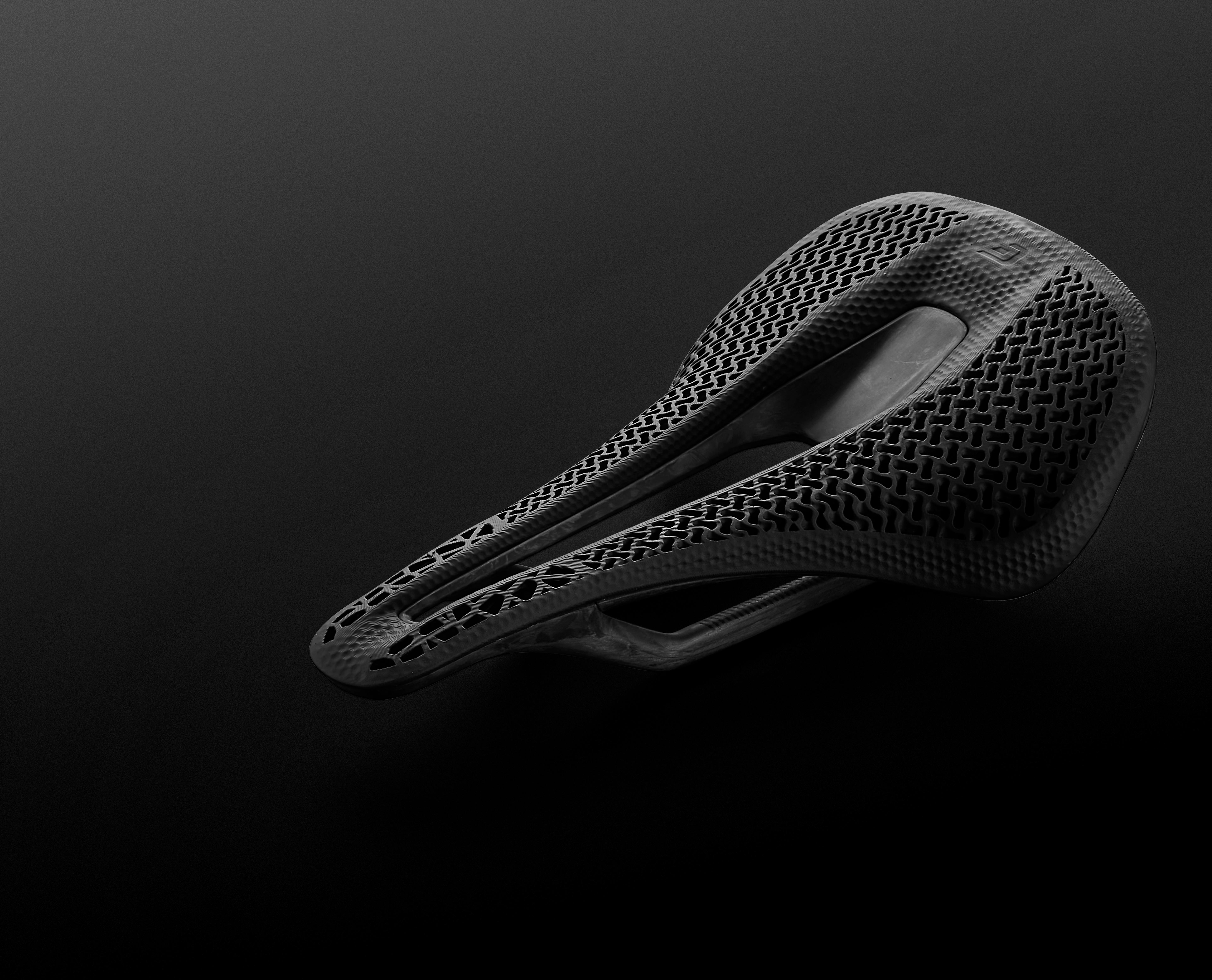

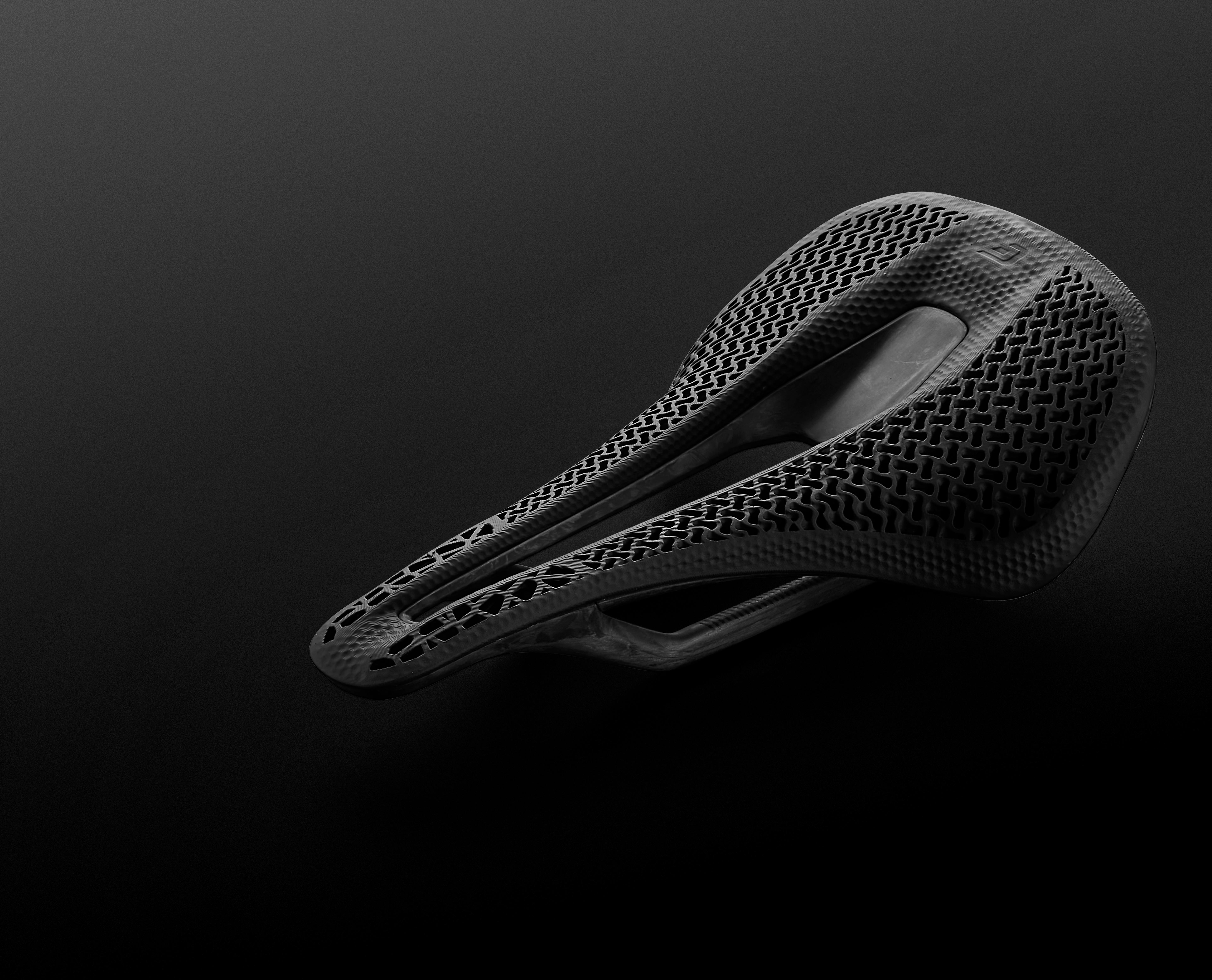

The Amp 3D saddle combines cutting-edge 3D-printed G3D gyroid infill with an ultralight carbon base for unmatched comfort, efficiency, and performance. Its precision-tuned Advanced Forged Composite structure optimizes pressure distribution, minimizes weight, and absorbs road vibrations for a smoother ride. Designed for maximum power transfer and durability, the Amp 3D delivers the perfect balance of support and speed.

