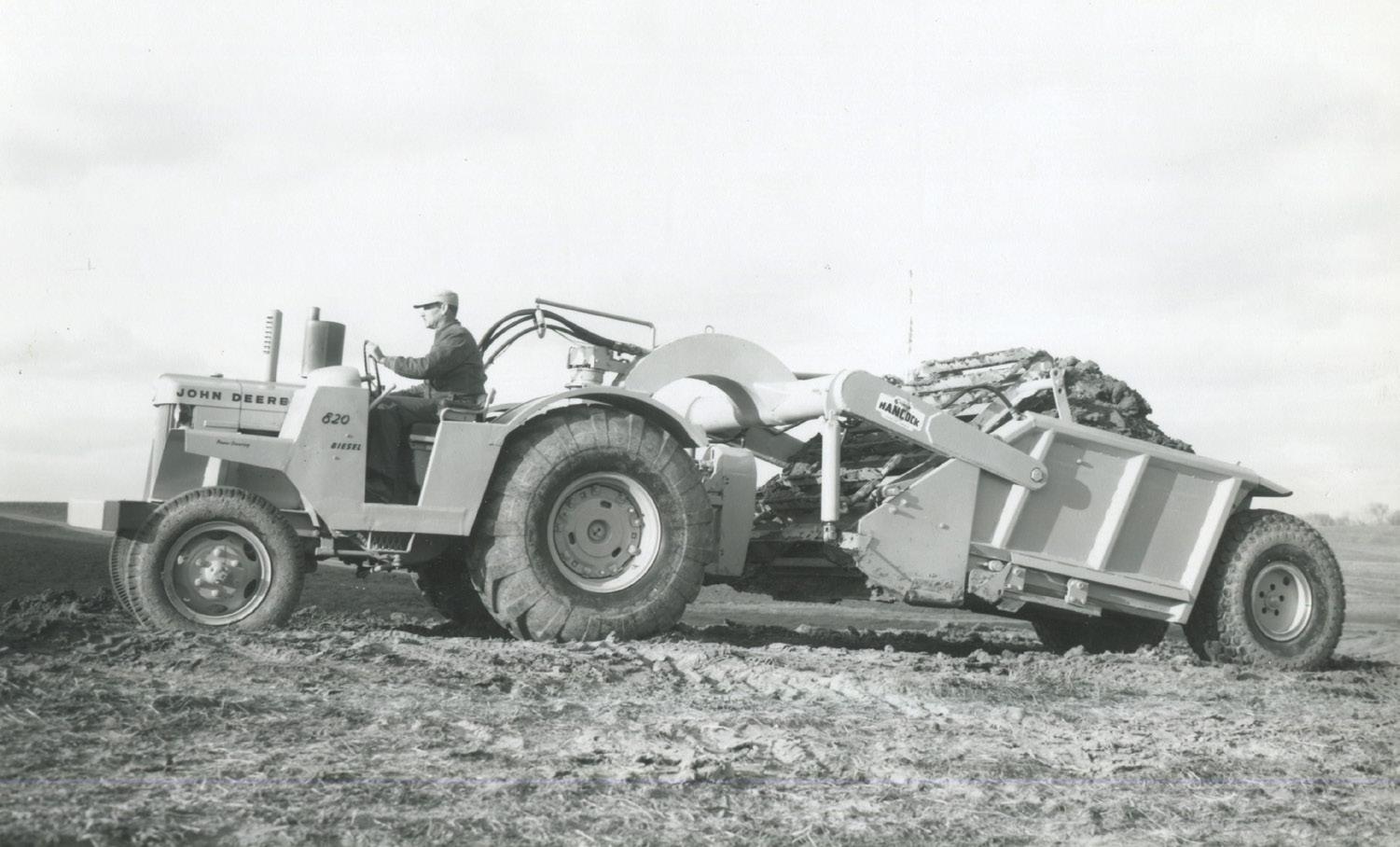

In past issues of Green Magazine, a gentleman wrote a couple of articles about using our old tractors for actual work, which is good for them. My friend, Flash, and I agree and if you have livestock, there are a lot of jobs you can use them for. Here are a couple of pictures of Flash using a couple of his tractors doing what they were built for. Keep up the great work on Green Magazine.

Moose McClure, IL

Page 6 May 2024 • Green Magazine

It is with mixed feelings that we, Travis and Shirley Jorde, write this. We have reached a point in our lives, at 85 years old, that we have decided to pass Jorde’s Decals on to a new owner. We have full confidence that they will continue to provide the same quality product and service that everyone has come to expect.

We would like to thank all of you we have become acquainted with over the past 48-plus years. Your loyalty and encouragement have brought us such joy. Many years of helping with tractors, attending shows, events and sharing information during seminars have brought us limitless new friends and opportunities.

The years have shown us innovative technology, such as cell phones, computers, printers, and shipping options. The growth we have experienced is amazing. We are thankful for all the opportunities that have been made available to us. We have been busy cleaning up our workspace and are finding that some orders have been overlooked, lost, duplicated, or forgotten and we apologize for this. We want you to order again, ask for

what you did not receive and please continue to enjoy your restorations. Please be patient as the transition takes place, procedures are updated, and adjustments are made. Smile and take one day at a time, just like we do. We have great confidence in the new owners, Dan and Jen Peterman, and know they will do an excellent job for all our customers. We have been blessed to spend the better part of a couple of years in discussion with them, and know they are ready to continue this business and help it to grow the way it should. Please continue to show them the support you have bestowed on us for all these years. The business name will not change, only the people who will continue to serve you in the best way possible. We plan to still attend shows and help where needed. We are always ready to sit and visit, share ideas, and make new friends. For the Jordes, it has always been about the people.

Blessings to our friends and family.

Travis and Shirley Jorde

1) Call 402-643-6269 with credit card in hand 2) Go online: www.greenmagazine.com 3) Send a check by mail with the subscriber’s name and address to Green Magazine, PO Box 95, Bee, NE 68314 For more info on subscription rates, see page 4. Questions? Call 402-643-6269 for great customer service! It’s easy! A letter from Travis

Green Magazine® • May 2024 Page 7

and Shirley Jorde

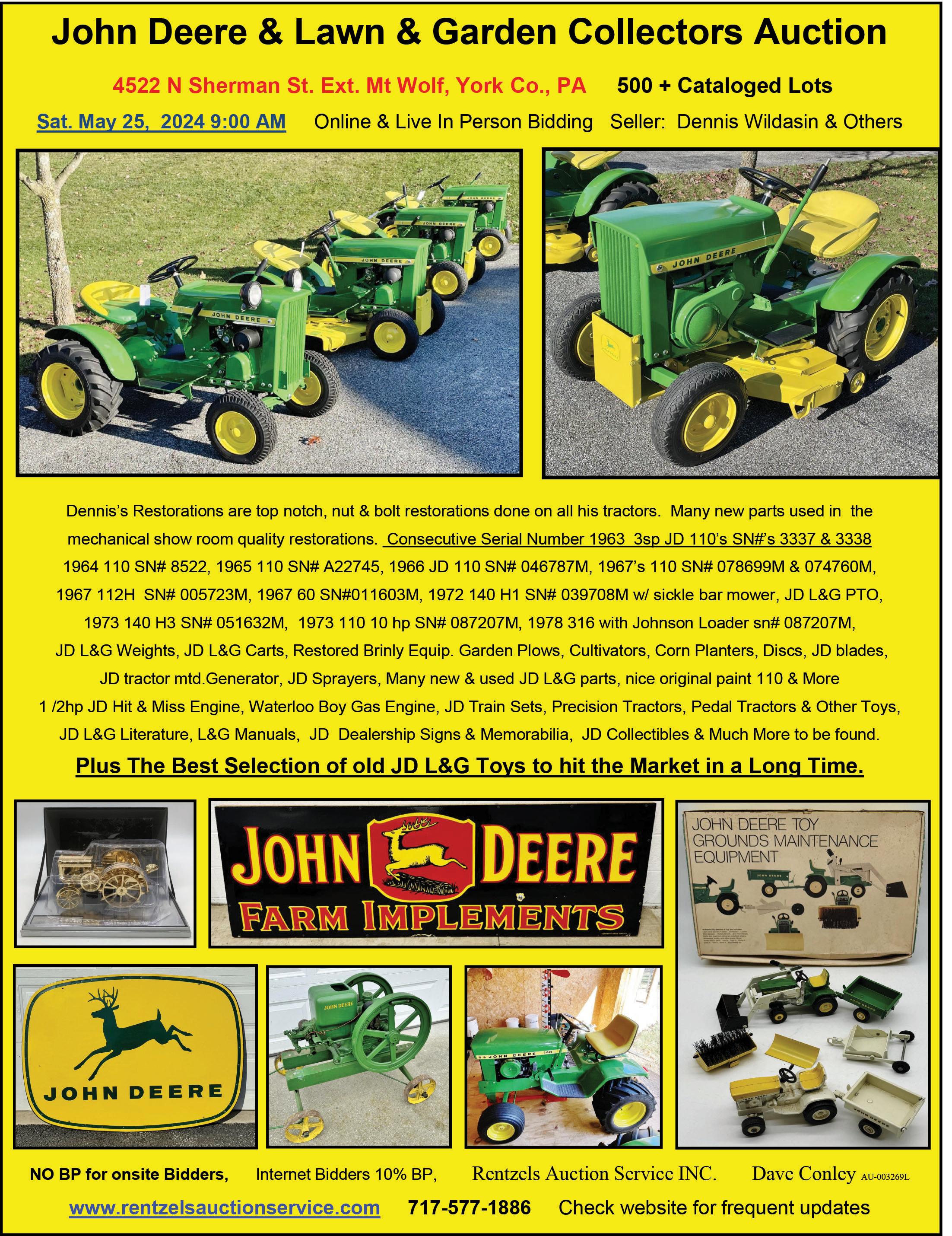

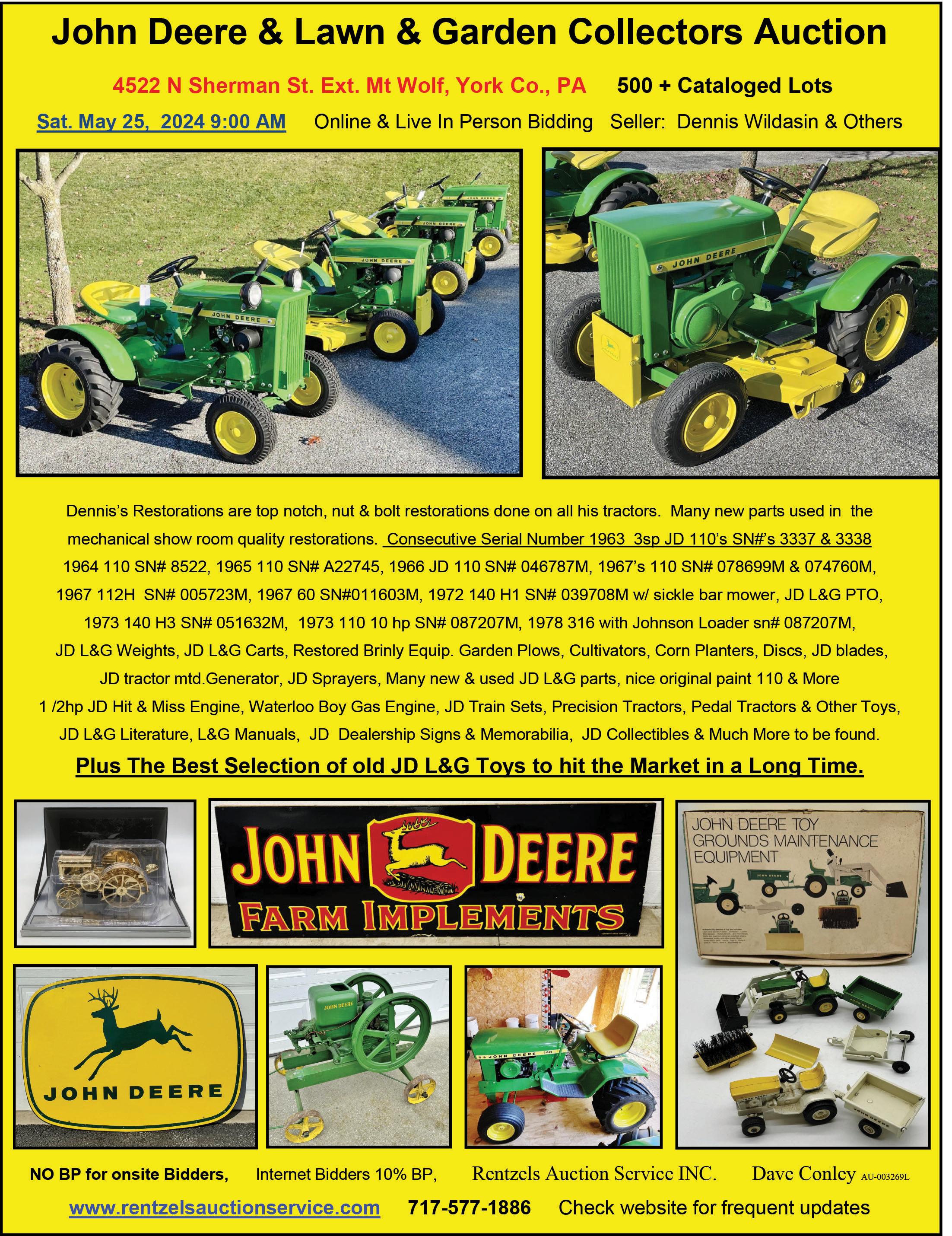

PUBLIC AUCTION

Saturday, May 18 • 10 AM Harrisburg, IL 62946

Location: 25 Veterans Drive at the Wilson Auction Center.

Turn N off Hwy 13 at the NAPA Store onto Veterans Drive and we are on the west side of the street. Signs posted.

• JD 630 gas, SN 6301667, rear hitch

• JD 60 gas, PS, SN 6046336

• JD styled B, SN B284269, new rubber

• JD 50, Roll-O-Matic, SN 500500

• JD model 60, SN 6020160

• JD styled A, SN 577770

• JD MT, SN MT12267, nice

• JD model H, w/Bramlet dealer sticker, SN 59350

• JD model B, SN B14518, w/broke steering unit

• JD model A, SN 451312, round rear spokes

• JD model 1010 w/3-pt. hitch, SN

Auctioneers Note: These are all in running and good condition, and some with new tires and new paint. They are from one person’s collection south of Eddyville, IL. We will move them to our location because the lack of parking on the farm. Terms: Cash, check or credit/debit cards accepted with proper ID; for out of area checks, should bring bank letter of credit. Absentee bids are always accepted.

Photos are on our website at www.wilsonauction.com

8th Annual Antique Tractor and Equipment Show

Show: 8th Annual Antique Tractor and Equipment Show

Reunion of front wheel assist and four wheel drive All makes and models welcome in any condition July 12, 13, 14, 2024 • Cornwell’s Turkeyville USA 18935 15-1/2 Mile Rd., Marshall, MI 49068

300+ tractors and engines on the grounds, tractor pulls, working exhibits, daily parades, plowing demos, children activities, pedal pulls, miniature train rides, onsite restaurant, dinner theater, ice cream parlor, state of the art campground and much more! Presented by the Calhoun County Yesteryear Association www.CalhounCountyYesteryearAssociation.com Email ccyatractors@gmail.com

Wilson

Auction Co. • Dennis Wilson, Auctioneer Harrisburg IL 62946 • IL. Lic. #44000030 Phone 618-252-1185

Page 8 May 2024 • Green Magazine

Call/text 517-795-7824

Green Magazine® • May 2024 Page 9

The 2023 Historic Farm Days was held in Penfield, Illinois on July 13-16, 2023. At this show, hosted by the I&I Antique Tractor & Gas Engine Club, John Deere was featured, along with the 100th anniversary celebration of the introduction of the John Deere “D” tractor and “E” engine. With more than 50 “Ds” at the show and an array of activities to profile the celebration, it was what I would call “D Days in Penfield”!

