Booth #20

Booth #20

HVAC technology keeps evolving and will continue to improve. By Ian McTeer

It’s time to take a second look at HPWH technology. By Doug Picklyk

12 EXPLANATION

Is the Heat Pump a Joke?

Customer education is still required for the uninformed. By Gerry Wagner

The True North development in Dartmouth, Nova Scotia, benefits from the electrical efficiencies of heat pumps for space and water heating. By Doug Picklyk

EDITOR

DIGITAL EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

MEDIA DESIGNER

CIRCULATION MANAGER

PUBLISHER

CEO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

Jack Burton (416) 510-6809 jburton@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson

HVAC technology keeps evolving and will continue to improve. BY IAN McTEER

In 16th-century France, King Henry IV dreamed of a future where every peasant could enjoy a chicken in their pot. If he were alive today, a modern King Henry might wish for every homeowner to enjoy the comfort and efficiency of a heat pump.

While this vision is undoubtedly worthy, achieving widespread electrification of residential and commercial buildings is a complex challenge, with significant obstacles still to be overcome.

Advancements in science and technology led to the development of practical and reliable mechanical refrigeration machines dating back to the early 20th century. Ironically, the seemingly relentless pace of widespread invention and innovation at that time created a plethora of devices leading some people to

think that everything that could be invented had been invented.

My own fascination with science and technology led me to visit the Ontario Science Centre in the early 1970’s. Incredible things were on exhibit there:

• Bell Telephone displayed a push button phone console with an integrated television screen – imagine being able to see the person on the other end of the line!

• An interactive machine with a push button and speaker…press the button and the speaker said, “coffee” as an affirmation; press the button again, “coffee?” as a question; once again, “coffee!” as an exclamation; another time, “coffee?!?” as a surprise – it took some time but eventually we started talking to machines

and now they answer back.

• The incredible Van de Graaff electrostatic generator meant to help demonstrate the nature of electricity and cause your hair to stand on end.

• An inspiring Model Laboratory designed to mimic a working laboratory.

• My favourite machine, Robbie the Robot (from the sensational 1956 science fiction film Forbidden Planet) might soon be a reality, I thought.

I do not recall any displays at the Science Center devoted to heat pumps, indeed, it was not for another 15 years before I encountered one.

That early heat pump, now that I think about it, was more of a prototype for our climate than a serious residential heating strategy. The poor beast, no one had Continued on p6

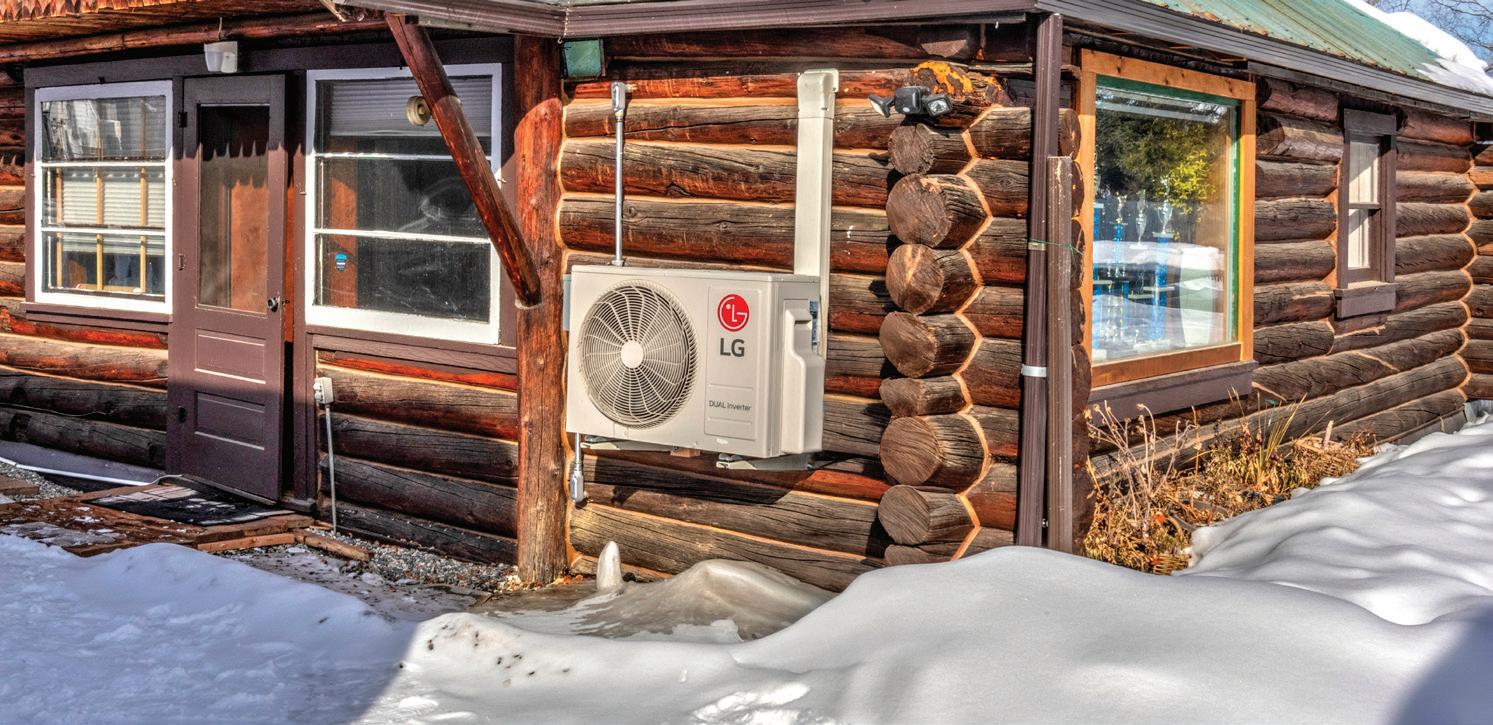

Engineered for Canadian winters – powered by LG innovation.