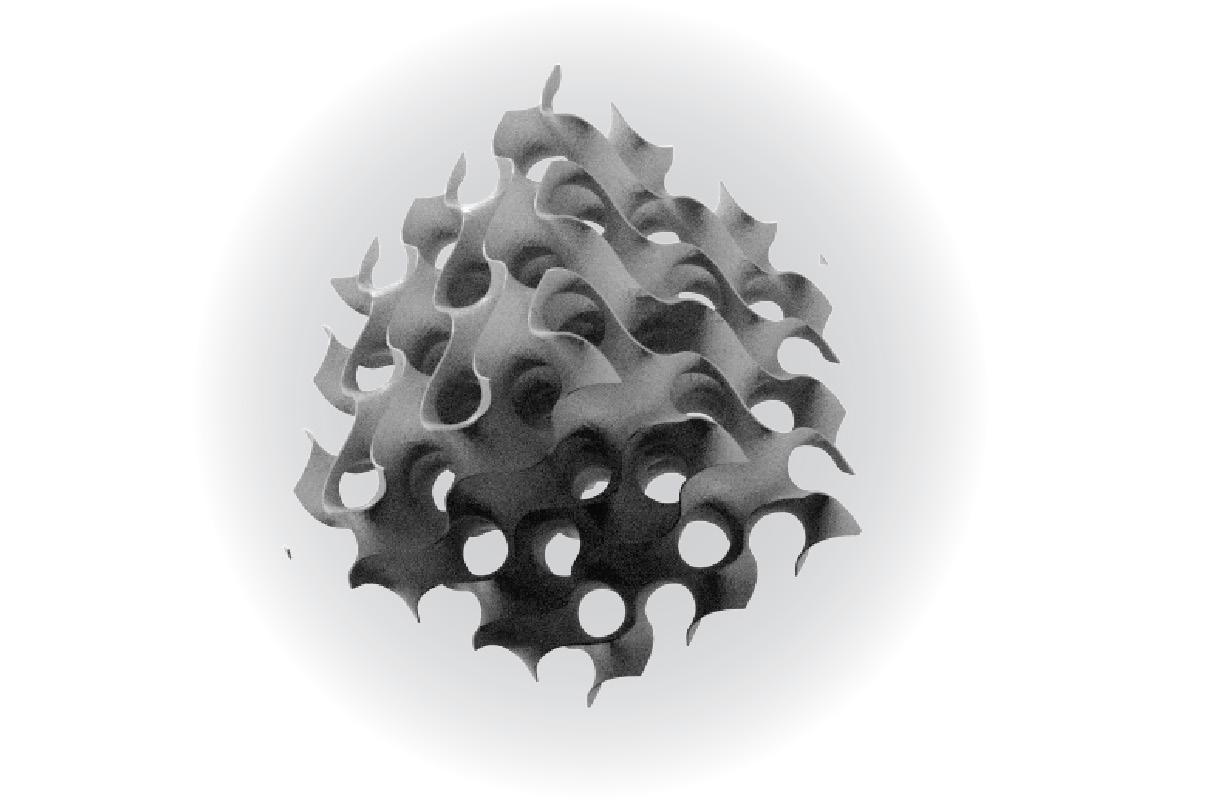

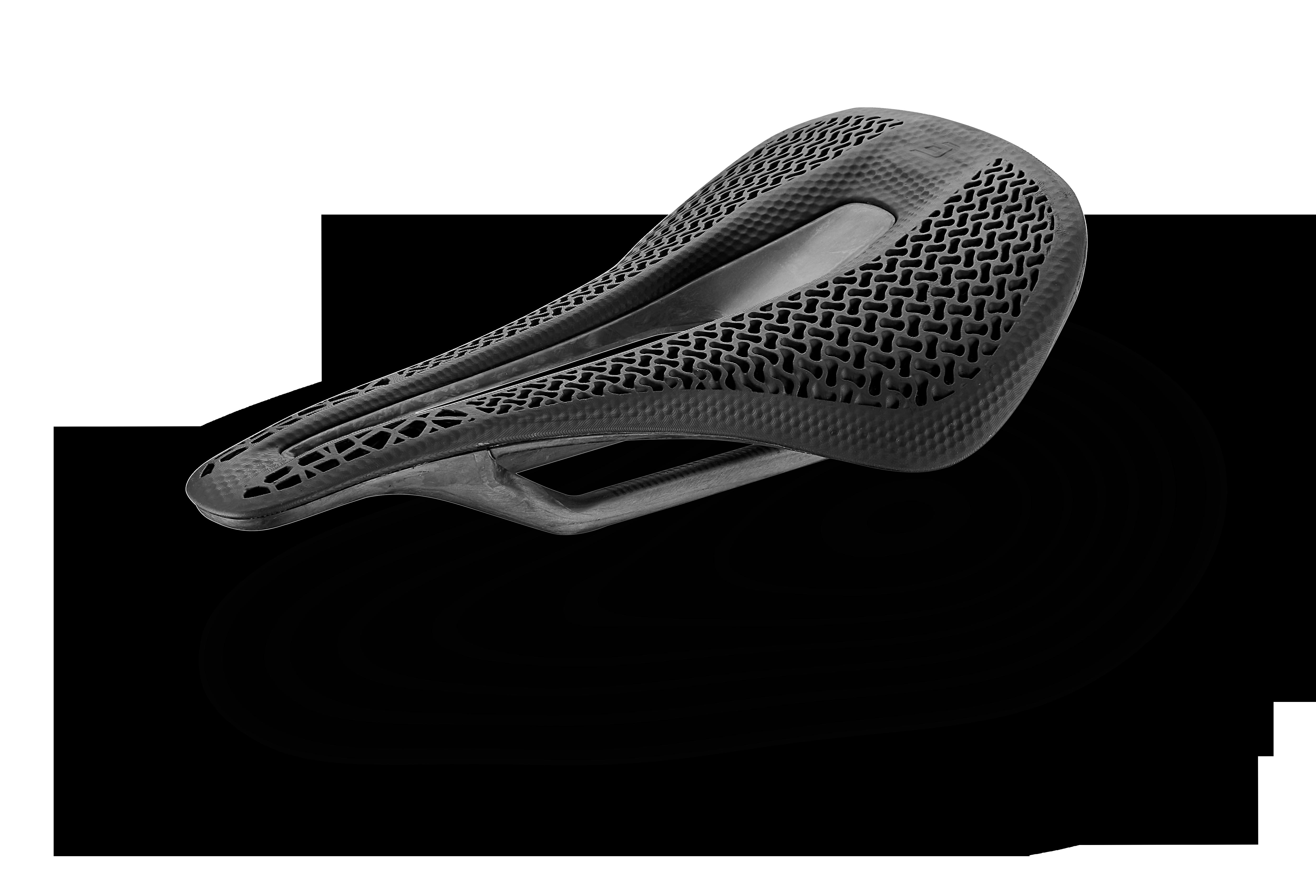

The Amp 3D saddle builds on the ultralight, one-piece Advanced Forged Composite base and ergonomic shaping of the acclaimed CADEX Amp saddle, enhancing comfort with precision-tuned G3D 3D-printed gyroid infill in the main support zone. This advanced structure features an intersecting 2D wavy line pattern that forms a strong yet lightweight framework with a superior strengthto-weight ratio compared to traditional grid or hexagonal infill. By distributing load and stress evenly in all directions, it ensures consistent support and durability.

