The 60 Series Gen II Fixing Solid State Ignitions How Deere Got in the Snowmobile Business June 2024 GREEN Magazine® In this issue...

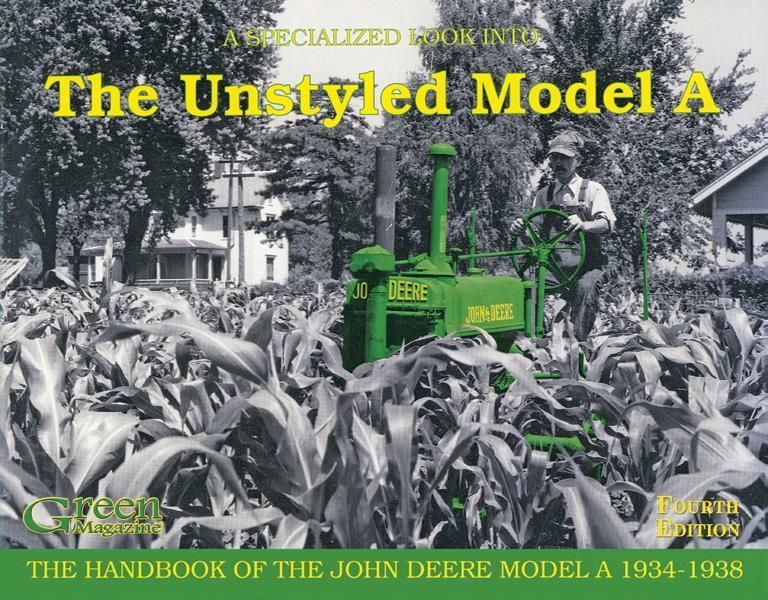

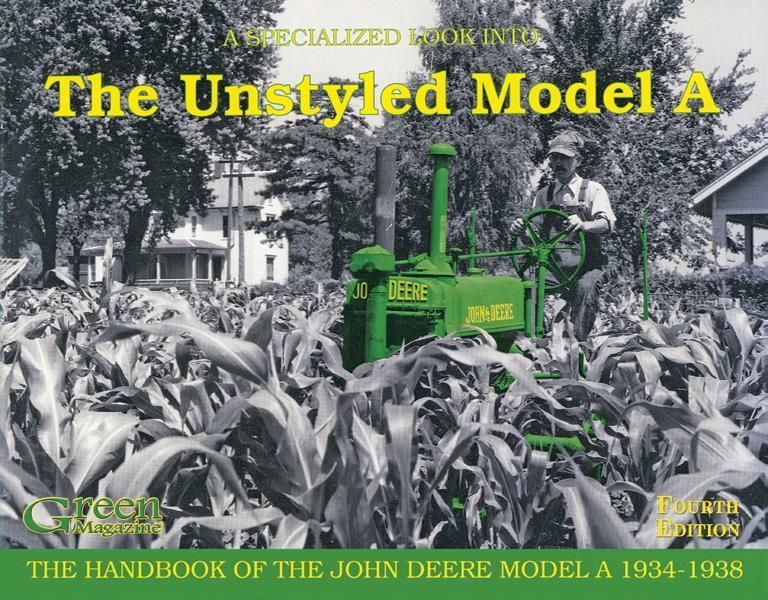

The Handbook of the John Deere Model A 1934-1938

Fourth Edition

• By Wes Malcolm

Now in its fourth printing with 15 more pages, this is the handbook of the John Deere model “A,” 1934-1938. A book that should be on the “must read” list of any unstyled “A” owner. There is probably no other book on the market that goes into so much detail on a single model of tractor. Shows illustrations of nearly every change made in the parts that make up the unstyled “A.” 95 pages, 11x8-1/2 inches, soft cover.

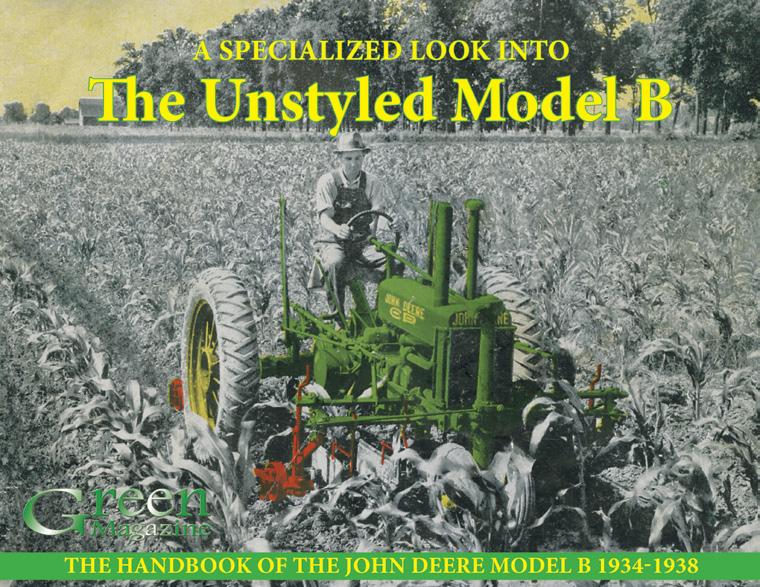

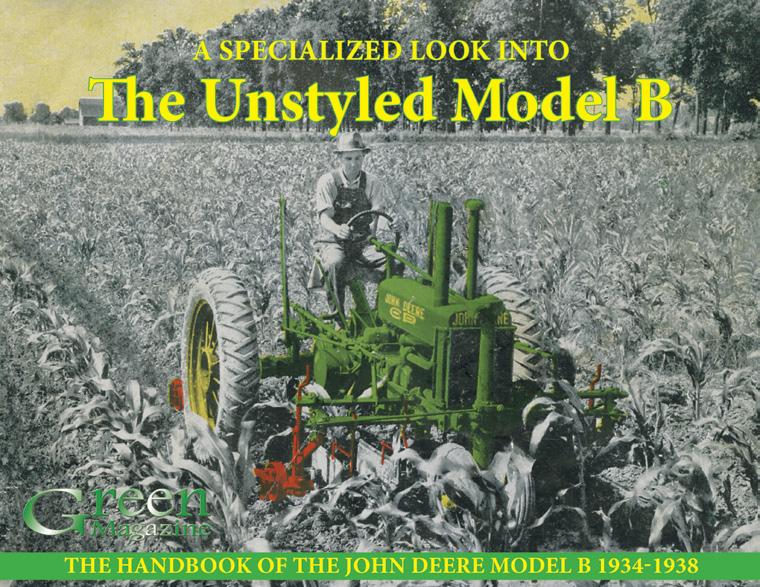

Both books include history, specifications, serial numbers, original prices and much more A Specialized Look Into

The Handbook of the John Deere Model B 1934-1938

The same types of information as available in the book above, except now about the model “B,” written and compiled by a panel of experts who have spent decades collecting and restoring the unstyled version of Deere’s most popular tractor. This book shows nearly every change made in the parts that make up the unstyled “B.” 84 pages, 11”x8 ½”, soft cover, over 200 photos - most in color.

WHAT A DEAL! SPECIAL BUNDLE PRICE on these TWO books published by Green Magazine A

The

A

Specialized Look Into

Unstyled Model

The Unstyled Model B

Order GMAB: $63.95 U.S. (Nebraska residents add 5.5% state tax) $76.95 Canada (US funds) • $89.95 Foreign (US funds) The prices shown here are for BOTH books shown above - the first time for this BUNDLE DEAL. •• Prices in this BUNDLE DEAL are up to 20% OFF the regular price •• Visa, Mastercard, Discover, American Express accepted • Nebraska residents add 5.5% sales tax • Price includes S/H Call 402-643-6269 • Email info@greenmagazine.com Online www.GreenMagazine.com Mail Green Magazine® • PO Box 95, Bee, NE 68314-0095

ESTATE AUCTION

JOHN DEERE TRACTORS:

3020, diesel • 3020, gas

6 - 4020, diesel • 2 - 4010 Hi-Crop, diesel

4 - 3020 Hi-Crop, diesel • 4430 Hi-Crop • 4020, LP gas

2 - 4020, diesel, Power Shift

2 - 4520, diesel, side console, cab • 3 - 2010 Hi-Crop 4230 Hi-Crop • 4230, not running • 3020 standard 4020 Hi-Crop, Power Shift, side console

2 - 4020 Hi-Crop • 2 - 3020 Hi-Crop

2 - 3010 Hi-Crop • 2 - 4020 Hi-Crop, Power Shift

3020 Hi-Crop, Power Shift • 3020 Hi-Crop, 3-point 4010 Hi-Crop • 3020 with loader • 4010 3010, gas • 3010, diesel, tricycle 3010, gas • 3010, diesel, tricycle • 4 - M

R, diesel • 1010 special, gas • 620 tricycle, LP gas

2 - M with cultivators • 430W, spin out wheels

2 - A, square seat, gas • 40T

MT with cultivators • 4010, LP gas

M with belly mower • 2 - MT

B with sickle mower • 430W 430T • B • 2 - 60 60, parts tractor • 7100 four row planter L frame • 2 - L, parts tractor

3 - 60, parts tractor • 60, LP gas, parts tractor

Auction: Jerry Braden

June 22, 2024 • Start time 9 AM • RJO Auction Co. Selling the estate of Jerry Braden 4340 Holland Chattoogaville Rd, • Lyerly, GA Visit our website for complete listing & photos: www.rjoauctions.com email: rjayop@aol.com

RJO Auction Co For info, call Ronnie Odom: 770-846-3225 Viewing dates: June 17 to June 21, 2024 • 9 AM to 6 PM Live onsite and online bidding Terms: 10% Buyers premium Online bidding with

“GREEN MAGAZINE®” (ISSN 0883-5462) is published monthly and released 12 times a year on or about the first of each month for $39.95 per year (Canada: $59.95 per year; Foreign: $69.95 per year) by Hain Publishing, Inc., 2652 Davey Road, Bee, NE 68314-9132. Periodicals postage paid at Bee, NE and additional mailing offices.

POSTMASTER: Send address changes to “GREEN MAGAZINE®, PO Box 95, NE 68314-0095.”

GREEN MAGAZINE® reserves all rights regarding reprints of this publication. Our phone number is (402) 643-6269.

Copyright © 2024 Hain Publishing, Inc. All rights

The

enthusiasts 10 Kevin McMath

Cindy Ladage 14 New Generation of Power— mechanical

Don Hulle 18 John Deere 60 series Benjamin Hain June 2024 • Volume 40 Number 6 Departments 5 Richard’s Column 6 Deere John 24 Tracks & Tales JD snowmobiles: Why and who? Joe Rainville 30 Tip of the month Small engine solid state ignition Dan Brotzman 38 Deere & There 40 The tractor doctor Headaches and carbs, Part 2 Ron O’Neill Each March issue of Green Magazine includes an index of major articles from past issues. The March 2024 issue features the newest index. 43 What’s new—and old? JD Lawn and Leisure line, Part 2 Greg Stephen 46 Scale models 2038R compact tractor Bill Proft 49 Product Review 50 Do you have one? 52 Auction highlight Generation II tractors Eric W. Mickelson 54 Aussie Ken Lots of tractor adventures Ken Nicklas 57 Saw it online Pricy toothpick Adam Smith and Benjamin Hain 59 How our hobby started Gathering of the Green Richard Hain 69 Advertiser index 72 Mr. Thinker ON THE COVER: Don Hulle restored this 3020. See article on page 14. Editor Richard Hain

Editor Carol Hain

Debbie Behne Order Fulfillment Karen Mayo Green Magazine® PO Box 95 Bee, NE 68314-0095 Hours: 8:30 AM to 4 PM M-TH Closed Fridays through Labor Day Phone: 402-643-6269 email: info@greenmagazine.com web: www.greenmagazine.com Check out the sample articles, catalog, ads and other features! NOTE: VISITS TO OUR OFFICE BY APPOINTMENT ONLY! Please call prior to visiting so we can be here to talk with you. At that time we can also give you our location. Thank you! Rates:

$39.95 / 1 year - 12 issues Nebraska residents, add 5.5% sales tax ($42.15) Canada: $59.95 / 1 year - 12 issues Foreign: $69.95 / 1 year - 12 issues First Class/Airmail delivery available: See page 5 Visa/Mastercard/Discover/AmExpress accepted Page 4 June 2024 • Green Magazine

reserved.

monthly publication for John Deere

and his John Deere collection

or mental

Managing

Layout/Design

U.S.:

After taking another look at the Product Review article I wrote, I realized that I forgot to mention portable air tanks, or “bubble tanks” as many of us call them. Yes, I know that they exist, but I have fallen out of like with them. First, you must fill them from the compressor at your shop, carry them to wherever the low tire is, fill the tire, and, maybe if the tire is a large one, do it all over again. The tire inflator written about in the article is ready at a moment’s notice and, if the battery is properly charged, can fill far more tires than a bubble tank.

In April, Carol and I, along with about 40 of our closest friends, visited the site of the 2025 Classic Green Reunion in West Bend, Wisconsin. The facilities are excellent, and I was seriously impressed with the progress the locals have already made with over a year to go until the show. Make plans now to attend; it’s going to be a great show.

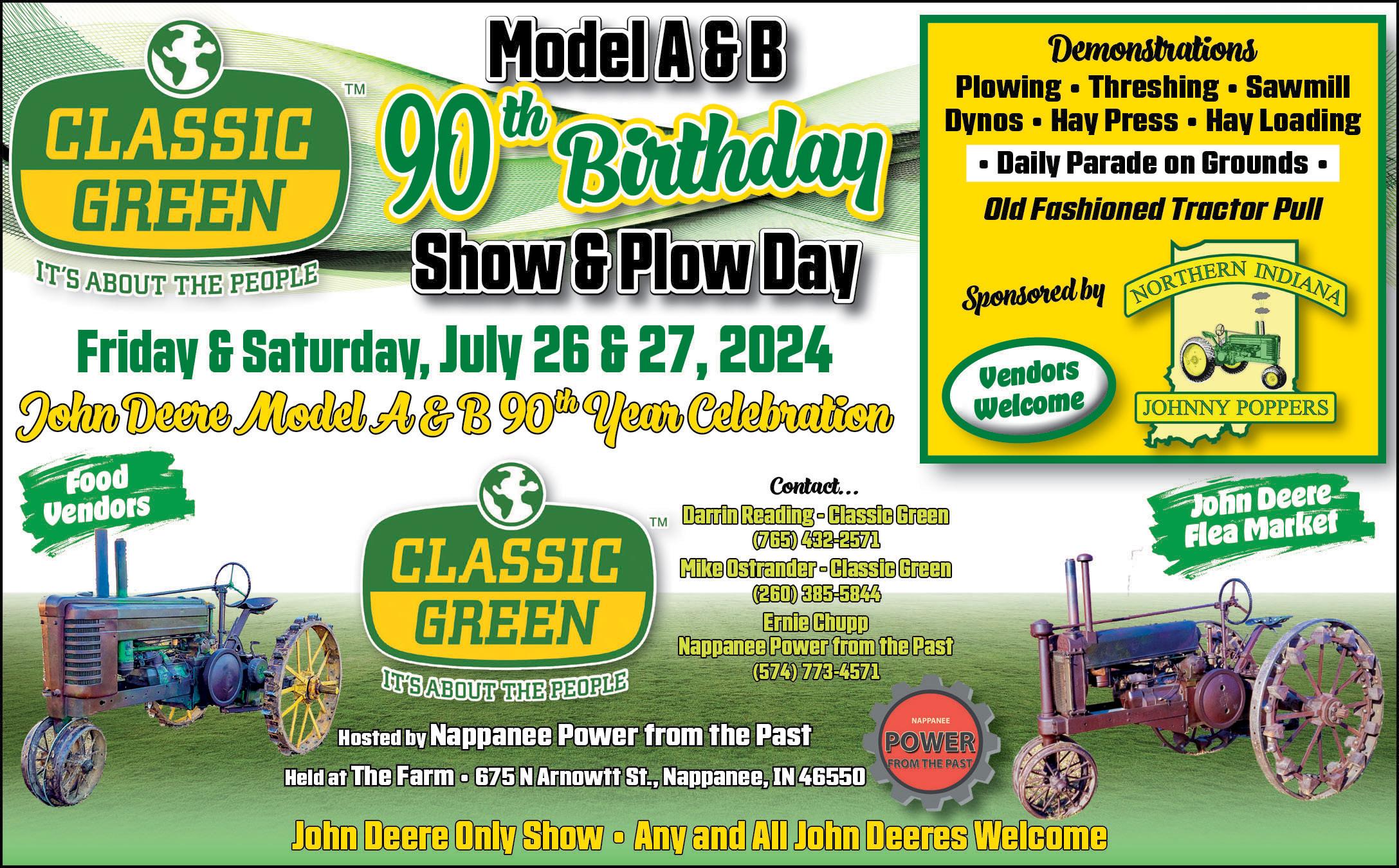

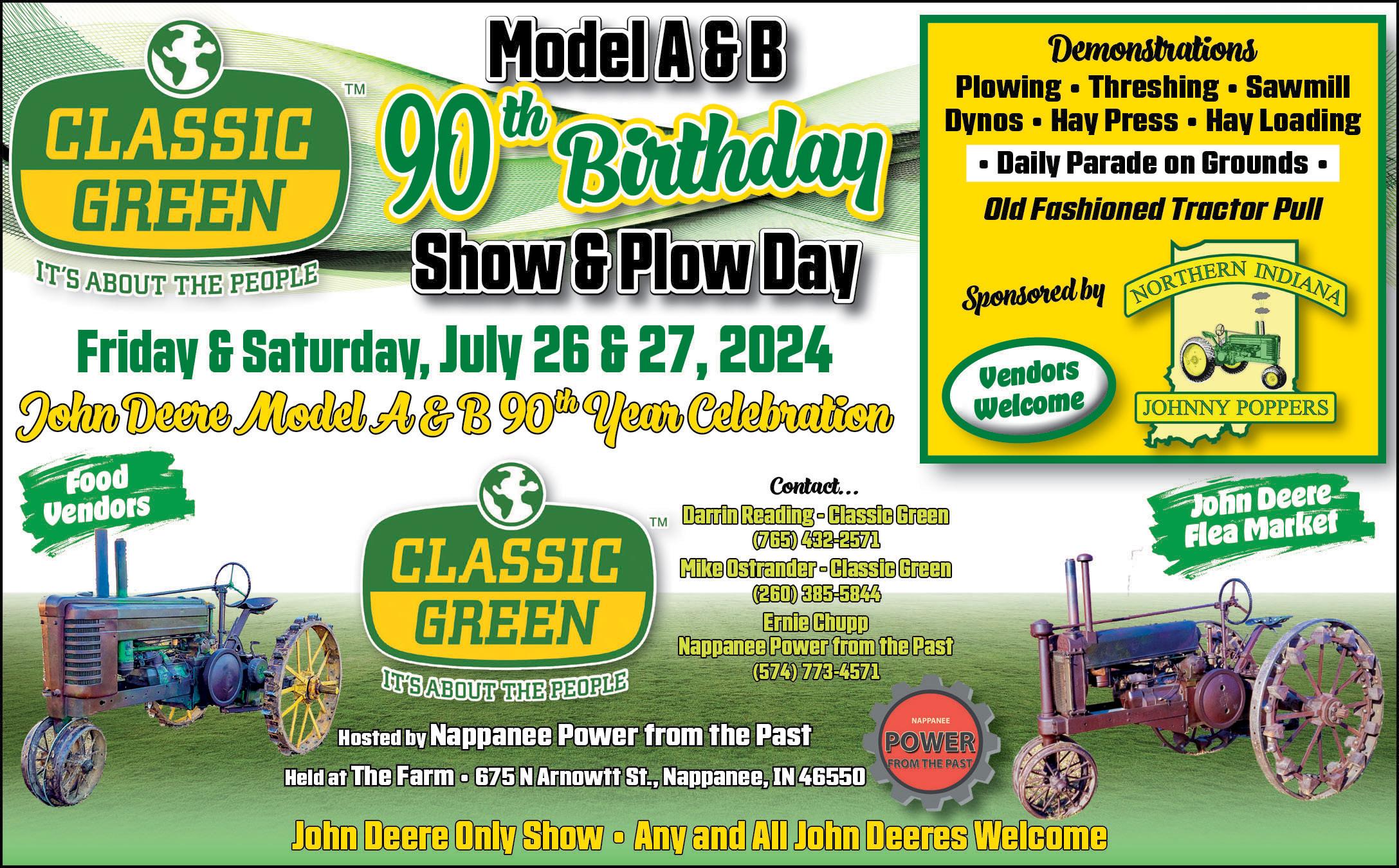

Speaking of shows, there are several on the agenda, though I am not sure which ones I will be attending. The list of “might be’s” include the Eastern National at Lancaster, Ohio; the plow day at Nappanee, Indiana; and Jake Rens’ open house, and the Albert City show, both in Iowa. Those of you who are geographically aware will notice that a couple of those are a fair bit of driving away from southeast Nebraska—hence the hesitance to state that we will definitely attend them all.

