Pieter Feenstra CEO, Addverb

Pieter Feenstra CEO, Addverb

Full offering

- Full range vehicles with the most advanced technologies

- Highly customized product driven by market needs and optimized Total Cost of Ownership

High capillarity of aftersales

- Repair and Maintenance contracts and competitive warranty conditions

- Origin 100% IVECO Parts and a widespread network coverage

European technology

- High quality complete line-up in terms of tonnage, power, torque, safety, ergonomics

- High performance and robust trucks for extreme Off-road conditions

Customer centricity

- Comfort, ergonomics and the latest safety technology to make on board easier

- Driver Style Evaluation tool on Heavy ON-road range and optimized vehicle design to improve customer profitability

SIGNATURE MEDIA FZ LLE

P. O. Box 49784, Dubai, UAE

Tel: 04 3795678

Email: info@signaturemediame.com

Exclusive Sales Agent Signature Media LLC

P.O. Box 49784, Dubai, UAE

Publisher: Jason Verhoven jason@signaturemediame.com

Editor: Abigail Mathias abigail@signaturemediame.com

Art Director: Johnson Machado johnson@signaturemediame.com

Printed and Distributed by Masar Printing and Publishing L.L.C., Part of Dubai Media Incorporated Dubai, UAE

Contributor’s opinions do not necessarily reflect those of the publisher or editor and while every precaution has been taken to ensure that the information contained in this magazine is accurate and timely, no liability is accepted by them for errors or omissions, however caused. Articles and information contained in this publication are the copyright of Signature Media FZ LLE & SIGNATURE MEDIA LLC and cannot be reproduced in any form without written permission.

Sustainability isn’t just a catch phrase; it is a way of life. The team at Global Supply Chain ensured we took this pertinent discussion to a public platform. An international event hosted by CTW and MIE Events was held at Atlantis, Dubai and I moderated a panel on Sustainability with Purpose. It was a truly learning experience as stalwarts of the community discussed using technology to ensure that the best practices are set in place for now and the future.

Smart, scalable, self-driven, that is Addverb’s blueprint for robotic logistics, our exciting cover feature for the month. Abdul Jebbar, Founder, Group CEO and Managing Director, Hotpack discusses ethical sourcing in the demanding food packaging industry.

We bring you insights from FedEx and Orbis which navigates the skies to reach remote corners of the globe to restore sight. It has been doing this relentlessly for the past 40 years.

We encounter powerful entrepreneurs like Marium Dahar, Founder & CEO of Bricks Executive Search and Angela Pernsteiner, driving force and visionary founder of WÜRTH Professional Solutions (WPS) and Executive Board Advisor to the WÜRTH Group. With vision and passion they each represent the best of this industry.

We bring you the latest details of a new Supply Chain Professional Club launched in the UAE.

We will be on the ground covering the TIACA Air Cargo Forum from the capital which coincides with ADIPEC.

This month also has a guest column from a moderator at Global Rail. Having a safer, faster option to travel between countries and cities sounds like a win-win for the planet.

As we wrap our arms around the cooler weather, lets ensure we do more to harness the power of Mother Nature.

Happy reading.

Abigail Mathias Editor

abigail@signaturemediame.com www.globalsupplychainme.com

1500+

150+

Addverb is a global robotics and automation company revolutionising warehouse and supply chain operations through advanced AI and robotics. Founded in 2016 and headquartered in Noida, India, it offers end-to-end solutions for material handling, storage, and intra-logistics. With a presence across five continents, Addverb serves major clients like PepsiCo, Johnson & Johnson, and Hindustan Unilever. Its portfolio includes autonomous mobile robots, automated storage systems, and AI-powered software for scalable, flexible logistics. This month’s cover story has special inputs from Ankur Yadav, VP, Sales & Strategy and Pieter Feenstra, CEO, Addverb EMEA.

GSC: What differentiates Addverb’s robotics and automation solutions from competitors?

Ankur Yadav: What truly sets Addverb apart is the breadth, intelligence, and reliability of our automation ecosystem. Our wide product portfolio offers both end-to-end automation and modular point solutions, capable of handling a diverse range of form factors, from individual pieces to totes, crates, bags, and pallets, enabling seamless picking, storage, and movement of goods. We combine fixed and flexible solutions powered by a single layer of AI-enabled, in-house software that not only orchestrates the entire operational flow but also integrates effortlessly with external ERP and warehouse management systems. This is complemented by robust after-sales support, including trained on-site engineers, dedicated hotline assistance, and a comprehensive service platform, ensuring a smooth, reliable, and future-ready customer experience.

We combine fixed and flexible solutions powered by a single layer of AI-enabled, in-house software that not only orchestrates the entire operational flow but also integrates

GSC: What motivated Addverb to expand into the UK and Ireland at this time and how does this move fit into Addverb’s broader global strategy?

Pieter Feenstra: Expanding into the UK and Ireland marks a strategic and natural progression in Addverb’s European growth journey. As one of the largest and most advanced markets for warehouse automation, the region offers immense potential for direct business engagement, particularly across Northern Europe. This move aligns seamlessly with our broader global strategy to strengthen our presence in key international markets through localised operations and customer proximity. Moreover, operating in English-speaking regions allows for smoother integration with our global

organisation, which is managed entirely in English, enabling efficient collaboration and support. The addition of a highly experienced local team in the UK has further accelerated our ability to establish a strong foundation and deliver immediate value to customers in this new market.

GSC: What unique challenges or opportunities do you foresee in the UK and Ireland logistics market?

Pieter Feenstra: Personally, I know that market quite well, as I was living there for several years, also doing business in the warehouse automation market. The market is big and many customers are automation minded, so that helps. At the same time, almost all international players have a presence there, so that is the

challenge. Addverb will be focussing on some solutions where we have competitive and innovative solutions. For now, the key opportunities seem to be in the pallet handling area, both in storage (with our 4-way pallet shuttle solutions), as well as in transports and picking. Another promising area is in robotics sortation. I am quite sure we will see our first orders in the next 3 months in the UK!

GSC: How does AI play a role in your warehouse orchestration and logistics systems?

AY: AI lies at the core of all Addverb products and solutions, driving intelligence, adaptability, and efficiency across warehouse orchestration and logistics systems. Our software stack integrates AI agents that operate on complex business

models to make processes smarter and more autonomous. In our Warehouse Management System (WMS), AI-powered prediction and optimisation models enable demand forecasting, inventory and stocklevel management, intelligent slotting, and SKU affinity optimisation. Within our Fleet Management System (FMS), vision and perception-based AI models empower AMRs and cobots with real-time decisionmaking and spatial awareness for seamless navigation and task execution. Furthermore, AI enables predictive and augmented reality-based maintenance in our after-sales and training modules, ensuring proactive support and enhanced operational reliability. Together, these capabilities allow Addverb to deliver intelligent, data-driven automation that continuously learns, adapts, and improves warehouse performance.

AI enables predictive and augmented reality-based maintenance in our after-sales and training modules, ensuring proactive support and enhanced operational reliability.

Addverb has forayed into advanced robotics with the launch of Cobots, Quadrupeds, and Humanoids. These next-generation robots rely on multi-modal data inputs, vision, audio, and touch, to navigate complex environments, perform intricate tasks, and make intelligent, realtime decisions

Branch Manager Ian Stevens and Project Manager Matt Pedley, Netherlands with Pieter Feenstra, CEO, Addverb EMEA.

GSC: Can you share examples of how your technology has transformed operations for clients?

AY: Addverb’s technologies have consistently transformed operations for clients across industries by enhancing efficiency, accuracy, and scalability. For instance, we deployed sortation robots for the Landmark Group, revolutionising their order sorting process and significantly improving throughput, order accuracy, and space utilisation while reducing manual dependency.

Our 4-Way Pallet Shuttle, a dense, flexible, and modular storage and retrieval solution, has optimised warehouse operations for a leading FMCG company by maximising storage density, improving inventory traceability, and enabling faster pallet movement across multiple aisles and levels. Additionally, our conveyor and sortation systems have powered seamless order fulfilment for large e-commerce and 3PL companies, streamlining material flow and reducing turnaround time even during peak operational loads. These implementations reflect how Addverb’s intelligent automation portfolio enables businesses to achieve higher productivity and operational resilience through tailor-made, scalable solutions.

GSC: How does Addverb incorporate sustainability into its logistics solutions?

