Sorting System and the intelligent logistic

An advanced logistics system that understands what it’s doing, to consign bottlenecks as a thing of the past.

Year 5 n. 1 - 2023 CONTENT

An advanced logistics system that understands what it’s doing offers an automatic solution able to adapt to programming changes to consign bottlenecks as a thing of the past.

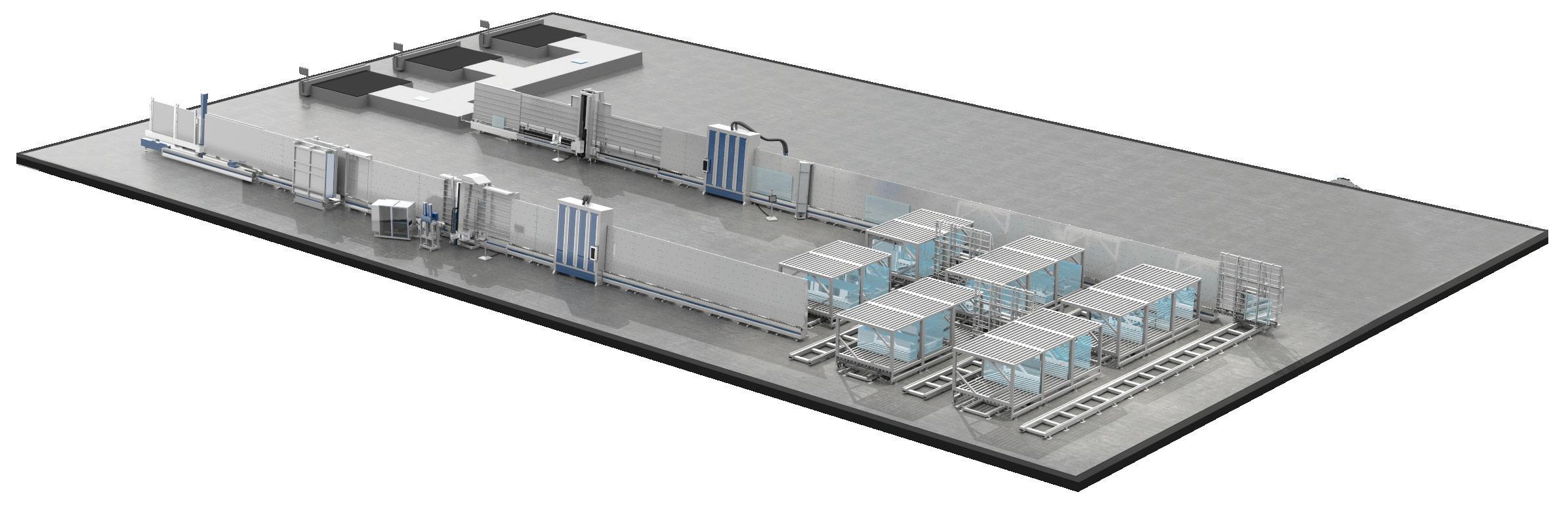

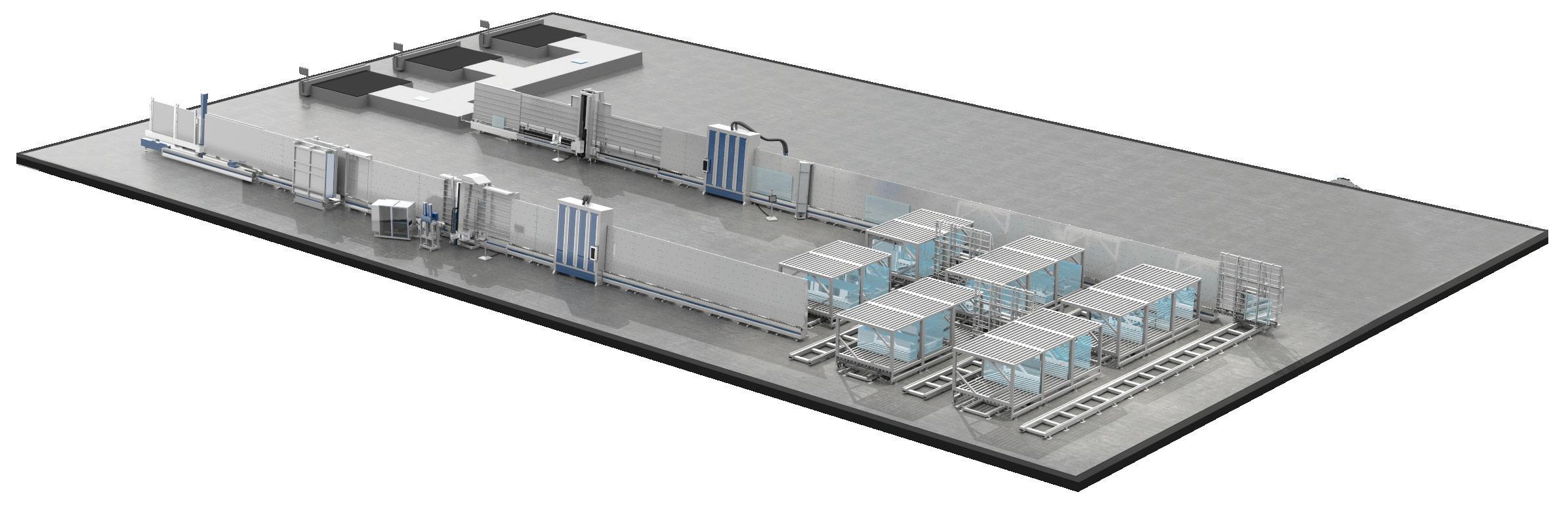

The Sorting System, Forel’s intelligent logistics solution, is all of this and more: an automated system to manage glass panels within the production process. The Sorting System can connect different production departments, creating a holding area for semi-finished products that are subsequently sorted automatically, depending on production programming.

In recent years, this solution has been frequently requested by major glass companies, as it automates and links production processes independently,

reducing manual work, whilst simplifying the operation. In fact, the work list is loaded into the system’s management software: regardless of the order in which the material arrives to the Sorting System, the self-learning mechanism will identify each individual piece, attributing a unique ID code and link that item to its respective order. This means that, as soon as the system is ordered to proceed with any given work list, it will call up all the associated items and send them to appropriate downstream processing line. If there is a programming change mid-cycle, it is possible to pause an order and continue with other production by simply inserting a different worklist as required. The Sorting System brings obvious benefits: reduced bottlenecks, errors and or indecision, with clear improvements in workflow management, output, identification, flexibility and safety.

