In this issue:

COMBUSTIBLE

DUST SAFETY

IN GRAIN MILLING: Past, present, and regulations

- IAOM ACE 2024 - An intersection for milling interests in Utah - Revolutionising roller mills

- Measuring pellet quality

- Mycotoxin Testing for Millers

Milling and Grain . Volume 135 . Issue 5 . May 2024 millingandgrain.com May 2024 Proud supporter of Download the Milling and Grain app to your smart phone YOUR GLOBAL PARTNER Volume 135 Issue 5

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

FLOUR MILLING

38 IAOM ACE 2024 - An intersection for milling interests in Utah

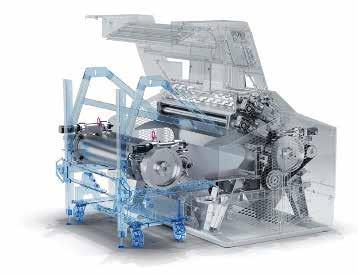

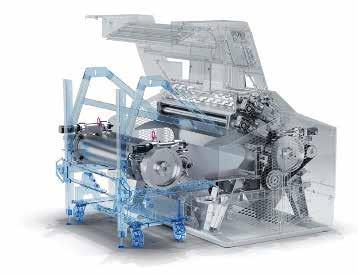

54 Revolutionising roller mills

62 Measuring pellet quality

66 Mycotoxin Testing for Millers

70 Leading with legacy STORAGE & HANDLING MAXIMISED 74 Combustible dust safety in grain milling

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 1242303792 darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286

dantef@perendale.com

Latin America Marketing Team

Cristina María Roldán Otero

Tel: +44 1242 267700

cristinaot@perendale.co.uk

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Social Media Journalist’

David Harvey davidh@perendale.com

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager James Taylor jamest@perendale.co.uk

Circulation & Events Tuti Tan tutit@perendale.co.uk

Development Manager Antoine Tanguy antoinet@perendale.co.uk

millingandgrain.com

ISSN No: 2058-5101

©Copyright 2024 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com

Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global

8 10 24 31 32 35 82 84 90 102 108 111 112 114

Miller’ news service Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 MAXIMISED

THE PUBLISHER Milling News Gems

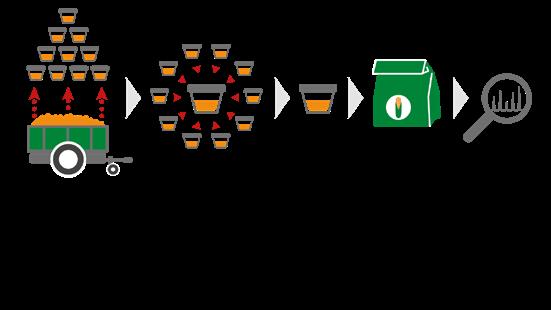

Archive Mill TRAINING FOCUS Product FOCUS Special CASE STUDY

INDUSTRY EVENTS PEOPLE 20 Mildred

Mills

Trust, UK 16 Andrew Bourne, Bourne Recruitement, UK 10 www.millingandgrain.com Find out more at: YOUR GLOBAL PARTNER VOLUME 135 ISSUE 5 May 2024

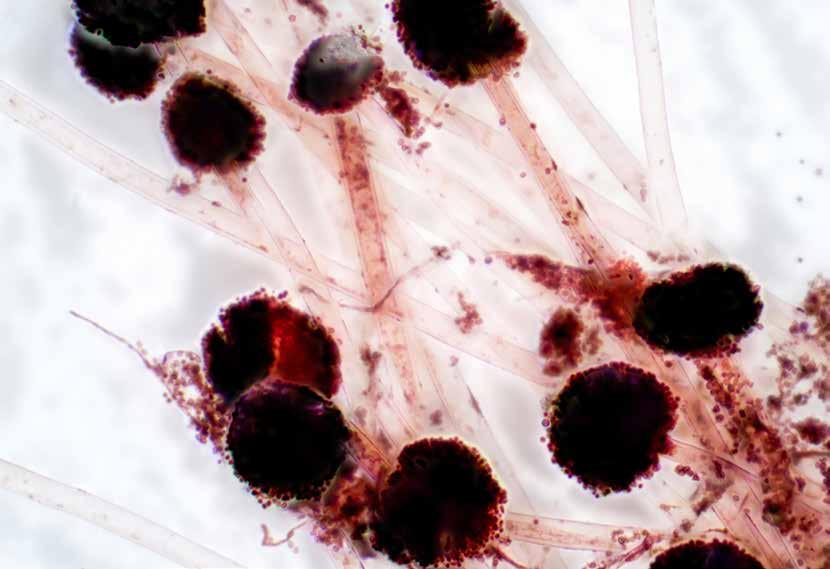

from the Mills

Commodities

Cookson,

Archive

Regular items Feature content

Industry Profile CHARITIES DIRECTORY the interview

THE PUBLISHER

It’s been another busy month for our Milling and Grain team - and the evidence of that is presented within the following pages, as we report on a wide variety of subjects and activities.

What, you may be asking, could be more relaxing than putting together an edition of a Milling and Grain magazine? Almost anything else would be my retort!

Roger Gilbert

All the excitement that comes with reviewing topics, consulting with authors and deciding which stories and features to run with and which to hold is just one aspect of the job.

However, in addition there are ongoing social media requirements, websites needing updates along with the compilation and publishing of weekly e-Newsletters for a discerning readership.

Oh, I’ve overlooked the work we have to do to get the edition laid up, translated and published into its six languages - and for all editions to then be uploaded to their respective Apps without overlooking the printer’s role and that of the mailing house to deliver copies to our ever-widening readership base for our printed versions.

Time to relax? Hardly

Keeping up with fast-moving industries, such as those in the milling sector, is the challenge we face every day. All our team, including our contributors. have to be committed to the cause and they are. We stand by our motto to publish in a Timely, Relevant and Visible manner daily.

We are not finished work yet. In the month we publish three other publications in the food production industries – two for aquaculture and one for petfood - all within an editorial team of 10. And we are equally committed to serve these industries.

Finally, throw into the above mix, the six events we have attended already this year and our workload is further expanded.

However, I believe magazines do much to support the industries they serve and play a vital role in identifying and encouraging, in our case, food producers to overcome the challenges they faces in meeting the goals of food security, food safety and food affordability for all.

IAOM ACE 2024

These goals are achieved not only by reporting on key topics and highlighting developments, but also meeting the people and the companies behind the innovations that the industry relies upon to move ahead.

For example, the most recent event we are attending typifies the exchanges needed between individuals in the supply chain and those in the production sectors of milling.

That was the IAOM ACE 2024 event held in Salt Lake City in midApril for the flour milling sector.

For the feed milling sector, we have also cover the co-located Victam Asia and VIV Health and Nutrition Expos, which were held in Bangkok, Thailand in our March and April edition; and we report specifically on the ‘Build My Feedmill’ event which we co-hosted

MILLING AND GRAIN | MAy 2024

with VIV at the latter event.

What is unusual in this edition is the way we are now reporting on the shows we visit to provide our readership with greater insight and relevant information.

For example, we take many pictures of exhibitors and their booths. In the past only a proportion have been published, although many have been posted through our social media during the event. We are slightly changing that approach.

We will publish all images that we undertake to do with exhibitors at the shows we visit.

In the April report on the GEAPS 2024 event in Kansas, USA we published 32 images, highlighting what we felt were the key development on display at the show. While the report talked about the show overall and the experience from a visitor point-of-view, we felt the pictures of the exhibitors we visited should contain information a little more about their respective technologies.

At the recent IAOM ACE 2024 show we took some 60-plus images - too many to publish in print, but possible in our digital editions. Therefore, you will find in our print magazine those images we feel warrant special mention while in the digital version of the magazine we publish all the images we took.

So, if you are exhibiting at an international event that Milling and Grain is attending, and you haven’t been interviewed by one of our staff, please be sure to stop us and talk to us. We will be happy to learn about your specific product being presented at the show and to reference that in our report using a picture-and-caption approach.

We will highlight one or two images that we feel are standout features of the event.

Please let me know how we are doing and where we can improve!

Elsewhere in this edition

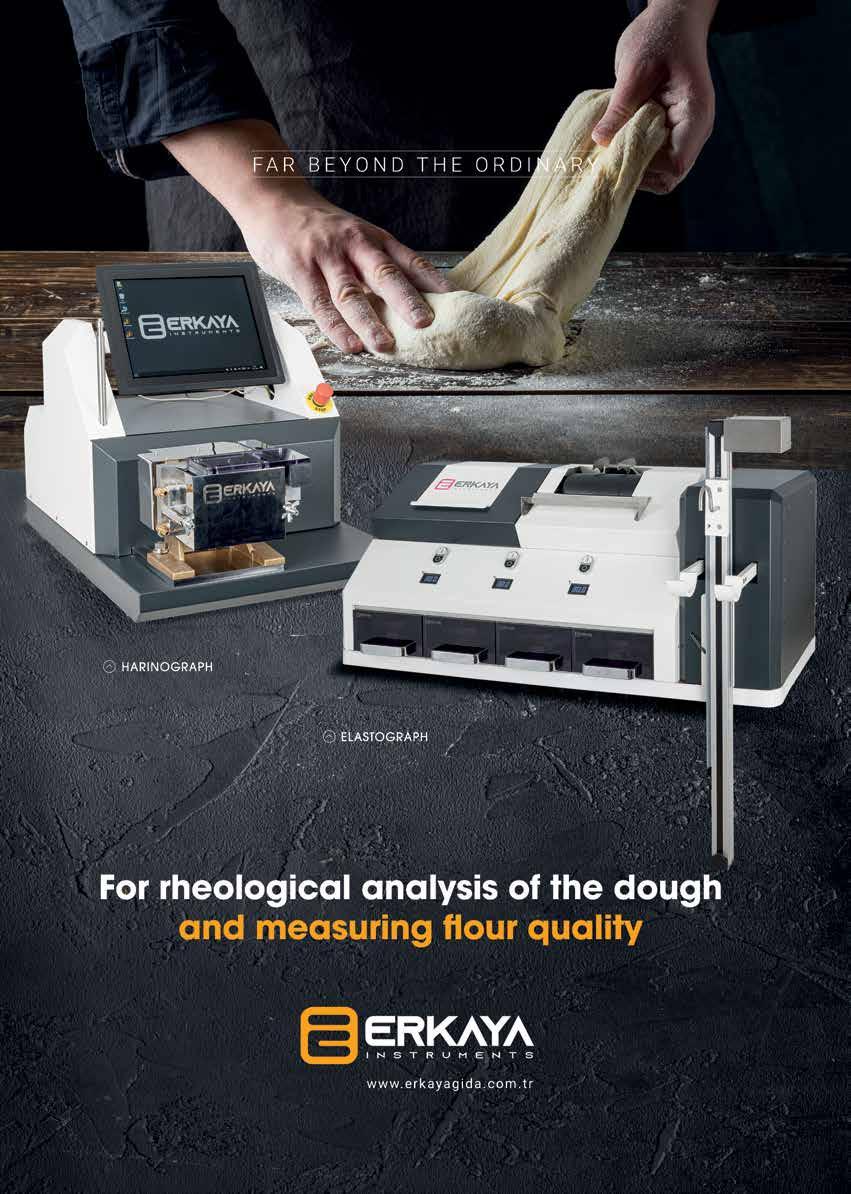

Besides our show visit reports, we feature the Swisca company and it’s brand new roller mill in a feature entitled ‘Revolutionising roller mills’ (page 54) prepared by our owner staff member Darren Parris.

