SHIPPER’S CHOICE AWARDS 2025

best carriers

Engineered

for

Strength, Designed for Flexibility –3D Storage Solutions Delivers More Than Just Racks

3D STORAGE S OLUTION

For the past 30 years, 3D Storage has been designing and constructing warehouse storage solutions for a wide variety of industries including,

• Manufacturing

• Third Party Logistics (3PL)

• Retail

• Distribution Centers

• Cold Storage

• Ecommerce

Publisher | Delon Rashid (416) 459-0063 delon@turnkey.media

Editor | Derek Clouthier (416) 605-5346 derek@turnkey.media

Contributing Writers | Jan Daske, Robert Vomiero, Victoria Jones

Creative Director | Samantha Jackson

Video / Audio Engineer | Ashley Mikalauskas, Nicholas Paddison

Sales | Delon Rashid, (416) 459-0063 delon@turnkey.media

Peter Bulmer, (585) 653-6768 peter@turnkey.media

Production and Ad-ops | Tracy Stone tracy@turnkey.media

Inside Logistics magazine is published by Turnkey Media Solutions Inc. All rights reserved. Printed in Canada. The contents of this publication may not be reproduced or transmitted in any form, either in part or full, including photocopying and recording, without the written consent of the copyright owner. Nor may any part of this publication be stored in a retrieval system of any nature without prior consent.

Canada Post Canadian Publications Mail Sales Product Agreement No. 43734062

“Return Postage Guaranteed” Send change of address notices, undeliverable copies and subscription orders to: Circulation Dept., Inside Logistics magazine, 48 Lumsden Crescent, Whitby, ON, L1R 1G5

Inside Logistics magazine (ISSN No.: 0025-5343 (Print); 1929-6460 (Digital) is published six times per year by Turnkey Media Solutions Inc., 48 Lumsden Crescent, Whitby, ON, L1R 1G5

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us.

Two issues dominating the conversation

President & Managing Partner | Delon Rashid Head of Sales & Managing Partner | Peter Bulmer

Corporate Office

48 Lumsden Crescent, Whitby, ON, L1R 1G5

ISSN 0025-5343 Online 1929-6460

IT WAS IN LAST YEAR’S Shipper’s Choice Awards issue that I wrote my first editorial for Inside Logistics, and since then, I’ve learned a lot about the supply chain sector. Whether attending events across North America, chatting with experts in various fields, or recording our podcast, The Logistics Lowdown, which we launched this past December, it’s become clear that over the past year, two issues have impacted the supply chain more than any others.

My first feature for Inside Logistics was about how geopolitical issues — such as disruptions in the Red Sea and the Baltimore bridge collapse — were affecting shipping times and prices. A little over a year later, that already feels like a lifetime ago. Today, the news is dominated by tariffs, which are having an even greater impact on the global supply chain.

Though most Canadian goods fall under the Canada-U.S.-Mexico Agreement, it appears our federal government is either unable to make progress on lowering U.S. tariffs or is being more strategic than what is being portrayed to the public. Canada now has the seventh-highest U.S. tariff rate in the world at 35 per cent, and product-specific tariffs — like those on steel, aluminum and auto parts — are even more impactful to those industries.

The other topic dominating the conversation lately is artificial intelligence. AI is sticking its nose in everywhere. Even while writing this editorial, I keep getting prompted by Microsoft’s Copilot on what I should write or how to better word a phrase. Soon, AI and automation will be commonplace in warehouses and elsewhere — making people’s jobs easier, but hopefully not obsolete.

If you’re a podcast listener like I am, you may have heard how some believe the progression of AI will be much more rapid than many expect, and that we’re only a matter of years away from the technology fundamentally changing how we live. Some believe there will be little need for “workers” in most industries, and that society will have to find new ways to give meaning to people’s lives — even suggesting a universal income may be needed.

It’s hard to wrap your mind around, but dismissing the possibility would be a mistake.

SHIPPER’S CHOICE AWARDS

At a time when product costs are rising due to global tariffs, the ability for shippers to rely on their carriers to deliver goods efficiently, on time and cost-effectively has never been more important.

This year’s Shipper’s Choice Awards revealed some familiar players in the transportation sector, as well as a few newcomers. As trade increasingly shifts to a regional focus — as we’ve seen in Canada with governments dropping some of the provincial barriers to trade within the country — carriers that align with our key benchmarks will continue to thrive.

OFFER REJECTED

Canada Post workers reject final contract offer

8

BRIDGING A GAP

CN builds new bridge at Port of Prince Rupert

Trump imposes steeper tariffs on Canadian goods, citing fentanyl concerns

By Inside Logistics Staff

MOVERS

+ SHAKERS

Appointments and promotions

U.S. PRESIDENT DONALD TRUMP has signed an executive order raising tariffs on certain Canadian imports, citing Ottawa’s alleged failure to stop the flow of fentanyl and other illicit drugs across the border.

As of Aug. 1, tariffs on targeted Canadian goods will rise from 25 per cent to 35 per cent. Products suspected of being transshipped — either rerouted through third countries or falsely labelled — will now face a 40 per cent tariff. The increased duties apply only to items that don’t qualify for duty-free access under the U.S.-Mexico-Canada Agreement (USMCA).

The Trump administration contends that Canada hasn’t done enough to block criminal activity and illegal substances from reaching the United States. The president also accuses Canada of responding with its own trade measures, prompting what the White House describes as a necessary escalation to protect national security.

The executive order instructs U.S. Customs and Border Protection to apply the new tariffs and investigate facilities

suspected of helping companies dodge trade rules. The Department of Homeland Security will monitor Canadian enforcement efforts and advise on any future penalties.

Prime Minister Mark Carney issued a statement expressing disappointment in the move but affirmed Canada’s commitment to the trilateral trade pact.

“The United States has justified its most recent trade action on the basis of the cross-border flow of fentanyl, despite the fact that Canada accounts for only one per cent of U.S. fentanyl imports and has been working intensively to further reduce these volumes,” Carney said.

He added that Canada is making historic investments to strengthen border enforcement, including thousands of new law enforcement and border officers, aerial surveillance, intelligence operations and legislative reforms.

“We will continue working with the United States to stop the scourge of fentanyl and save lives in both our countries,” he said.

Photo courtesy of Ken Lund/Flickr

U.S. suspends duty-free access for most low-value imports

THE WHITE HOUSE has announced a new executive order suspending duty-free treatment for most low-value imports entering the United States, including goods from Canada and Mexico, citing national security risks related to drug trafficking and unfair trade practices.

Starting Aug. 29, shipments valued under US$800 — known as de minimis — will no longer be exempt from import duties if delivered through commercial carriers such as couriers or freight firms. Only packages sent via international mail will continue to qualify for duty-free status, at least temporarily.

