The 620 Dealership Memories Increasing Hydraulic Power April 2024 GREEN Magazine® In this issue...

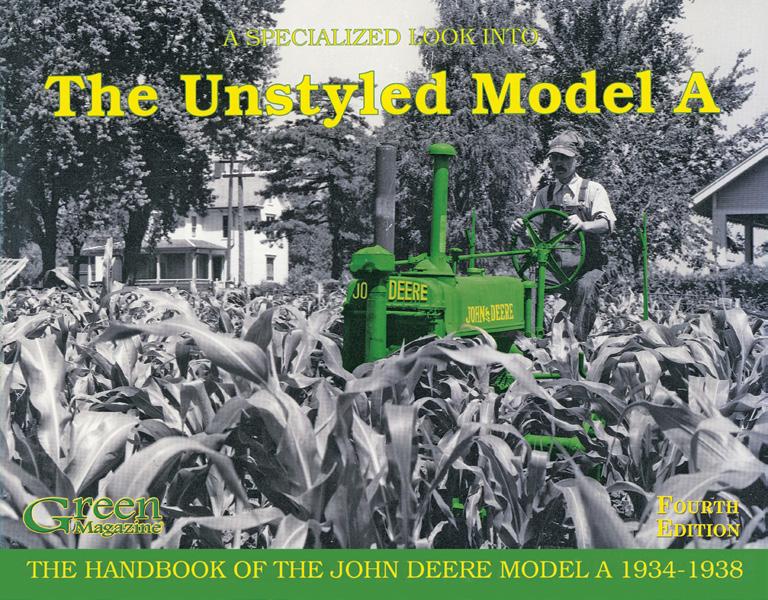

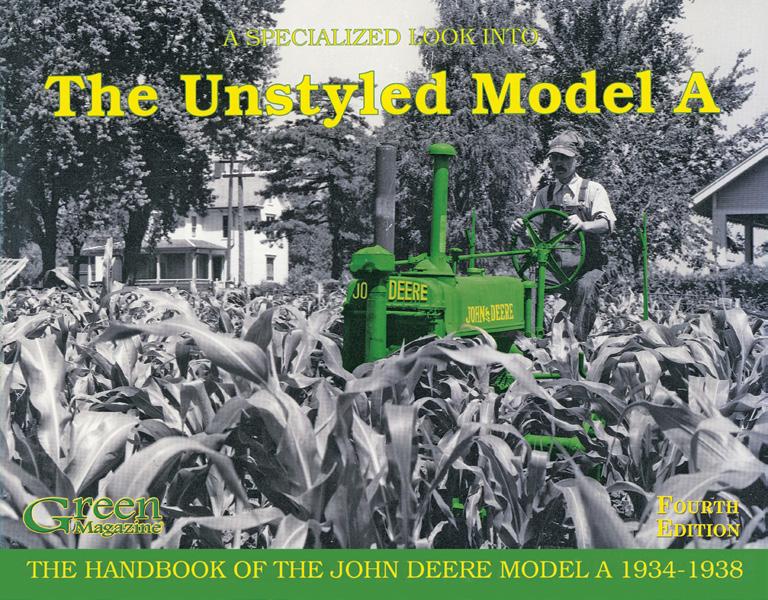

A Specialized Look Into The Unstyled Model A

The Handbook of the John Deere Model A 1934-1938

Fourth Edition • By Wes Malcolm

Now in its fourth printing with 15 more pages, this is the handbook of the John Deere model “A,” 1934-1938. A book that should be on the “must read” list of any unstyled “A” owner. There is probably no other book on the market that goes into so much detail on a single model of tractor. Shows illustrations of nearly every change made in the parts that make up the unstyled “A.” 95 pages, 11x8-1/2 inches, soft cover.

Both books include history, specifications, serial numbers, original prices and much more

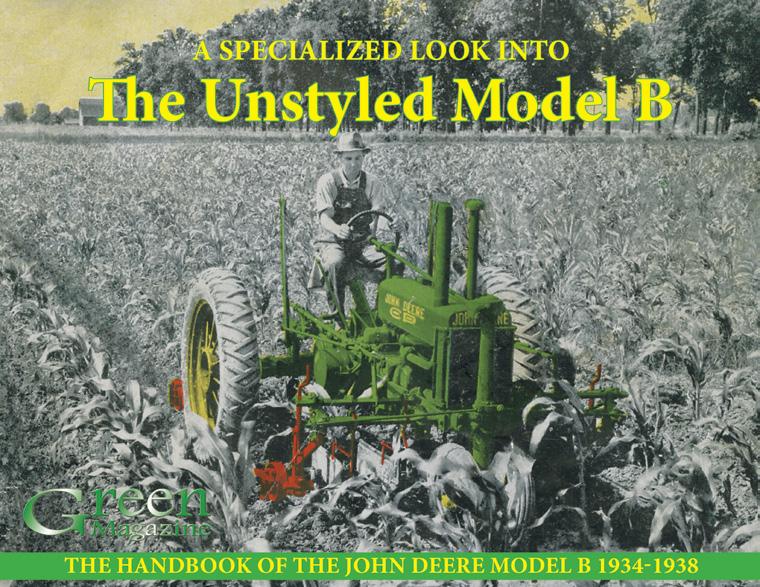

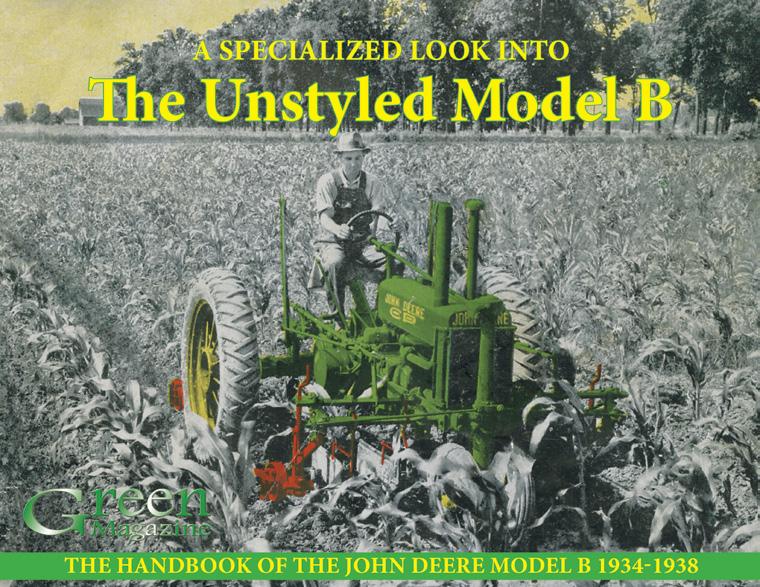

The Handbook of the John Deere Model B 1934-1938

The same types of information as available in the book above, except now about the model “B,” written and compiled by a panel of experts who have spent decades collecting and restoring the unstyled version of Deere’s most popular tractor. This book shows nearly every change made in the parts that make up the unstyled “B.” 84 pages, 11”x8 ½”, soft cover, over 200 photos - most in color.

published by Green

WHAT A DEAL! SPECIAL BUNDLE PRICE on these TWO books

Magazine

A Specialized Look Into The Unstyled Model B

Order GMAB: $63.95 U.S. (Nebraska

$76.95 Canada (US funds) • $89.95 Foreign

funds)

the first

DEAL. •• Prices in this BUNDLE DEAL are up to 20% OFF the regular price •• Visa, Mastercard, Discover, American Express accepted • Nebraska residents add 5.5% sales tax • Price includes S/H Call 402-643-6269 • Email info@greenmagazine.com Online www.GreenMagazine.com Mail Green Magazine® • PO Box 95, Bee, NE 68314-0095

residents add 5.5% state tax)

(US

The prices shown here are for BOTH books shown above -

time for this BUNDLE

Martin Parts & Repair Oversize pistons available again for many two cylinder tractors Radiator cores, water pumps, bolt kits Emblems Chrome stacks Ignition parts Lights & light parts Battery boxes Fuel sediment bowls Valve train parts & kits Manifolds & exhaust pipes Gasket kits Seats and seat parts Grill screens PARTS TRACTORS 5020, Unstyled G, 430T, 2510 gas, 730 LP, 2010D, 530, Late 520, ’39 B, BN, 40U, ’53 AO, ’41 H, ‘46 A, late A’s, ‘46 B, late Bs, slant dash B, unstyled B, sty. D, G, unstyled L, M, MT, R, 40T, 40U, 40W, 70D std., 70G, 420U, 420W, 440 w/reverser and power steering, 440 gas, early & late 50s, early 60, 60 w/power block, 620, 620 LP, 630, 630 single front, 70G, 720G, 720 LP, 720D pony, 730D, 730G, 820, 1010, 2010, 2010D, 2010RU, 2020, 3010D, 3020, 4020D. Most of these tractors are parted out & on the shelf—ready for quick shipment! Electric start kits Tachometers and cables Complete clutch rebuild kits and clutch lining kits Brake rebuild parts SUPPLYING PARTS for your CLASSIC JOHN DEERE NEW & USED • IN STOCK • READY TO SHIP Call or e-mail with all your parts & restoration needs or for a FREE CATALOG PTO clutch kits & parts Full round main bearings for 2 cylinder tractors Sheet metal bolt kits Wide front parts Complete carburetors, kits and parts 7487 E. 450 N. • Rochester, IN 46975 574-598-6083 • 844-720-2510 Email: sales@martinparts.net Now stocking USA MADE GAUGES LOTS OF NOS PARTS Email for a price list Unstyled G #6221 5020 serial 019483, hood available

U.S.:

Nebraska

Canada:

Foreign:

First

“GREEN

POSTMASTER:

MAGAZINE®” (ISSN 0883-5462) is published monthly and released 12 times a year on or about the first of each month for $39.95 per year (Canada: $59.95 per year; Foreign: $69.95 per year) by Hain Publishing, Inc., 2652 Davey Road, Bee, NE 68314-9132. Periodicals postage paid at Bee, NE and additional mailing offices.

Send address changes to “GREEN MAGAZINE®, PO Box 95, NE 68314-0095.”

MAGAZINE® reserves all rights regarding reprints of this publication. Our phone number is (402) 643-6269. Copyright © 2024 Hain Publishing, Inc. All rights reserved. The monthly publication for John Deere enthusiasts 10 Riechmann Bros.: Dealership celebrates 100 years Cindy Ladage 16 John Deere model 620 Benjamin Hain 32 Dealership memories and John Deere Days Jimmy Dale Rinne 59 Dad, me and a JD “GP” Ken Heipel April 2024 • Volume 40 Number 4 Departments 5 Richard’s Column 6 Deere John 24 How our hobby started Tractor shows and TV shows Richard Hain 26 Tracks & Tales 1973 JDX-8 Joe Rainville 30 Saw it online Circles in competition Adam Smith and Benjamin Hain Each March issue of Green Magazine includes an index of major articles from past issues. The March 2024 issue features the newest index. 34 Auction highlight Orchards lead the way Eric W. Mickelson 38 Deere & There 40 More hydraulic power Rich Collins 42 What’s new—and old? Invoices tell a story Greg Stephen 48 Scale models Vintage harvesting set Bill Proft 51 Aussie Ken Canadian working holiday, Part 4 Ken Nicklas 54 Index: Do you have one? 56 The tractor doctor Step on it Ron O’Neill 69 Advertiser index 72 Mr. Thinker ON THE COVER: Dan Kaler of Sioux City, Iowa owns this 620 standard. Editor Richard Hain Managing Editor Carol Hain Layout/Design Debbie Behne Green Magazine® PO Box 95 Bee, NE 68314-0095 Hours: 8:30 AM to 4 PM M-F Phone: 402-643-6269 email: info@greenmagazine.com web: www.greenmagazine.com Check out the sample articles, catalog, ads and other features! NOTE: VISITS TO OUR OFFICE BY APPOINTMENT ONLY! Please call prior to visiting so we can be here to talk with you. At that time we can also give you our location. Thank you! Rates:

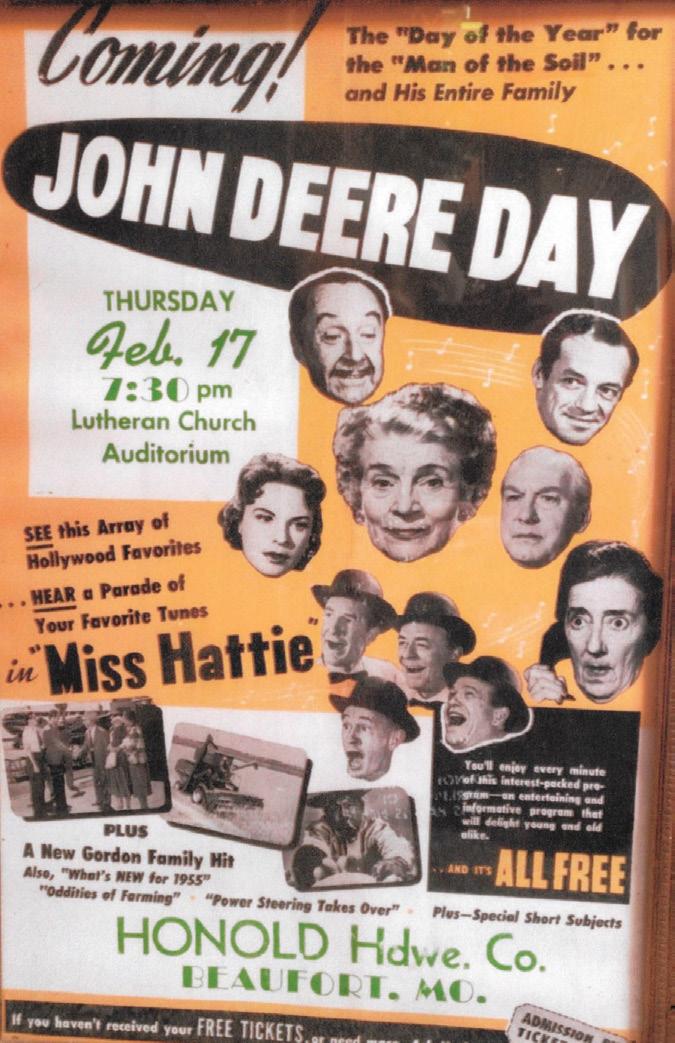

GREEN

$39.95 / 1 year

12 issues

-

residents, add 5.5% sales tax ($42.15)

$59.95 / 1 year - 12 issues

$69.95 / 1 year - 12 issues

Class/Airmail delivery available: See page 5 Visa/Mastercard/Discover/AmExpress accepted Page 4 April 2024 • Green Magazine

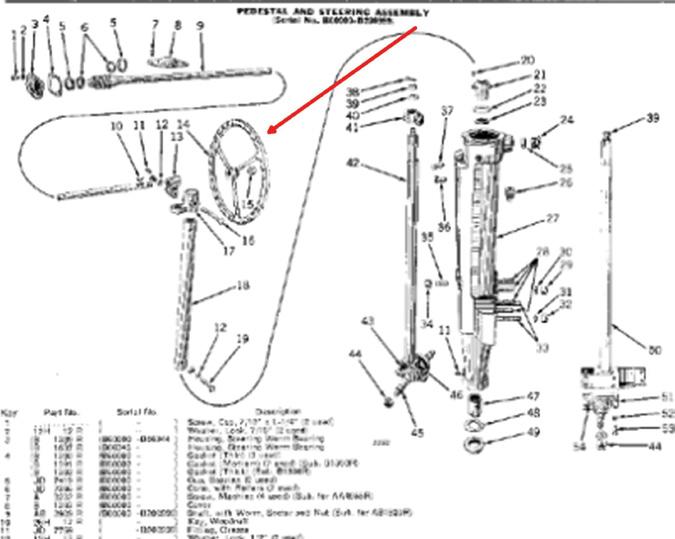

I’m finally getting back to working on the late styled “A” that has been apart in my shop for some time now. It’s running well and most of what I am doing is in preparation for painting. When I posted a photo of it online before I first tore it apart, quite a few told me not to paint it and leave it original. I have no problem with the trend of the last 10 years or so of keeping tractors in their original state, but this tractor has already been painted at least once and needs several repairs to its sheet metal. I don’t think that exposed Bondo and welds are a good look. At any rate, I need to clean some dirt from the tractor that has probably been riding along for 73 years and fix a loose steering wheel. The loose steering wheel is something that I have never run into before and I’m not sure how many times the steering wheel would have had to have been removed to wear out the end of the shaft, but in order to get the steering wheel on far enough to make it tight, it needs two large washers between the nut and the steering wheel. I’m going to try and use a shim designed for the rear axle of a model “A” Ford to get it tight. I will let you know if it works.