march 2023 - Forel News Page 1

MARCH 2023 FLAT GLASS & DOUBLE GLAZING SOLUTIONS

www.forelspa.com

MARCH ISSUE

History:

Talks with

Ulens Infographic: Investing in Sorting Italian Technology Awards P2 P5 P6 P7

Case

Polflam (PL) Market

David

NEWS

youtube.com/forelspa vimeo.com/forel forelspa.com

linkedin.com/company/forel-spa

The “new” Polflam (PL) and its Fire-Resistant Glass

Polflam’s site in Warsaw (poland) is a perfect example of a glassworks with a very high degree of automation, where the different processing areas are interconnected thanks to integrated logistics 4.0

Feb/23

Varsaw, Poland

A year has passed since the inauguration of Polflam’s new factory in Warsaw (Poland), which immediately became one of the most dynamic and interesting sites within the glass industry: with over 20,000 square meters of production area, it is a modern, fully automated factory dedicated to the production of fire-resistant glass. Since 2005, Polflam has chosen to specialise in fire-resistant Double Glazed

Units, achieved by filling the cavity between the two panes of glass with a special hydrogel interlayer. The resulting fire-resistant DGUs, which must pass strict quality tests, meets integrity and full thermal insulation for Polflam EI and integrity with reduced heat radiation for Polflam EW. In 2019, the company was acquired by the private equity group Baltisse, which enabled Polflam to expand into new regions which involved the construction of the new factory, the

organisation of production flows and the installation of a complete new fleet of equipment.