Father’s Day will be upon us in a few days, and if you are stumped on what to get Dad this year, how about renewing his subscription to this magazine, or if he isn’t a subscriber, a new subscription? Or how about one of our books? Does he have a copy of Mr. Thinker’s Almanac, the gift that keeps on giving?

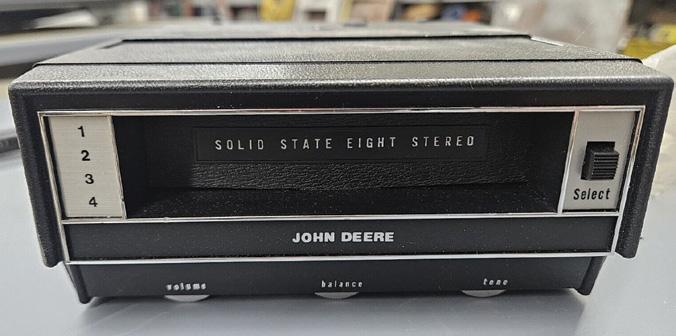

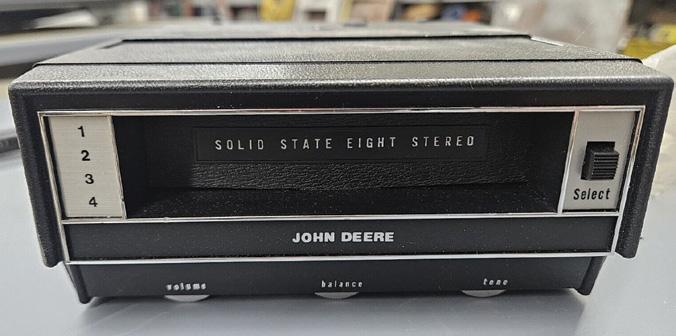

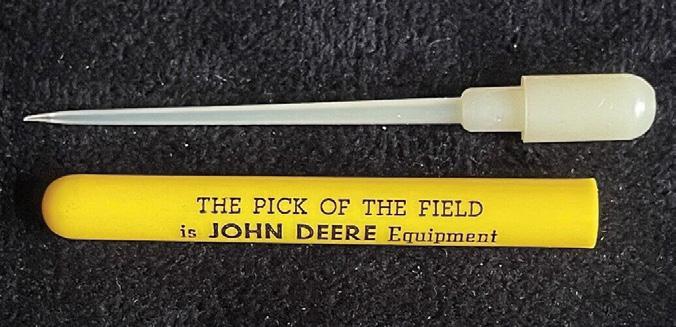

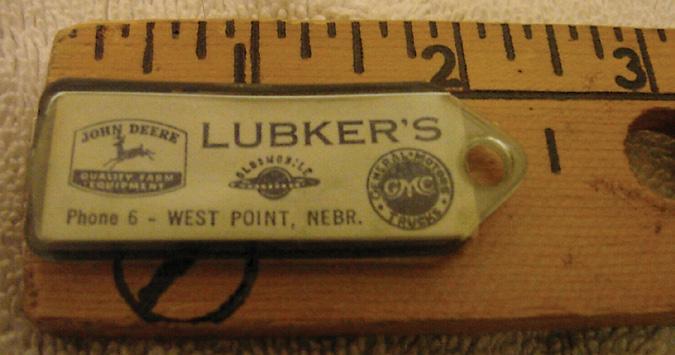

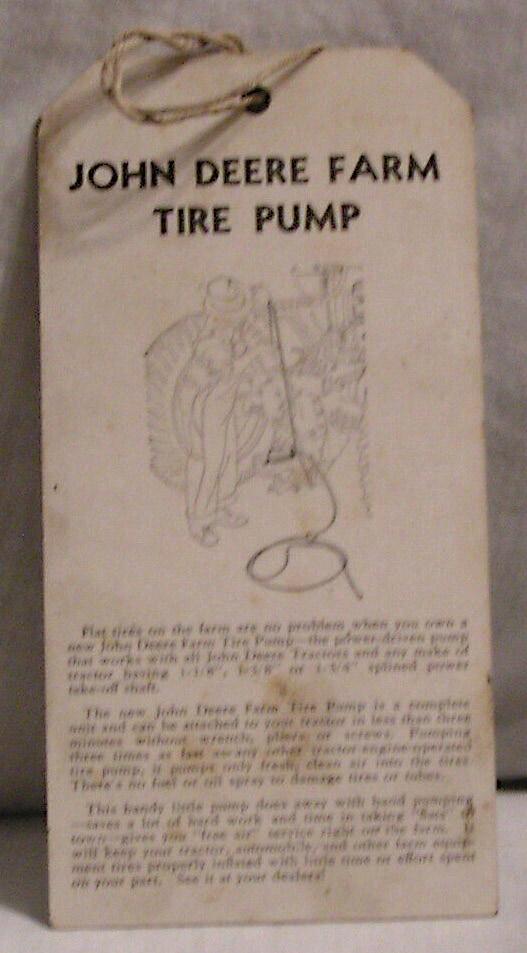

See you next month.

Those who want to call to place orders for magazine

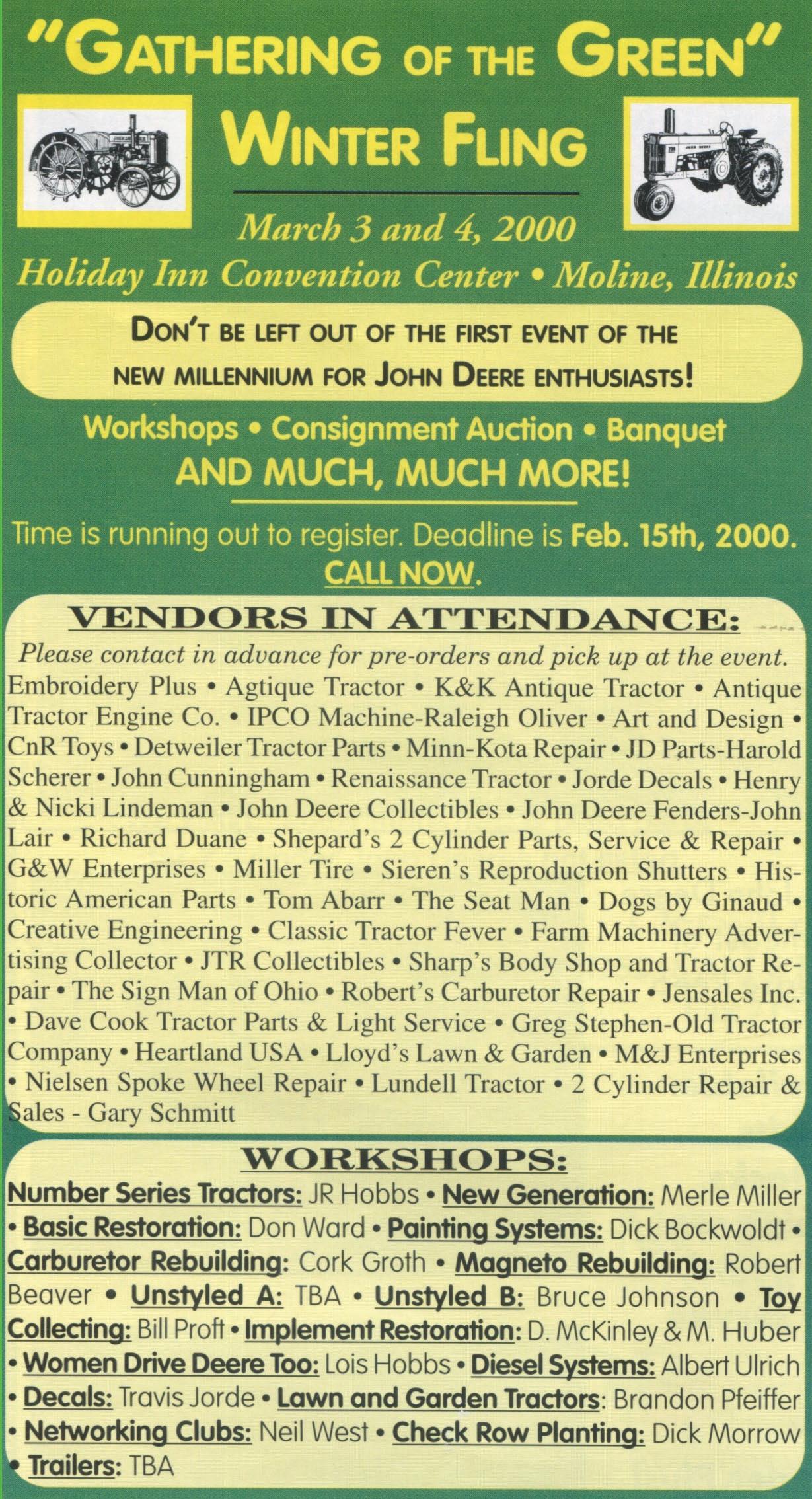

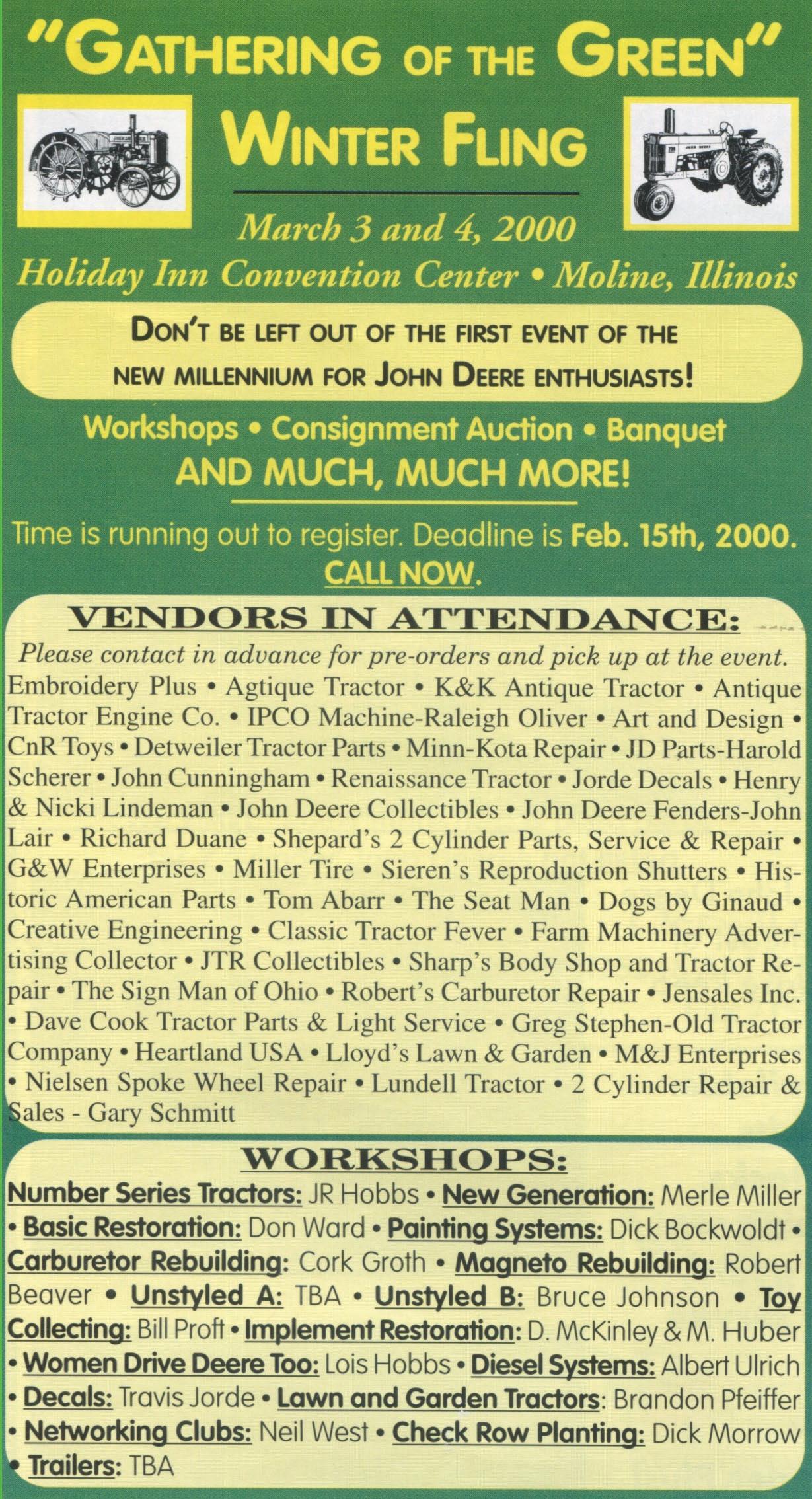

Missing an issue? We mail every issue by the first of the month. Please contact your post office if you suspect a problem with delivery. We will not replace missed issues three or more months past original mail date (four or more months for foreign subscribers) free of charge.

U.S. subscribers: If it is on or after the 20th of the month and you haven’t received your issue, call us for a replacement.

Canadian subscribers: Due to postage costs, we are forced to ask for a $2 postage fee (U.S. funds, please) for re-sending issues that do not arrive by the end of the published month OR we can add an issue onto your subscription for the missed issue.

First Class/Airmail delivery: Call for rates for First Class in the U.S. or Airmail to foreign countries.

Foreign subscribers: We will add an issue onto your subscription OR for a $7 airmail postage fee (U.S. funds), we will resend the missed issue two months after publication date.

Notice: If your address label shows an expiration date of “6/24” above your name, this is your last issue. Renew immediately for continuous service. If your address label reads “7/24,” you have one more issue on your subscription.

Renewal notice: We send postcards to let you know your subscription is about to expire (or has expired). We NEVER call to ask if you would like to renew your subscription. If you

receive such a call, it is most likely from another publication—NOT Green Magazine® for John Deere enthusiasts.

Address Changes: Please send or call with notification of an address change as soon as you know what your new address will be. Periodical mail cannot be forwarded. Green Magazine will not replace issues missed due to late notice of address change. Those missed issues will have to be bought at back issue price. See the back issue listing and prices elsewhere in this issue.

Looking for your photos and stories! Accepted material is subject to such revision as to meet the requirements of this publication. Payment will be made at our current rate within 90 days of publication. Submission of manuscript implies that the material is original and in no way an infringement upon the rights of others. Please send good, clear photographs. If you would like these returned, send us a stamped return envelope to help us get them back to you.

Free Issue Offer: It seems you, our subscribers, are our best form of advertising! More people find out about this publication by “word of mouth” than other forms of advertising. So if you're enjoying Green Magazine®, why not spread the word? Telling others about it can pay benefits. When you tell a friend about Green Magazine® and they subscribe, make sure they tell us who let them know about it. When they do, you will get an issue added to your subscription. These must be new subscribers, not renewals.

Green Magazine announces its spring/summer hours, in effect now through Labor Day : Monday through Thursday 8:30 AM - 4 PM • Friday: CLOSED

renewals, gift items or ads, please note this schedule. Our website, www.greenmagazine.com, is always open for orders and ads. Email info@greenmagazine.com with questions, if needed. Thank you!

subscriptions or

Green Magazine® • June 2024 Page 5

This picture of a 3010 gas with heat houser was taken March 23, 2024. The barn was built in 1896 and the tractor’s serial number is T44680. My story, “31 years with a 3010,” was in the July 2004 issue. When the tractor was working hard with the houser on, the carb would vapor lock and we had to loosen the front of the heat houser to let cool air in.

I’m 90 now so in a month it will be 85 years since I watched them unload our 1938 John Deere “D.” When I pull into my garage with my pickup, it’s right in front of me along with its helper, a 1941 Ford 9N. You have had several stories about the “D.”