The Trump administration says the move is aimed at curbing the use of small parcels by criminal networks to smuggle fentanyl and other illicit drugs. It also targets deceptive shipping tactics that disguise a package’s origin and contents.

The new rules also apply to goods from China and Hong Kong, as part of a broader series of

Carriers handling international mail will be required to collect and remit those duties, which will range from US$80 to US$200 per shipment, depending on the country of origin.

CBP has also been granted the authority to demand financial bonds from importers and carriers to ensure compliance with the new policy.

Become a Logistics Insider

“The uncertainty caused by potential tariffs on Canadian goods and newly imposed tariffs on China has made it very difficult for Canadian companies to plan, operate and stay competitive,”

– Alain Sawaya, national leader of KPMG.

national emergencies declared earlier this year. Trump said that while each action stands alone, they share a common goal: stopping bad actors from exploiting loopholes in the U.S. trade system.

Until U.S. Customs and Border Protection (CBP) develops updated systems for handling mail shipments, packages sent through postal services will remain mostly exempt, though a new fee structure will apply based on the originating country’s tariff rate.

Enjoy the benefits of affiliate membership with Canada’s Logistics Association

CITT is Canada’s Logistics Association and the home of Canada’s logistics community. If you’re involved in the business of logistics in Canada, officially join your national community of practice today!

As a member of CITT:

Be well-connected. Join Canada’s most interactive logistics community for networking events, online idea-sharing, exclusive job opportunities and more.

Be informed. Access industry reports, free webinars, and priority registration to professional development opportunities.

Be recognized. You’ll get a fully verified digital credential identifying you as part of Canada’s most respected logistics organization.

Canada Post workers reject final contract offers, leaving talks at impasse

A MAJORITY OF CANADA POST employees represented by the Canadian Union of Postal Workers (CUPW) have voted to reject the Crown corporation’s final contract offers for both the urban and rural and suburban mail carrier (RSMC) bargaining units.

The Canada Industrial Relations Board (CIRB) oversaw the vote, which leaves the two sides still without a deal.

“We are disappointed in the results, but we want to thank employees for taking part in the process,” Canada Post said in a statement. “This result does not lessen the urgent need to modernize and protect this vital national service. However, it does mean the uncertainty that has been significantly impacting our business – and the many Canadians and Canadian businesses who depend on Canada Post – will continue. We are evaluating our next steps.”

CUPW said the vote shows that the corporation’s proposals fell short.

“These offers don’t cut it,” the union said in its own statement. “Canada Post must now recognize that the only way forward is to negotiate ratifiable collective agreements that meet postal workers’ needs.”

The union said its bargaining team is ready to return to the table and urged the federal government to stay out of the process, opposing any back-to-work legislation or forced votes. A national overtime ban by postal workers remains in effect.

solutions behind the style.

Backed by one of the most experienced and collaborative teams in the business, our logistics automation solutions for retail and e-commerce are flexible and modular, increasing speed, accuracy, and e iciency in ways that will have you and your company looking good.

swisslog.com/cyclonecarrier

Photo courtesy of Canada Post

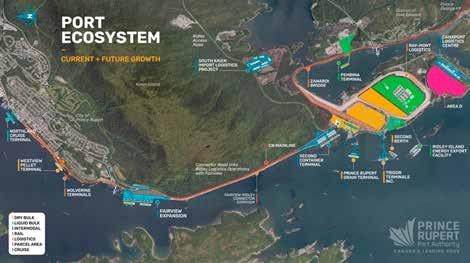

CN builds new bridge to boost rail capacity at Port of Prince Rupert

CANADIAN NATIONAL RAILWAY is moving ahead with a major infrastructure project aimed at boosting rail capacity and improving supply chain resiliency at the Port of Prince Rupert.

The railway is constructing the Zanardi Rapids Bridge, a 1,600-foot structure that will replace an existing bridge near the port’s entrance, currently a chokepoint that limits throughput. The new bridge will be connected to CN’s Class 1 continental network through expanded rail lines on both sides, preparing the corridor for increased train volumes beyond the current limit of 24 trains per day.

Located 500 nautical miles closer to Asia than ports in southern B.C., the Port of Prince Rupert offers faster shipping times and is home to North America’s deepest natural harbour. CN says its investment supports ongoing terminal expansions, including the CANXPORT

CN says the Zanardi

class trade gateway and key link in

Metro Supply Chain to open automated distribution centre in Brampton

METRO SUPPLY CHAIN plans to launch a new 230,000-square-foot distribution centre in Brampton, Ont., in spring 2026 as part of its effort to boost flexibility, automation and customer service in retail and e-commerce markets.

The facility will feature an AutoStore goods-to-person automation system, integrated by Bastian Solutions, and will include automated conveyors, high-capacity packing stations and high-density very narrow aisle racking. Installation of automation and racking is scheduled to begin in fall 2025.

“We are dedicated to using smart digital solutions to advance business results for our customers,” said Chris Fenton, group president and CEO of Metro Supply Chain. “Automation enhances our service flexibility and accuracy, keeping us at the forefront of supply chain innovation. This facility reinforces our commitment to exceptional value and sustainable growth.”

The Brampton centre will be Metro Sup-

ply Chain’s second location to use a goods-to-person system, following the launch of its Bolton, Ont., site in 2022. The company says the system increases picking efficiency fivefold compared to traditional methods and reduces training time by 80 per cent.

Metro Supply Chain adds that the advanced technology will also improve order accuracy, speed, inventory visibility and scalability, while promoting sustainability by optimizing space and lowering energy consumption.

bulk facility, Ridley Island Energy Export Facility (REEF), the Trigon terminal expansion and a new import container transload facility.

Rapids Bridge will help maintain the port’s competitive edge as a world-

North America’s supply chain.

Photo courtesy of Prince Rupert Port Authority

Photo courtesy of Metro Supply Chain Inc.

Radius Logistics opens new Mississauga distribution facility

RADIUS LOGISTICS HAS OPENED a new 75,000-square-foot warehousing and distribution centre in Mississauga, more than doubling its national footprint and strengthening its coast-tocoast logistics network.

The facility, strategically located near Toronto Pearson International Airport and major transportation routes, complements Radius’ existing site in Surrey, B.C., and is designed to support Canadian and cross-border customers with expanded warehousing, fulfillment and distribution services.

“We see this facility as a turning point—not only for our company but for the businesses that trust us to deliver,” said Kristy Doyle, president of Radius Logistics. “Amid economic uncertainty, Radius is investing in real capacity and long-term infrastructure. We’re building a national platform designed to help Canadian and cross-border businesses move forward with certainty.”

The new centre will feature racked and bulk storage, advanced order management systems, and direct integration with Radius’ transportation network. It is expected to be fully operational by July.

