4 minute read

SCIENTIFIC FOCUS

Industrial biotechnology (IB) is entering a golden age of opportunity. Technological and scientific advances in biotechnology have revolutionised our ability to synthesise molecules of choice, giving access to novel chemistries that enable tuneable selectivity and the use of benign reaction conditions. These developments can now be coupled to advances in the industrialisation of biology to generate innovative manufacturing routes, supported by high throughput and real-time analytics, process automation, artificial intelligence and data-driven science.

By harnessing the power of biology through innovative IB, the Future BRH is aiming to support the development of safer, cleaner and greener manufacturing supply chains, and processes that support the emergence of the bioeconomy that will place the UK at the forefront of global economic Clean Growth in key manufacturing sectors:

Advertisement

• Pharmaceuticals; • Value-added chemicals; • Engineering materials; • Advanced Biofuels

The strategy of the Future BRH is to address the entire manufacturing lifecycle, by considering aspects such as scale-up, process intensification, continuous manufacturing, and integrated and whole-process modelling. To achieve this the Hub is working to deliver new biocatalysts, robust industrial hosts and novel production technologies that will enable rapid transition from proof-of-concept to manufacturing at scale.

The emphasis is on predictable deployment of sustainable and innovative biomanufacturing technologies through integrated technology development at all scales of production, harnessing UK-wide world-leading research expertise (particularly across the Hub and Spokes) and frontier science and technology, including data-driven Artificial Intelligence (AI) approaches, automation and new technologies emerging from the 'engineering of biology'.

LINKING DISCOVERY SCIENCE, ENGINEERING, INNOVATION AND INDUSTRY TO ADVANCE UK BIOMANUFACTURING

ACADEMIC PARTNERS

Synthetic Biology (SYNBIOCHEM) Biocatalysis, Analytics, Automation, AI

Biocatalysis and Biotransformation Integrated Bio- and Chemocatalysis

Biochemical Engineering, High Throughput Bioprocess Development

Techno-Economics, Life Cycle Analysis, Process Design, Reaction Efficiencies

Synthetic Biology, Engineering Biology for Biomanufacturing The Future BRH is taking a leadership role within the national industrial biotechnology research and innovation landscape by partnering across the UK’s leading Centres with complementary expertise in the IB biomanufacturing space.

Future BRH has its Hub at the Manchester Institute of Biotechnology at The University of Manchester, with academic research spokes at Imperial College London, University College London, University of Nottingham and the UK Catalysis Hub.

INNOVATION CENTRES AND LARGE SCALE FACILITIES

Innovation and Knowledge Centre for Synthetic Biology, Accelerating Technology Commercialisation

De-risking Scale-up. Driving Industry-Academic Interactions in IB. Training for a Skilled Workforce

Leading UK Technology Innovation Centre, Supply Chains and Scale-up for Full-scale production Processes By partnering with Innovation Centres and scale-up facilities, the Future BRH aims to bridge the gap between academic innovation and commercialisation, to understand the risks and strategies needed to support industrialisation of biomanufacturing at full scale production.