Bird Vincent

I am Tristan Zimmerman and I hail from eastern Oklahoma. My brother, Conner, started getting Green Magazine a couple years ago and we enjoy reading it and looking at the pictures. A friend of mine sent me this picture. It comes from Manchester, Oklahoma, a few miles south of the Kansas line.

I know this is not a JD but it was the only one I ever saw hauled this way. I’ve read several stories about custom operators (all in the west) that did this, but they were always Masseys. My friend identified this as a Massey

Page 6 June 2024 • Green Magazine

combine and my boss (I work at a mechanic shop) said the truck is a Chevrolet, an older neighbor said it’s a 1948. I’m sure I don’t know.

The idea was that the truck hauled the combine to the field. When the combine was unloaded, side boards were put on and the truck hauled the grain to the elevator.

So here is my question. Were any of the JDs used like that? In the short time we have been getting Green Magazine, I have not seen any pictures or stories of anything like this. But if you had some in the past, I would like to get hold of the articles somehow.

As you have doubtless already guessed, I don’t know much about JD’s first combines. So, there is probably some real obvious answer that you have pointed out somewhere before.

I also understand that this was a short lived era because farms, combines and trucks grew in size so rapidly. There is one more possibility (I guess) and that it this picture and the stories I’ve read are all someone’s wishful thinking. But hoping it is true …

Tristan Zimmerman, OK

Editor’s Note: Does anyone out there have photos of custom harvest crews with Deere combines mounted this way?

In memory of Dad:

This is my 1937 JD “B.” My dad, Glenn Maresh, resurrected this old tractor from a creek bed in Bellville, Texas when he was 13 years old, shortly after my grandfather (Frank Maresh) died. With the help of a family friend (Wilbert Wendt), Dad got this old “B” running and used it to cut hay with a No. 5 mower. He quite literally assisted my widowed grandmother in putting food on the table at 13 years old.

Years later, when I was about four to five years old (1980ish), Dad restored this tractor and put it in the local county fair parade. Afterward, he would use this tractor to tend his one to three acre garden, among other light duty tasks, every year until he died. In fact, when Dad died in 2014, the old “B” had a New Holland hay rack hooked up.

I hauled this tractor from its home in Bellville, Texas during December 2021 back to my home in Windsor, Virginia where I restored it. These days, the old “B” is used for the local parades and I plan to take it to the county fair this summer. My youngest children (Tenley and Hudson) occasionally take the old “B” down the street to wake up the neighbors.

Dad loved old tractors, especially John Deere, and owned many during his life, including a JD “A,” 60, 450C dozer, Ford 8N, Minneapolis Moline, and many others.

Dad got me hooked on Green Magazine years ago and I look forward to getting a copy each month.

Jason P. Maresh

Send your submission today! We welcome your letters, photos and stories Green Magazine • PO Box 95 • Bee, NE 68314-0095 Email: info@greenmagazine.com Please include your phone number on all submissions Green Magazine® • June 2024 Page 7

8th Annual Antique Tractor and Equipment Show

Reunion of front wheel assist and four wheel drive All makes and models welcome in any condition July 12, 13, 14, 2024 • Cornwell’s Turkeyville USA 18935 15-1/2 Mile Rd., Marshall, MI 49068

300+ tractors and engines on the grounds, tractor pulls, working exhibits, daily parades, plowing demos, children activities, pedal pulls, miniature train rides, onsite restaurant, dinner theater, ice cream parlor, state of the art campground and much more! Presented by the Calhoun County Yesteryear Association www.CalhounCountyYesteryearAssociation.com

8th Annual Antique Tractor and Equipment Show

Show:

Detwiler

Parts Detwiler

Flat

•

brand

We can rebuild cutoffs back to steel High quality / very accurate reproductions We can also replace damaged spokes • The only source of original style rear rims Rear wheels can be custom sized for pullers • Will also rerim cutoffs front and rear ALSO: NEW JD

WHEELS TEXT FOR DETAILS

DETWILER

Email patdetwiler@gmail.com or call numbers listed DETWILER TRACTOR PARTS 206191 State Hwy. 13 • Spencer, WI 54479 30 years in the same location • 9 AM - 5 PM CT Mon - Fri Ph. 715-659-4174 • 715-659-4252 QUALITY NEW & USED PARTS Exhaust Pipes • U.S. Made Radiator Cores • Front Weights • Engine Parts • Manifolds • Mufflers • Airstacks • Battery Boxes • Fenders & Hoods • PTO Shields • Steering Wheels • Flywheels • Grill Screens • Clutch Parts • Grill Guards for D & GP • Airstacks - D & GP We do carb, magneto, tractor repair & restoration Call for FREE DELIVERY of JD 2-cyl fenders, hoods, weights, new and used parts to the Tri-State Gas Engine & Tractor Show, Portland, Indiana on Aug. 21-22-23-24, 2024 Page 8 June 2024 • Green Magazine

Email ccyatractors@gmail.com Call/text 517-795-7824

Tractor

Tractor Parts ReRimming FactoRy Round & R

Spoke WheelS F

Any

tractor

FRONT AND REAR

•

MACHINE Text 715-613-1520 •

Featuring unstyled tractors Restored and original ‘24 “D” • Exhibit A model “D” and other rare and unusual For info: 503-320-8819 Jake Rens & Sons OPEN HOUSE

2024

3452 510th Street

City, Iowa Green Magazine® • June 2024 Page 9

July 4-5-6,

9 AM - 5 PM CDT Location:

Orange

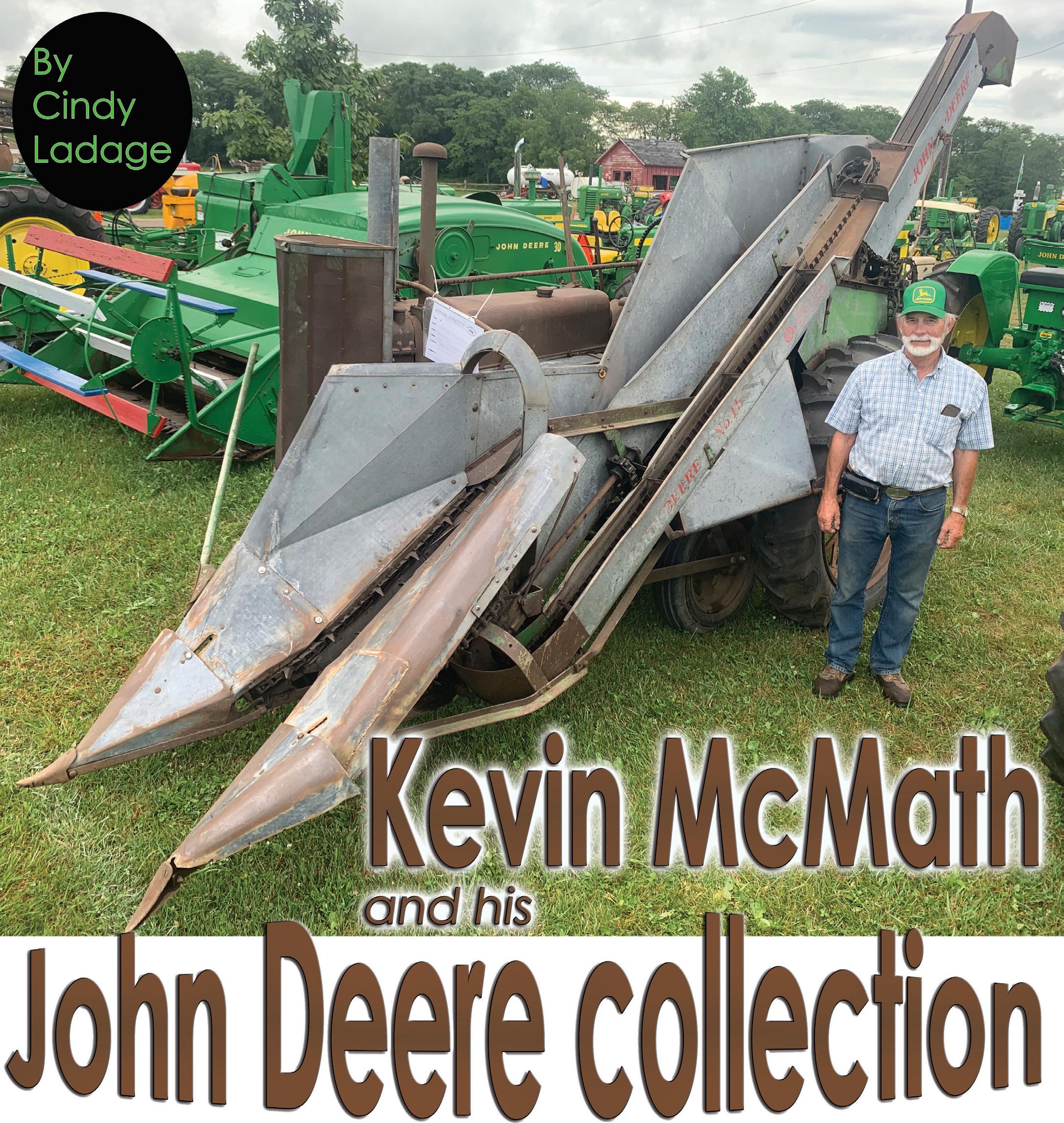

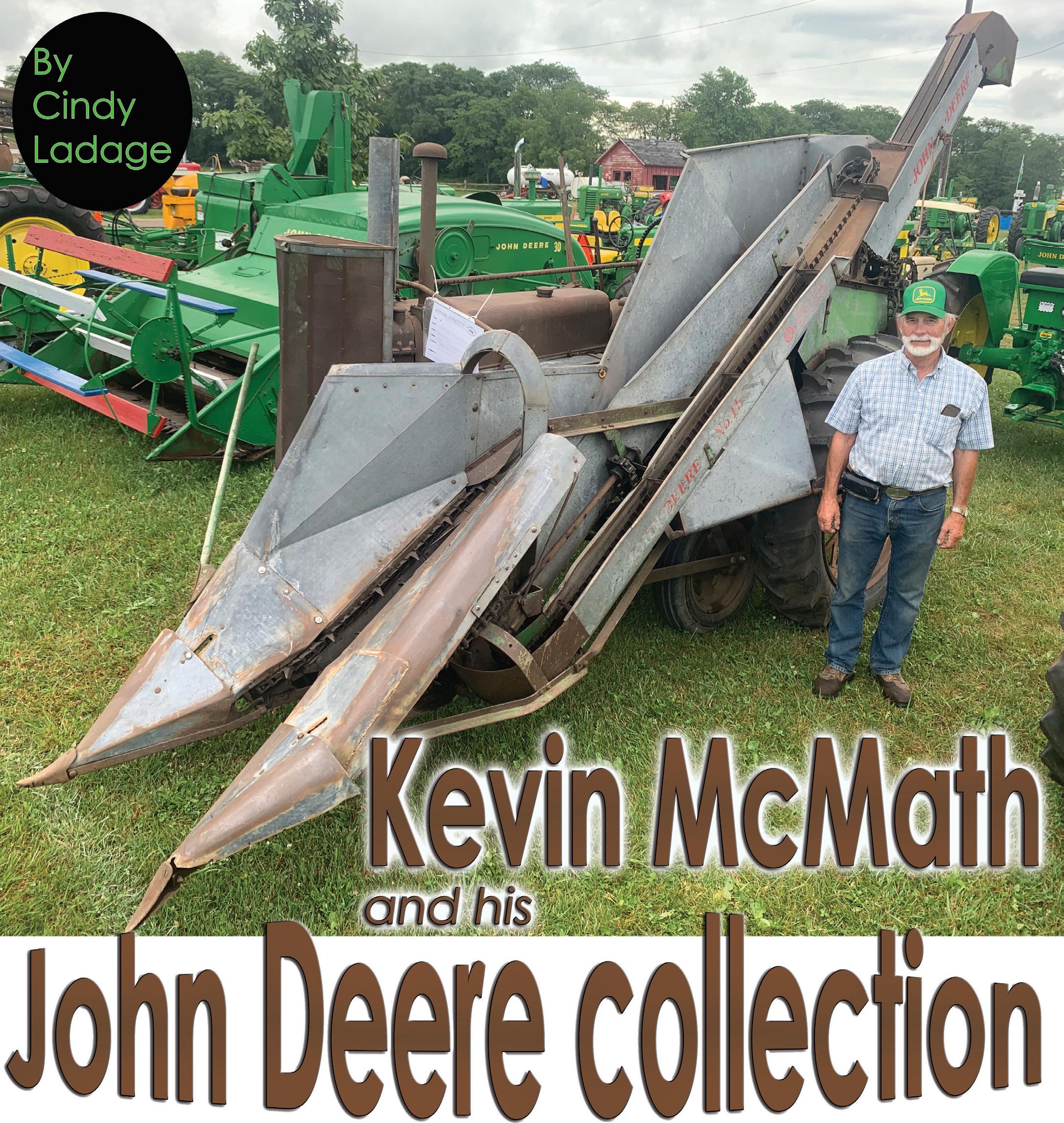

Kevin McMath has an array of antique tractors, but at last year’s Historic Days show in Penfield, Illinois where John Deere was the featured tractor, he brought some JD treasures to share! Kevin, a farmer, is from rural Clinton, Illinois. “My dad started collecting in the 1970s, and I started in the 1980s.”

The first tractor he got wasn’t planned. “I went to a guy’s place, and his uncle said he had a couple John Deere ‘Gs.’ I had never seen a ‘G.’ It was in a fence row with three flat tires. He said, ‘Can I interest you? You can have it if you get it out of here’.”

What is so ironic about this first JD collectible is that the tractor

belonged to the grandpa of Kevin’s neighbor. He ended up trading the tractor with him for a “GM,” which Kevin added, “They didn’t make many.”

This is how Kevin started collecting tractors. “I’m mainly a John Deere man, but also collect many colors and like Graham Bradley,” Kevin said.

Page 10 June 2024 • Green Magazine

Collecting is a family thing for the McMath family. It began with Kevin’s dad, went down to Kevin, and now his son Kade is also collecting. “My son Kade found a tractor on Marketplace, they had just posted it, and he learned that it was only six miles from the house. It is a 1938 John Deere ‘A’.”

While Cade bought the “A,” his very first tractor was a Case 530 he won at Penfield in 2008.

Kevin and his wife Barbara have two sons, Kade and Kolton. Kade’s John Deere “A” recently received a new coat of paint.

At this year’s show in Penfield, Illinois, one of the items Kevin had on

hand was a 1938 John Deere picker. “This came from Kevin Bos, who had a sale. They had an open house, and I went and looked and bid. I got it last spring.”

Kevin put his 1938 picker on a 1938 John Deere “A” with factory flats. “Both the tractor and the picker are original. You can still read the writing on the picker, even on the elevator,” Kevin pointed out.

The picker is in working order too. “Once you get it running, it runs nice. I can still use the belt pulley because the picker’s on the side.”

The picker has a nice safety feature. “There is a shield over chains, and over the muffler and the engine to keep corn shucks from catching on fire. Back then, Kevin said, “They were probably picking corn up into November.”

These shields are something that Kevin added. “I had to put the shields on and make a choke to be like the original book that Kevin Bos gave me.”

The picker also has a cool Super Snoot, which helps keep corn shucks from flying but lets air flow. “It keeps the shucks from clogging up the radiator,” Kevin added. Along with these options, Kevin said that the picker also “has a taller clutch that you almost need to stand up for.”

Besides the picker, Kevin also had a horse drawn disc harrow that also came from Kevin Bos’s sale. This is not just any disc harrow, though: “They said it was never sold, and it was

in the John Deere archives for years.”

This special piece was on display in the feature building. “I also have a No. 4 horse drawn sickle mower I got 10 years ago,” Kevin added.

Kevin thought the special disk harrow deserved a special home, and he donated it to the agricultural museum at Penfield. At the show, Kevin also had a couple John Deere “Ds,” the model which was celebrating its 100 year anniversary. Kevin also had his “E” engine, which was also the featured engine at the show. The “E” engine was hooked up to an ice cream maker!

Kevin has an amazing collection and, thankfully for collectors at Penfield, he brought several beautiful Deere pieces to share!

Green Magazine® • June 2024 Page 11

DECALS

Our vinyl computer cut decals are a Licensed Product of Deere & Company.

• For John Deere tractors & equipment!

• Looks like silk screening.

• Pressure sensitive die cut vinyl.

• No film between the letters...they are on pre-spaced application tape.

REPRODUCED PARTS

• Nameplate for 1010 thru 7520, stamped, raised letters, like original.

• Medallions for styled AR through 830, including industrial tractors. Also medallions for steering wheels, power steering and non power steering.

• Correct size medallion: 320, 420, 520 USA made.

• D306R D manifold gasket.

• F55R early G head gasket.

• Air stacks for A, AR, AOs & B, BR & G unstyled tractors; also styled A, B, G, R, 80, 820.

• Air stack adaptors for 620-630 & 720-730.

• Tool boxes.

• New valves and guides: GP, D, G, A, B.

• Replacement upper and lower water pipe for 2 cyls.

• Flat top fenders 530-730, New Generation.

• Clamshell and also New Gen Hi-Crop fenders.

• BO Lindeman steps, side plates and fenders.

• PTO shields & casting 520-730.

• GP dust shields for brakes and muffler parts.

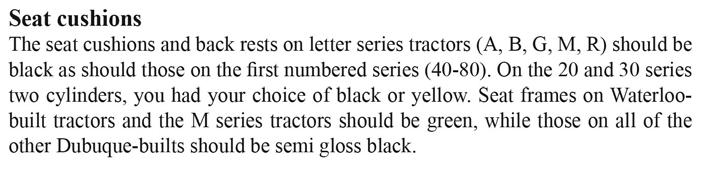

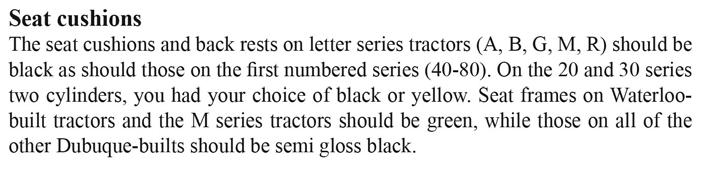

• Grill screens, back and seat cushions, arm rest.

• Spark plug wire looms for A, B, G, BR, BO & AR, AO.

• New radiator cores for John Deere and other tractors that use bolt up type radiators (made in USA).