“This expansion represents more than just square footage,” said Paul Chess, vice-president of supply chain solutions at Radius. “It’s a strategic move to lead the market. We’re growing alongside our clients and building infrastructure that reflects the future of supply chain management in Canada.”

Secure your supply chain with Hybrid Security

Hybrid Security combines ECAM’s AI-powered technology with GardaWorld’s expert manned guarding services for fast, efficient protection. With 24/7 monitoring, real-time alerts, and seamless integration, we offer proactive threat detection, rapid response, and cost-effective security that’s tailored to your needs.

garda.com/hybrid-security

Photo courtesy of Radius Logistics

Beyond racking. Beyond limits.

Alberta invests $114M in rural infrastructure

ALBERTA’S GOVERNMENT IS committing more than $114 million to rural infrastructure upgrades, focusing on improving transportation routes vital to moving goods.

A total of 51 projects across the province will receive funding through the Strategic Transportation Infrastructure Program (STIP), which provides support for repairs and upgrades to roads, bridges and airports in small and rural municipalities.

Key investments include a $3.5-million grant for an industrial rail extension in Coaldale, aimed at helping local producers ship southern Alberta-grown and manufactured agrifood products to global markets.

In Newell County, a $2.6-million grant will support reconstruction of Range Road 150, a future truck route linking Highway 1 and Highway 542 that serves both residential and commercial traffic. Other significant investments include $3.6 million to replace a bridge west of Innisfail and $2.5 million for airfield pavement upgrades at Lac La Biche County airport.

“Rural Alberta is the backbone of our province, driving economic growth, feeding the world and strengthening our communities,” said Premier Danielle Smith. “These are the essentials that support families, attract investment and keep

our rural economy moving.”

Transportation Minister Devin Dreeshen added, “We are making targeted investments to ensure rural communities across the province have effective transportation and water infrastructure to support their continued growth and prosperity.”

Photo courtesy of CN Rail

CFIB forecasts Canada’s economy to shrink for second and third quarters in 2025

THE CANADIAN ECONOMY is projected to contract for a second and third consecutive quarter in 2025, according to new data from the Canadian Federation of Independent Business (CFIB).

The CFIB’s latest Main Street Quarterly report, produced in partnership with AppEco, estimates a 0.8 per cent decline in the economy during the second quarter, with a further 0.8 per cent drop forecast for the third quarter. Inflation eased to 1.8 per cent in Q2 and is expected to tick up slightly to 1.9 per cent in Q3.

Private investment, which fell in the first quarter, is forecast to decrease by 13 per cent in Q2 and another 6.9 per cent in Q3.

“While we forecast a contraction in the economy, at the same time certain indicators point out that it is normalizing in some ways,” said Simon Gaudreault, CFIB’s chief economist and vice-president of research. “Inflation remains stable, which puts us in a favourable position to contemplate easier monetary policy for the second half of the year. However, with Canada seeing 1.9 per cent inflation and unexpectedly adding jobs in June, the Bank of Canada may now decide to maintain its interest rate on July 30.”

The private sector job vacancy rate held steady at 2.8 per cent in Q2, representing 397,500 unfilled positions.

“The ‘one step forward, one step back’ trade situation is driving low business confidence, translating into paused or cancelled investments,”

– Simon Gaudreault,

CFIB’s chief economist and vice-president of research.

disruptions, particularly for wholesale and manufacturing sectors. Many businesses expect lasting impacts from ongoing Canada-U.S. border delays and global trade tensions.

A special analysis on tariffs highlights worsening supply chain

“The ‘one step forward, one step back’ trade situation is driving low business confidence, translating into paused or cancelled investments,” Gaudreault said. “As trade tensions drag on, more businesses will be slowly adjusting to tariff threats and finding alternatives.”

Manitoulin Group acquires Quebec-based Martin Roy Transport

THE MANITOULIN GROUP of Companies has acquired Martin Roy Transport (MRT), a Quebec-based transportation company.

Founded in 1998 by Martin Roy and his mother, Claire, MRT operates out of Rouyn-Noranda, Que., with terminal facilities in Val-d’Or, Dorval, Timmins, Mississauga, North Bay, Sault Ste. Marie and Thunder Bay. The company serves both the less-than-truckload (LTL) and full truckload (FTL) markets.

UNLOCK THE POWER OF INTRALOGISTICS

“We are delighted to welcome Martin Roy and the entire MRT team to the Manitoulin Group,” said Jeff King, president of Manitoulin Transport. “With a comparable terminal network footprint in many locations, there are significant opportunities to enhance our service in this important market. We look forward to collaborating with the MRT team in the coming months.”

“Joining the Manitoulin Group of Companies marks an exciting new chapter for our company,” said Martin Roy, president of MRT. “Our companies share the same values on hard work and integrity, and we are confident this partnership will benefit our customers.”

Manitoulin says the acquisition will strengthen its presence and service capabilities in Northwestern Quebec and Ontario, improving efficiencies and expanding customer offerings.

“Joining the Manitoulin Group of Companies marks an exciting new chapter for our company,”

– Martin Roy, president of MRT

Photo courtesy of Manitoulin Group

movers + shakers

CN

CN announced that Janet Drysdale will assume the role of chief commercial officer on an interim basis. Drysdale is stepping into the role following the departure of Remi G. Lalonde.

Drysdale spent the first decade of her nearly 30-year career at CN in a variety of roles in sales and marketing. She is a seasoned and versatile leader with significant cross-functional experience having held executive positions at CN in investor relations, finance, corporate/business development, sustainability and most recently as chief stakeholder relations officer.

WestJet

WestJet announced that Amanda Ierfino will take on the role of vice-president, sales and cargo, a leadership update in support of its long-term strategy to grow the business, create new opportunities and continue to deliver quality service. Ierfino has been a key driver in the development

and execution of WestJet’s corporate and agency sales strategy, leveraging the airline’s presence in Calgary and building valuable partnerships across the industry. In her expanded role, she continues to lead the sales team while also taking on leadership of WestJet’s cargo operations.

Swisslog

in warehouse automation, logistics and software, coming back to Swisslog after serving as vice-president of consumer goods at Swisslog in 2021.

LOGISTEC

25_007014_Inside_Logistics_AUG_CN Mod: July 1, 2025 10:48 AM Print: 07/09/25 page 1 v2.5

Swisslog, a provider of warehouse automation software, announced Mike Barker as the company’s new president and CEO of Swisslog Logistics, Inc. Barker will drive the company’s growth in the Americas and key industries, bring renewed focus to evolving and enhancing Swisslog’s SynQ Software, enhance the company’s integrated solutions and develop strategies for further AI integration into Swisslog’s portfolio of best-in-class robotics and software solutions. Barker brings more than 34 years of experience

LOGISTEC, a marine and logistics services provider, announced the appointment of Texas E. Howard IV (Tex) as chief financial officer, to help accelerate international growth and further strengthen its position in the global logistics and supply chain industry. With 20 years in the industry, spanning manufacturing, rail equipment leasing and repair and transportation, Howard brings insight into leading high-performing teams across multi-national operations. He has successfully lead integrations and growth strategies in North American markets, which will be instrumental in delivering results to create value for all stakeholders.

