PORTFOLIO PRESENTATION

GIANLUCA ACCARDO

PRODUCT DEVELOPMENT

ENGINEER

TOYS DEVELOPMENT

PRODUCTION PROCESSES

DESIGN AND DEVELOPMENT

INNOVATION

GIANLUCA ACCARDO

PRODUCT DEVELOPMENT

ENGINEER

TOYS DEVELOPMENT

PRODUCTION PROCESSES

DESIGN AND DEVELOPMENT

INNOVATION

The Disney Frozen 2 collectibles “Whisper and Glow” collection bases its game-play on a simple function:

Kid blows on the figure's head and it lights up

The Disney Frozen 2 “Walk Projector” is wearable toy designed to cast snowflakes’ images on the floor while walking.

This is an electronic toy that had to fulfill several requirements to pass test and toy’s conformity. The biggest challenge was to find a solution to have as much light strength as possible without exceeding the regulation limits.

The Disney Frozen 2 “Magic Ice sleeve” and “Frost Action Sleeve” wearable items were developed simulate Elsa’s power to cast a frozen mist with hands.

Wearing this device, the kids can activate the “Sleeve” function through a mechanical lever and drizzle a frosty fog, using the “Frost Action Sleeve”, or a fake snow, using the “Magic Ice Sleeve”.

- Frost Action Sleeve: This is an electronic productthat turn water into steam. Since this item involve IC and water it was crucial to make the internal structure completely waterproof without affecting the production processand related cost.

- Magic Ice Sleeve: This is a manual activation product.It is simpler than the previous one and gives more reliability on the after-sales side. Here we have a made-in-Italy snow spray that, when is finished, can be replacedwith the provided water spray container to continue enjoying the game-play.

“Frost to her “Sleeve” frosty snow, that water completely and product. It reliability made-in-Italy with enjoying

OR SHARE IS FORBIDDEN - ONLY VIEW IS ALLOWED

Visualization of how the limbs parts are affected by the joint structure and where they overlap. this helps to foresee movements limitation problems

This study is divided in several section to explain the joint structure types and the related Limb.

Shoulder's joint orientation

SHARE IS FORBIDDEN - ONLY VIEW IS ALLOWED

This collection is designed to be sold in surprise bags and let the kids experience the revelation of unknown character each time they open a bag.

These figures are static and so they don’t have any articulation or designed movements.

Each part was developed considering all the pulling and drop test mandatory by this category of toys.

To fulfil these requirements, the development was focused on the connection area between each limbs and accessory. We made sure each limb matches each other in the steadiest way, also to prevent any possible production mistakes (i.e. Glue application)

The Gormiti 12cm Action figures belong to Giochi Preziosi's own brand development.

These figures are developed considering some movements to be activated manually.

Through a lever located on the back of the character, the kids can use their fingers to control it and activate the arm movements.

Because of the weak structure of the figure, it was not easy to calibrate the limbs and connector dimensions to fulfill the pulling and dropping test, but we achieve success after some tests (DOE).

These characters (Lord Keryon and Lord Electryon) are the new members of this range.

For this development, we had to integrate electronics inside the figure's structure to have light and sounds functions.

Unlike the previous 12cm, this one is 25cm and not difficult to fulfil the test requirements. The focus of this project was on cost and manufacturing processes.

The Brazer is wearable shooting device, designed to fire round discs that were specifically designed for this toy.

FIGURES + ANIMAL DEVELOPMENT

The HyperBeast Collection is directly linked to the new animated serie.

This Line is made by 2 Basic + 2 Deluxe Figures

While the "Riders" are simple articulated figures, the Animals have internal electronic integration to support Lights and Sounds

FIGURES + SLIME DEVELOPMENT

The Gloopers Collection is Giochi Preziosi’s own brand development.

The little monsters are designed to interact with a Slime compound. When squeezed, the Slime will cast out and when released, the Slime will be sucked in again.

This development focused on the characters’ internal area such that the “squeezing" game-play would be the same across all different figures. Each figure needs to fire out the Slime in the same way, giving players the same feeling.

EMOTION PETS - TOFFEE TOY DEVELOPMENT

EMOTION PETS are Giochi Preziosi’s own Brand development.

EMOTION PETS are Plush toys with movements and sounds integration.

Using a carrot or a brush, kids can activate the toy functions as the mouth eating simulation or petting appreciation sounds.

TOFFEE the Pony was developed following the original design of Mr. Marco Moroso, the Italian Engineer who originally created the brand.