Ed Winkleman, president of the Friends of Green, a branch of the I&I club, along with other members, had been promoting the show all year long. He said that prior to the show, he received calls from collectors in an array of states about the event.

Among featured events at the show were workshops put on by plow book author, David Wolfe. Growing up on a Wisconsin dairy farm and using two -cylinder tractors stuck with David, who is now a collector and restores his own tractors. A family man with 15 grandchildren, David said most everyone in the family has an interest in tractors.

A frequent presenter at Gathering of the Green and Classic Green Reunion, his first workshop at Penfield on Friday was on John Deere model “D” tractors. “Our hobby is a family-oriented hobby that you can enjoy for a lifetime,” he said, opening the workshop.

John Deere “Ds” were manufactured from 1923 to 1953, but they come in a wide variety of styles developed over the years. The “D” was built to replace Waterloo Boy “N.” David Wolfe pointed out the differences through the production timeline. At first, he said, “The John Deere ‘D’ was used a lot on the threshing machine.”

The “D” was longest produced tractor in Deere’s line and David said what made it revolutionary was the oil bath design that kept parts oiled. While sharing workshops and information is great, David said his favorite thing is plowing with this remarkable tractor, “I love to plow with the John Deere ‘D”—there is just nothing like it.”

On Saturday, David took a group of collectors on a walk-through, pointing out the differences in different John Deere tractors. He said that all tractor collectors should be praised for bringing their tractor to an event and that ways that a tractor has been “farmerized” just makes it more special to the owner.

Each day of the show, at noon, there was a John Deere “D” drive held on the grounds. It was fun to see “Ds” of

all ages parading by.

In the featured building on the Historic Day grounds, several beautiful John Deere pieces were on display, including Mark and Dana Haven’s 1953 Streeter “D.” The tractor is serial number 191655. The Havens are from Rolla, Missouri and Mark said he looked for years and years for the rare Streeter “D” and finally found this one in Knoxville, Tennessee. “This is one of the last 92 ‘Ds’ made and it is the 15th from the end of production. Deere made the ‘Ds’ until March of 1953, then the dealers kept asking for more since they were popular for rice production. Deere came up with enough parts for 92 more. They set up an assembly line in the street,” Mark said about this unusual production method. “Of the 92 made, 32 stayed in the U.S. and the other 60 were exported. The majority, I think, went to South Africa.”

This Streeter “D” was originally shipped from the New Orleans branch in Louisiana to Jonesboro, Arkansas on March 12, 1954. The tractor was sold new at Melton Brothers John Deere to the Johnson family. Then the tractor was sold in the early 2000s and finally ended up with Willis Freeman of Clinton, Tennessee before being sold to the Havens.

Although duals were put on new by the dealer, Mark

Page 10 May 2024 • Green Magazine

The daily tractor drive.

said they had to fabricate new ones since they were in bad shape. They only had to paint the rear wheels, and they credit Dave Nelson of Agri-Crafts with the effort. Besides Mark’s Streeter “D,” he said they have eight to 10 more tractors at home. “We’ll have the 4030 gas narrow front at the Half Century of Progress in the John Deere tent at Rantoul,” he added.

Another very special tractor in the featured tent was Kenny Read’s 1928 Spoker “D,” serial number 30404. “This could be the oldest John Deere ‘D’ tractor,” Kenny said. “The tractor was built June 3, 1923 and was fourth in the production line. There were 50 of these built, and 17, I believe, that still exist.”

“The tractor was shipped new to Minot, North Dakota, and spent its life there. He shared a few things that make this tractor unique. “The first 50 model ‘D’ tractors have skinny ‘John Deere’ letters on the radiator top, a ‘fabricated’ front axle, four holes in the steering wheel ‘spokes’ and a ‘ladder’ radiator (having four holes cast in the radiator sides).

A gentleman known as “Rumley Bill” owned the tractor along with four or five others and collected, you guessed it, Rumleys. “He sold these at Aumann Auctions along

with a ‘GP’ crawler, and this tractor came from that sale; it was bought by Ted Spoelstra, and I bought it from him.”

Since he bought it six or seven years ago, he also added a gear reduction that he found in California.

During the show, they brought out a birthday cake to celebrate Kenny’s 100-year-old tractor. Kenny did the honor of blowing out the candles, and collectors stopped by and enjoyed the celebration!

One other collector who had a rare 1930 John Deere “D” in the feature tent was Kevin McMath, who hails from Clinton, Illinois. “I bought it from Mecum Auctions. It came from California—that is about all I know about it,” Kevin said.

Attached to his 1930 “D” was a cool John Deere subsoiler with an unusual mole that he said would dig a trench. Kevin had four “Ds” at the show. “I didn’t want to be the one with the least number of ‘Ds’,” he joked.

Besides the 1930 “D,” he also had two 1936 “Ds,” one with a No. 15 JD subsoiler attached. “The reason I started with these is Dad had a “D” in the early ’70s. We had it running, but I learned it would be cheaper to buy new than try to fix it.”

The last of his four “Ds” was a 1937 “D” in its clothes that Kevin said, “I play with. I forgot to bring a plow, but my buddy said there’s a plow for sale…”

He will have to explain that to his wife, Barbara. Kevin had also brought an “E” engine for the anniversary celebration as well.

Historic Days was a great show with a “D” celebration for the history books!

Kevin McMath with his JD “D.”

Kenny Read with his 100 year old tractor.

Kenny Read with his 100 year old tractor.

Green Magazine® • May 2024 Page 11

The Havens with their “Streeter D.”

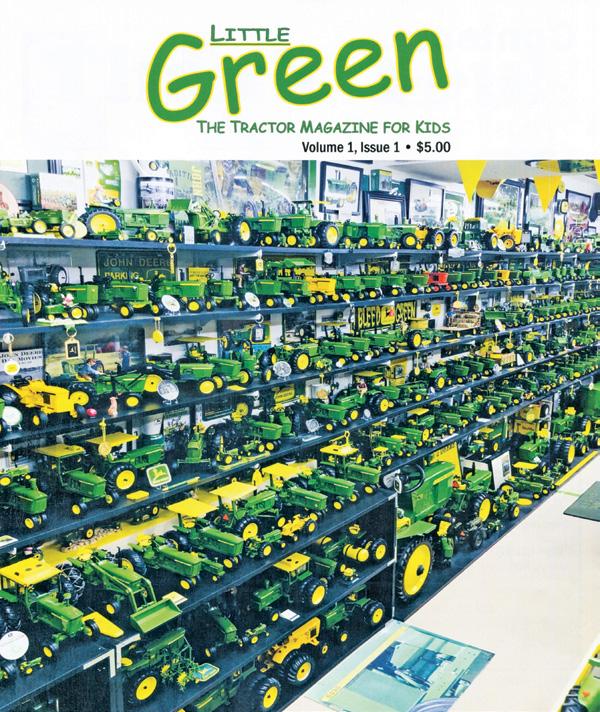

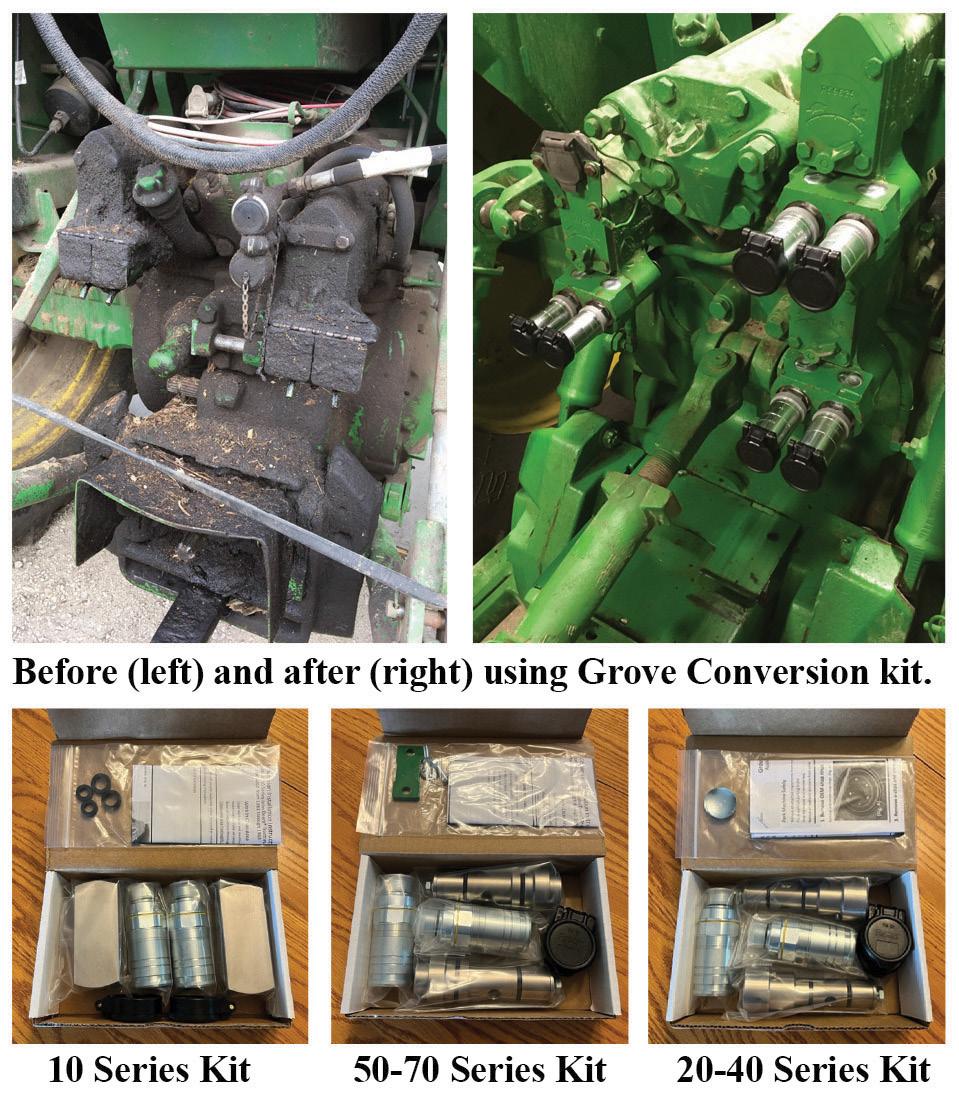

Kit Cleans Up Older Deere Hydraulic Mess

Scott Grove cleaned up leaky hydraulic valves on his older Deere tractors with a simple insert. The long-standing problem is one the company has yet to fix. Grove says it forces him and other owners of Deere tractors to replace O-rings on a regular basis, only to have the mess return. Grove’s fix eliminated the mess and the need to replace parts. With the Grove Conversion kit:

• Convert to ISO with easy push-pull connection

• Couplers connect under residual pressure with breakaway feature

• Kits available for 10 through 70 series JD tractors manufactured from 1961 through 1996

• Inserts are made in the USA. This product is protected under US Patent 10,760,725 B2 and other patents pending.

Installation consists of stripping the OEM outlets down to the block, removing the barrels and O-rings, and replacing them with the inserts. Grove then adds the aftermarket ISO coupler that threads into the insert. Installation instructions can be found on the Wapsi website.

Kits for 10 series are priced at $315, kits for 20-40 series are priced at $329, and kits for 50-70 series are priced at $355. Also watch the website for more additions coming soon. Grove suggests checking with local Deere dealers & local repair shops or Wapsi Innovations directly. DON’T

BE FOOLED BY THE “COPYCAT” version! Purchase “THE ORIGINAL” GROVE CONVERSION. We 100% guarantee our product from leaking or your money back! PH: 641-229-7413 • Wapsiinnovations.com Questions? Call or email It’s back! Little Green The Tractor Magazine for Kids US $24.00

6 issues per year Canada $32.00

funds) Foreign $36.00

funds) Plus 7% Indiana state sales tax Send payment with the subscriber’s name

address to: Mail: 1041

Rd, Williamsport

/

(US

(US

and

S Williamsport

IN 47993 Call: 765-585-9555

Subscribe today! Page 12 May 2024 • Green Magazine

Email: littlegreenmag@gmail.com Website: www.littlegreenmag.com

Today, when I reflect on the year 2020, it seems that I might be confusing reality with the memory of watching a late night episode of The Twilight Zone. I have read that it is quite normal for the human brain to block out or slow recall of bad or traumatic memories. With normal life going out the window for some time with fear of passing or catching the COVID-19 virus, memories of those times in my brain were put on the shelf and forgotten. However, from time to time, my mind wanders back into the “twilight zone.”

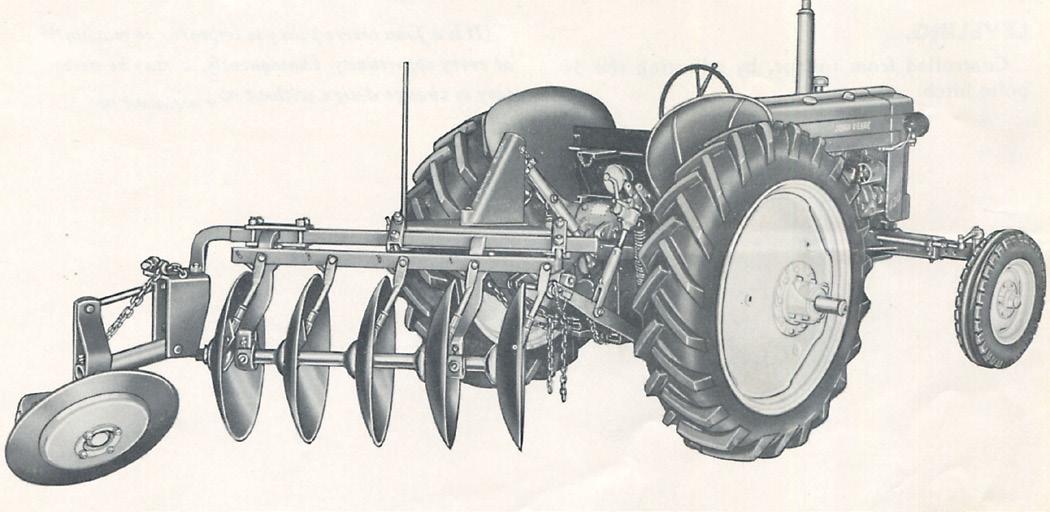

This month, I recall a fellow (Clyde) from Alaska in the year 2020, who reached out to me to ask my opinion on a plow listed for sale in Iowa. The plow in question was not just any old plow, it was a John Deere 825 two-way rollover plow. He found a for sale listing in the GM classified ads and was looking for information about a few missing coulter parts along with my opinion on the overall condition. We conversed back and forth a few times and, after identifying that the plow was missing several critical parts and that seller was not wanting to deal with the logistics of transport from the midwest to Alaska, he asked me if I knew of such a plow for sale.