When temperatures plunge, performance matters most. The new LG Cold Climate Heat Pump is engineered to deliver reliable heating down to -35°C , redefining what’s possible in extreme Canadian winters. Winner of the 2025 AHR Innovation Award – Sustainable Solution, this advanced system brings together:

ENERGY STAR® Cold Climate Certified

— Efficient heating and cooling designed for year-round comfort

— Core technology ensures 100% heating capacity at -25°C, and reliable operation at 70% capacity down to -35°C

Innovative design and features backed by a 10-Year Warranty:

— Soft Air mode, Dual Vane design for quicker cooling, heating and comfort

— Freeze-and-defrost cycle reduces dust and bacteria from the evaporator

— Built-in occupancy sensor for indirect cooling and smart comfort

— Wireless control with

prepared it for our cold climate. It had a ridiculously primitive defrost system that failed because the defrost pressure switch sensor tube became plugged with bugs and grass clippings. Not to mention the complicated set of add-on controls required to shut the unit off at balance point (a poorly understood concept at the time) along with another temperature actuated control meant to start the indoor furnace below balance point. Gaps in the electro-mechanical “programing” often caused no heat calls when an unanticipated dead zone occurred between various sensor settings.

Enough of that, what happened in the past led to decades of research and field experience culminating in today’s cold climate air source heat pumps and ground source heat pumps. So, a heat pump for every house then?

Well, it’s complicated!

One could argue that heat pump technology has outstripped its bounds in several important areas:

Far too often, residential HVAC replacement decisions are made at the worst possible time due to an emergency breakdown. No preplanning, just get the heat back on. In such cases the finesse of proper specification of equipment along with top drawer installation and commissioning of today’s sophisticated products is less likely to occur at every level. And proper operation and maintenance requirements, even though well communicated by many contractors, do not have a lasting impact or are entirely ignored by the equipment owners.

Today’s HVAC industry is facing an overhaul of system designs (SEER 2), expectations to enhance product knowledge (inverter vapour injected compressors), compliance regulations for A2L refrigerants, new installation methods, new tools, and new repair techniques— all of this literally at once!

Even more worrisome, our industry

“HVAC contractors assume their clients will demand the cheapest options over more innovative and sustainable solutions.”

does not have enough engineers, technicians, installers, or trainers to meet the current demand. As I have heard it said, “not enough hands, too many targets.”

In a recent report from Green Communities Canada, subsidies are not working as intended. Two fast facts published in the report are disappointing:

• The retrofits completed from 2020 through to the end of 2024 achieved roughly half the average savings per retrofit needed to support Canada’s 2050 net-zero targets. We need programs that support at minimum 50% reductions in energy use.

• Only 29,000 of the 600,000 retrofits have achieved the status of “deep energy retrofits.” A deep energy retrofit saves 50% or more of the energy

used in the house.

A possible solution could be to install a heat pump in every new house (Figure 1).

Subsidies should be provided for retrofits only when advance planning results in an optimized system design and the installation is carried out under favourable conditions, such as when there are no snowbanks. However, without first addressing workforce shortages, widespread implementation of technological innovations may face challenges due to the lack of professionally trained personnel.

In keeping with generations of scientific and technological advancements in every aspect of human activity, the way we heat buildings, especially residential buildings, has advanced remarkably in just the last decade.

From the conventional air source heat pump that failed to deliver impressive energy savings in cold climates to today’s inverter driven, dense vapour injected compressors combined with electronic expansion valves and sophisticated controls—now we have air source heat pumps that can deliver 100% of the heating load down to -20C and lower. Unthinkable a few years ago.

Today, homeowners and building owners have a growing number of alternatives to consider when upgrading their heating and cooling systems. I do understand why many Canadians decide to replace their existing systems with a 95% AFUE gas furnace and a 14.3 SEER2 conventional air conditioner. Typically, this choice is often driven by cost and the stress of a noheat emergency.

And these decisions are frequently made without a full understanding of the long-term benefits of modern solutions like cold climate heat pumps. As a result, short-term savings often out-

Continued on p8

HEAT PUMPS | VENTILATION | DOMESTIC HOT WATER

THE MITSUBISHI ELECTRIC ADVANTAGE

u Quality And Reliability You Can Trust

u Efficient Products Designed For The Canadian Climate

u Over 35 Years Of Successful Installation

u Strong Canadian Customer Support Team

u Local Supply of Products

A small Canadian R&D team is developing a new

In an industrial park north of Toronto in Richmond Hill, a company is focused on building a better heat pump, and after three years of R&D they believe they’ve done it.

Terravis Energy is a subsidiary of Worksport, a public company listed on the NASDAQ (WKSP) and founded by Steven Rossi. Incorporated in both Canada and the U.S., Worksport sells tonneau covers for pick-up trucks, but the company's Terravis Energy division, led by Lorenzo Rossi (Steven’s father), is a clean tech business that includes the focus on heat pumps.

In early March this year Terravis unveiled its AetherLux heat pump system with Zerofrost technology claiming it can “provide continuous heating without defrost cycles—even in extreme subzero conditions.”

Lorenzo Rossi, who has a masters degree in computer science, began investigating heat pump technology about three years ago looking for ways to improve system performance. With the assistance of a federal funding program he partnered with researchers at the University of Ontario Institute of Technology to develop his theories.

Two years ago, Kurt Bhatnagar, a G1 313A gas mechanic with Smith & Long, came on board to help bring Rossi’s visions to life. He was introduced to Terravis Energy by Tony Panetta of UA Local 787.