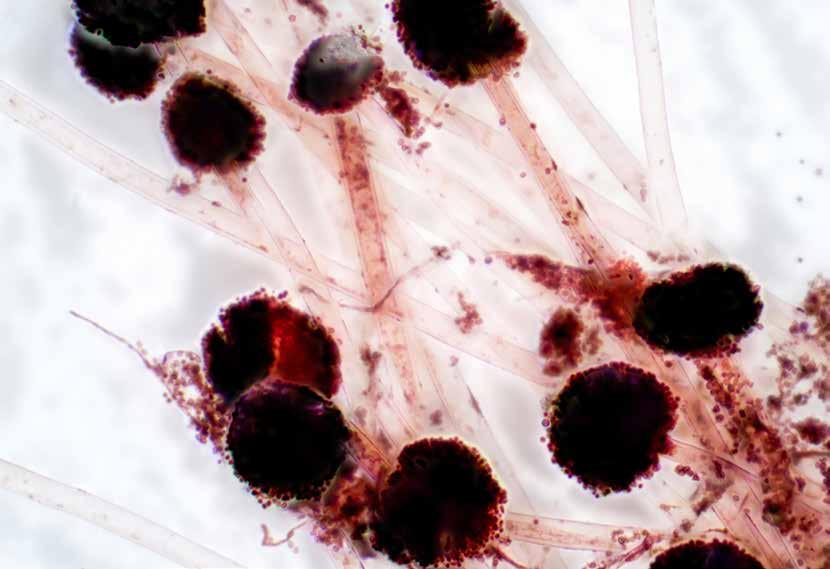

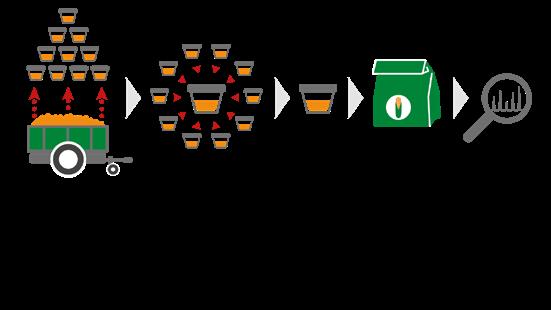

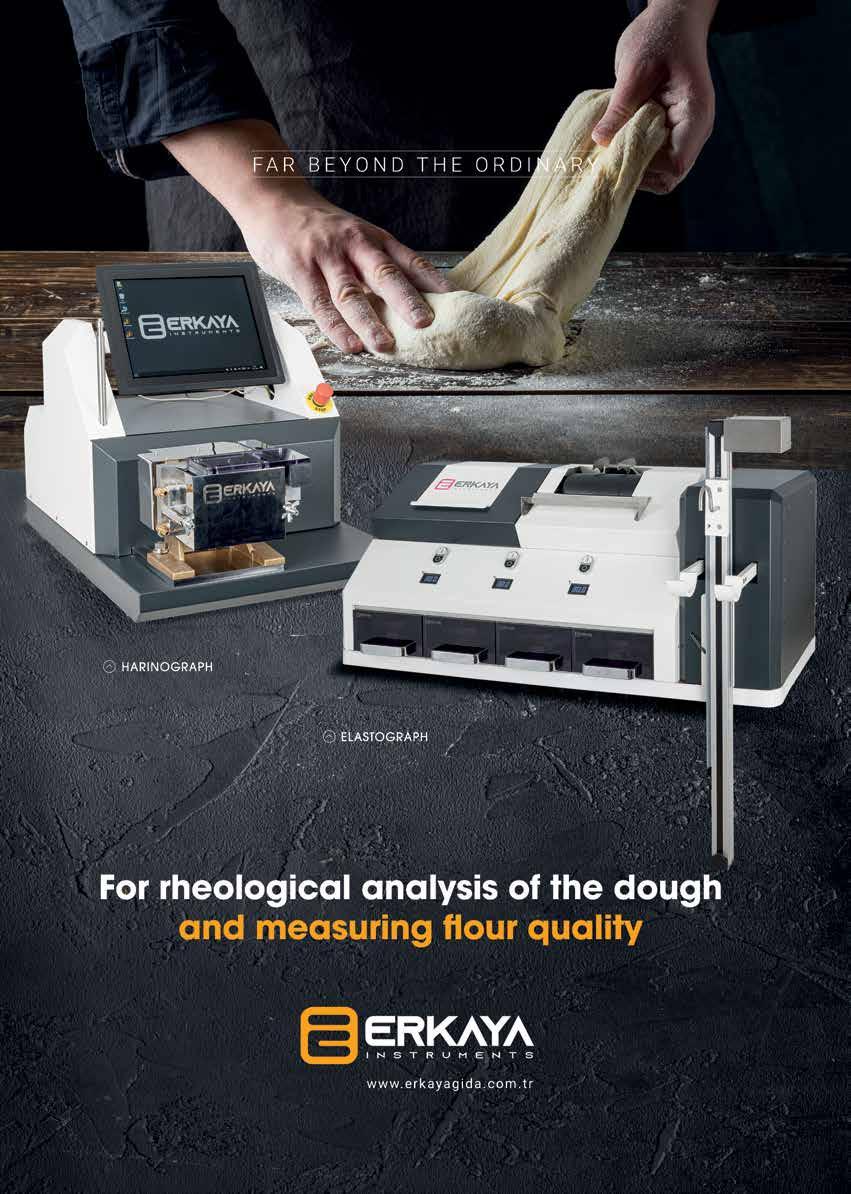

For our feed milling readers, we highlight ‘Pellet durability …’ and a test device that is providing an ideal solution to this aspect of production (page 62). And following that article we look at a topic that covers all those milling grains and cereals in a feature on ‘Mycotoxin testing for Millers’ (page 66) by Anneliese Mueller a technical expert at dsm-firmenich’s Animal Nutrition and Health division in Austria.

On page 70 you will find a feature on ‘Leading with legacy’ by Marcel Franitza, the Industry Director Animal Feed, at Andritz Feed and Biofuel while Jim Peters the Central States Regional Manager at Boss Products, in the USA reports on ‘Combustible dust safety in grain milling’ (page 74).

Don’t overlook our regular sections and our columnists. There is much in these sections to consider and reflect upon.

Enjoy the edition!

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information www.millingandgrain.com http://gfmt.blogspot.co.uk Milling and Grain has a cooperative partnership with COFCOET

8 | May 2024 - Milling and Grain

Greg Liu, Vice Chairman of Famsun speaks to Roger Gilbert, publisher of Milling and Grain magazine, at the 2024 edition of IPPE, in Atlanta, Georgia, USA.

Mr Liu shows us around the Famsun stand where the company has displayed two 3D-printed models of its extruders and pellet mills, to give their customers an idea as to how their equipment works internally. He tells us how the international market in the past year has been good for business, with petfood production growing by 40 percent year-on-year (and in China more than 60 percent). Famsun’s new developments are focusing more research on automation and AI.

mymag.info/SJyH

Interview with Simon Kolb - IPPE 2024

Simon Kolb, Projecting & Sales Manager for Frigortec speaks to Roger Gilbert, Publisher of Milling and Grain magazine, at the 2024 edition of IPPE Expo, in Atlanta, Georgia, USA.

Simon tells us about the importance of grain storage, and how his company’s cooling systems helps maintain and even improve the quality of grains in storage by managing the moisture and temperature levels as desired by the customer.

According to the FAO, approximately 20 percent of the grains harvest worldwide each year are wasted during storage – this amounts to around 40-45 million tonnes annually. Frigortec’s cooling technology can be applied to all kinds of storing processes and works intelligently to determine what to do with the moisture content on site. Operating worldwide, in approximately 100 countries, the company has a large distribution network, and finds the expo at IPPE to be a valuable event to connect with customers and explain the operation of its ‘Granifrigor’ grain cooling unit.

mymag.info/MmZQ

Welcome to the fifth edition of Milling and Grain magazine, and the fifth instalment of Global Miller this year. We’re in the middle of Spring now and beginning to feel things warm up. It’s almost time to hang up the scarf and gloves and grab the sun-cream ready for summer, but we still have another month to go for that.

Mentioning summer, we start May off in the European countries with May Day, that according to ancient origins, used to symbolise the beginning of summer. If you stand outside now without your scarf then you can likely tell that it’s not that hot season just yet from the chilly weather. It’s believed that May Day is also associated with the ancient Roman festival Floralia, dedicated to the Roman Goddess Flora, goddess of flowers, vegetation and fertility.

Linking with the Roman Gods, whilst there is speculation, it is possible that the etymology of the month May derives from the Roman Goddess Maia, mother to the God Mercury, and possible counterpart through Hellenisation to Greek Goddess Maia, mother to the God Hermes (Mercury’s counterpart). The Goddess Maia, both Roman and Greek, is fascinating as there is not a lot of information on her readily available. To figure out what she is a deity of is a little difficult as it isn’t very clear but most information points to her being connected to the Goddess of Earth, Gaia (Roman) or Terra (Greek). She is also known to be the

A note from our Editor

‘nursing mother’, a goddess of fertility, and more interestingly, fields. I’m not sure how true this is but it still seems exciting as it certainly would explain the link Maia would have to Gaia/Terra and Earth. It is incredibly fascinating learning how all the months and public holidays somehow tie into ancient festivals that then link back to farming in some way.

Speaking of farming, we have some news in this edition on how the UN has declared 2026 to be the International Year of Woman Farmer, an incredible show of recognition to our female farmers. We also mention how Cesco kicks off a new project in Cameroon and Depart Packaging Solutions announce their collaboration with Dolzan Packaging. Alongside this is how experts are mentioning that the grain sector is spurring new innovations in factory setups. In this edition you’ll read the latest on Milling and Grain’s adventures around the world, such as our report on VICTAM Asia 2024 and Health and Nutrition Asia 2024. We also have the very in-depth report for the 128th Annual IAOM conference that took place in Salt Lake City, USA. This report is super exciting for us so be sure to give it a read. Just a reminder for people that this month you can expect the Milling Hall of Fame Award on May 22 so expect to see our team there! If you’re going then let us now and we can take a picture with you for our socials!

In our March 2024 edition, we carried a feature (on page 46) entitled, ‘The Dirty Duo.’ We failed to provide a byline and source for the information contained which was pointed out to us by readers who were a little perturbed that they couldn’t associate the content of the article with a company nor an individual.

On reflection, we should have posted a panel explaining that this contribution would be controversial - and hence an unsourced Milling and Gain commissioned contribution - as it challenged some of today’s fumigation practices based on recent scientific findings around health and environmental impact. The article is worthy of discussion and has provided a view that should be considered and discussed openly.

The premise of the article asks some serious questions and proposes some alternatives that are worthy of discussion in order that we continue to protect grains from harvest, through storage and transportation to the mill while reducing the impact of fumigation has on the environment as well as responding to calls for calls to address food safety concerns. We accept the criticism and have learnt from this oversight.

10 | May 2024 - Milling and Grain

Milling News

Depart announced its collaboration with Dolzan Packaging

Depart Packaging Solutions expands its product range with new collaborations. Depart’s new collaborator Dolzan Packaging, has a wide range of automatic packaging machines and semi-automatic dosing machines which allows to package granular, powdery and liquid products in packages of different shapes and sizes. With its long experience accumulated in more than sixty years of history has allowed the company to become a point of reference for packaging of food and non-food products.

Depart’s General Manager Cengiz Tiryakioğlu made a statement regarding the agreement; “We have signed a new collaboration agreement with Dolzan Packaging which is one of Italy’s reliable, experienced and prominent company. This is our fifth business partner in packaging machine industry. Depart Packaging Solutions grew much faster than

we expected. We will continue to meet all the demands we receive worldwide with the most suitable machine systems.”

“As Depart packaging solutions we offer; shrinking machines, vacuum machines, customized vertical and horizontal flowpack packaging machines, depelletisers, carton formers, cartoning, automatic carton closers, palletisers, robot cells, strechwrappers, transports and many other solutions for producers. We have announced our brand in the packaging industry. So now its time to gain our product range in every packaging need.”

From now on, Depart will manage the sales and marketing of Dolzan Packaging machines. With its worldwide distribution network, after-sales services and high customer satisfaction, Depart Packaging Solutions meets the needs of all sectors that uses packaging.