GYROID STRUCTURE

3D printed gyroid structure features intersecting 2D wavy lines that form a strong yet lightweight framework with a superior strength-to-weight ratio over other 3D printed patterns.

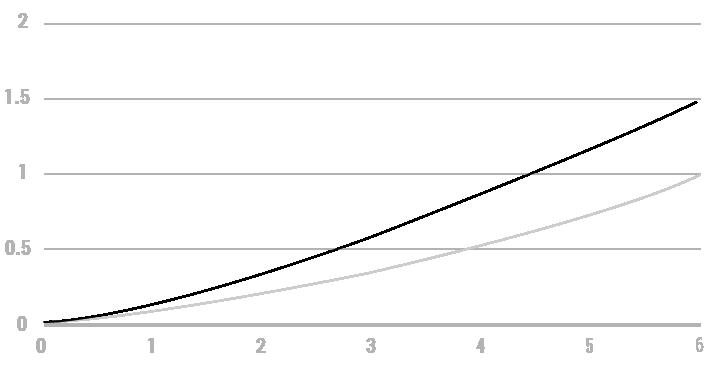

This test evaluated the structural strength and support performance of 3D-printed gyroid and hexagonal test pads. Both structures were printed using the same EPU material, with identical dimensions, weight, and controlled print settings to ensure consistency. A compressive force was applied using a stiffness testing machine, gradually increasing while recording the corresponding deformation.