PF: At Addverb, sustainability is embedded into every layer of our logistics and automation ecosystem. We engineer our robots and systems for energy efficiency, conduct cradle-to-gate life cycle assessments, and power our facilities like Bot-Verse through renewable sources, which now meet 13% of our energy needs. Our operations emphasise responsible waste and e-waste management under Extended Producer Responsibility norms, alongside a strong focus on ethical sourcing, local procurement, workforce well-being, and community engagement. Our internal commitment to achieve Net Zero by 2050 reflects our belief that true innovation is sustainable innovation, creating intelligent automation that powers progress while protecting the planet.

GSC: How is Addverb preparing for the next wave of AI and robotics innovation?

AY: Apart from its technological leadership in the intralogistics space, Addverb has forayed into advanced robotics with the launch of Cobots, Quadrupeds, and Humanoids, expanding into new domains such as medical, defence, surveillance, and core manufacturing. These nextgeneration robots rely on multi-modal data inputs, vision, audio, and touch, to navigate complex environments, perform intricate tasks, and make intelligent, realtime decisions. To prepare for this next wave of robotics, Addverb is continuously advancing its capabilities in AI, machine learning, sensor fusion, and edge computing, ensuring these systems become increasingly adaptive, perceptive, and capable of working safely alongside humans in dynamic, real-world scenarios.

GSC: The company is known for blending software intelligence with robust hardware to deliver smart, safe, and sustainable logistics solutions. Can you elaborate more on this?

PF: Addverb has a unique positioning, with a hardware portfolio that combines conventional fixed automation products like conveyors and stacker cranes with flexible automation solutions such as AMRs and sortation robots. This is complemented by a modern software stack that enables us to create holistic, intelligent automation ecosystems. We can deliver softwareonly solutions, focused product-based systems like robotic sortation, or complete integrated automation setups. Our broad range of capabilities allows us to compete across diverse market segments and design solutions that truly fit each customer’s operational needs, rather than tailoring them to a specific product.

Gulf Warehousing Company Q.P.S.C (GWC), one of the leading logistics providers in the MENA region, has acquired a strategic, noncontrolling stake in European technology and logistics scale-up Quivo. The move expands GWC’s footprint across three continents and will enable homegrown Qatari and GCC brands to gain fast access into major European and US marketplaces. It also provides access to millions of GCC consumers for leading international companies, powering growth across the region.

Sheikh Abdulla Bin Fahad Bin Jassim Bin

Jaber Al Thani, Group Managing Director, GWC, said: “This strategic acquisition strengthens GWC’s global presence and connects Qatar’s logistics expertise with new markets. It gives homegrown regional brands seamless access to international marketplaces and access point global companies to reach hundreds of millions of consumers across the region.”

In addition to its robust technology backbone and e-commerce expertise, Quivo boasts a network of six warehouses in Germany, France, Austria, UK, and USA. Its scalable infrastructure supports international brands in their growth, including a modern

‘GWC’s

global presence now spans 3 continents, carrying Qatar’s logistics expertise into new markets’

– Sheikh Abdulla Bin Fahad

‘The strategic stake acquisition of Quivo strengthens our position as a leader in tech-enabled e-commerce logistics’

– Mathew Kearns, GWC’s Acting Group CEO

warehouse management system, multichannel listing, API integrations, and easy marketplace integration with global platforms like Amazon and Shopify.

GWC has already integrated Quivo’s software into its warehouses in Qatar, with additional rollouts planned in the UAE and Saudi Arabia in the coming months. The two brands aim to capitalise on the GCC’s booming e-commerce market, projected to nearly double to US$ 47 billion by 2029, according to the Seamless GCC Market Report 2024.

While the acquisition expands GWC’s portfolio and gains access to European and US markets, Quivo gains access to a prime growth market in the GCC. Customers of both companies will benefit from being able to seamlessly scale their products between the MENA region, Europe, and the US.

Georg Weiß, Co-Founder and CEO, Quivo

Matthew Kearns, GWC’s Acting Group CEO, stated: “We are advancing how logistics and technology work together. The strategic stake acquisition of Quivo extends our reach across three continents and strengthens our position as a leader in tech-enabled e-commerce logistics. This acquisition delivers instant scalability. As brands grow, they can plug into our infrastructure without rebuilding operations. This unified platform allows brands to scale into new regions and channels instantly, with no fragmented setups or redundant integrations. Everything operates within one scalable backbone.”

Georg Weiß, Co-Founder and CEO, Quivo, said: “This partnership connects marketplace visibility to perfect order execution. With Quivo’s omnichannel SaaS and GWC’s regional logistics footprint, brands get a single command centre for catalogue, orders, payments, and performance, backed by dependable fulfilment across Qatar, the UAE, and Saudi Arabia. It’s the fastest way to turn intent into revenue in the GCC.”

GWC is a leading logistics provider in the MENA region that offers best-inclass logistics and supply chain services. As the largest private sector developer of logistics hubs in the region, GWC has developed over 4 million square meters of world-class logistics infrastructure, serving both local and international clients, while continually bidding on new projects and management agreements.

Hotpack Global is a leading manufacturer of disposable food packaging products, founded in Dubai in 1995. The company has been a leader in the production and distribution of packaging products for a wide range of markets, including food, retail, healthcare, pharmaceuticals, consumer packaged goods, and hospitality. To unbox its latest achievements, Global Supply Chain caught up with Abdul Jebbar, Founder, Group CEO and Managing Director, Hotpack.

Abigail Mathias: Congratulations on securing the EcoVadis Gold Medal, which placed the company among the top 5 % globally. What does this recognition mean to you and what were the key areas assessed?

Abdul Jebbar: Thank you. The EcoVadis Gold Medal affirms Hotpack’s strong, globally benchmarked commitment to sustainability. EcoVadis evaluates companies across four critical pillars -- Environment, Labour and Human Rights, Ethics, and Sustainable Procurement — and Hotpack achieved an overall score of 80/100, positioning us in the 97th percentile among over 150,000 companies worldwide.

This recognition reinforces our reputation as a trusted, forward-thinking manufacturer with

sustainability embedded across all operations — creating lasting value for our stakeholders.

AM: What recent sustainability initiatives contributed to achieving this recognition?

AJ: Hotpack’s EcoVadis Gold Medal highlights our results-driven sustainability approach, from reducing emissions through efficiency and renewables to installing solar rooftops that cut grid dependence.

We have also institutionalised global standards through ISO 9001, 14001, and 45001 certifications in over 20 facilities, ensuring consistency in quality, environmental stewardship, and occupational safety. On the product front, 96% of our packaging portfolio is now recyclable or eco-friendly, utilising rPET, paper-based, and lightweight materials that lower environmental impact without compromising performance.

Equally important is our commitment to ethical and responsible sourcing. Through supplier selection, engagement programs, and capacity-building initiatives, we ensure that our partners align with our environmental and labour standards.

AM: Hotpack operates across 20+ global sites and sources from multiple suppliers. How do you ensure that sustainability standards are upheld across your entire supply chain?

AJ: We follow a structured, tiered approach to uphold sustainability across our global supply chain. All suppliers must comply with Hotpack’s Supplier Code of Conduct, covering environmental, labor, and ethical standards. Our procurement and compliance teams conduct regular audits, risk assessments, and training to drive improvement.

Beyond compliance, we partner with suppliers to adopt eco-friendly materials, optimise resources, and implement circular practices that cut waste and carbon impact.

AM: How does Hotpack integrate sustainability into its procurement strategy, and what role does responsible sourcing play in your overall ESG goals?

AJ: We have embedded responsible sourcing criteria into vendor selection, evaluation, and contract management to ensure that every material and service aligns with our broader ESG objectives.

Our approach prioritises environmentally preferable materials, including recycled and certified substrates, and suppliers who demonstrate verified commitments to ethical labor practices, transparency, and emissions reduction. Through sustainability risk assessments and close collaboration, we encourage our partners to achieve globally recognised certifications such as FSC, PEFC, and ISO 14001, fostering shared accountability

and continuous improvement throughout the value chain.

Responsible sourcing directly underpins Hotpack’s ESG vision — driving resource efficiency, reducing Scope 3 emissions, and ensuring that our growth contributes positively to people, communities, and the environment.

AM: In terms of global operations, what steps has Hotpack taken to reduce environmental impact across manufacturing and logistics?

