safety

The Importance of

MAINTENANCE DOCUMENTATION By Michael Wrinch, P.Eng., and Matthew Keeler, P.Eng.

O

Ensuring functional safety ‘Functional safety’ is an important process that mitigates hazardous events for active equipment. The International Electrotechnical Commission’s (IEC’s) most senior safety standard in this respect, IEC 61508, describes a holistic approach to engineering as a requirement to determine a new system’s safety rating, with methods for designing, deploying and maintaining automatic protection systems. Another benefit of this standard is it allows for proactive management throughout the equipment’s life cycle, which begins with concept design and risk reduction, then continues with realization, maintenance and, eventually, decommissioning. Without understanding the full scope of a system’s integrity, the risk of failure will increase throughout its life. This can compromise safety and expose the operator to liability issues. Record-keeping is essential to functional safety, throughout all stages of a product’s life. Common wisdom may suggest the only required documents are design files and the manufacturer’s operations manuals, but to ensure functional safety over the lon24

www.canadianconsultingengineer.com

CCE_May 2020_AMS.indd 24

Hedgehog Technologies

perators of complex machinery are always faced with a challenge: equipment has a lifespan and without proper maintenance, a breakdown is inevitable. To ensure efficient operations and an acceptable level of safety, a system of regular documentation of maintenance can mean the difference between a safely managed facility and a catastrophic failure.

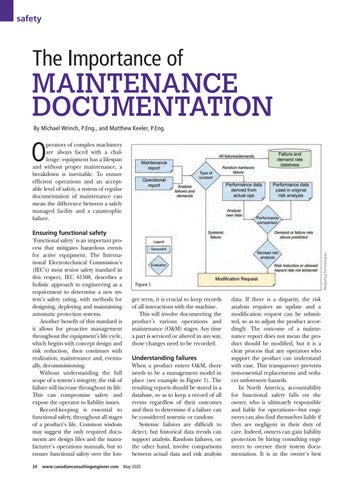

Figure 1.

ger term, it is crucial to keep records of all interactions with the machine. This will involve documenting the product’s various operations and maintenance (O&M) stages. Any time a part is serviced or altered in any way, those changes need to be recorded. Understanding failures When a product enters O&M, there needs to be a management model in place (see example in Figure 1). The resulting reports should be stored in a database, so as to keep a record of all events regardless of their outcomes and then to determine if a failure can be considered systemic or random. Systemic failures are difficult to detect, but historical data trends can support analysis. Random failures, on the other hand, involve comparisons between actual data and risk analysis

data. If there is a disparity, the risk analysis requires an update and a modification request can be submitted, so as to adjust the product accordingly. The outcome of a maintenance report does not mean the product should be modified, but it is a clear process that any operators who support the product can understand with ease. This transparency prevents non-essential replacements and reduces unforeseen hazards. In North America, accountability for functional safety falls on the owner, who is ultimately responsible and liable for operations—but engineers can also find themselves liable if they are negligent in their duty of care. Indeed, owners can gain liability protection by hiring consulting engineers to oversee their system documentation. It is in the owner’s best

May 2020

2020-05-01 11:57 AM