As Product Development Engineer, I followed-up, improved and delivered all the production related to Carrera Brands Products:

• Skiing Helmet

• Skiing Helmet Accessories

• Bycicle Helmets

• Bycicle Helmets Accessories

•Skiing Goggles/Masks

• Bycicle Goggles/Masks

• Packaging

• QC/QA

The New Carrera Foldable Helmet for Cyclist was a very Innovative project.

The early development was managed between Italy and Asia to define a preliminary designand structure.

In Hong Kong, I was the manager in charge of getting the production ready with the selected vendors and identifying all key-points for an efficientProduction and QualityControl.

In Safilo Far East, My work also included eye-wear projects . During that time I was their product development Engineer in charge of following up the projects throughout the entire development life-cycle.

Some of these brands included: Dior, Jimmy Choo, Tommy Hilfiger, Marc Jacobs, Fendi, Gucci, Max Mara, Pierre Cardin, Carrera, and Jack Spade

Rocket is a young, innovative company focused on the design and distribution of lifestyle household products. The 2 founders asked me to design and develop their first collection of 20+ lifestyle products. The work included the design, engineering of the components, injection tooling and production process until the assembly and packaging finalization.

Guitray

Dynamike

Bottle Opener

Salt&Pepper

From my time at Safilo together with my observation of the current trends, I combined the two ideas and was the first to release this innovation onto the market. This item was born by merging the standard technical performance with a hint of fashion, to make it into an accessory item.

Duringthedesignprocess,itwasnecessaryto verify the wholeproductoutlookbeforemaking samples or tooling. The best way to double check was to render the 3D files to see the finishedgoggleasifitwasrealandstillbeable to improve tiny details before starting with the prototyp-ingstep.

All 3D design projects are made using Pro/Creo (previously known as Pro/Engineering).

This is one of the most advanced 3D software used in almost all industry (WV for cars, Airbus for airplanes). With this software I designed all my projects because the level of visible details and conversion for CNC machining is unbeatable.

Keyshot is, instead, a simple software used to render as real photos 3D drawings.

According to my experience, this is the easiest to use and save time during the design process and can immediately give me an idea about the final product outlook in the reality.

As an engineer, my duty was to partner with the Art Department and convert their ideas into practical projects.

My main duties were:

• Engineering VM Projects

• Source and Select suitable materials

• Follow up Factory Development and Production

• Brainstorming and technical support

• rapid prototyping and samples making

• Installation

• Set-up assembly kits for shop

REPLAY - General VM engineering Production works

The Replay experience completely changed the way I used to look at products.

The Visual Merchandising industry was not like anything I was used before, it is purely for show and display.

The cooperation with a real artist allowed us to go above and behind to create one-of-a-kind installations

OR SHARE IS FORBIDDEN - ONLY VIEW IS ALLOWED

• DeSIGn

• DeVelOPMenT

• PRODUCTIOn

• MaCHIneRy

• aSSeMbly

• SOURCInG

• PROCUReMenT

• fInISHInG

• TeSTInG

• QUalITy

The Scuba Diving industry is one of the most important milestone of my career. Designing, Developing, Producing, Sourcing and Purchasing equipments and components for the biggest brands on the market built up a very strong knowledge in machining process, materials properties and characteristics, foresee and prevent potential problems, and also to understand factory capabilities for each production requirements.

Cressi Sub, Mares,

Scubapro are just few of the most important brands who saw Gianluca developed their products.

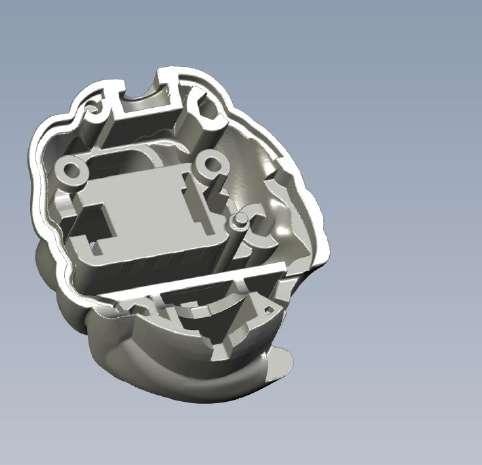

The development of different types of “Regulator” with all its components is just one of the many projects developed for the Diving industry. Apart from the metal parts, this involved the design, tooling production using CNC machines, plastic injection process follow up and final assembly.

These are just few of many products developed for the scuba diving industry.

Trivia: During the development of the ScubaPro mouth piece (showed in the picture) there was a last minute modification. To catch the delivery deadline, the tooling mod-ification was done by hand.

Other items include: Diving Mask, Snorkel and Mouth Piece, Fins, Spear Guns and many more.......