AJ: Across our global operations, Hotpack has made significant strides in minimising environmental impact through a combination of innovation, efficiency, and responsible logistics. Our manufacturing sites are increasingly powered by solar energy, supported by extensive energy-efficiency upgrades and process optimisation initiatives that reduce both energy consumption and waste generation.

On the logistics front, we have adopted smart route planning, bulk shipment models, and to further cut down our carbon footprint. These initiatives work collectively to reduce greenhouse gas emissions across our value chain and reinforce our sustainability practices.

AM: Describe some of the milestones and goals the company hopes to achieve?

AJ: Hotpack’s sustainability roadmap is anchored in a clear vision — to achieve netzero emissions by 2050 and make sustainability a driver of innovation and long-term growth.

A key milestone on this journey is to increase the use of recycled and renewable materials to 100% across our core product lines, ensuring that circularity becomes central to our manufacturing model.

In parallel, Hotpack is advancing transparency in ESG reporting by aligning with GRI frameworks and integrating low-carbon logistics solutions to further reduce emissions in transport and distribution.

AM: How do Hotpack’s sustainability and supply chain initiatives align with the UAE’s Year of Community?

AJ: Hotpack’s sustainability and supply chain initiatives reflect the UAE’s Year of Community values of unity and shared progress. For 30 years, we have advanced with the nation’s sustainable vision.

Our initiatives are designed to create real social impact. Through programs like the Hotpack Happiness initiative, we promote employee well-being and community participation across our global workforce.

Our sustainable sourcing and local supplier partnerships strengthen regional economies, while our carbon reduction and recycling projects support the UAE’s broader transition to a low-carbon, circular economy.

AM: In your role, how do you personally champion sustainability at Hotpack, and how do you ensure these practices are embedded across global sites?

AJ: At Hotpack, we lead sustainability by example. I am personally involved in shaping our ESG strategy — from setting policies to ensuring execution across all business units. Sustainability isn’t a standalone goal; it’s a mindset driving every decision in operations, procurement, R&D, HR, and marketing. We have built it into site-level KPIs and performance frameworks, supported by regular training and awareness programs. With 4,300 employees across 20+ sites, our focus is on building a culture of ownership, where accountability is recognised and sustainability becomes a shared value, not just a target.

Turkish Airline’s global air cargo brand Turkish Cargo has added its ninth Boeing 777 Freighter (777F) to its fleet. The carrier will take delivery of three additional Boeing 777F by mid-2026.

Standing out with its high efficiency, fuel savings and technical reliability on intercontinental flights, the Boeing 777F will operate on long-haul scheduled routes with its 9200 km nonstop range, primarily to the Americas and the Far East.

Turkish Airlines Chief Cargo Officer Ali Türk stated: “As Turkish Cargo, we will expand our Boeing 777F fleet to 12 aircraft in 2026, gaining an additional annual capacity of approximately 220,000 tons. This growth will contribute to our fleet streamlining and sustainability goals, while enabling us to offer our business partners greater capacity.

Beyond the advantages of fleet expansion, further addition of the Boeing 777F aircraft represents a strategic investment that enhances our operational capabilities with its extended range, superior payload capacity, and enhanced fuel efficiency. Guided by our growth strategy centred on wide-body freighters, Turkish Cargo will continue to deliver effective solutions to the needs of global trade.

Boeing Vice President of Sales and Marketing, Eurasia and India Paul Righi said: “We are excited to build on our partnership and support Turkish Cargo in its growth strategy with more 777 Freighters joining their fleet. The unique capabilities of the 777 Freighter will enhance their operations with the capacity and reach to support growing cargo market demand.”

Being one of the fastest-growing air cargo brands in the world, Turkish Cargo today provides services to more than 350 destinations in 134 countries and transports approximately 2 million tons of air cargo annually.

Within the scope of Turkish Airlines’ 2033 Vision and its target of a fleet of 813 aircraft, Turkish Cargo aims to increase its freighter fleet from 28 to 44. This growth is supported by the SMARTIST 2.0 investment, digitalization efforts, special cargo solutions, and a team of dedicated experts.

With the enhanced capacity and operational capability provided by the modern fleet, Istanbul’s position of being a strategic hub in global air transport is being reinforced further.

Returns and exchanges are inevitable but efficiency doesn’t have to be.

A smart reverse logistics strategy is no longer optional. It’s the backbone of operational resilience and customer satisfaction, especially during peak seasons.

With WAMAS Warehouse Management System, you gain end-to-end visibility, automate your warehouse processes and optimize every movement of goods, turning complexity into control.

Automate your warehouse today.

Why Choose the WAMAS Warehouse Management System?

Gain full visibility with real-time monitoring and control of every process

Synchronize workflows for seamless material flow

Customized dashboards tailored to your needs

Integrates easily with your existing systems

The collaboration powers the Orbis Flying Eye Hospital and has helped bring sight and hope to communities worldwide.

Ahead of World Sight Day, which falls on October 9th, Federal Express Corporation (FedEx), the world’s largest express transportation company, turned the spotlight to its over 40-year collaboration with Orbis International, during the Flying Eye Hospital’s goodwill visit in Dubai from September 30 to October 3. Orbis hosted guided tours of the aircraft for FedEx employees and other guests, providing an inside look at the oneof-a-kind aircraft and showcasing its shared commitment to advancing access to eye care worldwide. The visit also underscored the UAE’s role as a hub for knowledge exchange and humanitarian collaboration, making it an ideal location to raise awareness about the importance of access to quality eye care.

“We frequently bring the Flying Eye Hospital to Dubai between projects in Asia and Africa,” said Bruce Johnson, director of aircraft operations and maintenance at Orbis International. “For more than 18 years, FedEx teams at Dubai International Airport and Dubai World Central have played a vital role in supporting our aircraft—from logistics to maintenance—whenever we’re in the region. Every time we arrive, we’re welcomed like family. Their hospitality, dedication, and willingness to go the extra mile make our work smoother, more impactful, and ensure we’re ready to deliver sight-saving care wherever it’s needed next.”

Globally, an estimated 1.1 billion people live with vision loss, of which 90% live in lowand-middle-income countries. The Flying Eye Hospital was created to help close this gap. It is a fully accredited ophthalmic teaching hospital with an operating room, classroom, and recovery space. The current, third generation Flying Eye Hospital is a FedEx-donated MD-10 aircraft. Since its first flight in 1982, the Flying Eye Hospital has visited more than 80 countries, providing both training and surgeries to address avoidable blindness and vision loss. These projects equip local doctors, nurses, and other eye care professionals with the skills and knowledge to deliver life-changing treatment in their own communities.

FedEx has supported Orbis since the start, providing more than US$22 million in donations and in-kind shipping. Beyond donating the current aircraft, FedEx covers aircraft parts, maintenance, and pilot training, while FedEx pilots volunteer their time to fly the plane to all its destinations. In 2021, FedEx announced its renewed commitment to Orbis’s sight-saving mission with a US$3.5 million donation to help provide financial, logistical, and operational support to the organisation and its Flying Eye Hospital over the following five years. This collaboration is part of FedEx Cares, the company’s global community engagement program that delivers hope and opportunity to the communities FedEx serves.

“As World Sight Day approaches, FedEx is proud to stand with Orbis in creating a world without avoidable blindness and vision loss,” said Taarek Hinedi, vice president of Middle East and Africa operations at FedEx. “Welcoming the Flying Eye Hospital to Dubai is a reminder of the vital work being done across the Middle East, Indian Subcontinent, and Africa to expand access to eye care. By supporting these efforts with our resources and expertise, we are helping local communities strengthen healthcare systems and create brighter opportunities for the future.”

“With Orbis, I’m not just flying an aircraft— I’m part of a mission where people’s lives are changed forever,” said Captain Gary Dyson, chief pilot for Orbis International and a retired FedEx pilot. “Seeing a child regain their sight and knowing they now have a chance to learn, play, and one day support their own family is an incredible feeling. I’m proud to have spent a large part of my life working for FedEx, which made it possible for its pilots to give back in such a meaningful way.”

Alongside the Flying Eye Hospital, Orbis also works with local hospitals and clinics across Africa, Asia, and Latin America to expand access to quality eye care. Its awardwinning Cybersight e-learning and telehealth platform, along with artificial intelligence screening and virtual reality training, equip local eye care teams with the tools and expertise to treat patients more effectively.