Bhatnagar and Rossi have since collaborated and tested various prototypes aimed at raising the heat output of a heat pump system in extreme cold conditions. They tried a direct cascade system (multiple compressors all piped into the same refrigerant system) or an indirect cascade system using heat exchangers and different refrigerants, but recurring defrost cycles were always a limiting factor. So together they zeroed in on how to avoid the need for a defrost cycle at all. “The concept is we wanted to eliminate the defrost cycle, but we also developed a unit that is designed to go down to -55C,” says Rossi.

In a live demonstration with their Zerofrost PRO unit sequestered in a -35C cold chamber, sensors positioned on a mini-split head located just outside the chamber show it blowing 30.8C air. (You can see a similar demo on YouTube, search: Aetherlux Pro in Action.)

Running for over an hour, there was no defrost cycle required. While Rossi can’t divulge yet how they do it, he says a 60-page patent has been filed and it will take another six months or so to become public.

“At the end of the day we are not breaking any laws of physics, everything is just energy transfer,” says Bhatnagar.

“Our design is transferable to any heat pump,” says Rossi, noting that a primary objective now is to optimize the technology and then license it to other manufacturers. He’s already received interest from within the HVAC industry and also from the automotive industry, where heat pumps are used in electric vehicles for comfort and also to keep the batteries climate controlled.

Sadly, the next move for Terravis Energy is to a facility near Buffalo, NY. “At some point you have to stop engineering and start manufacturing, and doing it here in Ontario would be choice number one,” says Rossi, but he notes that a lack of incentives and the high cost of industrial space in the Greater Toronto Area is driving the business south. <> – By Doug Picklyk

weigh long-term value.

This is where contractors will begin to play a crucial role.

Far too many HVAC contractors assume their clients will demand the cheapest options over more innovative and sustainable solutions. But, with the right education and guidance, potential customers can gain solid information about how heat pumps will improve their comfort, reduce their energy costs, and contribute to a healthier planet.

Drew Tozer’s book Feel-Good Homes underscores this idea by emphasizing that “everyone deserves a comfortable, healthy, sustainable home.”

Tozer is part of Toronto-based Foundry Heat Pumps, a contractor serving the Greater Toronto Area. His book is not only a resource for homeowners but also a valuable tool for contractors seeking to become “ambassadors of electrification,” thus equipping them to share the transformative potential of heat pumps with their clients.

HVAC systems are generally tailored to buildings in three ways: new installations, retrofits, and replacements. Moving away from the outdated “bigger is better” philosophy, modern new construction and certain retrofit projects now benefit from advancements like improved insulation, high-performance windows, optimized ventilation, and enhanced air sealing. These innovations allow for the use of smaller, precisely engineered HVAC equipment designed to deliver the ultimate comfort, sustainability, and efficiency—a key pillar of the “feel-good home” concept.

While electrification of our HVAC world is a worthy goal, it is my opinion that many customers will continue to choose a gas furnace and air conditioner simply by way of a comforting inertia focused on the familiar. However, there are many other alternatives during this transitional period. Here are Continued on p10

HIGH-EFFICIENCY CENTRAL HEAT PUMPS WITH CASED COILS

Heat pump combination AHRI Certified for installation with ANY 3rd party furnace.

COLD CLIMATE DC INVERTER HEAT PUMP

Two-stage, two-cylinder compression and hot gas injection for unparalleled heating efficiency.

Eligible for financial incentives in certain provinces, contact us for more detail.

TO FULLY SUPPORT OUR DEALER NETWORK

OFFICIAL DISTRIBUTOR IN CANADA

*GREE Canada is not responsible for warranty on units sold outside GREE Canada’s sales channel.

For more detail, contact our team at proservice@gree.ca

some noteworthy options:

Ducted Cold Climate Air Source Heat Pumps (ccASHP): In my opinion, such systems set the gold standard when applied to properly specified and installed forced warm air applications. In my own heat pump experience living in southeastern Ontario, there was a lot of snow last winter, but the outdoor air temperature only briefly dipped below my balance point of -22C. My backup electric heat strips installed in the matching air handler were nonetheless ready to provide uninterrupted comfort. Every house deserves to benefit from this gold standard.

Mini-Split ccASHP Systems: Offering installation flexibility for buildings without proper ductwork, these systems include single-head, multi-head, low-wall terminals, and low/high static air handlers. Advanced models can even signal backup baseboard heaters when temperatures drop below balance point, optimizing energy efficiency and performance.

Dual-Fuel Systems: Combining inverter-drive outdoor heat pumps with efficient gas furnaces, these hybrid setups can provide enhanced energy efficiency and comfort for older houses not insulated or air sealed to modern standards.

Ground Source Heat Pumps (geothermal): Continual technological improvements are boosting their popularity, offering reliable, sustainable heating and cooling for properties with suitable land and installation conditions.

Innovative Compact Heat Pump Units: Products like window heat pumps and through-the-wall heat pumps are gaining traction in areas not necessarily considered to be cold climates. The New York City Housing Authority, for example, plans to deploy 4,000 windowunit heat pumps over the next two years following a successful pilot program.

Gas Absorption Heat Pump: These units burn fossil fuel yet deliver more efficient heating and operate in cold climates.

A company called Terravis Energy, conducting R&D work just north of Toronto, recently unveiled its AetherLux Pro heat pump. Their proprietary ZeroFrost technology eliminates the need for defrost cycles (see sidebar). The AetherLux Pro variant is expected to deliver full heating capacity down to -45C while maintaining a coefficient of performance (COP) of 3. (terravisenergy.com)

By combining extreme durability, energy efficiency, and AI-driven optimization, our industry will be expecting big things from Terravis Energy going forward.

Recently I learned that Copeland, a global provider compressors and more, has invested in a Netherlands based

start-up called Blue Heart Energy. This company has developed a thermoacoustic heat pump. Instead of traditional refrigerants, this heat pump design uses sound waves in a closed circuit to generate heat and cold. Blue Heart claims their unit is silent, affordable, and adaptable to both new and existing homes.