• Wire hose clamps for unstyled A, B, G, 50-630 & 80-830.

• Reproduction steering wheels A-830 and New Gen.

• Early D & GP fuel tanks.

• We bore and sleeve JD 2 cylinder blocks.

• We rebuild carbs and mags for JD & other tractors.

• We carry new parts for Wico mags, also for pony motors.

• Rebuilt mags and carbs for sale.

These exhaust pipes are made with smooth mandrel bends like the originals

MADE IN USA

We make styled and unstyled A, B, G, GP Top Steer and 50 through 730D.

4 MUFFLERS

D, AO, GP, GPO Spark Arrestor Style D, AO, AOS, BR, BO A, AR, B, G Styled and Unstyled 50 through 730D

50 through 530 horizontal, 60, 620 Orchard Made in USA • Restoration Quality

4 AR28048, AR28049 NAMEPLATE

Stamped, polished aluminum like originals Fits 1010 through early 7020

4 T10551 NAMEPLATE Like original, stamped polished aluminum with raised lettters, flat black background

3-3/8” x 27-3/4” • $140.00 per set plus S/H 4 HYDRAULIC OUTLET PLUG AF3001R, steel w/chain - 2 cylinder AR52623, plastic w/chain - New Gen 4 AR45915 RAIN CAP Fits 3020-4020 side console models

4 CHROME STACKS

Double walled, straight or curved 4 “ NEW” BATTERY TRAY For 4000 model with brackets

SERVICES AVAILABLE

Overseas shipping available - call today! K & K Antique Tractors Kent Kaster 5995 N. 100 W, Shelbyville, IN 46176 Ph. 317-398-9883 Check out our website: www.kkantiquetractors.com Email: info@kkantiquetractors.com

Each

Page 12 June 2024 • Green Magazine

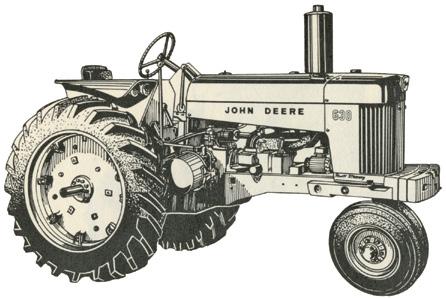

Most people visiting my shop in South Florida ask the same question: “What in Sam Hill are you going to do with that tractor?” They are talking about a 1968 John Deere 3020 diesel wide front row crop Synchro-Range sitting there like a locomotive looking for a train to pull. My answer is always the same. “Nothing.” No physical/mechanical reason but perhaps a mental one.

To help explain, let’s go back to 1968 in Westtown, New York, a rural area in western Orange County. Picture a 160 acre dairy farm milking about 30 Holsteins. I was a 15 year old kid driving a Ferguson 30 spreading manure. Down the road came a neighbor farmer driving a beautiful new John Deere New Generation tractor making a noise much different than I was used to hearing from his tractors. Most guys my age spent their time dreaming about women. I could not stop wishing that one day that owner/operator would be me.

To quote Elton John, “I should have stayed on the farm, I should have listened to my old man.” After high school graduation, I left for college and later started a refrigeration/air conditioning business. Fast forward 49 years, retirement was in order and now was the time to find that New Generation John Deere. The hunt began for a 3020 or 4020 row crop tractor. Facebook Marketplace helped me locate in North Florida the 1968 model 3020 now in the shop. It was sitting in a field with one bucket over the exhaust and one bucket under the load control shaft (Photo 1). The tach was showing 7,540 hours, but the

engine had been rebuilt about 200 hours ago, according to the seller. We agreed upon a purchase price of $5,000 plus $500 for transportation.

The tractor was now on jackstands with disassembly well underway (Photo 2). I took so many pictures that I had to increase my iCloud storage but each was studied carefully during reassembly. The John Deere parts book is outstanding because it includes hardware dimensions, a reverse lookup of the part numbers, and page/diagram numbers to indicate where that part is used. The owner’s manual shows some procedures not found in the service manual. As each part came off, all hardware was saved and tagged no matter what condition it was in. One part missing was the serial number tag. I called the seller, and he was able to provide the number from a note his father had written down many years ago. It must have been correct (or very close) because all parts ordered fit the tractor perfectly.

All tires, wheels, hubs and rims were removed for better access. All sheet metal parts and panels were removed, DA sanded to bare metal, and John Deere Buff Primer Sealer

was applied. The fuel tank location was well marked before removal for later alignment. The entire wide front assembly was removed as one piece for access and primed after the old paint was stripped. A local body shop applied the John Deere Classic green paint mixed eight to one with John Deere paint thinner.

When the fuel tank came back from the body shop, the inside was cleaned and sealed with Red Kote Fuel Tank Liner. Fittings were replaced because access later is very limited. After curing it was leak checked with water. No leaks!

The front wheels and tires were unusable and new ones were ordered. The rear tires were also replaced with new 16.9 by 38 rubber. Wheel hubs, clips, bolts, and rims were sandblasted, primed, and painted John Deere Ag and Turf Yellow mixed 10 to one.

All old paint on the chassis and frame was removed with a laser unit. At $120 per hour, it is not cheap, but the finished result was outstanding because it removes all oil and grease as well as paint. Primer was applied quickly to avoid flash surface rust. After at least 30 hours, John Deere Classic Green paint was used, and it looks like it just left the factory.

Assembly was truly a pleasure. All hardware was cross-checked with the parts manual. Worn or damaged fasteners were ordered and replaced as required. To my surprise, every cap screw, washer, nut, pin, spring, clamp, hose, belt, etc., was in stock. Three hydraulic lines and two fuel lines were also replaced and fit perfectly. I wish car restoration was this easy!

Page 14 June 2024 • Green Magazine

Photo 1

Changes were made to the electrical system. The conversion consisted of a 12 volt DC negative ground with alternator and a single John Deere battery. There is no such thing as a cold start in south Florida. The original wire harness had been altered but was saved to match up wire gauge and color of the new conductors. Since my business involved electrical control systems, all new switches, sending unit, neutral safety switch, oil pressure switch, gauges, tach, warning lights, circuit breakers, battery cables, and wiring were assembled and installed. The wire harness consisted of NAPA brand automotive grade wire and soldered terminals. Pull strings were installed under the operator platform to assist in wiring the rear 12 volt outlet and fender lighting later. As it turned out, original wiring terminations were the Packard 56 series used in many GM cars and trucks, which I had in stock along with the Delphi double crimper. NAPA provided two gauge battery cables custom made to length. The dash was painted using a spray can of GM low gloss black chassis paint (Photo 3).

To eliminate a lengthy “I wish I would have done it this way” list, I decided to purchase any new parts from John Deere (greenpartstore. com) that are not marked NLA in the online parts catalog. Hardware may be the most important, even when the local hardware store has similar items that cost less. One example is the square head rear hub to rim mounting clip bolts. After mounting the hub to the axle, I hung

the rim with a new tire mounted in place with my engine crane. Place the shifter in tow mode and spin the hub until the stem and driving lugs line up. I found the best way to align the rim to the hub is to install clips, bolts, and nuts loosely. Then tighten each nut until three threads are showing. Proceed to tighten each nut one-quarter turn while spinning the assembly by hand. After each round of tightening, tap on the square heads with a five-pound hammer to further help seat them in the clips. Bolts from other vendors would probably not allow this method to work.

Now sitting on four new tires, all new fluids, belt, hoses, filters, water pump, thermostat, gaskets, SCV ISO conversion, front wheel bearings/seals, load control shaft seals it was ready to start (Photo 4). Anxiety flew out the overhead door along with a plume of black smoke as she roared to life once again.

After a trial run around the building to check power steering, brakes, clutch operation, all forward and reverse gears, gauges, tach, and PTO operation, I re-torqued the rear

wheel hub and rim bolts. Rim runout was less than 3/16ths inch. A 0-3000 psi pressure gauge was used to check hydraulic pressure at the remote. Pushing the dash-mounted control lever forward yielded a reading of 2200 psi on the right side. Coolant temperature was by now reading normal and battery voltage measured at the starter solenoid was 14.3 VDC.

The day after engine start-up, my Green Magazine 2024 (1968) wall calendar arrived. I immediately turned to my birth month of February and what did I see but a 3020! Another mental moment.

Submitted by, Don Hulle donhulle@gmail.com

Photo 2

Photo 3

Photo 2

Photo 3

Green Magazine® • June 2024 Page 15

Photo 4

Page 16 June 2024 • Green Magazine

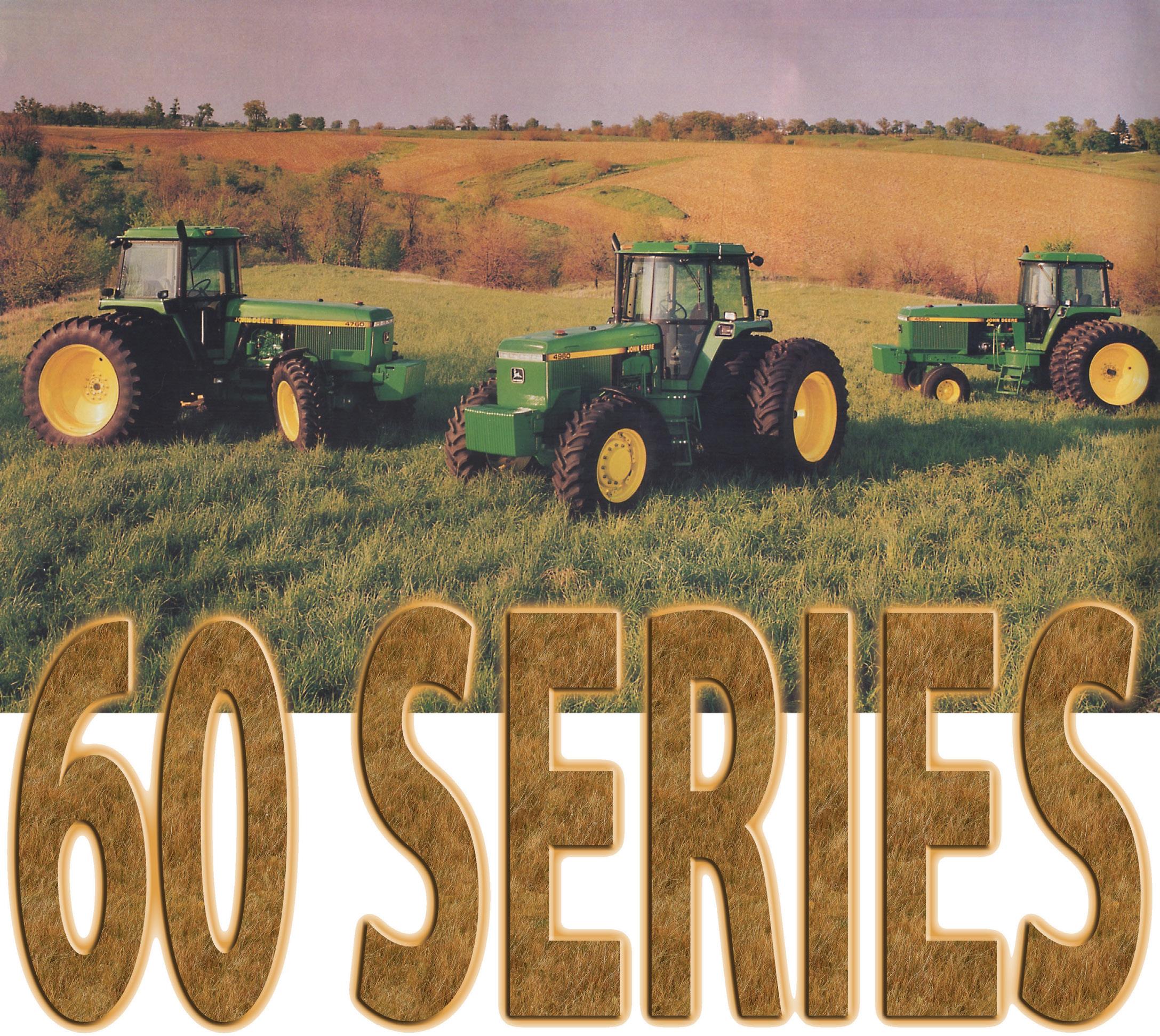

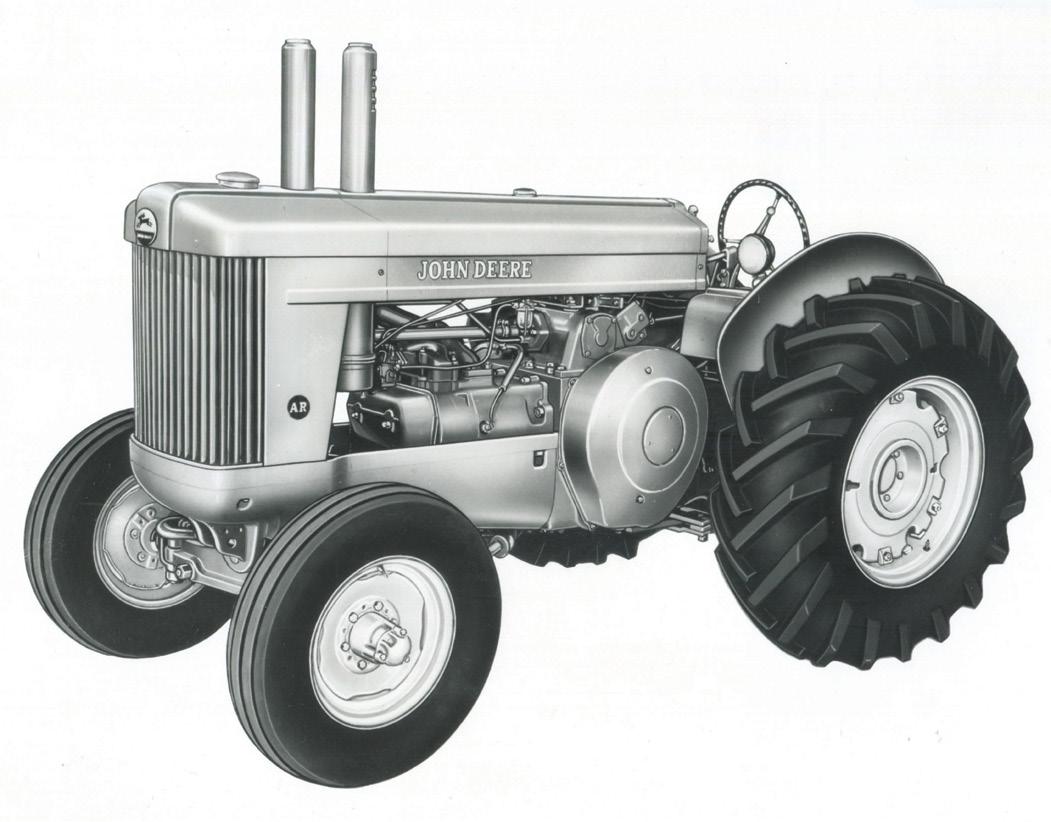

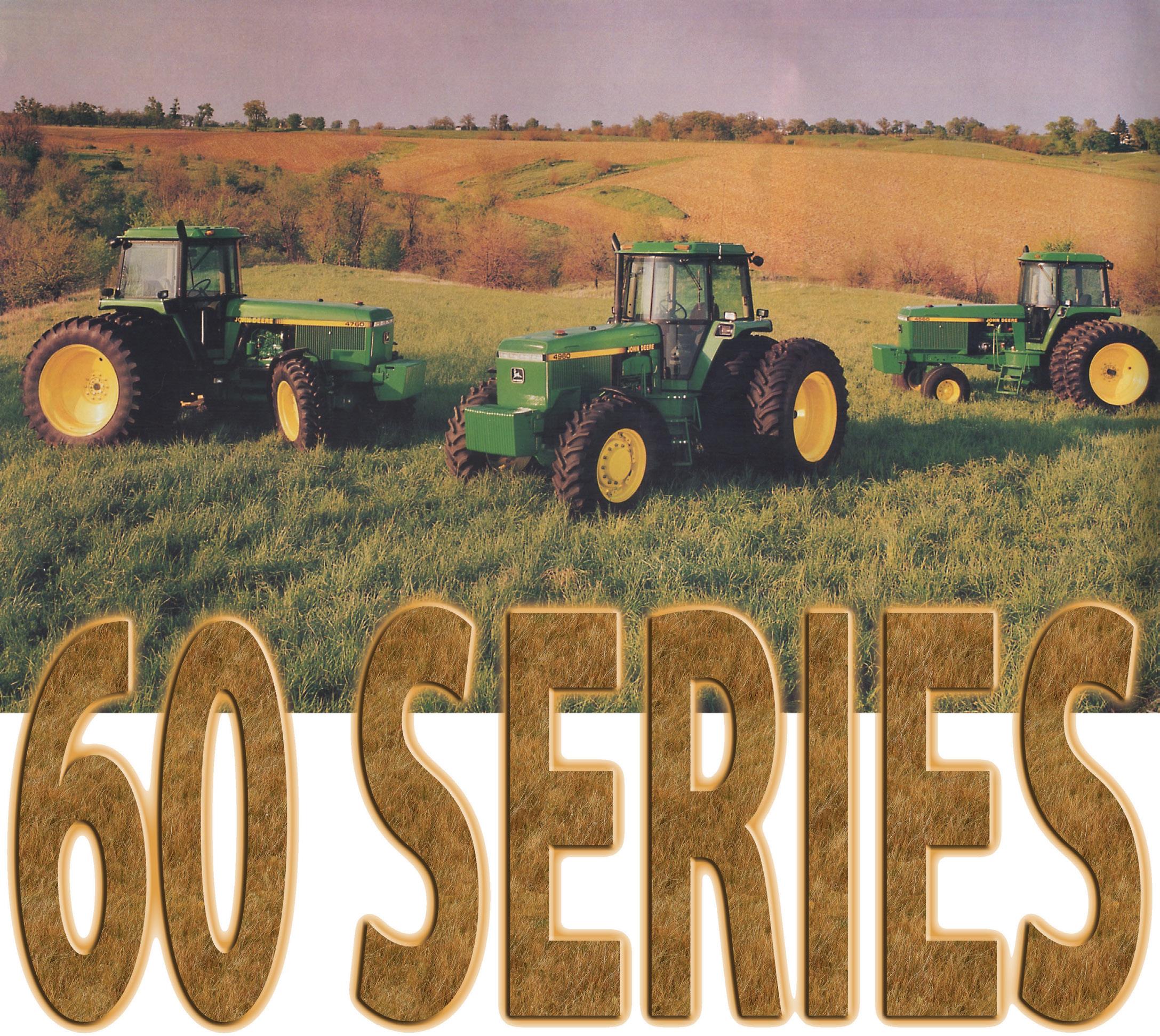

Deere’s Sound-Gard body was an absolute revelation in tractor design. When the Generation II tractors were released with this new concept, it completely changed what many people thought about the farm tractor. Suddenly, these machines could be quiet, comfortable, and a reasonably pleasant place to spend your day. The first Sound-Gard tractor was released in 1973. Deere was still using it almost two decades later when they released their new lineup in 1991, and it was still a top-of-the-line tractor cab.

