From Vision to Legacy: SSI SCHAEFER’s Path to Smarter, Sustainable Warehousing

A tribute to Carsten Spiegelberg

Managing Director, Middle

SCHAEFER

Drive the road of change.

Full offering

- Full range vehicles with the most advanced technologies

- Highly customized product driven by market needs and optimized Total Cost of Ownership

High capillarity of aftersales

- Repair and Maintenance contracts and competitive warranty conditions

- Origin 100% IVECO Parts and a widespread network coverage

European technology

- High quality complete line-up in terms of tonnage, power, torque, safety, ergonomics

- High performance and robust trucks for extreme Off-road conditions

Customer centricity

- Comfort, ergonomics and the latest safety technology to make on board easier

- Driver Style Evaluation tool on Heavy ON-road range and optimized vehicle design to improve customer profitability

GSDP CERTIFIED

SIGNATURE MEDIA FZ LLE

P. O. Box 49784, Dubai, UAE

Tel: 04 3795678

Email: info@signaturemediame.com

Exclusive Sales Agent Signature Media LLC

P.O. Box 49784, Dubai, UAE

Publisher: Jason Verhoven jason@signaturemediame.com

Editor: Abigail Mathias abigail@signaturemediame.com

Art Director: Johnson Machado johnson@signaturemediame.com

Printed and Distributed by Masar Printing and Publishing L.L.C., Part of Dubai Media Incorporated Dubai, UAE

Contributor’s opinions do not necessarily reflect those of the publisher or editor and while every precaution has been taken to ensure that the information contained in this magazine is accurate and timely, no liability is accepted by them for errors or omissions, however caused. Articles and information contained in this publication are the copyright of Signature Media FZ LLE & SIGNATURE MEDIA LLC and cannot be reproduced in any form without written permission.

My favourite month of the year, is finally here. Not only is December a time for reflection, it also causes us to take stock of what one aspires for the year ahead.

For us in the UAE, we begin this month marking the 54th Eid Al Etihad taking place from 1-3 December. As the country takes on a festive spirit, this is also a time when supply chain industries both big and small, rightly reflect on the many achievements of this remarkable, young nation.

Our cover story is one that the team has taken to heart. We were devastated with the sudden passing of Mr. Carsten Spiegelberg, Managing Director, Middle East & Africa, SSI SCHAEFER, an industry automation expert, he left an invaluable lesson to us on life’s fragility. We’ve carried our last interview with him and dedicate this issue to his memory.

As you make your resolutions for the year ahead, make sure you spend time with loved ones. Forge new friendships, build new bridges and keep your hopes up. The best is yet to come.

A very Merry Christmas to all our readers.

Abigail Mathias Editor

abigail@signaturemediame.com www.globalsupplychainme.com

1500+

150+

Putting people first: SSI SCHAEFER’s legacy

Editor’s note: The following interview with Mr. Carsten Spiegelberg, Managing Director, Middle East & Africa, SSI SCHAEFER, was conducted before his passing. His insights and reflections are shared here in remembrance of his invaluable contribution to the intralogistics industry.

Global Supply Chain: How is SSI SCHAEFER addressing the rising demand for cold chain logistics amid global temperature shifts? Carsten Spiegelberg: There is a growing need by logistics companies to develop cold chain logistics infrastructure as to support the growth in online grocery shopping, particularly in perishable products, as well as temperature-sensitive products in the pharmaceuticals and life sciences sector. It is about understanding the customers’ intralogistics challenges and working with them to develop a long-term solution that best meets their material handling objectives. There are many tested and proven solutions that can be adapted for cold storage warehouses, from manual to semi-automated and fully automated, while maintaining system’s modularity and operational traceability and compliance.

GSC: Can you elaborate on how the SSI Exyz system enhances efficiency in high-bay cold storage facilities?

CS: Fully automated storage and retrieval machines (ASRS) like the SSI Exyz can be utilised in high-bay cold storage facilities up to -30°C and can go up to a height of up to 45 metres. The system is compatible for single-deep, double-deep, or multi-deep storage and retrieval, thus allowing to individually cater for the optimum configuration in terms of balancing performance and storage density. Coupled with the SSI Orbiter load handling device, it can be utilised as a single-boom or twin-boom machine. Also, the SSI Exyz is an energy efficient

solution. Compared to conventional ASRSs, companies can save up to 25% in energy savings for the lifting process. This is owing to our Green Crane Technology - moving counterweights integrated into the boom can be fitted and compensated for up to two thirds of the pallet truck’s own weight. Furthermore, the compact design of the system translates into more storage capacity while maintaining access to every pallet location. The high storage density is an enabler to enhancing operational efficiency for high-bay cold storage facilities. Its modular design enables shorter delivery and installation times and easy maintenance from the ground. It can also be easily integrated with SSI SCHAEFER ’s WAMAS Software Solutions or SAP’s logistics solutions, critical for maximum efficiency in warehouse operations.

GSC: What are the biggest challenges in balancing energy efficiency with storage density in temperaturecontrolled environments?

CS: Balancing energy efficiency with storage density in temperaturecontrolled environments is one issue. At the same time, we also need to find the right balance between performance and selectivity on one hand, and the need for high density on the other.

It is in the interest of any temperaturecontrolled facility to maximise capacity as much as possible to achieve high energy efficiency, i.e. loss of energy for cooling void volumes. Simultaneously, higher storage density reduces air circulation and may requires additional machine

cycles to access specific products – thus increasing energy consumption. Every storage facility requires an independent assessment of storage requirements, SKU range, and performance requirement to identify the individually best compromise between storage density, choice of handling equipment and energy efficiency. This should include the consultation of specialist refrigeration engineers at an early stage of a project.

Fully automated solutions like the ASRS combined with intelligent software, can additionally help to keep an operation energy-efficient while enabling high storage density.

It is essential for any cold chain businesses to evaluate which solution best fits your warehouse operations.

“The

SSI Exyz is an energy efficient solution. Compared to conventional ASRSs, companies can save up to 25% in energy savings for the lifting process.”

A tribute to Carsten Spiegelberg

Managing Director, Middle East & Africa, SSI SCHAEFER

GSC: What role does the UAE play in your global supply chain strategy?

CS: The UAE is an important market to SSI SCHAEFER, not only because of its geographical location, but it’s vision for logistics excellence. The UAE logistics ecosystem and forward-looking policies make it an ideal location for advancing automation and cold chain solutions that are critical for the region’s food security, pharmaceutical integrity, and retail growth.

From our Middle East and Africa headquarters located in Dubai, we can deliver projects efficiently, provide responsive customer support, and ensure seamless software deployment across the Gulf and beyond. Having local, on-the-ground expertise is critical in resolving our customers’ intralogistics challenges quickly and effectively.

The UAE’s commitment to developing advanced infrastructure and sustainability perfectly aligns with SSI SCHAEFER’s “Think Tomorrow” vision. It allows us to showcase what the next generation of intralogistics resilience looks like when you integrate hardware, software, and service excellence into one cohesive ecosystem.

GSC: How do you tailor automation solutions to meet the unique needs of emerging markets?

CS: Every market develops at its own pace, and at SSI SCHAEFER, our role is to meet the customers at where they are and support them in taking a modular approach towards automation. In emerging markets, flexibility and adaptability are key. We consider not just in deploying advanced technologies alone, but the local ecosystem where labour availability, infrastructure, energy costs, and skill deployment matter. That means designing scalable solutions that grow at their own pace and evolve in complexity as our customers’ businesses mature.

That’s because at SSI SCHAEFER, we invest in building long-term relationship with our customers based on trust. As a family-owned company, this value is deeply ingrained in the way we do business.

Further, our extensive portfolio and expertise across multiple market sectors allow us to design automation as a journey for all our customers. A relationship that’s built on collaboration, shared learning,

and continuous improvement. In this way, our customers can always rely on us to take their next step together toward a smarter, more sustainable, and datadriven logistics and supply chain.

GSC: What are the latest robotics innovations SSI SCHAEFER has introduced to improve warehouse agility?

CS: This year, SSI SCHAEFER has taken some major steps toward solutions that could address fast-changing markets such as retail, e-commerce, and cold chain logistics, where throughputs are critical.

