4 minute read

INDUSTRIAL PARTNERSHIPS

GRAND CHALLENGE 2 (GC2): REALISING THE VALUE OF INDUSTRIAL BIOTECHNOLOGY AT SCALE

The aim of GC2 is to change the economic reality of scaling-up bio-based processes by addressing the entire manufacturing lifecycle, considering aspects such as process intensification, continuous manufacturing, and whole-process modelling.

Advertisement

PLATFORM 3 (P3): CONTINUOUS FLOW BIOCATALYSIS AND IMMOBILISATION

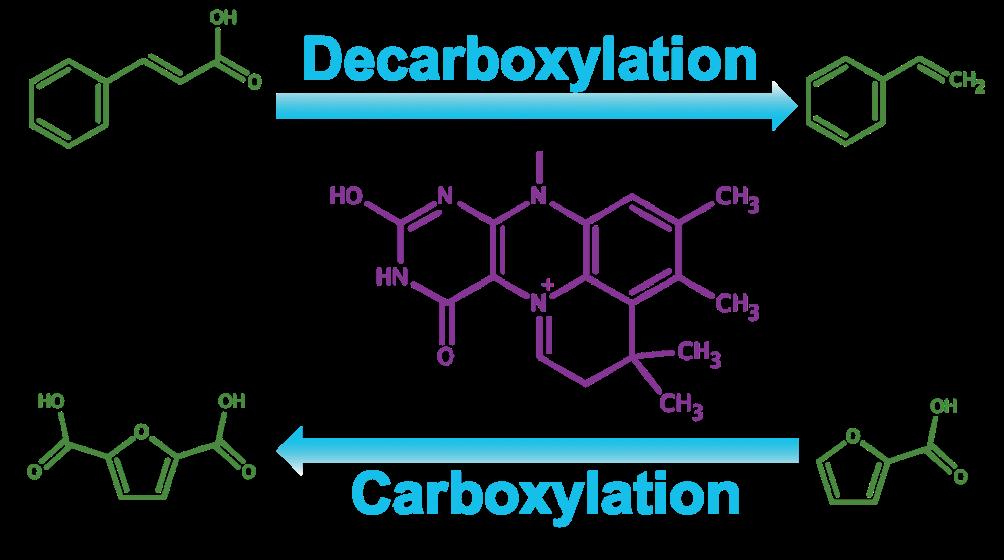

Modular continuous flow reactor systems using immobilised enzymes in packed bed reactors are being developed to exploit the inherent chemical orthogonality of biocatalysis in biomanufacturing. P3 is incorporating biocatalytic retrosynthesis and enzyme engineering in collaboration with industrial partners leading on enzyme production, immobilisation and flow reactor design.

Initial projects explore how different immobilisation methods could enhance the properties of biocatalysts and how these can be scaled up, primarily in continuous flow but also as recoverable batch catalysts. New immobilisation methods that could challenge established protocols are being investigated, focussing on utilising cheap and renewable feedstocks as immobilisation scaffolds.

PLATFORM 4 (P4): INDUSTRIAL HOST ENGINEERING

The future of biomanufacturing will depend on the successful development of robust industrial host strains able to utilise multiple feedstocks and tolerate non-sterile conditions. An early focus is developing a Design-Build-Test-Learn platform for Halomonas bluephagenesis production of platform chemicals in collaboration with the SYNBIOCHEM Centre.

A deeper understanding of this strain at a systems level is being developed through the combined study of its genomics, transcriptomics and proteomics under different conditions. A combination of approaches based on in silico methods, automated Ligase Cycling Reaction (LCR), and advanced genome editing (e.g. CRISPR methods and chromosomal integration) are being utilised to improve prototyping in cell strains and develop these for scale-up process conditions.