• DESIGN

• DEVELOPMENT

• PRODUCTION

• MACHINERY

• ASSEMBLY

• SOURCING

• PROCUR

• FINISHING

• TESTING

• QUALITY

The Swim related products industry is directly related to the Diving market. Even the biggest Scuba-Diving Brand created sub-brands dedicated to Swim. As per the Fashion industry that separates their collection i n different cate-gories, the sport equipments brand do the same to maximize sales targeting all marginal area around the diving market.

Design, Sourcing and Production are the main products followed up for the swim market.

During the years I worked on products with the same “production” process category s Goggles, Swim Caps, short Fins and general SwimAidsitemsasfloatingboardsandHandpaddles.

Aside from the “Plastic-made” products, I work on Swimwear Design, Development and Production of Swimwear. Garments based items require completely different ap-proach and understanding of the finalproductperformances.

The entire range of Swim Products include: Women and Men swimwear, Men trunk style swimwear, Swimming goggles, Swimming caps, Ear plugs, Swimming aid related product (paddles, short fins), and many others......

My hometown Genova is not only the Capital of the Scuba Diving industry but also a very important HUB for the Development and Production of Medical Equipments. Some of the most important hospitals in Europe and medical equipment companies have their HQ there. This gave me the opportunity to work directly with EASAOTE Biomedica for the development and production of Ultrasound machine parts, and also a chance to work with doctors for the development of their own patents and products production.

One of my newest product designed and developed for the medical industry is called “ADIPOPIMER”. This product is specifically designed for the plastic-surgery industry, giving each surgery operation more reliable sterilized standards and the possibility to re-cycle the products after using.

The whole project required to :

Design the whole internal mechanism including EC connection

Build up the outside cover using the internal structure as reference

Make an ergonomic shape

Add a ceramic blade and connect it to the internal engine through small

Finalize tooling and set up the final assembly line

Sedut perspiciatis undentl omniste natus error sivolupta tember accuantium doloremque laudantium totam rem aperiam eaquipsa quae abillo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptem sequi nesciunt. Neque porro quisquam estquied dolorem ipsum quia dolor siamet consectetur adipisci velitsed quia non numquam eius modi tempora incidunt utardn for laborghet doloret magnam aliquam quaerat voluptatem.

Example of projects for 2 of the most important medical companies known worldwided: Amplifon and Esaote Biomedica. For them I designed and produced:

• Hearing aid Silicone Earplug

• Plastic Hearing Aid related Components

• General Hearing Aid component production

• Ultrasound Plastic Probes Production

• Ultrasound Probes Silicone Components

• General Probes Productions

OR SHARE IS FORBIDDEN - ONLY VIEW IS ALLOWED

I grew up in a plastic injection tooling and plastic pro-duction factory watching and learning everything from my father. He spent his entire life making molds, working together together so that he could pass to me his expertise from the basics to the utmost advanced techniques of production.

To summarize my knowledge about plastic product production requirement, I am able to:

• Use any type of cnc machine operation through ISO programming and CAM system

•

• Understand any type of cnc machine and their ca-pabilities/limits

Understand set-up any type of plastic injection ma-chine

• Improve and implement any of these listed process with authomation support

Nowadays it is not necessary to program machining processes directly through a ISO programming input because it is possible to simulate and calculate machin-ing path using CAM softwares. However it is important to know how to program a cnc unit to be able to under-stand machining properly.

Plastic Injection is the most common process to produce parts in larger scale. From the Mold making experience i managed to get introduced to the injection world pretty early in my life. Here i had the chance to immediately see the molds I made in action and enjoy an amazing feeling of accomplishment.

Metal production processes are also used during my every-day work life As a secondary process i mainly follow up components of the final products that can be functional parts: as hinges, gears or special frames; or can be decoration items as charms, insert logos or also special frames.

I list the most important production processes that I use or I'm in contact everyday in my work. I use similar machining processes for the production of components for toys, scuba diving equipments, fashion accessories, etc.,

When I follow up each mass production from the start to finish, not only do I need to understand the required specification but also the final customer experience. With the customer’s satifsfaction in mind, I can prepare each production properly and prevent errors.

For this reason i always start the development in 2 way:

1) identify key samples to use as reference for: Material, Colors, surface Finishing and treatments Finishing

2) Sketches preliminary ideas on Pro/Creo (3D software) to confirm better development plans with customers

In the next page can see some of the post-production process i'm currently use in my everyday work:

• Spray Decoration

• Pad Printing • Silk Screen

• Laser engraving (4)

• Heat Transfer (5)

• Anodic coating (6)