Clyde was in luck as I had an 825 3-16 plow that I would sell. He was looking for one to buy and bring up to his farm near Fairbanks to use on his farm where he grows vegetables. He has a John Deere 720 gasoline standard tread tractor and noted that finding good used equipment in his part of the world is particularly difficult. The

tractor was sold new in Fairbanks and spent its life working ground around the area. He wanted to pair a two-way plow with his tractor to help with deep tillage between growing oats and cabbage.

The plow was in good condition but was missing coulters. It was also missing one of the rear bottom coulter

The 825 plow when Clyde first became interested. Notice it has no coulters.

Below: Zach snapped this photo of me right after the hydraulics quit on the 720 while demonstrating the function.

brackets (specific to the 825 plow). Knowing Clyde was planning to use the plow for production agriculture, I agreed to equip the plow with all six coulters so it would be ready to get to work for him. The hydraulic vanetype cylinder was functional and did not have any leaks and the wear parts were in good shape.

As Clyde and I struck a deal on the plow in late 2020, COVID-19 restrictions were still in play. He anticipated that the travel restrictions in Canada to ease, allowing him to drive through on the way to Illinois. His plan was to drive down into the lower 48 U.S., visit his brother in Indiana, and get the plow at my place in Illinois in his one-ton pickup truck; you might consider it a working vacation. As the then new presidential administration changed in early 2021, which canceled the XL oil pipeline project from Canada to the USA. Some have drawn the conclusion that travel restrictions got even more strict as a retaliatory move; motorists were only allowed to get out of their vehicle in Canada to fuel. Technically, bathroom breaks were not even allowed as it was non-approved so leaving the vehicle which could mean jail time! For reference, travel time by car from Fairbanks to Seattle is approximately 39 hours. Did I mention that a vaccine passport was required for travel to document a double COVID-19 vaccination?

Seeing how it was going to be difficult for Clyde to make it down to Illinois with all the travel restrictions, I agreed to store the 825 plow inside my shed until he could make arrange-

Page 14 May 2024 • Green Magazine

With the cylinder removed, we decided to go further and take off the front coulter brackets to make it more compact.

Below: The goal was to reduce the plow in size with the minimum amount of parts, making it easier to assemble later on.

ments to get it. Time passed and I sold my place in Illinois and moved the 825 to our farm in Missouri, where it again was stored inside under roof with a bunch of my other plows in an old shed.

Fast forward to late summer 2023 and Clyde began making plans to get his plow. Driving all the way from Alaska was not an option due to the time it was going to take (7,900 miles round trip) so Clyde explored shipping options. He found a company called Span Alaska, which would handle LTL transport from my farm in Missouri to the west coast and by ship from there to Alaska. To make this work, we would need to put the plow into a crate (to make it affordable). I measured the plow and estimated the size in which we might have to work. Clyde wanted to see about me hauling the plow to his brother’s place in Indiana, where they could disassemble and crate, but after realizing that Karl had no real workshop or front end loader to work

with, I offered to crate the plow myself at my farm in Missouri and just ship it from there. Clyde wanted a reason to visit his brother in Terre Haute, Indiana and he made plans to fly out to Indianapolis, where his brother, Karl, would pick him up and they would head west to Missouri. I had the equipment and tools necessary to get the job done and they would provide help and of course make decisions about how we would accomplish the task.

Clyde and Karl planned to travel out near my location, staying over in a hotel. They arrived early on a Saturday morning, ready to help deconstruct the plow and get it in a crate. I had some extra heavy duty pallet material that we could use to make the base as well as spare building material from my house and shed projects. I hooked up the 825 to my 720 diesel row crop tractor before they arrived as I planned to demonstrate the hydraulic cylinder action. I had rebuilt the rotary vane cylinder for Clyde some weeks earlier as it had begun weeping around the shaft during the three years in storage and wanted him to see that it functioned.

After looking the plow over, I started the 720 and began rolling it over only to find that it would turn just one-quarter of the way around. Upon closer inspection, I realized that the cylinder was timed 180 degrees out from where it was supposed to be. After a few minutes and some tinkering to remove the attaching pin, rotating the cylinder 180 degrees and reinserting the pin, we had it rolling

We tried to save all the bolts but a few of them required the liquid persuasion of the acetylene torch.

over correctly. I turned it one last time and before completing the rotation of the plow, the tractor hydraulics simply stopped. The engine did not labor nor did I hear any unusual noises—just nothing. The hitch would not lift nor would the remove valve function. Well, I was flustered to put it mildly, but the 720 hydraulics would have to be dealt with after the plow was made to fit inside of the yet to be constructed crate.

With help from my 4020 tractor with its 148 front loader, we lifted the plow up and disconnected it from the 720’s three-point hitch. With the plow sitting on the concrete pad outside of my shop, we sized up just how to make it fit in a crate. The goal was to make it work inside of a four foot wide by five foot long by four foot tall totally enclosed crate. I estimated the total weight of the plow with the crate at 2,000 pounds as the fully loaded 825 plow with coulters rates in the sales manual at approximately 1,750 pounds.

The 825 measured nearly nine feet long and a little over 40 inches wide by itself. I estimated that it would take four to five hours to partially disassemble and crate the plow. According to the 825 operator manual, these plows were shipped with the frames assembled but without the hydraulic cylinders, wheels, coulters, and plow bottoms. I guessed it to be easier to just leave the main frame assembled

Karl checking out the two bottom plow (after removing the third bottom and frame).

Green Magazine® • May 2024 Page 15

and remove the standards from the side plates, but it would require a tryand-see approach.

We decided to remove the cylinder from the plow (we marked the correct position of the cylinder so he would know how to time it upon assembly in Alaska) as it would make the plow more compact. We also removed the front coulters and coulter brackets so that the front of the plow was flush with the hitch assembly (which remained in place for the journey). To shorten the plow, we removed the rear wheels and axles. We needed to make another couple feet more compact so we decided to remove the third plow bottom standards and frame from the main part of the plow. We also removed the plow bottoms from the standards such that we could nest the third frame/standards into the first

Zachary helped us with the process by being our forklift operator.

Below: Notice the third bottom frame/ standard assembly nested into the main two bottoms. This way, the plow would sit flatly on the crate supported by both first and second plow bottoms so it would be less likely to tip or fall over in the crate.

and second frame standards. This way everything would fit together, not only to be more compact but also to intertwine everything so that it would likely survive any rough handling which could be expected on the long journey.

I handled the planning and execution of the mechanical disassembly with help from Karl and Clyde and they handled the crate building. It turns out that Karl and Clyde learned a great deal about carpentry early on in their upbringing on a dairy farm in Wisconsin and have kept their skills sharp as the years passed. While I had estimated only four to five hours, it took a little longer before we had the plow crated up and ready for the trip overland and oversea. With plow crated and ready for the LTL company to come and pick it up, Clyde and Karl departed for Indiana.

A few days later, the freight company arrived and I loaded up the plow crate onto the back of the semi trailer to begin the first leg of the journey. Clyde kept me up to speed on the progress of the plow as it took

With everything tucked into the four foot by five foot footprint of the pallet, Clyde and Karl built a framework to fasten the sheeting.

Below: Clyde and Karl putting the last side sheet on the crate.

less than a week before it was out at the docks near Seattle. In less than two weeks after arriving in Seattle, the plow had arrived in Alaska and Clyde was headed home with it, he informed me. His plan is to assemble it when the weather is warmer (by the time you read this he should be up and plow ready).

The hydraulic problem on my 720 diesel row crop tractor is still a work in progress to which I will cover in a future article. I will mention that the rollover plow had nothing to do with causing the hydraulic failure but again wait a little while and read all about it right here in GM. By the way, Zachary and I are still working to wrap up the 1941 “H” repair project and keep you up to date as soon possible.

Contact Tyler Buchheit by email at tyler@mrbtractors.com. His website is www.mrbtractors.com

The last view of the plow before sealing it shut with the top.

Below: It only took 19 days for the 825 plow to make it to Alaska just as the first snow of the season was falling! It is likely one of the only JD 825 plows in that part of the world.

Page 16 May 2024 • Green Magazine

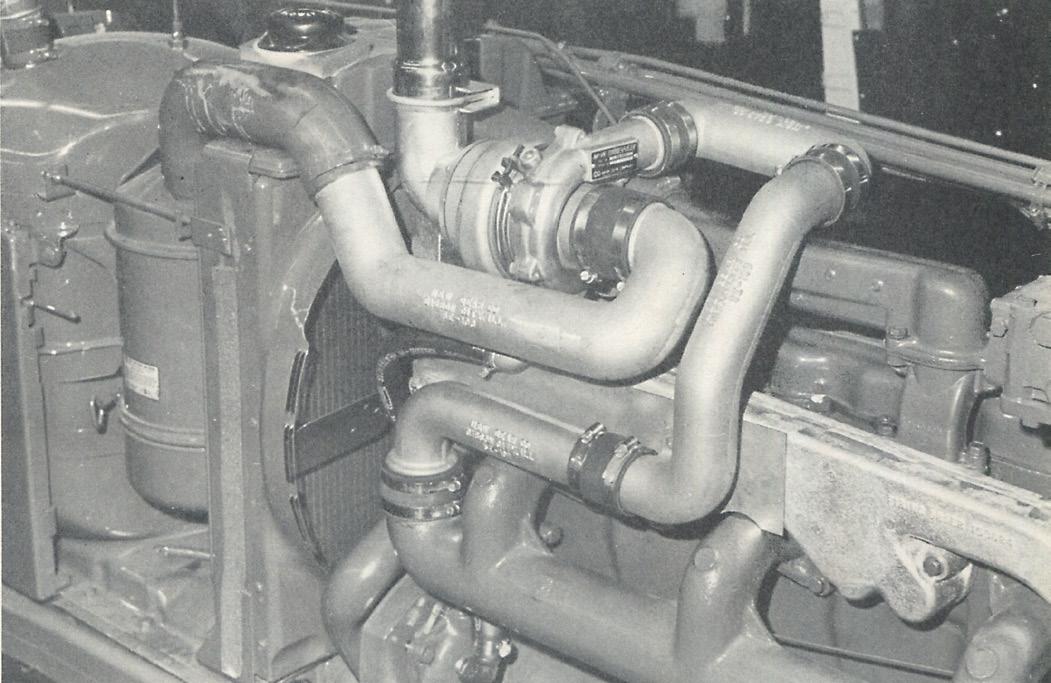

Deere and Company did not always spend many resources on industrial equipment. In their early days, they primarily left those clients to the firms that specialized in such things. Deere built a few specially modified tractors for industrial clients, but those orders were rare. When the economy tightened up, as during the Great Depression and World War II, Deere focused on their primary business and let the industrial sector wane or shut it down entirely. When World War II ended and the economy roared back to life, Deere began considering entering the industrial market again. Further encouraging the move was the slow dissolution of a deal between Deere and Caterpillar, which had previously kept Deere mostly out of industrial machines to avoid stepping on the other company’s toes.

Now, though, with the success of a couple of Deere’s “M” series tractors in industry, Deere began to look at the market once again.

Now, Deere looked at adapting their larger tractors for industrial custom-

ers. The model “R” was a beast in the field, as large and stout as any other on the market. Deere had its engineers explore what options and upgrades could be put into the tractor to make it fit for industrial use. In the end, Deere lost interest in that project. The main thing holding the

“R” back was its weak PTO gears. However, the heavy load transmission option for the “R” was born from these experiments, and lessons were learned along the way.

The successor to the “R,” the model 80, fixed a few of the previous tractor’s weak points and added a

John Craig stands next to his early style 840.

Page 18 May 2024 • Green Magazine

few updates to the machine, including custom Powr-Trol. The 80 was now an even more worthy tractor than the “R” for industrial service, and Deere revisited the idea, but model 80s that left Waterloo in industrial yellow still did so with the same hardware that the agricultural tractors had.

At about this same time, J.E. Hancock’s company in Lubbock, Texas was looking for a machine to power PTO-powered elevating scrapers. Hancock had been making land-moving machinery for some time but hoped that building a scraper that could be handled by heavy farm tractors would help to increase his sales since his selfpropelled units were costly singlepurpose machines.

Also during this time, a drought hit the Great Plains. With the prospect of crops failing, farmers looked at irrigation as a possible savior. However, irrigation could only be accomplished on very flat land, and little land is naturally flat enough to make it work. Center pivot irrigation was in its infancy, but those systems also required land with suitable contour. Farmers wanted to have earth moved to put their fields into shape for irrigation. Land-moving machinery suddenly came into higher demand, paving the way for a lucrative partnership between Deere and Hancock.

So, with the release of the model 80, Hancock searched for a heavy-duty tractor, and there was a greater demand for land-moving equipment. It was almost inevitable that Deere and Hancock would team up to build a great scraper. Exactly how the partnership began is unclear, but a model 80 with a Hancock scraper worked great. The tractor was one of the most fuel efficient on the market and had one of the best hydraulic systems available. Power steering made the work a lot less fatiguing for the operator. Rubber tires on both the tractor and the scraper made it so that the machine could be driven over the roads between jobs and made the ride more comfortable and agile at the work site.

Deere made the cooperative effort official in 1956. They approved five and eight yard model “N” scrapers, built by Hancock, for use with model 80 and 820 tractors. Deere formed their Industrial Division early the following year, and J.E. Hancock was offered an ownership share in a John Deere dealership.

The model “N” scraper was of the elevating type. Elevating scrapers required significantly less horsepower than fixed scrapers because the elevator did most of the work of cutting into the soil and loading the box. They also unloaded more easily because the elevator typically

broke up the soil as it was loaded. While they were more expensive to build and buy and required a PTO to run, the savings came in needing a smaller tractor and fewer passes required to level an area.

These first scrapers were on four wheels, with the front two on a dolly to attach to the tractor. The tractor’s PTO powered the elevator, and hydraulics raised and lowered the scraper. The combination worked well, was cost-effective, and got a lot of work done, but it suffered from one significant drawback. The tractor tended to lose traction as it pulled the scraper along, a problem that worsened as the machine filled with dirt. The dolly hitch put no weight on the tractor and did not provide any ballast; it was just dead weight. The chief engineer at Hancock, R.L. Rhinehart, believed that connecting the scraper to the tractor in a gooseneck configuration would make a big difference in its ability to create traction and move the pair through the soil.

The engineers at Hancock began to experiment with Rhinehart’s idea. They started with a model 820 tractor that they modified to accept a scraper with a gooseneck hitch. The front axle of the tractor was removed. Instead, the weight of the scraper at the back balanced the tractor, holding the front end off of the ground. The scraper body

Green Magazine® • May 2024 Page 19

Close up of the operator’s station on an early style tractor. Late style 840 operator station.

also had just one axle, turning the unit into a sort of articulated unit. This unit was much shorter than the eight-wheeled machines and was, accordingly, more maneuverable. The weight of the scraper was transferred to the scraper by design, and traction was improved as expected. However, the machine was hard to control when loaded and was unstable under many circumstances.

Hancock’s engineers concluded that the tractor’s instability had much to do with the location of the scraper’s connection point. It was too far rearward. Ideally, the gooseneck connection would be directly over the tractor’s rear axle. This should improve the tractor’s stability and traction and reduce the stress of the connection and weight on the frame. The problem was that this location was where the operator’s station was. Several significant modifications would have to be made to make the ideal scraper, but it was believed to be worth the effort.