Page 18 June 2024 • Green Magazine

The newest series comprised the 4560, 4760, and 4960 tractors. These four tractors shared the 7.6 liter engine. All were turbocharged, and the 4760 and 4960 also had an aftercooler. This aftercooler cooled the exhaust gasses so they would not heat the intake air as much as they passed near each other in the turbocharger. This allowed greater power to be made by those engines.

Deere did not make any significant changes to how the engines worked. The basic setup remained the same as it was in the previous generations. It had been working well for over a decade; there was no need yet for major departures. However, Deere did want to change one thing about the engine—the location of the intake and exhaust stacks. The Sound-Gard body was designed to hide these stacks, but they were still visible. Deere hoped they could almost completely eliminate the

operator’s view of these things. The intake was moved under the hood, where air was pulled in through a scoop above the radiator tank. Air was then sent through the air cleaner and air filters before heading into the engine.

On the exhaust side, Deere’s engineers were able to fit the muffler into the right rear of the engine compartment. From there, the exhaust had to be piped downward to go under the lower right window, then turn upward and follow the pillar at the right front of the cab.

A special exhaust pipe was used. It was double-walled with ceramic

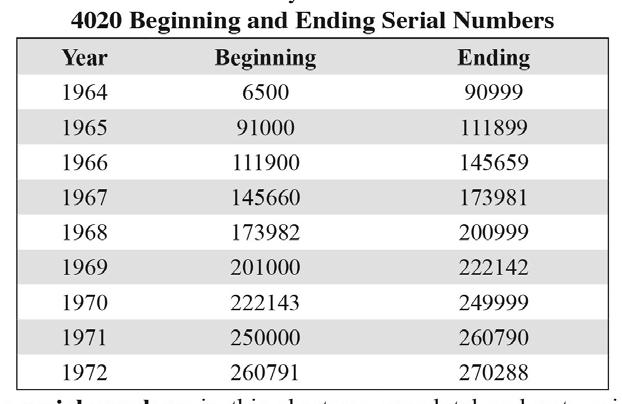

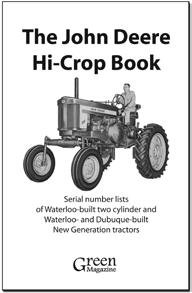

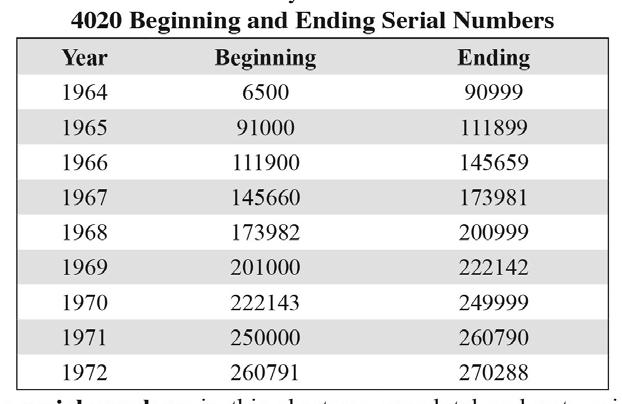

Starting serial numbers for JD 60 series

insulation to reduce noise and heat levels through the sides of the pipe. It was running right next to the cab, after all. After careful planning and consideration like this by Deere’s engineers, it becomes even more baffling why someone would replace this insulated tube with a piece of straight pipe.

The 60 series tractors did away with the fuel shutoff knob. Fuel was now automatically controlled by the ignition switch.

The 7.6 liter engine was connected to one of two transmissions: a 15-speed Power Shift or a 16-speed Quad-Range. Each of these was well proven by this point in time, and it was essentially a matter of buyer preference as to which was equipped on the tractor.

The hydraulic system included many more updates. The pump was a 4.0 cubic inch, variable displacement, eight-piston radial hydraulic pump. It provided the system with pressures of up to 2,530 psi. The pump was connected directly to the tractor’s crankshaft near the front of the engine. Power was ample and ready whenever it was needed.

Deere changed and added several hydraulic controls. A toggle switch was added at the back of the tractor. The switch controlled the

4560 1992 1001 1993 3221 1994 4501 4760 1992 1001 1993 2941 1994 5701 4960 1992 1001 1993 4535 1994 7901

Green Magazine® • June 2024 Page 19

three-point hitch. As anyone who has attached a piece of equipment to the three-point of a tractor can attest, it often involves at least a few trips to the cab to adjust the height of the three-point a few times. This new switch saves the operator from those trips, reducing time, exhaustion, and frustration. Of course, a switch so near the three-point could pose a danger to the operator, so Deere set it up to only move the three-point at very low speeds and to stop as soon as it was released.

There were more new switches inside of the cab for controlling the three-point. At the rear corner of the operator’s panel, behind the three-point lever, was a toggle switch that raised and lowered the three-point automatically to heights preset by the operator. This made the repetitive motion required to lift and lower the three-point at the end rows quick and nearly effortless.

Three more switches were there for the operator to control the three-point. The first allowed the operator to dial in the three-point’s load sensitivity and response

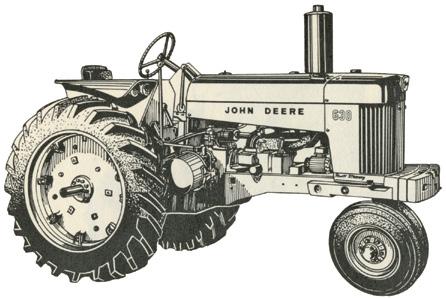

Representing the last of the Sound-Gard tractors, this 4560 sits in a dealer’s lot waiting to go back to work.

speed. The other two controlled how quickly the tractor would raise and lower the implement. Getting the tractor to do precisely what you needed was more possible than ever before.

The 60 series tractors could be ordered with mechanical front wheel drive. This system had been available on Deere’s tractors for decades and had only become better and more popular from one series to the next. MFWD could be engaged with the flip of a rocker switch. It automatically temporarily disengaged whenever a brake pedal was pressed, allowing for tighter turns. It also automatically disengaged when the tractor exceeded nine miles per hour. This was done to save wear and tear on the system and the front tires.

The front wheels in this system utilized a ball-and-socket kingpin joint that was tilted at 13 degrees. This tilted the wheels to the side to “lean into” the tractor’s turn. This helped push the front end of the tractor around through the turn and kept the turning radius of the tractor short, at just over 15 feet.

Deere’s IntelliTrak system made up the dash on these tractors. There were no more analog gauges. Instead, everything was displayed on a pair of screens behind the steering wheel. Engine

Page 20 June 2024 • Green Magazine

speed, PTO speed, engine temperature, fuel level, hour meter including time since the tractor’s last service, ground speed, area worked per hour, total area covered, distance traveled, and wheel slip percentage were all shown on these screens. There was now more information available to the operator than ever before, allowing him to make more informed decisions than he ever could in the past.

Deere put newly designed steps on the 60 series tractors. These steps started lower to the ground, were wider, were farther from the tractor, had a larger platform at the top, and included a couple of handrails for safe ascent and descent. Compared to the steps on older tractors, these were downright spacious. If you were concerned that the larger and lower steps may be in the way when working through a field of growing crops, you need not be. The steps could be rotated 20 degrees to clear crops or other obstacles. This new style of steps became very popular and has often been purchased to fit onto older machines, especially as their operators age.

A more modern set of lights was equipped on the tractor. Square lights in the top of the fenders were protected by louvers. These louvers directed light into the field while protecting the cab windows from glare. More lights could be added to the tractor to give a full 360-degree radius of light around the machine. Combined with the lights at the nose of the tractor and equipment lights at the back, little could escape the operator’s view, even at night.

One simple change to the engine made it much easier (or at least cleaner) to service. The oil filter was now attached to the engine in a vertical position instead of a horizontal one. Now, when removing the old filter or installing one filled with oil, less (or hopefully none) was likely to spill on the engine, frame rail, and the farmer’s boots. The air filter was also reoriented to make it easier to check and clean. It was now in an angled position so that it would slide nicely out from under the hood. Finally, the tractor included remote posts for the electrical system. If you needed a jump or to get battery power to an outside source, these posts were easily accessible for attaching cables. You did not have to pull off the panels that enclosed the tractor’s batteries.

The 60 series tractors were the final evolution of Deere’s Sound-Gard body design. They provided considerable power and efficiency in one of the most reliable packages ever built. While these tractors may have taken advantage of a few more computer-controlled systems and a little more electrical decision-making than previous machines, they were still under the operator’s control. The 60 series tractors were as popular as any of Deere’s previous offerings, and they sold well. These machines are still in demand, and just last year, a used 4960 in good condition was sold at an auction for $134,000. That’s more than Deere sold them for when they were new…a lot more. That shows beyond doubt that these tractors have proven themselves over the years.

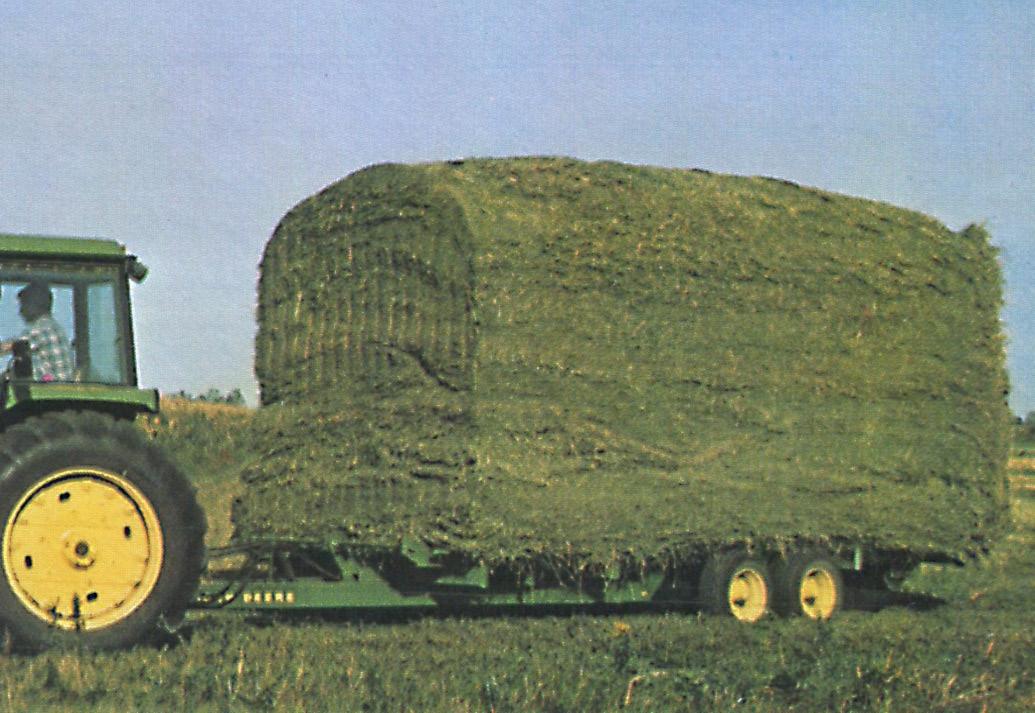

The cover of the 60 series brochure. Notice how the muffler gradually gets lighter and moves to the right side of the tractor.

Green Magazine® • June 2024 Page 21

Green Magazine® • June 2024 Page 23

Even the most diehard John Deere snowmobile collector might find it a bit interesting that a large and notoriously conservative agricultural company like Deere would ever give the turbulent snowmobile market a second look, much less invest heavily into it at a time when there were more than 100 brands of machines marketed for sale at one time or another. For Deere to end up being one of the “Big Four” manufacturers for the 1982 and 1983 model years and the last manufacturer to leave the market in the ’80s says that they gave more than the halfhearted attempt at it. But why would they risk their name and reputation in the fickle recreational market?

Interestingly enough, the Deere snowmobile can thank the 1963 introduction of the 110 lawn tractor for its own introduction of the 400 and 500 in the fall of 1971 for the 1972 model year. Deere was on a growth trajectory back then, and looking for new markets. The successful launch of the 110 out of the Wisconsin Horicon Works was the seed that the new “Consumer Products” division was formed around. Deere added snowblowers, chain saws, trimmers and other home maintenance products while expanding the lawn and garden offerings in an effort to keep their dealerships busy and growing year around.

According to Leonard and Teal, in the book John Deere Snowmobiles” (JDS, available on Amazon or from Barnes and Noble), the concept of Deere’s Consumer Products Division came together at an informal meeting at Deere COE William Hewett’s home on a Friday night in 1960. This meeting was attended by C.R. Carlson, (R. Hewitt’s vice president for Agriculture Equipment Marketing in North America), and Woody Curtis and George French, representing marketing, finance, and manufacturing. The agenda was how to overtake IHC as worldwide market leader. Aside from

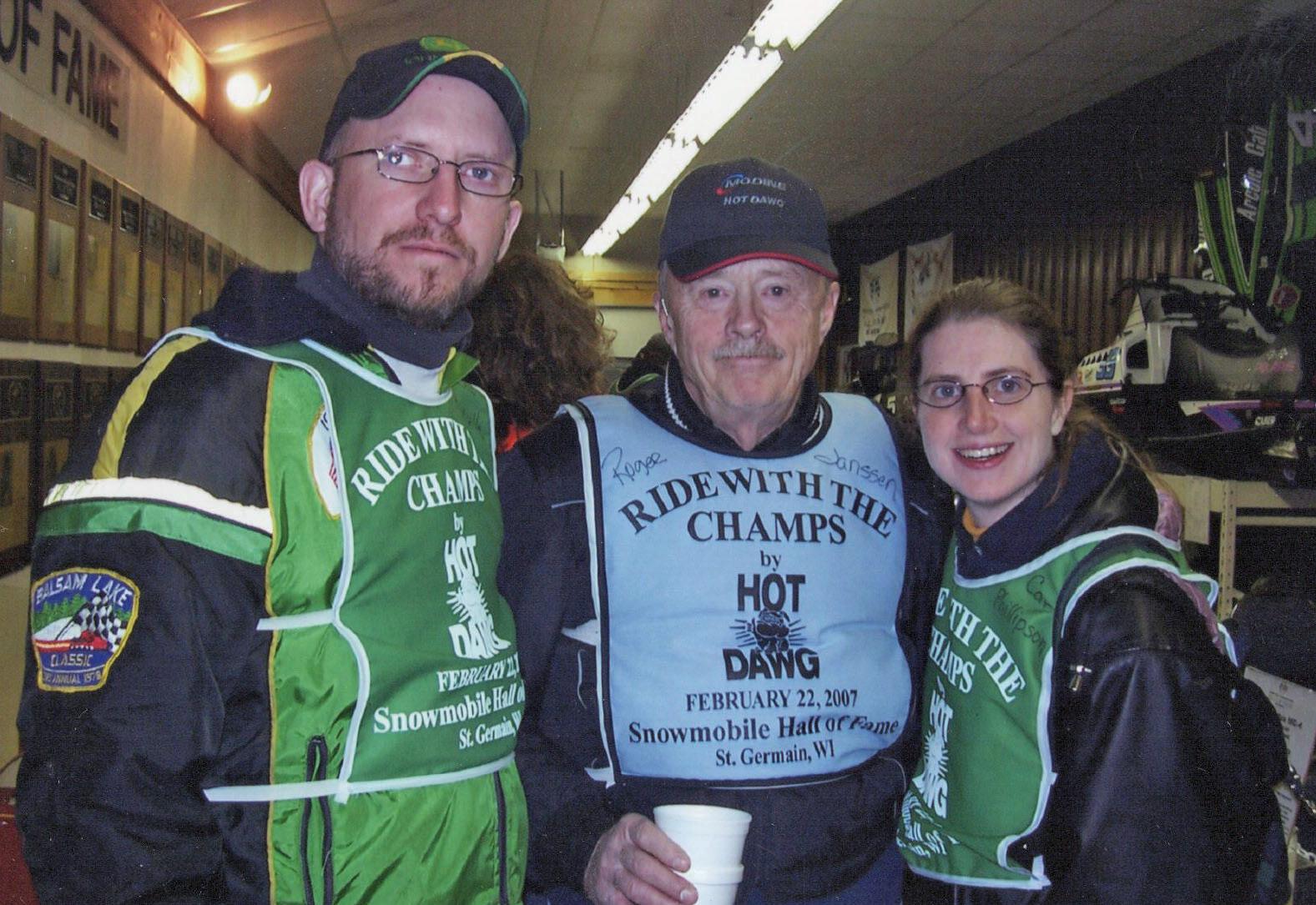

Dick Teal, co-author of the often quoted John Deere Snowmobiles book was at the meet and greet held the day before R.J. Carlson’s HOF induction on Feb. 22, 2007. Mr. Teal shared his notes and photos of his time developing Deere snowmobile clutching and systems.

more aggressive marketing for the new line of ag tractors and equipment, it was also noted that IH had something Deere did not: a garden tractor and “small retain stores in rural towns across North America.” By the end of the meeting, the Deere CEO “made it clear that the next growth business for Deere would be consumer products.”

So how did the snowmobile, a seasonal, recreational product fit into Deere’s new Consumer Products plan? Somewhat surprisingly, in several ways. With strong market acceptance of the first garden tractors being sold at the traditional Deere ag dealerships, “Deere added larger and smaller garden tractors to appeal to all segments of the market”

This Henry Dreyfuss Associates’ concept drawing for a next generation “JDX” machine was real hit at the meet and greet.

Page 24 June 2024 • Green Magazine

according to the JDS book. As garden tractor sales increased, the dealers themselves began to request Deere to make snowmobiles.