Copeland intends to assist Blue Heart Energy in bringing their innovative technology to commercial readiness. This partnership aims to accelerate the development of Blue Heart’s products, which suggests that their heat pumps could eventually become available in North America. (blueheartenergy.com)

In December 2024 researchers from

the U. S. Department of Energy Ames National Laboratory shared development of a magnetocaloric heat pump claiming to match current vapour-compression heat pumps for weight, cost, and performance. Magnetocaloric heat pump works by changing the magnetic field applied to a magnetocaloric material, a rare earth metal, while pumping fluid to move heat. (ameslab.gov)

Future heat pump technologies with no refrigerant is an interesting prospect.

Engineers in British Columbia have been exploring a new generation of electric load sharing devices designed to prioritize essential loads in buildings. Older buildings with 100-amp electrical panels, for example, could have an allelectric heat pump system installed using this technology to ensure the heat

pump only operates when there is enough capacity in the panel.

By carefully managing the timing and distribution of power, these systems prevent overloading the electrical panel, eliminating the need for costly upgrades. If household appliances are not using the full 100-amp capacity at a given moment, the device allocates the available power to the heat pump. Brilliant!

Also, I stumbled across this. Panasonic has developed the OASYS System for high performance homes (under 3ach50) utilizing a network of highly efficient bath fans, an ERV, a mini split indoor head, dehumidifier, and a bank of high efficiency air filters. All the components are installed in one no load “conditioning room” within the home. Every other room is ducted to its own bath fan in a home run configuration ideally providing 3.5 air changes per

hour per room 24 hours per day. The room access door serves as the return air filtration panel. (interesting concept: oasys.na.panasonic.com)

Have we reached the pinnacle of innovation when it comes to heat pumps? Hardly. Just as the clunky voice synthesizer at the Science Center in 1971 evolved into AI companions that speak English (and many other languages) better than I do, the journey of innovation is far from over. <>

Ian McTeer is an HVAC consultant with over 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician. He can be reached at imcteer@outlook.com.

Customer education is still required for the uninformed.

BY GERRY WAGNER

Igot my start in the HVAC trade/industry at the HydroTherm Boiler Company. The man I commonly refer to as my father, Elwood Weaver, the executive vice president and ultimately a partowner in HydroTherm, had a joke back in the 1970s. The joke was: “You would never install a heat pump north of Richmond, Virginia.”

Now this was said in a joking way, but it was a joke that had some real basis in truth.

You see, although the original heat pump dates much further back, it wasn’t until the 1970s where the technology was starting to gain some traction in North America.

Before 1980, many heat pumps had a seasonal energy efficiency rating (SEER) of 6 or less and a heating seasonal performance factor (HSPF) below 5. These numbers simply didn’t work for most climates north of Richmond, be -

cause the 1970s-vintage heat pump crapped the bed at approximately 47F/8C outdoor air temperature. They weren’t de-rated at this outdoor temperature, but rather they were OFF!

How the 1970s heat pump attempted to make up for this rather extreme limitation was with an electric heat backup, better known as the electric strip heater. When the outdoor temperature dropped below the lowest operating temperature of the heat pump, the electric strip heater kicked in, and so did your electric utility meter.

Again, the joke in the boiler business was that the “meter would spin right off the wall!”

Ok, let me jump to today and some recent occurrences in my own life that made me realize there still is a misperception among some (mostly civilians) that heat pumps still can’t perform in cold weather climates.

I was at an airport (story of my life) going through the security checkpoint. The security officer noticed I was wearing a shirt from an HVAC distributor, and he

said to me:

“You are into those heat pumps, yeah?”

I replied, “Yes sir!”

To which he replied, “Yeah, they aren’t any good here in Pennsylvania.”

In that moment, my instinct was to go into my full HVAC heat pump advocate mode and begin to tell him why he was so wrong, but then I thought again.

I simply smiled, thanked him, and moved on to place my backpack on the X-ray machine conveyor belt.

And another recent reminder revealed that even civilians who claim to be educated in such matters are often just plain wrong. In the state of Maine, someone running for a seat in the State House of Representatives, and whose resume claims he currently is a member of the National Conference of State Legislatures Committee on Agriculture and Energy, made the following statement:

“Fossil fuel use reducing devices such as heat pumps are insufficient for households.”

Wow! Pennsylvania and Maine, not heat pump territory?

Portland, Maine, being 1,349 miles/2,171 km south from St John’s, Newfoundland & Labrador where heat pump installations are on the rise with the support of Federal incentives and initiatives.

When I’m not travelling across Canada, I reside in central Pennsylvania where I installed an inverter-based heat pump unitary system in our home three winters ago, and our home is warm, comfortable and efficient!

I train HVAC installers and technicians on heat pump products that are as high as 38 SEER with HSPF as high as 15 with heating capability down to -22F/-30C (80% of rated heat capacity at these numbers, but heating capability well below these numbers).

We as a trade/industry still have much work to do to combat this misconception about heat pumps.

Another of my mentors early in my career was Harry Eklof, an icon in the HVAC manufacturer’s rep business. Harry use to say, “Perception is reality to the uniformed.”

I am an HVAC heat pump advocate. My career and income for the last decade has been solely based on the promotion of inverter heat pump technology, but I’m also a realist.

I do have great concerns that we may be a bit short-sighted in our goals to eliminate fossil fuels in both Canada and the U.S.

The electrical grids are not prepared for every home to be “electrified” and “de-carbonized” and every car to be electric, yet some political and industrial leaders seem to think otherwise— or maybe more accurately, haven’t considered the old adage, “Be careful what you wish for.”

Let me be clear, electrification and de-carbonization is the correct path; not only environmentally and economically but also to reduce dependency on unreliable (and often unfriendly) fuel sources globally.

Elwood Weaver never saw the heat pump as a real threat to his boiler business. He thought it was a joke.