Though it is probably an 840 underneath, this early tractor is wearing 820 sheet metal and pulling a Hancock scraper.

In 1958, Deere added several options and improvements to the 820. They increased the engine’s power and added heft to make it more durable. New options included a foot-operated throttle, heavy-duty drawbar supports, and an auxiliary hydraulic reservoir. Each option was a significant benefit when the tractor was used with a Hancock scraper and was developed

specifically with that equipment in mind. The foot throttle, for instance, made it so that the operator could steer, run the hydraulics, and change speeds simultaneously—a common need in earth moving. There was no official industrial version of the 820, but adding these options outfitted the tractor into something very close to one, and since Deere was also willing to paint the tractor in industrial yellow, it was tantamount to an actual 820 industrial existing.

With Deere creating modifications that helped their tractors work better with Hancock, and Hancock committed themselves to Deere’s big tractors, the relationship between the two companies grew stronger. The two began working together

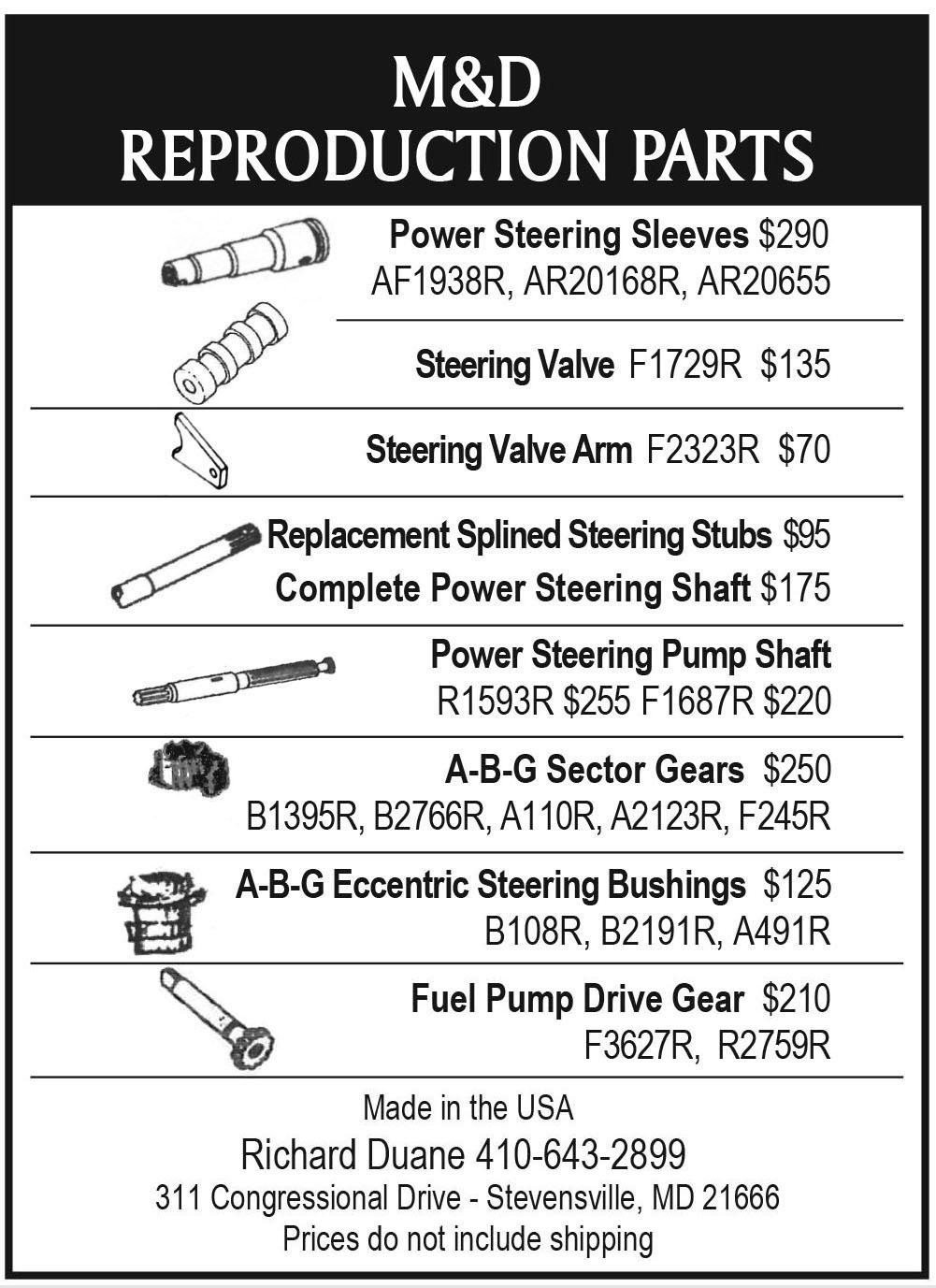

840 Production Numbers and Serial Number Breaks

Even though the serial number register shows that the last 840 was number 8400844, it is known that tractors as high as 8401154 exist. This makes it difficult to get a handle on the actual number produced, but it was most likely less than 1,200.

more closely. Deere handed an experimental 820 tractor to Hancock. Hancock pulled the tractor apart and found a way to move the operator’s station forward and to the left, between the front and rear wheels and left of the engine. There was now room at the back of the tractor for the gooseneck hitch, and visibility from the operator’s station was very good to the front and rear.

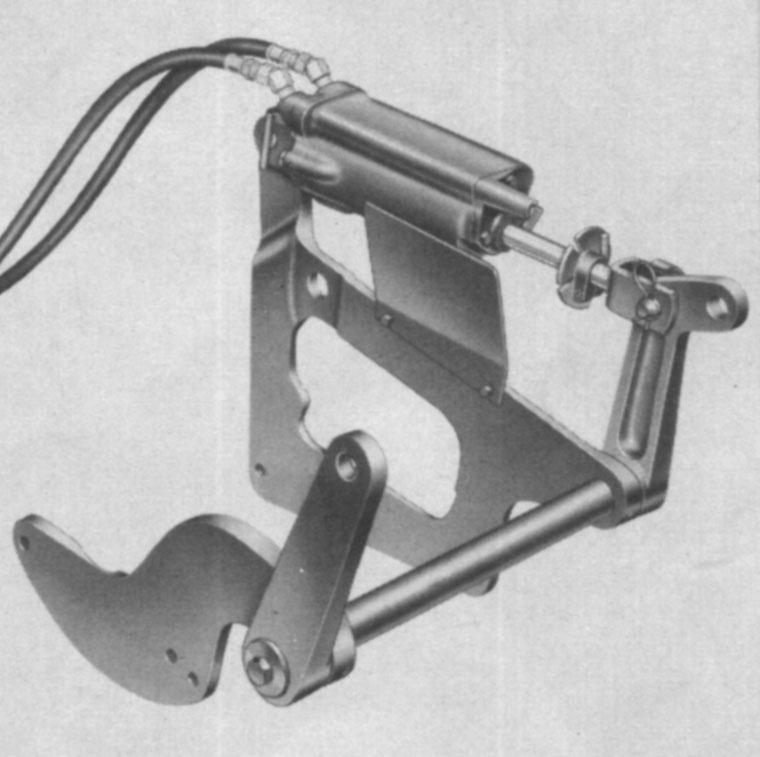

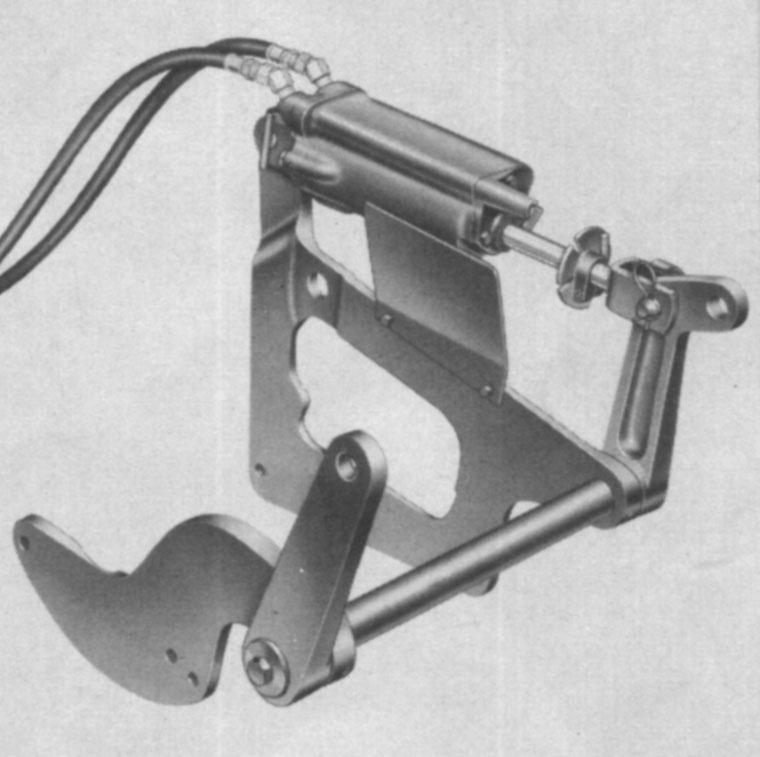

The new hitch tilted and rotated and put the weight of the scraper directly on the tractor’s rear axle. The hitch location also made it necessary to change how the PTO connected to the scraper. A set of belts and pulleys sent power up and behind the hitch. From there, a short shaft brought power into a gearbox, which tuned upward and then backward, sending power to the scraper via a driveshaft alongside the hitch. The hydraulics of the scraper were plumbed down the neck of the machine and connected to the tractor at outlets where the floor of the operator’s station used to be.

This concept machine was working well—a noticeable improvement over earlier machines. Deere was now completely behind Hancock’s work, providing the company with eight more model

Year Beginning/Ending SE EL Total 1959 8400000-8400505 137 538 675 1960 8400506-8400844 83 225 308 1961 8400845-? Total 220 763 983

Page 20 May 2024 • Green Magazine

820 tractors with a few parts left off of them. One more tractor was sent to Hancock, where they converted it to their side-saddle style and returned it to Deere. Deere did some of their own tests on the tractor. Various front axles were examined, and a few other modifications were considered. Heavy truck-type front wheels were installed on nearly all of these machines.

As far as the other eight experimental tractors go, Hancock kept two in Texas and the other six were sent to Montana and Minnesota. The tractors were tested, worked with, inspected, and tested again there. Those who worked with the tractors discovered them to be economical and effective in the field. Furthermore, the new scraper, the model “E,” was far more effective in the field than the older “N.” Both companies were happy with the setup and excited about the new union of the two companies. Deere accepted the new scraper into the lineup and added it to their lineup for the 1959 model year.

Deere decided to call the new scraper tractor model 840. The number was chosen because it matched Dubuque’s new 440 industrial

tractor. Deere and Hancock worked together on the new tractor. By this point, Deere had released the 830 tractor to replace the 820, so the tractors sent to Hancock in Texas were 830s. Basic 830 tractors were a heavy-duty front axle, machined front end support, heavy-duty rear axles and wheels, a power steering unit with steering parts, the hood, starting controls, and some other parts were sent to Lubbock, Texas. There, Hancock added fenders, the operator’s station, various linkages, and several pieces of sheet metal. Hancock then attached the tractor to a Hancock 7E2 elevating scraper and sent them out into the world to customers and dealerships.

Only 63 model 840 tractors were built before Deere had to stop production. The company was receiving so many complaints about the fit and finish of the machines— particularly the Hancock fenders and sheet metal—that they had to take a break. These parts did not fit the machines well or had to be modified to be used. It isn’t known how the conversation between companies went, but Deere seemed to believe that Hancock was not going to improve the work that

they were doing, so Deere brought all of the production back home. Deere was also displeased with the costs of sharing production with the Texas company. Shipping the tractors to Hancock and then on to their destination was expensive, especially since only one tractor/scraper combination could fit on a truck trailer. Having the scrapers sent to Deere, where the machines could be built and then sent out, would save money. It appears that those at Hancock were fine with this change. They were in the business of building scrapers, not tractors, so having Deere’s tractors stop arriving at the shop was not upsetting to them.

The first model 840 was given serial number 8400001. Production stopped at serial number 8400063 and then skipped ahead to number 8400200 for the beginning of the Deere-built machines. Deere incorporated the assistance of Henry Dreyfuss and Associates in building and finishing the 840 tractors, and the Deere-built machines were much more refined than the ones that were completed by Hancock. The new tractors got new fenders and updated sheet metal. They had improved lighting, linkages, and controls and better comfort for the operator. Changes were also made to make servicing the tractors easier. Given that the new 840s were being built just a month after Deere shut down production at Hancock, they likely had plans in the works for some time before it actually happened.

Not every 840 that Deere built was destined to pull a Hancock scraper. They were also purchased by companies that wanted one for pulling a sheepsfoot packer, a compactor, or for heavy-duty tillage. If you wanted to use one with a scraper one day and then for an-

Green Magazine® • May 2024 Page 21

Here we have a late style 840 with a John Deere 400 scraper.

other use the next, you could. Deere said that it took less than 25 minutes to disconnect the scraper from the tractor. While there were few options for the 840, a buyer could choose between an electric start or a gasoline-powered starting engine. The latter cost about $140 more than the base machine, which came in at $6,485.

The 840 became one of Deere’s most popular industrial tractors. Deere’s salesmen were more interested in selling it than they had been with the company’s prior industrial tractors. It sold pretty well and was relatively popular throughout the country.

The newer 840 tractors were such an improvement over the old ones that owners of the earlier machines soon began asking about updating their tractors to the newer style. Deere obliged, telling them that it would cost $500 to do so. For that price, plus freight, Deere would update the fenders and sheet metal, the linkages and controls, and everything else that was different between the first 63 machines

and the new ones, and they would get a new paint job to boot. Deere was even willing to update the first eight machines, which had been built from model 820 tractors. This program ran from August 1959 to March 1960, and Deere pushed the owners and branch houses to get the updates done. This means that few of the Hancock-built tractors remain today.

Deere made a few changes to the tractors at serial number 8400899, including modifications to the clutch assembly and a vertical drive 1000-RPM PTO. This PTO let the tractor run the new Deere-built 400 elevating scraper, which was released in 1961 for use with the upcoming model 5010 industrial tractor. This vertical setup created a more straightforward connection between the tractor and scraper, improving reliability.

Deere only built the 840 for about two years. They built and shipped the last one on September 27, 1960. However, Deere’s serial number register is somewhat messy regarding this tractor’s history.

First, it shows the final tractor built as serial number 8400848, but the above changes were made to the 840 at serial number 8400899. Furthermore, tractors with numbers as high as 8401154 have been found in the wild, and at least one Deere document written in 1962 states that the last tractor was numbered 8401200, so something odd has gone on here. This makes it hard to say how many 840 tractors were built, but something around 1,000 machines seems most likely.

An 840 won’t be a tractor for every collector. They’re big, heavy, uncommon, and built with parts that may be impossible to find replacements for. A complete tractor and scraper combination weighs over 12 tons and is 32 feet long, meaning that it would require a commercial driver’s license to haul to your home or a tractor show. But they’re rare, they’re unique, and they have that deep two-cylinder pop that is just so satisfying to hear. Plus, on an 840, you sit right next to that big engine, so your right ear will hear every beat!