The GCC’s logistics sector is entering a new era, where automation and digitalisation are reshaping traditional practices. At the forefront, Al Ostad Pallet Factory blends innovation with resilience to deliver smarter, more efficient pallet solutions. Under the leadership of Alex George, the company is positioning the region as a hub for sustainable, tech-driven supply chains.

As the GCC pallet and logistics industry evolves, we are seeing a transformative shift driven by automation, digitalisation, and smart supply chain solutions. At Al Ostad Pallet Factory, the focus remains on blending innovation with practical efficiency - whether through bespoke pallet manufacturing, real-time tracking, or expanding warehousing capabilities. These advancements enhance operations, while also bolstering resilience against disruptions, ensuring clients receive timely, reliable service.

By investing in technology and talent,

Al Ostad Pallet Factory - helmed by Managing Director Alex George - is preparing for the next decade of growth, helping position the region as a hub for advanced, efficient, and sustainable logistics solutions. Here, he shares insights on how these trends are shaping pallet manufacturing, smart logistics, and supply chain resilience in the GCC.

George has spent more than two decades shaping the timber and pallet industry across the GCC. Today, he leads one of the region’s most trusted names in pallet manufacturing, operating from an 80,000 sq. ft state-of-the-art facility in

Dubai Industrial City. Under his guidance, the company produces high-quality timber pallets for some of the region’s most demanding industries, while championing sustainable sourcing and innovative manufacturing practices.

Alex’s entrepreneurial journey began at just 25, when he branched out from his family’s business to set up a trading firm specialising in quality lumber. He quickly made his mark by building supply chains from Eastern Europe and Russia, establishing himself as the sole GCC agent for Severstal Group’s plywood division, and even expanding

into scaffolding and civil projects. After his father’s retirement, Alex returned to his roots, designing and launching the new Al Ostad facility and securing long-term raw material supply chains from Romania and other parts of Europe.

Global Supply Chain (GSC): How is pallet manufacturing evolving in the GCC, and what role does automation play in making operations more efficient and cost-effective?

Alex George (AG): The GCC pallet industry currently produces about 200 million units annually, and this is expected to double to 400 million in the next decade. Wooden pallets remain dominant, though plastic and corrugated pallets are gaining traction. Plastic pallets are preferred in industries prioritizing hygiene, as they resist moisture and are easier to clean. Saudi Arabia is set to build a corrugated pallet factory with a capacity of 10 million units per year.

Alex George , Managing Director, Al Ostad Pallet Factory

Automation has always played a role, especially in producing standard euro pallets efficiently on semi-automated lines. At Al Ostad, we focus more on bespoke pallets, where robotics could automate tasks like timber placement and nailing. However, automation must justify its capital expenditure in a region where manual labour remains cost-effective.

GSC: What are the key technologies or innovations in smart logistics that will reshape supply chains in the region over the next five years?

AG: E-commerce is driving the adoption of smart logistics, with robotics increasingly deployed in fulfilment centres. Automated storage and retrieval systems reduce labour costs and accelerate order processing. By combining machine vision to accurately identify items with robotic arms for picking, packing, and sorting, these systems improve accuracy and shorten cycle times.

AI-driven demand forecasting anticipates peak periods, such as holidays, while advanced sensors minimize spoilage of perishable goods. Cloud-based software allows inventory holders to coordinate seamlessly with logistics providers. The possibilities for smart logistics are vast, and

industry leaders like Amazon and Noon are likely to lead these innovations in the region.

GSC: How can regional manufacturers and logistics providers build greater resilience into their operations, and where do pallets fit into that strategy?

AG: Supply chain resilience has become a boardroom priority in the GCC, particularly in the wake of global disruptions such as COVID-19 and raw material shortages. Manufacturers and logistics providers are rethinking sourcing, storage, and last-mile delivery. Reducing dependence on a single country or supplier is a starting point. “Near-shoring” is a term that’s gaining steam - keeping strategic inventory in nearby GCC countries for easy access.

At Al Ostad, relocating to Dubai Industrial City aligns with the government’s Make it in the Emirates program. Proximity to Maktoum Airport supports logistics operations, while real-time pallet tracking with RFID improves transparency and traceability. Maintaining critical stock locally mitigates disruptions - for instanceshipping delays stress our manufacturing, as timber shipments are vital for timely client deliveries. In response, we invested in larger

warehouses to hold more raw materials and strengthen supply continuity.

GSC: What specific opportunities and challenges do GCC companies face balancing automation and digitalization with labour markets, regulation, and customer demand?

AG: It’s a double-edged sword. At Al Ostad, the cost of automation often outweighs the benefits of more cost-effective manual labour. Yet automation generates data that enables predictive analytics for demand forecasting, inventory management, and optimized routing. Technologies like RFID enhance trust in cross-border trade by providing real-time visibility.

Digitization requires skilled labour, making in-house upskilling and talent-attraction programs essential, as high-skill workers may eventually replace lower-skill roles.

National standards for smart cities, logistics automation, and e-commerce logistics are still evolving, and harmonizing these with global standards is essential for international expansion. While the human touch will always play a role in most industries, a hybrid system combining human expertise with automation is likely the near-term goal.

• MAN impresses with sustainable solutions at the largest international bus trade fair in Brussels

• New generation of batteries from inhouse production

With the Lion’s Coach 14 E, MAN is launching the first batteryelectric coach from a major European manufacturer. Under optimal conditions, the bus can achieve a range of up to 650 kilometres – a distance that allows many typical travel routes to be covered without recharging.

In May, MAN Truck & Bus became the first European manufacturer to present a fully electric coach with the new Lion’s Coach E. It is now celebrating its world premiere with a new design at Busworld in Brussels. We discover what drives them to success.

A second highlight at the MAN stand is the Lion’s City 12 E LE, which will be presented at the trade fair with numerous innovations for the 2025 model year. The vehicle thus represents the next major product update of the successful Lion’s City E. Particular focus is on the new battery generation with the latest lithium-ion battery technology (NMC) from MAN’s own production facility in Nuremberg. Production of the MAN BatteryPack is currently being ramped up there to a capacity of up to 50,000 units per year. The new packs feature even higher energy density, optimised safety systems and improved charging flexibility. For operators, drivers and passengers, this means greater efficiency and safety. In addition, the low-entry bus on display has Class II approval – another world premiere at the exhibition stand.

The premium brand NEOPLAN is also making a special impression at Busworld Europe. Two coaches are causing a stir in Brussels: the NEOPLAN Skyliner “Auwärter Edition”, which is celebrating its trade fair premiere, pays tribute to the brand’s heritage as a limited special edition. With its aerodynamic “Sharp Cut” design, state-of-the-art technology and nostalgic features, it combines tradition and the future. Another real eye-catcher is the NEOPLAN Tourliner C, whose D2676 LOH engine with increased power and torque,

optimised drivetrain and 353 kW (480 hp) delivers fuel savings of up to 2.5 per cent.

The latest member of the NEOPLAN family scores not only in terms of comfort and economy, but also in terms of functionality and safety. The Tourliner, which can be seen at the trade fair in an eye-catching “Safe and Secure” design, is equipped with numerous assistance systems, including the innovative MAN SafeStop Assist.

“With our eCoach, we are entering a new era of emission-free travel. With the electrification of our fleet, numerous innovations in equipment and technology, and modern services, we are consistently focusing on efficient, sustainable and digitalised transport,” said Barbaros Oktay, Head of Bus at MAN Truck & Bus.

With the Lion’s Coach 14 E, which is celebrating its world premiere in Brussels, MAN is launching the first battery-electric coach from a major European manufacturer. Following the success of the Lion’s City E family, with almost 3,000 e-buses already produced for urban and interurban use, the company is now setting the next milestone in sustainable mobility. The fully electric coach uses the proven drive technology

from the successfully series-produced eTruck and innovative NMC battery packs. These are manufactured in large series at the Nuremberg plant. “By drawing on proven components from the truck sector and our many years of experience with electric city buses, bus operators benefit from high reliability and synergy effects in service and spare parts supply,” says Heinz Kiess, Head of Product Marketing Bus at MAN Truck & Bus.

The Lion’s Coach E has a usable energy capacity of 320 to 480 kWh. Under optimal conditions, it can achieve ranges of up to 650 kilometres – a distance that allows many typical travel routes to be covered without recharging. In addition to the technology, the smart design concept, which significantly reduces the drag coefficient (Cw value), is also impressive. At the same time, the eCoach offers space for up to 63 passengers without any restrictions on luggage volume compared to the diesel version.