One of the highlights is our FastBots Solution, a new generation of autonomous robots that roam freely between storage and workstations. They enable highly dynamic material flow without the constraints of fixed conveyors, thus giving warehouses the freedom to adapt their layouts and processes according to the market demands. Under the precise control of the intelligent fleet controller, the FastBots transport various load carriers, including trays, cartons, containers, and even polybags. It is an ideal solution for

“The SSI LOGIMAT® has resulted in increased throughput, improved picking accuracy with 100% picking selectivity, and enhanced order fulfilment.”

markets such as grocery, healthcare, and 3PL operations where product variety and order profiles change periodically.

We also expanded our RackBot Systems portfolio to include RackBot System Elevate that is capable of running vertically and horizontally across the racks. These systems are suitable for small parts storage where speed and accessibility are paramount.

Finally, our roaming shuttle solutions, which include 4D pallet and roaming tote shuttles, solutions that elevate the handling of pallet, tote, tray, and carton movements in all directions within the storage racks. This setup is ideal for regional distribution hubs and especially cold storage facilities where storage density, fast access to goods, and ergonomic order picking are key.

Altogether, these solutions redefine warehouse agility, not just via technology but by empowering all businesses to scale intelligently and respond faster to their customers’ demands.

GSC: How do smart warehousing solutions contribute to sustainability goals and resource optimisation?

CS: Smart warehousing drives sustainability and innovation in intralogistics. It’s not only about future-proofing for growing demand but also about environmental and social responsibility. Through automation and intelligent software, these systems make goods-flow clearer, reduce wasted movement, idle time, and excess inventory.

Software is the cornerstone of smart warehousing. Solutions like the WAMAS Software Suite can analyse processes, identify inefficiencies, and provide actionable insights for decision-making. These may seem like small processes, but it goes a long way in streamlining processes. Furthermore, it can even eliminate the

need for manual labour in certain tedious processes such as picking and sorting. It’s also only with software where we can analyse system data to predict and prevent equipment failures − or what we know as predictive maintenance. All these helps improve warehouse efficiency while reducing resources. Additionally, sustainability is embedded throughout our value chain. SSI SCHAEFER’s innovation strategy is aligned with global sustainability frameworks, including the UN Sustainable Development Goals (SDGs), ensuring every solution is responsibly sourced and energy efficient. It’s about continuous improvement and being a responsible corporate citizen.

Smart warehousing sets the path for improved material flow efficiency, increased profitability while advancing sustainability commitments.

GSC: Can you share examples of how your automation systems have delivered faster ROI for clients?

CS: SSI SCHAEFER’s automation solutions have consistently delivered faster ROI for clients across industries and markets.

Coop Sweden transitioned from manual operations to a 95% automated facility using the SSI Case Picking system. Robots now handle depalletising and palletising of storefriendly mixed pallets, centralising material flow for both ambient and fresh goods. This shift has significantly improved operational efficiency, reduced energy consumption, and enhanced workforce productivity.

In Southeast Asia, Thai automotive spare parts distributor Chin Seng Huat has invested in a total semi-automated solution, including the SSI LOGIMAT, carton and bin conveying systems, the Mobile Racking System, and a Mezzanine system. This has

“Our momentum is our people. Across the Middle East, we are seeing incredible growth potential, and our team is motivated by the opportunity to shape the region’s logistics transformation.”

resulted in increased throughput, improved picking accuracy with 100% picking selectivity, and enhanced order fulfilment. Closer to home, our partnership with Noatum Logistics, a subsidiary of AD Ports Group, resulted in the largest mobile racking installation for deep-freeze cold rooms in the UAE. At the KEZAD KLP21 hub, storage capacity rose by over 90%, while cooling efficiency and safety were enhanced through PLC-enabled fail-safes.

These examples demonstrate how SSI SCHAEFER’s semi- and fully automated systems not only accelerate ROI but also support long-term competitiveness, sustainability, and operational excellence.

GSC: What trends do you foresee shaping the future of intralogistics and supply chain automation?

CS: The frontier of intralogistics lies at the intersection of agility and intelligence augmented by robotics, and we are already seeing the building blocks emerging. First, the ubiquity of connected systems and intelligent networks means the ‘Warehouse of the Future’ no longer functions independently, but rather as an ecosystem that is adaptable and ‘buildable’.

Next, we are seeing a shift in how automation is being adopted. It isn’t all about a ‘big bang’ approach, but rather, a modular and incremental rollout in phases. This is particularly important to the emerging markets and companies that favour lower upfront investments and agile response to environmental demands.

That said, while roaming shuttles, AMRs, and AGVs are becoming more common for their flexibility and low entry cost, reliability and system longevity remain non-negotiable. Traditional ASRS stacker cranes would continue to be the backbone of high-performance warehouses because they offer unparalleled longevity, precision, uptime, and safety – especially in temperature-controlled and missioncritical environments. These proven systems are scalable and seamlessly integrated into intelligent software, which makes them the preferred choice for operations that demand long-term reliability and predictable performance. Eventually, we believe that the future isn’t about choosing one technology over another. It is to design the right blend of automation that balances

innovation and trust. At SSI SCHAEFER, our focus has always been on building systems that not only meet today’s demands but continue to deliver value and support in the decades to come.

GSC: How is SSI SCHAEFER preparing for the next wave of digital transformation in logistics?

CS: Digital transformation is reshaping logistics, and intralogistics is at the heart of this evolution. At SSI SCHAEFER, we are preparing by developing solutions that empower customers to stay ahead—making operations more efficient, flexible, and scalable to meet dynamic market demands. We are integrating key technologies such as artificial intelligence (AI), Internet of Things (IoT), and robotics to enable real-time visibility, predictive analytics, and automated decision-making. These innovations allow warehouses to achieve smarter inventory control, optimised workflows, and improved responsiveness.

Across the organisation, we are ramping up testing efforts in areas such as AI in a safe and responsible

manner, ensuring full compliance with EU regulations such as the General Data Protection Regulation and the EU AI Act. SSI SCHAEFER strives to deliver futureready solutions that help customers achieve operational excellence.

GSC: SSI SCHAEFER has been at the forefront of supply chain innovation—what’s driving your team’s momentum right now?

CS: What drives us today is Purpose. Innovation in SSI SCHAEFER is more than just advanced technology for its own sake. Whether it is a straightforward semi-automated solution in improving cold chain reliability, or enabling a highly complex e-commerce fulfilment solution, every system that the team designs begin with understanding our customers’ realities. Being a family-owned company gives us the freedom to think long-term, where we value relationships and invest in systems that withstood the test of time. Our Purpose and Our People, I believe is the formula that keeps us moving forward with agility that is grounded in experience and trust.

GWC showcases innovative logistics solutions for the energy sector

Gulf Warehousing Company Q.P.S.C (GWC) — one of the leading logistics service providers in the Middle East and North Africa — showcased its leadership in the energy services sector and its strategic vision to strengthen its position as a regional and global leader in logistics and supply chain solutions, through its participation in the Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) 2025.

The event took place from 3 to 6 November at the Abu Dhabi National Exhibition Centre (ADNEC), Hall 16, Stand 16055. Matthew Kearns, Acting Group CEO of GWC, stated that the company’s participation in this international event is primarily focused on innovation, technology, and sustainability, in line with clients’ growing demand for more efficient and reliable solutions. He emphasized that this approach further strengthens GWC’s position as one of the leading integrated service providers in the region’s energy sector.

“GWC’s participation in ADIPEC coincides with the implementation of an expansion strategy across the GCC, under which the company has recently opened branches in Dubai, Abu Dhabi, and Sharjah. This move comes as part of our broader plan to strengthen our regional presence and extend our portfolio of advanced logistics solutions. GWC currently provides its services across all ports in the UAE, Bahrain, and Qatar, reflecting the company’s strong operational capabilities and fully integrated logistics network that efficiently and flexibly supports energy, oil, and gas operations across the region.” He added:

Kearns emphasised that GWC showcased its innovative logistics solutions for the global energy industry during its participation in the event. He noted that the GWC brand stands for flexibility, readiness, and reliability, as the company continues to develop cutting-edge solutions that meet the evolving needs of its partners across every stage of the energy supply chain. He added that participating in ADIPEC 2025 provides a key platform for highlighting GWC’s latest innovations and

services and for engaging with global industry leaders, reaffirming the company’s ongoing commitment to contributing to a more sustainable and efficient future for the energy sector, and advancing a path of shared growth and progress.