HEY, SNOWBIRDS and anyone else who is moving Whether you are heading south, going back home or moving to a new location, remember to call Green Magazine® with your address change FOUR WEEKS PRIOR to the move. Missed issues will NOT be resent free if your address has not been changed due to a seasonal move. NOTE: ANYONE moving should call or email Green Magazine® FOUR WEEKS PRIOR TO A MOVE to change the address on a subscription. Call or email Green Magazine® to change the address on your subscription Ph. 402-643-6269 info@greenmagazine.com Page 22 May 2024 • Green Magazine

Auction: June 29, 2024 AUCTION JUNE 29, 2024 • 10 AM We will have 27 John Deere tractors • 15 hit and miss gas engines of various brands • 11 Dodge trucks • 8 Dodge and Plymouth cars • 28 implements of various brands Watch for updates at website: MeltonAuctionRealty.com SALE CONDUCTED BY: MELTON AUCTION & REALTY CO LLC ROGER MELTON, AUCTIONEER & REALTOR • NIXA, MO PHONE 417-830-0153 OR 417-725-1801 • EMAIL: roger@meltonauctionrealty.com ANNOUNCEMENTS MADE ON SALE DAY WILL TAKE PRECEDENCE OVER ANY OTHER PRINTED MATERIALS. NOT RESPONSIBLE FOR ACCIDENTS OR LOSS OF ARTICLES ON OR NEAR SALE SITE. Green Magazine® • May 2024 Page 23

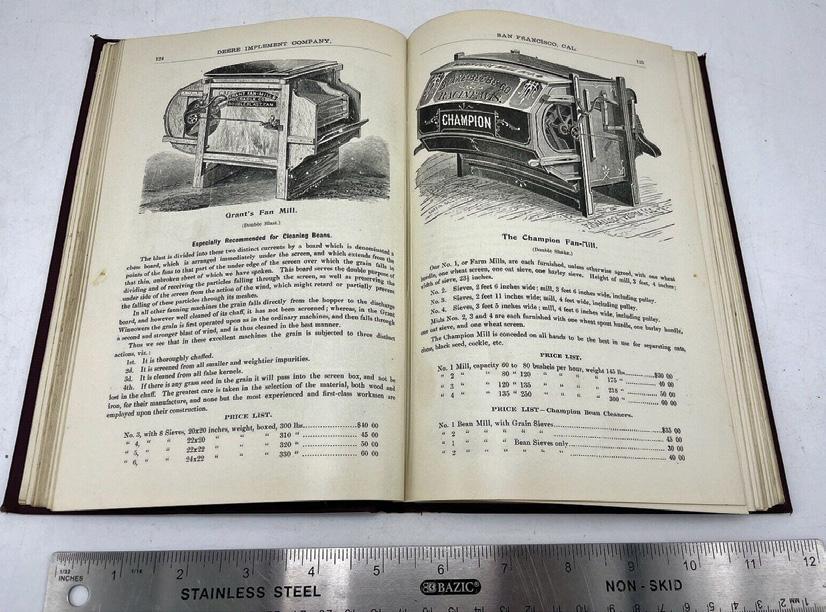

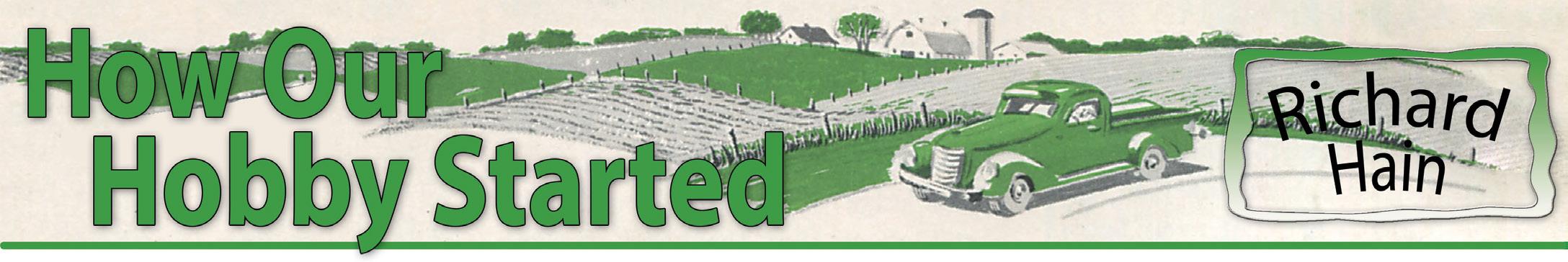

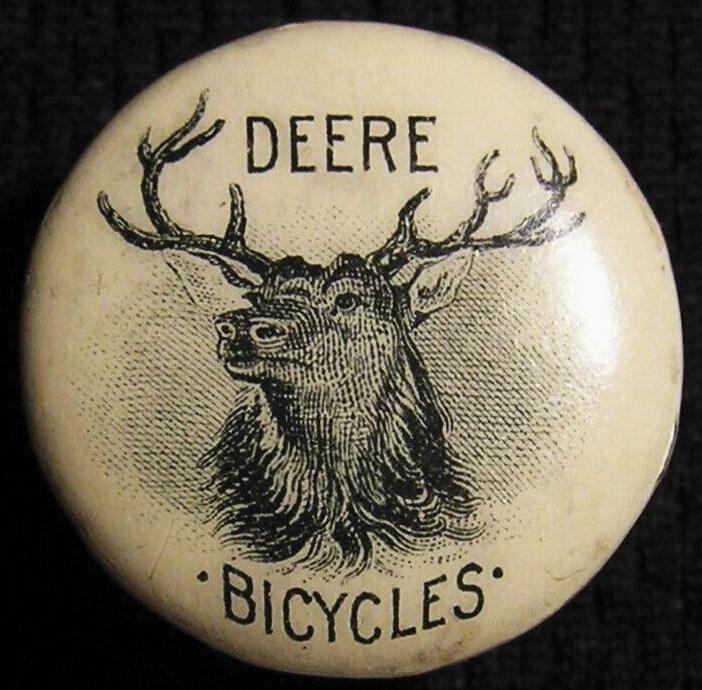

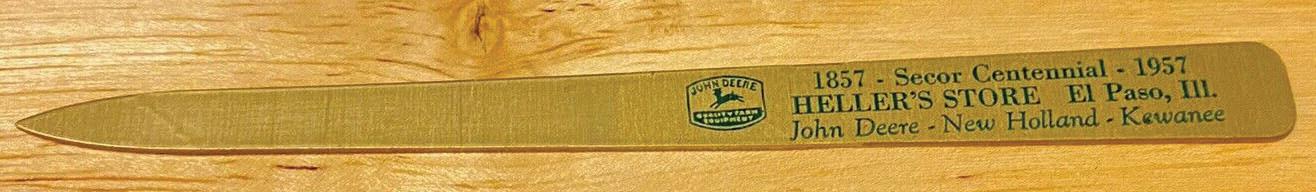

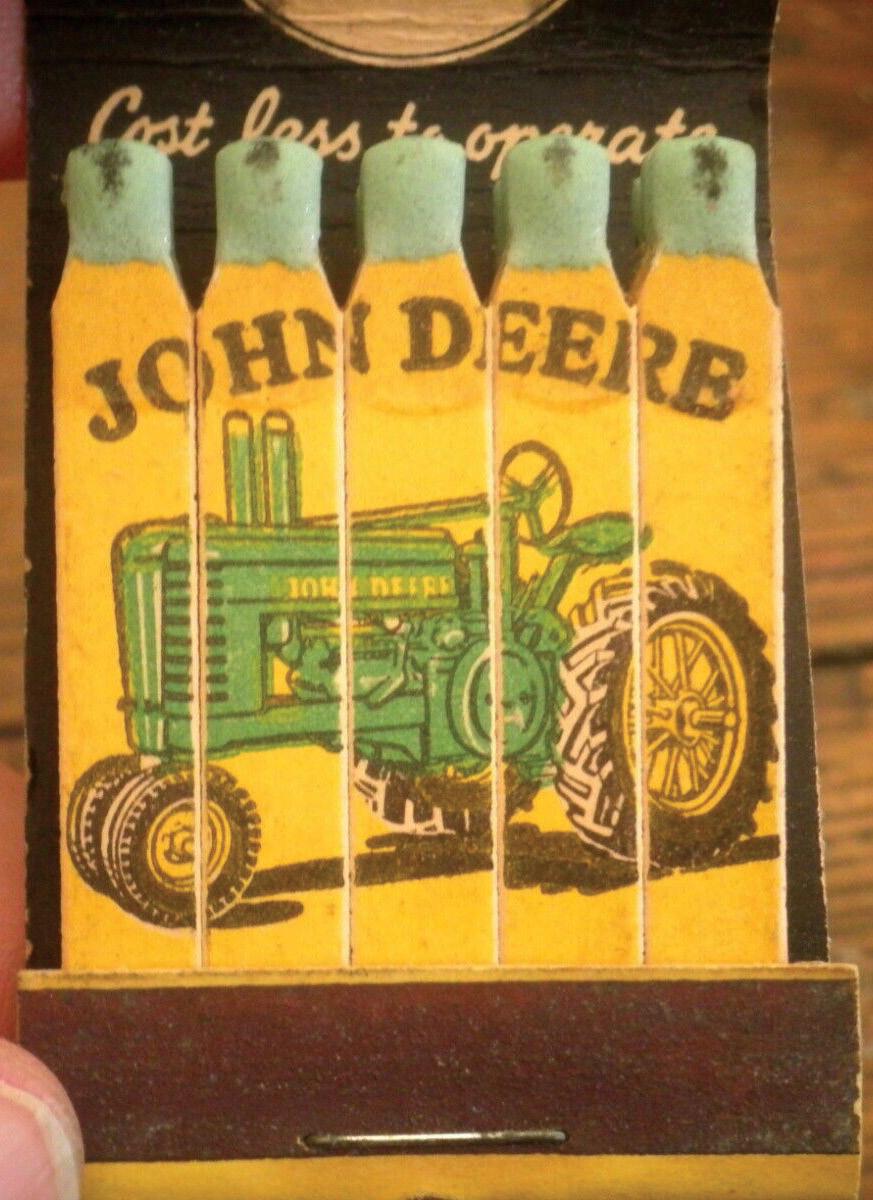

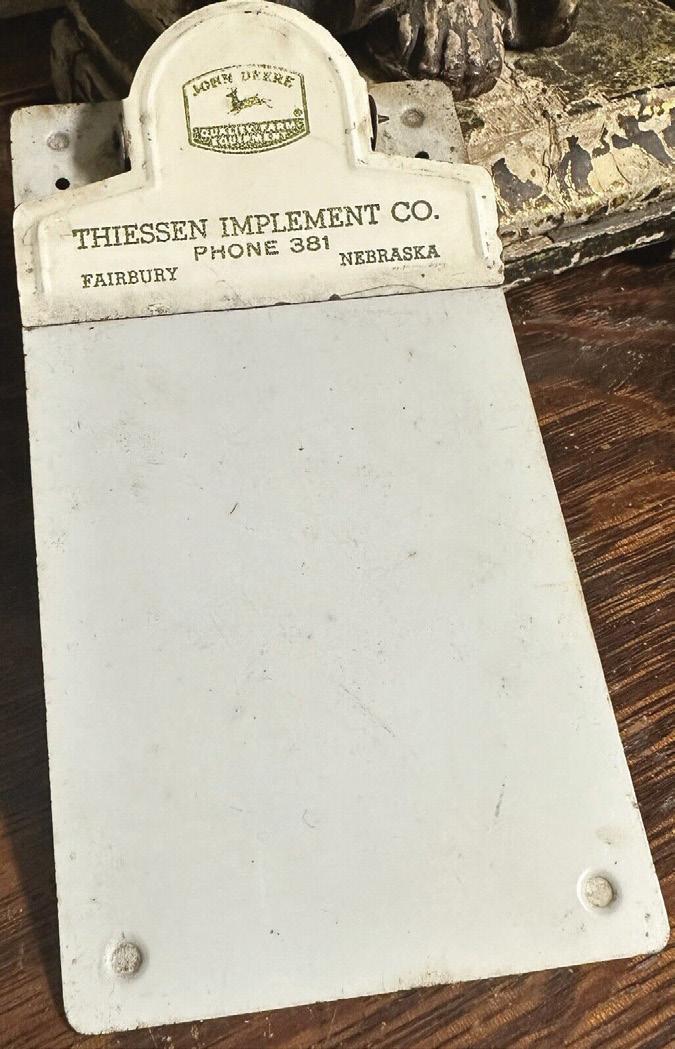

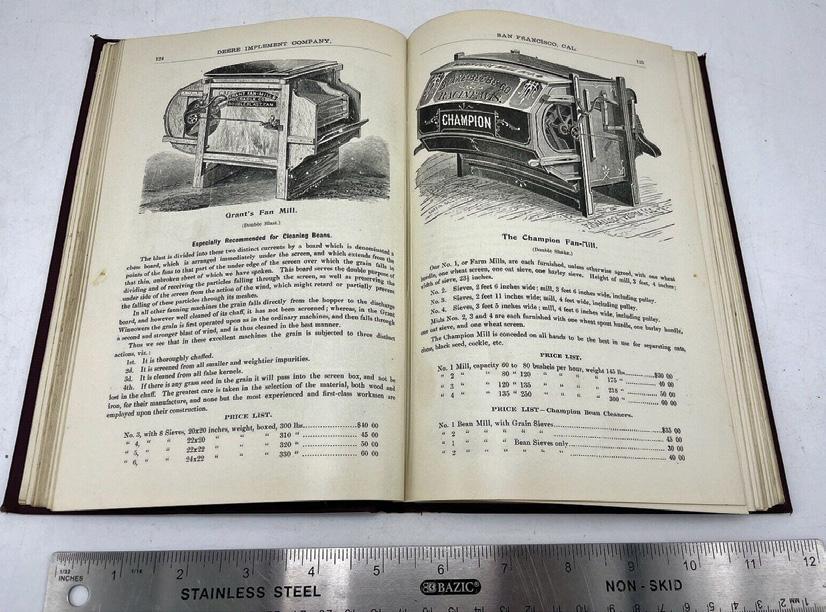

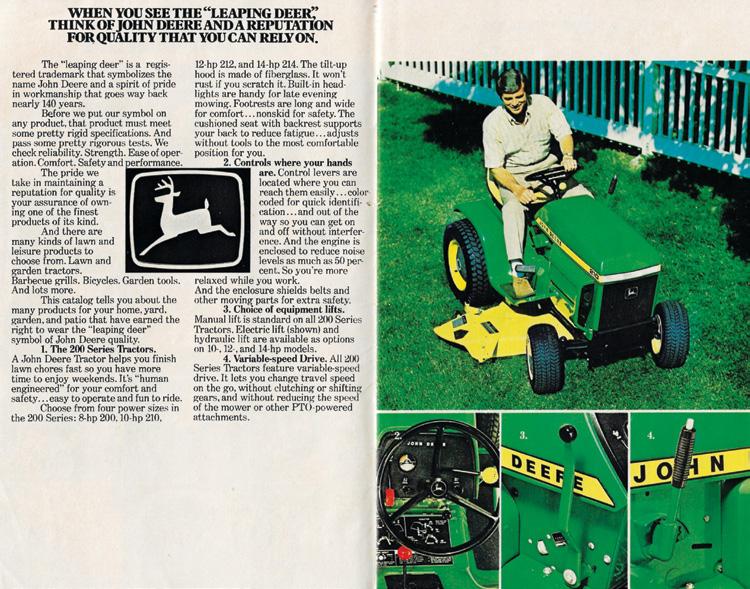

In 1996, we moved into a new, larger office building and decided that the extra space would allow us to stock more items, enough that we could fill a small catalog. The impetus for this was a consistent request we were receiving for more Deere themed items. We contacted companies that were producing Deere licensed products and soon had 150 items. There was everything from afghans to windchimes including mailboxes, magnets and matchbox holders, wag-

ons, wallpaper and weathervanes, pillows, paintings and plaques. We did this for about six years with a few items being dropped and a few new added each year. In those pre-internet days, phone and mail orders kept our office quite busy during the holiday season. An interesting side note is that we stopped selling one of our most popular items, what I would call a dealer clock produced by Yoder Clock Works of Indiana, because no matter how we packaged them

or how we shipped them, far too many were arriving damaged.