I’m still trying to figure out the order in which to paint this tractor. I suppose that getting all of the nooks and crannies painted and then putting the tractor back together is a problem with any model, but to me, the late styled “A” and “B” are the worst of any with the way they go together,

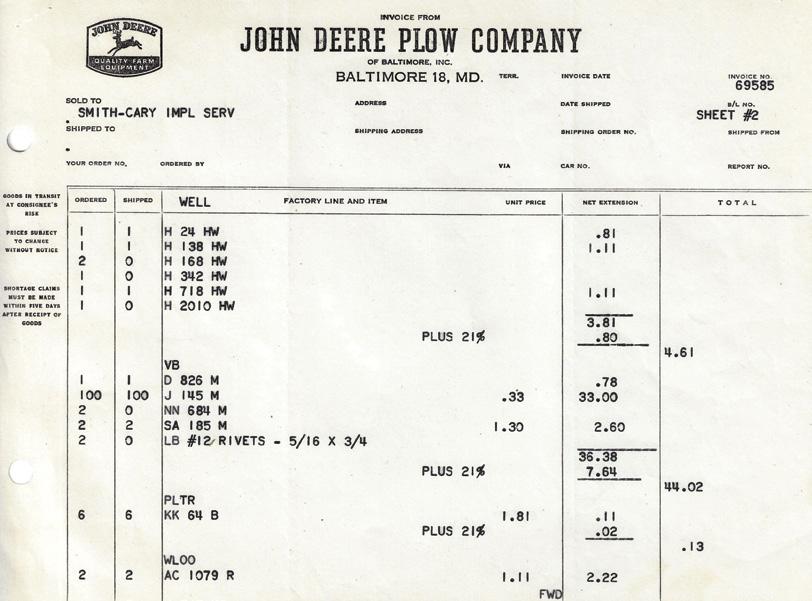

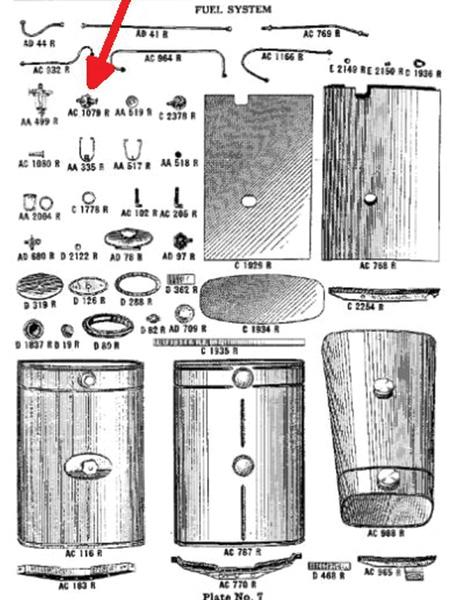

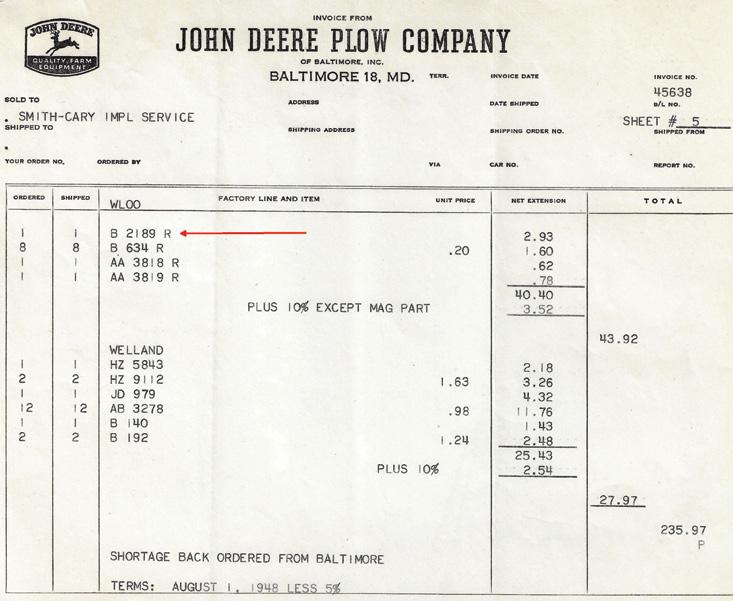

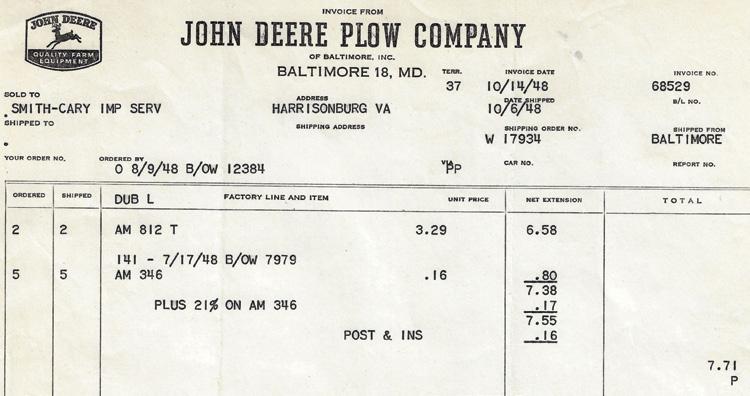

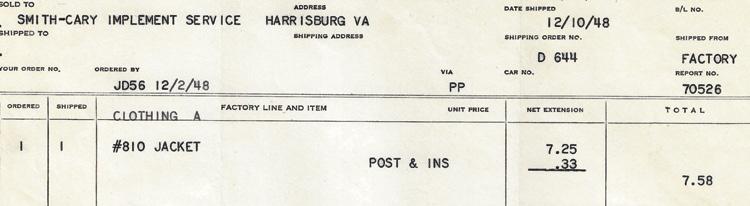

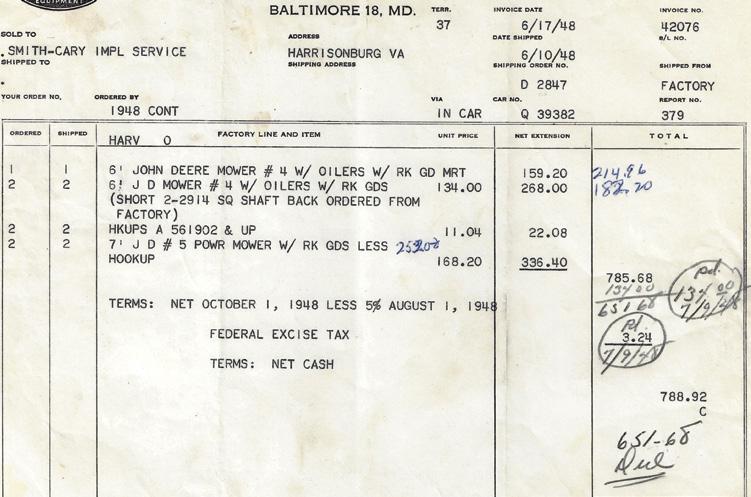

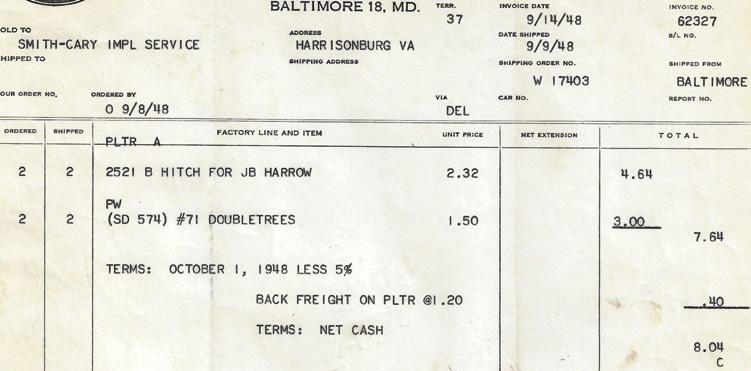

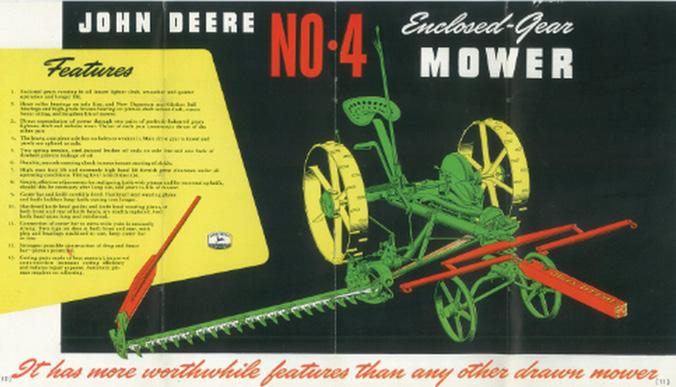

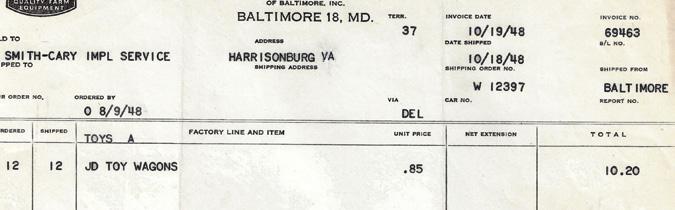

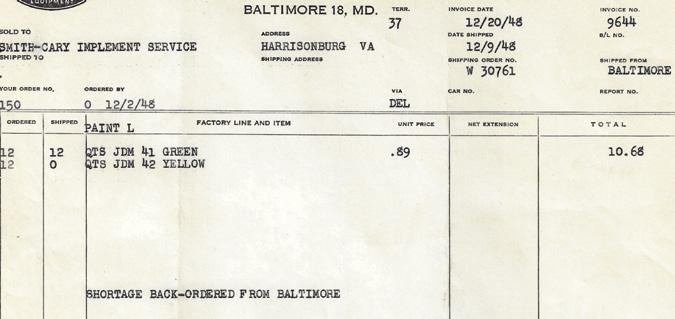

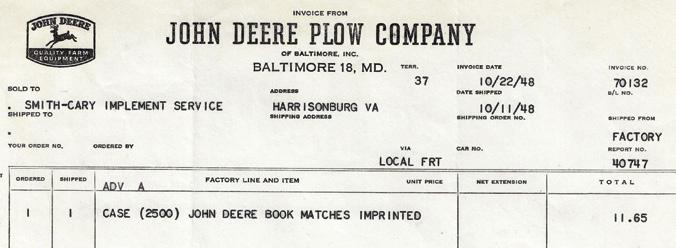

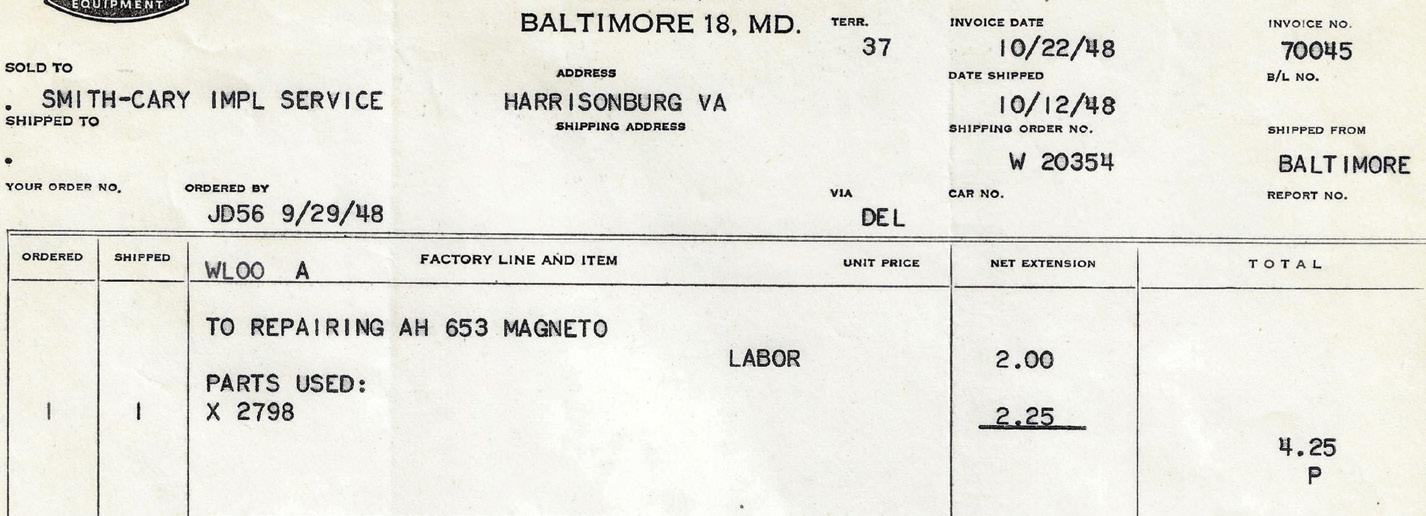

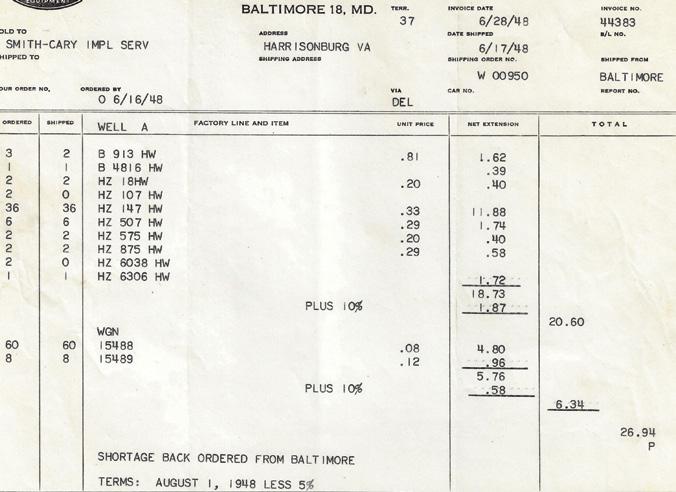

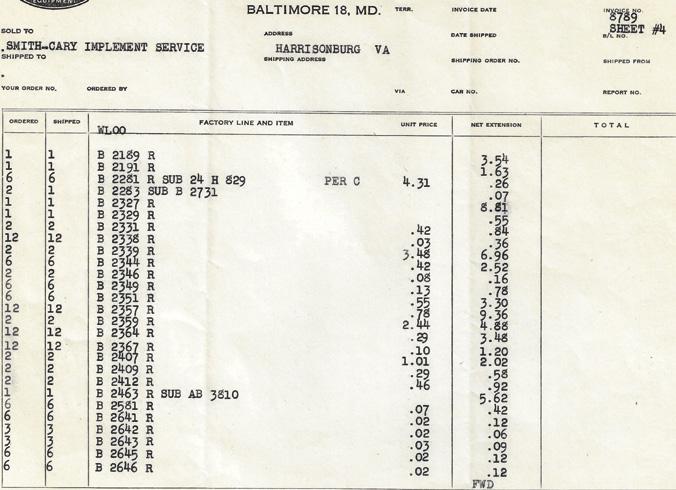

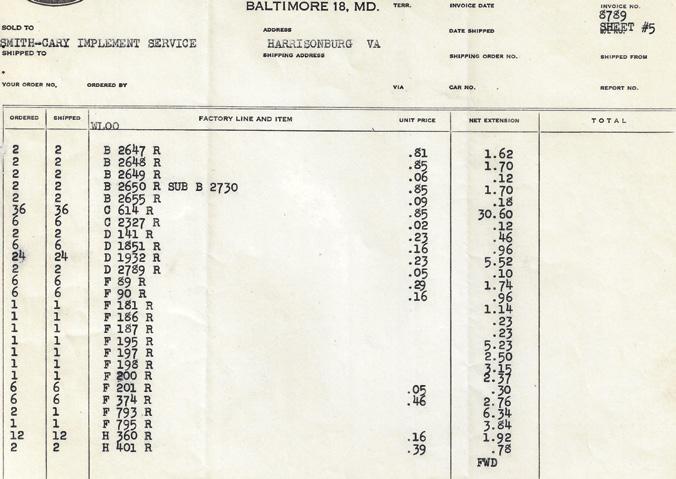

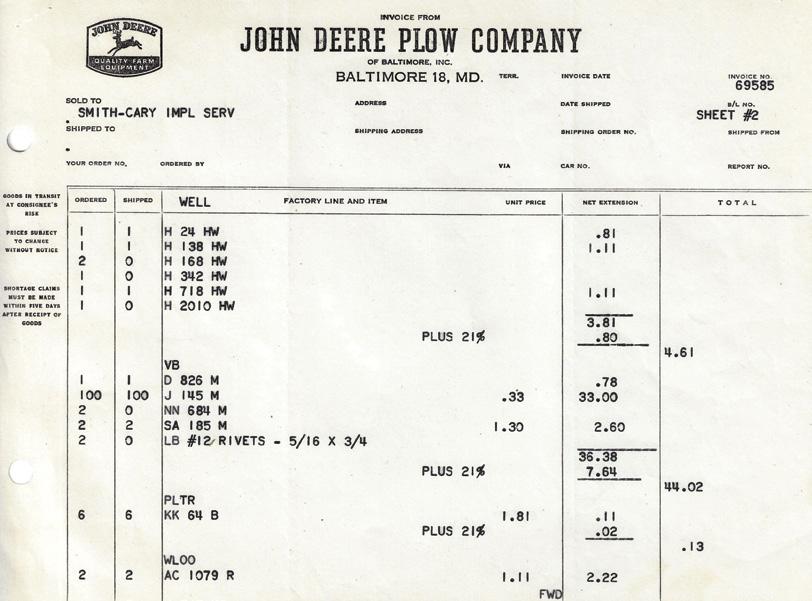

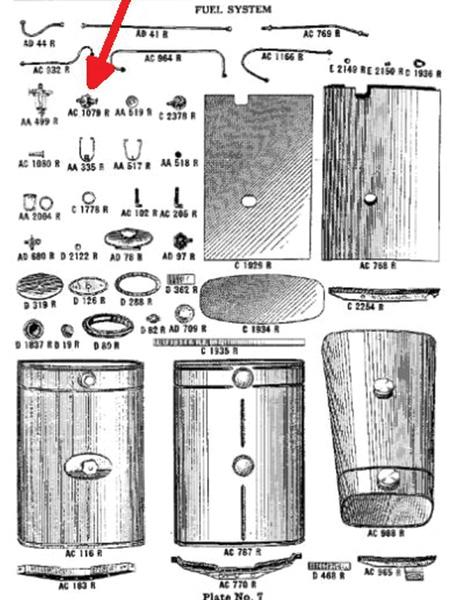

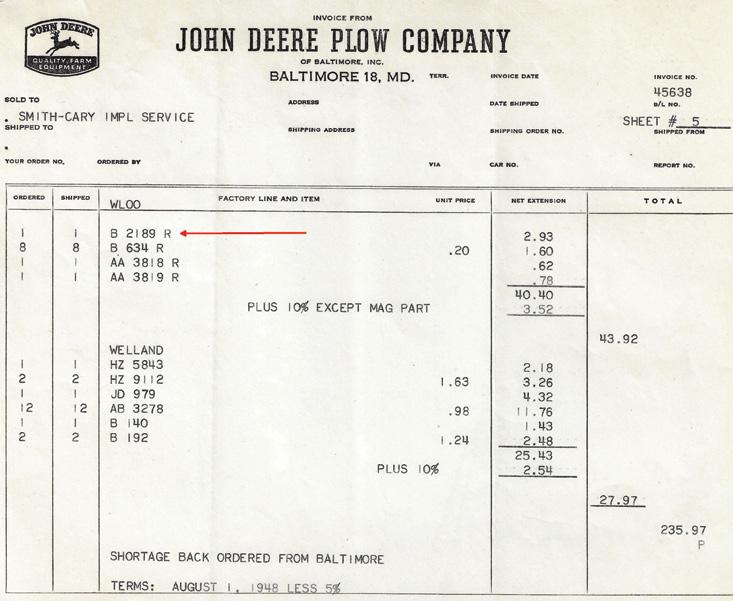

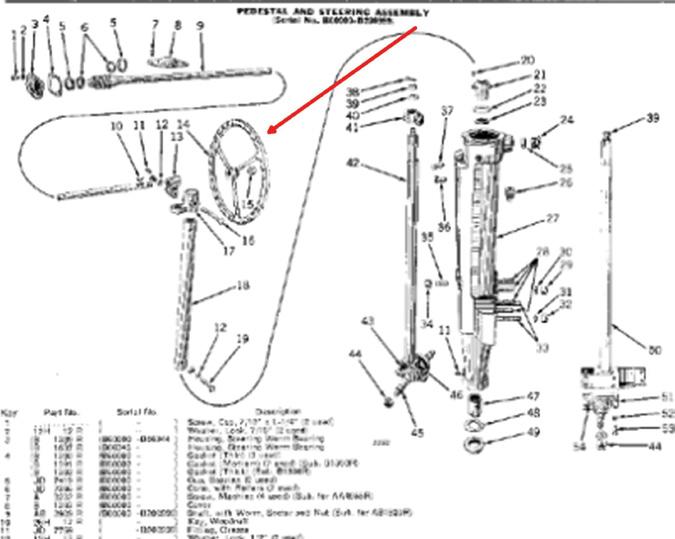

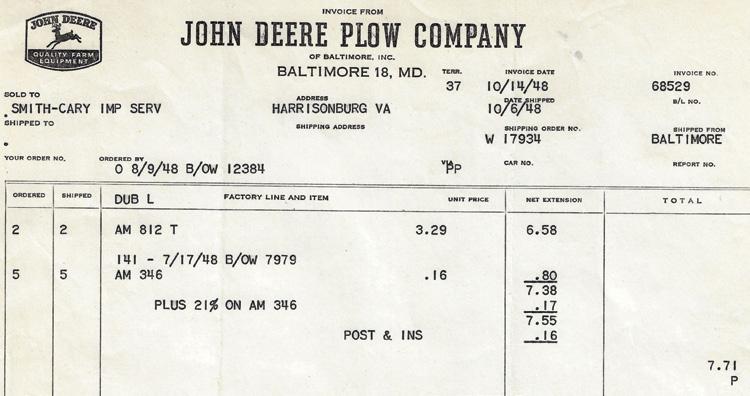

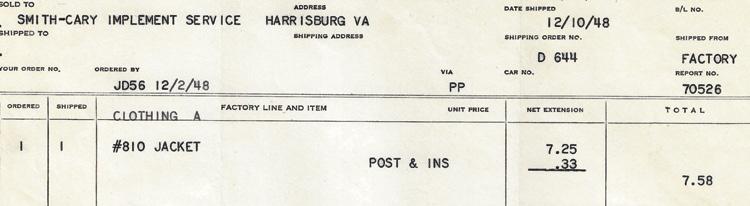

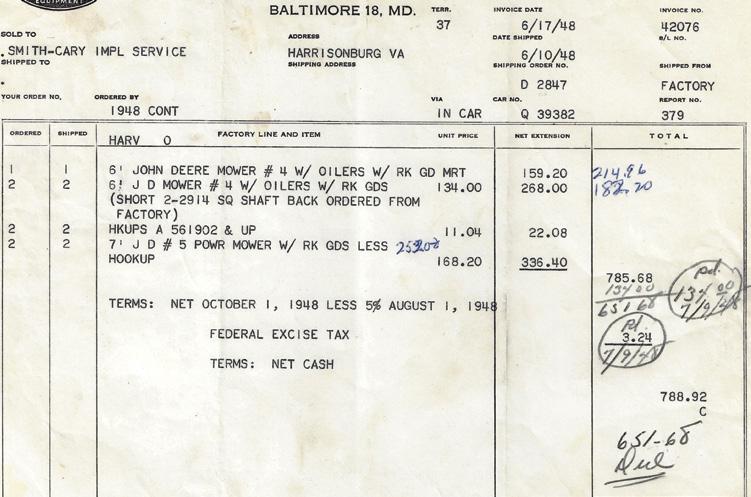

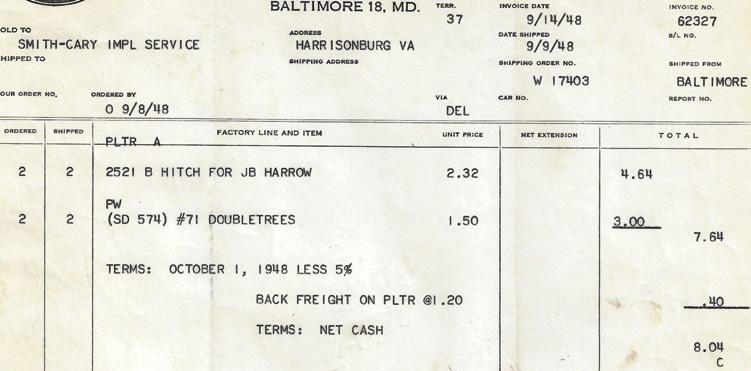

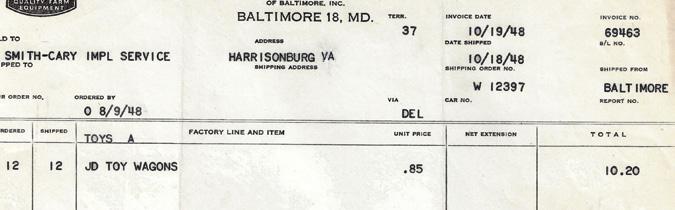

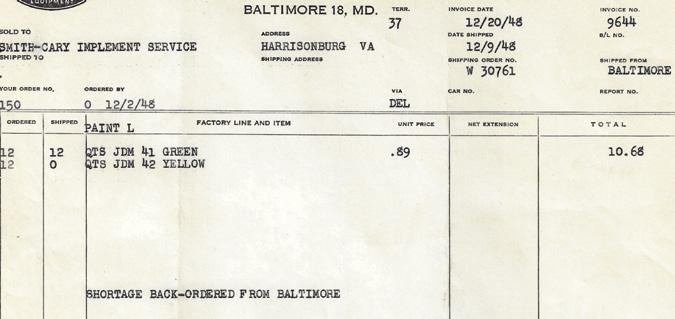

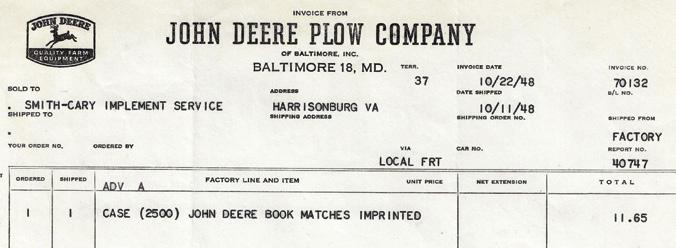

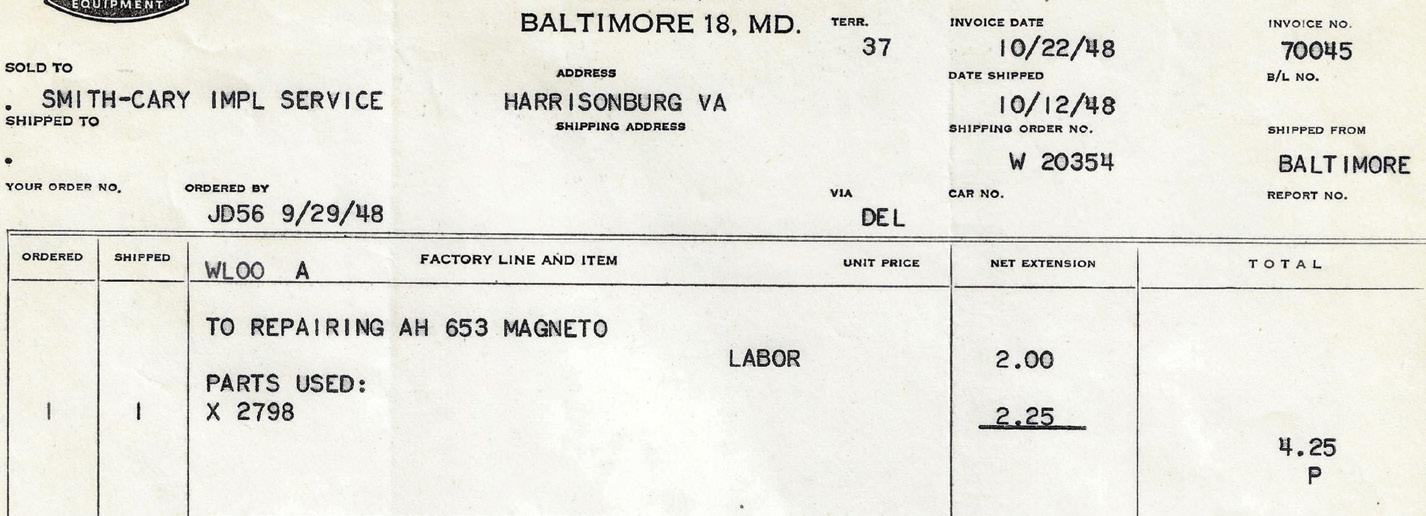

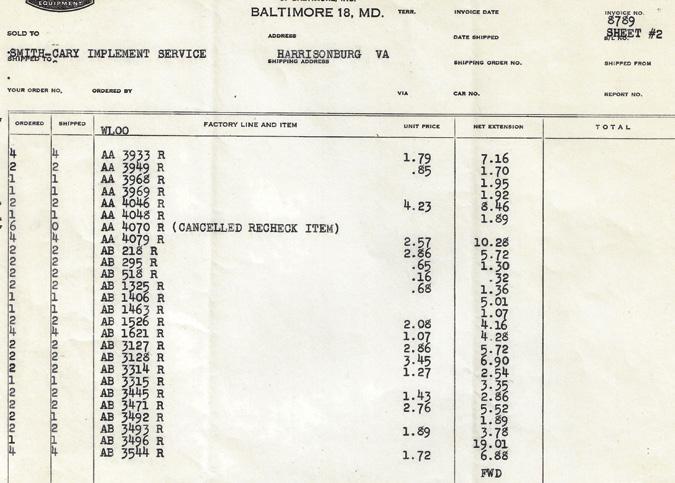

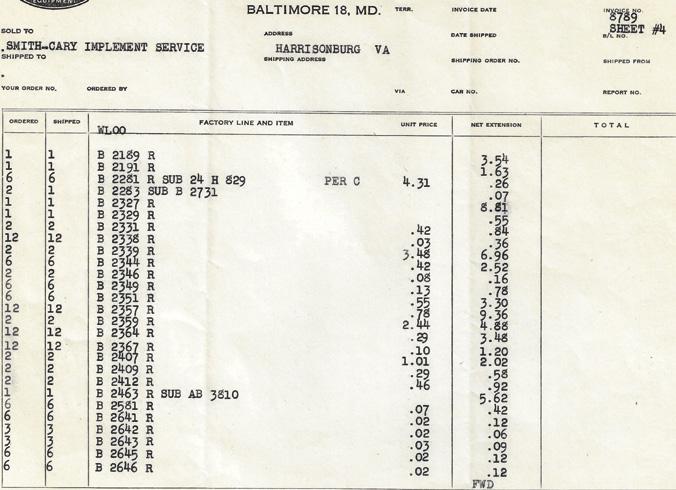

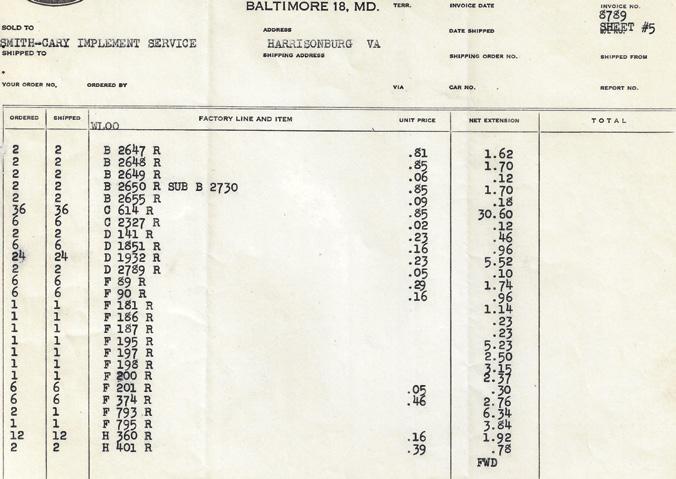

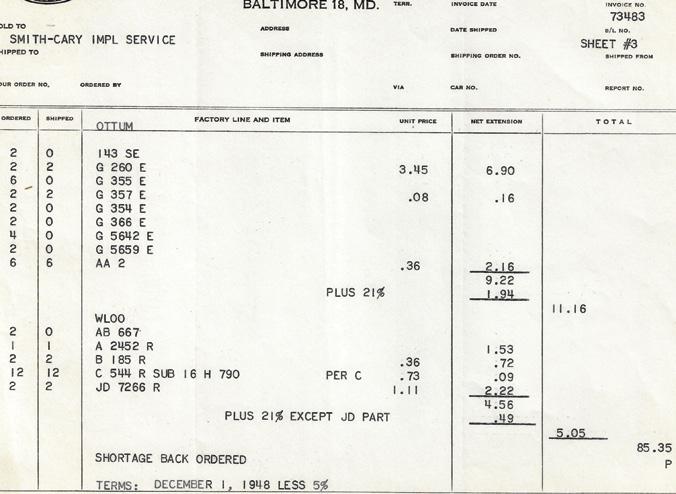