GWC adheres to the highest global sustainability standards, reaffirming its commitment to driving positive change, promoting responsible logistics practices, and contributing to sustainable development. Through initiatives aimed at reducing emissions, optimizing energy consumption, and advancing green storage solutions, the company continues to align its operations with international sustainability benchmarks and the principles of Environmental, Social, and Governance (ESG) excellence.

As the company continues its rapid growth, safety remains at the core of GWC’s logistics operations, with its comprehensive safety programs, ongoing

training initiatives, and advanced monitoring systems underscoring a steadfast commitment to protecting people, assets, and the environment.

ADIPEC 2025 is held under the patronage of His Highness Sheikh Mohamed bin Zayed Al Nahyan, President of the United Arab Emirates, and brings together global leaders from across the energy, industrial, and technology sectors to discuss the future of these vital industries.

The event welcomed over 205,000 visitors from more than 172 countries, along with 2,250 exhibiting companies and 1,800 speakers, including a wide range of industry leaders, investors, innovators, and policymakers who will explore new opportunities and accelerate the development and adoption of solutions shaping the future of the energy sector.

The upcoming edition of ADIPEC, held under the theme “Intelligent Energy for a Faster Future,” featured over 380 sessions, where global leaders and policymakers will convene to address key challenges across emerging economies, natural gas, refining and manufacturing, diversity and leadership, as well as artificial intelligence and digital transformation. The event also hosted the world’s largest technical conference, with the participation of more than 1,100 industry experts.

The exhibition featured the participation of 54 national and international energy companies and 30 international pavilions, in addition to four dedicated zones focusing on digital transformation, emissions reduction, marine operations, and artificial intelligence. As part of the event, a new platform for chemicals and low-carbon solutions was also launched.

Matthew Kearns, Acting Group CEO of GWC

GoComet redefines supply chain intelligence with AI at Odyssey Dubai 2025

Against the backdrop of Dubai’s awe-inspiring skyline, GoComet hosted ‘Odyssey Dubai 2025’ at The St. Regis hotel, marking the 8th edition of their supply chain innovation summit. Global Supply Chain brings you the exclusive details.

The event gathered 70+ leaders from Novartis, Henkel, L’Oréal, Goodyear, Max Retail, and more, to explore how technology is transforming GCC supply chains. It also marked a milestone for GoComet with the launch of Agentic AI, advancing its vision for intelligent, autonomous, and resilient logistics ecosystems.

Building with purpose:

The GoComet story

GoComet’s journey began with a simple conviction, to transform how logistics decisions are made and bring clarity to an industry once shrouded in mystery. As CEO, Chitransh Sahai recalls, the company’s early days were defined by late-night coding sessions in shared workspaces, united by a vision to make global supply chains transparent, intelligent, and connected.

What began as an effort to simplify logistics complexities has evolved into a global logistics intelligence platform, one built on purposeful technology and a deep understanding of how businesses move the world.

Even through the rough times, like the pandemic, the company stayed true to its mission, turning chaos into clarity through automation. The company today continues to redefine how supply chains think, act, and evolve autonomously, with Agentic AI.

Trusted by 500+ global brands including Unilever, Al Khayyat, ETG World, Qatar Airways, Himalaya Wellness, and many more across 70+ countries, GoComet unifies data, automates workflows, and integrates seamlessly with leading ERP systems. Headquartered in Singapore, GoComet is on a mission to simplify global logistics – making it more transparent, resilient, and intelligent.

Driving efficiency through automation: Keynote insights

The keynote address was delivered by Mohamed Ismail, Head of Manufacturing Capability, and Ma’an Felemban, Head of Logistics at GoodyCo (Basamh Group).

The duo walked the audience through Basamh Group’s journey towards building a digitalized, disruption-proof, and resilient supply chain.

With a legacy spanning over six decades, the company manages 6,000+ containers annually from 70 manufacturing sites in 25 countries through more than 60 ports worldwide. But with such scale comes complexity, and as Felemban noted, “In logistics, Murphy’s Law always applies. If anything can go wrong, it will.”

Today, Basamh Group has unified its operations by connecting GoComet with

“Whatever product we build, it has to solve this individual’s tedium. It has to get them out from their routine, mundane tasks, and empower them to strategically contribute to the business. This is what makes me get up every day to build GoComet.”

— Chitransh Sahai, CEO, GoComet

its existing ERP and supply chain software. This seamless integration has automated nearly 60% of their core processes, ensuring data consistency, faster collaboration, and end-to-end visibility across procurement, planning, and logistics.

Mohamed Ismail reflected on the transformation: “What we were able to do is use GoComet as the central nervous system of our logistics. It literally became a logistics operating system for us — a full 360-degree ecosystem handling all tasks

and processes in one place.”

Predictive alerts and real-time visibility have equipped the group to navigate port strikes in Northern Europe, Red Sea congestion, and regulatory changes with agility, shifting from monthly reaction cycles to real-time planning.

Their “ADAPT” strategy — Active collaboration, Digital integration, Agility, Predictive analytics, and Talent building — now serves as the cornerstone of their supply chain vision. As Ismail

emphasised, “Resilient supply chains aren’t built in calm times; they’re built through disruption. Every challenge teaches us to bounce back stronger, faster, and smarter.”

Both speakers emphasised that AI and automation empower, not replace, teams — freeing personnel from routine firefighting to focus on proactive, strategic decisions. Reflecting on lessons from the pandemic, they highlighted how resilience comes from learning, adaptability, and a strong digital backbone.

Looking ahead, Basamh Group aims to further leverage AI and predictive analytics to enhance agility, performance, and disruption management — continuing its journey towards a smarter, data-driven supply chain.

The product demo

In a fitting finale to Odyssey Dubai 2025, Sahai, took the stage to showcase how AI is no longer a concept for the future but is actively transforming logistics today.

Launching a new part of their ecosystem, Agentic AI, he highlighted how GoComet’s technology can understand user intent, extract insights from emails and PDFs, recommend the next best steps, identify risks, and trigger workflows across systems, completely without manual intervention.

He also unveiled the Incidents Lens, GoComet’s latest advancement in realtime risk monitoring across the globe. The solution integrates live port, weather, and geopolitical data with your shipment data, enabling companies to anticipate disruptions, assess risk exposure, and make informed decisions in real time.

A glimpse into the future of supply chain AI

Odyssey Dubai offered a preview of how Agentic AI will transform logistics from reactive coordination to autonomous execution. Through GoComet’s suite of solutions, businesses now gain predictive risk control and contextual visibility.

The future of supply chains lies in building intelligent systems. AI that learns, adapts, and acts on your behalf, enabling businesses to reduce lead times by 20 percent, and cut costs by nearly 25 percent.

The next frontier in logistics innovation is not manual, it’s mindful.

Chitransh Sahai, CEO, GoComet at the event

The Rise of the UAE’s Renovation Economy

A quiet transformation is reshaping homes across the UAE. The country’s property sector, long defined by rapid growth and new developments, is entering a new era, one centred on renovation, retrofitting, and responsible design.

The home renovation market, valued at around USD 32.4 billion in 2024, is projected to reach USD 42.6 billion by 2030, growing at a steady rate of 4.7 percent per year (PS Market Research, 2025). This growth reflects a shift in mindset, as homeowners and investors move beyond aesthetics and location to focus on performance, sustainability, and smart functionality.

This “renovation economy” aligns perfectly with the UAE’s long-term sustainability goals. National initiatives such as the UAE Net Zero 2050 Strategy and the Dubai Clean Energy Strategy 2030, which aims for a 25 percent share of clean energy by 2030 (DEWA, 2024), have created strong incentives for greater efficiency across all sectors, including housing. Until recently, most renovations in Dubai or Abu Dhabi were aesthetic, new marble, lighting, or cabinetry. Today, the motivation runs deeper. Homeowners are asking how to reduce their water and energy use while maintaining comfort and design quality.