The new packs feature even higher energy density, optimised safety systems and improved charging flexibility. For operators, drivers and passengers, this means greater efficiency and safety. In addition, the low-entry bus on display has Class II approval – another world premiere at the exhibition stand.

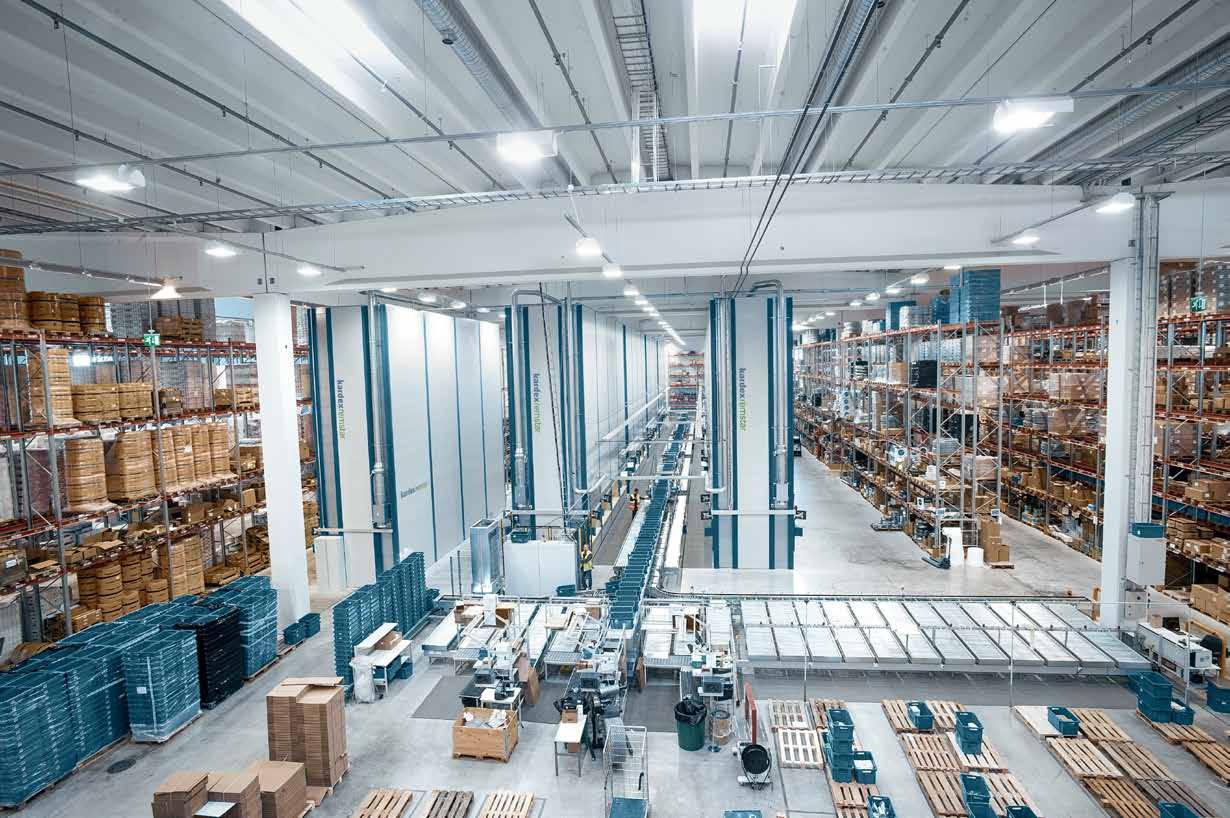

Founded in 1979 and joining ClMC Group in 2014, we are a proud member of ClMC TlANDA and a global leader in intralogistics and material handling solutions. With 40+years of expertise and 1000+ large-scale projects, we provide customized automation system solutions for industries including 3PL, retail, express, pharmaceuticals, FMCG, petrochemicals, new energy, F&B, cold storage, and CHS.

Seamless Integration: Enhance your warehouse with our automated storage systems and robotic picking solutions.

Advanced Control: Real-time monitoring and predictive analytics to optimize performance.

Scalable Solutions: Adapt to growing demands with flexible, customizable systems.

Aron.Schiller@stas.cimc.com

Linkedin: https://www.linkedin.com/in/aron-schiller/

Automation, robotics, and Artificial Intelligence (AI) are transforming global supply chains at breakneck speed. Companies are investing billions to digitise warehouses, streamline logistics, and future-proof their operations.

By 2030, the global logistics automation market alone is projected to exceed $80 billion, while PwC (PricewaterhouseCoopers) estimates automation could contribute up to $500 billion annually to global GDP by the next decade.

Marium Dahar, Founder & CEO of Bricks Executive Search, reveals more.

This is not just an industry trend; it is an economic imperative. Yet behind the headlines of smart warehouses and autonomous vehicles lies a quieter truth: technology is only as powerful as the leaders guiding it. And in supply chain, leadership remains overwhelmingly male.

The talent gap meets the gender gap

According to Gartner, women account for only 19% of supply chain executives worldwide and fewer than 10% of seniormost roles. At the same time, McKinsey research shows companies with diverse executive teams are 25% more likely to achieve above-average profitability.

That mismatch is more than a statistic. It represents a blind spot worth billions. Businesses are pouring resources into automation while ignoring half the leadership pool that could unlock its true potential. In effect, we are trying to build the supply chains of the future with yesterday’s leadership models.

The value of female leadership is not symbolic, it is strategic. Studies consistently show that women in executive roles score higher on collaboration, resilience, and long-term thinking. Deloitte found that gender-diverse teams are 30%

more innovative, while BCG reports that companies with above-average diversity generate 45% of their revenue from innovation, compared to just 26% for less diverse peers.

Real-world examples reinforce this. DHL’s Women in Logistics initiative has been credited with boosting both employee retention and customer satisfaction scores across multiple regions. In Saudi Arabia, Aramex has steadily increased female participation in logistics roles as part of Vision 2030, positioning itself as an early mover in inclusive supply chain leadership.

If innovation is the lifeblood of supply chain transformation, excluding women from leadership isn’t just inequitable, it’s economically unsustainable.

A regional advantage

The Middle East has an extraordinary opportunity to change the narrative. The region is making some of the world’s most ambitious investments in logistics infrastructure, smart warehousing, and robotics. PwC forecasts that by 2030, transport and logistics could account for

12% of the UAE’s GDP and a similar share in Saudi Arabia, where Vision 2030 prioritizes logistics as a key diversification pillar.

At the same time, the UAE boasts one of the highest rates of female STEM graduates globally (over 55%), far ahead of most developed markets. Across the Gulf, governments are embedding gender diversity into their national strategies, from ministerial appointments to corporate board representation.

This means the raw ingredients for transformation are already here: visionary infrastructure programs paired with a pipeline of educated, ambitious women ready to lead. By tapping into this pool, the region could set a global benchmark: not just in building advanced supply chains, but in building inclusive leadership that matches the scale of its vision.

In my role as Founder & CEO of Bricks Executive Search, I work with global automation and robotics companies on their most critical leadership hires. And I see a clear pattern: companies that

actively seek diverse leadership pipelines don’t just attract stronger candidates; they outperform.

Take, for example, a European warehouse automation provider I worked with recently. By bringing women into senior commercial and operations roles, the company not only improved internal culture but also achieved measurable improvements in client retention and market expansion. Diversity became a driver of performance, not a line in a CSR report.

These outcomes are consistent with global research: organisations with above-average diversity generate almost twice the revenue from innovation compared to less diverse peers. Diversity is not about optics. It is about building leadership teams capable of solving complex problems in a disruptive era.

The supply chain of the future will not be built by machines alone. It will be built by people, leaders who can inspire teams, navigate complexity, and unlock innovation. Until we break the ceiling on female leadership, we are running our supply chains with one hand tied behind our backs.

The Middle East, with its unique combination of investment ambition and female STEM talent, has the chance to lead globally, not only in building the most advanced supply chains, but in redefining what inclusive, future-ready leadership looks like.

This is not charity. This is not PR. This is competitive advantage. The businesses and nations that recognise this first will be the ones shaping the global supply chain narrative in the decades to come.