or apart. Most of you know the unorthodox way that these things go together where the first thing you need to do in order to replace the muffler is to remove the steering wheel. It seems like doing all that in reverse order with freshly painted parts is an invitation to scratching something. I’ve talked to several people about their processes and heard several schools of thought. Some paint the basic tractor and hood separately, put them together and give them both a couple more coats. A few others paint the engine, frame and drive train, mask or put tarps on everything that is already painted, install the unpainted sheet metal over it and then hit it with paint. Still others paint everything, put it together and then fix any scratches. There might even be some other methods I haven’t heard of.

We’ve had a good response to our request for 20 series two-cylinder tractors for our 2025 calendar, but keep them coming, especially if you have an uncommon variation. Remember, though, the tractors should be restored like original which means no chrome stacks, oversize tires or non-original fenders. I’m glad to publish those photos in the magazine, but not on the calendar which is supposed to look like the tractors came straight out of 1958 advertising.

By the time you read this, many of you will be hitting the fields, so please be careful out there.

See you next month.

Missing an issue? We mail every issue by the first of the month. Please contact your post office if you suspect a problem with delivery. We will not replace missed issues three or more months past original mail date (four or more months for foreign subscribers) free of charge.

U.S. subscribers: If it is on or after the 20th of the month and you haven’t received your issue, call us for a replacement.

Canadian subscribers: Due to postage costs, we are forced to ask for a $2 postage fee (U.S. funds, please) for re-sending issues that do not arrive by the end of the published month OR we can add an issue onto your subscription for the missed issue.