“Abu Dhabi’s Department of Energy recommends reducing electricity consumption by 22 percent by 2030”

The environmental stakes are significant. The UAE consumes roughly 9 billion cubic metres of freshwater annually, and desalination, which provides most of the country’s supply, requires about 25 terawatt hours of electricity each year (MDPI Sustainability Journal, 2024). Every litre saved lower both carbon emissions and costs. The market for efficient fixtures and smart systems is expanding quickly. Modern flow regulators and aerators can reduce water consumption by up to 50 percent without affecting pressure, while cold-start mixers eliminate unnecessary heating. Over time, a single household can save tens of thousands of litres, a meaningful difference in a desert climate.

Digitalisation is accelerating this change. Smart thermostats, motion-sensing lights, and leak-detection systems have become standard features in many mid- to highend renovations. What began as a luxury

is now mainstream, because the benefits are immediate: control, visibility, and lower utility bills. These advances align with the UAE’s smart-city agenda. As urban infrastructure becomes increasingly connected, households are embracing the same technologies. A home that learns user habits, monitors consumption, and prevents waste is fast becoming the new standard for modern living.

The country’s design scene is evolving in parallel. Architects and interior designers are embracing natural materials, minimalist layouts, and energy-efficient lighting to reduce cooling demand and create calm, sustainable spaces. Sustainability has become a design language in itself, one that conveys modernity and responsibility in equal measure. Regulatory initiatives reinforce this direction. Sustainability and liveability are core pillars of Dubai’s 2040 Urban Master Plan, while Abu Dhabi’s Department of Energy recommends reducing electricity consumption by 22 percent by 2030 (DoE, 2024). What was once aspirational is now an operational standard; every renovation permit and material specification carry an environmental responsibility.

The strength of this new renovation wave lies in collaboration. Policymakers, architects, developers, and technology providers are working together to embed sustainability into every phase of the home’s lifecycle, from planning and specification to installation and education. At LIXIL, we see this shift as part of a broader regional movement. Through the GROHE brand, we support homeowners and professionals with waterefficient and intelligent fittings that combine design, performance, and sustainability. By aligning global expertise with local codes, the private sector can help accelerate progress toward national targets without compromising comfort or aesthetics.

Guest Column by Stefan Schmied, Leader IMEA, LIXIL International

Efficient Logistics

Begins With Automated Picking

Smarter Picks, Perfect Sorts With A-Frame & Order Verifier

Automate

Stay ahead with automation.

Smoother day-to-day workflow

Delivers consistent and accurate picks

Maximize space utilization

Eliminates time-consuming and labor-intensive picking

Allison Transmission accelerates growth with new fleet wins in the GCC region

In partnership with UD Trucks, a leading Japanese OEM, Allison Transmission is accelerating its market penetration in the Gulf Cooperation Council (GCC) region with a series of municipal and commercial vehicle fleet wins across the United Arab Emirates (UAE), Oman, Bahrain and Kuwait.

In the UAE, more than 200 Allisonequipped trucks are already in service, with a further 50 units scheduled for delivery in 2025 to support ongoing municipal projects. In Kuwait, Allison has achieved a milestone with its first-ever tender win in the country, supplying 16 UD Croner trucks for a key waste management initiative. In Oman, a leading waste management company has ordered more than 60 UD Croner trucks fitted with Allison transmissions, expected to enter operation in 2026. Meanwhile, in Saudi Arabia, Allison’s technology continues to demonstrate its versatility, with over 50 trucks currently operating within a Fast Moving Consumer Goods (FMCG) distribution fleet and more than 40 additional units scheduled for delivery soon.

The surge in demand reflects the GCC’s drive to modernise waste management fleets in response to growing urban

populations, rising service expectations and the challenges of high-frequency, stop-start collection in extreme temperatures.

Allison’s 3000 Series transmission installed in the UD Croner PKE model and the 2500 Series transmission installed in the UD Croner LKE model are engineered to handle these demands. The torque converter boosts engine torque at launch, delivering stronger low-speed driving performance, while Continuous Power Technology™ ensures uninterrupted power delivery and a smooth drive for the driver and vehicle. The fully hydrodynamic torque converter without mechanical clutches results in less wear and tear on all parts of the drivetrain and therefore reduces costly breakdowns and repairs, reducing downtime.

“Waste collection in the Middle East presents unique operational challenges, from extreme heat to constant stop-start driving,” said Muhammad Ibrahim Khan,

Allison Transmission’s Area Manager for Middle East & Pakistan. “Our partnerships with fleet operators and OEMs like UD Trucks show how Allison’s technology is enabling cities and service providers to deliver reliable, efficient services.”

Since 2020, hundreds of UD Croner trucks featuring Allison transmissions have been sold across the GCC for urban waste collection tenders and FMCG distribution, a milestone that reinforces Allison’s role as a preferred technology partner for both municipal and commercial fleets. These vehicles continue to perform reliably in challenging conditions, underscoring the brand’s reputation for durability and efficiency.

Allison Transmission remains committed to supporting fleet operators with innovative driveline solutions that enhance reliability, lower operating costs, and contribute to sustainable infrastructure development across the region.

AEDLER Logistik Solutions and KNAPP revolutionise healthcare logistics

In the Middle East, where healthcare markets are rapidly expanding, pharmaceutical distributors are under growing pressure to deliver medicines quickly and accurately while meeting strict regulatory requirements. AEDLER Logistik Solutions, in partnership with global automation leader KNAPP, is responding to these challenges by introducing state-of-the-art automated storage and retrieval systems (ASRS) designed specifically for the pharmaceutical sector.

Traditional manual processes in pharmaceutical distribution can no longer keep pace with rising demand, complex inventory, and strict quality standards. KNAPP’s portfolio of automated systems offers an advanced solution, ensuring that pharmaceutical distributors operate with unmatched reliability and accuracy.

Automated storage and retrieval solutions

The Central Belt System is a comprehensive solution for pharmaceutical distribution centers that not only increase productivity, but also throughput and picking performance in a relatively small space.

This system mitigates the effects of peak workloads and allows resources to be put to best use. The KNAPP-Store is a sophisticated and innovative system for storing and picking single items. It covers everything from automatic goods-in to automated processes and stock management – all while keeping investment and storage location costs low. By combining this system with the Central Belt System, customer orders can be fulfilled faster. Equipped with various grippers and AI-based object recognition, the Pick-it-Easy Robot recognizes the

items and calculates the perfect gripping points. The articulated-arm robot safely grips items of various sizes, weights, shapes and packaging. Shuttles solve material handling challenges through space optimization and cutting-edge material flow solutions and are the right choice for logistics applications demanding the highest performance in order fulfillment. Its modular design allows warehouses to expand capacity without disruption, accommodating both steady growth and sudden surges in healthcare needs. Beyond efficiency and accuracy, these

innovative systems also contribute to a safer and more sustainable workplace. By automating repetitive and physically demanding tasks, employees are free to focus on quality assurance and other value-added activities.

Your partner for Pharma Handling Automation

AEDLER Logistik Solutions combines local expertise and deep understanding of Middle East healthcare logistics with KNAPP’s global leadership in intelligent automation. Together, they deliver tailored solutions that integrate seamlessly into pharmaceutical supply chains. Automated storage and retrieval systems are no longer optional but a necessity for companies looking to stay competitive. With AEDLER Logistik Solutions, pharma distributors in the Middle East can achieve new standards of efficiency, compliance, and scalability, ensuring that medicines reach patients quickly, safely, and reliably.