But I know if I could have a conversation with him today, that even Elwood would see that the heat pump in Canada and the U.S. is no joke … it is our future! <>

Gerry Wagner is the president of Education, Services & Products Company (ESPCO). He has 45 years in the HVAC/R industry working in manufacturing, distribution, contracting and training. gerry@ESPCOtraining.com.

•No

It’s time to take a second look at HPWH technology. BY DOUG PICKLYK

Heat pumps are making front page news across the country, but it’s the ducted or ductless systems used for seasonal space heating or cooling grabbing all the headlines. The real heat pump warriors that deserve to be recognized are the money saving and environmentally friendly systems that are giving homeowners and building operators hot water every day of the year.

Heat pump water heater systems were first introduced in North America in the 1980s, but not unlike heat pumps for home heating/cooling the technol -

ogy needed to mature. The combination of poor performance and lack of demand for the solution kept adoption very low.

The design of most residential heat pump water heaters (HPWH) positions a small heat pump system on the top of an insulated water tank. To explain how the heat pump works, Steve Goldie, HPAC plumbing contributor who works with Ontario plumbing and hydronics wholesaler Next Supply, compares it to appliances we already have in our homes. “When I do training sessions and we talk about heat pumps I always

ask people, ‘Does anyone have a heat pump in their house?’ And then I often get blank stares.

“Then I ask, ‘How do you keep your beer cold?’ And I explain that your refrigerator is a heat pump, using the refrigeration [or vapour compression] cycle to move (or pump) heat out of the fridge.

“With a heat pump water heater, we’re doing the same thing in reverse. We’re pumping, or moving, heat that we’re extracting from the ambient air of the room and we’re using it to heat the water in the tank.”

Maximize energy savings for every customer with heat pump technology.

Electronic display and built-in Wi-Fi controls to set modes and review diagnostics. Smaller minimum space required (450 ft3) without added ventilation.

Whisper quiet operation at only

Interactive Control: Touchscreen LCD display to select modes, view run information, get troubleshooting alerts, and more.

Quick Installation: Integrated design and pre-charged refrigeration system make for a quick and easy install.

High Performance: First-hour delivery exceeds 150 GPH and heat pump power rating of 3.15 HP.

Durable Design: Glass-coasted tank. Electric elements that feature incoloy sheathing for protection from oxidation and scaling.

Aside from the design difference, heat pump water heaters distinguish themselves from traditional gas and electric tank water heaters through their improved energy efficiency, which can be illustrated through the uniform energy factor (UEF) rating given to water heating appliances. The higher the UEF rating for a device, the higher its energy efficiency will be.

As described by Goldie, on average a conventional gas or electric water heater will have a UEF rating of between 0.65 and 0.95. The UEF range for heat pump water heaters is between 2.3 and 4.

Most heat pump water heaters on the market are also called “hybrid” electric water heaters, because the units can switch between heat pump mode and standard electric resistance water heater mode. “The primary reason is to ensure consistent hot water delivery during periods of high demand, very low ambient temperatures, or if the heat pump components require maintenance or operational issues,” explains David Neufeld, senior product manager with A.O. Smith. All A.O. Smith residential heat pump water heaters are hybrids.

While HPWHs excel at energy efficiency, their water heating performance needs to measure up. A unit’s recovery rate refers to how quickly it can heat a full tank of cold water, measured in gallons per hour (GPH) at a specific temperature rise. “HPWHs typically have a lower recovery rate than standard electric units,” notes Neufeld.

“In heat pump-only mode, recovery is slow — often half or less than a standard electric. In hybrid mode (using both the heat pump and backup resistance elements), recovery can match or slightly exceed standard electric models,” he says. Standard gas tank units deliver a better recovery rate.

As all heat pumps use the vapour compression cycle to “pump” heat from one place to another, like an air conditioner or dehumidifier they also require a condensate drain line. “As they pull heat from the surrounding air, they also extract moisture, which condenses on the coils inside the unit,” says Neufeld. “This non-acidic condensate needs to be drained away to prevent water damage and ensure proper operation.”

He notes that as a replacement unit in some basements, garages, or utility rooms, there may be no floor drain or plumbing nearby to handle condensate, so this may require running a new drain line, installing a condensate pump, or drilling into a floor or wall. “Most installation challenges can be managed and often resolved with pre-planning during installation,” he says.

As for electricity draw, Neufeld explains that a HPWH uses less power overall, but the full 240V/30A service is still needed for backup elements and peak demand.

And because heat pumps require air flow to extract heat out

Bradford White’s Aerotherm heat pump water heater includes connectivity making it a smart connected appliance that can be controlled with a phone.

The GE Air & Water Solutions’ GE Profile GEOSPRING heat pump water heaters were introduced at AHR 2025, available in 40- and 50-gallon units now, and 65and 80-gallon models at the end of the year.

of the air there are space requirements. He notes that HPWHs typically require a minimum of 450 cubic feet of air space, and they need to be in a relatively warm room to operate effectively, but they can be installed in smaller areas if ducted.

If a HPWH is operating in a space that’s too small or enclosed it can lead to reduced efficiency and possible short cycling. In which case the unit may switch to less-efficient electric-only mode.

On the maintenance side, one often neglected item in conventional electric and gas tank water heaters is the anode rod, and yes, most HPWHs do have anode rods and for the same reason: corrosion protection of the tank.

Of course, the introduction of a heat pump adds more complex components including the compressor, evaporator, fan, sensors, and a control board. This in turn requires more diagnostics and digital interfaces with error codes—this is not your grandfather’s water heater.

Other maintenance issues include regular air filter cleaning and checking that condensate line for clogs or leaks.

So, while water heater installations have long been the domain of plumbers, the integration of heat pumps with water heaters is also causing some hesitation in the market.