AIR CARGO INDUSTRY TRANSFORMS

Canadian air cargo sector evolves with global shifts, tariff

uncertainty, tech upgrades and sustainability goals

Canada’s air cargo sector is undergoing a dynamic transformation as geopolitical trade shifts, digitization and sustainability targets reshape how freight moves through the skies.

Valerie Khalemska, manager of national accounts at Air Canada Cargo, said one word defines the current air freight climate.

“Uncertainty is the right word for the current state of the industry,” she said, adding that global trade lane volatility is disrupting traditional routes but also creating openings for Canadian gateways to emerge as alternatives.

“Shippers are starting to avoid the more traditional gateways in the U.S., and that creates opportunity for Canada and South America.”

The ever-changing situation when it comes to U.S. tariffs continues to pose challenges to shippers and transportation providers. Most recently, U.S. President Donald Trump announced that his administration would impose 35 per cent tariffs on all non-Canada-U.S.-Mexico Agreement-compliant goods, as the two countries had not yet come to a new trade agreement.

The rerouting trend that is being seen as a result is leading to a pivot, particularly in Toronto and Vancouver, where both Air Canada and freight forwarders like EFL Global are seeing a spike in demand.

“This is the better chance in the Canadian market,” said Partheepan Vasanthan, national airfreight manager for pricing and compliance at EFL Global. “Previously, 80 per cent went to the U.S., but now we’re seeing a lot of charter flight inquiries to Vancouver or Toronto.”

Air Canada Cargo is responding to these global challenges with strategic investments in both its infrastructure and fleet.

“We placed a firm order for 18 Boeing 787-10s as part of our ongoing fleet renewal strategy,” Khalemska said. “We’ve been investing into our hubs globally with a special focus on our cold chain facilities in Toronto and London (England).”

She said Toronto remains the airline’s largest cargo hub, and pointed to substantial developments at Lester B. Pearson International Airport as a key reason why.

EFL Global is also adjusting its infrastructure to meet the rapid rise of e-commerce air freight, and aims to speed up turnaround

and automation.

“Most companies are transitioning from traditional warehouses to air freight e-commerce models,” he said. “That’s our focus for the next five years.”

Tech and digitization

As air cargo operations evolve and visibility becomes more essential, real-time data, AI and automation are becoming necessary tools.

“There’s growing pressure that visibility, real-time tracking and digital integration are almost a given,” Khalemska said. “We’re leveraging real-time data and AI to track performance against customers’ KPIs and deliver more responsive solutions.”

For Vasanthan, the push toward automation and transparency is being driven more by customer expectations.

“Customers don’t want to wait,” he said. “Now they expect rapid updates and automation.”

Robert Khachatryan, CEO and founder of Freight Right, also noted that several air cargo carriers are increasingly relying on software such as CHAMP Cargospot and SkyChain for end-to-end cargo management and routing optimization.

“Canadian operators typically use global tracking and visibility platforms integrated with IATA’s (International Air Transport Association) ONE Record initiative, which aims for a single, standardized data exchange,” said Khachatryan. “Technologies like Descartes CORE and Unisys’ Logistics Management System enable real-time shipment tracking, status updates and customs documentation flow, which is critical given Canada’s large geography and multimodal connections.”

Jamilyn Trainor, senior project manager and owner at Müller Expo Services International, manages time-critical logistics for international installations that are often led by air cargo movements into and across Canada. He said Air Canada Cargo is an adopter of the SkyChain technology, which allows for dynamic route planning when changes to aircraft availability, weather and load adjustments necessitate planning changes.

“(Software) is also important to consider for next-level efficiency,”

said Trainor. “Avoiding expectations on fuel burn and finding the highest flight yield throughout Canada’s landscape, even as routing and environmental variables specifically increase. This is also evident as seen through the stark realities across Canada in winter for routing and capacity.”

For security and customs compliance, Khachatryan said systems like eAWB (electronic air waybill) and digital cargo screening logs reduce paperwork and help carriers meet Transport Canada’s air cargo security regulations.

“Many carriers also employ integrated screening tracking software to comply with Canada’s Air Cargo Security Program,” he said.

Despite digital advances on the carrier side, customs clearance remains a key issue with air freight.

“Our Achilles’ heel is customs — everything is still paper-based,” Khalemska said. “We need to bridge the gap between paper-based processes and the seamless digital experience customers now expect.”

Greener skies

Both Air Canada and EFL Global are making sustainability central to their operations, aligning with broader industry goals of reducing aviation’s carbon footprint.

“Air Canada’s long-term aspiration is net-zero greenhouse gas emissions by 2050,” said Khalemska. “We offer a Leave Less Travel program, allowing forwarders to purchase SAF or carbon offsets associated with their shipments.”

The carrier has already begun electrifying its ground support equipment, starting with Quebec City airport.

“We’ve started transitioning our ground equipment to electric since 2019,” said Khalemska, “with full electrification of Quebec City airport’s support equipment coming by end of 2025.”

At EFL, the focus is on carbon reduction through operational efficiency.

“We always try to consolidate shipments to reduce the carbon footprint overall,” Vasanthan said. “We now have an in-house sustainability and green environment role to guide our efforts.”

Khachatryan said airlines are using emissions monitoring tools like SkyBreathe or SITA OptiClimb to reduce fuel consumption during the climbing phase and at cruise altitude.

“For cargo loads specifically, digital weight and balance software helps avoid unnecessary fuel usage due to poor load distribution,” he said. “These sustainability modules are often part of broader airline operations suites that major players like Air Canada Cargo leverage.”

Khachatryan added that platforms like Cargo.one and WebCargo are becoming more common with Canadian air cargo carriers.

“They allow shippers and forwarders to instantly compare rates and book capacity in real time,” he said. “This digital connectivity helps optimize capacity utilization and cuts down on empty space, which ties back to both profitability and emissions reduction.”

Sustainability also applies to people, as both Air Canada and EFL Global are facing a shared challenge of attracting and retaining skilled talent.

“Cargo isn’t something many young people dream of pursuing, but that’s changing,” said Khalemska. “We’re partnering with schools to attract young talent and create career pathways that help us retain them.”

Air Canada has also made DEI a strategic priority through mentorships, inclusive hiring and scholarships supporting women in aviation.