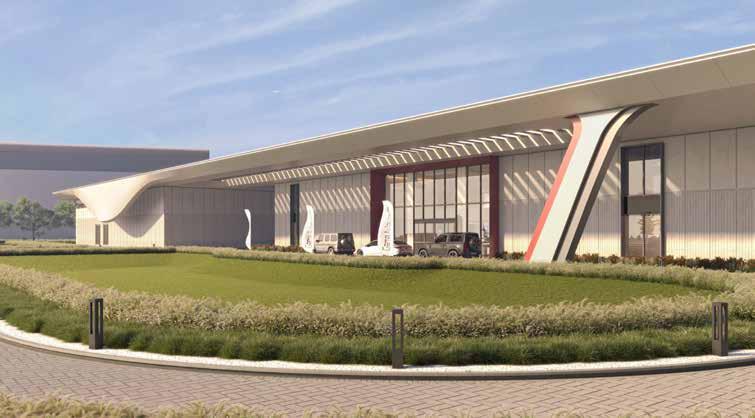

Gama Aviation develops state of the art BAC at Sharjah International Airport

Sharjah’s strategic location places it within an eight-hour flight radius of more than 5.4 billion people, connecting major markets across Europe, Asia, and Africa.

Gama Aviation’s new Business Aviation Centre (BAC) at Sharjah International Airport represents a defining step forward for private aviation in the UAE — combining a purpose-built design, operational efficiency, and refined luxury in one seamless experience.

The company has invested over $65 million in the facility, which is designed ground up, for the exclusive use of the business aviation and private jet traffic.

Global Supply Chain visited the facility recently. Scheduled for completion in early 2026, the Business Aviation Centre occupies a site of over 80,000 square metres within the Sharjah International Airport estate. The development supports the emirate’s infrastructure and diversification objectives, aligned with the UAE’s Vision 2030 roadmap for sustainable growth and connectivity.

Unlike conventional FBOs that repurpose existing airport infrastructure, every element of the BAC has been designed

from the ground up to deliver a bespoke experience. With unrestricted access, direct apron connectivity, and minimal aircraft taxi times, guests enjoy a smooth, efficient transition from arrival to facility to take-off — redefining what business aviation can offer different in the region.

The terminal provides top-of-the-line luxury amenities, ensuring convenience, comfort, and privacy for guests. This facility is a dedicated space that enables Gama Aviation to provide seamless and personalised service every step of the way. Its exclusive design and high level of service create an environment where every detail is tailored to elevate the guest experience.

“Our investment in Sharjah underlines our confidence in both the emirate and

the region’s aviation future,” said Marwan Khalek, Group CEO, Gama Aviation. “It supports the UAE’s Vision 2030 framework by delivering world-class aviation infrastructure and creating high-value employment, while giving our clients an efficient, well-connected alternative to more congested hubs. Sharjah’s probusiness environment and accessibility make it an ideal location for a new generation of business aviation services.”

Sharjah’s strategic appeal has strengthened further following the announcement of Dubai International Airport (DXB)’s planned closure and the future consolidation of operations at Dubai World Central (DWC). With operators and owners now assessing long-term alternatives, Gama Aviation’s investment in the BAC positions Sharjah as a credible, high-quality option offering both proximity and efficiency.

This large-scale, purpose-built hangar delivers operational efficiency, flexibility, and capacity — enabling Gama Aviation to support a diverse fleet mix under one roof. Its strategic design reduces ground handling movements, enhances safety, and allows engineers and clients to benefit from a modern, fully integrated maintenance environment. The facility gives a viable alternative for parking for aircraft and protection from weather conditions.

“The Sharjah Business Aviation Centre will set a new benchmark for private

aviation in the Middle East and beyond,” said Tom Murphy, Managing Director –FBO Services, Gama Aviation. “We are not building this facility to meet expectations — we are designing it to exceed them.

Historical legacy

Sharjah is recognised as the birthplace of aviation in the UAE, home to Al Mahatta Airport — the nation’s first airfield, established in 1932. The BAC continues this legacy, positioning Sharjah once again at the heart of regional aviation excellence.

Operational efficiency

Purpose-built FBO, Apron, Taxiway link, and hangar design, minimal aircraft holding, 24/7 no slot restrictions, and rapid ground handling processes deliver consistently smooth operations.

The terminal provides top-of-the-line luxury amenities, ensuring convenience, comfort, and privacy for guests. This facility is a dedicated space that enables Gama Aviation to provide seamless and personalised service every step of the way. Its exclusive design and high level of service create an environment where every detail is tailored to elevate the guest experience.

Alternative to congested hubs

With no slot restrictions and an uncongested operating environment, Sharjah provides a faster, more predictable option compared to neighbouring airports.

ISCM tackles navigating the geopolitical push for GCC Supply Chains

The International Supply Chain Management or ISCM Forums is backed by the Institute of Supply Chain and Management Pvt. Ltd. – India’s leading education, training, certification, research and consulting firm focused on supply chain domain.

With over 35 speakers and more than a 100 participants, ISCM is expected to once again showcase the impact of Supply Chain the GCC region. The event was held on 26 November at Dusit Thani Hotel, Dubai.

ISCM hosts the Gulf Supply Chain Leaders Senate (GSCLS), the only exclusive leadership conference in the GCC. The conference has helped senior supply chain professionals interact, exchange, and share world-class supply chain practices. It is designed for practice leaders to identify the mega trends, understand geo-politics and geography of supply chains, to build your views on an agile, resilient, sustainable supply chain for the future.

One of the many discussions involves a CXO Panel the topic is reimagining supply chains in the new world order - managing risk and resilience.

Dr. Rakesh Singh, Chairman ISCM -a global thought leader, author, researcher, academician, and consultant with a deep understanding of global supply chains and trade flows will deliver the keynote.

Three key components spell future success for supply chains – digitalisation, resilience – the ability to both absorb shocks and recover quickly, and sustainability. And the driver will be digitalisation – using a number of emerging technologies to create smart, connected, and agile supply chains. CSCOs and CLOs need to refocus their attention from cost containment to creating a network for the future. The Gulf Supply Chain Leaders Senate will intersect the strategic and execution aspects of supply chain transformation.

Al Gharbia Pipe Company’s reinforces status as Industry 4.0 technology leader in LSAW pipe manufacturing

• UAE’s Ministry of Industry & Advanced Technology (MoIAT) certifies AGPC as Industry 4.0 Digital Leader

• Recognition reflects AGPC’s focus on strengthening its manufacturing processes and quality control through technology

• Assessment highlights company’s strong adoption of advanced technology and sustainability efforts

Abu Dhabi-based producer of longitudinally submerged arc welded (LSAW) steel pipes, Al Gharbia Pipe Company (AGPC), recently received recognition from the UAE’s Ministry of Industry & Advanced Technology (MoIAT) as an Industry 4.0 Digital Leader.

This latest certification demonstrates AGPC’s commitment to quality and its focus on continuous improvement of its manufacturing processes. Furthermore, this reinforces its place at the forefront of LSAW pipe manufacturing technology in the Middle East.

“This certification is an important milestone for AGPC, as we harness technology and make significant contributions to the UAE’s manufacturing sector,” said Noritsugu Mifune, CEO of Al Gharbia Pipe Company in an exclusive interview with Global Supply Chain.

“This certification confirms AGPC’s

leadership in digital transformation and positions us as a top performer within the LSAW steel pipe sector. This was made possible by the innovation, dedication, and teamwork of every member of our organisation, and we will continue to strengthen the UAE’s industrialisation efforts as the leading and most technologically advanced LSAW pipe manufacturer in the region.”

The Industry 4.0 Digital Leader certification is given by MoIAT to companies that demonstrate advanced digital maturity and leadership in adopting Industry 4.0 technologies, such as AI and machine learning. It signifies that a company is a leader in leveraging state-of-the-art technologies in the areas of operational efficiency, sustainable growth, and industrial competitiveness.

This recognition and certification is part of the UAE’s National Strategy for Industry and Advanced Technology, also known as

Operation 300 Billion. The strategy aims to increase the industrial sector’s contribution to national GDP to AED 300 billion by 2031 by transforming the UAE into a global industrial hub.

As part of the certification process, AGPC underwent an Industrial Technology Transformation Index (ITTI) assessment. Such assessment is designed to improve industry competitiveness through technology adoption, enable evidence-based policymaking, accelerate innovation in manufacturing, and promote sustainability and efficient resource management. Ramesh Chandra Pathak, General Manager – Operations & Innovations, together with the Innovation Team, played a pivotal role in steering AGPC through the assessment and leading the digital transformation initiatives that resulted in the company’s successful certification, officially awarded on 20 September 2025.