Results showed that the gyroid test pad required 1.5 times more force than the hexagonal test pad to reach the same level of deformation. This indicates that the gyroid structure offers superior strength and support compared to the hexagonal design while maintaining the same weight.

FORCE (N)

DEFORMATION (MM)

Gyroid Pad Hexagonal Pad

The gyroid structure withstands 1.5x more force before deformation than the hexagonal structure

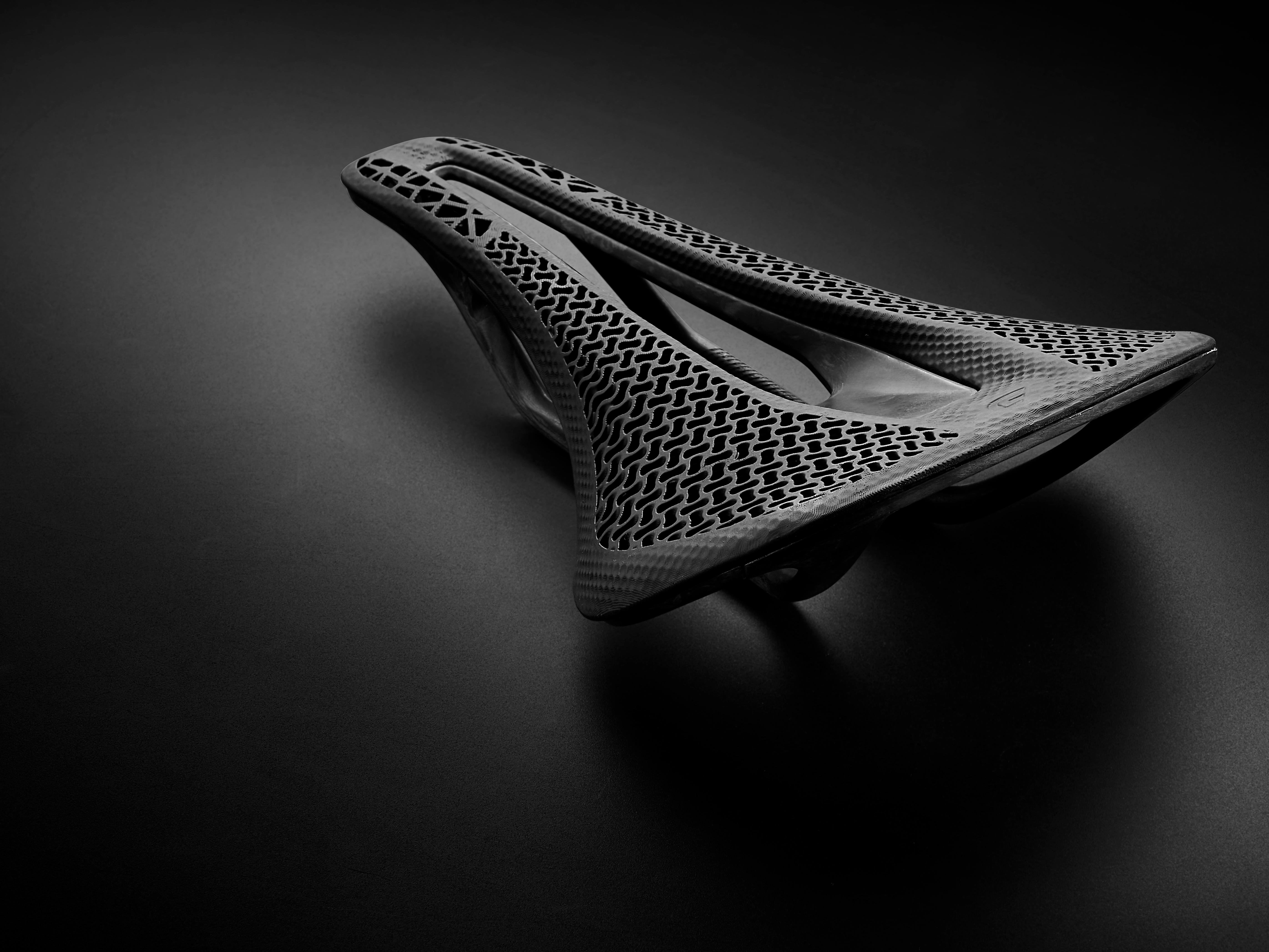

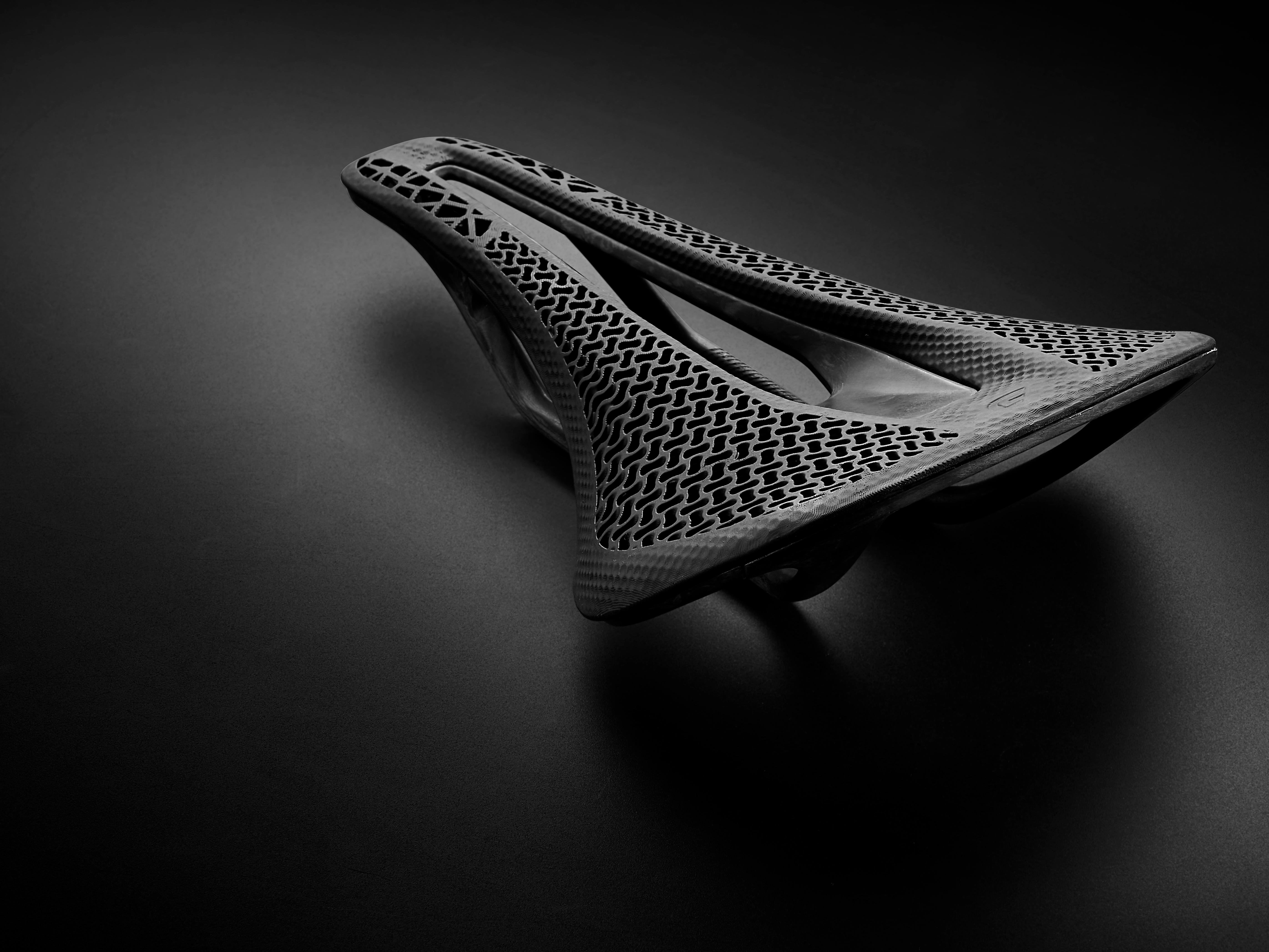