For Vasanthan, workforce development is a matter of long-term planning.

“Finding the right people is really hard, especially mid- to senior-level with deep industry knowledge,” he said. “Canada is an immigrant country. We need to give newcomers a chance, as the fundamentals of freight forwarding are the same globally.”

Looking ahead

Going forward, Khalemska said she is excited about Air Canada Cargo’s digital investments, as they have made communication seamless across the entire supply chain. However, a digital gap remains when it comes to customs.

For Vasanthan, the pace of change is what motivates him, and though challenges exist, the industry is embracing change.

“In this industry, it’s not traditional anymore, it’s a constant learning curve and that’s what motivates me,” he said. “We’re always asking, ‘What’s next, how can we do it better,’ not just for business, but for employees too.”

ECONOMIC OUTLOOK

Tariff-driven slowdown won’t tip Canada into recession, RBC says

Although the Royal Bank of Canada is not predicting a recession in Canada, unlike several other financial institutions, the impact of U.S. tariffs is expected to bring on a material economic slowdown.

“We are not forecasting a recession… and I’m here to tell you they [others] will be wrong,” said Rachel Battaglia, economist with RBC, during the CITT’s annual Canada’s Logistics Conference in Toronto in June. “Whether you have one slightly negative quarter or two… you probably won’t notice the difference.”

Battaglia also pointed out that despite the recent increase in tariffs, Canada is still the least-tariffed nation in the world, with countries like China, South Korea, Japan, the U.K. and even Mexico seeing higher tariff rates.

She said Canada’s growth forecast for 2024 and 2025 remains stable at 1.5 per cent, while the U.S. is expected to drop from 2.8 per cent in 2024 to 1.3 per cent in 2025. For 2026, RBC predicts Canada will see one per cent economic growth, while the U.S. will reach 1.2 per cent.

The impact of U.S. tariffs will also vary by province. Provincial exposure to U.S. demand is highest in Alberta, where nearly 35 per cent of the province’s GDP (merchandise) is exported to the U.S. Canada as a whole exports approximately 18 per cent of merchandise to the U.S.

Ontario and Quebec are expected to be most affected by targeted U.S. tariffs on specific industries.

“Canada does still face now 50 per cent tariffs on Canadian steel and aluminum as of yesterday… and a lesser 10 per cent tariff rate on energy,” said Battaglia. “Fifty-seven per cent or so of goods were eligible for CUSMA, but not yet using it… that number has shrunk. Primary metal manufacturing, autos, aerospace — extremely high reliance on U.S. demand.”

She added that U.S. tariffs, along with Canada’s retaliatory tariffs, could reignite inflation, which has eased since peaking in 2022–23, and may impact interest rates.

“Tariffs are threatening to reignite inflation in the very near term in both Canada and the U.S.,” she said. “If we weren’t in the middle of this trade war escalation, we could have seen the Bank of Canada end its rate-cutting cycle here.”

Consumer confidence is also at record lows in Canada, while spending remains stable, with a focus on “maintenance spending” — smaller, essential purchases.

“In March, [consumer confidence] fell to the lowest level we’ve ever seen on record — worse than COVID-19,” said Battaglia. “Consumers are keeping their heads and spending pretty much as normal.”

Labour market outlook

Immigration will also decline after record highs in 2023 and 2024. As Battaglia noted, Canada now plans for a net outflow of non-permanent residents this year and next, which could risk labour shortages in certain sectors.

“Newcomers also contribute to demand for labour just as they may offer a unit of supply,” she said, adding that the recent increase in the jobless rate is due to Canada’s population growth outpacing job creation.

Though not as severe as during the pandemic, Canada is seeing job losses, particularly in manufacturing and in Ontario.

“Ontario’s unemployment rate is now the second highest in Canada,” said Battaglia.

“We are not forecasting a recession… and I’m here to tell you they [others] will be wrong.”

– Rachel Battaglia, economist with RBC

IMPROVING YOUR END-TO-END SUPPLY CHAIN

Longer

Supply chains are becoming increasingly complex. With growing tariff threats, rising customer demand for faster service, work stoppages and supplier issues, shippers and service providers must stay ahead of the curve.

Jim McKay, CEO, North America, with GLS Canada, said global supply chains continue to lengthen due to outsourcing, even as customer expectations become more demanding.

“Supply chains are getting longer and longer, but customer demands are continuing to get shorter and shorter,” McKay said during a presentation at CITT’s Canada’s Logistics Conference in Toronto.

The continued push for rapid, low-cost delivery has placed constant pressure on logistics providers. Operating within a supply chain affected by volatility — including tariffs, labour shortages, rising costs and supplier disruptions — McKay said providers must focus on planning and adopting an end-to-end supply chain strategy, which can yield long-term savings.

“You shouldn’t have to go to work in the morning and think, ‘Who the hell is going to come pick up my packages today?’” he said. “The key to a successful supply chain is balance: cost, service, quality. You can have any two … at the expense of the third.”

To improve efficiency, McKay said minimizing the number of times a product is handled within the supply chain helps reduce costs. McKay recommends four best practices to help shippers and service providers improve their supply chain strategies.

The first step is to identify which issues you are trying to address: cost, service, quality.

“You can’t solve your problem if you can’t define it,” he said.

Next, McKay said to choose the right network for your products, and then to choose the partners you want to be part of that network.

“Are you working with an established carrier or with someone working out of their basement using a minivan in a parking lot?” he said.

Finally, once the problems have been identified and a network with quality partners has been established, McKay said building trust with those partners is key to maintaining a lasting business relationship.

“The RFP is just the start, a transactional relationship is fine, but it’s not enough,” he said. “You need your supplier in the same way they need you.”

SUPERL A TIV E CARRIERS

The 2025 Shipper’s Choice Awards are presented to the carriers that surpass the industry’s benchmarks of excellence according to our annual survey of transportation buyers.

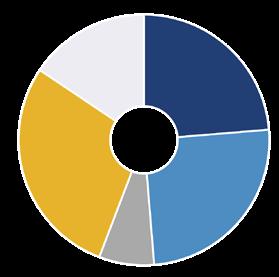

EXPLAINING the scores

The annual Shipper’s Choice Awards measure how well carriers perform against our Benchmarks of Excellence. In our annual survey, the scores are estab lished by shippers, 3PL service providers and freight forwarders from across Canada.

These transportation buyers rate each of their top three carriers on a five-point scale against six key per formance indicators, and use another five-point scale to rate the importance of the key performance indica tors themselves. The weighted rankings are determined by multiplying the two numbers together.

These weighted rankings are then compared to the Benchmarks of Excellence, which represent averages of the weighted scores for each category’s key performance indicators.

Twenty-six carriers met or exceeded the benchmarks established for the 2025 awards. Four companies earned the coveted Carrier of Choice designations because they have scored above the benchmarks for at least five years in a row (see page 31).