12 | May 2024 - Milling and Grain Milling News

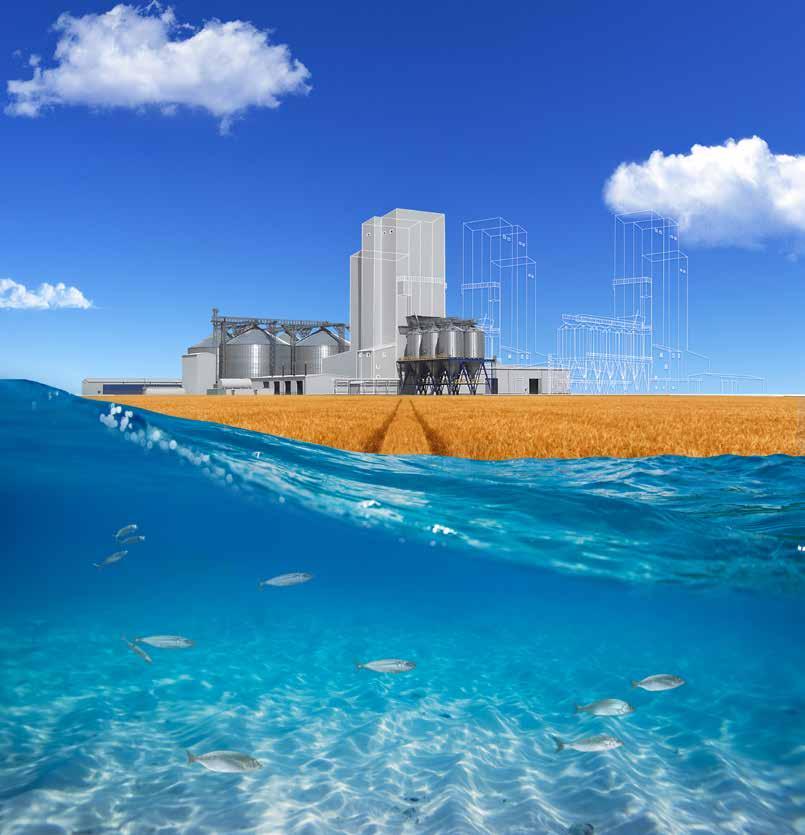

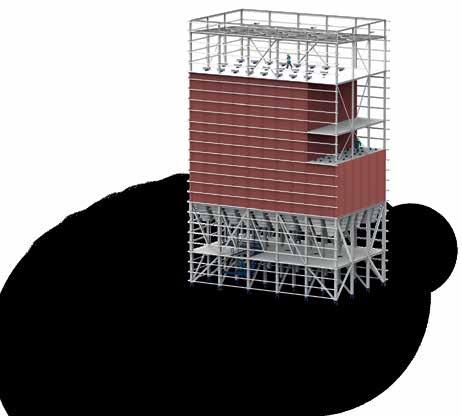

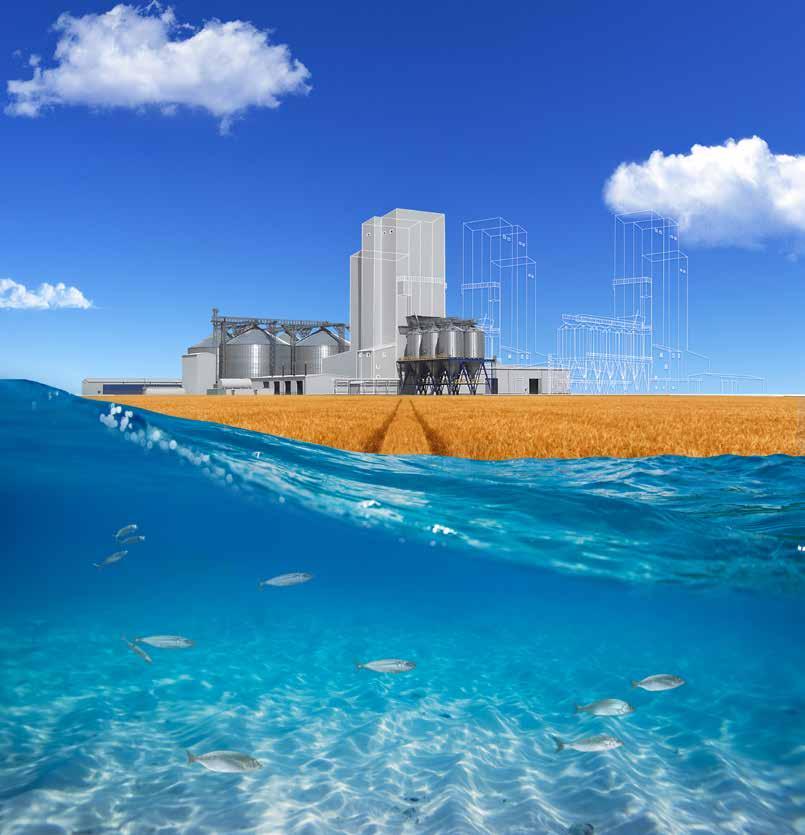

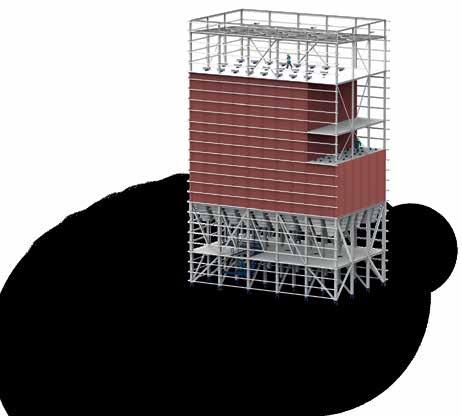

Grain sector spurs innovations in factory setup, says industry expert

The global grain industry is witnessing a remarkable surge in demand, notably for wheat and flour, driven by the burgeoning world population. As per Statista, wheat production has soared from 582 million tonnes in 2000 to a staggering 784 million tonnes by 2023, underlining the sector’s escalating significance in the global food supply chain.

Samet Taşkın, a distinguished member of Ortaş Mill’s board of directors, has provided insightful assessments concerning the grain sector’s trajectory. Taşkın underscored the pivotal role of flour and wheat consumption in historical contexts but highlighted contemporary challenges facing enterprises in establishing efficient production facilities.

“The protracted and arduous process of erecting a flour production facility has emerged as a paramount concern for enterprises,” Taşkın stated. “It not only entails substantial capital investment but also necessitates a profound accumulation of knowledge.”

In response to these challenges, Taşkın outlined Ortaş Mill’s innovative approach to streamline factory setup processes. “We specialise in crafting turnkey facilities within compact multi-story steel and concrete structures housed in hangars,” he elucidated. “Whether our clients require pre-

fabricated structures or comprehensive factory equipment, we provide end-to-end solutions, alleviating the burdens associated with installation.”

Taşkın emphasised the indispensable role of feasibility studies in ensuring the seamless establishment of flour production facilities. “Clients must articulate their demands accurately and prioritise comprehensive feasibility studies encompassing cost, quality, and post-installation support,” he emphasized. “By adhering to stringent quality standards and meticulous planning, we empower enterprises to optimise their production processes.”

Furthermore, Taşkın advocated for the modernisation of existing grain factories to enhance efficiency and embrace digitalisation. With nearly three decades of expertise, Ortaş Mill offers a spectrum of services encompassing consultancy, construction of steel structures, automation of production, and compliance with European Union standards.

“Our commitment to excellence extends beyond geographical boundaries, with our services spanning over 30 countries worldwide,” Taşkın affirmed. “As the grain sector continues its upward trajectory, we remain steadfast in our pursuit of innovation and excellence, anticipating a 15 percent growth in 2024.”

Get insights in the quality of the steam process

With the IVS Smart Steam Dosing Unit

Anticipating data facilitates predictive maintenance

Recommendations for optimisation

Increases user expertise of steam dosing

Insight into the quality of the steam network

www.ivsdosingtechnology.com info@ivs.nl +31(0)413 29 19 76 Milling and Grain - May 2024 | 15 Milling News

Retaining Talent in Flour Milling

Andrew Bourne, Bourne Recruitement, UK

Recruitment in the flour milling and grain sector is still facing issues about how to find and attract new talent into the industry. Whilst advancements in technology have hugely impacted plant efficiency, this has also contributed to a decline in the number of people working within the industry. The industry therefore finds it difficult to attract new talent, as the younger generation are attracted to modern new jobs that didn’t even exist a few years ago.

So, what can the industry do to retain and attract staff? One solution that I totally believe in is creating a company that has very strong values and does everything it can to create an environment where staff feel valued. If the company also trains and develops staff and gives them the tools to do the job itself, they are less likely to leave as they will feel valued and have job purpose. As I’ve always said, it’s not always about the money, particularly as you advance in your career the money factor isn’t the number one reason people quit. But from a candidate’s point of view, how can you make yourself stand out from the rest? I receive many CVs every day and unfortunately have limited time to focus on everyone. The way forward is for you to make yourself an asset to the company you currently work for and ensure you are trained to the very top level and that people in your industry know about you. Regardless of social media and the high-tech world we live in, word of mouth still counts for everything. I believe our industry is still a people-focused business where communication gets around. If I receive a phone call or an email from one of the industry leaders, I sit up and take note. This gets more attention than, for example, me receiving an email with your CV attached without context or recommendations.

I also believe that as a candidate, it’s good to have a CV and career where you have done something different. This can be that you’re fluent in another language or that you’ve worked overseas. If you open yourself up to other opportunities and take yourself out of your “comfort zone” this will make you stand out from the crowd.

Reduce costs and prevent risks Optimize your entire production chain Guarantee higher quality products BESTMIX® Feed Formulation, Quality Control, Ration Calculation and ERP solution. Scan to learn more: www.bestmix.com The most advanced software solutions for feed production: MAXIMIZE YOUR PELLET PRESS’S POTENTIAL WITH TAILOR-MADE DIES. At PCE, precision engineering meets custom design to produce dies that fit all pellet press models. Our dedication to quality ensures your operations are seamless, efficient, and high-quality. Our dies are essential for top-notch performance in feed, biomass, or any material pelleting. Elevate your pellet production now. Visit www.pce.eu www.pce.eu 16 | May 2024 - Milling and Grain Milling News

UN declares 2026 as International Year of the Woman Farmer

United Nations Linda Thomas-Greenfield and US Department of Agriculture Deputy Secretary Xochitl Torres Small, the UN General Assembly declared 2026 as the International Year of the Woman Farmer last week. The resolution, and the US government’s efforts to generate support for it, were spearheaded by USDA and garnered more than 100 co-sponsors, underscoring the global importance of uplifting women throughout the agriculture sector.

The worldwide observance will call attention to the vital role that women play in global food and agricultural production. It will also raise global awareness of the unique challenges women in agriculture face, catalyse action to help address those challenges and support many of the UN Sustainable Development Goals, including those focused on gender equity, food security and poverty.

“From the field to the factory, from the classroom to the boardroom, women are fundamental to the future of agriculture. As leaders, it is our responsibility to make sure the next generation of women farmers have equal access to economic, educational and leadership opportunities, and that we dismantle the unique barriers they

face so they can continue to take on the challenges of meeting the world’s growing food, fuel and fiber needs,” Deputy Secretary Torres Small said. “USDA is proud to have led the US government’s efforts in support of declaring 2026 as the International Year of the Woman Farmer, and we thank the many nations that signed on in support. We look forward to working with partners worldwide to scale up efforts that empower and advance women farmers while tackling global food security in 2026 and beyond.”

Women are responsible for roughly half of the world’s food production, and in many countries they produce between 60 and 80 percent of the food. Yet globally, the prevalence of food insecurity is higher among women than men. By shining a spotlight on women’s role in farming across the world, the International Year of the Woman Farmer will also raise awareness of constraints women face in areas including property rights and land tenure, access to credit and markets, and lack of technical and educational support. it will emphasise, as well, the importance of women in leadership roles to better ensure representation at the highest levels of decision-making.

Milling and Grain - May 2024 | 19 Milling News

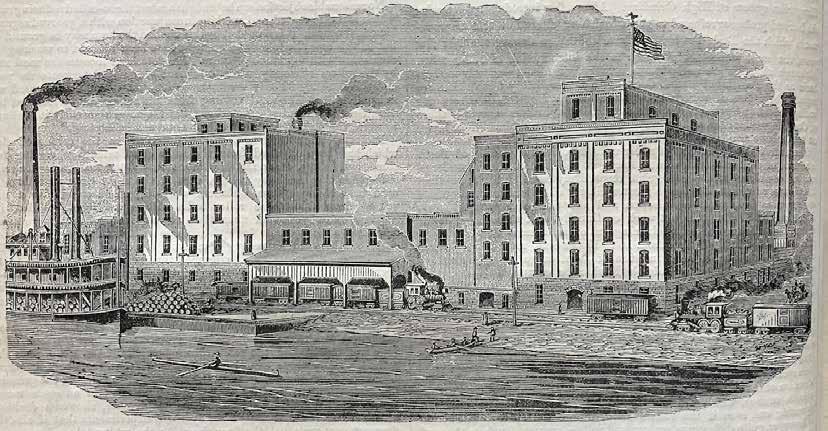

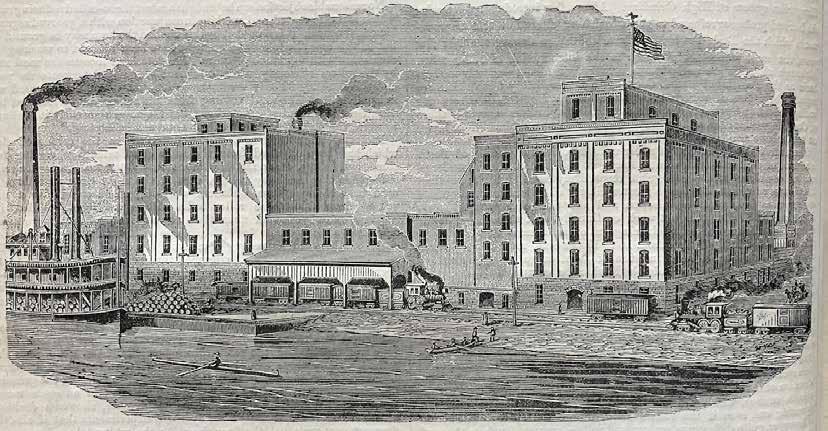

TThe Diamond Mills, Red Wing, Minnesota

Milling journals of the past at The Mills Archive

by Mildred Cookson,

Mills Archive Trust, UK

he Miller reported (4 March) that this mill was the most recent and complete flour mill to be built in the relatively young days of the roller mill revolution. Ten years previously milling in Minnesota was insignificant, but during 1877 mills in the state turned out flour valued over US$15,000,000, with Minneapolis alone manufacturing over a million barrels. Minnesota wheat was prized by millers as one of most valuable varieties and the flour was rated with the best in the US or any other country. By degrees, Minnesota millers had learned how to grind their wheat and the introduction of middlings purifiers soon demonstrated that wheat, which had formerly been deemed unfit for milling, possessed a strength that fitted it for producing the highest grades of flour.