“When training sessions are offered, the majority of contractors that express an interest are HVAC installers, as opposed to plumbers,” says Graham Gilbert, business development man-

ager, national accounts, with Bradford White. “I believe the words “heat pump” to a plumber makes them assume the product is exclusively HVAC related. Since the actual products are hybrid electric/heat pump water heaters I believe promoting the correct category name “hybrid” would create more interest with plumbers. Some plumbers have also assumed you need a refrigeration ticket to install [you don’t]. Finally, being a conservative trade, plumbers will not promote or pursue a technology they are unfamiliar with.”

Gilbert’s colleague Damon Williamson, district sales manager, Ontario with Bradford White agrees, “The serviceability piece is huge … this might dissuade a plumber from promoting this as an option to homeowners. That’s where manufacturer training kicks in to assist in the education of HPWH technologies, installation and service best practices.

That thought is echoed by Mike Heeps, regional sales manager, western Canada at Bradford White, “Residential retrofits, in my experience so far, don’t have the interest from the trades. These are most often urgent replacements and trades so far aren’t comfortable recommending a HPWH as a replacement. Skilled trades need to be as comfortable and confident putting in a HPWH as other technologies.”

The HPWH has been around for a couple of decades, but today’s models are significantly better in several key areas including more user-friendly compared to earlier generations.

For homeowners, newer models are quieter running at less than 45 dB (like a refrigerator), and the efficiency keeps improving with UEF ratings regularly up to four times better than standard electric-only units.

Concerns about how the HPWH will affect indoor air temperature is also be -

Available in 50, 65 and 80-gallon capacities, the Midea HPWH features automatic shut-off valve and frost protection, a 91-gallon first-hour rating, and a 49.5 dBA inverter fan for quiet operation.

The Rheem ProTerra hybrid electric water heater has universal side and top water connections, zero side clearance and a duct-ready design to simplify installation.

top and side connection options, and

ing mitigated with the ability to duct the intake and exhaust outside so no air inside the home is used if necessary.

And more units are able to connect via Wi-Fi to phone apps allowing users to control settings, track energy usage and receive alerts.

Plus, for installers, the HPWH unit designs allow for more flexible installations, better condensate management, slimmer profiles, simple setup instructions and easier servicing.

Along with improved technology from existing manufacturers, new competitors are also entering the HPWH market. At the AHR Expo 2025 trade show in Orlando there were new introductions from GE, LG and Navien.

The Rinnai electric heat pump water heaters REHP series come in 50, 65 and 80-gallon options. With a first hour rating (FHR) of up 91 gallons (80-gallon unit).

Navien is manufacturing its own HPWH and differentiating it from most of the market by offering a stainless steel tank. “This allows our unit to not require an anode rod,” notes Adam Wills, director for Navien in Canada. The unit is also among the lighter products on the market, he says.

With more products coming online, is there a growing market to match?

Looking to introduce an all-new product to the Canadian market, Wills is optimistic that the opportunities are out there. “I personally feel there are two specific areas that fit best for this product. Consumers that wish to move away from fossil fuel usage—so this would address the water heating in an extremely efficient manner—and new construction projects that wish to achieve Net Zero designation.”

Over the past few years, despite government incentives it appears market growth hasn’t been surging. “The Greener Homes Grant, which ended last year, offering $1,000 for a hybrid [HPWH], raised awareness and interest (much like rebates for EV and hybrid

Continued on p18

The SANCO2 is a split type of heat pump water heater system with the heat pump and hot water storage tank separated and connected by ½-in. water piping. The heat pump uses CO2 (R744) as its refrigerant.

cars), but once removed the level of interest declined,” suggests Gilbert from Bradford White.

Williamson noticed a slightly unique trend in Ontario, “We saw an uptick of interest because of the Greener Homes Grant. Surprisingly, when the rebate was terminated, we saw a higher level of sales. In Ontario we sold more Aerotherm units in 2024 without a rebate than we did in 2023 with a rebate. It made up only 5% of total residential electrics sold in Ontario in 2024, up from 3% the previous year.” He notes that nationally the percentage is only about 1%. “The market is small today, but interest is growing. The re-introduction of incentives and rebates hopefully will grow this product segment.”

One of the more unique heat pump water heater products that has been on the market for a while is the Sanden SANCO2, a split system with the heat pump located separately from the tank. The heat pump also uses CO2 as its refrigerant, producing hotter water than other heat pump units, and it can operate outside in colder ambient conditions. With its capabilities this product crosses the line between residential and light commercial.

The Veritus air source heat pump water heater from Lochinvar is a modular commercial product delivering a COP up to 4.61 and operating in ambient temperatures down to 23F/-5C.

For commercial applications, the Mitsubishi QAHV modular HPWH system uses CO2 as refrigerant and can supply water up to 80C/176F.

“The customer, especially in the residential market, does vary,” says John Miles, managing director at ECO2 Systems, the system supplier in North America. “Some are looking at the environmental side of the product with the lowest GWP refrigerant, CO2, where others prefer the performance level of the SANCO2, as we can offer more hot water performance as the tank will be full of 140/145F hot water and this will mix down to handle the family DHW use.”

On the commercial side, Miles sees customers seeking to decarbonize and move from gas to heat pumps for water heating, and his product’s ability handle the colder ambient temperatures along with a variety of installation options when it comes to matching up the heat pumps and variety of tank sizes makes it appealing.

For buildings and businesses with highvolume hot water demands, the economics of reducing energy demand and cost using heat pumps together with the environmental benefits of replacing gas-fired systems seems like a no brainer.

The commercial solutions available for heat pump water heaters generally

The iE1 Electron series from Intellihot is a tankless heat pump water heater that uses CO2 as its refrigerant and uses a specially designed thermal battery

involves an outdoor heat pump supplying high heat to large volume tanks indoors to store and distribute the hot water as required.