PARTNERING BEST WITH BEST

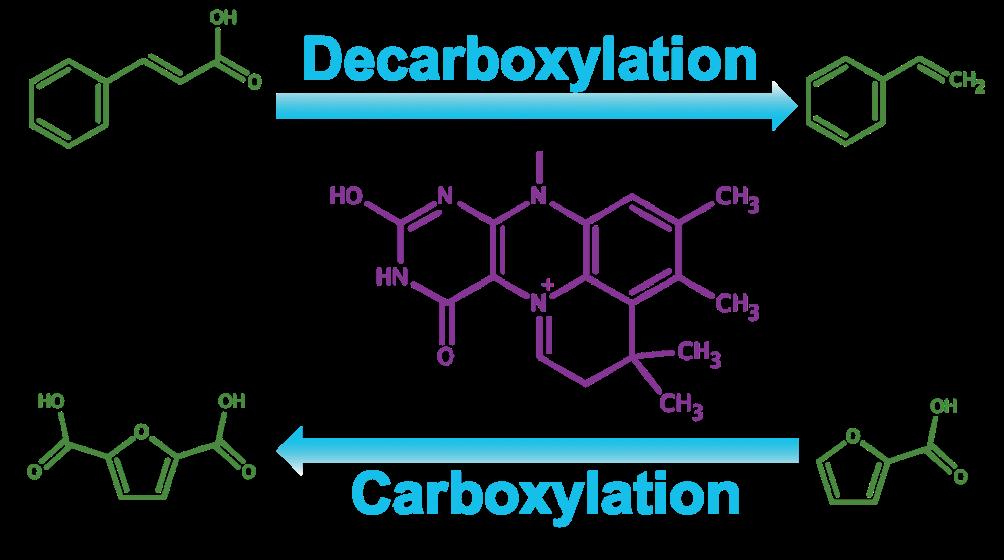

GRAND CHALLENGE 1 (GC1): ACCELERATED DEVELOPMENT AND INTEGRATION OF BIOCATALYST ENGINEERING

The impact of industrial biotechnology on many industrial processes is currently limited by the rate of protein engineering. It simply takes too long to optimise enzymes for their widespread use in manufacturing supply chains. The goal of GC1 is to engineer biocatalysts up to an order of magnitude faster than the current industrial timeframe.

Each biomanufacturing process requires enzymes that are optimised for that specific application (e.g. reaction catalysed, catalytic efficiency, enzyme stability, etc). P1 is focused on the front end of an automated Design-Build-Test-Learn cycle for directed evolution (DE) to enable rapid enzyme optimisation. Intelligent methods for designing controlled variant libraries are being developed to overcome current limitations of DE on combining mutations and applied to automated library build methods. The aim is to rapidly engineer enzyme variants that fit these criteria by combining rational in silico design and DE into a fully automated data-driven process.

The resulting large sequence-activity datasets can then be used to create models capable of predicting enzyme function directly from amino acid sequences using machine learning approaches. This will greatly enhance our understanding of enzyme sequence-activity relationships, ultimately providing better predictability for design, and thereby reducing the lead-time for identification of optimised enzyme variants.

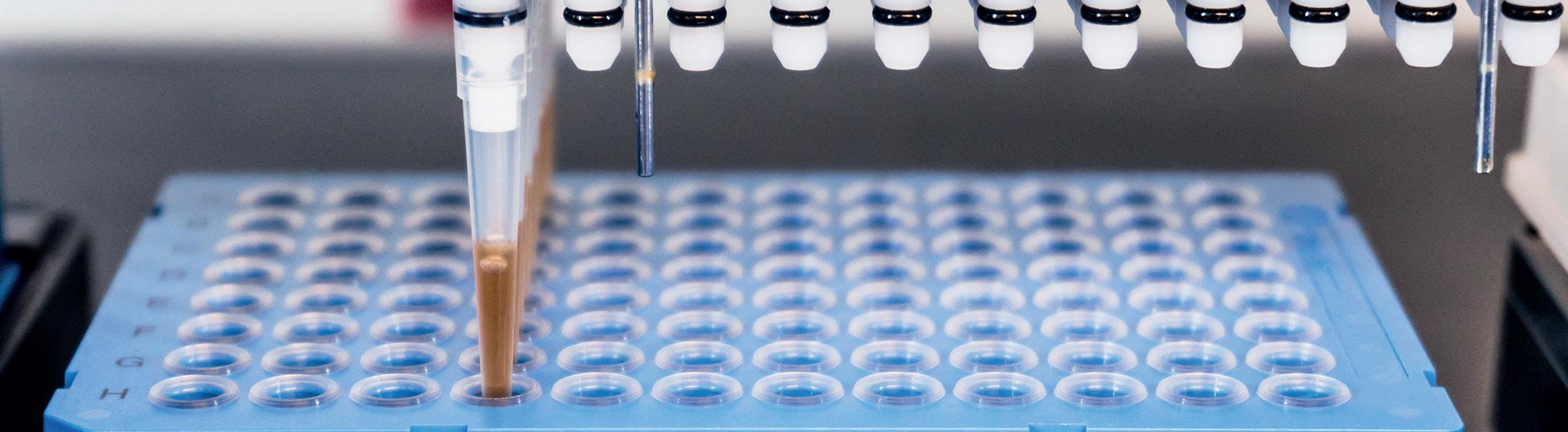

Automated DE platforms, which combine smart library creation with HTP analytical screening in P2 and Next Generation Sequencing (NGS), will provide the enabling technologies to fully realise the potential of enzymes in biomanufacturing. Initial target enzymes used to establish workflows and develop the automated pipelines, have a wide range of potential applications in the pharmaceuticals, fine chemicals, materials, and biofuel industries.