First Class/Airmail delivery: Call for rates for First Class in the U.S. or Airmail to foreign countries.

Foreign subscribers: We will add an issue onto your subscription OR for a $7 airmail postage fee (U.S. funds), we will resend the missed issue two months after publication date.

Notice: If your address label shows an expiration date of “4/24” above your name, this is your last issue. Renew immediately for continuous service. If your address label reads “5/24,” you have one more issue on your subscription.

Renewal notice: We send postcards to let you know your subscription is about to expire (or has expired). We NEVER call to ask if you would like to renew your subscription. If you

receive such a call, it is most likely from another publication—NOT Green Magazine® for John Deere enthusiasts.

Address Changes: Please send or call with notification of an address change as soon as you know what your new address will be. Periodical mail cannot be forwarded. Green Magazine will not replace issues missed due to late notice of address change. Those missed issues will have to be bought at back issue price. See the back issue listing and prices elsewhere in this issue.

Looking for your photos and stories! Accepted material is subject to such revision as to meet the requirements of this publication. Payment will be made at our current rate within 90 days of publication. Submission of manuscript implies that the material is original and in no way an infringement upon the rights of others. Please send good, clear photographs. If you would like these returned, send us a stamped return envelope to help us get them back to you.

Free Issue Offer: It seems you, our subscribers, are our best form of advertising! More people find out about this publication by “word of mouth” than other forms of advertising. So if you're enjoying Green Magazine®, why not spread the word? Telling others about it can pay benefits. When you tell a friend about Green Magazine® and they subscribe, make sure they tell us who let them know about it. When they do, you will get an issue added to your subscription. These must be new subscribers, not renewals.

Please wait until AFTER the 20th of the month to report a missed issue of Green Magazine Ph. 402-643-6269 or email info@greenmagazine.com Green Magazine® • April 2024 Page 5

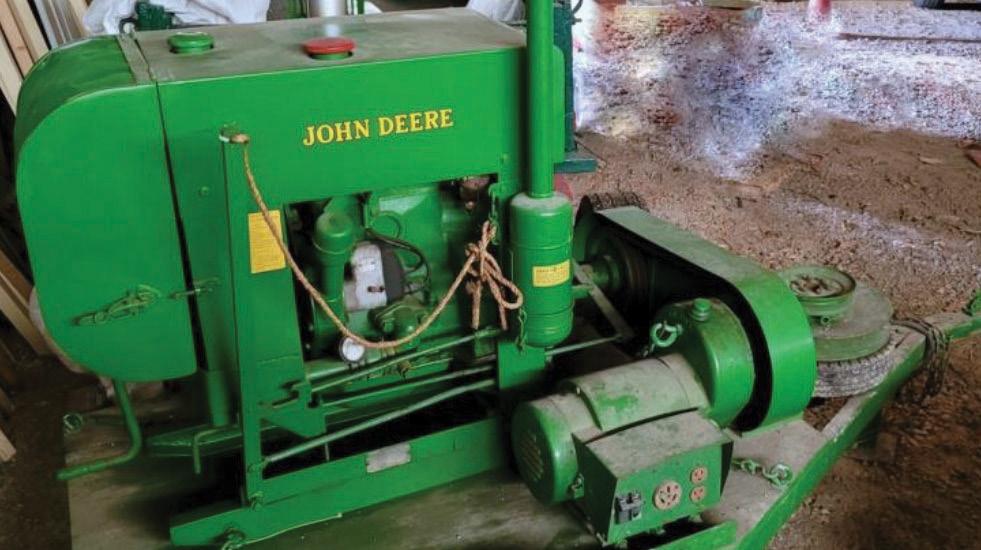

This is a picture of our 8850 powering a 16 inch by 125 foot grain auger. Here is the story:

I purchased this 8850 in 1988. It had 1,100 hours and one season’s use. The farmer traded six of these for six more unused 8850s, remembering the machinery glut on the 1980s.

Prior to 1993, I had this tractor “top end” overhauled three times in less than 1,000 hours and then it completely destroyed itself. John Deere has a firm in Kansas that completely remanufactures/rebuilds engines for them. More expense and in less than 200 hours, the crank shaft broke.

There is a reason that Kinze Manufacturing and others made a big business changing out Deere engines and installing mostly Cummins engines. Very reluctantly, I became one of their customers. The tractor now performs like I thought it would many thousands of dollars ago.

Model 8850s were of so little value to sell that we kept it. It is a backup tractor. When a 16 inch by 125 foot auger was purchased, requiring a 350 horsepower plus tractor, we were ready. The cheapest source of power was an 8850 with a 450 horsepower Cummins.

Our “backup” tractor backed right up and has been trouble free. Power, PTO stamina and hydraulics to help. All of a sudden, it became the “big engine that could.” I always liked it and now I am proud of it.

A little like Rudolph the red nosed reindeer, it took over 30 years to find its special place.

Cal Hayenga, SD

We welcome your submissions • Deere John letter • Restoration stories • Deere & There photos • Other stories, photos and more Green Magazine PO Box 95 • Bee, NE 68314-0095 Email: info@greenmagazine.com Please send high resolution photos if submitted electronically Include your phone number/address on all submissions Send your story today! Submissions accepted for publication will receive a monetary compensation. Page 6 April 2024 • Green Magazine

Bill & Sharon DeVries collection - Thursday, May 2, 12 NOON, 3694 S. Luce Ave., Fremont, MI 49412, Newaygo Co. 13 restored John Deere 2 cyl. tractors including 730 diesel plus 19 other brand tractors, JD manure spreader, JD farm toy collection, JD parade wagon, JD collectibles, etc.

#1:

Saturday, May 11, 10 AM, 49 W. 112th St. Grant, MI 49327, Newaygo Co. 16 antique tractors including restored JD 730 diesel Hi-Crop, farm toy collection, large quantity of JD collectibles, farm equipment, vehicles, tools & farm primitives.

#2:

Dale Snieder Estate,

John Kleyn Estate, Saturday, May 18, 10 AM, 7490 Taft St. Coopersville, MI 49404, Ottawa Co. Complete farm estate - 16 tractors including JD 7520, 5020, 4020 & others, full line of farm equip., lg. farm toy collection, antiques, collectibles & farm primitives. www.artsmithauctioneers.com or call for flyer • Ph. 616-308-0854 3 PUBLIC AUCTIONS! INCLUDING 70 ANTIQUE TRACTORS! GREATER MINNESOTA TWO-CYLINDER CLUB 32nd Annual FIELD DAYS and SWAP MEET Friday and Saturday, May 3 & 4, 2024 Morrison County Fairgrounds, Little Falls, MN FEATURING: John Deere models with multiple letters • All other brand models with both letters and numbers • All brands of garden tractors • Snowmobiles (Scorpion and Brut) Tractor, Garden Tractor, Gas Engine & Snowmobile Displays. Field Ready, Antique Tractor, Garden Tractor and Pedal Tractor Pulls. Swap Meet and Activities for Adults and Kids. ALL EXHIBITORS WELCOME Swap & Toy Vendor or General Info, contact: 320-733-0111 • www.gmntcc.com 1) Call 402-643-6269 with credit card in hand 2) Go online: www.greenmagazine.com 3) Send a check by mail with the subscriber’s name and address to: Green Magazine, PO Box 95, Bee, NE 68314-0095 For more info on subscription rates, see page 4. Questions? Call 402-643-6269 for great customer service! A&L Parts NEW, USED & REBUILT 2 CYLINDER PARTS Hundreds of tractors parted: Wide fronts, 3-point, carbs, starters, etc. • NOS parts MODELS A THROUGH 730 A&L PARTS 432 N. Flat Street • Penn Yan, NY 14527 Phone 315-536-0543 • We ship DAILY • Major credit cards accepted NEW PISTON KITS and RADIATOR CORES Green Magazine® • April 2024 Page 7

#3:

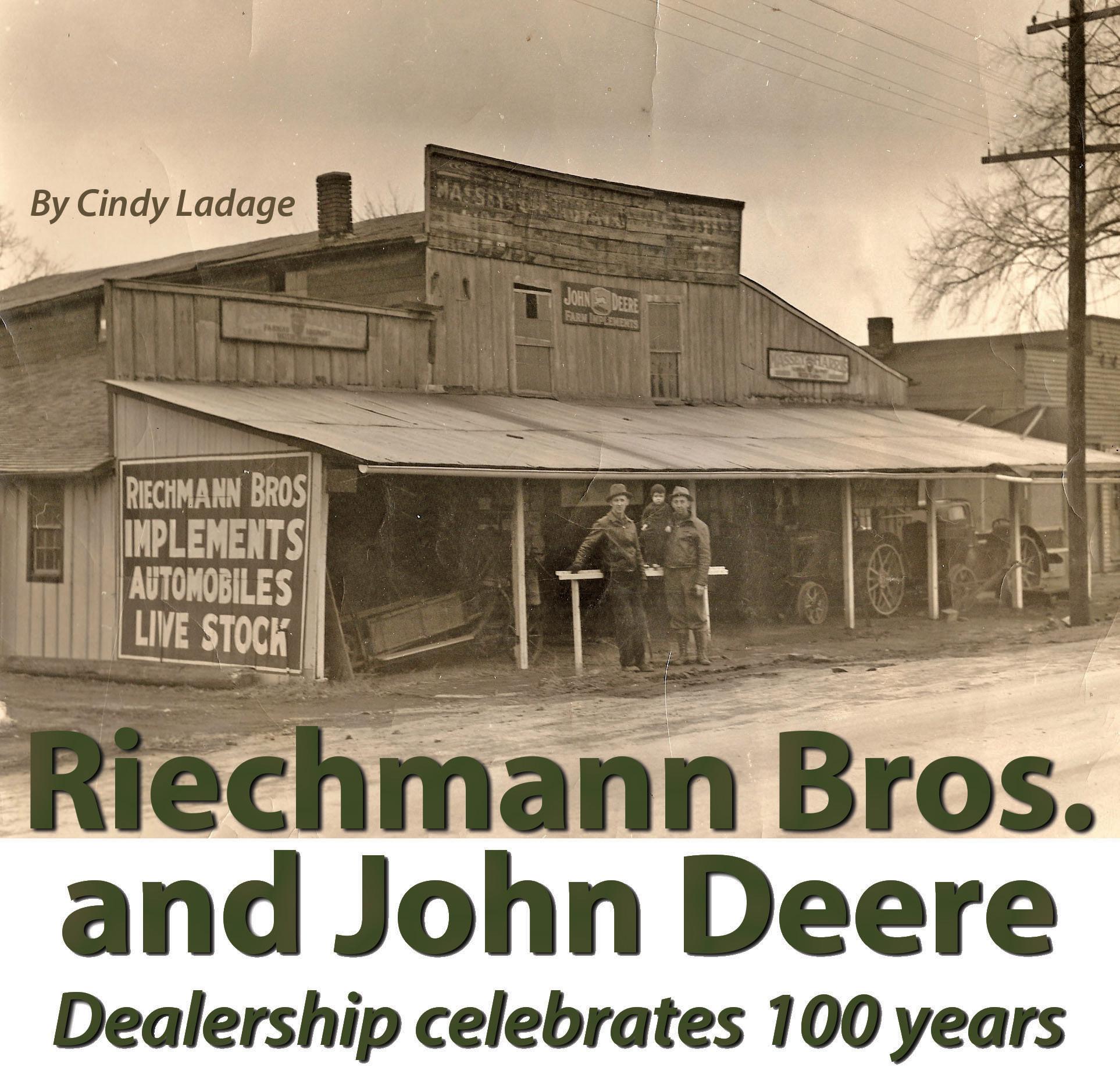

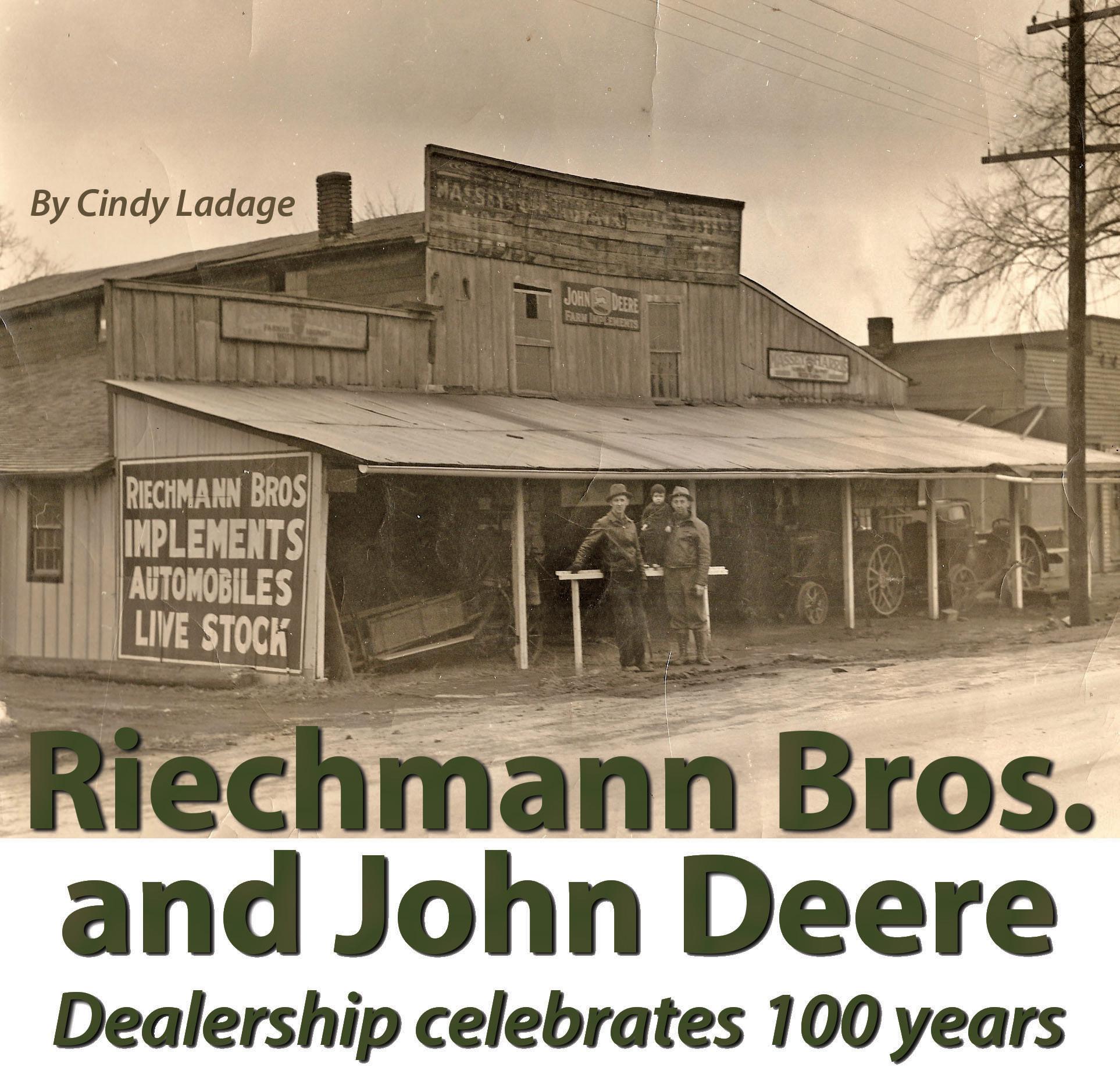

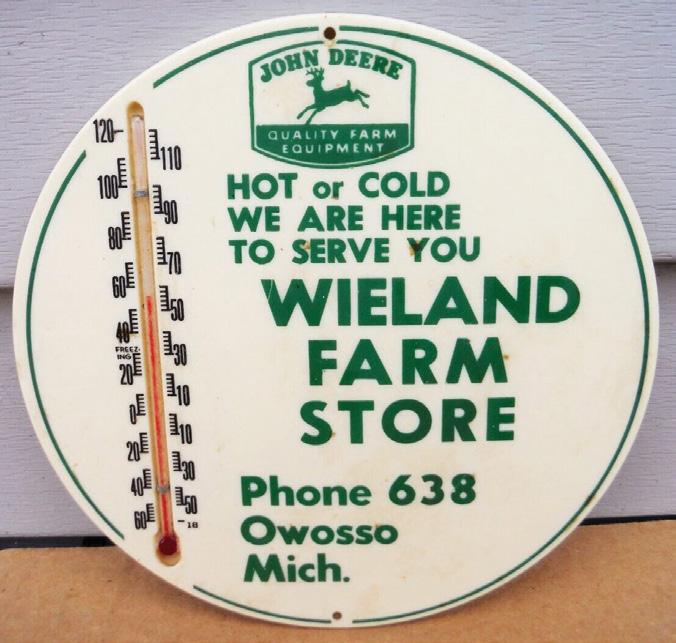

My friend and fellow John Deere collector, Mark Berkel, told me about Riechmann Bros. in Okawville, Illinois. This dealership is the oldest, continuous John Deere dealership in Illinois, and this past summer they celebrated their 100-year anniversary. Members of the Riechmann family shared the story about their dealership that has remained in the family since the beginning.