The snowmobile market was on a huge growth trajectory in the ’60s, rising from a few thousand units at the beginning of the decade to topping out at over a half a million machines by 1970. Inaccurate growth projections at the time predicted sales hitting one million units by middle of the ’70s. Some snowbelt Deere dealers, like Enn’s Brothers in Manitoba, Canada, for example, were selling other makes of snowmobiles to get in on the action. From the supplier standpoint, many of the lawn and garden component suppliers also made parts for the new snowmobile market, as

Jon Carlson organized the warm up event to honor his father, R.J. Carlson. This gave the sled collectors a great opportunity to meet our heros, like Raymon Kunts is doing here, speaking to Bob Enns and John Orvis. The Deere engineers, technicians and racers were very welcoming of all the questions from us.

I-500 finisher Jeff Larken is shown here with his former 295/s racer, with Robert “R.J.” Carlson and Bob Enns (from left) outside the Hall of Fame. About 30 collector sleds were brought to show our appreciation and to celebrate R.J.’s induction.

JDS states: “…so it was logical for suppliers to urge Deere to get into the business…”

While C.R. Carlson helped sow the seeds of the Consumer Products Division, after his retirement in 1967, his son, R.J. Carlson, became director of marketing at Deere’s world headquarters in Moline by 1968. It was the Carlson family Christmas held at Balsam Lake where fate, and an eager son, stepped in to nudge Deere alone. The late Jon Carlson told this story in person several times to the John Deere snowmobile collectors, and he thankfully repeated it to Ron Leonard and Dick Teal for their book. To quote Jon in John Deere Snowmobiles: “I begged my dad to rent a snowmobile for us to ride [over the Christmas of ’68 holiday]. I had seen the lights at night going past our house and heard the roar of the machines…” The 13-yearold Jon talked his father into renting a bright red Rupp for two hours, but they ended up keeping it for two days instead. “After that, R.J. embraced the opportunity to grow the consumer products business with snowmobiles.”

Now, just because R.J. embraced snowmobiles does not mean it was an easy sell to Deere. According to stories from Jon, his father had a vision for Deere consumer products (CP) dealerships to be market leaders, carrying everything from lawn and garden equipment, outboards, motorcycles, snowmobiles, etc. He wanted to see Deere enter and dominate the recreational markets, not just the home maintenance market. But even before R.J.’s push, personnel from the Horicon Works began to study the snowmobile market under the authority of their manager, Jack Moore, according to JDS

Some of the team at Horicon were already investigating snowmobiles as early as 1967 when engineering manager Martin Berk “recalls that he proposed Deere manufacture snowmobiles at (Product Review Meetings) in 1967 and 1968.” However, Horicon did not receive formal

Your author and then girlfriend, now wife, “Cari Deerest,” post with legendary racer Roger Janssen inside the HOF. I was just thrilled to meet Roger and he was extremely gracious about signing autographs and telling racing stories from his amazing history.

Green Magazine® • June 2024 Page 25

At breakfast the morning before the induction ceremony and the “Ride with the Champs,” my table was honored to have the three Carlsons join us. Jon, Robert and Mrs. Carlson were honored guest and it’s a great memory to have of them.

approval from HQ back in Moline, but “Horicon began to investigate the snowmobile market anyway and to evaluate competitive snowmobiles in 1967.”

During this time, Kohler Engines of Wisconsin was a supplier of garden tractor engines to Deere’s Horicon Works and Kohler also built two and four stroke snowmobile engines that were used in several brands of machines by 1968 such as Arctic Cat and others. According JDS: “Kohler invited Horicon factory personnel to attend a competitive snowmobile evaluation in Winter Park, Colorado, in the winter of ’68.” Martin Berk, Jack Moore and Jack Hoffman were flown out in the Kohler company plane with Kohler management to “observe and participate” in the evaluation. By March of 1968, Jack Hoffman issued a report on the complete cost study of the 1968 Polaris snowmobile, one of the machines Deere purchased for analysis after the trip to Colorado with Kohler. By the fall of 1968, JDS states that “Jack Hoffman and Gerry Buelow were back in Winter Park with the competitive (’69 model year) sleds to determine the design direction for a JD snowmobile.” It’s stated that Jack’s notes don’t say which machines were evaluated, but that one did have a front mounted engine, as compared to the mid-mounted position many

Low snow unfortunately closed the local trails in St. Germain in 2007, so about a dozen of us trailered our machines into Moniqua and rode around the lake chain for the afternoon, making the best out of it. Up to this, this was the largest gathering of vintage sleds at the HOF and the beginning of an annual event.

sleds of the day used. It was after this evaluation trip that “Horicon Works issued an Engineering Order to begin the design of a JD snowmobile.” And so began the office start of the Deere snowmobile project.

Jon Carlson related another story to us collectors at a Hall of Fame function years before his untimely passing about riding Deere’s prototype and competitive machines with Hewitt’s twin daughters. I will quote the passage again from Leonard and Teal’s book: “I took a call at home on Friday afternoon in late 1969 from Bill Hewitt,” Jon said. “Mr. Hewitt asked me to tell my dad we were to meet him Saturday morning at the maintenance building at the company headquarters.” R.J. Carlson, Jon’s father, “had made arrangements for competitive snowmobiles and one Horicon prototype to be shipped to Moline for such a meeting with Hewitt.” The story goes that Mr. Hewitt brought along his twin daughters and R.J. brought

Jon to the meeting, but Mr. Hewitt was not wearing snowmobile gear. Jon was demonstrating machines from Arctic Cat, Polaris, Ski-Doo and Grand Prix while the Hewitt daughters rode machines separately. Jon was reported to be friends with the Hewitt girls, as he had attended their birthday parties previously. Interestingly enough, there was some discussion between the CEO, Mr. Hewitt and R.J. about engine placement, style, and his dislike of white color. “At the end of the demonstration, Hewitt authorized R.J. to develop a comprehensive plan to enter the snowmobile business” quoted the book. Jon was quoted as saying that, “Following this meeting, there was no more indecision. Horicon was authorized to design and manufacture snowmobiles.” It is interesting that Mr. Hewitt never rode one himself, but delegated that role to his daughters. Meanwhile, there are several pictures of R.J. riding and even racing machines himself in the mid ’70s.

Page 26 June 2024 • Green Magazine

After the late 1969 meeting between R.J. Carlson and William Hewitt, Horicon was full speed ahead on planning, designing, and building four different machines for a 1972 introduction, noted back then as “models I, II, III and IV.” Due to scheduling and logistics, only the models II and IV actually made it production as the 400 and 500. The other models had to wait a year or two. A Kohler powered machine, the “Blitz Black” JDX-4, did not make production until 1973, but Deere kept one Kohler powered machine in the line up from 1973-79. So, it seems Kohler inviting Deere on an evaluation trip was not a bad idea.

Unfortunately for Deere, even after being promoted to senior vice president and having a seat on the board of directors, R.J. left Deere in 1979 for United Technologies. By 1982, Deere had stopped further snowmobile development work. After the small production run of ’84 models, Deere announced they sold the snowmobile division and rights to produce Deere machines to Polaris in February of 1984. It seems to many casual observers that the loss of their snowmobile champion was the end of the road for the product. More unfortunately was that Deere missed a large rebound in the market soon after they exited. Fortunately, Deere had Polaris sign a five-year contract to provide parts for the machines, which helped protect the JD faithful with service parts availability. This is probably why, even with Deere sleds being out of production for four decades, parts availability is better than most defunct brands.

On February 22, 2007, R.J. Carlson was inducted in to the Snowmobile Hall of Fame in St. Germain, Wisconsin for his part in bringing John Deere snowmobiles to life and for his efforts to organize factory cross country racing, especially with founding “Enduro

Robert Carlson gave a commanding and thoughtful speech. One thing he said that struck a cord with all the Deere collectors present was how he “was ashamed and embarrassed…” because he had no idea that guys collected, restored and rode Deere snowmobiles like we did. He seemed honestly flattered we showed up from all over the country to show our support and ride our machines together. We are glad he got to see all that before he passed in 2018. Now 17 years later, many of us still make the pilgrimage to St. Germain to ride with our friends each February. We think that Deere is still the fifth largest registered brand in the state of Wisconsin. Thanks for everthing, R.J.

Team Deere” and partly the “ICCSF” racing organization. I was fortunate to have been at the induction with many other JD snowmobile collectors where R.J.’s speech was both interesting and captivating. A few things he mentioned were how not one Deere board member ever rode a John Deere snowmobile. R.J. was a proponent of the “keep your foot in the furrow” mentality, and seemed downright disappointed at the lack of interest shown at the top for something he personally enjoyed. A board member once remarked to him that “the name Liquidator didn’t sound like a nice name” for the new ’76 racing snowmobile. To which R.J. remarked

to the crowd: “If I wanted to give it a nice name, I would have called it Bambi!” We loved that one.

And finally, Lowell Swenson, the COE and majority shareholder of Artic Cat, was looking to sell the company in the late ’70s. R.J. tried to make a deal with him, and took it to the Deere board. R.J. was given full approval from Deere’s board of directors in 1977 to cut a check for Arctic Cat lock, stock and barrel. Unfortunately, R.J. and Lowell could not come to terms on a share price, so the deal never happened. But what if… Joe Rainville is from Fort Worth, Texas. To contact him, send an email: joerainville@hotmail.com

Send a Deere John letter Email: info@greenmagazine.com or send by mail: Green Magazine/Deere John • PO Box 95 • Bee, NE 68314 Green Magazine® • June 2024 Page 27

2-Cylinder Plus Tractor Salvage 2-Cylinder Plus Tractor Salvage A’s, Bs, 420s, 430 thru 4010, Hs & Ms Hay Equipment, Balers, Disk Binders & Hay Bines David and Robin Marlin 417-589-2634 • 417-589-3337 322 Marlin Prairie Dr • Conway, MO 65632 Only 70 miles northeast of Branson, Missouri Obsolete parts - The Old Tractor Company OBSOLETE PARTS CHECK YOUR PART NUMBERS against one of the largest inventories of obsolete and reproduction John Deere parts in the world www.theoldtractorcompany.com The Old Tractor Company • Box 89 • Franktown, CO 80116 TEXT: 303-594-3074 (texting preferred) Ph. 231-846-8243 Page 28 June 2024 • Green Magazine

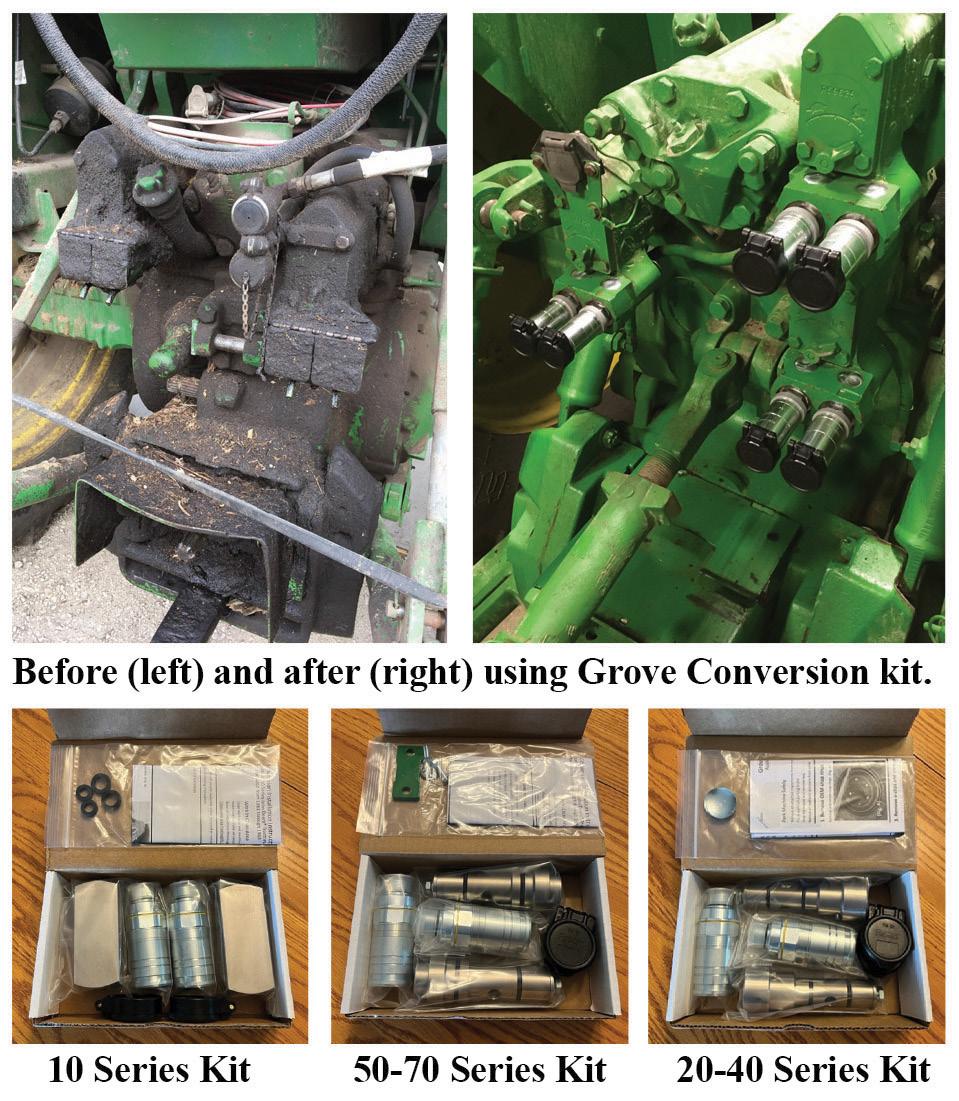

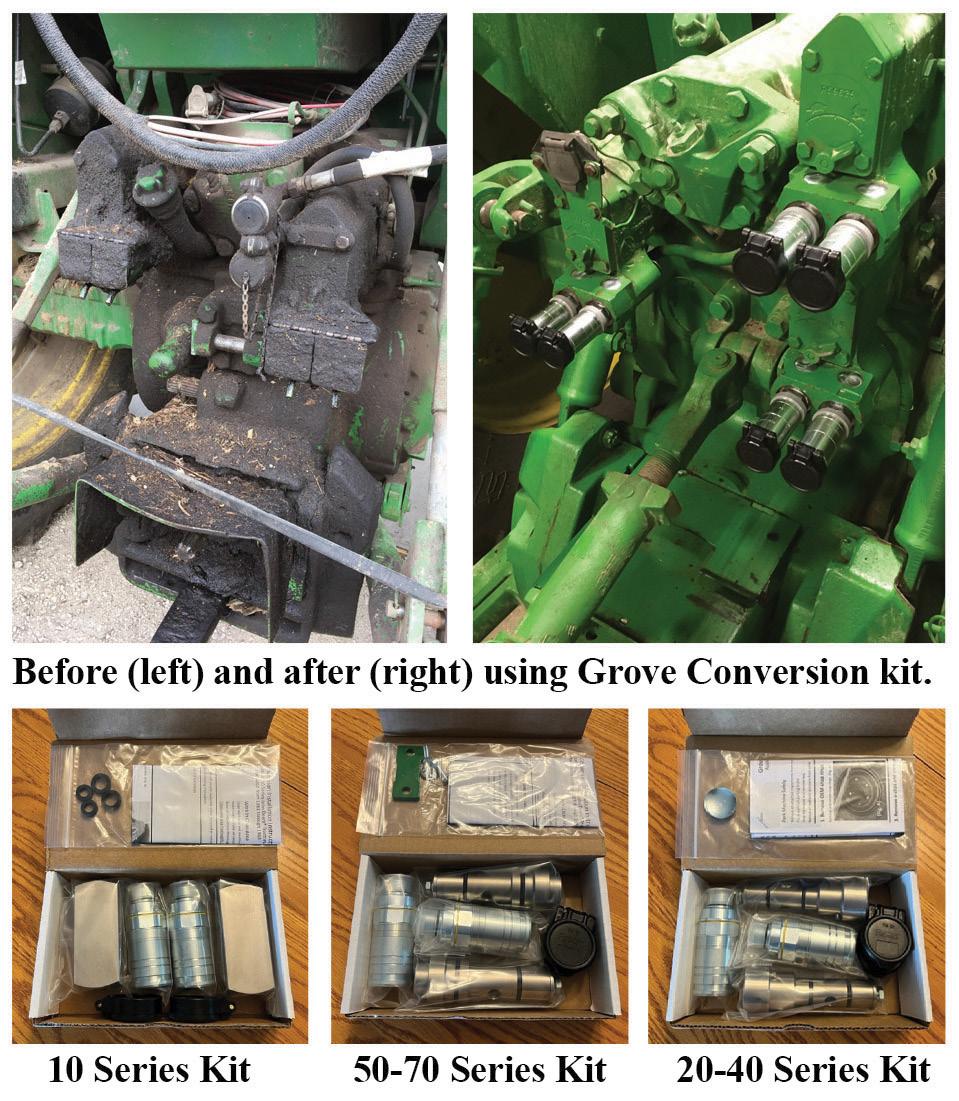

DELUXE CONVERSION KIT NO

MORE DRIPS!

• An easy leak-free ISO conversion kit for John Deere tractors from 1964-1982

• Push-pull design eliminates levers

• Breakaway action includes all seals and dust covers

Remanufactured stepper motor

Fits models:

6000 SRS tractors ‘00, ‘05, ‘10, ‘15 & ‘20 SRS

OEM part #AL181805

$450.00 exchange

$200.00 core value Ph.

$315

GreenLight Products LLC Rebuilt in our facility Green Magazine® • June 2024 Page 29

315-536-3737

Small engine solid state ignition— or tractor magneto on steroids

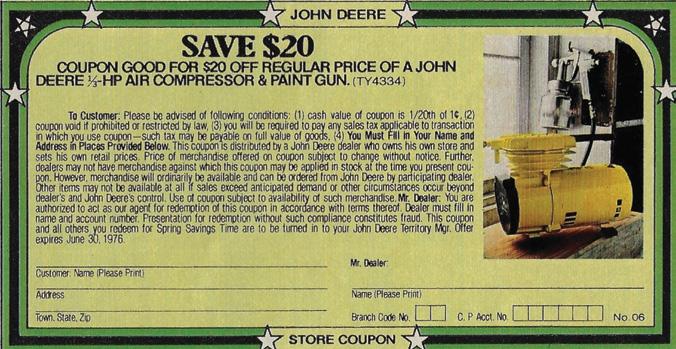

Over the years, John Deere has dabbled in many, many “consumer products” and still offers a huge variety of “consumer products.” Some items, like riding lawn mowers and lawn tractors, still remain in Deere’s offerings, but other items, like John Deere branded chainsaws, leaf blowers, push type mowers, snowmobiles, and garden roto-tillers, were once offered through Deere’s dealerships under

the John Deere brand name, but have faded into history (Photo 1). In recent years, though, this segment of John Deere collectors has been growing by leaps and bounds! In fact, we’ve seen multiple articles here in our fantastic publication of Green Magazine from Jon Rainville regarding John Deere snowmobiles. Unlike farm tractors that were, and are, still built for a long, hard working life, many consumer products are built for a relatively short service life, and therefore fade into history and disappear without hardly leaving a trace. Maybe that’s the mystique of collecting John Deere consumer products because so many examples have ended up in landfills, or on the scrap pile out behind the barn.