In consequence of this discovery, mills arose as if by magic, and the culture of wheat became the leading community occupation. In 1878 it was estimated that the wheat crop of Minnesota reached the enormous amount of 40,000,000 bushels, larger than that of any other one state. Red Wing is the county seat of Goodhue County, situated on the Mississippi river about fifty miles below St Paul It was the largest primary wheat market in the world, receiving yearly about two and a half million bushels from farmers’ wagons alone. Red Wing aimed at becoming a great milling centre and, even by 1878, had a number of fine mills.

The Red Wing Mills Company was formed in 1873, when it built the mill illustrated known as “Bluff Mill”. It had eleven sets of burr stones, three sets of iron and four sets of porcelain rolls, along with all the necessary machinery for a first-class New Process Mill.

Connected with the Bluff Mill by a warehouse, with a capacity of 150,000 bushels was the splendid building just completed in 1878, the “Diamond Mills” which were notable as being the first attempt to introduce into the country the Hungarian half-high grinding system, the

The Diamond Mills, Red Wing, MN

Flour packing in the heyday of the wooden barrel

The Diamond Mills, Red Wing, MN

Flour packing in the heyday of the wooden barrel

20 | May 2024 - Milling and Grain

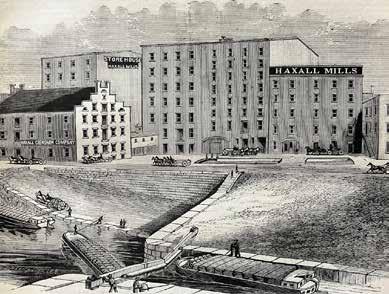

Haxall Mills, Richmond, VA

chief features of which were four or more grindings of the wheat, elaborate purification and the reduction of middlings to flour by means of rolls or of rolls and stones combined.

The plans for the mill were designed by Oscar Oexle, a celebrated civil engineer and millwright of Augsburg, Bavaria who had constructed some of the best mills in Europe and in 1877 visited America to introduce the Wegmann Porcelain roller mills. The millwright work was carried out by Gunn & Cross of Minneapolis.

Wheat cleaning was done in the five-storey warehouse adjoining the mill and separated from it by a brick wall, without openings, except for the shaft and wheat spout. The machinery was driven from the end of the engine shaft by a friction coupling which could be thrown on or off without stopping the mill. In here were two Eureka Smutters made by Howes and Babcock of Silver Creek New York; two Dustless Separators by Barnard & Leas; two graders for sizing the wheat; two pair of four and a half foot stones: two Victor Brush Scourers, and one Kurth’s Cockle Separator

The mill was heated by steam and lit by gas. All precautions were in place in case of a fire with a Knowles’ fire pump, standpipes with hose attachments on each floor and Babcock extinguishers and water barrels on every floor. The cost of the mill and wheat-cleaning department was around US$140,000.

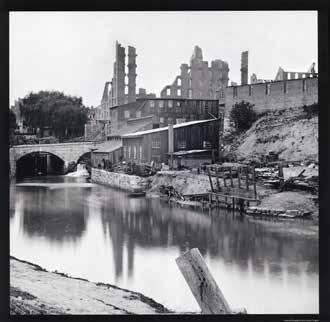

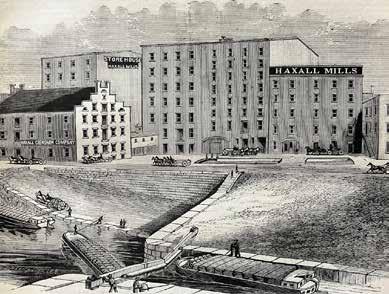

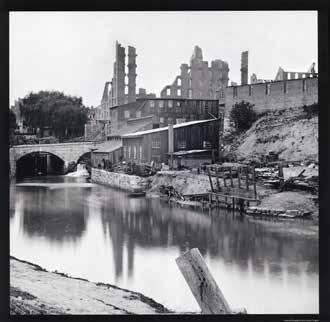

Haxall Mills, Richmond, Virginia

In April 1878 Haxall Mills in Richmond, Virginia was unique in having the largest number of millstones under its roof than any other mill in the United States. It was claimed that no southern state had displayed such energy in recovering from the prostration caused by the civil war as Virginia. Milling in Virginia had always

Milling and Grain - May 2024 | 21

Catalogue for Howes and Babcock smutters

pubblicità italiana_MOD.pdf 1 27/01/22 10:59

C M Y CM MY CY CMY K

22 | May 2024 - Milling and Grain

been considerable. Its capital, Richmond, was famous for the size of its flour mills and the excellent flour they produced. Destroyed during the war, the Confederates burned areas of Richmond on 2 April 1865 to prevent the Union Army from taking them. Gallego flour mill (illustration MCFC-WAR-USA-001) fell victim.

Even though most mills were destroyed by the war, by 1878 so many mills had been rebuilt that milling was once more a leading branch of industry. So much so that the exports for Richmond flour for shipment to its suburbs and South American ports alone frequently amounted to 10,000 barrels a month. At the forefront

was the Haxall Mills of Richmond.

As early as 1808 Philip Haxall and his brother William purchased the site on which stood a grist mill known as the ‘Columbian Mill”. Here in 1809 they erected the mill called by their name. Following successive additions and constant improvements, the mill appeared as in the 1878 engraving.

Although the Haxall Mills had been twice reduced to ashes, once in 1830 and again in April 1874, they have been rebuilt each time with additions and improvements. In 1831, the year of the first rebuild, Philip Haxall died and R Barton Haxall took over as head of the firm even though he was only 26.

The mill building illustrated was erected in 1874 at the end of 12th Street between the canal and St James River. The principal building was the flour mill proper, the wheat house, general storehouses, corn mill, blacksmith and wheelwright shops, millwright shop, cooper shops the residents of the millers and a large brick stable block.

The corn mill had six runs of Esopus stones, (conglomerate stone from the Hudson Valley), with a capacity of around 1000 bushels of corn per day. Only carefully selected white Southern corn was used. These stones were run by waterpower from six overshot waterwheels each 18 feet diameter as well three turbines, one by Leffel which drove the wheat cleaning machinery, a second one by Burnham drove the corn mill and the third made at Baird’s Foundry, Richmond drove the machinery in the millwright and repair shop.

Many types of flour were produced under various names, ‘Patent Family’, ‘Haxall’, ‘Crenshaw,’ ‘Padeiro’ extra, ‘Tremont’ superfine and ‘Orange’ fine. Some of these brands found their way to the West Indies, South America, Africa, Canada, Great Britain, and the continent.

We train the workforce of tomorrow. Expand your knowledge, exchange ideas and gain experience in our academies around the world. Let’s shape the future together. Scan the

Innovations for a better world. Milling and Grain - May 2024 | 23

Gallego flour mill, Richmond, 1865

QR code for more information. millingacademy@buhlergroup.com

Gems from the Mills Archive

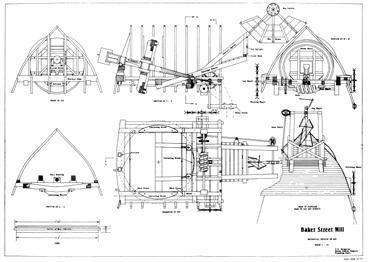

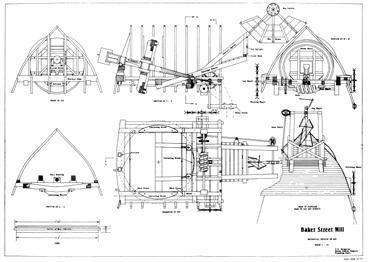

Drawing of Baker Street Mill

by Nathanael Hodge, Mills Archive, UK

The drawing shown here is one of over 200 architectural plans showing the structures of historic windmills in the UK, drawn by millwright Vincent Pargeter over the course of his career and now preserved by the Mills Archive.

This drawing shows Baker Street Mill in Orsett, Essex. This corn smock mill was constructed in the 18th century, and a steam powered mill was later built nearby. The windmill stopped working around the time of the First World War and gradually became derelict. By the 1960’s there was no roof left, and only one of the four sails remained hanging from the cap. It seemed the mill would not be around for much longer. It was at this time that Vincent Pargeter got involved. He was employed as County Millwright for the Essex County Council and was asked for advice on its repair. The owner, a local builder, had converted the steam mill into his home and now wanted to repair the windmill. He had erected scaffolding and removed the remains of the cap and sail. These were laid out and roughly reassembled on the ground, so that Vincent Pargeter could measure and draw them. Although they were rotten and falling apart, he was able to work out what each part was and how they related to each other, and thus produce this drawing showing how the mill would have worked. The drawing was then used by the restorers to create a new cap and sails.

The mill was eventually fully restored, and then converted into a house while retaining the historic machinery that had survived. The plans that Vincent Pargeter made, together with his photographs and accounts of his work have been preserved by the Mills Archive as an invaluable record of the history of this building.

www.millsarchive.org

24 | May 2024 - Milling and Grain

If you can think it, we can pack it!

With over 150 years of combined experience, we help you find your individual packaging solution. Over the years, we have developed machines that cover a range of weights from 50 grams to 25 kg for flour based products. In addition, we help you meet global environmental challenges without compromising on performance.

Let’s create your perfect flour packaging solution!

The Packaging Group GmbH · Germany · www.tpg-packaging.com

Visit us online at www.perryofoakley.co.uk sales@perryofoakley.co.uk +44 (0)1404 890300 Perry of Oakley Ltd. The UK’s Most Experienced Manufacturer of Bulk Drying, Handling & Storage Equipment Twin Trace Conveyors | Belt Conveyors | Screw Conveyors Flat Bottom & Hopper Bottom Silos | Square Bins 26 | May 2024 - Milling and Grain Milling News