The Beginning

The story begins with Hugo and his brother Walter Riechmann. They founded Riechmann Bros. on December 23, 1922. “They borrowed $4,000 to

start the business,” Bill Riechmann Jr. shared. “They were the second generation of German immigrants.”

The brothers bought the business from C.H. Erke. Their website history states, “The first check stubs, which are framed on the west wall of the Okawville showroom if you come visit us, show that the first check was written to C.H. Erke, who had employed Hugo as a salesman the prior two years. The $3,400 check paid for the entire business inventory. The remaining $600 was left to do business as they had no money of their own.”

Loyd, Hugo’s son, said his ear-

liest memory is, “of being born and raised right here. Dad had worked in the blacksmith shop, and sold lightning rods, and whatever they could to make a living.”

Riechmann’s first sale was a buggy whip to his brother, William. At that time, they traded in buggies, converting them for farmers to use to haul milk cans and supplies.

When Hugo and Walter bought the business from C.H. Erke, they had contracts with both Massey Harris and John Deere. “I was born in 1937,” Bill Sr. said. “And Dad liked the Massey binder but didn’t care for the Massey

Page 10 April 2024 • Green Magazine

The Erke building, razed in 1938.

Harris tractor. He thought John Deere tractors were a coming thing.”

Both companies, Massey Harris, and John Deere, wanted the brothers to commit to selling just one of the brands. Since Hugo saw a future with the Deere tractors, they thankfully chose John Deere.

Roads were not easily traversed. Many were still using horses in those early days. So, both John Deere reps and the parts came to Okawville by rail. “Everything came on the train and arrived at the dock right here,” Bill Sr. said.

Loyd remembers the smoke from the trains. “Mother had to watch to take clothes off the line when the steam engine was coming because of the soot.”

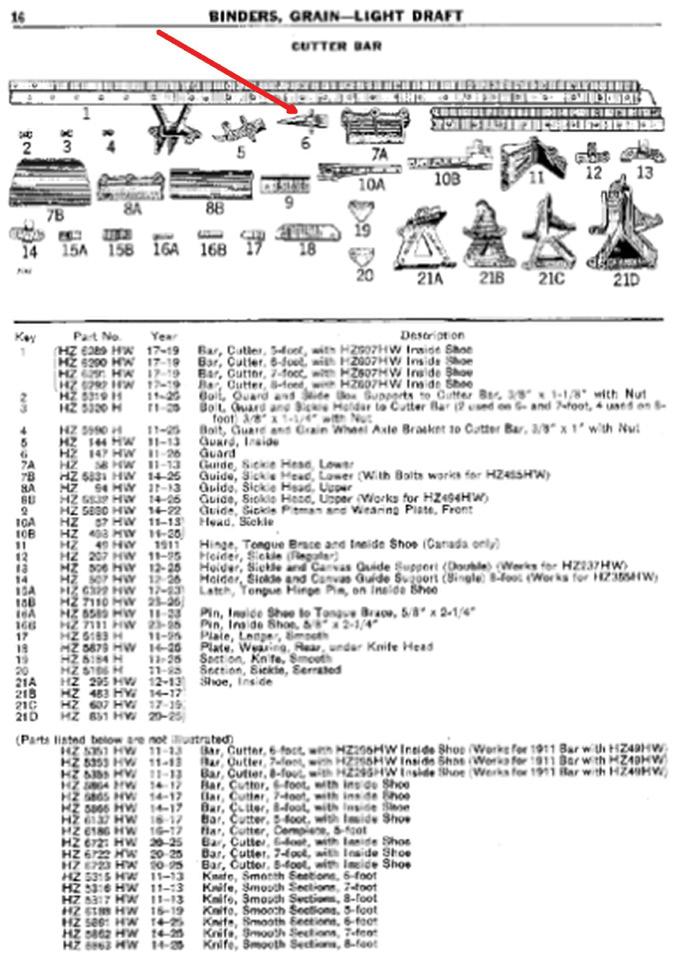

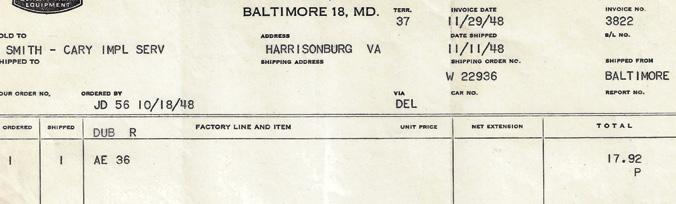

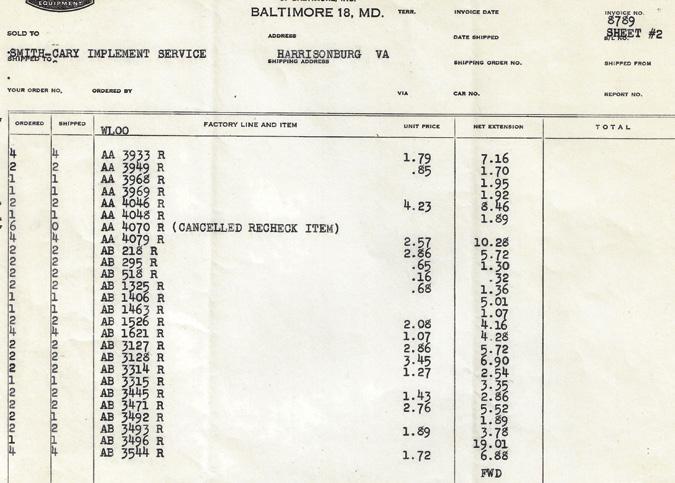

The Riechmanns traveled to St. Louis to pick up parts and equipment after stopping to drop off livestock at the stockyards. Back then, some of the parts included grain binder parts, plows, cultivators, disks and hit and miss engines. “As a boy, I would go to St. Louis every week. We would take cattle in, and then go to 2212 N. Broadway at the warehouse to load equipment after washing the truck. We had a 1937 Dodge truck until we traded it for a 1947 truck that we still have. It had an Omaha bed on it with cattle racks that folded down.”

Livestock was an active part of the business. “We traded for a lot of horses, cows, and mules,” Bill Jr. said.

One trade in 1939 was six head of mules for a 1939 John Deere “A” trac-

tor. “When a man didn’t have money, he traded cows,” Loyd added. At the outset of World War II, they started handling more cows. It is interesting to note on the website they shared, “If a customer had a certain number of cows to milk, then he could keep a son at home. It was Walter’s job to feed the cattle, horses, and mules, and he was assisted by William and Loyd when they grew old enough. They remember the horses going to their stalls and cooperating, but the mules would bite, kick, and were a problem.”

During the war years, Loyd said they often would stay nights at the shop. “We sold gas and worked on cars and played a lot of pinochle. You didn’t have anything to do or spend money on.”

All metal was precious. Loyd added, “During 1943 to 1945, there were no automobiles built, the license plates were all cardboard. The government put a ceiling price on tractors during the war. At auctions, we would say, ‘If you want this tractor, put your name in this hat,’ then we drew to see who got it. They had money, but no tractors.”

There was a blacksmith shop during the ’20s and ’30s that kept the blacksmith busy sharpening plow shares and doing welding projects. The importance of the blacksmith shop is not overlooked. “The business evolved from the blacksmith shop to this,” Bill Jr. shared.

During the quiet winter months, Loyd said, “Dad collected iron and rags. There were no paper products back then, and the only toilet paper was Sears & Roebuck! My first six to eight years, we had no plumbing in the house.” They then sold the iron and rags for winter cash.

In 1928, Riechmann Bros. expanded into automobiles by buying the business next door. They sold Dodge and Plymouth models. “We sold a lot of tires too—the tread only lasted 3,000 miles,” Bill Sr. said.

During the ’40s and ’50s, they were known to sell as many cars and trucks as farm equipment. They eventually moved out of the automo-

Green Magazine® • April 2024 Page 11

The Riechmann brothers: Bill Sr. and Loyd.

tive business. “We sold Shell products too,” Bill Jr. said.

It took a while for customers to take to combines. “I just remember the end of the binders. A lot of people both combined and threshed. They thought they needed the straw pile,” Loyd said.

Loyd remembers when limestone came into play. “When limestone first came in, farmers would come in and scoop it into their wagons and spread it.”

Hugo told his sons that you could always tell who had used limestone to fertilize their fields and who had not because the dewberries grew well in fields without limestone. “The dewberry was a short bush crop you could pick and bring in and ship to the city.”

The second generation of Riechmanns took over when tragedy hit. Hugo Riechmann had a heart attack. His son, William, was only 21 and Loyd was just 15. “Dad died when I was 21,” Bill Sr. said. “I was sitting next to him in church on June 1, 1958.”

Second Generation

The boys had to step up to the plate. Bill said, “Dad and Mom’s first three children died. Then it was just my brother and me. Dad let us do just about anything. We were spoiled. But you knew what was right, and wrong.”

With a loving background and the help of their bachelor Uncle Walter who lived with them, they forged ahead. At first, though, Walter thought perhaps they should sell, but Bill said, “I want to keep going. Walter was good with parts. He said ‘Okay, we’d do our best’.”

Bill had experience selling from an early age. “I sold my first tractor when I was 13. It was a used JD ‘BR’.”

He sold it while his father was away at the DuQuoin State Fair. With Walter taking care of the parts and service, and William trading horses for tractors, business moved ahead.

Riechmann Bros. picked up parts at the St. Louis John Deere branch until the parts department there closed in 1953. This branch was only 45 miles away. They then got parts from Memphis, Tennessee, which was 4-1/2 hours away. Then, parts had to

The business’ main building until 1979.

be shipped from the East Moline, Illinois branch, which was 4-1/2 hours away. Next, Riechmann Bros. was moved to the Kansas City, Kansas branch, which was 4-1/2 hours away. John Deere Complete Goods continued out of the St. Louis branch until 1969, and Bill Jr. remembers going along on trips to pick up items at the St. Louis branch.

When the St. Louis Branch closed in 1969, Bill and Loyd purchased all remaining inventory after John Deere had moved out what they wanted. This stock inventory purchase provided Riechmann Bros. with tons of items, and they still have new in-the-box items from that purchase today. This buy included items that were shipped to the St. Louis branch from the New Orleans branch when it closed, and Bill Jr. said they acquired a few pieces of literature in French from that move.

There were a lot of equipment changes through the years. The first corn head was sold in 1958 because in the area they were still picking corn. Customers wanted to shell corn but had no storage so Riechmann Bros. entered the grain bin business until FS started selling bins, much to their relief.

“I remember the first draper head combines and thought how lucky we were to get rid of the draper combines for auger feeding combines,” Loyd said. “A few years ago when Deere came out with draper heads again, I was very concerned knowing how much trouble we had with them in the early days, but they turned out great.”

“We had wire balers with aircooled Wisconsin engines and sold a

lot of them. Farmers would not shut them off when they had lunch because they had trouble restarting the balers when they were hot,” he explained.

D-Day in Dallas

“I got along with the big wheels. I knew Bill Hewitt, and met Charles Wiman once,” Bill Sr. said. “I was married in 1959 and had never been on an airplane. The first time was on a plane to Dallas.”

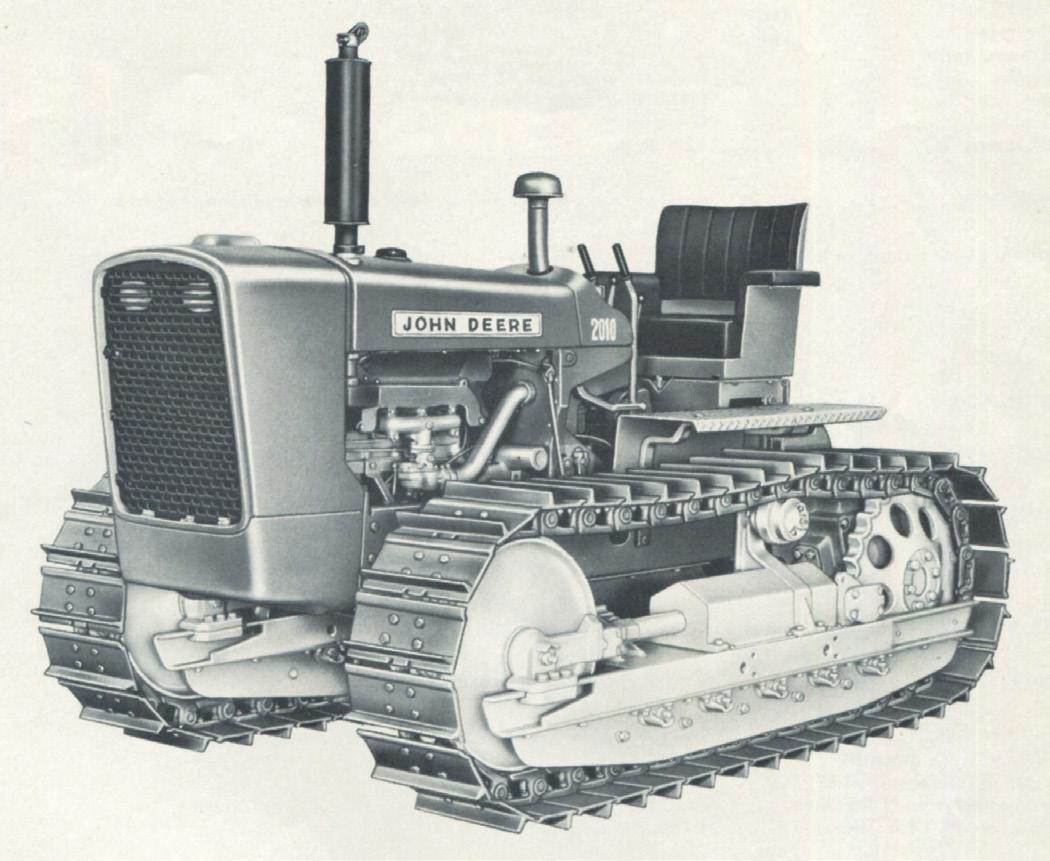

In August of 1960, William had the opportunity to attend the John Deere event that unveiled the New Generation tractors in Dallas. “John Deere chartered a plane out of Lambert Field. Only one person from each dealership could go. I went by myself. I took off and got to go up in the cockpit and talked to the pilot.”

This was a TWA flight: “We flew into Dallas, then it was a two-hour drive on a bus.”

More than 5,000 dealers attended and he was one of the youngest ones at the age of 22! “The first day they didn’t show us anything. That night the Rockettes from New York danced and sang. They said tomorrow we will show you something you have never seen before. They then introduced the New Generations, one at a time with dancers for each tractor. It was quite a production.”

“Not long after Dad died, twocylinder tractors ended,” Loyd added. “We had to convince ourselves that we could sell the New Generation tractors.” Bill Sr. said that he was worried because he had been touting the glories of two-cylinders to his customers.

Loyd recalls that his father only

Page 12 April 2024 • Green Magazine

sold one John Deere “D” tractor; the “GPs” were the big sellers. “The GP was the first tractor I ever drove.”

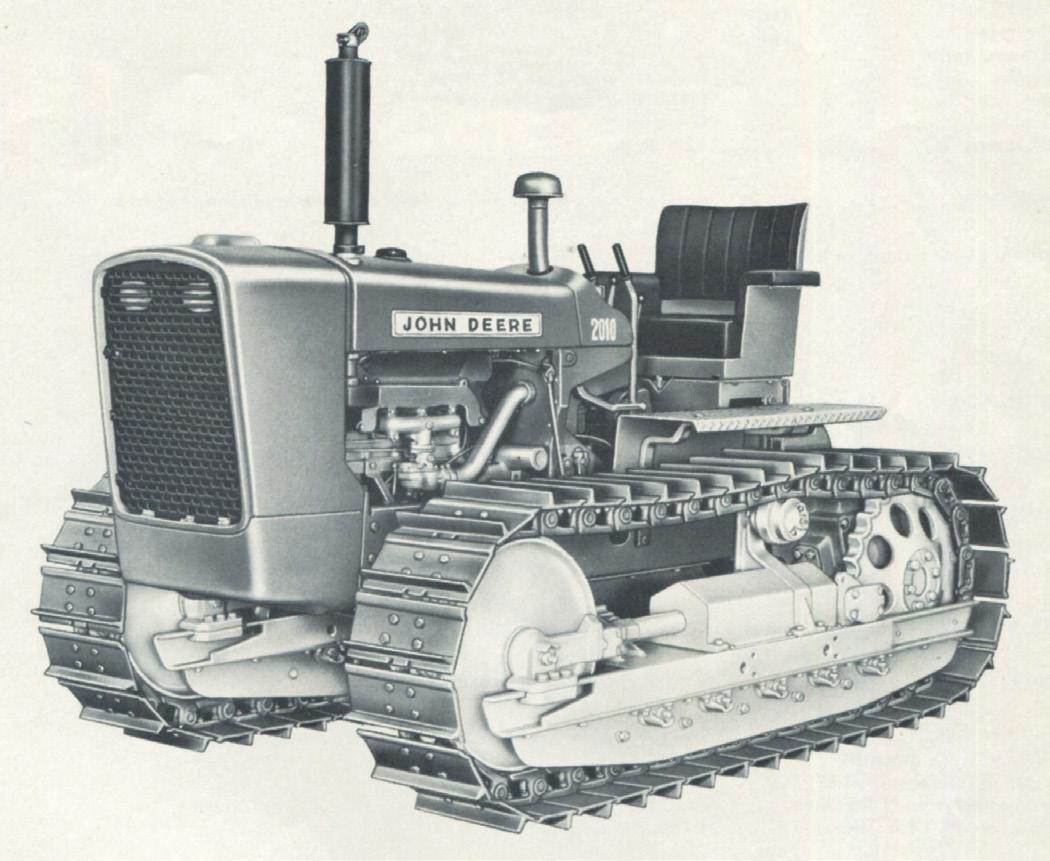

It wasn’t long before Bill ordered the New Generation tractors; in fact, there is a picture of the first shipment in the showroom. “The first New Generation tractor I sold was a 2010. Within a week, I sold one of each size, except for the 1010 and 5010,” Bill Sr. said.