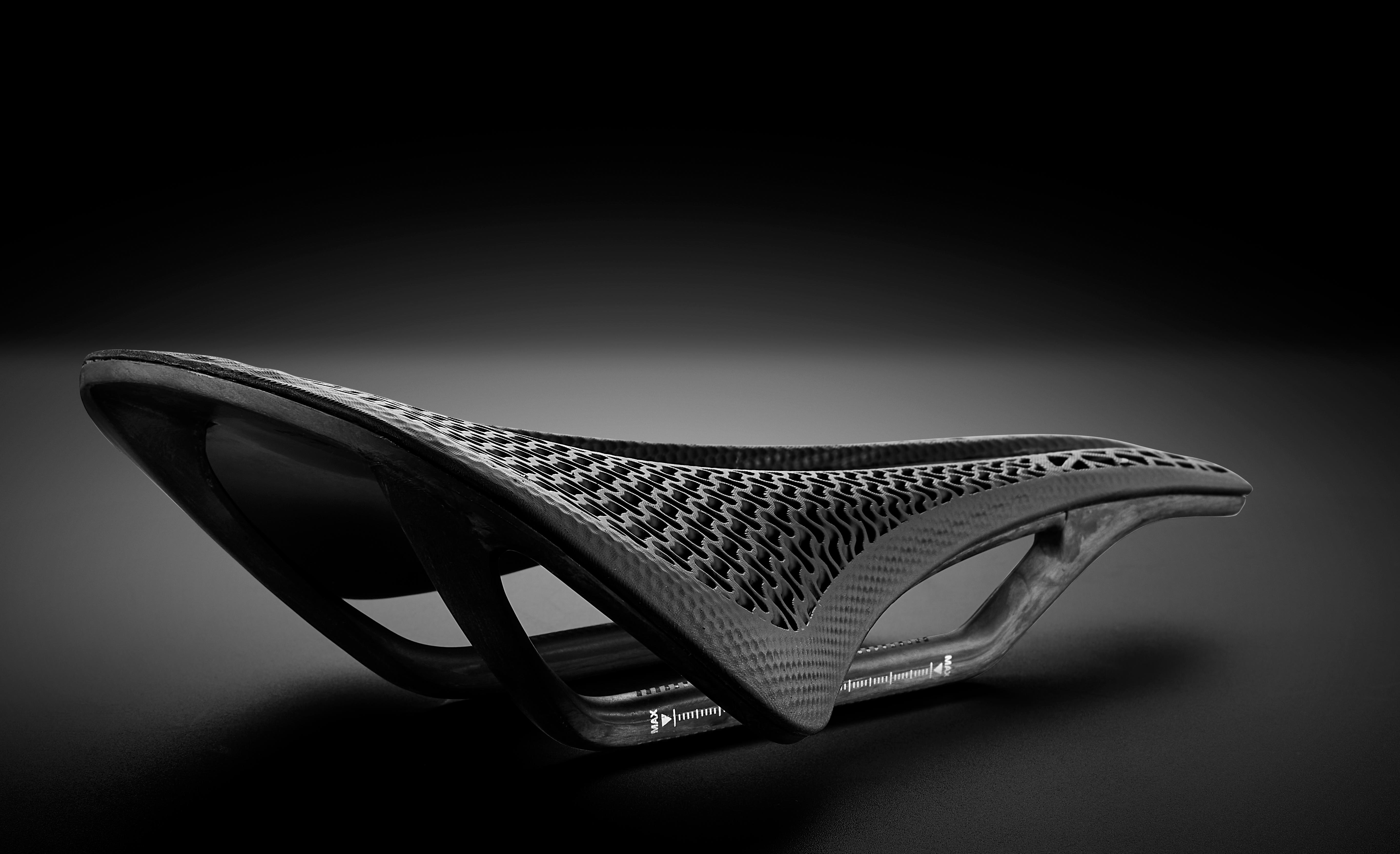

Amp 3D Upper

Nose Zone (Lattice Structure)

A lower-density lattice of AI-generated shapes provides compliance and adds cushion to the nose of the saddle while still maintaining a light weight.