Marium Dahar is the Founder & CEO of Bricks Executive Search, a Dubai-based boutique firm specialising in leadership hiring across warehouse automation, intralogistics, and robotics. With over five years of global talent acquisition experience, she partners with leading automation and robotics companies to solve senior talent challenges across the Middle East, Europe, Asia, and the US. As one of the few female founders in this niche sector, Marium brings a unique perspective and is a vocal advocate for advancing female leadership in supply chain and automation.

Aforklift is a powered industrial vehicle used to move materials over short distances. It is a crucial element for the daily functioning of warehouses and distribution centres, and hence necessary that any downtimes or damages in forklifts are avoided. A downtime in a forklift not only means repair costs but it also means the indirect costs which will affect the overall performance of a warehouse.

A forklift repair can take between a few hours to several weeks, depending on the cause of the downtime. It is advisable to conduct regular maintenance checks to prevent major repairs. According to the Occupational Safety and Health Administration (OSHA), human error is a major contributing factor in roughly 70% of all forklift incidents. The forklift market in the Gulf Cooperation Council (GCC) countries is valued at approximately $1.41 billion. A 2024 industrial survey revealed that the average cost incurred is $260,000 for just one hour of unforeseen forklift downtime in the manufacturing industries.

Direct costs due to a forklift malfunction include repair expenses, such as purchasing spare parts and hiring a technician. These costs accumulate rapidly and end up draining the management budgets. Whilst this is the essential problem, we often fail to notice the hidden impact that downtimes have on supply chain performance. Forklift downtimes have a significant impact on the functioning of warehouses, from idle resources to dropped production efficiency which disrupts the flow of the entire supply chain.

It is important to understand that such disruptions have a ripple effect on the functioning of warehouses. Without forklifts it becomes significantly harder to move materials and inventory at the same pace rendering mobile resources effectively immobile. This results in lower efficiency among workers and within the warehouse as a whole causing production to take place at a much slower pace. This leads to delays in order fulfilments and customer dissatisfaction.

Customer dissatisfaction can lower the morale of the workers and the management. Another significant effect that equipment outages have on the supply chain are the inflated or excessive costs which could have been avoided. With delays in production, the workers and other equipment remain idle, yet the same wages and maintenance costs are paid leading to inflated costs.

This remains one side of the hidden impact of downtimes; another major aspect is the recovery period. Even after the forklifts have been restored to working order, a considerable amount of time is spent in catching up with the delays and recovering from all the logistical disturbances. Along with this, the companies also have to deal with the reputational damage caused due to missed deadlines.

In the GCC’s fast growing logistic hubs such as Dubai’s Jebel Ali’s port and Saudi Arabia’s King Abdullah’s port, even a minor forklift outage can have a multiplier effect in delays across the regional supply chains. Therefore, to avoid such significant consequences we must aim to have stricter maintenance scheduling for forklifts. It is a rule of thumb that 200 forklift hours is equal to 3000 car miles and generally forklifts should be serviced every 500 hours to minimise the risk of frequent or unforeseen downtimes.

Forklift downtimes seem like a technical setback, but their impact runs deeper. It not only affects the logistical functioning of the manufacturing industry but also has a significant impact on delivery deadlines and supply chain performances, triggering a chain reaction of counterproductive outcomes. In a region like GCC, where logistics drive economic activity and growth, it becomes a necessity to ensure that forklift maintenance is regular and such downtimes are minimised. Regular servicing, operational training and proper maintenance technologies are essential investments to ensure operational efficiency and keep the regional supply chain moving.

The pressure on bus fleets to save fuel, reduce emissions and reduce whole life costs is relentless. So, why delay the benefits of the new Allison T 2100 xFE ™ transmission, with Fuel Sense ® 2.0 software, until your vehicles are replaced? Our xFE upgrade programme is now live, offering fleets a mid-lifecycle switch with proven fuel consumption improvements of 7.13%-16%. To learn more, and join fleets such as First Bus, please contact one of our Allison Authorized channel partners Mitchell Powersystems or Powertrain Products.

Würth Professional Solutions (WPS) delivers a wide range of advanced solutions across key sectors, including construction, automotive, and manufacturing. With an annual revenue of over $22 billion, over 80 years of global experience, and a network of more than 400 companies in 80 countries, the company’s growing footprint in the Middle East is a testament to its broader commitment to supporting the region’s ambitious growth. The company launched its extended operations in the UAE on October 1 this year.

We caught up with Angela Pernsteiner a visionary creator, catalyst, and serial entrepreneur recognised for her dynamic leadership and innovative impact across diverse industries. She serves as the driving force and visionary founder of WÜRTH Professional Solutions (WPS) and as an Executive Board Advisor to the WÜRTH Group.

Abigail Mathias: What is your vision for Würth Professional Solutions? Although it’s a complex question, I’m sure you’ve given it considerable thought.

Angela Pernsteiner: Absolutely. To understand our vision, it’s important to first understand our heritage. The Würth Group has an extremely strong legacy of eight decades. Our greatest strength has always been our immense assortment—we offer over five million articles. However, for years, we didn’t fully leverage this comprehensive portfolio in the GCC market.

We came to a pivotal realisation: the big contractors here require a complete one-stop shop. They need everything from facades and interiors to concrete, and we have it all within our group. We just hadn’t presented ourselves that way. Interestingly, the Würth Group’s structure mirrors the large, diversified family businesses common in the GCC. We are not just about our core assortment of fasteners, tools, anchors, and fixing systems. We also own three hotels, a marketing agency, a bank, and insurance and leasing companies.

This intrinsic diversification allows us to present many different faces to our clients,

attracting a very colourful portfolio because they feel understood. A company with a niche product line can’t do that. By bunding 80 years of learnings from serving diverse clients across 80 countries, we created Würth Professional Solutions (WPS) for the Middle East. This is a completely new venture for us.

In other markets, a client might go to Würth Electronics for components, to Liqui Moly for lubricants, and to Woodcraft for fasteners. Here, for the first time, we have launched a single, unified platform. You can think of us as an ‘Industrial Amazon.’ It’s a highly complex operation, requiring specific warehouses, engineers, and clientengagement strategies. We see ourselves as chameleons, adapting to and bringing out the specific strengths each client requires.

To bring this one-stop-shop industrial platform to life, we are making a substantial investment, including building a new Middle East hub in Dubai National Industries Park (NIP). The first milestone will be reached at the beginning of 2026, with a ceremonial event, and the hub will be fully operational by 2027.

WPS is structured into four key verticals to serve the market precisely. Construction, with a sub-focus on infrastructure.

Operations, manufacturing, and multiples, our newest addition, focusing on large-scale vertical farming projects.

The vertical farming initiative leverages our highly efficient LED technology. While other brands provide efficient light, our “light recipes” uniquely mimic the true solar cycle, with intensity that rises and falls like the sun, promoting a more natural growth. Given the less nutritious soil in the region and relatively affordable electricity, the potential here is enormous.

The primary requirement is the efficient LEDs calibrated for different plants—basil, rocket, and tomatoes all need different light spectra. This adaptability is what WPS is all about.

Our brand identity is also evolving. In Europe or the US, Würth is known as a screw and tool company. That’s how we started in 1945 as a trader. But we quickly evolved into a producer, and this is a critical differentiator. Owning our factories gives us unparalleled control over our supply chain. We have few

third-party producers, allowing us to adjust quality for specific formulas, like silicon or chemical anchors, and to run 24/7 shifts to meet sudden, massive client demand.

This is crucial in the GCC, where forecasting is entirely different from Europe.

The market is characterised by a “stop-andgo” dynamic with ad-hoc demand; plans change suddenly, and huge quantities of fasteners are needed overnight. Our in-house production makes us incredibly flexible.

This new chapter coincides with a leadership transition. In January 2025, the new generation—Benjamin and Sebastian Ruud, the grandsons of the founder, Reinald Ruud—took over the helm. Their leadership marks a decision to set a major cornerstone in the GCC with significant investments in infrastructure and talent, recognising the region’s immense potential for growth and diversification.

Our new brand slogan, “Decades of Mastery and Transformational Resilience,” encapsulates who we are today. Our new €80 million R&D centre in Germany, where even competitors come to test products on seismic machines, underscores our commitment to German quality—which is why we refer to it as “Decades of Mastery.” But we also understand that a client in the GCC, facing sand, sun, and unique challenges, needs different solutions than one in Europe—this is our “Transformational Resilience.” Our strategy is built on a global portfolio of experience with a deeply localised implementation.