“Before Baltisse Group’s investment, Polflam was still a semi-craft business, where processing was 85% manual,” explains Jean Luis Canelle, Director “Our goal was to transform the company, increasing productivity and sales globally especially into Western European markets. But this was not possible from the old site”. “The production capacity of the initial factory was already at maximum,” commented David Ulens, CEO of Polflam. “We could not grow anymore there. Moreover, the manual processing did not make it possible to establish standard levels of quality, cycle times, precision. We had to start from the basics and completely rework the production process”.

“The choice of machinery to be used was decisive,” continues Jean Luis Canelle. “We looked at several options, but then narrowed the field down to three main suppliers, among which Forel played a

march 2023 - Forel News Page 2

special role, installing the 2 integrated logistics systems, the edge processing and IG assembly lines. There are three reasons why we chose this brand. Firstly, Forel immediately understood that we were talking about a special and complex project and offer us an effective solution. The technological aspect was the second point: I think that Forel offers the best

solutions, especially for the assembly of insulating glass. The third point is service, which is essential: a machine is a tool and can be the subject of negotiations, but the availability of a good service system is decisive. It is indispensable, from the installation of the machinery onwards. And with Forel, our expectations were 100% fulfilled”.

The production flow in Polflam

While the ‘challenge’ of setting up an entire new factory was a very demanding and complex job, it allowed for the organisation of space and processing flows to be optimized. Production at Polflam begins with the arrival of Jumbo glass stock sheets, which are stored within a large, automated warehouse, which is connected to the horizontal cutting tables. Once the glass is cut

..continues at pag. 5

CUTTING

SORTING

SEAMING

TEMPERING

march 2023 - Forel News Page 3

march 2023 - Forel News Page 4

SORTING IG PROCESSING

into the required sizes, it is loaded onto an initial sorting system: this system, recognizing each pane with a specific ID, organises the material and then sends it to the three different edge processing lines, according to the production and process schedule. Two of these lines are equipped with processes necessary to feed the two toughening plants. After the tempering process has been completed, the glass panes re-enter the downstream sorting system, which sorts them into pairs ready for the insulating glass line process. An advanced tracking system assigns an unique ID to each pane of glass as it enters

MARKET TALKS

“Compared to our competitor’s, our glass has added values,” continues David Ulens. “Firstly, we can increase the level of fire resistance without making the glass unit heavier. For example, if we manufacture a fire-resistant glass unit acting as a barrier against hot gases and effectively blocking heat transfer for two hours, we simply

increase the thickness of the cavity and therefore the amount of hydrogel inside but still only using two panes of glass. Instead, most of our competitors create a glass unit with either triple or quadruple glass panes. Result: for the same performance, our glass weighs less, which makes it much easier to handle and install. The other

the flow, so that each pane is monitored throughout the process. Overall, this reduces manual handling, minimizing operator intervention allowing them to (in most cases) just supervise the process.

big advantage of Polflam’s product is the format: by using Forel’s systems, we can assemble large fire-resistant glass units of up to 5 meters by 2.80 meters, delivering a performance/weight to size ratio of our product that is ranked very high and we are amongst a few in the world that can offer this performance”.

The investment in Polflam was considerable, but well-motivated and understood by clear market prospects. Fire-resistant glass, in fact, is a product that is not chosen ‘spontaneously’ but is imposed by safety regulations that are becoming more recognized and required by all nations.

“Fire-resistant glass is, in many cases, simply mandatory by law” concludes David Ulens. “Housing density is increasing throughout Europe: new regulations will require buildings to be fitted with fireresistant glass. It is therefore easy to deduce that our market will continue to grow in the long term: and Polflam has equipped itself to increase its competitive edge and play a leading role.”

march 2023 - Forel News Page 5

“Fire resistant glass is not an optional: it’s mandatory”

- David Ulens, Polflam CEO

We’re producing a fire resistant glass with added values. Just a few companies in the world can reach these levels.