Noritsugu Mifune, CEO of Al Gharbia Pipe Company

The assessment noted AGPC’s strong adoption of Industry 4.0 technologies. A key feature of its this is that all of AGPC’s plant processes are connected through its smart Manufacturing Execution System (MES) 4.0, which executes, monitors, tracks and reports operations on the plant floor in real-time. MES acts as the brain connecting manufacturing and testing processes, as well as adapting production plans and schedules according to real-time conditions on the shop floor. In addition, its ISO/IEC

17025-certified testing laboratory ensures that each pipe conforms to stringent quality standards across all stages of the manufacturing process.

AGPC was commended for having a fully integrated production process, encompassing production execution, utilities, sourcing, and sales processes. Furthermore, the company’s efforts to improve sustainability, such as establishing emissions reduction and water reuse, were recognised.

Since commencing production in 2019, AGPC has continually ramped up its production and quality control capabilities by adopting advanced technologies. Today, its factory can produce up to 360,000 metric tons, or an equivalent of 760 kilometres of pipeline, each year. It uses computer vision technology to detect micro-defects that may escape traditional methods. Through machine learning, these systems continuously learn and improve, ensuring that every pipe meets the highest standards of safety and durability,

AGPC is certified to ISO, API, and international standards, and each pipe is custom-engineered to project specifications, including carbon steel pipes up to API X80 grade. Its pipes are used by major oil and gas, industrial, and renewable energy companies in the Middle East and beyond.

The company was proud to participate at the recently concluded ADIPEC in the capital.

Al Gharbia Pipe Company (AGPC) is an Emirati-Japanese joint venture based in Abu Dhabi that manufactures longitudinal submerged arc welded (LSAW) steel pipes.

It leverages AI-driven, Industry 4.0 manufacturing and global partnerships to deliver project-specific LSAW steel pipe solutions that meet the highest international standards, ensuring full transparency, regional scale, and uncompromising quality. AGPC is certified to ISO 17025, API, and international standards.

AGPC combines JFE Steel’s world-class expertise in LSAW pipe manufacturing with Marubeni Itochu Steel’s global trading network, strengthened by ADQ’s vision focused on critical infrastructure and global supply chain, for a sustainable and competitive UAE sector. These provide AGPC with unmatched capability to serve high-demand markets at home and abroad.

Timeline and Production

Milestones:

May 2015: Al Gharbia Pipe Company LLC officially incorporated September 2019: Production commenced

September 2022: 100,000 tons produced

March 2024: 200,000 tons

November 2024: 400,000 tons

March 2025: 500,000 tons

June 2025: 600,000 tons

October 2025: 700,000 tons

Annual Production Capacity: 360,000 tons (equivalent to 760 kilometres of pipeline)

Product range

• Sour service line pipe (80% of output) (Offshore and Onshore)

• Structural pipe

• Conductor pipe

• Non sour line pipe

• Dredging pipe

• Other applications

Smart sensors, smarter logistics

As Dubai cements its role as a global logistics hub, GND Solutions is driving a new era of intelligent, reliable, and energy-efficient cold-chain management.

Cooling intelligence for a warming world

The business of keeping things cool is heating up fast. Across the Gulf Cooperation Council (GCC), demand for temperature-controlled logistics is rising rapidly from pharmaceuticals and vaccines to fresh produce, seafood, and frozen foods. In Dubai, where summer temperatures exceed 45 °C, reliable cold-chain systems have become essential for both business performance and public health.

That’s where GND Solutions, a Bengalurubased IoT and analytics firm, is making an impact. Through its thinxfresh smart coldchain platform, the company is helping Dubai’s distributors, warehouse operators, and logistics firms monitor and manage every degree of temperature variation in real time.

“Temperature control is the invisible backbone of modern trade,” said Siva Reddy AV, Managing Director of GND Solutions. “Whether it’s dairy, vaccines, or meat exports, our goal is to give logistics operators complete visibility from cold room to customer.”

From cold rooms to cargo: total visibility

GND Solutions’ thinxfresh ecosystem integrates wireless sensors, gateways, and cloud analytics to provide continuous monitoring of temperature, humidity, and vibration across all cold-chain assets from storage rooms to reefer trucks and distribution centres.

If conditions deviate from safe ranges, instant alerts are triggered, allowing operators to act before spoilage occurs. The platform works across BLE, LoRa, and cellular networks, ensuring uninterrupted data even in remote areas or warehouses with limited connectivity.

In Dubai, thinxfresh is already in use in pharmaceutical storage hubs in Dubai Investment Park, cold rooms in Al Quoz,

and logistics facilities in Jebel Ali Free Zone. These systems not only protect product quality but also help businesses comply with Good Storage and Distribution Practice (GSDP) and Dubai Municipality regulations.

One 3PL provider reported preventing AED 120,000 worth of temperaturesensitive losses after thinxfresh detected an early compressor fault in its cold room. Another distributor achieved full traceability for high-value pharmaceutical shipments by integrating thinxfresh with its ERP system.

Built for Gulf conditions

Designed for the region’s extreme environment, the thinxfresh sensors operate between -30 °C and +70 °C and can withstand high humidity. All data is securely stored in AWS Middle East (Bahrain) to meet UAE data residency and compliance standards.

The system’s dashboard allows logistics teams to access real-time data on mobile or desktop, while predictive algorithms examine shipment history to identify recurring risks such as inefficient delivery routes or malfunctioning cooling equipment.

“Dubai is setting the benchmark for digital logistics in the GCC,” said Siva Reddy AV. “We’re enabling companies to move from reactive monitoring to predictive, data-driven cold-chain management.”

Dubai success story

In a recent deployment, GND Solutions partnered with a Dubai-based logistics firm handling both food and pharmaceutical products. By installing thinxfresh™ across its reefer trucks and cold storage units, the company achieved:

- Zero temperature excursions in 150 monitored shipments.

- 40% reduction in spoilage losses through early fault alerts.

- 30% faster audit completion, thanks to automatic digital records.

- 15% lower energy consumption in refrigerated facilities.

The system’s continuous monitoring also provided verifiable records for Dubai Health Authority audits, helping

the operator strengthen trust with healthcare clients and regulators.

Cold-chain momentum in the GCC

Globally, the cold-chain industry is projected to grow 17.9 percent annually, reaching $585 billion by 2026, driven by booming e-commerce, organised retail, and food exports. In the GCC, that growth is mirrored by increased demand for reliable, traceable, and energyefficient logistics to meet both regulatory standards and consumer expectations.

With its regional hub at Dubai Silicon Oasis, GND Solutions is helping UAE businesses modernise their infrastructure through IoT-enabled transparency, AI-driven analytics, and sustainable energy practices. Its technology supports industries that depend on consistency from pharmaceuticals to perishables while optimising operations for the Gulf’s unique environment.

A smarter, cooler future

From Dubai’s high-tech logistics hubs to its sprawling cold-storage facilities, the region’s supply chains are becoming faster, cleaner, and smarter. By merging IoT sensing, predictive analytics, and local expertise, GND Solutions is helping the GCC build a cold chain that’s not only reliable but resilient for decades to come. “From Dubai’s heat to Doha’s humidity, smart sensors safeguard every shipment,” said Siva Reddy AV. “Our mission is simple — every product, every time, arrives safe and uncompromised.”

By Adhiyan K, Corporate Journalist & Product Designer, GND Solutions.

Our SynQ software delivers data-driven intelligence that empowers your business by synchronizing the performance of your people, processes and machines. The result is a level of efficiency and performance you never thought possible.

swisslog.com

Managing human factors and cognitive load in crane operations

A crane in the world of logistics refers to a heavy-lifting machine used in construction and industries. It is used to move materials vertically and horizontally including tasks such as moving building materials, assembling equipment, and loading/unloading cargo in ports, warehouses, construction sites and more.

Crane technology is advancing rapidly through automation, remote operation, real-time monitoring address, and digital integration leading to more efficiency, precision, and safety for the workers in heavy lifting by addressing the root cause of such accidents, including human error, equipment failure, and hazardous working conditions.

Human element

When one usually thinks of cranes, we picture towing machines moving massive loads with ease. But behind every lift is a skilled operator and a team making countless decisions to ensure the work is done safely. Operation of cranes is heavily dependent on workers and anything which affects the workers, will affect the efficiency and this is called the human factor.