“The New Generation tractors put us on the map. The John Deere technicians and services are what kept us in business. Their support has been very good,” Loyd added.

The Auction Business

When Loyd turned 18, he went to auction school in Mason City, Iowa in 1960. “I went in a Greyhound bus, and it stopped every five miles,” Loyd recalls.

He held his first auction that same year. “I hired my math teacher to be my cashier,” Loyd said.

Since then, they have offered auctions over the years and started a tradition of a consignment auction in Okawville Park on the third Saturday in March, and third Saturday in August. This is still a huge sale, and today Loyd’s son, Michael, and nephew, Keith, are also auctioneers. “We used to have auctions every Saturday, but now we have the two big sales a year. Four auctioneers run it and we have several hundreds of items and antique tractors are a good addition. The auction draws a crowd from Iowa to the East Coast, Mexico and Belize.”

In Mexico and Belize, there is a large German Mennonite population that comes to the auction, Loyd said.

Today, Bill Sr. is 86, and Loyd is 80. Loyd still runs the auction business,” Bill Jr. said.

Expansion

Riechmann Bros. expanded into its third and current building in 1979. The older building was still used, but then just recently suffered the partial loss of the roof from a tornado. “The original building was built in 1939 with additions in 1948 and 1949.”

“For 30 years when we didn’t know what to do with things, we put

them in the old shop,” Bill Jr. explained. He added that is how they ended up with so many new in the box parts, models, signs, etcetera: “Old Germans never throw anything away. I found the first check ever written by us just a few years ago.”

Riechmann Bros. acquired their Breese dealership in 1988, Centralia in 1998, Farina in 2017, and built a new Breese dealership building in 2021 that opened in 2022. Today they continue selling combines, tractors, hay and tillage equipment, and they have expanded to add lawn and garden and utility vehicles.

Third and Fourth Generations

Several members of the third generation are involved in the business. Members of the third generation in the business working are all of Bill’s children: William, Kevin, and Keith Riechmann, and Donna Rabenort; and all of Loyd’s children: Mark, Michael, and Matthew Riechmann. “My sister, Donna, she’s the oldest,” Bill Jr. said., “and she came into the business 15 years ago.”

“My first job was herding sheep,” Bill Jr. said. “There were a lot of weekend farmers that came to the junkyard. The sheep kept the grass down. We would let the sheep out into the used equipment lot to eat grass, and it was mine and my sister’s job to keep them off the highway.”

The sheep and the yard are still part of the operation today.

The fourth generation is also now working at the dealership. Bill’s grandchildren—Kirk, Trey, and Logan Riechmann and Lance Rabenort—all work full time. Loyd’s grandchildren working full time are Zachary and Reed Riechmann.

The family has some collectible tractors like the John Deere 40 utility that Bill Jr. said: “It was our first loader tractor, and it never was sold or left the store.”

They also found that John Deere “D,” the only one that Hugo Riechmann sold, and they have restored it. They bought it from the late Verlan Heberer when he decided to sell a few tractors. “He sold it back to us for about what he bought it for,” Bill Jr. said appreciating Verlan’s kindness to return the tractor to the family at a good price.

“We have the 3300 combine with no cab that we first sold to Loyd’s father-in-law, Morey Stieg.”

Bill Jr., is also an antique tractor puller and has two beautiful John Deere pulling tractors. In his home, Bill has a wonderful collection of memorabilia, and a display case that was once in his other grandpa’s store in Covington, Illinois.

At the 100th anniversary celebration, their family brought out their 1927 Dodge and cool 1946 Jeep that Loyd said they used as a service truck. “My brother, Keith, and I tore it down to the frame,” Bill Jr. said.

During the celebration, one lucky visitor won a John Deere “A”!

Moving Forward

While Cherishing the Old

While many things have changed over the years, the Riechmann Bros. still cherish their history. Many items are collectible, like an original model of a patio set in an original box. Then there are family heirlooms like the desk originally used by Hugo, and more. A walk through the showroom and buildings brings a view of still new in the box John Deere parts, pictures from the past, and pieces of equipment reminding us of the 100 years of continuous service they have provided and continue to provide today. In fact, in 2022, they were named dealership of the year!

For more information about the dealership, check out their website at riechmannbros.com

Photos for this story provided by Bill Riechmann Jr.

Green Magazine® • April 2024 Page 13

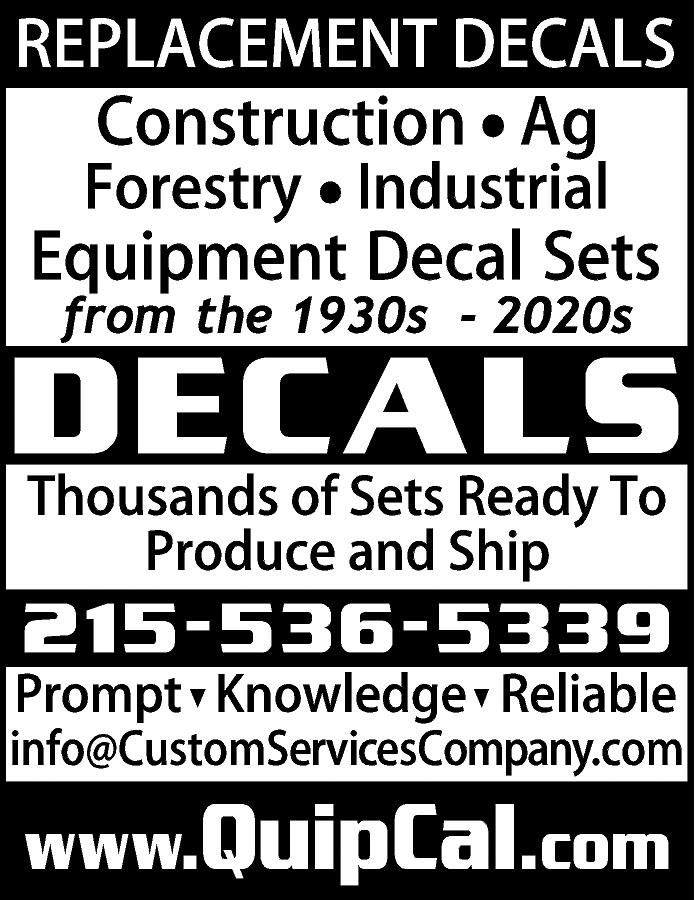

DECALS

Our vinyl computer cut decals are a Licensed Product of Deere & Company.

• For John Deere tractors & equipment!

• Looks like silk screening.

• Pressure sensitive die cut vinyl.

• No film between the letters...they are on pre-spaced application tape.

REPRODUCED PARTS

• Nameplate for 1010 thru 7520, stamped, raised letters, like original.

• Medallions for styled AR through 830, including industrial tractors. Also medallions for steering wheels, power steering and non power steering.

• Correct size medallion: 320, 420, 520 USA made.

• D306R D manifold gasket.

• F55R early G head gasket.

• Air stacks for A, AR, AOs & B, BR & G unstyled tractors; also styled A, B, G, R, 80, 820.

• Air stack adaptors for 620-630 & 720-730.

• Tool boxes.

• New valves and guides: GP, D, G, A, B.

• Replacement upper and lower water pipe for 2 cyls.

• Flat top fenders 530-730, New Generation.

• Clamshell and also New Gen Hi-Crop fenders.

• BO Lindeman steps, side plates and fenders.

• PTO shields & casting 520-730.

• GP dust shields for brakes and muffler parts.

• Grill screens, back and seat cushions, arm rest.

• Spark plug wire looms for A, B, G, BR, BO & AR, AO.

• New radiator cores for John Deere and other tractors that use bolt up type radiators (made in USA).

• Wire hose clamps for unstyled A, B, G, 50-630 & 80-830.

• Reproduction steering wheels A-830 and New Gen.

• Early D & GP fuel tanks.

• We carry new parts for Wico mags, also for pony motors.

• Rebuilt mags and carbs for sale.

These exhaust pipes are made with smooth mandrel bends like the originals MADE IN

We make styled and unstyled A, B, G, GP Top Steer and 50 through 730D.

4 MUFFLERS

D, AO, GP, GPO Spark Arrestor Style

D, AO, AOS, BR, BO

A, AR, B, G Styled and Unstyled

50 through 730D

50 through 530 horizontal, 60, 620 Orchard Made in USA

• Restoration Quality

4 AR28048, AR28049 NAMEPLATE

Stamped, polished aluminum like originals Fits 1010 through early 7020

steel w/chain - 2 cylinder

AR52623, plastic w/chain - New Gen

4 AR45915 RAIN CAP

Fits 3020-4020 side console models

4 CHROME STACKS

Double walled, straight or curved

4 “ NEW” BATTERY TRAY

For 4000 model with brackets

SERVICES AVAILABLE

• We bore and sleeve JD 2 cylinder blocks.

rebuild

• We

carbs and mags for JD & other tractors.

Overseas shipping available - call today! K & K Antique Tractors Kent Kaster 5995 N. 100 W, Shelbyville, IN 46176 Ph. 317-398-9883 Check out our website: www.kkantiquetractors.com Email: info@kkantiquetractors.com 4 T10551 NAMEPLATE Like original, stamped polished aluminum with raised lettters, flat black background Each 3-3/8” x 27-3/4” • $140.00 per set plus S/H 4 HYDRAULIC OUTLET PLUG AF3001R,

USA

Green Magazine® • April 2024 Page 15

As the agricultural tractor went from a novelty to a necessity on American farms, the farms themselves began to change in reflection of the power and efficiency that tractors could provide. Farms grew bigger, first tearing up the pasture and hay land once needed to feed draft animals. Then they began to break new ground. Many of the smallest farms bought more land or sold their own to another farmer eager to work a larger area. With larger farms came the demand for more powerful tractors, and the cycle continued. Between the 1920s and the 1950s, the horsepower of Deere’s most popular tractor more than doubled, and it continued to increase from that point to the present day.

Deere’s engineers were already busy planning and designing what would become the New Generation tractors in the late 1940s. By the early 1950s, they had built a few experimental tractors. As time and test-

ing went on, it was realized that it would take still several more years of research before the new tractors were ready for production. So it was decided that another generation of tractors would be issued between the numbered series and the New Generation. The first focus of this set of tractors for both company and customer would be more power. A

Bryce Heithold of Wayne, Nebraska owns this 1958 model 620 row crop with wide front. Many 20 series tractors used the larger 30 series muffler after they were introduced.

Page 16 April 2024 • Green Magazine

20 percent increase in power was anticipated across the board, so Deere created the 20 series.

The 620 was created to replace the model 60—the middle child of the lineup. The 620 was a four-plow tractor that could also work four or six rows of crops, but was a bit lighter, cheaper, and more efficient than the 720 for those farmers who didn’t need its extra power. It was versatile and maneuverable and fit well with a loader, a blade, or just about any other piece of equipment for work around the farmyard. It hit the market in the fall of 1956.

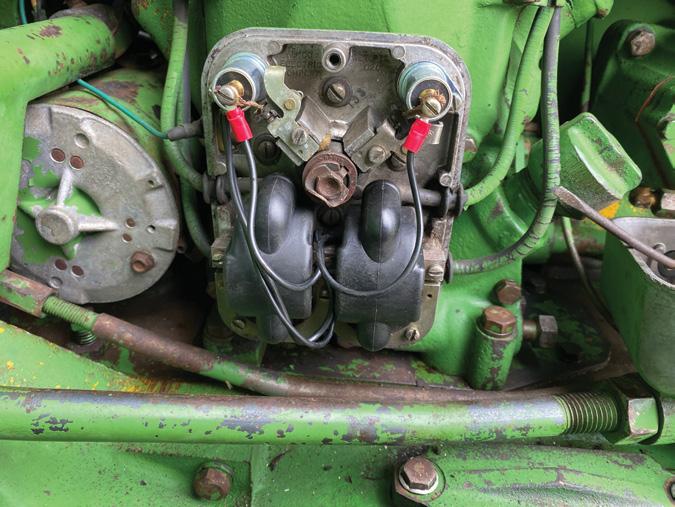

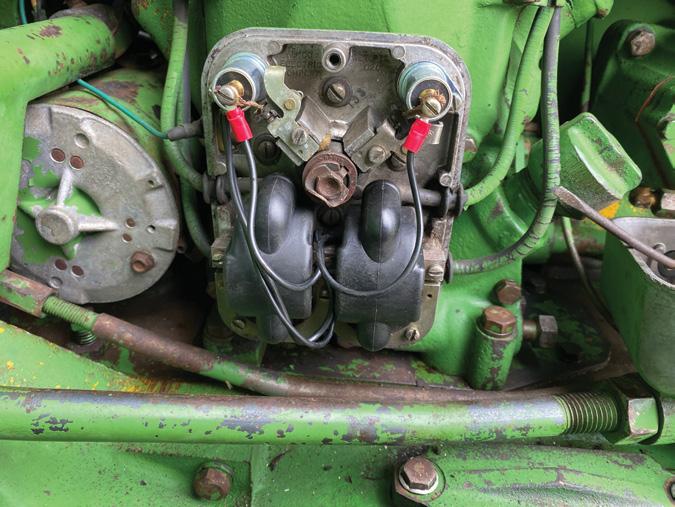

The 20 percent increase in power for the 620 came through an increase in engine speed. To accomplish this and maintain reliability, Deere shortened the engine’s stroke from 6-3/4 inches to 6-3/8 inches. The bore remained the same at 5-1/2 inches. The steel pistons were replaced with lighter aluminum ones. The rod, main bearings, crankshaft, and connecting rods were all bulked up to withstand the extra power. A new engine block was created for the more powerful engine. The petcocks (or the space for them) was eliminated, since electric start was now a standard feature of the tractor. The spark plub holes were moved to the cylinder head. An extra stud and two pins were added to the block to improve the seal between it and the head. Leaking head gaskets were much less frequent after this change than they had been in the model 60.

Deere’s engineers further increased power through an improved combustion chamber. The ports and manifolds for the engine were also revised and improved, providing superior air movement through the engine. Valve rotators were added. With these, the valves wore more evenly and at a slower pace and deposits built up on them less than before. Compression in the engine was able to be increased without any knocking.

Of course, all of these improvements couldn’t be made without

also increasing the refinement of the electrical system. The distributor was moved to be driven at half speed by the crankshaft. At half speed, the spark plugs only fired on every compression stroke but not the exhaust stroke. The points and the plugs had their longevity doubled by this change. Having the distributor run at half speed also increased its precision, allowing for tighter ignition tuning and more power.

With everything put together, the engine now produced 48.68 horsepower at the belt and the LPgas engine made 50.34 horsepower. These figures were very close to the 20 percent increase that Deere had planned for the tractor. It is also important to note that both of the engines set new records for economy when they were tested at Nebraska.

The boost in power created a need to improve other parts of the tractor, since they would now be under more stress than before the upgrade. The rear end gear ratios were altered because of the engine speed change. If left alone, the travel

speed of the tractor would have increased. Deere changed them to keep ground speed the same. Gears and bearings in the rear end were strengthened, and the final drives were upgraded with a wider differential pinion. The bevel gears for the PTO were enhanced by mounting them in anti-friction bearings, reducing power loss and increasing their longevity. The clutch pack for the PTO was upgraded from seven disks to nine, and Raybestos woven material was now used in them.

On the topic of the PTO: the transmission-driven PTO was eliminated with the release of the 620. There was little demand and even less utility for the setup. Only the “live” PTO was offered for the 620. Furthermore, every tractor was built with the PTO internals already in place, so farmers who decided down the road that their tractor needed a PTO found it easy to add one. The PTO was operated by a foot pedal on these tractors and included a neutral position that made it possible to spin the PTO by hand to ease alignment of the splines on the shaft

Green Magazine® • April 2024 Page 17

Dean Vinson’s 1958 620 row crop is still hard at work.

to a piece of equipment.

Bypass starting was built into the 620. A full 12 volts was sent from the battery to the coil during ignition, providing maximum spark during startup. When the starter was disengaged, the tractor sent only six volts to the coil. Spark was still ample to avoid misfire, but the longevity of the electrical system was improved since it mostly ran at the lower voltage.

Deere revised the front end support for the tractor. They made it heavier for better balance and added attachment points for a new front weight package and a front-mounted rockshaft. Tractors with power steering had a heavier front end because of the system and showed better balance than tractors with manual steering. So Deere added 100 pounds of weight to the front pedestal on tractors with manual steering to better match power steering tractors and their superior balance.