IMPORTANCE OF PERFORMANCE CRITERIA

EXPLAINING THE SCORES

WHO ANSWERED THE SURVEY

The methodology

This year 224 respondents – buyers of transportation services and those who manage shipments handled by freight forwarders or 3PL providers – completed our survey.

To qualify, carriers need to receive a minimum number of evaluations. To prevent tampering, we watch for multiple submissions by known respondents; look for similar IP addresses; and if carriers have invited customers to submit scores, we compare those email addresses to our own database.

The Shipper’s Choice Awards survey is undertaken through a continuing partnership with CITT and the Freight Management Association of Canada (FMA), and is conducted by an independent research firm.

TL WINNERS

The TL mode has historically been the toughest for carriers to score above the Benchmark of Excellence. The TL mode had the highest benchmarks in four of the six KPIs tracked by this year’s Shipper’s Choice survey: on-time performance, competitive pricing, customer service and leadership in problem solving. Six TL carriers surpassed the Benchmark of Excellence this year.

LTL WINNERS

Managing so many different shipments, sharing space on one trailer and touchpoints between terminals makes the LTL business complicated. The demands from buyers of LTL services are high and carriers have to navigate a tightrope between providing excellent customer service while keeping prices competitive.

This year’s survey found LTL carriers had the second highest benchmark for on-time performance, competitive pricing, customer service and leadership in problem solving. Seven LTL carriers surpassed the Benchmark of Excellence.

O CEAN WINNERS

Buyers of ocean freight services have traditionally been very price sensitive and this year’s Shipper’s Choice survey found little difference. Competitive pricing had the second highest benchmark among the ocean carrier KPIs, with on-time performance edging it out for top spot. Five ocean carriers surpassed the Benchmark of Excellence this year.

AIR FREIGHT WINNERS

Outside of trucking, air carriers have the highest overall Benchmark of Excellence this year. Buyers of air freight services have high expectations when it comes to on-time performance, quality of equipment and operations and customer service, setting high individual benchmarks in the air category this year. Three air freight carriers surpassed the Benchmark of Excellence this year.

Not Your Carrier

Not Your Carrier

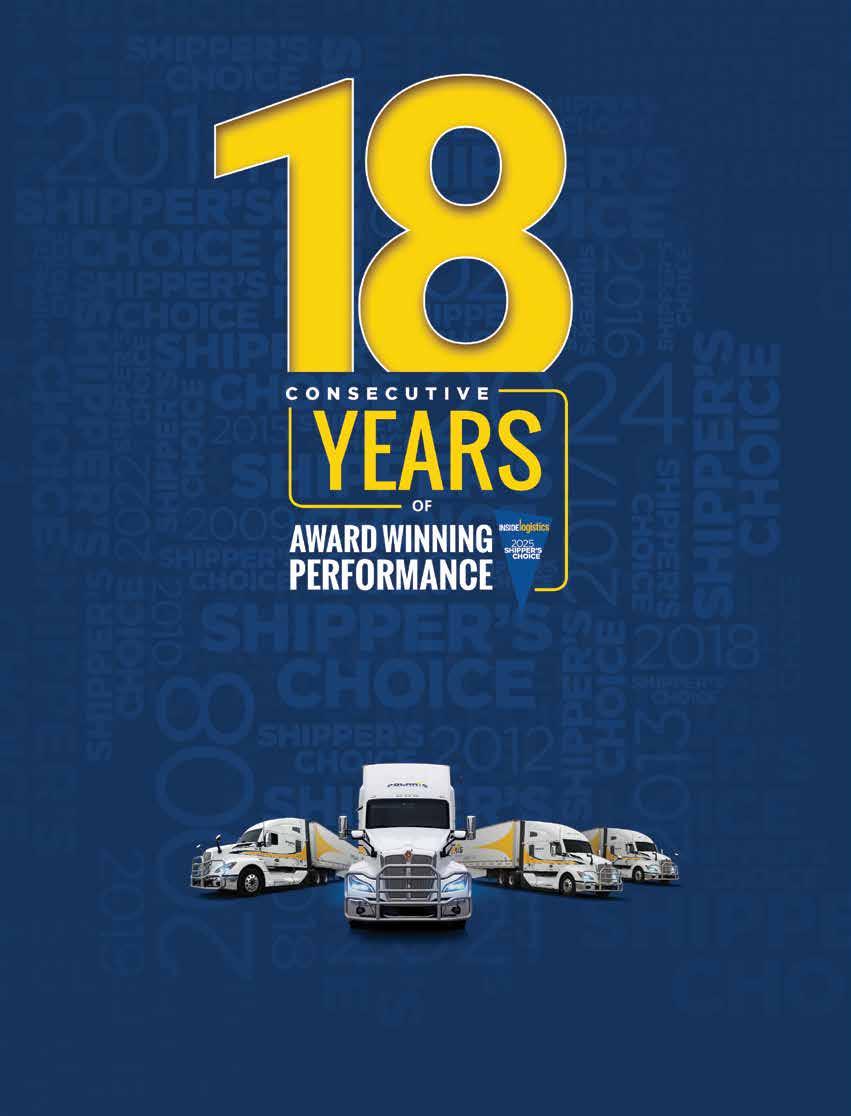

For the 1 th consecutive year, Cardinal has been recognized for the Shipper’s Choice Award and years in a row for Carrier of

Without your loyalty and appreciation over the years, Cardinal would not be where we are today. Now more than ever, your devotion to our business has never been more valued; and this award could not have been won without you.

Cardinal’s Pre 8am transportation solutions and unique night network provide a competitive advantage where first to market comes standard. Expect Cardinal’s night network with unattended pickups and deliveries to deliver a competitive advantage to your business.

RAIL WINNERS

Rail freight service buyers place an emphasis on competitive pricing, with it being the highest level of importance in the survey. Buyers also looked for on-time performance. Three rail companies made the benchmark this year.

COURIER WINNERS

Buyers of courier services have high expectations when it comes to on-time performance, so it’s no surprise this area had the highest benchmark for the mode. Buyers also look for competitive pricing and information technology. Three courier companies made the benchmark this year.

CARRIERS OF CHOICE

Carriers are presented with this prestigious award if they have demonstrated the consistency necessary to attain the highest levels of service by surpassing the industry Benchmarks of Excellence for a minimum of five consecutive years. This is a particularly difficult task. Aside from having to maintain consistent excellence in their operations, carriers have to meet a standard that rises every year, while also responding to changing priorities. To remain part of this exclusive fraternity, carriers must requalify each year.