Cesco kicks off a new project in Cameroon

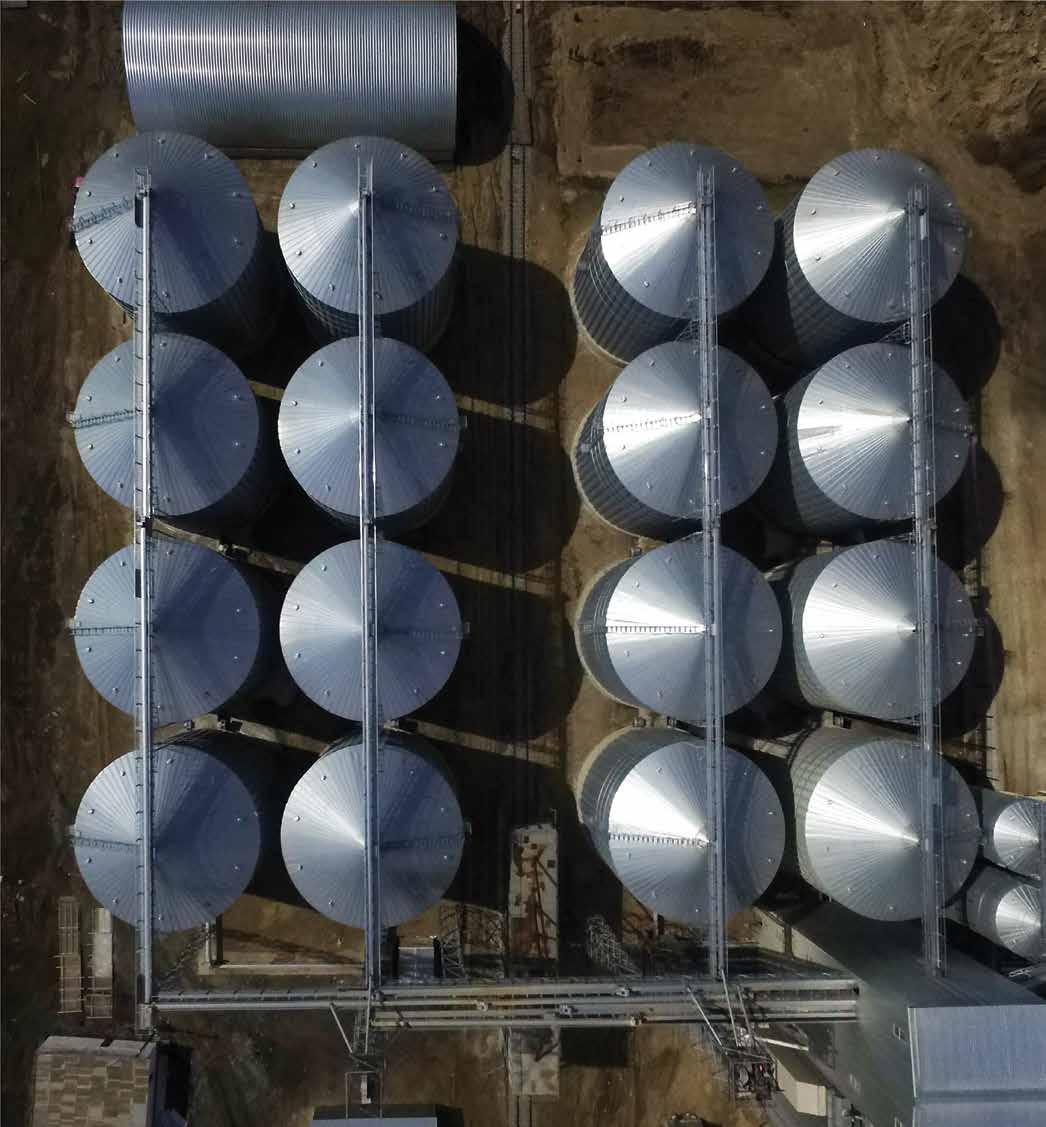

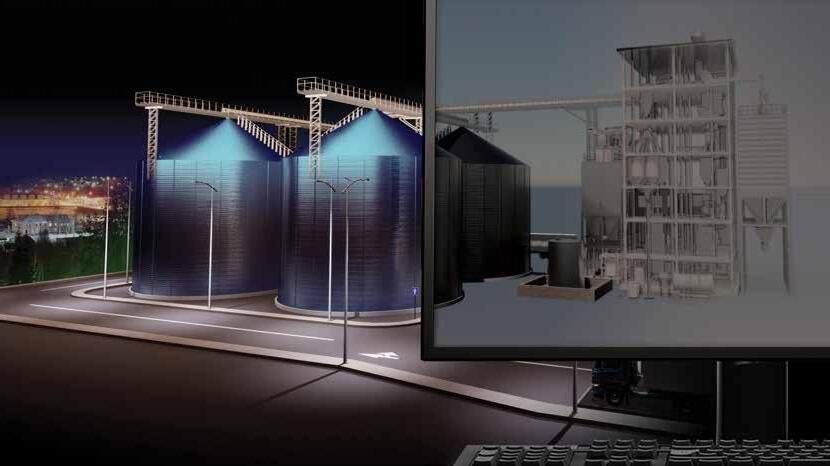

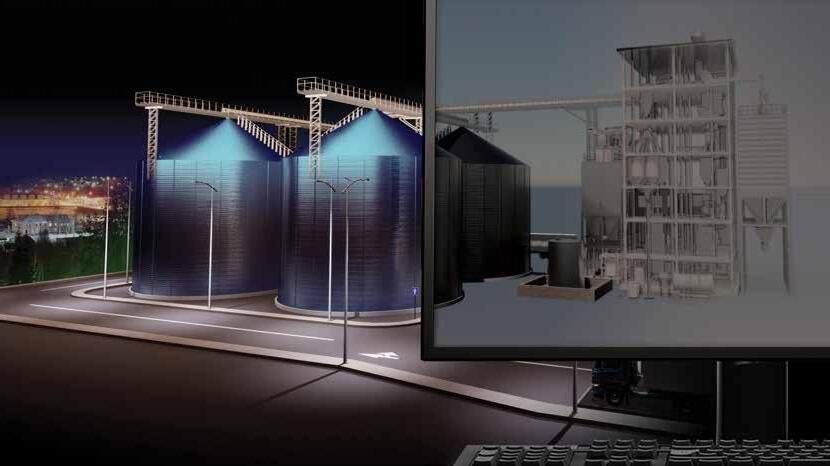

Cesco begins a new project in Cameroon, in collaboration with a German company with international operations specialissing in designing and supplying industrial plants for grain storage and handling, a leading European company responsible for processing equipment, and the investor Société Camerounaise de Transformation de Blé (SCTB SA), a company specialised in wheat processing and its derivatives, playing a pivotal role in Cameroon’s agro-food industry.

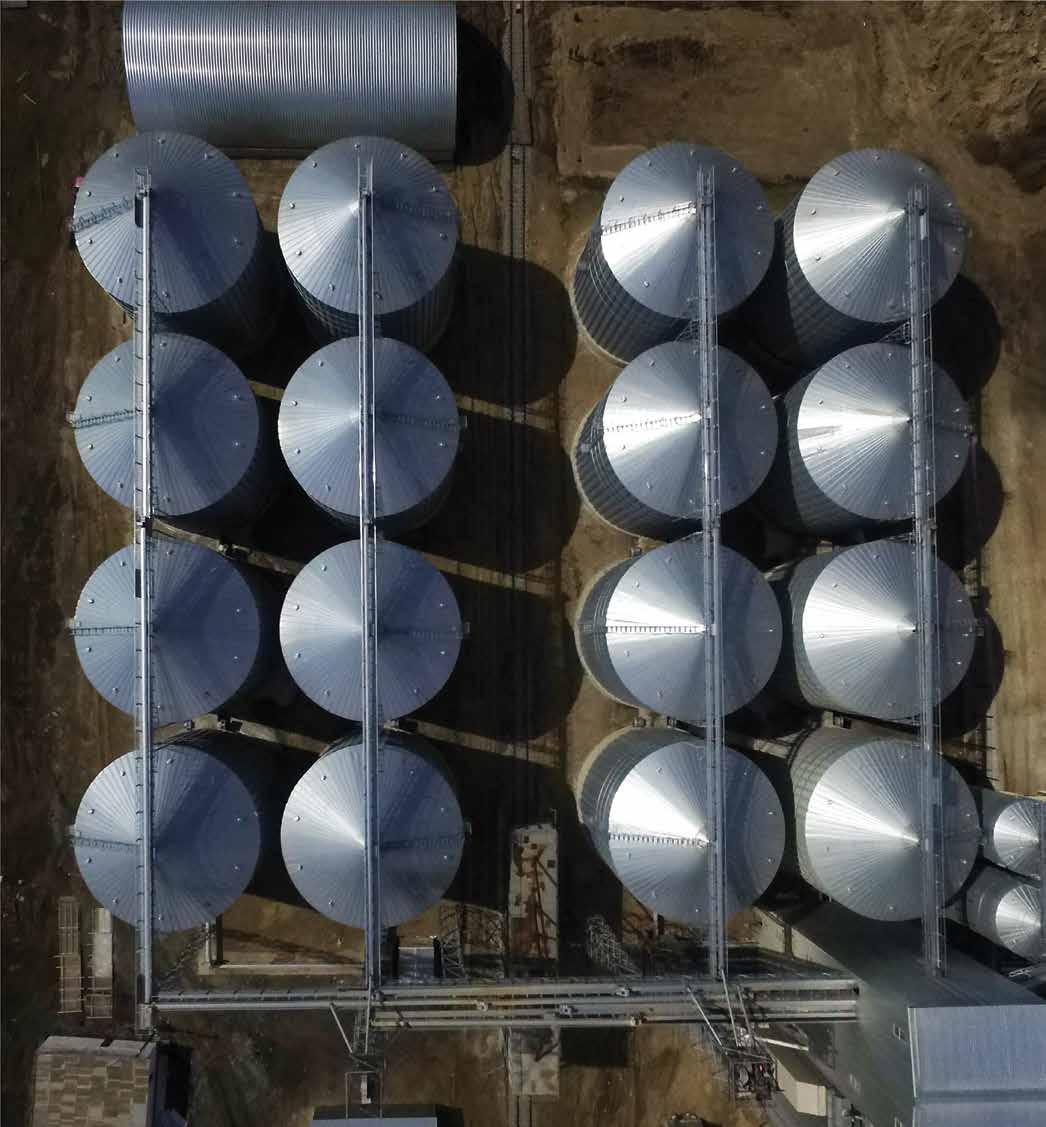

The facility includes a storage section with corrugated steel sheet silos capable of holding 20,000 metric tonnes, a conveying system for intake and pre-cleaning with a capacity of 250 tonnes per hour, a durum wheat mill processing 250 tonnes per day, a soft wheat mill processing 250 tonnes per day, smooth-wall prismatic silos for raw materials, smooth-wall cylindrical silos for finished products, and bulk outloading silos for bran and finished products.

“To facilitate the realisation of such an ambitious project, Cesco has assisted the customer in securing financing from the German bank AKA-Bank, with Export Credit Insurance provided by Euler Hermes in Germany,” stated Celeghini. “This project showcases Cesco’s ability to offer African customers not only technical and commercial support but also financing solutions from Germany, enabling them to undertake urgently needed projects to stabilize and secure food supplies in the region.”

Cesco’s philosophy of “smart concept, easy operation” guides the selection of equipment for designing grain storage facilities. State-of-the-art conveying and handling equipment used in this project include CC420 chain conveyors, BBE280 and BBE370 bucket elevators, as well as FBS 13/21 large flat-bottom silos and prismatic and cylindrical process steel silos for the mill section.

Significant effort has been invested in the integrated design of the intake, mill, and outtake buildings as steel structures.This integration offers several advantages, such as enhancing static cooperation between process silos and buildings, simplifying foundation design, standardizing grid layout, preventing the creation of unnecessary rooms, and installing smooth wall cladding and roofing to limit the need for additional supports.

The building structure comprises warm-rolled H-sections for portal frames, various other warm-rolled sections for secondary components bolted together and finished with hot-dip galvanisation. Floors are constructed with reinforced concrete using corrugated steel sheet formwork. Cladding and roofing consist of galvanised and pre-painted steel sheet sandwich panels with mineral wool insulation, providing excellent thermal and sound insulation as well as fire resistance. Additionally, the buildings are equipped with handrails, access platforms for each machine, steel stairs for enhanced functionality, and necessary openings like windows, roller gate doors, and personnel doors.

In March, the Cesco Senior Supervisor conducted a thorough site inspection to ensure correct groundwork and foundation preparation before commencing the erection phase, including precise positioning of anchor bolts and finalizing concrete pouring preparations. Deliveries of crucial components from Germany, Italy, and Spain are progressing smoothly, further cementing the project’s timeline.

“We are thrilled to witness our vision taking shape in Cameroon,” said Celeghini. “The meticulous inspection of civil works underscores our commitment to quality and efficiency. We eagerly anticipate maintaining this momentum as we transition into the erection phase.”

With this milestone achieved, CESCO remains steadfast in its commitment to delivering exceptional industrial plants and contributing to the growth and development of the region

AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY

BOURNE

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

We

Distance learning Distance learning PROGRAMME

will be seeking enrolments from June ...

Spread over the study year, the cost of a module is

C O S T E F F E C T I V E

£12

T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E

increases competence thereby freeing up your time

students

a tutor with a wealth of specialist knowledge

less than

a week

Study

All

are allocated

. . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

Vertical Mill training by Make UK

Make UK has begun offering a five-day Vertical Milling Machine training course in Birmingham from June 10-14 and July 29 – August 2, 2024. The course gives delegates the skills and knowledge to safely operate a vertical milling machine as well as giving them the baseline skills and knowledge for more advanced techniques used for CNC type machines.

While the course does involve some theory, it mainly focuses on the practical application of using the Vertical

Miller via a hands-on approach that allows them to make the most productive use of a Vertical Milling machine. You do not need any previous experience with milling machines in order to be accepted for the course however the organisers do say that some previous engineering or manufacturing knowledge may be useful. You will also not need to complete any formal assessment in order to finish the course, instead you will only need to demonstrate that you can operate a vertical milling machine safely and effectively by the end and you will then receive a certificate of attendance. The course is £850 plus VAT for members and UK£940 plus VAT for non-members and you can apply through the ‘Training’ section of the Make UK website.

Milling and Grain - May 2024 | 31 Mill TRAINING

FOCUS Product

May 2024

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

Maize grinder by Pingle

The maize grinder is developed on the basis of a hammer mill. For the integral maize kernels that have been moisture conditioned, this machine is able to finish dehulling, degerming and grinding operations in one step, and the processing efficiency is improved. Technically speaking, the power consumption for producing one tonnage of maize grit is reduced by 20-30 percent when compared with traditional machines, thereby significantly enhancing the economic returns. With the help of this machine, a complete granule of maize is shattered into 4-6 fragments with a tidy appearance. The embryo breakage rate is less than 10 percent, and the hull is kept whole. This brings great convenience for the following separation of embryo, hull and grit. So, this maize grinder is highly recommended.

www.plflourmill.com

mymag.info/LbzB

New Similago II by Alapala Alapala’s NEW SIMILAGO II roller mill is equipped with high technology electronic control systems for a continuous and consistent performance in the grinding of cereals, such as wheat, maize (corn), rye, spelt, barley and sorghum. The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly. Rotational speed of feed rolls is monitored against an unexpected stop due to belt problem, etc. Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls. The main motor load is constantly measured for protection against any possible damage, and the rotational speed of grinding rolls is monitored against an unexpected stop due to belt problem, etc.

The NEW SIMILAGO II is built to comply with the high sanitation standards and ensure food safety. The roller mill’s all front structure is isolated and smoothened against adhering and condensation risk.

https://alapala.com

mymag.info/uGzs

Farm silos by Simeza

Simeza steel sheet Farm Silos are designed for storage of feed on livestock, poultry and pork. They can be designed according to either ASAE/ANSI American or Euro-Code European norms as per client choice.