The human factor encompasses everything from operator fatigue and stress to communication breakdown with ground crews and the physical design of the crane cabin. This physical and psychological stress is mainly caused due long shifts, inadequate training or experience, high concentration demands, environmental noise, conditions of the workplace and fatigue. Human errors contribute to 80% of crane accidents and this mainly stems from poor ergonomics, unclear communication, or mental fatigue overload rather than incompetence.

Cognitive overload

At its core, crane operation is about responsibility. Operators must balance confidence in their skills with humilityknowing that it demands exceptional

concentration. When a worker is aware of how catastrophic a single mistake can be and also acknowledges that it is their responsibility, multitasking becomes significantly harder as they have to interpret several data points while keeping everyone’s safety in mind and their mental fatigue exceeds their mental capacity resulting in cognitive overload. Cognitive overload leads to slower reaction time, decision errors, brain-freeze moments and near misses resulting in potential calamities. Introduction of complex technologies to their work routine without adequate support will only worsen the situation.

Strategies to manage human factors and cognitive overload

It is key to manage the workload as well as sensory overload of the workers for everyone’s safety and the unit’s efficiency. The main measures which can be taken are:

• Shift schedule management: Use rotational schedules, mandatory rest periods, and wearable tech to monitor alertness. Avoid monotonous routines to maintain mental fitness.

• Communication protocols: In busy workplaces, ensure simple and clear communication through standardised hand signals, digital tools, and teamwork drills to minimise fatigue from miscommunication.

• Ergonomic design and HMI improvements: Improve workplace conditions with better cabin layouts, intuitive controls, and anti-vibration seats to reduce physical strain. Simplify machine interfaces using colour-coded alerts and AI assistance to ease cognitive load.

• Training and simulations: Conduct regular VR/AR-based training sessions to strengthen situational awareness and decision-making under pressure, ensuring safer and more efficient crane operations.

Crane operations have a significant impact on supply chains, with efficient and well-maintained cranes improving logistics and productivity, while breakdowns can cause major disruptions, delays, and financial losses. Improvements in human performance by reducing their cognitive overload will have a positive impact on supply chain outcomes i.e. fewer accidents, reduced downtime, and higher throughput. Investing in human-centred designs improves efficiency, reliability and resilience in logistical operations. As automation increases, human factors must be a design priority, not an afterthought.

Blue Yonder rethinks MENAT’s returns management dilemma

Returns are now a normal part of the buying journey. Yet, each return adds cost, complexity, and carbon emissions for logistics providers and retailers alike; while they are under pressure to protect margins, meet service levels, and operate more sustainably.

Amid this dilemma, Blue Yonder, the AI company for supply chain and a global leader in end-to-end digital supply chain transformation, alleviates these industry pain points. With a unified, AI-driven platform and multi-tier network, the company powers 3,000+ retailers, manufacturers, and logistics service providers to operate sustainably and scale profitably.

We sat down with Yahyah Pandor, VP & GM, MENAT – Blue Yonder, who unpacked some of the untapped regional opportunities in returns management and retail logistics.

AM: Over the next 3–5 years, how will returns management evolve in the MENAT region, especially with the rise of omnichannel retail?

YP: If you looked at returns data from my own household, you’d probably conclude returns are already a way of life here. That’s actually a good reflection of MENAT. We have a very generous returns culture, especially in fashion, beauty and perfumery. In the UAE, a significant share of online orders in those categories comes back, and retailers have become excellent at the front end – fast delivery, easy pickup, quick refunds. The strain is at the back end, as returns carry costs in transport, handling, storage, markdowns and lost selling time.

Our Global Consumer Retail Returns Survey shows you can’t fix this with harsher policies: 84% of consumers say they will stop shopping with their favorite retailer if returns policies tighten, and two-thirds are already reluctant to buy because of stricter rules. Today, many of these challenges are hidden because e-commerce, stores,

transport and warehousing run on separate systems that don’t talk to each other. With integrated platforms and end-to-end visibility, returns stop being an afterthought and become part of how you plan inventory, cash and loyalty.

AM: What roles do AI and predictive analytics play in transforming returns from a cost center into a strategic advantage?

YP: AI is what turns returns from a headache into a design opportunity. It sees patterns no human planner can track at scale: products with high return rates by size or color, neighborhoods where returns spike, or loyal customers who struggle with sizing. Retailers can then move away from “one-policy-for-everyone” approaches and consider rewarding low-return customers with generous terms while giving frequent returners tighter – even paid – options that convenience still makes acceptable.

Our returns management capabilities, strengthened by the acquisition of Optoro, use AI and predictive analytics from the moment a return is initiated . It ultimately decides the smartest path for every return, including when not to send it back, enabling retailers to turn returns into margin and loyalty versus cost.

AM: Are retailers in MENAT approaching returns differently than their global counterparts? What cultural or logistical factors influence this?

YP: Culturally, MENAT is very serviceoriented. Consumers are used to “tap to order, tap to return” experiences. It’s normal to order multiple sizes, try things

at home, and send back what doesn’t work. As I mentioned earlier, our data shows that stricter policies will only deter consumers from exercising their purchasing power, meaning this convenience is not optional – it’s part of the value proposition . Logistically, though, MENAT is complex. In the UAE, you’re dealing with dense urban areas and heavy traffic; in Saudi Arabia, you’re dealing with significant distances between cities. Every return involves a vehicle, a driver, a route and a decision about which facility – Jebel Ali, Sharjah, Riyadh and so on. Multiply that by thousands of parcels and you have a serious optimization problem.

Leading MENAT retailers are keeping returns convenient while tightening the economics behind them, aligning policies with real cost-to-serve by region and segment, and using transportation and warehouse management platforms to orchestrate those flows rather than relying on manual judgment. That’s where integrated solutions like ours help bridge gaps between cultural expectations and operational reality.

AM: What innovations in reverse logistics are you most excited about, and how close are we to seeing them widely adopted?

YP: AI-driven decisioning, dedicated returns infrastructure and early pilots with autonomous vehicles and drones are reshaping reverse logistics – setting us up for a future where returns are faster, more automated and fully

integrated with forward logistics, even if we’re not at mass adoption yet.

AM: What’s the first step for retailers who want to make returns more sustainable?

YP: You can’t manage what you can’t measure. To avoid pursuing sustainability in the dark, retailers need a solid transportation and warehouse management foundation, one that allows them to optimize routes and cut empty miles. Our acquisition of Pledge enables retailers to access accredited emissions reporting aligned with global frameworks . With that visibility, they can redesign their returns network; steering volume to lower-emission options and avoiding unnecessary cross-border moves.

AM: And how can they do that without hurting the customer experience?

YP: Our sustainability survey shows most consumers say environmental considerations matter in their purchase decisions, and many are willing to pay more for greener everyday products, including beauty and clothing . That gives retailers room to design attractive, lowercarbon return options, such as incentivized drop-off points or slower consolidated pickups that reduce empty miles. The secret is to keep the front-end experience simple and convenient, while using technology to run much smarter, more sustainable logistics behind the scenes.

AM: How do you see the role of supply chain leaders evolving as returns become more central to profitability and customer loyalty?

YP: So much disruption demands a new approach to returns, pushing supply chain leaders into a more strategic role, where customer experience and profitability are always top of mind. When doubledigit percentages of sales can come back, and a poor returns experience can lose a customer for good, returns simply aren’t a back-office issue anymore. How you manage them can make or break profitability and customer loyalty.

Arvato becomes Montblanc’s new logistics partner for global fulfilment operations

• Arvato supports Montblanc with high-quality, secure, and fully integrated omnichannel logistics

• Fast, precise, and value-added fulfilment services ensure a premium customer experience

• Global fulfilment for B2B and B2C from Arvato’s site in Düren (Germany)

Montblanc, one of the world’s most renowned luxury brands, has chosen Arvato as its new logistics partner for global fulfilment operations. The collaboration marks another milestone in Arvato’s growing portfolio of global brand clients and underscores the company’s capability to deliver excellence in quality, speed, and customer experience.