AUTOMATION ALONE WON’T CUT IT

Why software is an important factor in the performance of warehouse automation

Automation control software plays a critical role in the return on investment companies can realize through the use of warehouse automation. With the right software, companies can reduce their upfront investment without compromising future flexibility, enhance inventory management in ways that reduce costs, improve service to customers and improve day-today operating efficiency. This is why it has become essential to carefully evaluate software capabilities before selecting a warehouse automation solution.

Most companies generally understand that warehouse automation can increase storage density and reduce the labour required to fill orders. As a result, those factors tend to dominate the business case for automation. However, they don’t encompass the full value automation can deliver. Much of the added value that can be achieved is made possible by the software that controls the automation solution and integrates the

Moving what Matters

automation into warehouse, supply chain and delivery processes.

How software enhances the business value of warehouse automation

Warehouse management systems (WMS) play a critical role in managing warehouse inventory, labour and costs. However, these systems are not able to control the operation of automation systems such as an automated storage and retrieval system (ASRS). For that, an automation control system (ACS) is required, and the right ACS can bring added value through bottom-up digitization from the shop floor.

It starts with capabilities that reduce the investment in automation by eliminating the need to oversize systems due to inefficient management. For example, it’s important to find

For over 100 years, Oceanex has been providing efficient and reliable intermodal transportation services safely and with environmental leadership. With our fleet of 3 vessels and the largest dedicated fleet of containers and trailers servicing the province of Newfoundland and Labrador, we keep retail shelves stocked and deliver the materials that build and support our communities, keeping the economic engines of the province running.

software that uses algorithms to optimize ASRS management, reduce wait times and deliver pallets in the sequence required for efficient material flow. This allows right-sized solutions to deliver speed and performance that meet or exceed oversized ones.

Digitalization brings greater intelligence to inventory and order management. By enabling the precise tracking of item locations and movements, the ACS can virtually eliminate human errors like misplacement or miscounting, reducing stockouts and overstock. It also enables flexible and granular shelf-life management. Through intelligent inventory and order management, an ACS can calculate the remaining shelf life at delivery for each order, allowing product retrieval based on delivery times and customer priority.

In addition, digitalization improves the speed and predictability of order fulfilment by optimizing picking and routing based on order priority, inventory availability and resource capacity.

Through these capabilities, the right automation control software can strengthen the business case for automation by reducing capital investment, lowering inventory costs, improving order accuracy and enhancing customer service.

How software improves operations in automated warehouses

ACS software delivers day-to-day operational value by efficiently managing demand variability, supporting better decision-making and streamlining the response to events like product recalls.

Software capable of controlling all components of an automation solution – including the ASRS, conveyors, AGVs and

PROUD WINNER OF THE 2025 SHIPPER’S CHOICE AWARD

palletizing systems – as well as manual processes can synchronize workflows and dynamically balance resources to eliminate bottlenecks during demand peaks. The visibility and analytics provided by the software also allow managers to effectively use warehouse data to improve operations, including monitoring key performance indicators in real time.

Certain software can also reduce the costs of a recall. For instance, the system could quickly locate impacted products, including those already shipped, based on batch, best-before date or other information.

Must-have capabilities for automation control software

Not every automation control platform delivers the same functionality. Look for:

■ Modular, preconfigured architecture: Integrates automation control, warehouse execution and management, with industry-specific preconfigurations.

■ Intelligent inventory and order management: Manages inventory based on batch, expiry or best-before dates and aligns with customer expectations.

■ Resource orchestration: Controls both automation and manual processes to avoid siloing.

■ Traceability and analytics: Supports detailed tracking and 3D visualization of warehouse operations.

■ Intuitive user interface: Easy to use, consistent and multilingual.

■ Maturity and security: Ensure a roadmap, secure development, global support and a standardized platform.

Trusted. Proven. Award-Winning.

At Saini Logistics, we deliver more than freight — we deliver confidence. Voted a top Canadian transportation provider, we offer:

✅ Intra-Ontario TL & LTL

• White glove delivery

• Temperature-controlled or dry service

✅ Cross-Canada TL & LTL

• Reliable coast-to-coast coverage

• Temperature-controlled or dry service

Experience the service that earned us the Shipper’s Choice Award.

CANADA RETHINKS ITS TRADE FUTURE

AS WE CROSS THE HALFWAY mark of 2025 – the year of tariffs – the landscape continues to shift atop what little certainty the supply chain has managed to maintain.

In early July, U.S. President Donald Trump formalized a sweeping plan to escalate tariffs on key trading partners, which once again includes Canada. Set to take effect Aug. 1, Canada is facing an increase from 25 per cent to 35 per cent on non-Canada-U.S.-Mexico Agreement (CUSMA) goods, along with sector-specific duties, including 50 per cent on steel and aluminum and 25 per cent on non-CUSMA autos and parts.

This could, however, be delayed due to the ongoing injunction heard May 28 in the U.S. Court of International Trade, where the “Liberation Day” tariffs were ruled unlawful under the International Emergency Economic Powers Act. The Federal Court of Appeals is set to review the case July 31, leaving the August tariffs and trade talks in legal limbo.

Canada continues to respond to the tariffs with domestic diversification strategies. In late July, the government imposed a 25 per cent tariff on steel imported from other countries containing Chinese-melted and integrated steel. This preventative measure aims to stop diversion through Canada following the U.S. steel escalation. Also enacted in July, the Supply Management Law – Bill C-202 – came into effect, restricting foreign dairy and poultry deals but retaining provincial flexibility for internal reforms.

The effects of these tariffs on the Canadian supply chain and industry are already being felt amid the uncertainty and potential delays, with Canada’s auto industry taking one of the biggest hits. GM reported a US$1.1-billion Q2 earnings hit due to tariffs on Canadian imports, with profits dropping 35 per cent and a projected tariff-related loss of US$5 billion in 2025 alone.

Canada is currently looking to other countries for potential free trade deals with Mercosur – a South American trade bloc and customs union established in 1991 that includes Brazil, Argentina, Uruguay and Paraguay – while also exploring trade with

VICTORIA JONES

is a supply chain specialist at Tyers Foods

“Canadian leaders are taking a new approach to the tariff pushback as the country’s limited leverage becomes increasinglyclear.”

scrapped by Prime Minister Mark Carney in an attempt to ease tensions with the U.S. president. The Canada Revenue Agency has already begun refunding fees collected under the tax, which was implemented before Carney’s time in office.

As the August tariff talks continue to unfold, there is potential for more delays, with the Court of International Trade possibly postponing enforcement as it prepares for the appeals hearing set for July 31. While U.S. Commerce Secretary Howard Lutnick has insisted the Aug. 1 deadline will stand regardless of the court ruling, he did acknowledge negotiations may continue even as the new tariffs take effect.