Larger brakes and a larger fuel tank were the final standard improvements to the 620 over the 60. The sheet metal remained the same from the previous generation, but Deere included a yellow stripe painted down the hood and grill sides. This stripe served to differentiate the new series from the old. It also happened to draw in the eye and made more than a few farmers jealous enough to paint a yellow stripe down the side of their model 60. Deere also created a new front grill medallion to complete the new look.

A universal three-point hitch was finally available to Deere customers. Henry Ferguson had held the patents on the three-point but they had expired and Deere took advantage. A new type of rockshaft was built into the 620 for the threepoint. The tractor benefited with more accuracy for the tools attached to it and more work capacity on the three-point.

Deere initially created three different chassis types for the 620.

The most popular, by far, was the row crop model. Many combinations of axles, wheels, and tires were offered for the 620 row crop. The standard equipment was a solid narrow front end with 6.00-16 inch front tires and 12.4-38 inch rear tires. 13.6-38, 15.5-38, and 11-42 inch rear tires were available. 11-38 and 12-38 “open” or “closed” tread rice and cane tires were also available for the rear. A “dish” style cast offset wheel was also available for the 620 with any tire size.

The standard rear axle was adjustable from 58 to 88 inches. A long rear axle was an available option, and it allowed tread from 62 to 98 inches. Equipped with offset rear wheels, the tractor could set six inches narrower or wider than these measurements. Deere also offered an extra-long rear axle with range spreading from 61 to 120 inches. This axle was installed by the dealer, not at the factory, and Deere had a stated load limit for a tractor with this axle and wheels set to full width lest it bend or break the axle or put too much strain on the bearings.

At the front of a 620 row crop,

the farmer could replace the fixed narrow front with a Roll-O-Matic narrow front, a single front wheel, a 38 inch fixed-tread front end, or a 48 tp 80 inch adjustable “square” front axle. All two-wheel front end options came with 6.00-16 inch six-ply front tires. The single front wheel was either in 9.00-10 or 7.50-16 inch size. Deere still offered steel wheels for front, rear, or both.

Deere also built the 620 in a standard tread version. This tractor had a lower center of gravity and a fixed front axle. It created a more stable tractor and was a good platform for small grain farmers. The tractor was on 13-30 inch rear tires and 6.00-16 inch front tires on a 551/2 inch width front axle. 14-30 and 15-30 inch rear tires were available, with the 15-30s on either 14 or 16 inch rims and in regular tread or rice and cane. The front axle could be replaced with an adjustable version allowing spacing from 52 to 68 inches, and 6.50-18, 7.50-18 and single-rib 7.50-18 inch tires were available on either front axle. As on the row crop, steel wheels were available on the standard tractor.

Finally, there was the 620 Hi-

Page 18 April 2024 • Green Magazine

Dan Kaler’s 620 orchard.

Crop. Deere had been building an extra tall version of some models of their tractors for decades and they were not about to quit. The 620 HiCrop had 12.4-38 inch rear tires and 7.50-20 inch front tires, but could be ordered with 13.6-38 inch regular tread or 12-38 rice and cane tires. Deere did not offer any axle options for the tractor, but radius rods were offered for a price and gave a bit more support to the front axle.

Many options were offered for the model 620. The most exciting of these was custom Powr-Trol. This allowed full control of up to three separate hydraulic circuits, each with unmatched accuracy and finesse. No other manufacturer could provide so much precision to a farmer and his implements. Tractors equipped with custom Powr-Trol came with a rockshaft installed. Single or dual hydraulic controls were extra. The row crop and standard tread tractors had a universal three-point hitch as an option, while the 620 Hi-Crop had a special three-point hitch option. There was the option of leaving the rockshaft off of the 620 standard. In this case, the tractor could still

have remote hydraulics installed. The row crop and Hi-Crop tractors could be equipped with a solid or split front rockshaft. The Powr-Trol on tractors with a front rockshaft could be set up to perform a delayed lift. This caused the rear-mounted equipment to be raised later than the front-mounted equipment, with the aim that the delay would cause both sections of the implement to come out of the ground at approximately the same point in the field. The neat thing about this was that it was all done with a single hydraulic cylinder.

Power steering was another very popular option. Deere’s was easily the best power steering system on the market. In situations where steering was traditionally difficult, the system shined, making steering all but effortless even when the front of the tractor was heavily loaded, was moving slowly, or was in wet ground or a rut. In optimal condition, Deere’s power steering was still fantastic, as it made steering so light and responsive that it went from being a chore to an afterthought.

The Float-Ride seat made its debut with the 620. This seat added adjustable rubber torsion springs to the seat as a suspension. These springs allowed the seat to move somewhat independently of the tractor, isolating the operator from some of the bumps and jostles that the tractor ran over. The Float-Ride seat also provided some fore and aft adjustment, helping the operator find a more comfortable position for his ride. Deere may have been exaggerating when they claimed that the seat made “fields seem superhighway smooth,” but it was certainly an improvement over what came before.

Other options for the tractors were a “live” 540 RPM PTO, electric fuel gauge, speed-hour meter, precleaner, vertical air stack, rear exhaust, heavy duty batteries that provided 30 more amps, cigarette lighter, front frame weights, front wheel weights, rear wheel weight packages, heavy-duty drawbars for the Hi-Crop and standard tractors and a foam rubber seat cushion. Row crop tractors could have clamshell fenders. High altitude pistons

At the time this photo was taken, the beautiful collie and 620 standard were both owned by Louie Bartley.

Green Magazine® • April 2024 Page 19

for gasoline and all-fuel tractors were automatically installed by Deere when the destination of the purchased tractor had an altitude over 3,000 feet. Deere did not charge for these.

The gap in power between the gasoline engine and the all-fuel engine in Deere’s tractors was widening. In the 620, the all-fuel engine could create only 32 horsepower— about 70 percent of the gas engine. This fact was causing the interest in the all-fuel engine to wane, especially as the price difference between gasoline and distillate fuels was shrinking. Deere still sold all-fuel engines, but tractors ordered with them were now less common than ever before.

About 13,000 model 620 tractors were built in the first year of production. The public was very excited by the machines and so they sold quite well and were successful at work. Deere had thought of a way to entice even more buyers however, and released the 620 orchard in May of 1957. Deere had continued to build the model 60 orchard even while the 620 was being sold. This gave grove and orchard growers a Deere tractor to buy, even though it was a slightly out-of-date one.

The 620 grove and orchard tractor was the beneficiary of all of the improvements that had been built into the rest of the model 620 tractors. Deere also added a speedhour meter and electric fuel gauge as standard equipment. Options for the tractor included the Float-Ride seat, “live” 540 RPM PTO, heavy duty drawbar, rear exhaust, and a cigarette lighter were all optional. The 620 grove and orchard did not have enough room to fit the “advanced” power steering system, but Deere could put a cylinder-assisted system on the tractor. This was not as nice of a setup, but it made the 620 the first of Deere’s orchard tractors with any available power steering. Other options for the tractor included citrus fenders, fender sides, engine side shields, and an opera-

tor’s shield. The full set of these cost $189, but they could be ordered separately in whatever combination was desired.

A 620 orchard in full shields is quite a site to behold, but they are quite rare. Many orchard tractors were purchased with few or none of the shields, and many more lost their shields over the years when they were removed and never returned. So if you are interested in finding a 620 orchard for your collection, don’t be surprised if you struggle to find the shields for one.

The 620 orchard had 13-26 inch rear and 6.00-16 inch front tires. 1426 inch rear and 7.50-16 inch front tires were available on the options

list. Regular and diamond tread were available on any of these tires, making the purchaser decide if traction or smooth ground was more important. The 14-26 inch rear tires could be installed on 16-inch rear rims for enhanced flotation. Again, steel wheels were available to those who wanted maximum gripping power.

Deere had a bit in store for the 620 for the 1958 model year. At serial number 6213100, sealed beam headlights replaced the older headlamps. The power steering and clutch were both updated and improved. A new, larger steering wheel covered in plastic was outfitted. The muffler was replaced by a part that

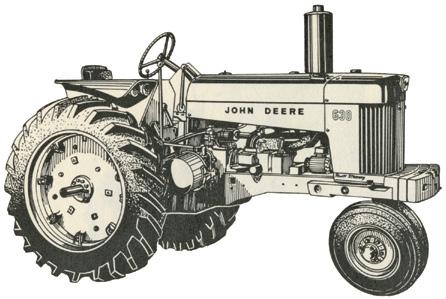

620 Row Crop Production Numbers and Serial Number Breaks

620 Standard Production and Serial Number Breaks

620 Orchard Production and Serial Number Breaks

620 Hi-Crop Production and Serial Number Breaks

Year Beginning/Ending Gas All-Fuel LP Total 1957 6200000-6213099 10,468 266 1,614 12,348 1958 6213100-6222686 6,302 182 642 7,126 Totals 16,770 448 2,256 19,474

Year Beginning/Ending Gas All-Fuel LP Total 1957 6200195-6213099 607 18 31 656 1958 6213100-6222524 281 13 5 299 Totals 888 31 36 955

Year Beginning/Ending Gas All-Fuel LP Total 1957 6211100-6213099 28 25 22 75 1958 6213100-6222686 40 21 18 79 1959 6223000-6223156 26 116 39 181 1960 6223157-6223247 7 24 5 36 Totals 101 186 84 371

Year Beginning/Ending Gas All-Fuel LP Total 1957 6201604-6211168 10 7 4 21 1958 6213508-6222550 12 11 4 27 Totals 22 18 8 48

Page 20 April 2024 • Green Magazine

had stainless steel on the interior to help reduce rusting. Ball-joint tie rod ends were installed on the standard and row crop tractors. Deere also decided to begin painting the dash panels in black instead of green, and these tractors are often now referred to as “black dash” 620s.

New options for the 1958 model 620 included power-adjusted rear wheels for the row crop tractors. These made changing the rear wheel tread much easier and allowed a range from 56 to 94 inches. The power-adjusted wheels were available with 12.4-38, 13.6-38, or 15.5-38 inch tires. The 620 row crop gained a step as standard equipment, where it had been just an option before. A heavy duty Roll-O-Matic front end with 7.50-16 inch tires joined the options list partway through the model year. 18-26 10-ply road grader tires were also available for the model 620. These were mostly aimed at industrial customers.

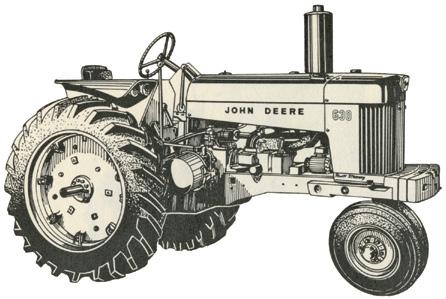

The 630 was released and replaced the 620 in July of 1958, marking one last half-step between the two-cylinder era and the New Generation tractors. The 620 orchard tractor continued to be produced beyond this date, however, and was not terminated until 1960. Deere felt that it was cost prohibitive to create a 630 orchard, but they did add a few of the improvements from the 30 series tractors to the 620 orchard.

The 620 sold very well. Because no diesel version of the tractor was produced, it sold extremely well, and nearly matched the 720 in sales numbers. A total of 22,532 620 tractors were built in all, and over 21,000 of those were row crop machines. Obviously, then, a 620 row crop is quite a common tractor. This also means that the three other chassis types were divided between just 1,000 tractors. Only 48 of the 620 Hi-crops were built, and just eight had LP-gas engines, making some 620s extremely rare.

In February 1958, Deere tooled up their Monterrey, Mexico assem-

bly plant to build about 40 model 620 tractors. These tractors were numbered from 6217400 to 6217439. Deere sent kits to the factory where they were put together into complete tractors. Most of these tractors were row crops with all-fuel engines. A few may have had gasoline engines, though. Deere added the words “John Deere de Mexico” to the serial number tags, but the tractors are otherwise basically identical to a tractor built in Waterloo.

Deere’s industrial version advertised and sold the model 620 to its customers. Most of the machines that they sold were standard tread tractors, but were little changed from any agricultural machine. There is the possibility that Deere sold a 620 to an industrial firm who wanted it painted in industrial or John Deere yellow, but there is no evidence showing that happened and no tractor painted that way has been unearthed. So, if you happen to find yellow paint on your 620, it is almost definitely a result of the yellow primer that Deere was using in this period. The sheet metal on

these tractors often did not have that primer on them so again, don’t be surprised if the yellow only shows up on certain parts of the tractor. Furthermore, Deere painted every tractor with a yellow stripe down the side of the hood. They did not paint them white. Any tractor with a white stripe has simply had the yellow paint bleached to that color by their time in the sun.

Model 620 tractors with a serial number prior to 6213100 should have green dash panels and black generators. After that serial number, the tractors would have black dashes and green generators. All tractors had black headlight housings and seats of either black or yellow—picked by the customer.

The 620 is another one of those tractors that is the quintessential two-cylinder John Deere machine. Besides being reliable, powerful, and versatile, the 620 is what many people picture when they close their eyes and think “classic John Deere tractor.” The tractor fit a wide range of farms in its day, and it would fit into a wide range of tractor collections today.

A restored 620 Hi-Crop.

Green Magazine® • April 2024 Page 21

5010,

Dust Shields

5010 Right, AR35334, $320 5010 Left, AR35335, $320

5020, 6030 RC Right, AR40930, $350

5020, 6030 RC Left, AR40931, $350

5020, 6030 Whd R, AR36772, $350 5020, 6030 Whd L, AR36773, $350

Rock Shaft Cover

5010, 5020 Right, R36420, $295

5010,5020 Left, R36422, $160

5010, 5020, 6030 Center, AR55756, $70

6030 Right, AR55755, $295

6030 Left, R51485, $160

Toolbox Cover

5010, 5020, 6030 - AR35050, $65

Hood Air Cleaner Cover 4050, 4520, 7020 - AR43256, $165

Hydraulic Dipstick Cover 5010, 5020, 6030 - R36421, $80

Step w/Pads

5010, 5020, 6030 - AR40914, $165

Step U Bolts $18

Seat Base Cover for Tractor w/o Rock Shaft - AR26846, $295

4000 & 4020 Std SN 201,000 & Above

AR40773 LH Rear Eng Panel = $80

AR40774 RH Rear Eng Panel = $80

AR40871 Platform (can modify AR48727) = $155

AR41097 Platform Support = $84

AR41098 Platform Support = $84

AR41137 Dust Shield RH = $315

AR41138 Dust Shield LH = $315

AR41174 Support To Dust Shield=$27

R41253 Ext Front Right = $156

AR41451 Ext. (RH) = $74

AR42594 Step Bracket w/2 pads = $215

F3195R Step Pad = $30

AR42989 Cover Battery Box = $80

AR45129 Battery Box Support = $75

AR45130 Battery Box Support = $75

AR45131 Ext L Ft AR48964 = $184

AR45207 Battery Box = $340

AR46289 Weight Bracket = $102

AR48964 Ext L Ft AR45131 = $176

3020 Standard Tractor

R34944 Floor Panel 3020 Std PS

R34943 Floor Panel 3020 Std PS

AR34801L Dust Shield = $325

AR34801R Dust Shield = $325

R42893 Fastener Pin for Battery Box = $36

Dave Haala: dave@haala.com or 507-920-9181

22 April

Burrey Carburetor Repair • We rebuild ALL John Deere models • We make carburetor parts no longer available from Deere • Single & dual induction bottom repairs • To personally drop off your carburetor, please call for an appointment • WE STOCK carburetors—rebuilt and ready to install on your tractor • ALL carburetors carry a 1 year guarantee • ALSO BUY, SELL & TRADE CARBURETORS Burrey Carburetor Repair Kurt & Mindy Bleke • 5026 Maples Road • Fort Wayne, IN 46816 Tollfree: 800-287-7390 Phone/Fax: 260-447-6347 Website: www.burreycarb.com Email: info@burreycarb.com 9 AM to 6 PM EST M-F • Saturday 9 - 12

Bracket

Fabricated tractor parts - Dave Haala Tractor Parts We Fabricate Weight

5020, 6030: AR58358, Pr $320

Engine Panels

Right, AR43290, $155

Left, AR51804, $255

Right, AR38206, $300

Left, AR38207, $220

Right, AR38838, AR38202, $300 2520 Left, AR38839, AR38203, $220 5010, 5020 R, AR35023, $300 L, AR35024 OR AR36796 $300

AR53645, $350 6030

AR53646, $350

Rear

4620

4620

2510

2510

2520

6030 Right,

Left,

Page

2024 • Green Magazine

Lakeside Service & Supply

New and Used Parts for Vintage JD Two Cylinder Tractors

We ship parts daily!

Lakeside Service & Supply

325 S. Main Street • Elmer, NJ 08318 856-358-2444

deereblaze@verizon.net

Like us on Facebook!