“I have seen a few hybrid applications where heat pumps have been mixed with traditional gas, or electric water heaters,” says Grant Erickson P.Eng., vice president, sales and marketing, with Aqua-Tech, representatives for the Lochinvar Veritus commercial HPWH.

“Ambient temperature is very important. The colder the temperature, the less efficient the heat pump will be,” says Erickson. “The lowest ambient temperature the Veritus can operate at is -5C, so if installed outdoors, a backup system will be required.”

For the commercial market, Erickson sees HPWHs working in both retrofit and new construction applications. “I believe you will see more heat pumps specified on new construction projects than retrofits, with government projects representing many of the retrofits.”

There are a growing number of HPWH’s addressing the commercial market including the Mitsubishi QAHV, the LAARs E-Therm, and the unique Intellihot iE1 (a tankless heat pump water heater). All of these systems also use CO2 as their re -

frigerant, and they’re not alone.

“The Aegis domestic heat pump water heater is a commercial product that is ideal for multi-family housing, dormitories, hospitals, hotels, and commercial kitchens with room for the heat pump(s) and storage tank(s) or anywhere large amounts of potable water are needed up to 170F,” says Jake Bucklin, product manager with Lync, a Watts company.

The Aegis HPWH line uses CO2 refrigerant which, as explained earlier, allows for a higher stored water temperature, this allows the storage tanks to be smaller to meet the same demand because they have a higher energy density per gallon and can be mixed to satisfy DHW use.

Bucklin agrees that commercial HPWHs are finding homes in both new build and retrofit applications. “Building codes and new housing developments are mostly focused on decarbonizing new construction which makes up the majority of Aegis installations,” he says. “Retrofit solutions are often looking for lower operating cost equipment where electricity is cheaper than fossil fuels, or they have building owners/local code requirements that are pushing for decarbonization.”

Bucklin notes that Lync has numerous commissioned installations of the Aegis air source heat pump product in B.C. and Ontario. “The Canadian market has accepted this product without issue. On days below -4F(-20C) ambient temperature the domestic hot water system would have an electric tank or other means of water heating backup equipment that will run in place of the Aegis heat pump.”

The commercial market in Canada does seem to be warming to HPWHs. “I am finding the engineering community is more interested in commercial applications especially with many municipal and provincial jurisdictions passing

The Lync Aegis A, air source heat pump operates at temperatures as low as -4F/-20C and uses the natural refrigerant, CO2 (R744).

“Plumbers will not promote or pursue a technology they are unfamiliar with.”

rules and regulations banning gas and oil-fired appliances for new installations,” says Gilbert from Bradford White.

And Williamson is also seeing greater interest among builders in the high-rise market who are looking to differentiate themselves. “One said to me: “If my competitors and I both have a condo for sale, both at $850,000 each, but mine is a Net Zero building, that might be the difference maker for a buyer to look at mine versus others.”

As the global warming headlines continue to drive the push for decarbonization, the rallying cry for heat pumps as the solution for space and water heating will get louder.

“I am asked quite regularly what Navien’s plans are to support electrification and this NWP500 is our first product to meet this demand,” says Wills. “While our fossil fuel products offer tremendous stepping stones with Energy Star ratings and ultra-low NOx exhausts, the HPWH allows us to have a Navien-manufactured solution for appli -

cations that are looking for all-electric.”

Growth in the residential market will depend on greater awareness among consumers to drive the replacement market, and in jurisdictions where water heater rental contracts dominate it could take a while for those service companies to recommend a product that requires additional installation steps and maintenance demands.

According to John Miles, market growth for HPWHs is being driven by regions where rebate programs are promoting decarbonization, but the efficiency message should be a selling point.

“There are close to 9 or 10 million water heaters sold annually across North America, so this is a significant opportunity for HPWH’s especially if you look at realistically 50% of that market is electric water heaters that to deliver hot water using 4.5kw of electricity versus the 0.5 to 1kw use of electricity from a HPWH, so the annual cost saving are massive despite the initial capital cost investment to have a HPWH.” And those savings are compounded when looking at commercial applications, where demand is growing. “The Veritus is currently being specified and fills this growing need. I do believe the future is bright for heat pump water heaters in Canada,” says Erickson.

And despite recent pullbacks on the environmental front in the U.S., momentum for HPWHs remains on track. “Based on market trends over the last decade the domestic heat pump water heating market has been growing at an accelerated rate,” says Bucklin. “Lync has seen very large increases in sold equipment year over year, and we do not anticipate it to slow down. Heat pump water heaters are incentivised and driven at a local level in cities and states [and provinces] all over North America that value renewable energy, this has been stable despite the economic and political landscape changes.” <>

The True North development in Dartmouth, Nova Scotia, benefits from the electrical efficiencies of heat pumps for space and water heating.

BY DOUG PICKLYK

Nationwide, Canadians are being faced with an affordable housing crunch. For years the combination of rising demand for homes and a limited housing supply has led to rapidly rising prices. Stagnant wages have made keeping up impossible, and as a consequence, individuals and families are struggling to find affordable places to live.

But the challenge of meeting the demand for affordable housing for economically challenged Canadians isn’t a new phenomenon. Groups from coast to coast have formed to help provide shelter for local citizens. One such group is the Affordable Housing Association of

Nova Scotia (AHANS), a not-for-profit that has been actively involved in building affordable housing and upgrading existing housing stock since the mid-1980’s.

Part of the group’s aim is to build resilient housing with a vision towards net-zero-ready infrastructure, and one of their latest projects combines the benefits of passive design with hydronics and heat pump technology to deliver an optimized and efficient housing solution with no gas-burning appliances.

The True North project in Dartmouth consists of a multi-phase multi-unit rental housing development funded by the Federal Rapid Housing Initiative and built on land received from the Halifax Regional Municipality. The goal of the project is to offer a variety of affordable rental rates for three- and four-bedroom townhouse units in a family-oriented mixed income community.