SIMEZA Farm Silos cover a wide range of models from 1.8 meters to 3.5 meters in diameter and from 4 to 58 m³capacity. They are entirely manufactured in galvanised steel and with Z600 galvanised coating or pre-painted in green.

They are designed with a cone angle of 62 ° to allow a perfect discharge. The Farm Silos are equipped with their corresponding access stairs to the roof.

Optionally they can be supplied with an opening system from the ground or pneumatic load, visors, cone doors for cleaning, emergency exits and weighing cells.

www.simeza.com

mymag.info/HrnK

PRINCIPAC by Statec Binder

The PRINCIPAC is a fully automatic high-performance bagging machine for open-mouth bags and, with up to 2000 bags per hour, it is one of the fastest in the world.

The PRINCIPAC is characterised by high performance and flexibility. Both pillow bags and gusset bags with a filling weight of 10 kg to 50 kg can be processed. The bags can be made of woven PP, PE and paper. This fully automatic open-mouth packaging machine is ideally suited for any type of free-flowing bulk material and with additional equipment such as a dustproof filling spout also for powdery products.

Depending on customer requirements, the high-performance bagging machine can also be made entirely of stainless steel. Further options enable the PRINCIPAC to be optimally adapted to customer requirements.

mymag.info/gQmh

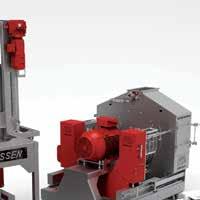

Crusher CR from Tietjen

The crusher CR is a versatile machine for coarse crushing of bulk materials. It is suitable for crushing agglomerates or for pre-crushing coarse material pieces for further grinding.

By homogenising the raw material in the crusher, energy is saved in the further grinding in the hammer mill, as the desired grain spectrum is achieved more quickly. At the same time, the screens of the hammer mill are protected against screen breakage. Especially in pet food and fish feed production, particularly fine screens used, here the use of the crusher is particularly worthwhile.

The crusher is designed for continuous industrial operation. It convinces with its robust design with generously dimensioned inlet, long-life rotor and hardened impact plates. The beaters are also optimised for primary crushing and are made of Hardox. A variable grain size range can also be achieved in pre-shredding by using different screen sizes.

www.tietjen-original.com

mymag.info/vOlG

32 | May 2024 - Milling and Grain

Multiplexa plansifter by Imas High-capacity

flour mills

The new Multiplexa plansifter (MQA) is designed by the Imas R&D team, with the synthesis of over 30 years’ experience in grain milling technology and new engineering standards. Officially introduced in March 2024, the new Multiplexa plansifter meets high-capacity requirements in flour mills with models available for up to ten passages.

Moreover, the new Multiplexa presents increased reliability, performance, sanitation and insulation all together for its users, thanks to significant design improvements.

Developed using software-based testing and analysis methods

Finite Element Analysis (FEA) is used today as an indispensable part of the engineering world, especially in the defence and aerospace industries.

Imas R&D team utilises the latest FEA virtual modelling technology for the dynamic behaviour analysis on plansifters and measuring the performance with the simulation of real operating conditions. Then, various validation tests are carried out with prototype sifters at the manufacturing plant (strain gauge, acceleration and tension points etc) to verify the performance under the actual load.

Performance

Multiplexa presents non-stop and trouble-free operation thanks to its strong drive system. The weight chassis of the drive system is made of a three-layered steel sheet, in order to provide high durability against excessive vibrational loads. Also, balance springs are used on the top and bottom of housings and ball bearings, which balance and distribute the operational load and provide a safe operation.

The new Multiplexa plansifter is equipped with a central lubrication system for bearings in the drive system, which provides ease and functionality in the periodic maintenance operation.

Produced with ‘No Welding’

The traditional manufacturing method of a plansifter chassis is to use welding in joints, which may result in cracks, wears and tears over time. The ‘No Welding’ design of the new Multiplexa plansifter helps eliminating standardisation problems by welding during manufacturing.

In this method, special

FOCUS Special

aluminium extrusion profiles and cast-iron top/bottom frames of the pan sifter are connected to each other with a special screwing technique. This structure provides excellent geometric precision, advanced insulation properties and extended long-term durability for the new Multiplexa, as well as its easy sieve replacement.

The new Multiplexa plan sifter’s isolation thickness in passage walls and doors has been increased from 5mm up to 14mm, compared to previous models. This provides optimal thermal insulation in the plansifter and prevents high internal temperatures, condensation and food safety related risks accordingly.

Sanitation

The plansifter provides excellent sanitary conditions with its increased insulation, as well as excellent impermeability against microorganisms and similar hygiene problems.

Also, all interior walls in contact with the product can be covered with stainless steel insulation (optional), which significantly reduces condensation. This is especially a perfect solution for B1B2 passages under high ambient humidity and temperatures.

Increased Distance of Flow Channels

The distance between the plansifter passage walls and sieve boxes is increased by around 40 percent (from 45mm to 63mm) in order to ensure smooth product flow and better sanitary conditions in the plansifter.

All internal corners of passage walls, doors and tension boxes of the plansifter are rounded with a wide radius. This prevents against product adhesion or accumulation, contamination, moulding, risks and provides better sanitation.

New Design of Passage Doors

Laminated chipboard passage doors are still used by many manufacturers, however they can be deformed easily over time due to humidity in the working environment. The new Multiplexa has its stainless steel coating on passage doors, along with an increased isolation thickness. Industrial type leakproof rubber sealings are used on passage doors, which can also be easily replaced.

Milling and Grain - May 2024 | 35

ai-lati.com

simaimpianti.net

BEYOND MAKES US SEE KNOWLEDGE THE HORIZON paglierani.com ocrim.com

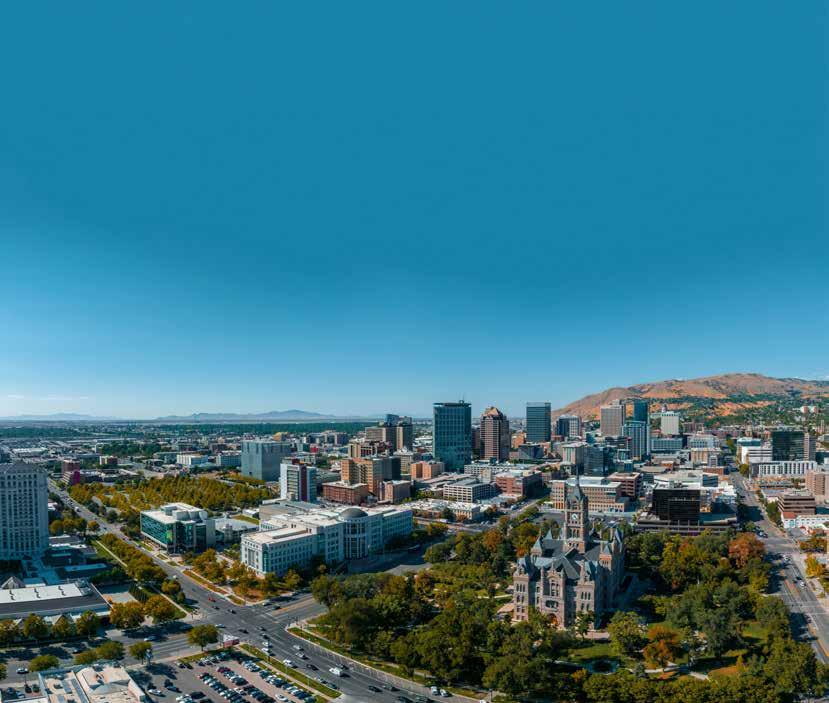

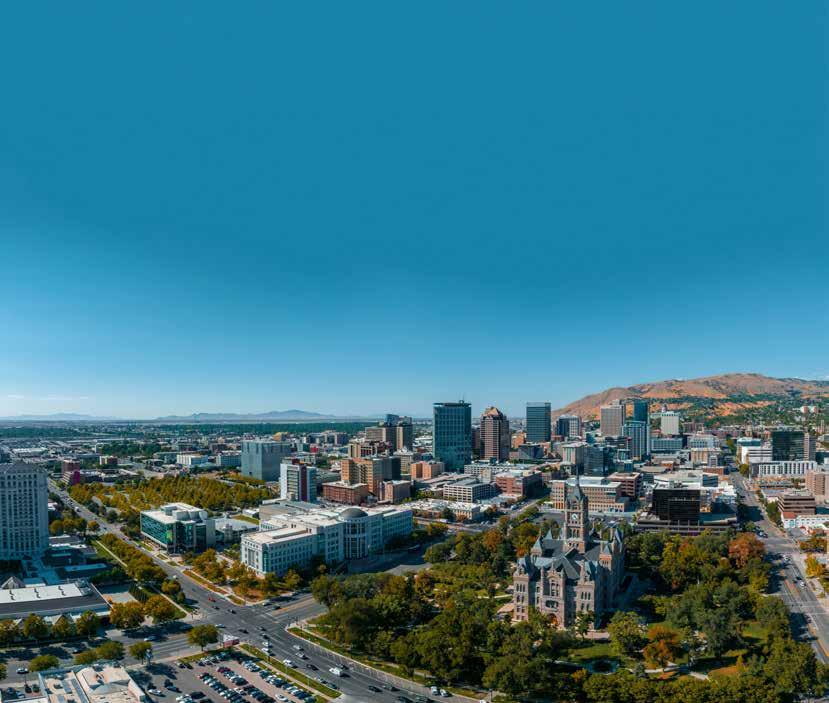

An intersection for milling interests in Utah Salt Lake City IAOM ACE 2024

by Roger Gilbert, Milling and Grain, UK

by Roger Gilbert, Milling and Grain, UK

This was not a noisy or vociferous event!

This was an event characterised by quiet conversation, contemplation and consideration. Visitors did not rush but took their time, stopping to talk when their attention was taken and moving on without fuss.

Exhibitors waiting, responding and being respectful.

This was no ordinary Expo, this was IAOM’s 128th Annual Convention and Exhibition (ACE) in Salt Lake City last month.

IAOM, the International Association of Operative Millers, held

its annual home meeting in Salt Lake City in the state of Utah, USA.

Even this might be considered exceptional - an alternative destination for one of the world’s most significant flour milling events to take place in, but the location reflects the historic ‘intersection’ in North America’s history where both highways and railroads first conjoined to link traffic and trade across the continent, and to bring trade to the city, dating back to the early 1900s.

Swisca presented a limited-edition jigsaw model of its new Romil to Luke Weinheimer of Miller Milling Company, Eden Prairie, Minnesota in thanks for his company’s input and purchase of the first roller mill to be produced

Find out more about the revolutionary Romil on page 54 of this edition

38 | May 2024 - Milling and Grain F MAXIMISED FLOUR MILLING F

Gelpac: Joel Jackson (left), Scott Friend and Michael Ream all of Gelpac of Lubbock, Texas, Since 1956, the Gelpac team has steadily designed and produced standard and custom multiwall paper bags that have helped leading North American companies enhance the value of their products, build production efficiencies and boost their sales and probability

Sefar: Sefar demonstrates its Sefar Tensockeck 200, an electronic gauge for monitoring the screen tension within very strict tolerances. A QR code takes users to an ‘Instruction for use’ manual and video

In addition, this location for the IAOM’s 128th ACE was outstanding, not only for its salt lakes and salt flats but also for its majestic mountain ranges that seem to encircle the city and the Convention Centre.

Spending a few days in mid-April 2024 taking in the fresh spring mountain air and meeting with flour millers and their equipment and service providers from throughout the country and across the globe, was a learning experience that made this an exceptional event.

Unlike others that either are conference or expo focused, IAOM’s ACE presented a balanced combination of the two centred around an eating area that allowed visitors, delegates and exhibitors to intermingle not only for work and to lean but also to socialise - all within the same ‘footprint’. To compliment the two

Behn-Bates: (From L-R) Davor Marusa, Henry Nowakowski and Rim Boltong from Behn+Bates. This company is recognized as a manufacturer of packaging systems for valve bags and open-mouth bags, automatic bag applicators and sealing, high-speed rotating systems, big bag filling, net weighers, robot and more

days of the event itself there were evening functions such as the Allied Trades Event, the Annual Banquet and Awards Ceremony including the outcome of the silent auction to name just two.

There was a strong turnout from companies exhibiting, totalling 124, with many representing more than one brand or organisation, especially those that represent international companies which hosted representatives from their parent companies. It was striking to see the number of international brands on display and countries such as Italy and Turkey being well represented among others from Latin America.

In fact, this again is proving that the USA is becoming more of a global meeting place for industries involved in milling activities - and I include such events as IPPE in Atlanta in January, GEAPS in Kansas in March and now IAOM in April

in Salt Lake City

Donaldson: Karilyn Smith of Donaldson Company from Minneapolis, Minnesota, with (left) Zach Peterson and Patrick Stumpt. Building the world’s finest dust collectors this company’s real goal is to provide customers with comprehensive dust collection solutions

Great Western: Jeff Seeger and the team at Great Western Manufacturing along with Garip Cantemir from Ugur Promilling . Great Western manufactures sifting equipment for the cereal grain processing industries including finished product quality assurance applications

Omas/Synergy: Dennis and Niolino Di Cicco of Synergy Milling Contractors is with Sergio Dipasquale of Omas which has an office in Des Moines, lowa and Pietro Barbalarga of Omas, from San Giorgio, Delle Pertiche in taly

40 | May 2024 - Milling and Grain F MAXIMISED FLOUR MILLING

(Re)defining the grinding gap!