After about six years, we decided to end the catalog venture, for several reasons. First of all, with the cost of printing and mailing the catalogs, postage to send items out, paying the employees to do so and all the other associated costs, there just wasn’t enough profit left over at the end of the year to justify it. Secondly, somewhere around the turn of the century, Deere and Company seemed to have had a change of

Need a John Deere grill or coal shovel? We had them in our catalog; however, we no longer have any of these items.

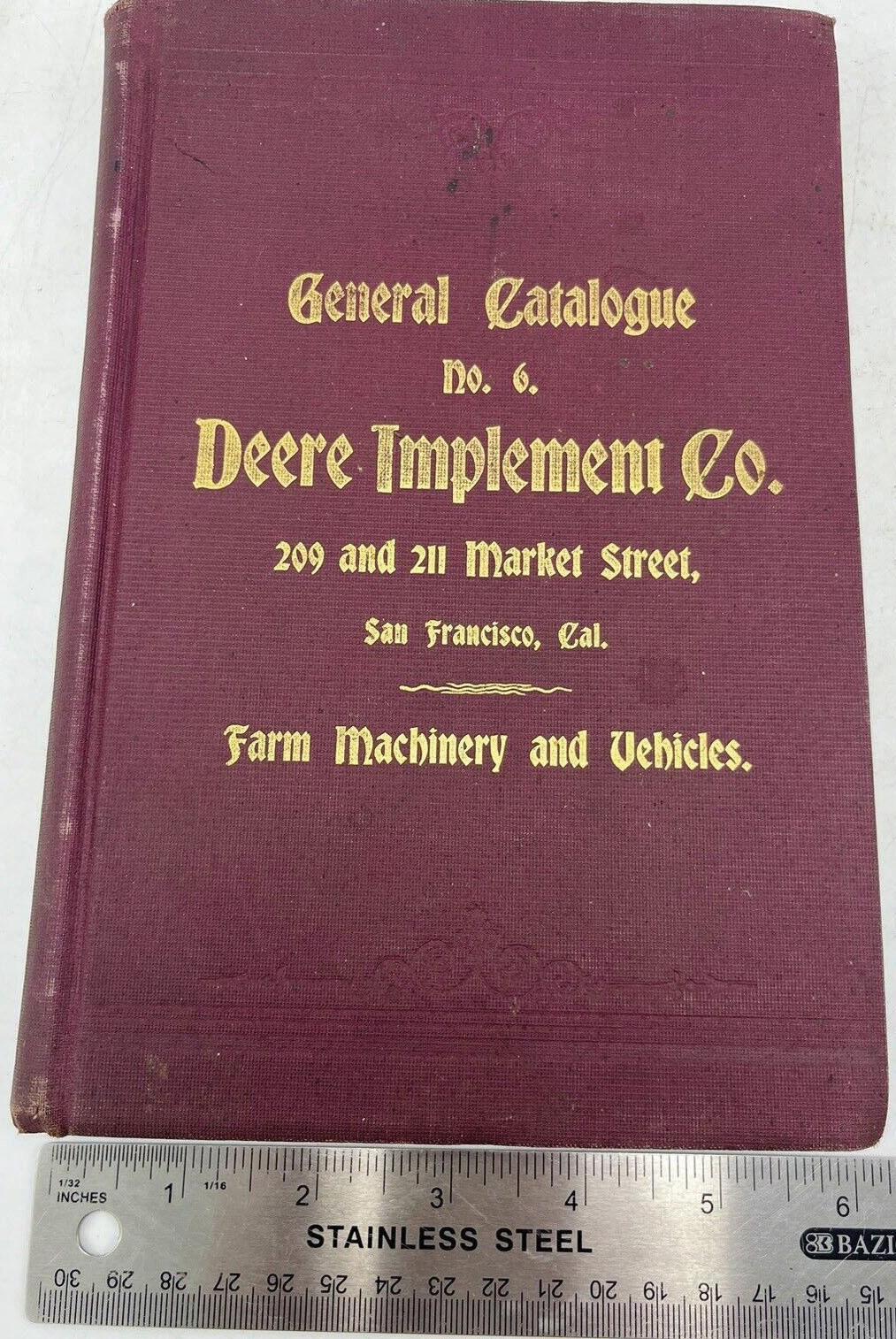

The front cover of one of our catalogs.

The front cover of one of our catalogs.

Page 24 May 2024 • Green Magazine

heart on what and how many items they would license. This meant that we were having an increasingly hard time finding items to include in the catalog. Another factor was that we were competing against some of our advertisers, who were selling the same items. With all of that in mind, we we stopped sending out catalogs and gradually sold off the remaining inventory through ads in the magazine.

Up until somewhere in the late 1990s, just about anyone could climb the stairs of the old Deere Spreader Works building where the archives were located and do some research. However, you now had to be either working on articles for a magazine or writing a book. The “average” hobbyist couldn’t just walk in and look up information on their tractors. The other was that the 8-1/2 by 11 inch glossy photos of tractors that we routinely run in articles went from being free, to costing $50 each. This was in the days before electronic files could be emailed to the customer, so Deere did have some expense in process-

These clocks were a popular item and this one still hangs on the wall of the Green Magazine offices. No, it is not for sale.

ing and mailing the photos, so I can’t say that I thought the decision was unjust. However, everything that I have talked about in this article so far was perhaps an indication of the beginning of a new and different attitude by Deere toward the hobby.

In July of 1998, a show labeled as “Missouri’s First Worldwide Expo” was widely advertised and promoted and held near Conway,

Missouri. Called “Deere-Nado,” it had everything you could want in a show—besides displays, there were parades, tractor pulls, a tractor rodeo, vendors, an auction with some rare tractors consigned and many more activities. The facilities were nice and it was located not far from Branson, where there were hotel rooms and all manner of other things to do while in the area. Everything was in place for it to be a great annual event. However, for whatever the reasons might be, the tractors and spectators just didn’t show up in large numbers. The organizers gave it another try two years later, but it still didn’t attract enough people to keep the show going.

In April of 1998, we published Bill Proft’s first column on models/ toys then called Deeres On a Smaller Scale. He has been writing ever since without, as far as I can tell, missing a month. Along with Dan Brotzman, Greg Stephen, J.R. Hobbs, Ralph Hughes and others, we were providing a lot of new information to our readers.

MOVING? Whether your move is seasonal or permanent, contact Green Magazine® with your address change AT LEAST four weeks in advance of the move. Missed issues will NOT be resent free if your address has not been changed due to a move. Ph. 402-643-6269 • info@greenmagazine.com Green Magazine® • May 2024 Page 25

Detwiler Tractor Parts

ReRimming FactoRy Round & R

Flat Spoke WheelS F • Any brand tractor We can rebuild cutoffs back to steel

High quality

Wiring Harnesses - Cables - Switches

We build restoration quality wiring harnesses to fit these John Deere models and their variations:

AG Models: A, B, D, G, GM, L, LA, M, R, 40, 50, 60, 70,80, 320, 420, 430, 435, 440, 520, 530, 620, 630, 720, 730, 820 2 cyl, 820 3 cyl, 830 2 cyl, 830 3 cyl, 920, 1010, 1020, 1520, 1830, 2010, 2020, 2030, 2040, 2040, 2130, 2240, 2350, 2355, 2440, 2520, 2550, 2555, 2630, 2640, 2840, 2855, 2950, 2955, 3010, 3020, 3150, 3255, 4000, 4010, 4020, 4030, 4040, 4050, 4250, 4230, 4240, 4430, 4440, 4455 Mexico, 4630, 4640, 4840, 5010, 5020, 6030, 7020, 7520, 8010, 8020, 8430, 8630, 8440, 8640, 8560, 8760, 8960, 8770

Harnesses available for other models & brands

See website for complete listing

Due to numerous variations, call to order Shipping/handling not included Visa, MC & Discover accepted

Prices subject to change without notice

Circuit protection kits for Diesel tractors

From $35 (2 cylinder)

From $60 (New Gen)

Industrial Models: Al, Bl, DI, 300, 301, 302, 302A, 310A, 350, 350B, 350C, 380, 400, 400 Scraper, 400B, 400C, 401, 410, 410C, 410D, 440I, 450, 4508, 450C, 450E, 455E, 480B, 500, 500A, 500C, 510D, 540E, 544A, 548E, 600, 7E Scraper, 700, 700A, 710D, 750, 755, 840, 1010C, 1010W, 2010C, 2010W, 3010I, 4010I AG Machinery: 45, 55, 4710, 5730, 5830

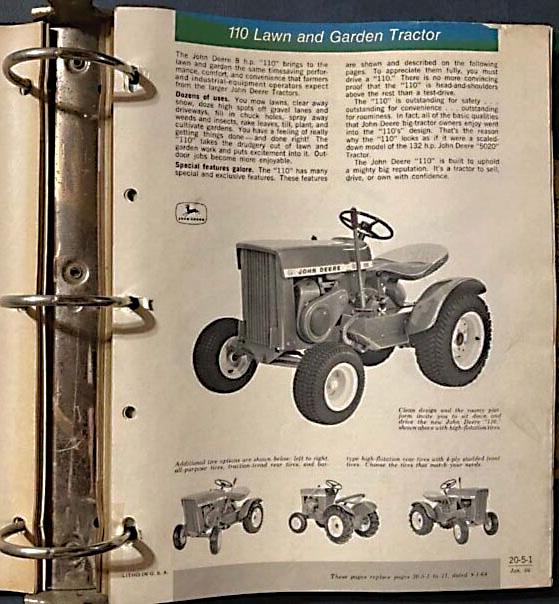

Lawn and Garden: Commercial mowers: 38”, 48”, 54”, GX1320, 727

Z-Trak, 60, 70, 110, 112, 120, 140, 200, 208, 210, 212, 216, 245, 300, 312, 314, 316, 318, 285, 320, 322, 330, 332, 420

Compact Tractor: 790, 850 Snowmobiles: 340 Cyclone

We also carry: Starters, Regulators, Generators, Alternators, Relays, Coils,

Lights, Alternator

We make alternator conversion harnesses Call for a FREE 100 PAGE CATALOG! CALL: 716-937-6618 • WORLDWIDE SHIPPING International phone: 001-716-937-6618 Email: agriserv@rochester.rr.com 13899 North Road, Alden, New York 14004 www.wiringharnesses.com

Brackets, Pulleys

/ very accurate reproductions We can also replace damaged spokes • The only source of original style rear rims Rear wheels can be custom sized for pullers • Will also rerim cutoffs front and rear ALSO: NEW JD FRONT AND REAR WHEELS CALL FOR DETAILS • DETWILER MACHINE Text 715-613-1520 • Email

or call numbers listed DETWILER TRACTOR PARTS 206191 State Hwy. 13 • Spencer, WI 54479 30 years in the same location • 9 AM - 5 PM CT Mon - Fri Ph. 715-659-4174 • 715-659-4252 QUALITY NEW & USED PARTS Exhaust Pipes • U.S. Made Radiator Cores • Front Weights Engine Parts • Manifolds • Mufflers • Airstacks Battery Boxes • Fenders & Hoods • PTO Shields Steering Wheels • Flywheels • Grill Screens Clutch Parts • Grill Guards for D & GP • Airstacks - D & GP We do carb, magneto and general tractor repair NEW ITEM: Airstacks for D and GP $315 DELUXE CONVERSION KIT NO MORE DRIPS! • An easy leak-free ISO conversion kit for John Deere tractors from 1964-1982 • Push-pull design eliminates levers • Breakaway action includes all seals and dust covers Remanufactured stepper motor Fits models: 6000 SRS tractors ‘00, ‘05, ‘10, ‘15 & ‘20 SRS OEM part #AL181805 $450.00 exchange $200.00 core value Ph. 315-536-3737 GreenLight Products LLC Rebuilt in our facility Page 26 May 2024 • Green Magazine

patdetwiler@gmail.com

Green Magazine® • May 2024 Page 27

Featuring unstyled tractors Restored and original ‘24 “D” • Exhibit A model “D” and other rare and unusual For info: 503-320-8819 Jake Rens & Sons OPEN HOUSE July 4-5-6, 2024 9 AM - 5 PM CDT Location: 3452 510th Street Orange City, Iowa Call for more information on these tractors 4430 Syncro, running engine PARTING OUT! 4020D, dual remotes, running engine • PARTING OUT! EverGreen EverGreenRestoration Restoration Gauge prices: $65 for oil/amp $80 - $90 for temp, depending on length of the lead Oil, amp and temperature GAUGES with white or black faces for most 2-cylinder models for the unstyled to the 30 series, Waterloo and Dubuque built models Made in the USA • All gauges have real glass • On hand, ready for shipping • Painted, ready to install • Gauges come with mounting clamp and hardware • Faces made by Jorde Decals and have all details of the original gauges • All gauges are calibrated EverGreen Restoration Jerry Trcka W7619 Walnut Dr Spooner, WI 54801 Cell 715-520-7876 tractorgauges@yahoo.com www.evergreengauges.com NEW GENERATION GAUGES now available! RECOVERING ORIGINAL STEERING WHEELS - CALL! Oil, amp and temp gauges available for OTHER BRANDS of antique tractors Page 28 May 2024 • Green Magazine

• Used parts include: weights, 3-pts., toplinks, dual hydraulics, float ride seats, clutch parts, hubs, transmission gears, sheet metal, tires and rims, 720-730 ES parts, all-fuel manifolds, brake parts, square and round tube WFEs, heads, blocks and PTO parts.

• New parts include: manifolds, battery boxes, carburetor kits, air stacks, mufflers, grill screens, radiator cores, lights and overhaul kits.

• Rebuilt parts include: Taper-Loc flywheels, electric start conversion kits, float ride seats, starters, carburetors, cleaned and lined gas tanks. Also have crack checked heads and blocks.

Lind Bros Tractor and Parts, LLC

G, H, M,

330, 40, 420, 430,

720, 730,

820, 830, 3010 3020, 4010, 4020.