Unlike in other countries where we might start with a sales office, here we began immediately with large warehouses and facilities because we are committed to becoming truly local. This infrastructure is essential to deliver on our 360-degree product portfolio.

A key part of our strategy is moving beyond just products to systems. For instance, we are the biggest Gatorade supplier for a major American client. We are not a drink producer, but our collective purchasing power gives us better economies of scale than the client itself.

“As a global family business, we stand for stability, reliability, and progressive growth. The Würth Group shares many parallels with the UAE, where a single visionary leader created an outstanding impact from scratch through the exceptional courage to view struggles and challenges as infinite opportunities.”

We then supply these drinks through our vending machines, or SIMATs, guaranteeing 24/7 supplies in the most remote locations—inside tunnels or at far-flung construction sites. This is a service previously unavailable in the Gulf.

In large projects, work rarely stops because a major panel ( part) is missing. The crisis often comes from running out of small, essential parts— screws, gloves, tape, silicone or adhesive. This halts the site, forcing emergency purchases that blow the budget, or leads to costly overstocking, leaving thousands of unused items after project completion.

The GCC market presents a unique supply chain landscape. Project scopes are exceptionally ambitious and fluid, scaling up or pivoting with incredible speed, making long-term forecasting a challenge. The value of a resilient and adaptable supply chain partner, therefore, becomes paramount. A contractor might need to mobilise 10,000 workers in a week and require a vast quantity of PPE—from shoes and helmets to masks—almost immediately. This is the specific need we are equipped to meet.

We provide a foundation of stable quality amidst these fluctuations. We secure operational continuity by ensuring the uninterrupted flow of all necessary materials, especially those critical C-parts that are overlooked until they are desperately needed. This is the philosophy behind our “one-touch supply chain”—a seamless process from our warehouse to the end-user.

We understand the standard procurement process for major expenditures is necessary. But applying a lengthy process involving RFQs, multiple supplier comparisons, and ten signatures to a box of screws incurs massive hidden costs. We specialise in driving the process cost for C-parts to almost zero, delivering real, measurable savings for our clients.

From a client perspective, we serve top players across all verticals. We can be their partner from the initial sketch of a building through its entire lifecycle, precisely because we provide everything from one place.

— ANGELA PERNSTEINER

AM: How large is your team in the UAE currently?

AP: We launched WPS with around 50 people and are growing fast. This is just year one of our offices in the region. Once our new warehouse is operational, the workforce will expand dramatically. Our growth is simultaneous across the GCC. We are already laying the groundwork in Saudi Arabia, with plans to launch a fully owned company there in 2027.

A fundamental aspect of our identity is that we are a fully family-owned company with no outside investors or banks. This gives us the flexibility to invest wisely and provides our clients with security. This philosophy extends to our employees, many of whom have been with us for 20-30 years. This stability, maintained despite our global size, is our founder’s legacy and distinguishes us. There is a strong family presence in day-to-day operations; we are not just signatures on a page.

AM: Looking ahead, what do you hope the company will be recognised as in the GCC in the next five years?

AP: In five years, WPS will be the major go-to partner for any industrial problem, across construction, manufacturing, and operations. We bring not just products, but eight decades of mastery. We are advisors with implementation in our pocket. In markets like Saudi Arabia, which is undergoing rapid transformation, the challenges contractors face are ones we solved decades ago in other countries. They are eager for us as a knowhow sharing partner.

Our family-owned structure allows us to co-invest in R&D for client-specific challenges, like a glue that must endure 50-degree heat for years. If it’s a relevant problem for the market, we can decide on the spot to develop it, sharing the cost rather than passing it to another client. Starting from a two-man show to a $22 billion company, this combination of heritage, innovation, and financial strength is a powerful starting point for the new generation. The GCC is hungry for know-how, growth, and quality, and we are positioned to deliver.

• Smart Hubs with RFID Gates: These gates revolutionise inventory control and security by automating the tracking of materials and assets entering or exiting a site. This provides real-time data on stock levels, prevents material loss, and ensures total transparency and control for largescale projects.

• Smart Vending Machines: Providing 24/7 access to essential tools, fasteners, and materials right at the job site, these intelligent machines use advanced inventory software to automate reordering, track usage, and dramatically boost productivity by eliminating downtime.

• Innovative PV Facade Solutions: Designed for modern architecture, these solutions combine aesthetic excellence with superior performance.

• Smart Watches: A rugged wearable designed for rigorous operational sites; it prioritises worker safety and wellbeing.

• Vertical farming with Würth LED: New and highly innovative plant-optimised lighting solutions with horticulture lights will promote the development of indoor vertical farming in the UAE and will ensure sustainable, highyield food production with minimised environmental impact.

Würth Rapid Response, is a vehicle designed to revolutionise on-site operations by providing fully functional mobile workshops and business units. This solution is a testament to the brand’s long-standing partnership with Mercedes-Benz in Germany, a strategic collaboration that now extends to the UAE in partnership with Gargash Enterprises

RSA Cold Chain, the region’s premier cold chain operator and a joint venture between UAE-headquartered RSA Global and US-headquartered Americold, announces the opening of its cold chain facility inside the Jebel Ali Free Zone, DP World’s flagship free zone in Dubai. This milestone cements RSA Cold Chain’s leading role in transforming food supply chains across the Gulf Cooperation Council (GCC), leveraging RSA Global’s digital supply chain expertise and Americold’s worldleading temperature-controlled logistics capabilities.

Located in JAFZA, the facility offers 40,000 pallet positions, increasing RSA Cold Chain’s network capacity to 62,000 pallet positions. With multi-temperature capabilities, and bonded and non-bonded storage offerings, the facility serves as a critical import-export hub connecting global food producers to the Gulf Cooperation Council (GCC)

and nearby markets. With dedicated road access to the UAE mainland, 27 loading docks, and smart monitoring systems, the site is designed to streamline regional and domestic distribution.

“At RSA Cold Chain, we’re reshaping the food distribution landscape of the Middle East, with the aim of being the single partner to scale across the region with our customers ” said Abhishek Shah, Co-Founder & Group CEO of RSA Global. “This facility is designed for tomorrow’s supply chain, digitally enabled, scalable, and resilient. Our alliance with DP World not only unlocks strategic opportunities for our customers but also reinforces Dubai’s status as the region’s anchor hub for safe, efficient, and sustainable cold chain logistics.”

“Americold is uniquely positioned to build one connected global flow of food,” said Rob Chambers, Chief Executive Officer of Americold. “The RSA Cold Chain facility in

Dubai is another step in that journey, linking producers and consumers more efficiently through strategic infrastructure and trusted partnerships. Together with RSA Global and DP World, we’re addressing real inefficiencies in the region’s food supply chain and creating long-term value for our customers.”

This facility supports traditional cold storage trade and serves quick service restaurants (QSRs), retailers, and Q-commerce platforms, offering flexible handling operations at piece, case, and pallet-level along with, co-packaging, inventory management, and customscompliant consolidation. It meets the highest international food safety standards and has earned ISO 22000 and HACCP certifications, ensuring rigorous hazard control and traceability across all operations.

DP World’s partnership is fundamental, providing unique connectivity and access across the region.

“The addition of RSA Cold Chain’s new facility boosts our ability to handle fastgrowing demand for temperature-sensitive goods, while cutting waste and accelerating time to market. Together with Americold and RSA, we are integrating infrastructure to build an efficient cold chain and advance the UAE’s food-security goals. This is exactly the kind of future-ready infrastructure that Dubai’s D33 vision calls for,” said Abdulla Bin Damithan, CEO and Managing Director, DP World GCC.

“The launch of RSA Cold Chain’s advanced regional distribution hub in Jafza marks a new chapter in Americold’s global expansion,” said Richard Winnall, President, International, Americold. “By integrating infrastructure and expertise across continents, we’re unlocking smarter, faster, and more resilient food flows for our customers.”

RSA Cold Chain serves as the catalyst for GCC food security, trade resilience, and supply chain growth, solidifying Dubai’s reputation as the Middle East’s gateway for safe and efficient food distribution.

Founded in 1995, Al Laith is a trusted partner in delivering demountable infrastructure and site services across the GCC and beyond. For 30 years, the company, which is based in the UAE, has supported construction, events, film, oil & gas and national programmes, helping to shape many of the region’s most iconic moments.