ROMIL’s servo-controlled grinding gap, operated via electronic handwheel, ensures on-point milling. Time and time again.

Swiss premium milling technolog y

Features: feeding with radar sensor and distribution screws, servo-controlled grinding gap, 10” touch screen and electronic handwheel, large sight glass, stainless materials & insulated covers. Options and extras: Entirely independent roll passages, bearing & roll temperature monitoring, direct pick-up (pneumatic system), roll lifting device. ROMIL versions: 4-800/250, 4-1000/250, 4-1250/250, 4-1500/250, 8-1000/250, 8-1250/250, 8-1500/250 ROMIL: Next Generation Milling Technology – Made in Switzerland

FNA: Grant Garcia (left) of FNA Inc Scottsdale, Arizona with colleague Richard Mendez tells Milling and Grain that they are the official North American distributor for Firefly products from Sweden. Firefly is a leading developer of systems for preventing fires and dust explosions in process industries. The concept is to detect, analyse and extinguish different types of ignition sources before a fire or dust explosion has occurred!

Engsko: Mads Andersen of Engsko A/S of Midtylland in Denmark shows off the company’s mill stone for the manufacturer of stone ground flour. It has over 110 years of manufacturing milling solutions and exports to more than 65 countries worldwide. Customers are milling spelt flour and Frederick cake flour for a discerning market

MPI: Gage Andrews of MPI, which is based in Metro Detroit, Michigan, explains the ‘intell-i-mag’ electronic inspection systems controlling its magnetic products. MPI helps achieve food safety while minimising the risk of a product recall. It detects and remove metal contaminants automatically while recording and logging any incidences for food safety audits.

John Bielecki and Mark Enninga, both of EnviroLogix in Portland, Maine, which is a world leader in the development of mycotoxin and GMO testing solutions for the grain industry. It provides a comprehensive line of LFD test kits for commodity grains is fully quantifiable through its QuickScan system. It also tests onsite for salmonella contamination and offers onsite molecular testing for grain elevators and feed mills

(although this latter event re-locates each year) - which are all held annually.

However, while the exhibition attracted a wide range of equipment manufacturers and featured many technologies from supporting sectors, such as the IT industry, the construction and planning industries to the transport industry, it was the educational aspects of the event that attracted large audiences.

The future of milling

The event proper kicked off with a keynote presentation by Peter Levangie, the President and Chief Executive Officer at Bay State Milling in Quincy, MA and who is responsible for all functional areas of the company and its daily operating activities. He addressed ‘A view on the future of flour milling in the 21st Century, navigating the intersection of AI, plant genetics, public health, sustainability and shifting consumer demands.’

Mr Levangie had joined Bay State Milling in 2004 as the Vice President of Strategic Planning but by early 2009, the Board had elected him as its President and Chief Operating Officer and in 2016 as its Chief Executive Officer and President. Before coming to the Company, he was Chief Operating Officer of EFS Network, the supply chain solutions network for the foodservice industry, which he helped found in 2000.

Educational programmes

The first conference day saw nine sessions equally divided into three concurrent presentation rooms covering Employee Management, Product Protection, and Technical Operations.

On the second half-day the educational programme concluded with a 1.5-hour Facility Management Session presenting three lectures followed by the closing Main Line Session which comprised the ‘Capturing the Science in the ‘Art’ of Milling’ by Alex Young of General Mills, where he is the Supply Chain Manager in the North American Food Service Segment.

42 | May 2024 - Milling and Grain F MAXIMISED FLOUR MILLING

EnviroLogix:

Phosphinesafe

AIO and AIO+: All-In-One Sensor Cable

The AIO Sensor Cable monitors CO2, grain moisture, temperature, and more Now also available as phosphine safe sensor cables

The iGRAIN AIO Sensor Cable combines several different digital sensor technologies into one sensor cable. Ensuring a cost efficient total monitoring system, the AIO Sensor Cable can be used as the only monitoring solution in a single silo. However, it may be supplemented with additional iGRAIN Temperature Sensor Cables.

All-In-One Sensor Cable

All-In-One

• CO2 monitoring (infestation control)

• Moisture monitoring

• Temperature monitoring

• Headspace humidity monitoring

• Grain level monitoring

• Additional sensors according to customer needs

• Advanced total monitoring system in one cable

• Intelligent use of sensor technology reduces the amount of monitoring cables needed

• MODBUS communication Advantages

• MODBUS communication

• Sensors connect directly to the iGRAIN Control Board or any PLC/SCADA system or other platforms

• Automatic aeration control including roof vent control

• Inventory management Interface / Software

Phosphine safe cables

The AIO Sensor Cables are now also available in a phosphine safe version. This ensures that the sensors are not damaged during phosphine fumigation.

Technical specs. AIO Sensor Cables AIO+ Sensor Cables

Automatic monitoring with the iGRAIN Smart App

iGRAIN - Denmark - info@i-grain.net - www.i-grain.net

CO Hot spots CO CO

Temperature sensors One temperature sensor per 2.0 m, up to 30 sensors / cable Measure range -20°C to +70°C, resolution +/- 0.2°C iGRAIN moisture sensor 8-24% H2O, resolution 0.1% moisture Head space humidity 5-99% rH, resolution 0.1% rH CO2 sensor 0-40,000 ppm iGRAIN inventory management Accuracy typically 2-4% (depending on number of sensor cables) Organic volatile gases * - 0-10,000 ppm iGX sensor * - 0-100% (calibrated)

The special AIO+ Sensor Cables can be calibrated to different appllications. Standard calibrations exist for: Wheat ripeness, oil seed vapours, wood chips/pellets, or feed pellets.

infestation

*

Early detection of

Mollers: Kirk Briggs, Sales Manager at Mollers North America, who manufactures in Grand Rapids, Michigan, and is one-stop for the design, manufacturing and installation of bag and unit material handling systems, including automatic bag filling, palletizing, and load unitisation systems

Neospectra: Seth Bryan, Senior Account Manager at NeoSpectra NeoSpectra enables businesses to bring the laboratory to the field, to analyze anywhere through devices that produce lab-level results with an analysis solution platform built on a family of single-chip FT-NIR spectrometers

Andreas Jeppsson, CEO of BoMill with Roger Gilbert. Bratney Companies partners with Cimbria, Concetti, Omas, Schule including BoMill to offer customers state-of-the-art equipment technologies. All are leaders in design, engineering, construction and equipment supplier to the milling, grain, feed and process industries

He has managed engineering and operations within their flour mills, in addition to their retail businesses leading masa and tortilla manufacturing within their 29 plants across North America.

He spoke as an employer saying “We are faced with hiring and retaining our workforce and have the added challenge of teaching the art of milling at the pace we need.

“With turnover and ‘how our workforce

iRely: Jeff Leong is out of Chicago, Illinois while Sara Reiken is from Garfield, New Jersey where on duty explaining the benefits behind their software support systems for the flour milling industry suitable for both within North America and beyond. iRely’s software solution are web-based, fully integrated platform covering the entire lifecycle of the businesses. Its solutions cover contract management, scale, inventory management, storage, settlement, risk management, quality management, processing, traceability and distribution with integrated accounting

Fawema: Fawema’s representative Kody O’Brien (left) from Chilliwack, British Columbia, Canada is with Thomas Krimmel of Fawema in Engelskirchen, Germany promote quality packaging equipment for flour, mixes, cereals and others. Its packers are unmatched and produce clean and perfectly shaped and closed bags and pouches

Buntings: Robert Bunting (right) explains that his company builds and designs magnetic separation systems from both grain handling and for milled flour, to identify detect metal within a product. Metal detector on a conveyor belt checking bags up to 100lb (45kg) bags placed at the end of a production process before dispatching to the customer

learns’ drastically different than even five years ago, we have to implement processes to not loose efficiencies.

He highlighted a ‘Foundational System’ toolkit that he uses which builds system knowledge through repetitive action that prioritises how the health of mills are maintained to produce high-quality and safe flour.

“We establish leading indicators to deliver

From

West and Federico Galli representing the Saati Americas Corporation out of Fountain Inn, SC at the IAOM 2024 gathering in Salt Lake City were on hand to demonstrate just how to perfect the art getting the best from precision woven fabrics used sifting and food processing application

and Shawn

both sales specialists with Perten show off NIR equipment that offers exceptional performance when it come the grain testing solutions. Its solutions are based on extensive expertise and designed to help food processors ensure quality while optimising use of resources

lagging results and drive planned vs reactive actions, which is critical to the longevity of our operations. The three foundational systems are the trilogy of how we do work,” he added.

His session was followed by The Millers Panel moderated by Sunil Maheshwari of Siemer Milling Company and who has been in the milling industry for over 40 years, which included panellists: Georg Schafler

BoMill:

Golfetto Sangati: Eleonora Rubinato and colleagues from Golfetto Sangati

Omas: Sergio Dipasquale and Pietro Barbalarga from Omas Industries

Perten: Kathleen Trivette

Gartside,

44 | May 2024 - Milling and Grain F MAXIMISED FLOUR MILLING

Saati:

left, Zoie Christian, Shane Boland, Jazmin

New: Brabender Portfolio for the Baking and Milling Industry

Explore our extended, market-leading portfolio of Brabender products for grain, flour, starch, gluten and dough analysis

Analyze physical properties of your samples such as water absorption, gelatinization, enzymatic activity, and moisture

With Brabender on board, Anton Paar offers the ideal characterization portfolio from raw material checks to final QC

Enjoy service and support from 37 subsidiaries around the globe in your local language

www.anton-paar.com

of Buhler who is head of technology in the wheat and rye business and also forms the interface between the technology platforms in North and South America for his company; Marco Galli of Ocrim, who is a Brazilian but joined Ocrim in 1983and is Ocrim’s chief technologist; Stefan Schmitz of Swisca, who was a miller at Plange Mühle Neuss,and the Wehrhahn Milling Group and trained as a miller technologist at the Swiss Milling College and master craftsman’s certificate in the milling trade at the Braunschweig before working for Buhler and joining Swisca and Joe Woodard of ADM Milling who before retiring was the Regional Operations Director overseeing 14 milling sites and led teams to improve milling yield and economic efficiency.

With the comprehensive line-up of specialist and experienced speakers on its educational programmes tis is the event that is the intersection between experience and leaning for the milling industry and is a credit to all the staff and the membership of IAOM that brings together this army of knowledge and information sharing to help the industry develop its skill base and provide direction and insights.

The

show

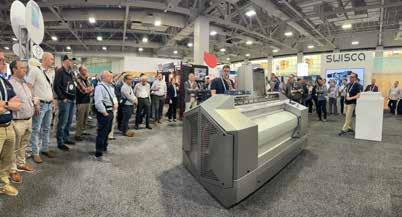

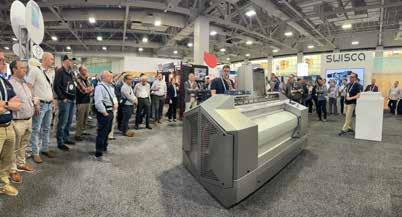

The trade show itself did not overlook the need to educate and two companies held impromptu gatherings on each of the two days to announce and discuss equipment developments.

Imas presented its Aluminium Multiplexa Plansifter, the MQA, on the Expo floor on the Wednesday to a large audience, A Product Showcase was held by Qi Sifter while BoMill provided insights to its latest grain analysis system that may have a longer-term significant impact on the way we separate grains by protein content.

Product Showcases continued the Thursday with Swisca presenting the launch of its new Romil to the largest crowed to gather – some 170 individuals.

The company thanked all those involved in providing advice and suggestions in what a futuristic mill should include.

In fact, the presentation included a limitededition model of the new Romil being presented to the first company who had not only provided inputs in its development but had also pre-purchased the first mill to be built for sale – that went to the Miller Milling Company.

The second Product Showcase included Packing Line Automation by Gravista-D. Traditionally, stands spaces booked by exhibitors at IAOM are relatively small and except for those bringing larger equipment, which requires more space to move around and display, the majority of exhibitors

founded Ocrim in 1945. Ocrim’s activity is concentrated in the design and manufacture of state-of-the-art milling complexes to give high production yields, product adaptability, low operating costs, maximum reliability as well as guaranteeing the utmost sanitation standards through the use of stainless steel

Hasan Duman, Area Sales Specialist at Henry Simon who manufactures highperformance machinery to achieve in highly developed and stateof-the-art production facilities for customers. It focuses on wheat flour mills, semolina mills, corn flour mills, feed mills, cereal storage systems, weighing, conveying, packing , etc. Satake offers equipment suitable for conventional and specialty flour milling processes under the Henry Simon brand

Ocrim

Fabrizio XXX and Marco Galli from Ocrim. Continuing an age-old family tradition in flour milling, Guido Grassi

The Bühler team was out in force at IAOM 2024 with the most dominant stand at IAOM 2024 in Salt Lake City. A global specialist supplying plants, equipment and services for grain and food processing as well as dry ingredient handling systems. Customised solutions a speciality

46 | May 2024 - Milling and Grain F

Henry Simon

Made in Britain, Trusted Worldwide.