Main Support Zone (G3D Gyroid Structure)

The G3D upper refines comfort by allowing precise variations in padding density, creating a seamless transition between pressure zones for a more natural, adaptive ride.

The firm center section provides a stable, supportive platform for powerful, efficient pedaling in an aggressive position, minimizing energy loss. As the rider shifts weight backward, the padding gradually transitions from medium to soft, cushioning the sit bones and reducing pressure points for lasting comfort.

Engineered for peak performance, G3D infill structure provides uniform strength and material properties in all directions across the main support zone, ensuring superior pressure distribution and eliminating discomfort. This optimized support minimizes pressure points, enhancing pedaling efficiency and comfort.

Advanced Forged Composite Technology creates an ultralight carbon base with integrated rails that reduces flex while remaining compliant, effectively absorbing fatigue-inducing road vibrations. Additionally, the saddle’s crowned shape, with rapidly dropping wings and a lower-seated base, increases pedaling space for friction-free power transfer, maximizing efficiency and control.

Weighing just 147g, the Amp 3D sets a new standard for lightweight performance in 3D-printed saddles. The precision-engineered G3D infill minimizes material use while delivering targeted support and cushioning exactly where it’s needed. Meanwhile, a slightly heavier hexagonal honeycomb structure reinforces the outer edges as a lattice of AI-generated structures covers the nose section, enhancing durability and ergonomics without compromising weight savings. This strategic combination of advanced materials and cutting-edge design makes the Amp 3D the ultimate choice for riders seeking the perfect balance of comfort, efficiency, and ultralight performance.

KEY TECHNOLOGIES

The Amp 3D saddle combines cutting-edge 3D-printed G3D gyroid infill with an ultralight carbon base for unmatched comfort, efficiency, and performance. Its precision-tuned structure optimizes pressure distribution, minimizes weight, and absorbs road vibrations for a smoother ride. Designed for maximum power transfer and durability, the Amp 3D delivers the perfect balance of support and speed.

• Exclusive Gyroid Structure – High-resilience EPU 3D-printed padding integrates a cutting-edge gyroid design, delivering superior pressure distribution, enhanced support, and maximum comfort at minimal weight.

• Precision-Tuned G3D Padding –3D-printed gyroid infill padding allows precise variation in density across the center of the saddle, optimizing support and comfort in key pressure zones while keeping weight to a minimum.

• Optimized Performance Shaping – A crowned profile that quickly drops away at the wings increases pedaling space, improving fit options and reducing clearance issues.

• Smooth-Edge, Truncated Nose – Minimizes inner thigh interference for unrestricted pedaling motion.

• Advanced Forged Composite Technology Base – A low-seated, SMC carbon base eliminates flex, enhances support, and maximizes pedaling efficiency.

• Integrated Rail Design – Relieves pressure points while improving compliance for a smoother ride.

• Ergonomic Center Cut-Out – Reduces pressure on soft tissue areas for long-lasting comfort.

• PRECISON-TUNED CADEX G3D TECHNOLOGY

• ADVANCED FORGED COMPOSITE TECHNOLOGY

• INTEGRATED RAIL DESIGN

G3D GYROID 3D PRINT TECHNOLOGY

3D-printed gyroid infill padding allows precise variation in density across the saddle, optimizing support and comfort in key pressure zones while keeping weight to a minimum.

ADVANCED FORGED COMPOSITE TECHNOLOGY BASE

A state-of-the-art high-pressure molding process, used to produce complex-shaped carbon composite components, creates a unique two-piece SMC carbon composite base that yields the perfect balance of support and comfort.

INTEGRATED RAIL DESIGN

Relieves pressure points by positioning the saddle rail connections to the base in an area that’s not a contact point for riders. The shape of the rails also helps dissipate road vibration. And weight is minimized by eliminating the overlapping joint area that’s normally used for saddles.