The initial 18-unit apartment complex made up of two buildings in an L-shape, designed by Passive Design Solutions, features a tight building envelope and a solar PV array on both rooftops making it Net Zero ready.

“We are heating 18 units, and producing all of the domestic hot water, using two five-ton heat pumps,” notes Benoit Maneckjee, founder of ThermAtlantic, the Newfoundlandbased developer of air-to-water heat pump components and controls. With a

focus on affordability and simplicity, without sacrificing comfort, the mechanical engineer on the project, William Marshall, president of Equilibrium Engineering in Kentville, Nova Scotia, specified the ThermAtlantic products for the build.

Designed as split system air-to-water heat pump, the ThermAtlantic direct expansion to water module (DX2W) module is located indoors and can pair up with various outdoor air-source heat pumps to supply refrigerant into the building.

Although designed to work with reversible heat pumps for heating and cooling, for this affordable housing project the design called for a heating only mechanical room, and instead of in floor heating they elected to go with low temp radiators in the units.

The outdoor design temperature for the Halifax/Dartmouth area is -18C, and based on modeling for passive design of the building the design temperature for the space heating is 105F [40.5C].

“The ThermAtlantic product is cool because you can hook anything to it,” says Scott Carvery, owner of Scotia Mechanical, who handled the HVAC installation, working alongside Blackburn Bennett Plumbing and Heating on the project.

In the trade for 20 years, Carvery incorporated Scotia Mechanical in 2013. After years as a chiller mechanic, now his company works more on high-end residential and medium to light commercial jobs along with a lot of service work.

Something of a fluid mechanics spe -

cialist, Scotia Mechanical has worked on a lot geothermal and an increasing number of air-to-water systems.

“The biggest difference from what we’re used to doing, is we basically bought a heat exchanger with controller from ThermAtlantic, and we were able to buy any appropriate heat pump. At True North we went with a two-stage Trane XL outdoor unit with a nice roof cover on it. There are two outdoor units, so it’s got some redundancy,” notes Carvery.

The mechanical room is located in the middle of the L-shape project design. From the DW2W modules the heated water flows through a 120-gallon buffer tank then through a back-up 15 kW electric boiler for supplemental heating if required.

“The supply temperature is 105F and we have the capacity to put up the 110F if we really need to,” say Carvery, noting that the backup boiler will not engage unless supply water drops to 95F. “And we’ve only ever seen it there once, and it was actually a heat pump issue. Water was coming off the roof onto the unit and it iced up one of the machines, and then the water did drop to 95F. But outside of that, I don’t believe the backup heating comes on period.”

The buffer tank satisfies the space heating demand for the complex with one Wilo smart circulator in constant pressure mode feeding the space heating supply with a zone valve for each apartment.

The heat pumps are not only supplying the space heating but also providing preheat for the DHW. “What’s really important, is that once you get into the multi-unit residential market, you start to realize that domestic hot water is a huge portion of the energy bill,” notes Maneckjee. “With the systems I’ve been Continued on p22

doing since 2018, we are fully electrifying domestic hot water production.”

It’s a design he calls “airdronics,” a play on hydronics. The True North system uses a two-stage cascade, with the outdoor air source heat pumps used for pre-heating the water through an 80-gallon double coil indirect tank, and then feeding two 80-gallon Rheem hybrid heat pump water heaters which lift the temperature to the desired output.

The design also includes a fan coil located in the mechanical room to heat the air in the colder months to assist the heat pump water heaters.

“Normally one of those heat pump water heaters is recommended for a family of four, and in conventional applications it’s responsible for bringing 45 to 50F cold water up to 125 to 130F. But when you feed it 105F water, it has a lot less work to do,” explains Maneckjee, “So we are able to maximize the capacity of those two heat pump water heaters so they can service the roughly 80 people that live in those units.”

Carvery was also impressed with the water heating design. “We’re not only preheating our domestic water with heat pump, but then we’re actually heating it a with heat pump. We’re really able to leverage the electricity substantially.”

The multi-unit complex also takes advantage of hot water recirculation, which is monitored and optimized.

ThermAtlantic has been installing air-to-water systems for over a decade, and every one of its systems comes with and Internet monitoring service. And with the advancement in technology, now installing contractors and building managers can also access an online dashboard through an app that can send alerts to their phones, and if something goes awry they also have a real-time view and can make adjustments to the system.

For this project, the dashboard keeps track of kWh consumption, output, net efficiency, and breaks it down between the heat pumps, the heat pump water heaters and the auxiliary electric boiler.

According to Maneckjee, one of the benefits of monitoring is an 80% reduction in call backs. “The sad reality is that with the increased complexity of HVAC systems now that heat pumps are becoming prevalent, people must get used to the fact that there are going to be more call backs.

“And the next problem is that your technicians are going to have to be more experienced on this technology than most are today.”

He suggests that any HVAC company that is going to offer monitoring is going to need people who understand the very systems that they’re monitoring — eventually he foresees AI being able to monitor and regulate systems, but for now it requires expertise.

Carvery is impressed with the tracking features: “It was cool being involved in that and hopefully, a sign of things to come with engineers and designers putting a little more emphasis on energy efficiency and monitoring.” He also sees real value in finally getting a monitoring system like this for lower-budget smaller builds.

The mechanical system for True North was commissioned in August of 2023, and the next phase of the development is underway. Carvery was happy to be part of the project. “This area in Dartmouth has seen next to no growth in the last 30 years. To say we need housing is an understatement, and it’s an exciting time to be a part of this,” says Carvery.

“There’s just so much innovation, so much change in trade right now. I really think the sky is the limit when it comes down to what’s possible and who’s out there really putting rubber to the road with making this change.”

“It’s this type of work that will get the next generation interested in the industry as well.” <>