Join the growing number of the worlds most successful feed companies already trusting Holmen equipment to check, monitor, and continually maintain their animal pellet durability...

An extract from the Opening Keynote Presentation delivered by Peter Levangie, President and CEO of Bay State Milling, USA to the IMEF Breakfast at IAOM’s 128th ACE event in Salt Lake City

‘A view on the future of flour milling in the 21st Century, navigating the intersection of AI, plant genetics, public health, sustainability and shifting consumer demands’

“We are living in a time of rapid and profound change – the accelerating integration of Artificial Intelligence (AI), advancements in plant genetics, climate change & sustainability imperatives, heightened public health awareness, and evolving consumer preferences. The presentation will explore how these external forces might impact the future of flour milling and how flour millers might want to think navigating these potentially revolutionary changes.

“The forces at play:

“AI Revolutionising Flour Milling:

“Artificial Intelligence is set to revolutionise the world and the flour milling industry will not be immune. AI-driven technologies are enhancing precision and efficiency across manufacturing processes. Real-time data analysis and predictive algorithms optimise grain selection, milling techniques, and quality control, ensuring consistent flour quality while reducing waste. As AI continues to evolve, it will become an indispensable tool for millers seeking to maintain competitiveness.

“Plant Genetics and Flour Diversity:

Plant genetics play a pivotal role in the future of flour milling. Ongoing research is yielding wheat varieties tailored to specific milling and nutritional requirements. This innovation extends beyond yield improvements, focusing on disease resistance, nutritional content, and functional attributes. Flour millers are leveraging these advances to meet diverse consumer demands, from artisanal specialty flours to allergen-free and nutritionally enhanced options.

“Public Health and Nutritional Awareness:

Public health considerations are increasingly influencing the food and agricultural system. As nutrition and human science advance while health care costs continue to escalate, incentives for investing in preventive health through our diets will grow. This is both opportunity and risk for flour millers.

“Climate Change and the Growing Sustainability Imperative:

Climate change and its costs will continue to motivate stakeholders to elevate sustainability for governments, companies, NGOs, and citizens. Reducing environmental impacts, minimising waste, and addressing water and energy consumption are key priorities. Companies are already taking active measures today against these priorities. What might the future look like?

“Navigating Shifting Consumer Preferences:

With the COVID years of consumer choice constrained by supply issues behind us, the diversification of consumer preferences within food is reemerging. Consumers are wanting more from their food experiences – more taste, more wellness, more convenience, and more personalisation. In the US, flour-based foods still maintain a dominant role in most American diets. How can milling companies contribute to preventing a loss of share of stomach?

“As seen through these large scale trends, the future of flour milling looks more dynamic than ever. The presentation will conclude with some recommendations on how flour millers might prepare for and perhaps even thrive in this evolving environment, delivering flours that meet the demands of a changing world while upholding quality, health, safety, and sustainability standards.”

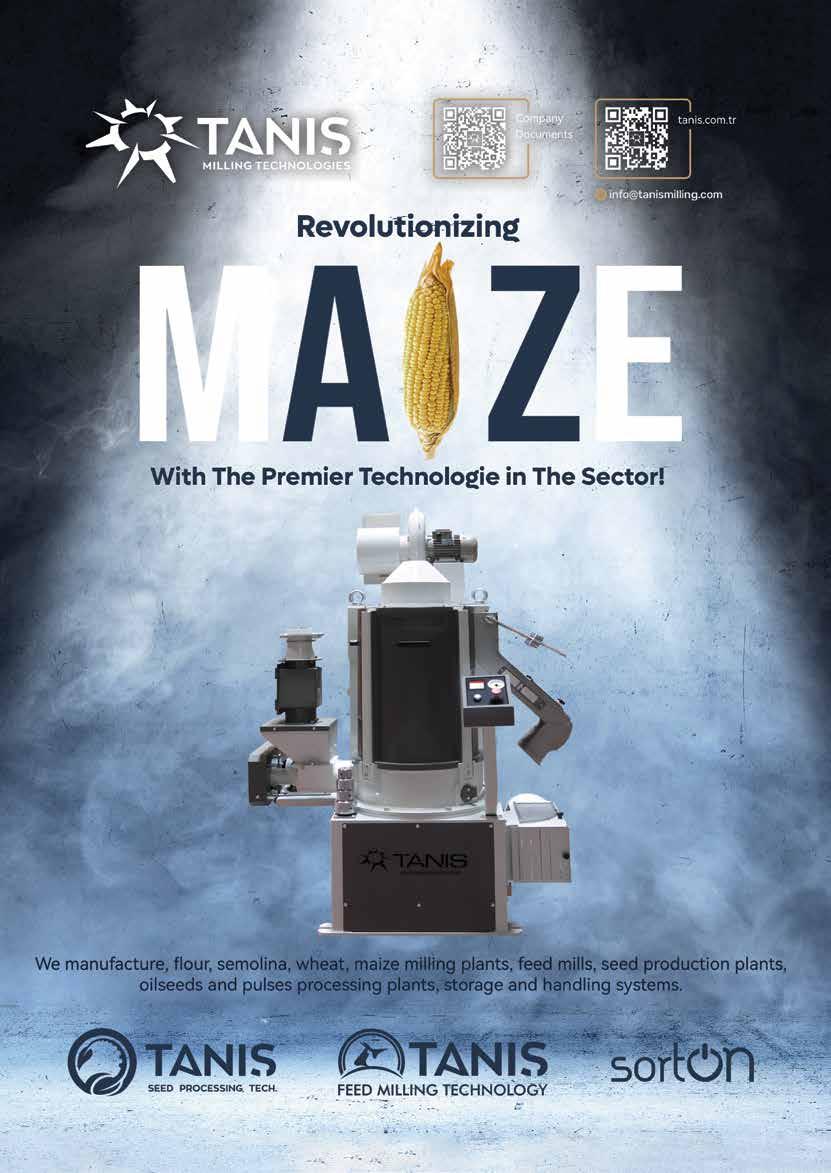

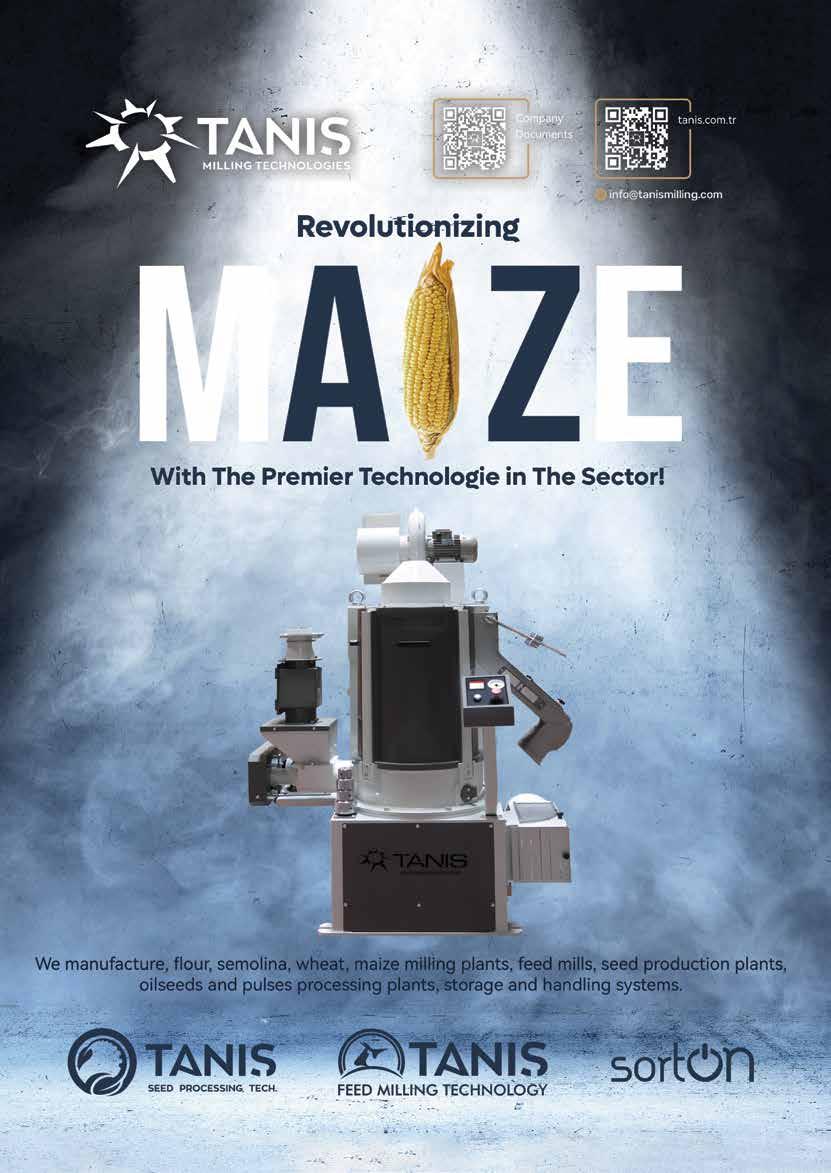

Tanis Colombian representative Cenk Apa (left), is with Tacettkin Tan and Enc Sevatson of Tanis Milling Technologies of Akdeniz. Mersin, Turkiye

Bestmix

Bestmix’s Michael Murphy is showing off the company’s full suite of software for the milling industry at IAOM 2024 which includes the company’s ‘Enterprise resource planning’, ‘Full business systems’ and its approach to improved custom functionality

Milling and Grain - May 2024 | 49 F

Ortas Mahmut Taskin and XXX from Ortas Milling Group

Verbruggen: Freya Jansen (right) with her colleague from the Dutch company Verbruggen, which is based at Ameland north of Amsterdam, was promoting its palletising robotic machines that can work with anything that goes into a bag and is designed to be able to ‘double-pack’ pallets using a specialist compression mechanism and ensures bags are exactly where they should be

Enviro Tech: Mark Vandenberg of Enviro Tech an Arxada Company supplies peroxyacetic acid (PAA) in formulations that effectively address food safety concerns. Its sanitise solution disinfects surfaces, packaging, raw food and aid also has a place in grain processing.

Timken: The ‘Flour Power’ belt from Timken is specially engineered and constructed to meet the demands of automated machines operating in today’s highly engineered flour milling industry. Here, Timken staff Brad Trost (left) of Maple Grove, MN is with Timothy Hickle of Colorado Springs, CO and Ryan Kogler from Pennsylvania

Zaccaria: Zaccaria with its 97 years of experience in the development of grain processing systems and solutions talked maize and well as flour milling from its tans at the IAOM 2024 in Salt Lake City. The maize degermer and associated equipment was a central feature of this companies offering

Mehmet XXX with XXX Alapros offers integrated solutions

grain milling and processing technologies ranging from custom developments and flour milling machines with integrated

for a 4.0

Ecolab: Nathan Stocker of Ecolab of Morganton, North Carolina (left) with Alexander Luce and Falcon Sprinkle. Ecolab Specialty Pest Services provides fumigation expertise to protect products and structure to maintain a safe, healthy and pest-free environment. It promoted microbial decontamination with chlorine dioxide gas

are happy with the floor layout and the neighbourly environment. This configuration might also have to do with the limited time allocated to the Expo, being one full day followed by a half day.

The schedule certainly made the best use of everyone’s time and left ample space in an attendees’ calendars to make any off-site arrangements for meetings they wished.

The most dominant stand was that of Buhler which did impress given its height and design and it is good to see this company back at the centre of things, given its longstanding, worldwide presence and support for the milling industry.

Bühler had a significant team of technical experts to hand and participated in the Education Session with a presentation by Jay O’Nien, who leads the Environmental Impact Services for the Bühler Group, on ‘The business case for sustainability in the milling industry’. His presentation and the accompanying white paper provide an overview of the key sustainability requirements from various stakeholders, including governments, companies and consumers.

It considers how environmental sustainability using both greenhouse gas (GHG) accounting and life cycle assessments can be quantified and the key steps in reducing the environmental footprint of the milling process and in the cereals and grains value chain.

“By quantifying environmental impacts, companies can create a data-based discussion, enabling them to create a competitive advantage and build a favourable business case for sustainable products. When sustainability is profitable, it will create impact at scale,” he says.

Finally …

If you wanted to know what was new or different about roller mills of today,

parts Conveyor chains www.vav.nl contact@vav.nl

Elevator

Alapros:

in

solutions to producing competitive products suitable

smart mill

50 | May 2024 - Milling and Grain F