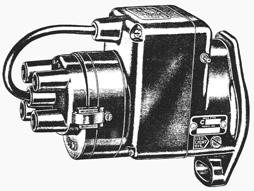

The technology of things like chainsaws, push mowers, garden roto-

tillers, and other consumer products bearing the John Deere name that have faded into history used the old ignition points that came out in the first magnetos used on two-cylinder tractors (Photo 2). Since we are all familiar with the old tried and true ignition points, let’s move up to a technology that has been used for the past 50-plus years—“solid state ignition.” Yup, this “new” technology has been used in consumer products for 50-plus years already.

molded into the high voltage coil out of sight. We can’t physically see the low voltage circuitry in this Stihl coil/ignition module, but it’s there to replace the physical ignition points of a tractor magneto. Let’s just say the solid state circuitry is the old points we were used to, only on “steroids.” It functions the same, only some mechanical components have been replaced by electronics to perform the same job.

In our title “Small engine solid state ignition—or tractor magneto on steroids,” some folks are already asking how these two topics can be related. The small engine, solid state ignition operates using spinning magnets just like the old tractor magnetos. To shut down an old tractor with a magneto, you simply grounded the ignition points to stop the spark. The same thing happens with a small engine solid state ignition; you must ground the low voltage side to stop the spark. A small engine magneto system has every function that an old tractor magneto system has. The only difference with the small engine magneto we are going to deal with this month and an old tractor magneto is that the mechanical low voltage part of the tractor magneto has been replaced by electronics doing the exact same job, and those electronics have been

When Deere corporate decided to abandon consumer items like chainsaws and leaf blowers, Deere recognized the profit potential for their dealerships and approached a well known company that had established itself as a quality manufacturer of these products called Stihl USA. Deere recommended that their dealers carry the Stihl brand of small power tools when Deere stopped offering many of these power tools under their own brand name, and the majority of dealers did follow Deere’s recommendation. That brings us to our tip for this month on a Stihl leaf blower that wasn’t running very well, and finally wouldn’t start at all. Some folks might be asking what a leaf blower has to do with our world of green tractors and equipment. Well, nothing really other than your local John Deere dealer more than likely sells them, and most of us use these products on our farms.

Photo 1

Page 30 June 2024 • Green Magazine

Photo 2

If you’ve ever cleaned your shop floor with a leaf blower, you’ll not be in a hurry to ever pick up a broom again. Cleaning the shop floor with a leaf blower is not only faster, it does a much better job of getting rid of the fine dust that collects on all of our shop floors versus a broom.

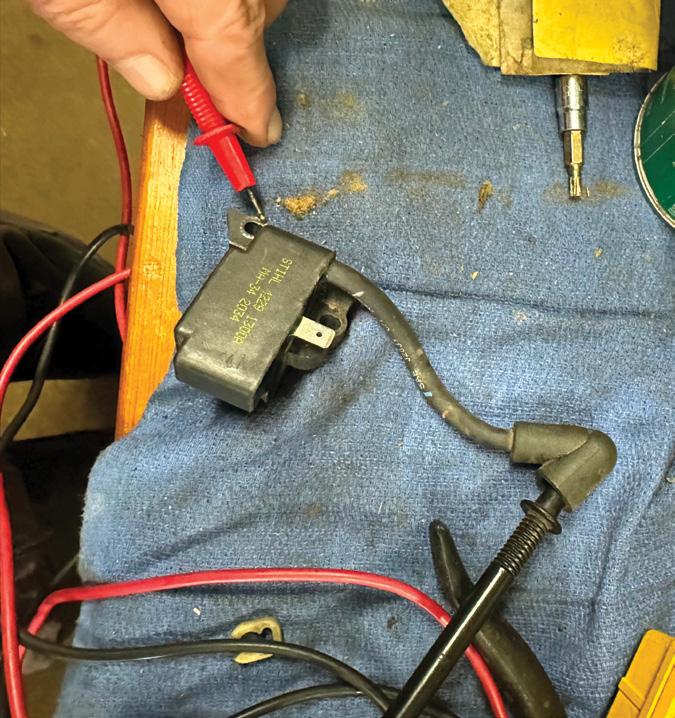

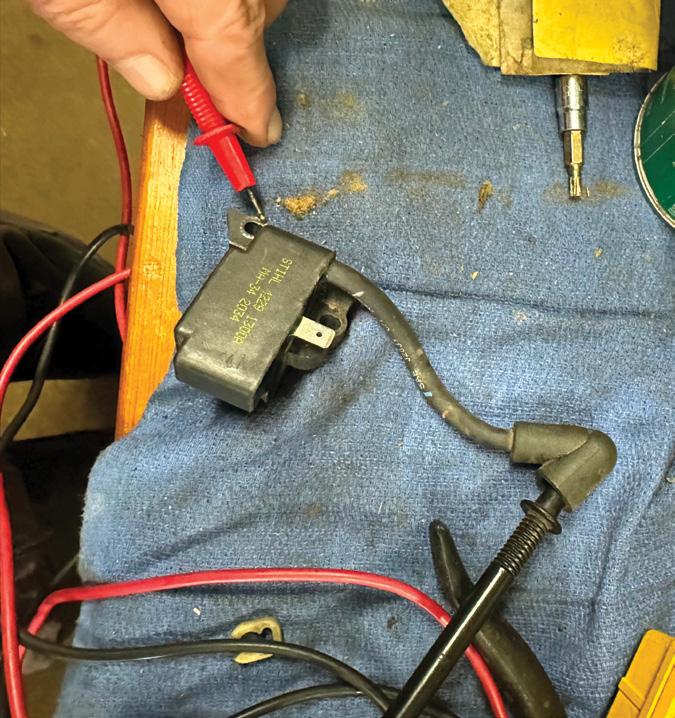

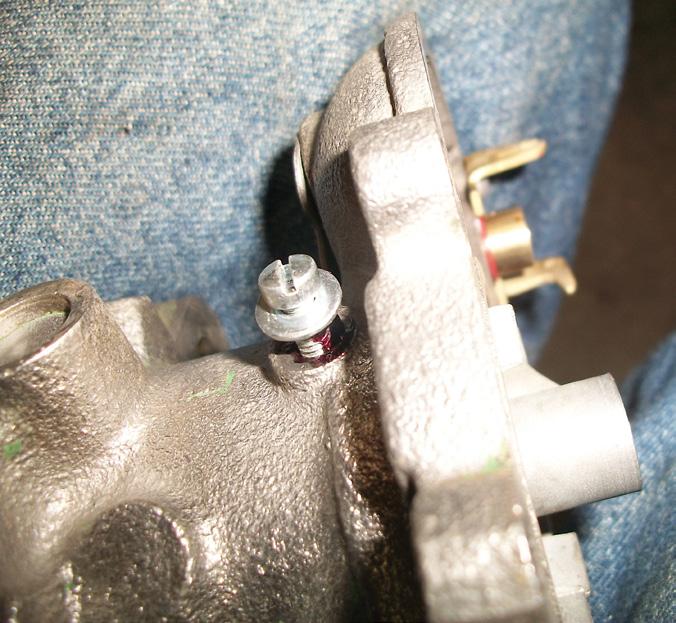

This Stihl leaf blower started showing symtoms of a problem when it wouldn’t reach governed RPM, and it was “four-cycling” instead of firing every piston stroke like it should. Then finally it would not run at all. A simple test for spark at the spark plug revealed there was no spark. Our first step is to remove the recoil starting housing because we need to do a couple ohm meter checks to dial into where our problem is (Photo 3). You need to pay attention to what style screw comes out of each location because three screws are a machine thread, and one screw is a course thread for threading into plastic (Photo 4). All the screw heads for this little project are going to be a number 25 Torx head (Photo 5). With the recoil starter housing off, this will expose the flywheel, and ignition module (Photo 6). After detaching the two small wires from the ignition module, and removing the spark plug wire from the spark plug, we can remove the two

screws that attach the module to the engine, and remove the module (Photo 7). Some of us may want to call this the coil, which technically it is, but Stihl calls it a module because there is solid state electronics molded into this coil that replaces the old style ignition points many of us are familiar with inside a tractor magneto.

Now it’s time to figure out where our problem is. The first thing we’ll do is verify the ignition switch is working correctly. For this, we’ll touch the terminal of each of the two small wires that go up to the ignition switch in the leaf blower handle. With our multimeter on

the ohms scale and the ignition switch in the “O,” position we should have a complete circuit indicated by zero, or very few ohms of resistance (Photo 8). This is the “off” position of the ignition switch because it grounds the ignition module so no spark is created. In the “–“ position (run position) of the ignition switch, we should have an open circuit, or no connection between the wires as indicated on our multimeter as unmeasurable ohms (Photo 9). This confirms our ignition switch is working correctly.

Next we’ll check the ignition module with our multimeter. Place one multimeter lead on the spade terminal of the module, and insert the second meter lead in the spark plug wire cap until it contacts the metal

Photo 3 • Photo 4, below

Photo 8 • Photo 9, below

Photo 6 • Photo 7, below

Photo 5, below

Photo 3 • Photo 4, below

Photo 8 • Photo 9, below

Photo 6 • Photo 7, below

Photo 5, below

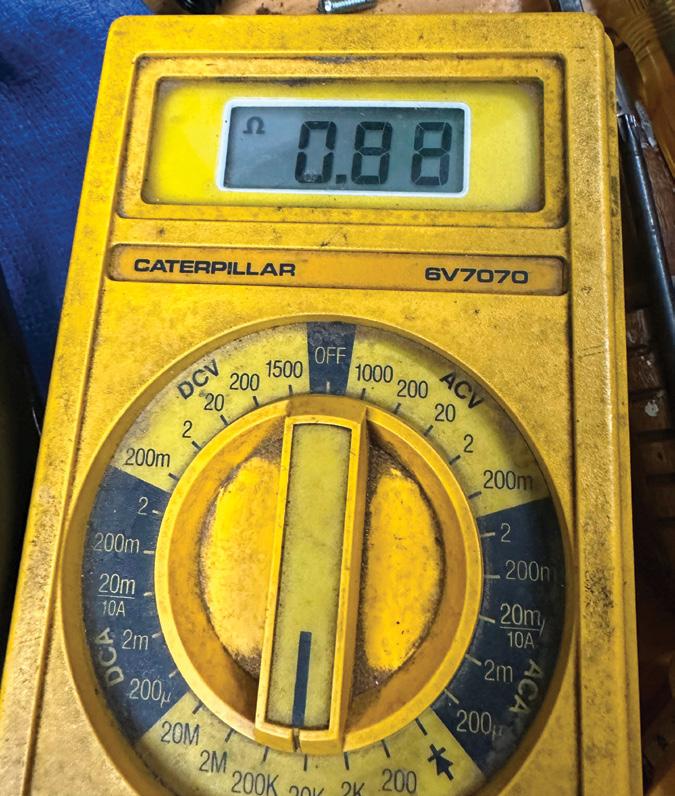

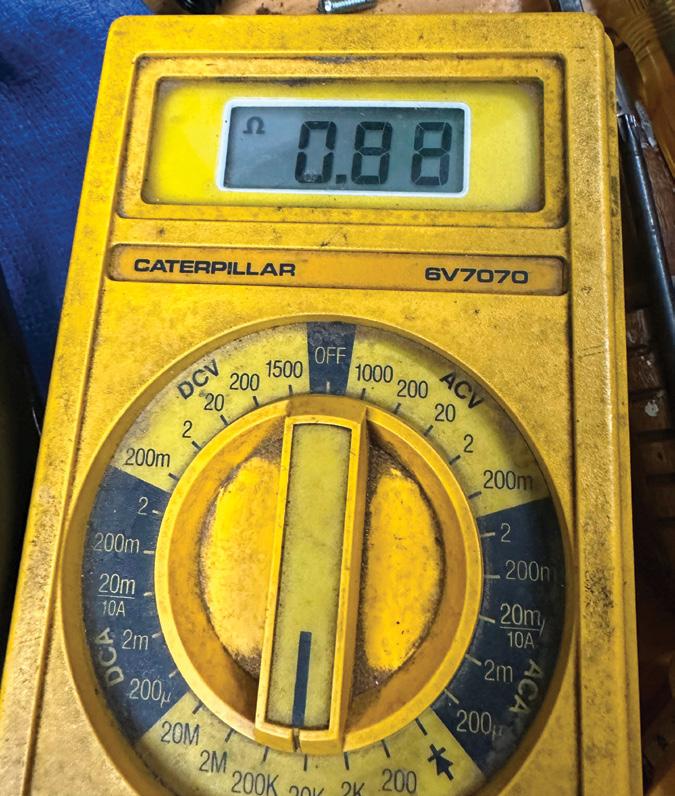

terminal inside. You should have an ohm reading between 2,500 ohms and 5,000 ohms. In this case, our meter tells us there is an open circuit in the module because the resistance is so high, the meter can’t read any type of connection (Photo 10). This tells us the module is no good on the low voltage side of the module, and the reason we couldn’t get a spark. There is another ohm reading you can perform to check the high voltage side of the module and that is to leave the one meter lead in the spark plug wire touching the terminal inside the plug wire cap, and place the second lead on the metal bar of the module (Photo 11). This reading was 880 ohms on this module, telling us the high voltage side of the coil is good (Photo 12). An open circuit on either the low voltage, or high voltage side of the module will result in a “no spark” condition.

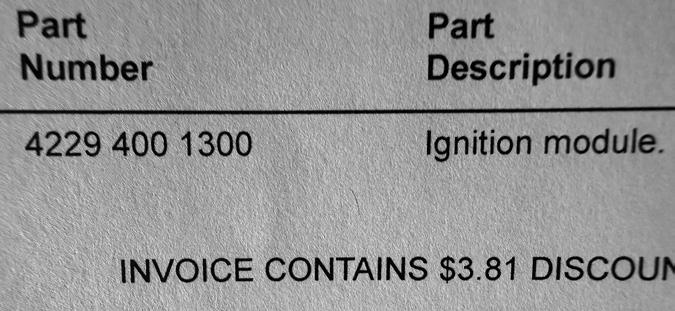

Since our multimeter confirmed the ignition module was not good, a new module was ordered (Photo

13). A quick multimeter check of the new module tells us the low voltage side of the module has 3,480 ohms of resistance, which falls right in the range specified of 2,500 to 5,000 ohms of resistance (Photo 14). I thought the price of the new module was actually quite reasonable through our local Deere dealer at $32 for a genuine Stihl module. This leaf blower is between 15 to 18 years old so a person should be happy with that many years of service. It would be a miracle if a standard set of conventional ignition points lasted this long, so I would say we can chalk up a win for the solid state circuitry versus old style ignition points.

Before we install the new module, we need to look at the flywheel.

There is a counter balance without any magnets (Photo 15), and the two magnets embedded in the flywheel opposite of the counter balance (Photo 16). I like to rotate the flywheel so the counter balance will be in line with the module when we install the module. Set the module in place and install the two retaining screws. Remember the small ground spade terminal goes on the top screw as a ground for the ignition switch. Do not tighten the screws at this time. Push the module up as far as it can go toward the spark plug and lightly snug down the two retaining screws. Next we’ll rotate the flywheel so the magnets are under each metal pole (or bar) of the module and place a .010 inch brass feeler gauge between the module poles (bars) and the flywheel magnets (Photo 17). It’s hard to see the feeler gauge in that small gap, but it’s there. The reason

Photo 15 • Photo 16, below

Photo 14, below

Photo 12 • Photo 13, below

Photo 10 • Photo 11, below

Photo 15 • Photo 16, below

Photo 14, below

Photo 12 • Photo 13, below

Photo 10 • Photo 11, below

I like using a brass feeler gauge is so it doesn’t stick to the magnets. Metal feeler gauges stick to the magnets and just make the task a little more difficult. Some folks like the fact that the steel feeler gauges stick to the magnets, but I don’t—guess it’s just a personal preference. The service manual calls for an air gap between the module and flywheel magnets of .008 inch to .012 inch, so I just use a .010 inch feeler gauge. With the feeler gauge in place, loosen the two retaining screws and push the module down onto the feeler gauge, then tighten the two screws (Photo 18). With the module screws tightened, we can remove the feeler gauge (Photo 19). It’s always a good idea to rotate the flywheel at least one complete revolution to verify the module does not touch any part of the flywheel.

Attaching the two ignition switch wires to the module is a no-

brainer because the two spade terminals are different sizes. Imagine that, the engineers made it so we can’t attach the wires incorrectly! Remember to reattach the plastic retaining clip that holds the two ignition wires to the spark plug wire and push the spark plug wire onto the spark plug (Photo 20). Last but not least is to reinstall the recoil starter housing with the three machine bolts and one plastic thread screw (Photo 21). Once you start working on the Stihl line of power tools, you will appreciate how simple they are, how many parts are common between different power tools, how easy it is to locate parts, and how long Stihl keeps common parts in production (Photo 22).

While we didn’t work on a John Deere branded item, we did work on an item offered through your local Deere dealer, and a brand of tool many of us have on our farms. To many of us, the idea of a solid state ignition system may seem like “new technology” because the old ignition points are gone, but the reality is this technology is well over 50 years old. The old breaker points began disappearing in the 1970s in favor of the solid state ignition modules on automotive vehicles, and the small engine industry followed right along. Deere never offered a breakerless, solid state ignition system on their tractors and continued with the old style ignition points right up to the time Deere dropped the option of a gasoline engine in their 30 series ag tractors. Do you find it odd that Deere kept the old style ignition points into the mid 1970s, yet used fiber optic cables to back light the gauges on their ag tractors in the early 1970s?