• New aftermarket, rebuilt and used parts for JD A, B , D,

R, 320,

50, 520, 530, 60, 620, 630, 70,

80,

Lind Bros Tractors and Parts, LLC 830 Saint Peter’s Church Road SE • Corydon, IN 47112 sales@lindbros.com • www.lindbros.com 812-952-3010 • 833-952-3010 Call or email today! Orders can also be placed online. McDonald Carb & Ignition McDonald Carb & Ignition 1001 Commerce Rd. • Jefferson, GA 30549 Ph. 706-367-4179 info@mcdonaldcarb.com Guaranteed Quality Parts and Service Virtually All Makes and Models Stock or Modified Buy, Sell, Trade Check us out on the web for info and online ordering: www.mcdonaldcarb.com Green Magazine® • May 2024 Page 29

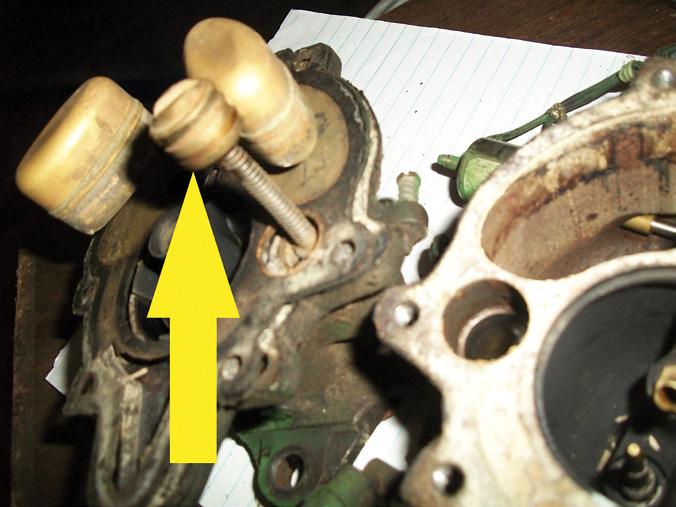

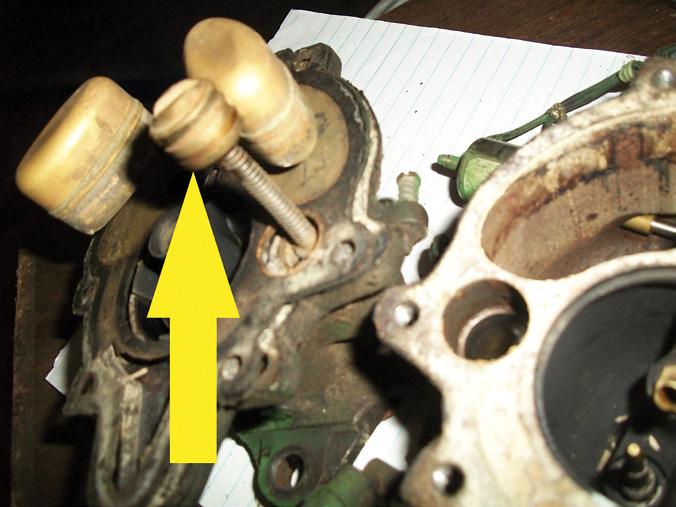

Jumpy clutches on two cylinders

Ever have a two cylinder clutch that wants to jump and grab when you try to engage the clutch smoothly? Ever try to back up to an implement slowly with a jumpy clutch? The cure is often easy, very inexpensive and not very time consuming. Imagine that— something in this hobby that doesn’t cost a ton of money to fix!

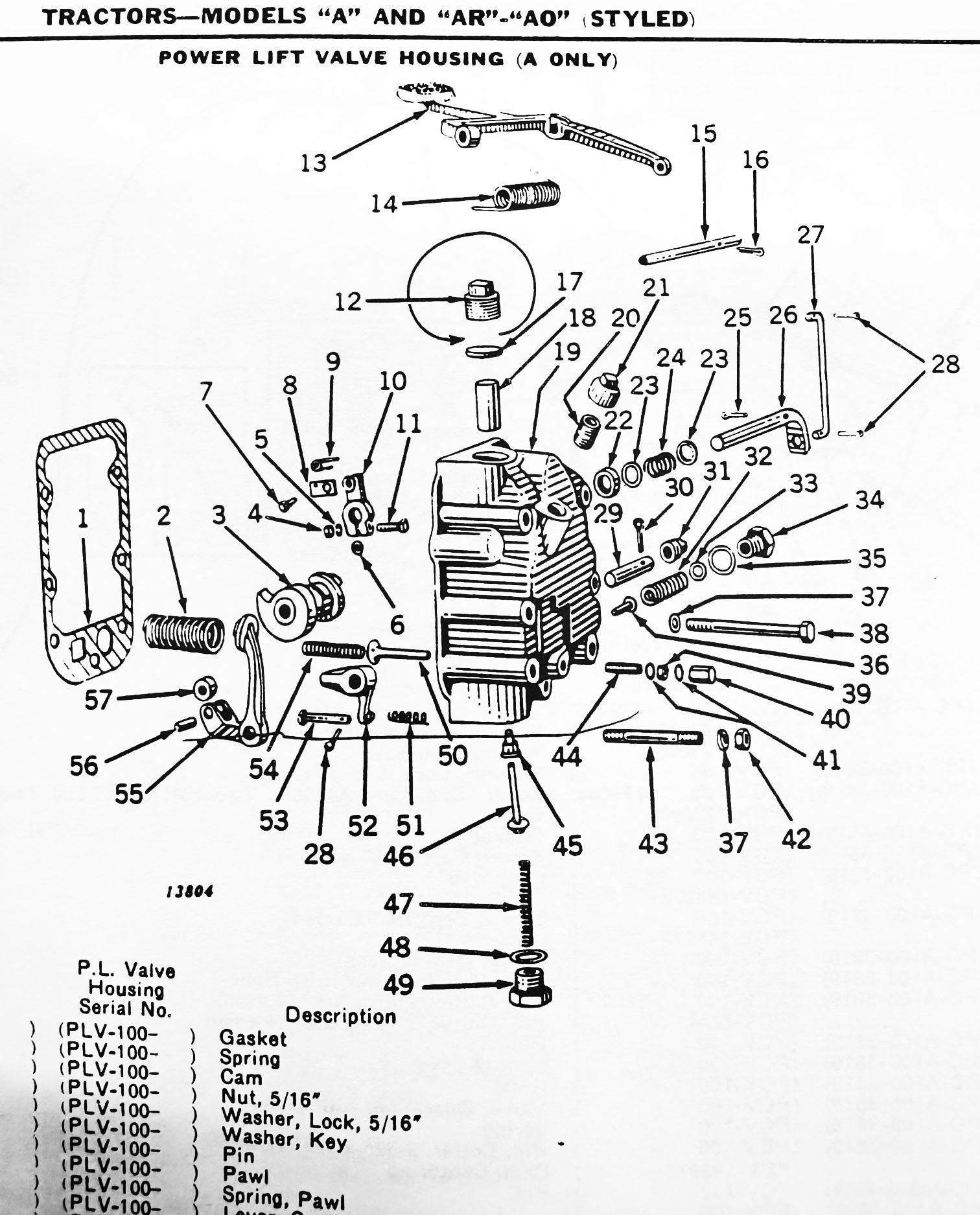

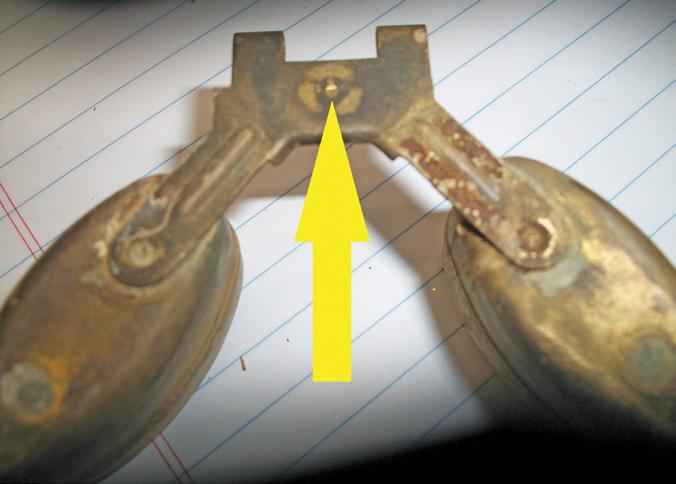

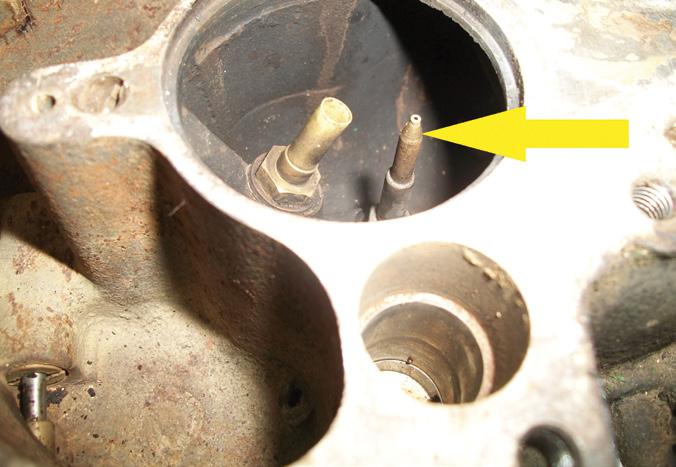

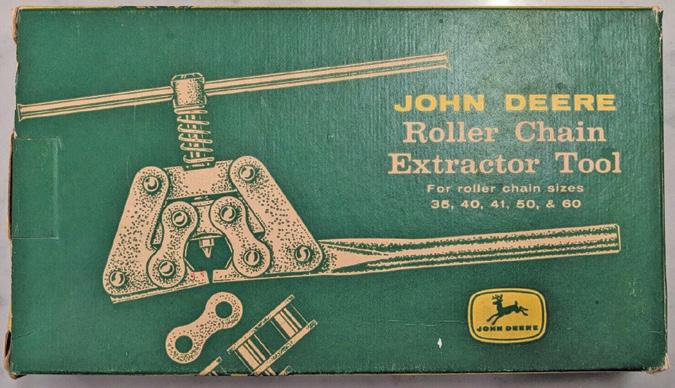

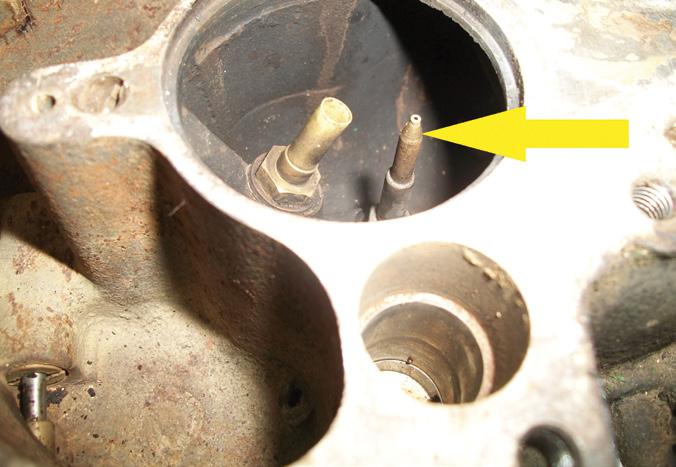

Often a clutch that grabs or jumps when engaging is caused by a dirty, sticky clutch. Many times, a good cleaning will cure the problem. There are a few places on a horizontal two cylinder clutch that seem more susceptible to problems than other parts. The horizontal two cylinder clutches are what is commonly called a “dry” clutch. These clutches are designed to operate without lubrication. John Deere designed its tractors to be simple to work on and easy for the average person to repair. The clutch on a horizontal two cylinder is not separated from the engine oil by an oil seal as we know them today. I’m not sure if John Deere engineers did this to keep the design simple or if they felt an oil slinger arrangement would outlast a lip type oil seal. Anyway, nearly every tractor we collect and restore today has been up and down the field more than a couple times, so most of the parts will show wear.

To begin fixing a jumpy, sticky clutch, remove the dust cover on the belt pulley. Next remove the cotter pins from the three adjusting nuts and remove the adjusting nuts. Pull the pressure plate off the three clutch bolts. Now remove the first clutch disc

and set it on the pressure plate in the same position as it was on the tractor. This practice is just good common sense and makes assembly a lot easier.

On some two cylinder tractors, there is another disc splined to the main drive disc with a second clutch disc behind it. This disc just slides off without a puller.

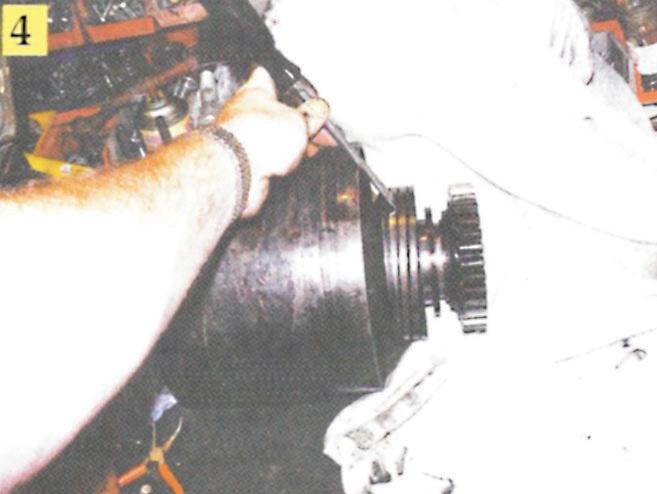

Now inspect the drive disc and crankshaft for timing marks. There should be a “V” on the drive disc and one on the crankshaft pointing at each other. It is strongly advised to find these timing marks before you pull the drive disc off. If you can’t find any timing marks, make your own. The drive disc is counter weighted for engine balance and must be timed correctly to prevent engine vibrations. Now you can pull the drive disc off. This will require a puller. I have made a puller out of scrap iron for several two cylinder tractors. They are nothing special. The drive disc and crankshaft are a tapered spline so once you get the drive disc to budge, it will come easily. With the main drive disc removed, remove the last clutch disc from inside the belt pulley.

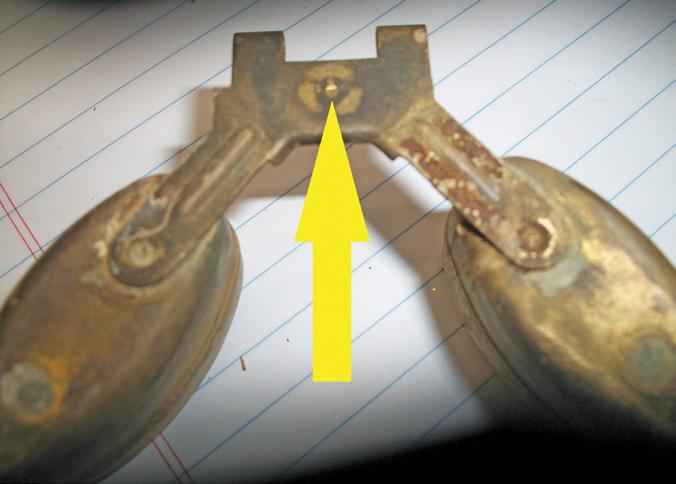

Pull the pin that connects the hand clutch lever to the pulley brake. Then remove the clutch fork assembly by removing the four bolts that hold it to the reduction gear cover. Pull the clutch fork assembly forward to remove it from the tractor. Inspect the clutch fork for wear and replace if worn more than 25 percent.