Arvato’s site in Düren (Germany) will manage Montblanc’s warehousing and fulfilment operations, serving as a centralised hub for global distribution. From there, shipments to more than 60 countries will be managed via road and airfreight.

With same-day shipping capabilities and close proximity to major airports, Arvato ensures fast and reliable delivery that meets the high expectations of Montblanc’s discerning customers. The logistics concept combines a one-stock omnichannel setup for B2B and B2C with advanced automation, paperless workflows, and real-time visibility across all channels.

By combining deep industry expertise with the right technologies, Arvato develops

innovative supply chain management and e-commerce solutions for its clients.

Arvato focuses on consumer products, tech, healthcare, automotive and publisher industries and has aligned its organisation to meet the needs of its global clients and their industries. More than 18,000 employees work at 100 locations with state-of-the-art cloud technologies.

By integrating these systems, Arvato achieves exceptional stock accuracy and efficiency – key pillars for maintaining Montblanc’s premium service standards worldwide. To further enhance the brand experience, Arvato provides value-added services (VAS), performed by a specially trained team, ensuring that each item is handled with the utmost care and precision to meet Montblanc’s standards of craftsmanship and excellence.

“We are very proud to start the partnership with Montblanc combining operational excellence and precision with a clear focus on the best customer experience along the entire shopping process,” said Julia Börs, Member of the Board at Arvato. “Luxury brands expect perfection at every

step of the Press Release process and we have designed a solution and built a team to ensure precisely these requirements are also met in the supply chain.” Following the already successful go-live of B2C operations, the B2B integration is set for July 2026, completing a fully harmonized logistics setup for Montblanc’s global business. The partnership is based on a strong cultural fit, close collaboration, and a shared commitment to delivering exceptional customer experiences.

“Montblanc is proud to partner with Arvato to strengthen its delivery of seamless, high-quality experiences to customers at every single touchpoint. Finding the right logistics solution is important to elevating our client centric approach, ensuring continued excellence in execution from reliability to flexibility, from speed to delivery,” says Sebastien Vinet, International Supply Chain Director at Montblanc.

Arvato is an innovative and leading global 3PL service provider in the field of supply chain management and e-commerce.

Launching the collaboration (from left to right): Gerald Hofer (CEO KNAPP), Giorgio Sarné (CEO Montblanc), Frank Schirrmeister (CEO Arvato), Marie-Theres Mangelsdorf (Chief Client & Digital Officer Montblanc), Sébastien Vinet (Montblanc), Julia Börs (Member of the Arvato Board), Philippe Fortunato (CEO Richemont)

SILZ Company showcases integrated logistics opportunities at Lisbon’s Web Summit

The Special Integrated Logistics Zone Company (SILZ) participated at the recently concluded Web Summit Lisbon 2025, as part of the Invest Saudi delegation, spotlighting the Kingdom’s USD $76 billion digital economy.

As a world-class destination for investment across technology, artificial intelligence, e-commerce, and integrated logistics, Saudi Arabia is rapidly advancing its position as a digital and logistical powerhouse. With more than USD $14.9 billion in technology investments , 1,300 megawatts of data centre capacity , and 20 subsea cables connecting East and West , the Kingdom is laying the infrastructure to support high-growth sectors and enable the emergence of over 300 start-ups.

Amid this transformative landscape, SILZ Company stands as a critical enabler, accelerating trade and digital commerce

through next-generation integrated logistics infrastructure. Established in 2022, SILZ Company is the award-winning developer and operator of specialized logistics zones in the Kingdom. Named Logistics Hub of the Year, the company connects global markets through innovation, smart infrastructure, and operational excellence, supporting the creation of over 60,000 jobs in the process.

At the heart of SILZ Company’s mission is Riyadh Integrated, the Kingdom’s first Special Integrated Logistics Zone. This flagship development spans 3 million square meters and offers a suite of globally competitive benefits from 100% foreign ownership, 50-year tax relief, and direct access to King Khalid International Airport. These advantages position Riyadh Integrated as a vital node in Saudi Arabia’s integrated logistics and e-commerce value chain.

Phase 1 of the zone is already 55% occupied, attracting major players across ICT, pharmaceuticals, consumer commerce, and aerospace sectors. Among the landmark developments are a 200,000 square meters Lenovo manufacturing facility and a 40,000 square meters Chalhoub Group logistics hub. Additional high-profile investors include Unipart Logistics, Bahri Logistics, CJ Logistics, Sapphire, iHerb and SHEIN; underscoring the zone’s global appeal and operational readiness.

The Special Integrated Logistics Zone Company (SILZ) is the developer and operator of the first Special Integrated Logistics Zone in Saudi Arabia. Leveraging advanced technology and deep industry expertise, the company provides comprehensive and innovative logistics solutions.

Global Airports Forum (GAF) focuses on innovation and launch of new Hub

Saudia, Amadeus, and SolitAir are among new exhibitors Travel experiences set to become more seamless technology is redefining airport operations. High priority for enhanced passenger safety touchless technology making journeys enjoyable.

The 4th edition of Global Airports Forum (GAF), to be held at the Riyadh International Convention and Exhibition Centre (RICEC) from December 16 to 17, will see over 50 new exhibitors including flag-carrier Saudia and global travel technology giant Amadeus, along with Airport Innovation Trail and Airport Innovation Hub making its debut.

Organised by Niche Ideas, with Matarat Holding, an arm of the General Authority of Civil Aviation (GACA), as its main sponsor, the largest dedicated airport B2B platform in the Kingdom will feature over 250 exhibitors from 100+ countries, along with over 10,000 participants over two days.

An unprecedented 1,000+ buyers will be coming from within the Arabian Peninsula’s largest country Saudi and the wider Middle East region. There will be 5,000+ pre-scheduled meetings during the Forum’s duration. Additionally, over 100 international speakers are attending the

two co-located events: the Global Aviation Issues Conference (GAIC) and the Women in Aviation (WIA) General Assembly.

This edition will see four new features: Future GSE Display, Airport Innovation Hub, Airport Innovation Trail, and the Startups Hub. Additionally, there will be dedicated pavilions by various countries, including Italy, Germany and the United Kingdom, with a special focus on game changing innovations for the airports industry.

Daksha Patel, Event Director at Niche Ideas, remarked: “With most of the world’s leading aviation industry players coming onboard, Global Airports Forum 2025 will be a power-packed edition that will display new technology and discuss issues that are of vital interest to the rapidly expanding industry. It has been our endeavour to bring the best innovations and ideas to the show for our attendees and the number of new launches this year is a testimony to the global industry’s commitment to Saudi Arabia’s vision to transform global air travel.”

The Maritime Standard Awards 2025 winners showcase high levels of operational excellence

The maritime sector’s leading awards event, The Maritime Standard (TMS) Awards 2025, announced this year’s winners from across the Middle East and Indian Subcontinent. The Awards showcased achievement and innovation in 25 categories covering shipping, logistics, ship repair, offshore services, marine technology and related sectors, as well as a series of special awards for individual achievement. The prestigious event took place at Atlantis The Palm, Dubai on October 29th, attracting over 1,000 senior executives, decision-makers and industry leaders, from the region, and across the globe. We bring you all the action.

TIACA at Air Cargo Forum 2025 in Abu Dhabi

The recently concluded Air Cargo Forum 2025 held in Abu Dhabi was a resounding success for TIACA (The International Air Cargo Association). Attended in large numbers by air cargo experts and industry analysts, it was held from November 3rd to 6th at the Etihad Arena.

At the event, the organisation announced the official handover of the office of the Chair to Roos Bakker, Manager of Business Development & Contract Management at ICTS Europe. Ms. Bakker succeeds outgoing Chair Steven Polmans, marking the beginning of a new chapter of leadership for the association.

It also announced that the two CoVice Chair positions will be filled by Emir Pineda, Director of Marketing and Air

Service Development at Miami-Dade Aviation Department, and Tushar Jani, Chairman of Cargo Service Center (CSC) Group and SCA Group of Companies.

In other developments TIACA and HAUS61 GmbH signed a Memorandum of Understanding (MoU) to strengthen cooperation and promote innovation, entrepreneurship, and Start-up development within the global air cargo and logistics industry.