Watch the video on the official You Tube Forel Channel!

Investing in a Sorting System

There are many reasons to install a Sorting System inside a glass factory, but we can summarise them as: this technology allows us to produce more, in an easier way.

The Sorting System assigns a unique ID to every pane it receives, so that it can recall the right panes for each order and the panes themselves can be identified at any point in the work program.

#LOGISTICS

Glazing businesses today can be divided into two categories: those with processes still involving a large number of manual handling operations, and those which have already adopted automated logistics systems. The Sorting System, on the other hand, takes the process to a whole new level: with intelligent logistics.

#FLEXIBILITY

Load a work list and start production. Put a current job on hold and start another order. Put the second order on hold to finish an urgent order. Resume the original work list. Load a fourth order. All of this without leaving the office.

#AUTOMATION

The Sorting System is a fully automated tool. No human interaction is necessary other than through the management software.

#INTEGRATION

#QUALITY

Advanced quality control systems ensure that only items meeting the standards required are fed into the sorting system. This means that any process errors are identified and intercepted before any other processing is carried out.

Efficiency means adaptability: The Sorting System is designed to integrate with the ERP of the glazing factory it is installed in. So the latest addition becomes part of the family, right from day one.

#MODULARITY

The Sorting System is a modular system designed to fit seamlessly between existing lines and processes.

#SPEED

No dead time. Bottlenecks are a thing of the past. Will the Sorting System increase production speed? It does even better than that: it takes production to new levels of efficiency.

march 2023 - Forel News Page 6

FOREL SORTING SYSTEM PRODUCTION

CUTTING

IG

GRINDING

#TRACKING

“Italian technology Awards” winners visit Forel plant

From various USA Universities, a group of “glass students” visit Forel Headquarters in Treviso

Feb/23

Treviso, Italy

The delegation of US students from the Italian Technology Awards program have been guests of Forel on 16th of January.

During the visit, the delegation received presentations about the company’s history and its relative technology through the ages. Students also attended a series of machine demos within the production area, to observe the flat glass processes directly.

“It was a pleasure to host such young talent who, like us, decided to devote themselves professionally to glass,” commented Carlo Zuccarello, Forel’s Sales Director “We are sure that the visit was an enjoyable experience and a good training opportunity, given that our sector is a specialised, limited world however I’m convinced that there will be an opportunity for us to meet again”.

ITA Program

The Italian Technology Award Program is comprised of a competition asking upperlevel students that attend premier United States universities, to submit a paper on the relative innovation taking place in mechanical engineering-related industries and the issues they face. The aim of the program is to enrich the engineering education of students and to advance knowledge on issues of importance within the industries of Metalwork and Glasswork to the next generation of engineering professionals.

march 2023 - Forel News Page 7

It was a pleasure to host young talents who, like us, decided to devote themselves professionally to glass.

EXHIBITIONS 2023

CHINA GLASS

6 may - 9 may

Shanghai (China)

WINDOOREX

6 may - 8 may

Cairo (Egypt)

BATIMATEC

7 may - 11 may

Algeri (Algeria)

GLASSTECH MEXICO

19 jul - 21 jul

Mexico City (Mexico)

AUSFENEX

29 aug - 31 aug

Benowa (Australia)

VITRUM

5 set - 8 set

Milan (Italy)

GLASSBUILD AMERICA

31 oct - 2 nov

Atlanta (USA)

EURASIA GLASS

11 nov - 15 nov

Istanbul (Turkey)

GLASSTECH ASIA

29 nov - 1 dic

Bangkok (Thailand)

GULF GLASS

4 dic - 7 dic

Dubai (UAE)

march 2023 - Forel News Page 8

Via per Monastier 4

Vallio di Roncade - 31056 (TV)

05 07 sales@forelspa.com

ITALIA +39 0422 84

Forel Spa Unipersonale