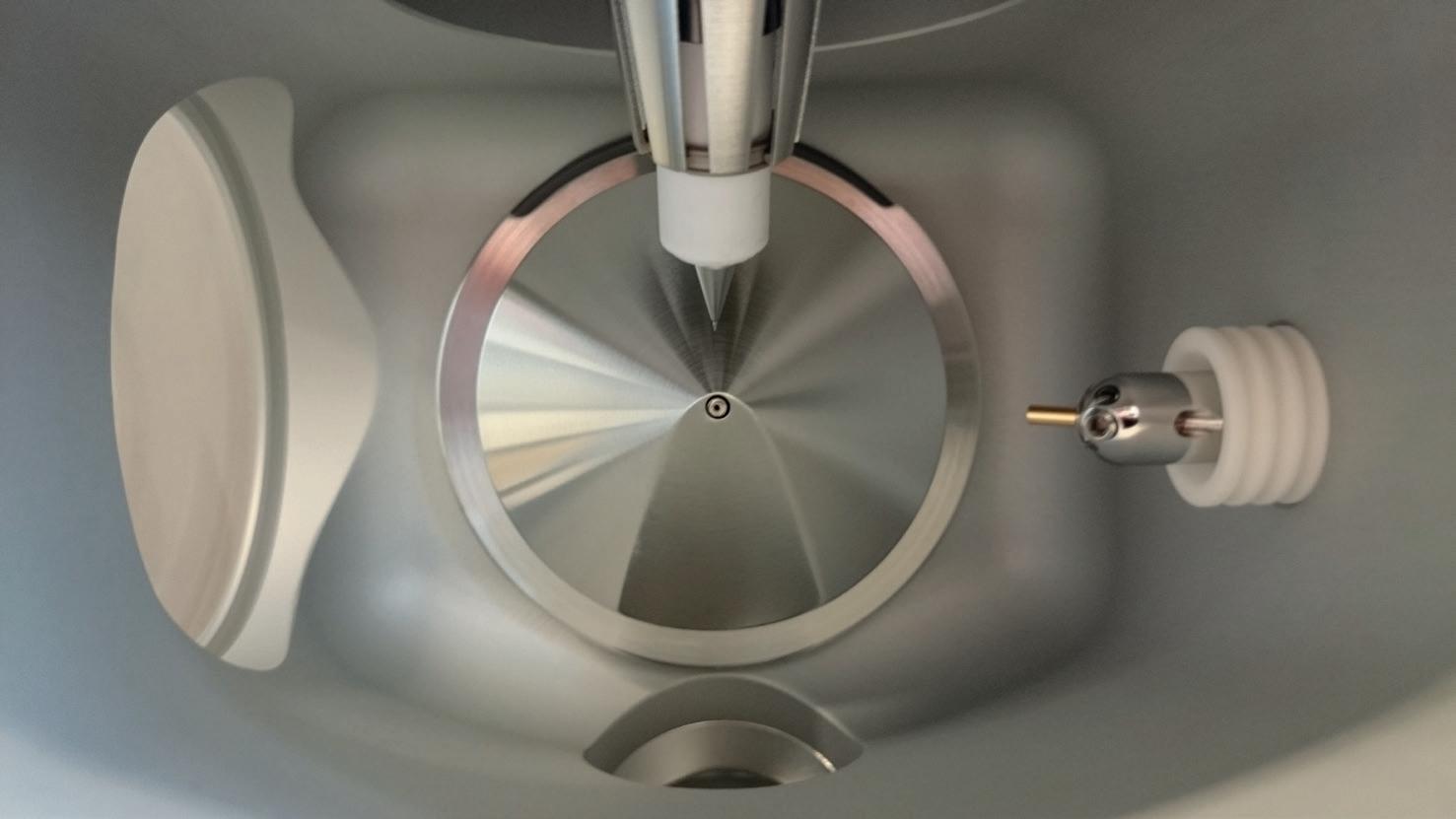

P2 aims to develop fast reliable advanced spectroscopic assays for different enzyme classes, focussing on mass spectrometry (MS) as a label-free technology to accurately measure biological processes and reaction profiles.

Direct on-colony screening and sample-chip analysis are supporting rapid biocatalyst delivery (GC1), and pico-droplet based ion mobility MS aims to allow analysis of single live cells to screen combinatorial libraries for industrial strains (GC2).