Visa/Mastercard/Paypal accepted

Wiring Harnesses - Cables - Switches

We build restoration quality wiring harnesses to fit these John Deere models and their variations:

AG Models: A, B, D, G, GM, L, LA, M, R, 40,

50, 60, 70,80, 320, 420, 430, 435, 440, 520, 530, 620, 630, 720, 730, 820 2 cyl, 820 3 cyl, 830 2 cyl, 830 3 cyl, 920, 1010, 1020, 1520,

1830, 2010, 2020, 2030, 2040, 2040, 2130, 2240, 2350, 2355, 2440, 2520, 2550, 2555, 2630, 2640, 2840, 2855, 2950, 2955, 3010, 3020, 3150, 3255, 4000, 4010, 4020, 4030, 4040, 4050, 4250, 4230, 4240, 4430, 4440, 4455 Mexico, 4630, 4640, 4840, 5010, 5020, 6030, 7020, 7520, 8010, 8020, 8430, 8630, 8440, 8640, 8560, 8760, 8960, 8770

Harnesses available for other models & brands

See website for complete listing

Due to numerous variations, call to order Shipping/handling not included

Visa, MC & Discover accepted

Prices subject to change without notice

Circuit protection kits for Diesel tractors

From $35 (2 cylinder)

From $60 (New Gen)

Industrial Models: Al, Bl, DI, 300, 301, 302, 302A, 310A, 350, 350B, 350C, 380, 400, 400 Scraper, 400B, 400C, 401, 410,

410C, 410D, 440I, 450, 4508, 450C, 450E, 455E, 480B, 500, 500A, 500C, 510D, 540E, 544A, 548E, 600, 7E Scraper, 700, 700A, 710D, 750, 755, 840, 1010C, 1010W, 2010C, 2010W, 3010I, 4010I AG Machinery: 45, 55, 4710, 5730, 5830 Lawn and Garden: Commercial mowers: 38”, 48”, 54”, GX1320, 727 Z-Trak, 60, 70, 110, 112, 120, 140, 200, 208, 210, 212, 216, 245, 300, 312, 314, 316, 318, 285, 320, 322, 330, 332, 420 Compact Tractor: 790, 850 Snowmobiles: 340 Cyclone We also carry: Starters, Regulators, Generators, Alternators, Relays, Coils, Lights, Alternator Brackets, Pulleys We make alternator conversion harnesses Call for a FREE 100 PAGE CATALOG! CALL: 716-937-6618 • WORLDWIDE SHIPPING International phone: 001-716-937-6618 Email: agriserv@rochester.rr.com 13899 North Road, Alden, New York 14004 www.wiringharnesses.com Green Magazine® • April 2024 Page 23

I am not real sure where I got the idea to commemorate the 10th anniversary of Green Magazine with a model tractor, but as some of us so often say about bad ideas, “It seemed like a good idea at the time.” There are two basic ways to offer a tractor, and both will subject you to criticism. You can either take a shelf model and change the wheels or add a cab or some other accessory and apply a commemorative sticker. The other way is to pay someone

to develop a new model. This involves making patterns, having the parts cast, assembling them, painting them, adding wheels, and decals, etc. If you do the first, people will say, somewhat rightfully so, that it’s just a shelf model with a sticker, and ask why you didn’t offer something new. If you do the second, many will complain that they are too expensive and only those born with a silver spoon

in their mouth can afford them. We chose the second option, and hired Paul Stephan to create our commemorative tractor. Being that it was our 10th anniversary, no one had built a toy of this model and I was really into collecting 10 series tractors, having the model be a 1010 seemed like a no brainer.

We began taking orders for the models in January of 1995 at a retail subscriber price of $199. Yes, some people complained that they were too expensive. We sold about 500 of them though, and if we made any profit on the endeavor, it wasn’t much. Notice we never did it again. Actually, eight or nine years later, Bill Proft (who by then had begun writing toy articles for us) asked if he could investigate the possibility of a tractor to commemorate our 20th anniversary. Though a bit skeptical, I told him to go ahead and investigate if he wanted to. I believe he contacted Deere, Ertl and maybe some others but soon grew so frustrated with the whole process that we put the whole idea to rest.

One of the big events of the 1990s was the Wheatland Poppin’ Johnnies indoor swap meet and tractor pull held at the Kansas Coliseum Pavilion in Wichita, usually the last weekend of October. It was an annual event that many looked forward to attending. It was held for more than 20 years, but like the Central Hawkeye Swap Meet we discussed a few months back, outside forces led to its demise. Eventually one of the local aircraft companies purchased the facility and its use was changed to component storage.

In the early spring of 1996, a new television program called The Tractor Show premiered. The half hour program was hosted by Rachael Landau and Gerald Devine. The hosts took phone calls, showed videos and toured enthusiasts’ collections. It aired Thursday nights right after Seinfeld but not on NBC, rather transponder 302, channel 5. What that means is that you had to have one of those

Page 24 April 2024 • Green Magazine

big movable satellite dishes to watch. It was interesting but the production values were nowhere near what you see today on RFD TV or even a lot of YouTube videos. For reasons that were never explained, it disappeared from the airwaves after a few months.

In July of 1996, the Illinois Valley Two-Cylinder Club held their extravaganza, which also featured an 8020 reunion. At the time, I owned an 8020 and I managed to have it hitch a ride on my local John Deere dealer’s semi when he was going that way. If I recall correctly, there were about a half dozen 8020s at the show. My tractor made it home safely, though I sold it a few years later and it now resides in Washington. I managed to sell it just before the price they bring quadrupled.

In July of 1996, A Specialized Look Into the Unstyled Model “A” was first introduced in Green Magazine. This first edition was self-published and sold by the author, Wes Malcolm. I don’t remember if it was Wes’ idea, or my idea, but a few years later, when his first run of books was sold out, we took over production and sales of the now somewhat famous book. Wes gave us some corrections and additional information that he wanted to see in the new edition and soon a printer was working on a new batch. We have done four more printings of this book, all but one of them with additional information. Next month we will look at changes Deere made in archives access and licensing that continue to affect the hobby today.

Send in your info today! Developing a new product? Or a new service? Let Green Magazine readers know about it in Product Review. New products and/or services will be considered for Product Review, a regular feature in Green Magazine. If you have a new product or service, write down the pertinent details, include a photo (if possible) and send to: Product Review / Green Magazine PO Box 95 • Bee, NE 68314-0095 Information can be emailed to: info@greenmagazine.com Green Magazine® • April 2024 Page 25

1973 JDX-8: Tough sledding in the high performance market

Every John Deere collector’s story starts somewhere, and back in 1983, my four-decades long obsession with John Deere snowmobiles was kicked off with the purchase of a rough 1973 JDX-8. Deere was still in the snowmobile business in 1983; I was a curious 14-year-old snowmobile fanatic who was thrilled to own a machine you could actually buy parts for at our local John Deere dealer, Falls Farm and Garden in Hudson Falls, New York. Parts availability was a major improvement over the out of production brands I tended to drag home before then. Come to think of it, parts availability 40 years after Deere exited the snowmobile business is still better than most of the brands that came and went over Deere’s 12 years of production.

For Deere’s second model year building snowmobiles, the 1973 JDX-8 was their first attempt at a hiperformance model. The new JDX line up, including the 440cc JDX-8 and the 292cc JDX-4, were intended to be the “top of the line” machines for the expanded and improved 1973 model year. The story goes that Deere VP RJ Carlson challenged the engineering team at Horicon to “pull ahead” the JDXs from the original 1974 planned introduction up to the 1973 model year. According to the book, John Deere

Snowmobiles by Leonard and Teal, when RJ Carlson called a meeting in the summer of ’71 to discuss tripling snowmobile production numbers from 12,660 machines from the ’72-model year to 36,000 for ’73, he also brought up “the possibility of producing the JDX performance machines as 1973 models that were originally planned

as ’74 models. These machines were to have more powerful engines and improved suspensions.”

This meant the team was going to have to make some compromises and test and development would be significantly compressed to get the JDXs to market a full year sooner. According to Leonard and Teal’s book, Deere was

Page 26 April 2024 • Green Magazine

Brian Lindner loaned us his restored 1973 JDX-8 for a photo model. It’s been updated with a few custom touches like modern plastic skis and of course a full coverage windshield.

already planning to expand the 1973 line-up from the original two machines built for 1972, the 340cc model 400 and 440cc model 500. Before the JDX pull ahead, two new models, the 300 and 600, were already scheduled for ’73 introduction that were originally planned for 1972 but were unable to get into production that first year. The 600 was a “wide track” that was basically a model 500 with the same powertrain but an 18 inch wide track instead of 15 inch and deeper chaincase gearing. The 600 did go into production as planned for ’73. The 300 was intended to be an entry level 292cc Kohler powered model below the model 400 but ended up getting pulled into the JDX family for ’73 as the new JDX-4. The Kohler powered model 300 with bogie wheels would have to wait until 1974 to finally appear as an update of the original JDX-4, while a significantly different 340cc machine called the “JDX-4 Special” was released with updated and expanded 1974 JDX machines.

The front view of the Lindner JDX-8 shows why most riders updated the windshield from the small factory bikini “sporty” windshield to the full size windshield from the 100 series “green machines.” The NOS front chrome steel bumper and rechromed rear grab bars contrast sharply against the Blitz Black paint scheme.

The “all new” ’73 JDX-8 featured CCW’s (Canadian Curtis Wright) allnew case reed 440cc engine, manufactured for them by Kioritz of Japan. The “KEC-440/21” was rated for 40 horsepower, four more than the piston ported model 500. While a step in the right direction for a family trail sled, it was off the pace for a “hi-performance” machine. Instead of sharing the green color with the ag line as the “100 series” snowmobiles did, the JDXs received a high quality all over “Blitz Black” paint job in an era when many snowmobiles had their aluminum tunnels left unpainted.

For a “sporty look,” the X-8 received a small “bikini” windshield that offered minimal wind protection. Deere added significant safety equipment across the board for ’73, such as a molded snowflap, a round hi/lo beam headlight and, on the JDX-8 and 600, a handlebar pad.Other standard equipment the JDX-8 received included carbide ski runners, ski shocks, a speedometer, and it was the only ’73 to receive a tachometer standard. Electric start, a passenger back rest kit and a matching black “JDX-8” cover were available as accessory items.

Deere was marketing the machine with “superior performance and distinctive styling” when the poor girl was unfortunately based on an already dated chassis. They called the somewhat “narrow-ish” 28 inch ski stance “wide” while other performance sleds of the era were up to four inches wider and, worse off, the engine was placed directly under the handlebars, or “mid-mounted,” the same as the ’72 machines.

On top of that, most all the major players had already introduced longer travel and better riding slide rail suspensions, while Deere plowed on with trailing arm bogie wheels suspending the track with steel flanged wheels literally purchased from a conveyer company. Interestingly enough, the entry level JDX-4 received Deere’s first aluminum flanged bogie wheel containing a sealed bearing that became standard equipment for all Deere bogie sleds from 1974 to ’77. The ’73-era front

“power unit” that housed the steering system, fuel tank, motor and chain case mounts was still steel while the rest of the chassis from front to back was stamped aluminum. The “power unit” was switched to aluminum construction for the ’74-model year, shaving 17 pounds off the front of the machines. The JDX-8 had a good, high-quality chassis, just not a hi-performance engine placement or ski center to center to promote competitive handling.

Just to add to the stress of increased production and pulling head the JDX a full model year, many of the new engineering features for ’73 caused headaches for Deere’s Horicon Works that designed and manufactured the snowmobile line. According to word-of-mouth stories and detailed in John Deere Snowmobiles , the new 40 horsepower case reed engines, the KEC 440/21 was not ready in time for the JDX8s to roll down the assembly line. The book quotes Jack Hoffman as recalling “that JDX8 production was assembled and crated for shipment without engines.” So Deere’s new flagship ran down the line without motors being installed. The solution was supposedly to have hired local schoolteachers on summer break to perform the final assembly in a separate area of the factory. The JDS book

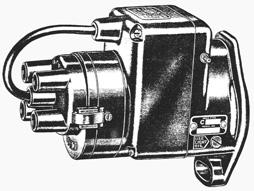

Kioritz of Japan manufactured the KEC-440/21 case reed motor expressly for CCW, for use in the 1973 JDX-8. The 40 horsepower motor provided an 11 percent power increase over the model 500, but not industry leading performance. Optional electric start shown here adds a nice convenience to the machine.

Green Magazine® • April 2024 Page 27

authors admit that the schoolteacher part of the story was not verified but considering that Jack Hoffman was an engineer on the program, the story about the sleds being built short engines seems quite legit. Stories also flew out of Horicon that Kioritz air freighted the new engines to Deere in a 747 as soon as they were built. Not surprisingly, no pictures of this or the offline assembly work can be located.

Aside from increased power, improved suspension was another stated goal of the JDXs. Yet, the ’73 JDX-4 and JDX-8s utilized Deere’s conventional bogie wheel system on an all-rubber Gates track, a total carryover from 1972. However, several years ago, I noticed something was different in the 1973 snowmobile brochure. Both JDXs pictured had the all rubber track but did not show the shiny external rear pivot plates typical of Deere’s bogie wheel suspension. I posted on www. jdsleds.com about it, to which Deere factory snowmobile technician Ed Kruel responded about a prototype steel slide bar suspension that ran directly on the rubber track. Apparently while it had more travel, and I

Interestingly enough, the Lindner JDX-8 was one of the few that did not receive the Mod Kit 160 clutch update, as it was optional for machines already in customers’ hands at the time the kit was released. Brian chose to update his machine with the newer 102-C drive but used the originally intended 90D driven clutch. Brian also installed the later optional “1974 muffler” update kit that included the extended motor plate that the updated muffler attaches to.

assume shocks to dampen that travel, the system did not work as hoped. Jack Hoffman was quoted in the JDS book as saying: “…the polyurethane track and steel slide arrangement is dependent on fairly generous amounts of snow for lubrication. Although we continue to try to make the combination of the poly track and the steel slide work, it appears the only satisfactory option…will be to use a track with steel clips running on a replaceable plastic rail.” So, while the brochure shows this unique suspension, all the production JDXs for 1973 stayed with the proven bogies until a slide rail with plastic hyfax and cleated track were released for 1974.

All the 440cc 1973 machines, the 500, 600 and JDX-8, received the new Salsbury 850 drive and matched driven clutches. This was the clutch that Deere technician Ed Kruel said “wouldn’t last a day” under harsh race conditions. Apparently, it did not hold up particularly well under aggressive trail riding either, as Deere issued a recall to replace it. Modification Program 160: PN BM21064 included a new Comet 100-C drive and 94D driven clutch, a drive belt and hardware. The update was mandatory on all 1973 440cc machines in dealer inventory and optional on customer owned units. The new Comet 100-C was standard on most of

It’s pretty uncommon to see a JDX-8 with the original Salsbury 850 set up, as most were replaced by the recall. Fortunately, Brian grabbed a picture of his set up before tearing his machine down. The vapor lock kit was also not originally installed before Brian got hold of the machine.

the ’74 machines (except the 300 that used the durable Salsbury 780) and eventually led to the development of the famous 102-C that was used by Deere from ’75 to ’84, and spread to other manufacturers. In fact, you can still buy new 102-Cs today that are used by racers, collectors, and hobbyists so the switch to Comet was a wise one.

The sound reduction effort caused even more grief. To help quiet the machines down to 82 dB at 50 feet, the engines had to be further enclosed, and carb intake sound attenuators and quieter exhaust mufflers had to be developed to reduce sound levels without lowering performance. After what was definitely a huge effort, the sound goals were met, and the power levels were maintained, but at a cost. That price was vapor lock. With the engines and carburetors more enclosed, it became too easy to heat soak the fuel system, causing hard starting and performance issues. The fix was another “PIP” or Product Improve Program, called “Modification Program 150” but this time to thermally insulate the fuel system.

This kit consisted of a two-piece aluminum heat shield that was covered in foil faced insulation that bolted to the tunnel of the machine, straight up behind the engine, allowing the

The full two-page 1973 brochure picture shows the unique prototype steel slide bar rear suspension that did not make production. You can also see the lack of a right side engine panel that the production sleds used for ’73 along with small “sport” windshield that added a little style but little wind protection.

Page 28 April 2024 • Green Magazine

The 73 JDX-8 and all ’73 machines fully enclosed the engine, unlike the ’72 machines that had the recoil exposed with no cover. This helped promote the vapor locking issue that the later vapor lock kit then had to solve.

carb to poke through, capped with a new vented engine access cover to allow cool air to enter the carburetor. The fuel lines were also wrapped in insulation where they passed under the engine to prevent heat absorption. There were three kits designed to cover the variety of engines used that were supposed to be installed on all 37,000 machines built for ’73. The kit instructions additionally had instructions for several other of the Mod Kits, including Mod Kit 100, a JDX-4 carb spacer, Mod Kit 140, to add clearance to the throttle lever using sand paper, instructions to remove a carb fuel screen, a fuel filter and a reminder about clutch Mod Kit 160. This must have cost Deere a bundle. And much like the Comet 100-C / 94D clutch set, the “vapor lock kit” was standard on all ’74 and up machines.

The final significant issue with the JDX-8, that also affected several other ’73 machines, was carburetion and calibration. With so much work needing to be done in a compressed timeline, made worse by late availability of motors, the Walbro WDA34 carb flowed way too much fuel according to John Deere Snowmobiles. The fix, according to the book, involved somewhat crudely using a ballpeen hammer to close one of the fuel ports down to reduce flow. This allowed the high-speed needle

The production JDX-8 used the carry over tried-and-true steel wheel bogie, sourced from Aetna Bearing Company. 1973 was the last year of the steel bogie wheel, as the ’73 JDX-4 introduced aluminum wheels that became standard for the green machines until ’77.