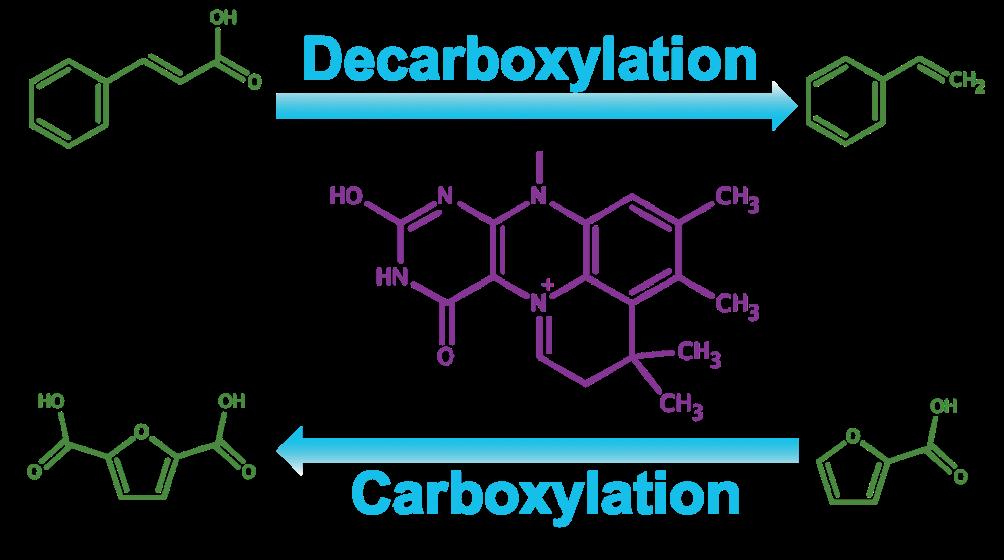

CASE STUDIES CASE STUDY: BP BIOMANUFACTURING OF ORGANIC ACIDS, AND OTHER SUSTAINABLE CHEMICALS Biorefineries offer the potential to provide petrochemical replacement products by using biotechnology to produce value-added chemicals from renewable feedstocks. However, biomass conversion processes are often hampered by high costs of product purification and recovery, which can be as high as 50%-80% of the total process cost. One example of valuable commodity chemicals able to be produced through biomanufacturing processes are organic acids, however their production can be expensive as the process often requires neutral pH to ensure optimal performance of the fermentation microorganisms. As the organic acids are produced, the pH decreases requiring base addition to control pH, resulting in salt formation and adding cost to product recovery. In an attempt to overcome these problems, scientists at the BP Biosciences Center (San Diego, USA) and the Manchester Institute of Biotechnology are collaborating on a BBSRC funded project to investigate novel yeast microorganisms able to thrive in low pH conditions. The research will initially focus on characterising known yeasts at a molecular level, with follow on research exploring how novel hybrids could produce organic acids at higher yields, without the need of pH control. BP have also joined the Future BRH to further investigate the biomanufacturing of organic acids, and other sustainable chemicals. Through combining the efforts of the Biosciences Center and the Future BRH the goal is to unlock the potential of biotechnology to accelerate chemicals manufacturing into a lower carbon future.

CASE STUDY: DSTL SYNTHETIC BIOLOGY FOR ADVANCED FUNCTIONAL MATERIALS In recent years, the UK’s Defence Science and Technology Laboratory (Dstl) has supported several research projects with the Manchester Institute of Biotechnology with the goal of developing exploitable innovative technologies to further advance the UK’s strategic defence and security interests. Capitalising on Manchester’s world-leading multidisciplinary research capabilities in synthetic biology, advanced materials and biomanufacturing, these projects have included: • Synthetic spider-silk fibres and biomimetic fibre spinning for wearable personal protection • Transparent protein-based adhesives for use in ballistic glass • Porous silk/activated-carbon fibres for protection against chemical warfare agents • Production of strategically significant material precursors (e.g., Kevlar® and other aramids) from engineered microorganisms • Graphene-aramid composite fibres for wearable personal protection • Active camouflage materials based on synthetic proteins derived from cephalopods Under its Engineering Materials theme, Future BRH is advancing these projects though its platform capabilities including biocatalyst engineering (Platform 1) and industrial host strain engineering (Platform 4). To advance these projects, the Future BRH is working with the Henry Royce Institute for Advanced Materials, Dstl and other industry partners, using technologies at the interface with synthetic biology and advanced materials.

FUTURE BIOMANUFACTURING RESEARCH HUB | futurebrh.com | Annual Report 2020

14