Earlier this week, Ontario Premier Doug Ford hosted Canada’s 13 premiers in Huntsville for a three-day summit focused on tariffs and trade disruptions. Carney was also in attendance, announcing his plans to participate shortly after Trump threatened the new round of 35 per cent tariffs on non-CUSMA goods. Carney offered a stark outlook, stating that a tariff-free trade deal with the U.S. is highly unlikely and should be viewed as the new reality. Quebec Premier François Legault said that while the trade talks are still developing, there must be some assurance that whatever deal is reached will endure.

China, India, Ecuador, the United Arab Emirates and Indonesia in an effort to reduce reliance on U.S. trade.

On July 21, a delegation of Republican and Democratic U.S. senators visited Ottawa in an attempt to salvage a Canada-U.S. deal before the looming Aug. 1 deadline. Among the topics discussed were softwood lumber quotas – which have recently come under scrutiny – as well as digital services taxes, which triggered the latest tariff push from Trump. These taxes have since been

Canadian leaders are taking a new approach to the tariff pushback as the country’s limited leverage becomes increasingly clear. Following the leadership meeting, officials downplayed the likelihood of meeting the August deadline, emphasizing that a good deal is more important than a fast one. A team of Canadian negotiators is set to head to Washington prior to Aug. 1 in a final attempt to secure an agreement in Canada’s best interest for future trade relations with the U.S.

There has been a clear narrative shift from the premiers and Carney, who campaigned on his economic record and claimed he was best positioned to negotiate with the U.S. president on looming trade issues. As the possibility of reaching a tariff-free agreement grows dimmer by the day, expectations are being recalibrated accordingly.

real- time visibilty

TEEING IT UP FOR A GOOD CAUSE

The CITT Toronto Area Council held its 13th Annual Golf Tournament at Piper’s Heath Golf Club in Milton, Ont, July 10. The sold-out event saw 144 golfers participate, with proceeds being donated to the Daily Bread Food Bank, which has multiple locations across the Greater Toronto Area.

THE LOGISTICS LOWDOWN SCAN

WITH DEREK CLOUTHIER

TO LISTEN

BUDGETING FOR WAREHOUSE SAFETY WITH CARL BONELLO, A SPECIALIZED CONSULTANT WITH WORKPLACE SAFETY AND PREVENTION SERVICES

Discussing the topics that impact the supply chain and logistics sector

CSA UPDATE: WHAT YOU NEED TO KNOW

CSA will release its updated industrial robot standard early next year

Association (CSA) is updating its Z434 Standard for Industrial Robots and Robot Systems. Essentially, CSA is in the process of nationally adopting the recently published international robot safety standard— ISO 10218:2025 Parts 1 and 2—as Canada’s new industrial robot safety standard.

Since most distribution centres use robots in their operations for various tasks, such as wrapping pallets and order fulfillment, companies need to be aware of the upcoming changes.

Part 1 of the standard will outline the requirements robot manufacturers must meet when designing and building robots. Part 2 will focus on the safety requirements when integrating a robot into a robot cell or application. Robots on their own are not a complete machine until the end-effector—the device at the end of a robotic arm designed to interact with the environment—is added, they are integrated into a robot cell and then programed to complete a task or process.

Robot integrators should pay particular attention to the changes in Part 2 of the standard because that is where they will find the requirements for integrating a robot into a robot cell and safely using it in a warehouse or distribution centre.

Workplace Safety & Prevention Services (WSPS) anticipates that the updated CSA Z434 will also include an additional component that will provide end-user guidance on the safe use of industrial robot cells. Topics such as collaborative application technology selection guidance, end-user risk assessment, training, verification and validation and requirements for maintaining acceptable end-user risk will be covered.

Greater guidance for collaborative

One of the main things we expect with this update is an expansion of the requirements for collaborative robot applications, where robots and humans work side-by-side. In the past, humans were kept completely separate from the robot application. But now, with advances in safety functionality, humans and robots are able to work together collaboratively.

While many companies are excited about implementing new collaborative applications, I still see misconceptions and misunderstandings

ROBERT VOMIERO, is a professional mechanical engineer, certified machine safety expert and certified functional safety engineer who sits on the CSA Z434 committee. He provides health and safety consulting services for Workplace Safety & Prevention Services as a robotics and machine safety specialist.

about the technology when visiting workplaces. A robot may incorporate the safety functionality for collaborative applications; however, that does not mean it is inherently safe out of the box and ready to work with humans. It must still be set up and tested according to the standard, which is where we currently see gaps. The new standard will provide the clarification and guidance necessary to reduce the risk to humans.

If a robot in a distribution centre picks an item and then hands it off to a human as part of a collaborative task, the risk that comes with that contact needs to be mitigated—which is the goal of the updated requirements in the new standard. If a comprehensive risk assessment is carried out and the robot application is designed and integrated accordingly—ensuring the robot’s safety functionality appropriately limits factors such as speed, force and pressure outputs—the risk of injury to the human will remain low.

Worker training is another important safety element when dealing with collaborative applications. Training should focus on the worker’s movements and precision in the execution of their task to minimize unplanned contact with the robot.

When it comes to order fulfillment, more and more distribution centres are using industrial (autonomous) mobile robots (IMRs). These applications may not include intentional contact between the robot and a human worker. However, when articulating robot arms are added to IMR platforms and there is a need for the human to work collaboratively with the robot (e.g., at hand-off or drop-off locations), the new CSA Z434 standard will provide important safety requirements for those interactions. As human/robot collaboration in warehouses and distribution centres becomes more prevalent, I believe the new CSA Z434 standard will provide important guidance for minimizing the risk to humans performing collaborative tasks alongside robots.

Key updates coming in the new standard

If your workplace is planning to implement a new robot application soon, follow ISO 10218:2025 in addition to any legislative requirements specific to your jurisdiction. This will ensure the integration will align with the requirements of the new CSA Z434 when it is released.

Here are a few more details of what you will find in the new standard:

■ Additional requirements for cybersecurity to protect networks from being hacked, including requirements for secure access to controls, network segmentation and fail-safe behaviour during periods of communication loss

■ Clear descriptions for collaborative applications, such as hand-guided control, speed and separation monitoring, power and force limiting and their associated safety functions

■ Biomechanical force and pressure limits not to be exceeded across 29 body areas during human-robot contact in collaborative applications

■ Additional clarity on functional safety requirements for various robot safety functions such as emergency stop, normal stop, protective stop, interlocking, reset, start/restart interlock and mode activation

■ Measurement methods for validating pressure and force during contact events for power and force limiting (PFL) collaborative applications

■ The addition of risk assessment protocols specifically focused on robotic applications.

Manitou offers gas/diesel models with multiple mast options and attachments to meet all industrial material handling needs.

Manitou means forklifts. Manitou means industrial.

See our full range of solutions for your business at Manitou.com.