Contact Dan Brotzman at W14729 Meisner Rd., Tigerton, WI 54486; phone 715-535-2595; email danb4230hc@yahoo.com

Photo 17 • Photo 18, below

Photo 19 • Photo 20, below

Photo 17 • Photo 18, below

Photo 19 • Photo 20, below

Green Magazine® • June 2024 Page 33

Photo 21 • Photo 22, below

Book: Mr. Thinker’s John Deere Almanac, Fourth Edition Mr. Thinker’s John Deere Almanac 4th Edition! All of the same great information you’ve found in earlier editions Order MRT4 $19.95 U.S. • $28.00 Canada (US funds only) $36.00 Foreign (US funds only) Green Magazine PO Box 95 • Bee, NE 68314-0095 Ph. 402-643-6269 www.GreenMagazine.com info@greenmagazine.com Prices include postage Visa, Mastercard, Discover, AmExp accepted Nebraska residents, add 5.5% sales tax ORDER TODAY! A book makes a great gift— for yourself or someone else! McDonald Carb & Ignition McDonald Carb & Ignition 1001 Commerce Rd. • Jefferson, GA 30549 Ph. 706-367-4179 info@mcdonaldcarb.com Guaranteed Quality Parts and Service Virtually All Makes and Models Stock or Modified Buy, Sell, Trade Check us out on the web for info and online ordering: www.mcdonaldcarb.com 1) Call 402-643-6269 with credit card in hand 2) Go online: www.greenmagazine.com 3) Send a check by mail with the subscriber’s name and address to Green Magazine, PO Box 95, Bee, NE 68314-0095 For more info on subscription rates, see page 4 Questions? Call 402-643-6269 for great customer service! Page 34 June 2024 • Green Magazine

Wiring Harnesses - Cables - Switches

We build restoration quality wiring harnesses to fit these John Deere models and their variations:

AG Models: A, B, D, G, GM, L, LA, M, R, 40, 50, 60, 70,80, 320, 420, 430, 435, 440, 520, 530, 620, 630, 720, 730, 820 2 cyl, 820 3 cyl, 830 2 cyl, 830 3 cyl, 920, 1010, 1020, 1520, 1830, 2010, 2020, 2030, 2040, 2040, 2130, 2240, 2350, 2355, 2440, 2520, 2550, 2555, 2630, 2640, 2840, 2855, 2950, 2955, 3010, 3020, 3150, 3255, 4000, 4010, 4020, 4030, 4040, 4050, 4250, 4230, 4240, 4430, 4440, 4455 Mexico, 4630, 4640, 4840, 5010, 5020, 6030, 7020, 7520, 8010, 8020, 8430, 8630, 8440, 8640, 8560, 8760, 8960, 8770

Harnesses available for other models & brands

See website for complete listing

Due to numerous variations, call to order Shipping/handling not included Visa, MC & Discover accepted

Prices subject to change without notice

Circuit protection kits for Diesel tractors

From $35 (2 cylinder)

From $60 (New Gen)

Industrial Models: Al, Bl, DI, 300, 301, 302, 302A, 310A, 350, 350B, 350C, 380, 400, 400 Scraper, 400B, 400C, 401, 410, 410C, 410D, 440I, 450, 4508, 450C, 450E, 455E, 480B, 500, 500A, 500C, 510D, 540E, 544A, 548E, 600, 7E Scraper, 700, 700A, 710D, 750, 755, 840, 1010C, 1010W, 2010C, 2010W, 3010I, 4010I AG Machinery: 45, 55, 4710, 5730, 5830

Lawn and Garden: Commercial mowers: 38”, 48”, 54”, GX1320, 727 Z-Trak, 60, 70, 110, 112, 120, 140, 200, 208, 210, 212, 216, 245, 300, 312, 314, 316, 318, 285, 320, 322, 330, 332, 420 Compact Tractor: 790, 850 Snowmobiles: 340 Cyclone We also carry: Starters, Regulators, Generators, Alternators, Relays, Coils, Lights, Alternator Brackets, Pulleys

alternator conversion harnesses

We

Call for a FREE 100 PAGE CATALOG! CALL: 716-937-6618 • WORLDWIDE SHIPPING International phone: 001-716-937-6618 Email: agriserv@rochester.rr.com 13899 North Road, Alden, New York 14004 www.wiringharnesses.com Burrey Carburetor Repair • We rebuild ALL John Deere models • We make carburetor parts no longer available from Deere • Single & dual induction bottom repairs

To personally drop off your carburetor, please call for an appointment • WE STOCK carburetors—rebuilt and ready to install on your tractor • ALL carburetors carry a 1 year guarantee • ALSO BUY, SELL & TRADE CARBURETORS Burrey Carburetor Repair Kurt & Mindy Bleke • 5026 Maples Road • Fort Wayne, IN 46816 Tollfree: 800-287-7390 Phone/Fax: 260-447-6347 Website: www.burreycarb.com Email: info@burreycarb.com 9 AM to 6 PM EST M-F • Saturday 9 - 12 Questions? Call or email It’s back! Little Green The Tractor Magazine for Kids US $24.00 / 6 issues per year Canada $32.00 (US funds) Foreign $36.00 (US funds) Plus 7% Indiana state sales tax Send payment with the subscriber’s name and address to: Mail: 1041 S Williamsport Rd, Williamsport IN 47993 Call: 765-585-9555 Email: littlegreenmag@gmail.com Website: www.littlegreenmag.com Subscribe today! Green Magazine® • June 2024 Page 35

make

•

Lind Bros Tractor and Parts, LLC

• New aftermarket, rebuilt and used parts for JD A, B , D, G, H, M, R, 320, 330, 40, 420, 430, 50, 520, 530, 60, 620, 630, 70, 720, 730, 80, 820, 830, 3010 3020, 4010, 4020.

• Used parts include: weights, 3-pts., toplinks, dual hydraulics, float ride seats, clutch parts, hubs, transmission gears, sheet metal, tires and rims, 720-730 ES parts, all-fuel manifolds, brake parts, square and round tube WFEs, heads, blocks and PTO parts.

• New parts include: manifolds, battery boxes, carburetor kits, air stacks, mufflers, grill screens, radiator cores, lights and overhaul kits.

• Rebuilt parts include: Taper-Loc flywheels, electric start conversion kits, float ride seats, starters, carburetors, cleaned and lined gas tanks. Also have crack checked heads and blocks.

Lind Bros Tractors and Parts, LLC 830 Saint Peter’s Church Road SE • Corydon, IN 47112 sales@lindbros.com • www.lindbros.com 812-952-3010 • 833-952-3010 Call or email today! Orders can also be placed online. Page 36 June 2024 • Green Magazine

This 820 is owned by Ben Miller from Middlefield, Ohio.

Right: Steve Manternach sent us this photo of his 620 and “BW” disc.

This 820 is owned by Ben Miller from Middlefield, Ohio.

Right: Steve Manternach sent us this photo of his 620 and “BW” disc.

Page 38 June 2024 • Green Magazine

Right: Rich Erwin of Laurel, Nebraska makes ice cream for the grandkids with this rig.

Left: Sam Harris of Buffalo Valley, Tennessee owns this 1969 John Deere 2520 in its original paint, which was purchased in 2001.

Below: Kevin Uphoff of Cottage Grove, Wisconsin is shown on his 3010 with his grandson, Braxton Uphoff, at the 2023 Stoughton, Wisconsin Junior Fair. A stop at the fair was part of the 15th Annual Utica Benefit Antique Tractor Ride.

Left: Here’s a photo from an old atrazine ad showing a “G” pulling a sprayer. It had to be the least fuel efficient spraying job in history.

Green Magazine® • June 2024 Page 39

Part 2

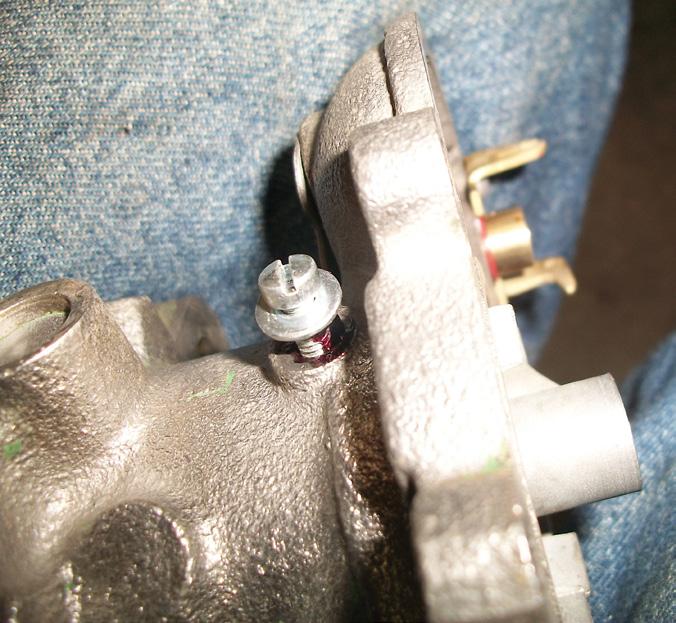

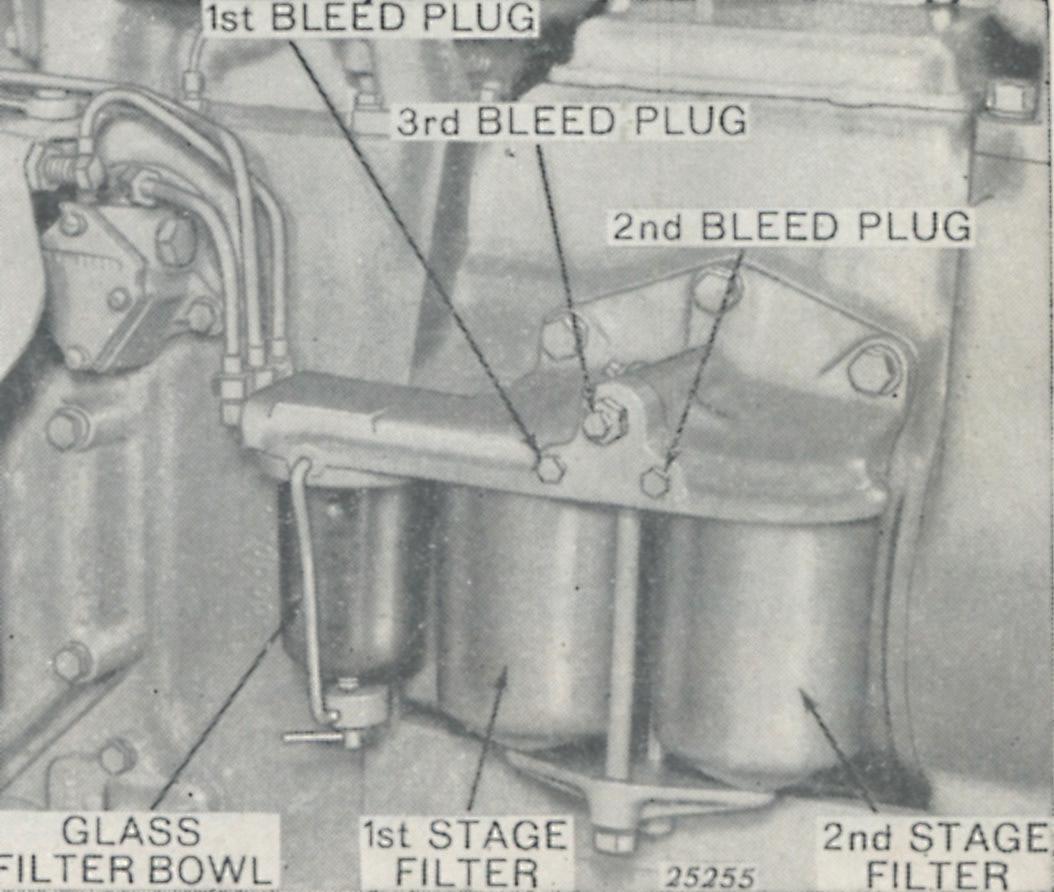

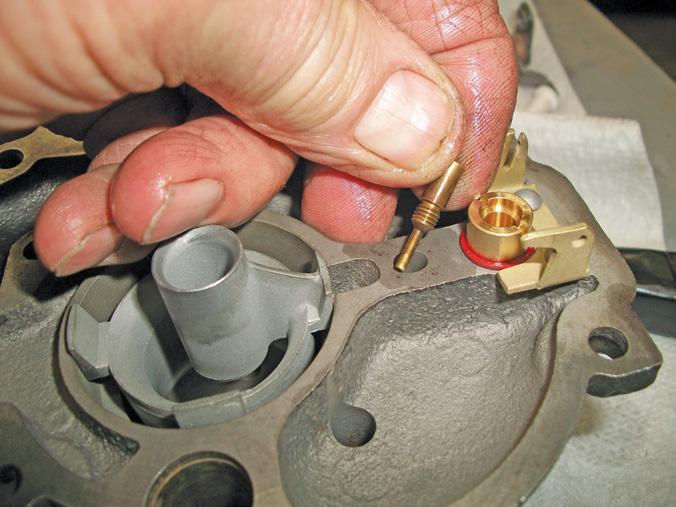

Let’s go back to the beginning of this carburetor’s issue when it was handed to me and I noticed that the choke door would not open sufficiently to bring it parallel with the incoming air flow—that is where it should be when the choke is not needed. Before I stripped all of this mechanism out of the casting, I looked it over in an attempt to see why the choke would not unload. I found that the choke door lever is spring loaded to the choke shaft, but the lever is positioned to the shaft by a series of holes in the outer race by

a cotter key. The outer race has a series of holes in it that will position the lever to the shaft as it should be, in order to put the choke door ON and to unload it in the off-choke position. Removing the tiny cotter key and repositioning it to another hole on the outer race left me with this position (Photo 21) with the choke door closed.

Somewhere in days past, this carb had been “operated” on. I can always tell by a path of half stripped out screws and jets where removal had been attempted, but then left “as is” with a stripped out screw driver slot in them. The project was abandoned at that point AS IS. So often these things are a “previous attempt to make

repairs” before they come to ME. But anyway, to leave a unit such as this to go back to the owner with the choke door only half open is surely going to

Photo 21 • Photo 22, below

Photo 23 • Photo 24, below

Photo 25 • Photo 26, below

Photo 27, below

Photo 21 • Photo 22, below

Photo 23 • Photo 24, below

Photo 25 • Photo 26, below

Photo 27, below

Page 40 June 2024 • Green Magazine

run the engine rich at any idle or slow speeds. The owner stated that it was always that way for as long as he had owned it. He just learned to “live with it” and changed spark plugs as they fouled from a rich fuel mixture. I can’t help but wonder what sort of shape the rest of this John Deere 3010’s engine is by now. The pistons, rings, and cylinder walls have certainly been washed down with the excess gas mixture, and I assume the seals are ruined. Beyond that, the gas dilution in the engine oil

has likely taken its toll on the crankshaft bearings and on the shaft journals as well. The 3010 has already gotten a bad rap from its owner, but I feel that the fault is not that of the tractor, but with the fellow who last said that he had FIXED the carburetor. Right is right and wrong is WRONG in life and in carburetors; know the difference and choose RIGHT!

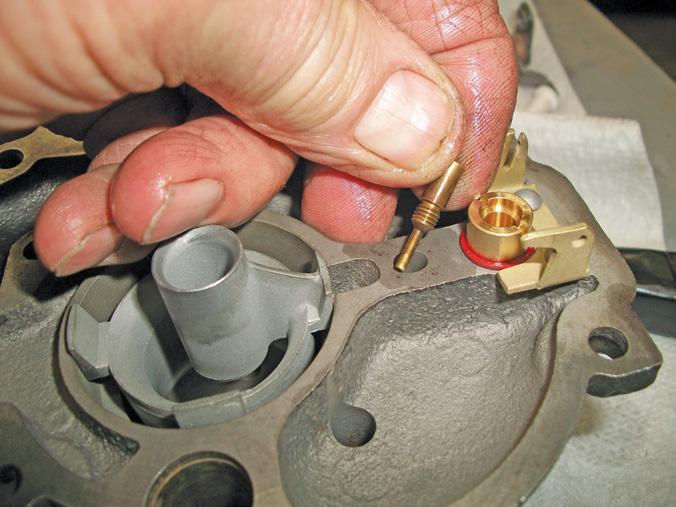

My carburetor rebuilds all start the same way with completely stripped and cleaned castings (Photo 22). This carburetor features a dual Venturi (Photo 23), which by the way was loose in the carburetor casting from a stripped out locater bolt. We can see the float reconditioned at its pivot point with the needle as I have mentioned before (Photo 24). The next photo shows the carburetor kit (Photo 25) that included all gaskets, a new needle and seat, a new idle needle, shaft seals, and a pump check valve. Putting a longer new screw with washers through the side of the carburetor throat and into the Venturi with a DROP of Loctite got the Venturi tightened up again (Photo 26).

Now we are installing the upper casting idle bleed jet (Photo 27), and then Photo 28 shows installing the lower casting idle jet; be sure to get

them in the CORRECT place. This is the installed float (Photo 29) set to the correct height. And here is the throttle shaft, the new seal, and retainer (Photo 30). The high speed or load jet (Photo 31) is installed through the side of the casting. The electric solenoid is reinstalled (Photo 32), the newly assembled carburetor showing the idle speed screw (Photo 33); this then is the assembled carburetor showing the new idle mixture screw (Photo 34). As always, the carburetor will be bench tested for any external leaks, and also for any internal leaks past its new needle valve. I will also, on this carburetor, be making a vacuum test to be sure that its accelerator pump system is working as it should. There you go…I LOVE doing carburetors this way but it takes a lot of time and patience.

The 620 block replacement… okay, the tractor has been washed, a section of the shop has been cleared out, the floor even scrubbed, and the parts benches have been strategically placed on two sides of the tractor. It is TIME to dive into replacing this 620’s block and pistons. Off comes the carburetor, the generator, and everything in front of the cylinder head. The manifold assembly is removed next (Photos 35 and 36), then the tappet cover and rocker shaft (Photo 37). Now there is enough forward room to slide the head off the block studs (Photo 38) and then turn it sideways on the frame rail OPPOSITE of the air cleaner and get it out to a metal bench setting on that side of the tractor.

I decided to do a little investigative work on it before proceeding any further. I have some suspicion that