With a portfolio spanning more than 20 service lines – from cabins, logistics and access solutions to mega-structures and full site overlay – Al Laith acts as a onestop partner for complex projects. As part of CG Tech, it combines regional agility with global governance, guided by a culture of safety, responsibility, agility and people first. Known for being reliable, consistent and value-creating, Al Laith specialises in making the complex simple, enabling clients to deliver with confidence.

“For three decades Al Laith has helped the region build, stage and tell its stories. Our 30th anniversary is a celebration of the people, projects and partnerships that have made us a trusted partner for the Gulf’s most ambitious moments,” said Jason English, Group CEO, CG Tech & CEO, Al Laith.

The company’s regional footprint is spread across UAE, KSA, Bahrain, Oman and Qatar, with expansion into Uzbekistan. It delivers demountable infrastructure and site solutions for construction, culture and live events, including stages, roofing, seating, bridges, sound stages, modular buildings. The company is backed by in-house expertise in logistics, planning, fabrication and EPC capabilities to ensure projects are safe, fast and reliable.

It prides itself on the following principles:

• Safety First – We prioritise our safety and that of everyone who interacts with our services and equipment. People Centric – We improve the lives of colleagues, clients, and all who engage with us.

• Agile – We respond swiftly to changing client needs and industry innovations.

• Responsible – We act with ownership, accountability, and integrity.

• 1995 – Founded in Dubai as a scaffolding company

• 2000 – Launched plant and machinery rental services in the UAE

• 2005 – Entered the UAE events sector, supporting major public and private events

• 2007 – Expanded into temporary facilities solutions

• 2010 – Regional expansion into Oman

• 2016 – Acquired by CG Tech, reinforcing commitment to innovation and safety

• 2019 – Expanded into Saudi Arabia’s events market

• 2021 – Advanced oil & gas capabilities in the UAE with specialised tank farm access solutions

• 2022 – Broke ground in KSA’s oil & gas sector with scaffolding services

• 2023 – Acquired Mecton Qatar, expanding cabins and SPIR solutions; introduced specialist low-level access equipment for enhanced safety

• 2024 – Entered Uzbekistan; introduced Flydeck to the Middle East with Pilosio

• 2025 – Expanding into Saudi Arabia’s film & entertainment sector; celebrating 30 years of safe, reliable, people-first delivery

Leading members of the supply chain fraternity gathered at Atlantis, Dubai on October 8 and 9 for CTW’s awaited event. From Sustainability with Purpose, Women in Logistics – Breaking the barriers and Warehouse Automation, to Sustainable Trade, the event hosted a number of panel discussions engaging for audiences that arrived from across the world. The event also saw discussions on design and hosted a large interactive exhibition. We take you behind the scenes straight to where all the action took place.

For over 15 years, Oliver Wyman has been a key strategic advisor embedded in the pioneering economic diversification plans of the UAE. Positioned at the forefront of advising on the most complex transitions in transportation, logistics, and public infrastructure, the firm’s pivotal role was exemplified at the Global Rail Transport and Infrastructure Exhibition and Conference in Abu Dhabi, from September 30 to October 2, 2025, at the Abu Dhabi National Exhibition Centre (ADNEC).

The event brought international stakeholders together to discuss the future of rail, highlighting the themes of infrastructure, global connectivity, and sustainable and intelligent mobility solutions.

This deep regional commitment was illustrated by Alessandro Tricamo, partner, Transportation and Services Practice, Oliver Wyman.

Tricamo moderated a panel discussion on shaping the future of mobility and tackling the data sharing dynamic. Bringing 20 years of valuable experience in consulting and industrial practises to the table, his expertise represents the practical insight that Oliver Wyman delivers to the clients.

Abigail Mathias: What are some of the key takeaways from your panel, “Shaping the future of mobility: tackling the data sharing dynamic.” Alessandro Tricamo: The common theme was that data is obviously critical for innovation in the space of mobility. Everything that is linked to mobility as a service, customisation, bespoken solutions, etc., is linked to data. Data will train AI models and now will push for this level of, bespoken solutions for mobility.

The discussion allowed the opportunity to discuss both with operators, CEOs of different mobility operators, and the Director General of ITC. There were, three major takeaways. The first one is that the use of data needs to be encompassed in a clear regulatory framework, so that privacy and information protection are both critical.

However, at the same time, that should not limit the possibility that the collection and use of data would provide. What is needed is for the operator and regulator to find the right balance and to define what are the clear rules for the use of this data, which link directly with the second takeaway, which is partnership between different entities. The importance of operator and regulator to partner for the benefit of passengers through the use of data, was also highlighted.

The third takeaway was how to make sure that the data is used properly in a way that the regulator takes a bit of the driving role. The Director General of ITC mentioned the creation of data warehouses or data pools. Being under the control of the regulator would facilitate protection at the same time.

AM: In your opinion how will the rail sector contribute to the economy of the GCC region?

AT: There are multiple answers to this question. I think that there are several ways that rail can contribute. Firstly, the rail concept has always been taken a backseat in the GCC.

While plans were made, there were delays when it came to implementation. In the last three to five years, there has been a big push in accelerating the deployment of rail. This is because finally it was clear that connectivity across the different GCC countries would provide a big upside in economic development. The free flow of material across the different countries, the cost saving that rail provides compared to trucking, the fact that there is a push on industrial development that goes hand in hand with the development of a mass transport system like rail, facilitating the potential of trade across the different countries, but even beyond.

The connectivity of the GCC through rail will provide a big benefit in terms of potential trade and free flow of people and material. Looking beyond this, the ability to connect the region with other countries in the broader Middle East and potentially through that with Europe, Asia and the

like, will open a set of new possibilities in terms of trade and economic development and new logistic corridors. There is a lot of discussion around the logistic corridor in Iraq with Turkey and Europe. Think of the potential that connecting the GCC rail through Kuwait or Saudi Arabia to this corridor would create for the entire region.

In a nutshell, the possibilities are limitless. Obviously, there is a big push on spending that unfortunately goes with mega projects, but the upside is such that potentially we will see big development in the coming years.

AM: Could you explain how Oliver Wyman is tracking the growth of the rail industry in the Middle East?

AT: Events like this are proof that there is interest in pushing rail connectivity and rail deployment in the Middle East. Hopefully, we can help keep the momentum alive.

It would be helpful if the sector, the community of the rail industry can work together to identify where potential alternatives to the traditional government funding schemes available. Obviously, the government will always, play the lion’s share in such large projects. However, there are specific selected opportunities where private sector financing can make the difference.

Most of the passenger lines in the Middle East are also operating freight, so they operate on a mixed traffic solution. That is because, as we said, the development is costly, so you try to maximise the capacity and efficiency.

High above the city skyline, 77 floors up at ZETA Seventy-Seven, supply chain leaders from across the Middle East gathered for a different kind of networking experience- one that prioritised people over products and conversation over competition.

The inaugural Supply Chain Professionals Club (SCP Club) Networking Event marked the official launch of a new movement designed to transform how the region’s decision-makers connect, collaborate, and lead. Brought together under the theme “Breaking Silos. Building Futures,” senior executives, directors, and innovators from diverse industries engaged in discussions that went far beyond operational KPIs and quarterly targets.

Unlike traditional industry events, the SCP Club deliberately adopted a non-sales, peerled approach, fostering an atmosphere of openness and trust. Conversations focused on shared challenges, leadership growth, and the evolving role of collaboration in building resilient supply chains.

“In today’s environment, the leaders who thrive are those who connect, listen, and collaborate beyond boardrooms,” shared one founding member during the event.

The Supply Chain Professionals Club MEA was founded with a simple yet powerful mission: to place people at the heart of progress. Operating as an independent, non-commercial community, it is built on five key principles- curation over quantity, leadership-led collaboration, confidentiality and trust, cross-industry connection, and purposeful contribution.

The club’s approach goes beyond oneoff gatherings. Each quarter, the SCP Club will host a curated networking experience complemented by an executive learning or thought-leadership session. These sessions will focus on key themes such as innovation and AI, sustainability, market intelligence, and leadership development.

Through these initiatives, the SCP Club aims to bridge gaps across industries, functions, and geographies- breaking down the silos that have long hindered collaboration within the supply chain ecosystem.