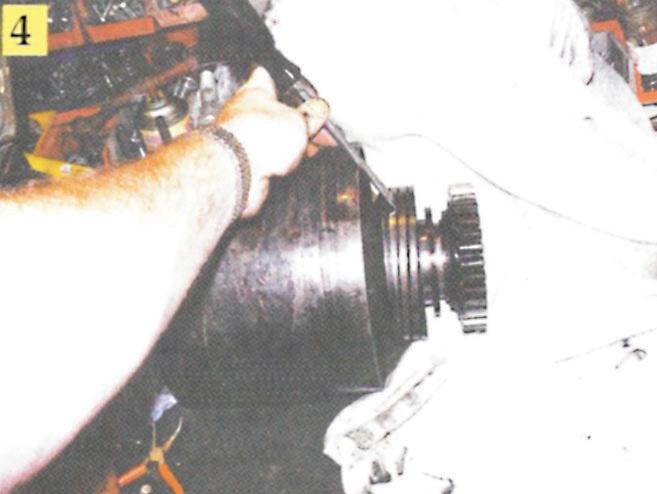

With the clutch fork assembly removed, you can slide the belt pul-

Page 30 May 2024 • Green Magazine

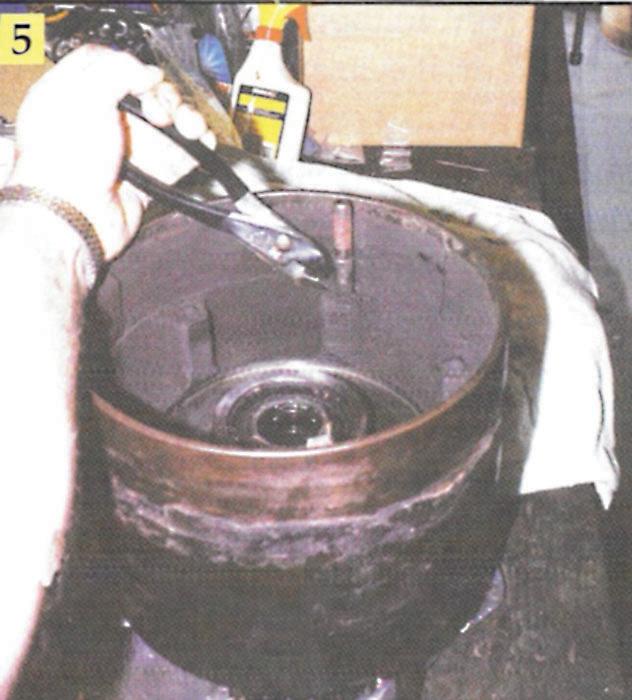

ley off the crankshaft. Belt pulleys are heavy little critters, so be careful if you have back problems like me. Place the belt pulley on a sturdy bench and remove the cotter pins from the three clutch bolts. Push the three clutch bolts out the back side of the pulley. If the bolts appear worn to the point the bolt diameter has been reduced at all, replace the bolts. This is one area of a two cylinder clutch that will receive a fair amount of wear. This is also one of the areas of the two cylinder clutch that can give you a jumpy clutch or one that grabs and, in a few cases, I have seen them sticky enough that the clutch will not release or disengage. Place a rag inside the center hole of the pulley to keep dirt from getting in the main clutch bearing. Thoroughly clean and buff these three bolts and the holes they came out of. Oil vapors and clutch dust tend to collect on these bolts and fill the holes they slide in. These three bolts must move freely in the holes they came out of. Coat these three bolts with a very light coating of Never Seize before reinstalling. If you want to inspect the “dog bones,” you can turn the pulley over and remove the cotter pins holding the bell crank levers and pivot pins in place. These parts do not wear as rapidly as other clutch parts and are often in good condition. Before reinstalling, put a light coating of Never Seize or good grease on these parts before reassembly.

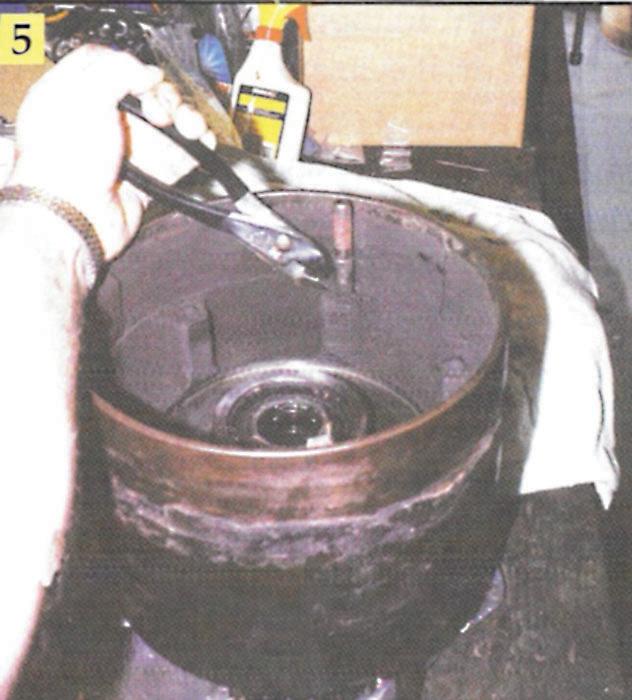

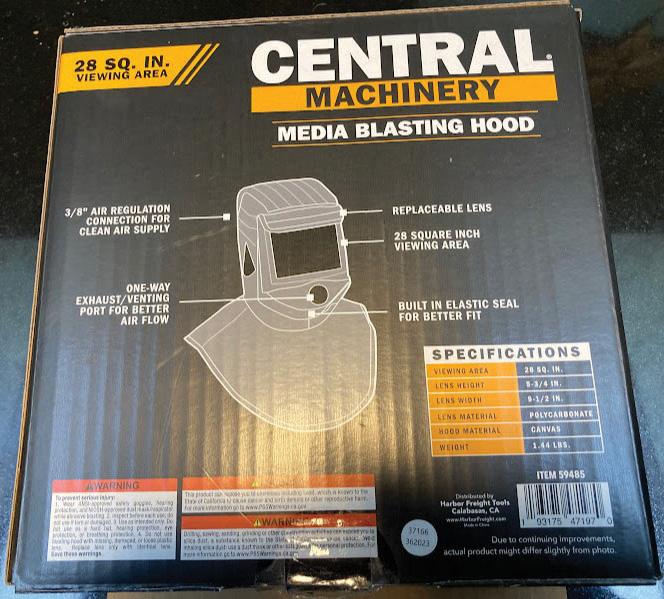

Spray the inside area of the belt pulley with brake cleaner and wire brush the gummy areas. Oil vapors and clutch dust make a very sticky mess so expect to spend a little time cleaning up the inside of the belt pulley. Clutch dust may actually contain asbestos fibers so refrain from using compressed air to blow out the dust, but rather wash it out with brake cleaner.

Inspect the oil slinger area of the pulley to make sure none of the oil grooves are filled in. Next check the bottom oil drain hole in the reduction gear cover. In theory, if oil gets past the oil slinger, it is to exit this hole and drip on the ground (don’t mention this design to any “tree huggers”). Often

times, this area is caked with crud and needs a good cleaning.

Spray the clutch discs with brake cleaner and sometimes I will lightly sand them with 320 grit sand paper to remove glazing. There are wire strands in the clutch facing so sand with caution. Having dry clutch discs is critical to having a smooth clutch. The clutch disc located behind the main drive disc is the most susceptible to become oil soaked. If you get a real oily one, your best bet is to replace it. Clutch discs are not that expensive and would be a good investment.

Using a good quality solvent, flush and clean the roller bearing in the center of the belt pulley. This bearing and the brass bushing spin on the crankshaft when the engine is running with the clutch disengaged. For those who leave their tractor run with the clutch disengaged, you are putting unnecessary wear on these bearings. After cleaning and drying, pack the roller bearing with a high quality, high temperature grease and put a light coating of grease on the brass bushing.

Now you are ready to reassemble the belt pulley. Use new cotter pins when reassembling. The final step will be adjusting the clutch by tightening the nuts evenly that hold the pressure plate against the drive disc. Tighten the nuts evenly to assure the pressure plate contacts the drive disc evenly. When the clutch is adjusted correctly, you will hear a sharp “snap” when the clutch is engaged and disengaged. The manual says it should take about 80 pounds of force to engage and disengage the clutch. If you have young people drive your tractors, or people without a lot of physical strength, you do not need to adjust the clutch that tightly. It will work just fine if it is not adjusted to the 80 pounds stated in the manual.

This article first appeared in the January 2002 issue of Green Magazine.

Contact Dan Brotzman at W14729 Meisner Rd., Tigerton, WI 54486; phone 715-535-2595; email danb4230hc@yahoo.com.

Green Magazine® • May 2024 Page 31

John Deere 1929 “GP”

Serial number 202042

Warehouse date:

8 December 1928

Ship date:

8 December 1928

Branch: Lansing, Michigan

Destination: Hastings, Michigan

Purchased from Larry Darling in Hartford, Michigan on 2 October 2020 for $5,000

Hi, I’m Eric Sherman from Louisville, Kentucky and I’ve been a lifelong John Deere enthusiast. I have an “O” scale John Deere train layout, two ice cream makers (five gallon and two quart), 1973 Weekend Freedom Machine 70, 1955 70 diesel standard, and the reason I’m writing to Green Magazine, a 1929 “GP.”

To begin, I grew up in Eaton Rapids, Michigan, graduating from high school in 1990. Shortly after graduation, I joined the United States Air Force, serving 21 years as a jet engine mechanic and flight engineer. Side note: my son graduated Space Force Basic Training this past December 2023 and is currently learning how to be a geospatial intelligence analyst.

Onto the story:

So, this 1928/1929 JD “GP”

has been in my life since 1982 at the ripe ol’ age of 11. My dad and all his John Deere buddies used to attend tractor shows in Michigan (Buckley, Delton, Hastings, Mason, and Oakley). Starting in 1982, we would start the tractor show season at Charlton Park, located in Hastings. At that show, they would fill everyone’s gas tank and have a wonderful parade through all the old buildings (like a town square), located next to Thornapple River.

During the time of 1982 until 1990, I so looked forward to summer vacation from school and visiting all of those tractor shows again! I remember Sam Scobey bringing his beautifully restored electric start 830 diesel, Danny Crane and his son, Daniel, would bring a standard and wide tread “GP,” Larry Darling would bring his beautifully restored “H,” Gordy Bridleman would bring the standard “GP” that this whole story is about, and, lastly, my dad

My first words were, “Is it for sale?”

Next was the Michigan Steam Engine and Threshers Club in Mason. Back then, a big metal sled was used to flatten the roadway at the show by using one tractor to pull the sled, while the other tractor would drive onto it. The Mason show even had a big steam crane that ran on compressed air due to the boiler being too rusted out. I remember going to Prairieville Old Fashion Farm Days in Delton and watching tractor pulls and people trying to catch chickens and oiled down pigs. I don’t remember Buckley and Oakley too much since they were far away and we wouldn’t take any tractors.

and I would bring a 1935 “D” and a 1938 “L.”

Fast forward to August 2020— almost all my dad’s tractor buddies had long since passed, except for Larry Darling of Hartford, Michigan. One day, I wondered if I could find anything on the internet about Larry or to see if he was still alive and well. After some searching, sure enough, I found he still has his business selling used automobiles and that there was a phone number listed. At this point, I had no idea Larry had Gordy’s old “GP;” I just wanted to see how he was doing since it had been more than 30 years since the whole gang was together

Page 32 May 2024 • Green Magazine

at a tractor show and ask him if he remembered any history on the 1908 4-1/2 horsepower hit and miss Waterloo Boy he sold my dad back in the late 1980s.

After talking to Larry about the good old days and letting him know about my Air Force career and my own family, Gordy’s “GP” was brought up again and this time Larry said, “Eric, I have Gordy’s ‘GP’.”

My first words were, “Is it for sale?”

many old John Deeres, she came to life once again! We could not believe how well the “GP” was running, considering the amount of time she sat in the barn. Not knowing if my luck would run out, I quickly drove the standard “GP” up on the trailer and quickly learned the front tires are much narrower than the rear tires. So glad I kept the clutch engaged and just went for it. Once the “GP” was chained down, the check was written, goodbyes were said and I headed five hours south

amount of help you can get today when doing a John Deere restoration due to the internet. Growing up, you had to use Mother Deere, a tractor show, magazines, or word of mouth to find parts.

By July 2023, I had the opportunity to take Gordy’s “GP” back to the Charlton Park and Mason tractor shows to once again relive my childhood memories. I truly believe Gordy was smiling down from heaven! We also had the “GP” and my two ice cream makers at the Classic Green show in Lebanon, Tennessee (there is video of me in the parade).

Larry and I agreed on a price and on October 2, 2020, I drove from Louisville, Kentucky to Hartford, Michigan and bought Gordy’s “GP”!

The “GP” had not run since the year after Gordy passed away in 1993. I had to file the points, run a new rubber fuel line from fuel tank to the Ensign carburetor and have Larry give me a tug and, like so

back to Louisville, Kentucky, arriving about 11:30 at night. What a long day that was!

I spent two years fixing so many worn/broken items on the old “GP.” Without the help of my tractor buddies, the “GP” Facebook page, Mother Deere and the Lind Brothers, I have no idea if the old girl would be running today. It is incredible the

A little background about Gordy Bridleman and the 1928 “GP” from Hastings, Michigan. Gordy passed away in 1993 of a heart issue at the age 55. We all loved Gordy; he was an architect by profession and would do drawings to make heavy duty tri-axle trailers for pulling all of our toys to the show back in the day. As a little guy, I would stay with Gordy in his canvas tent during the shows. I sure wished those days would have never ended. Being around Gordy and all my dad’s tractor buddies sure made some incredible childhood memories.

The “GP” was originally on steel wheels and restored in the early ‘80s. By 1984, Gordy had converted the “GP” over to rubber wheels using cut downs on the front and F&H on the rear. I remember riding on the “GP” when it was steel wheels and wondering why would Gordy not have rubber tires—this thing is rough!

Submitted by, Eric

Sherman

Louisville, KY

Green Magazine® • May 2024 Page 33

A&L Parts NEW, USED & REBUILT 2 CYLINDER PARTS Hundreds of tractors parted: Wide fronts, 3-point, carbs, starters, etc. • NOS parts MODELS A THROUGH 730 A&L PARTS 432 N. Flat Street • Penn Yan, NY 14527 Phone 315-536-0543 • We ship DAILY • Major credit cards accepted NEW PISTON KITS and RADIATOR CORES SMV emblem support bracket - K&K Antique Tractors K & K Antique Tractors Kent Kaster • 5995 N. 100 W, Shelbyville, IN 46176 Phone 317-398-9883 Website: www.kkantiquetractors.com • Email: info@kkantiquetractors.com A v A il A ble P A rts in s tock * Complete battery tray assembly Headlights Fenders * Step kit * Gauges Radiator core * Safety plate * Front & rear side panels Hydraulic outlet plugs * Raincap for late side console * Nameplates $245 per set * Decals Hood ornament Pre-cleaner bowl * 3-piece seat kit * Battery boxes * Rockshaft covers Fuel cap & radiator cap Steering wheels & centers * Side & front grille screens Order today! NEW ITEM * SMV Emblem Support * Original part number AR46282 * Selling bracket ONLY * Made in USA Lakeside Service & Supply Lakeside Service & Supply New and Used Parts for Vintage JD Two Cylinder Tractors We ship parts daily! 325 S. Main Street • Elmer, NJ 08318 856-358-2444 deereblaze@verizon.net Like us on Facebook! Visa/Mastercard/Paypal accepted Page 34 May 2024 • Green Magazine

Martin Parts & Repair

Complete clutch rebuild kits and clutch lining kits

PARTS TRACTORS