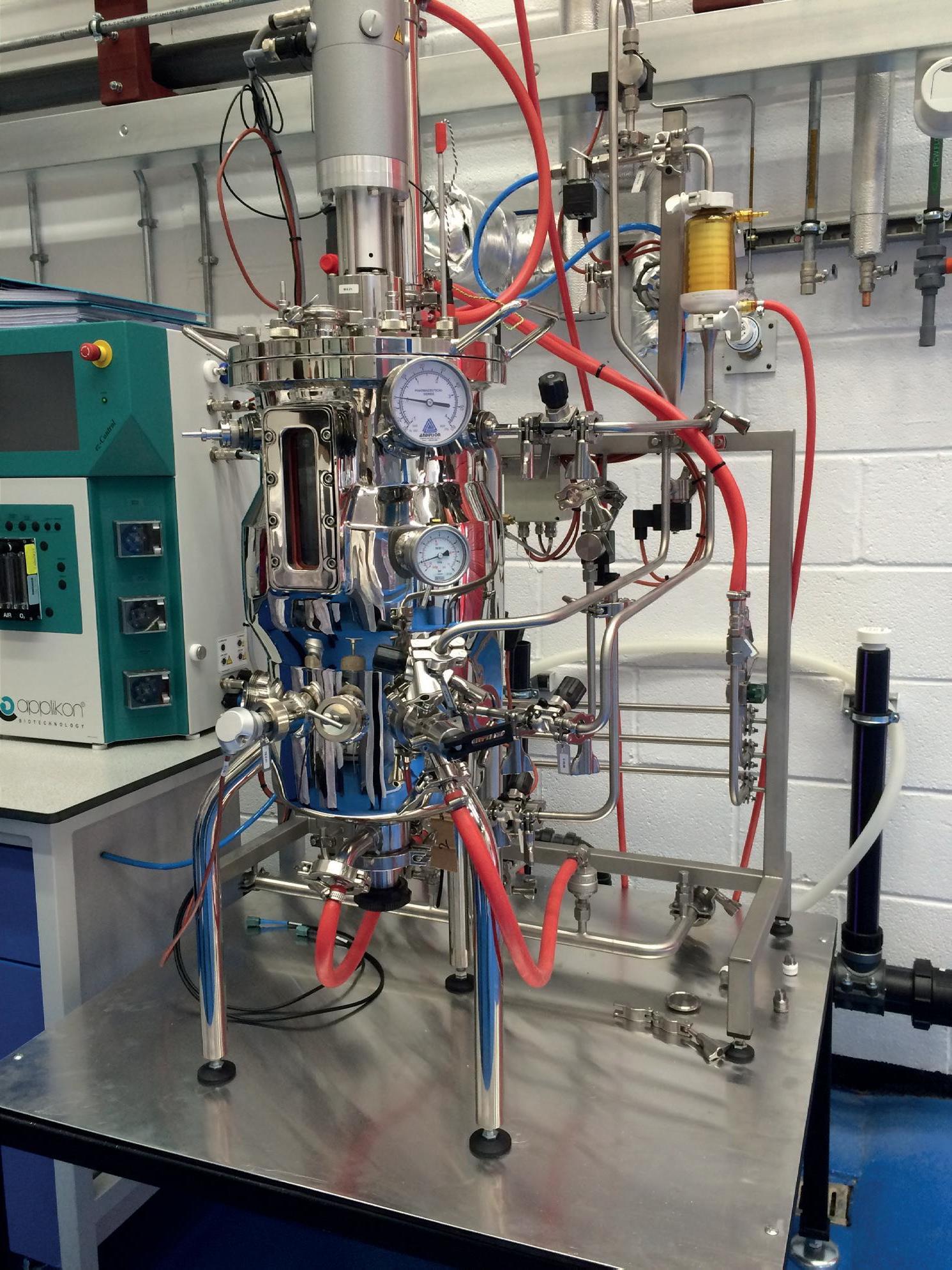

PLATFORM 5 (P5): SCALED BATCH AND FLOW FERMENTATION

P5 is focused on developing integrated, continuous processes for large-scale chemicals manufacture. Innovative bioprocesses at various scales coupled with robust downstream processes are being developed to allow efficient recovery of final products, to guide optimisation and inform techno-economic comparisons with incumbent processes (where relevant). Next generation bioreactors with integrated analysis will also be developed to allow real-time monitoring, feedback control and robust scale up of reactions.

The global market is shifting towards a circular and more sustainable economy. Legislation restricting single-use plastics and the promotion of bio-based products has accelerated the adoption of industrial bio-manufacturing processes as alternatives to the petrochemical industry.

Downstream processing (DSP) often accounts for up to 70% of process costs so identifying efficient, cost-effective methods for isolation of targets is crucial. Using scale-down bioreactor models in parallel to bio-production allows for bespoke engineering to integrate DSP with fermentation, thus informing the next generation of bioreactors featuring real-time monitoring and optimal product recovery. DSP development also enables early techno-economic analysis of the entire bioprocess life cycle, identifying bottle-necks which feeds back to our bio-process development, this is intrinsic to the platform’s success.

This holistic approach of targeting the entire bio-process lifecycle will allow us to succeed where other biomanufacturing processes have been hampered by low productivities, low product concentrations and usually ad hoc and inefficient DSP.

RESPONSIBLE RESEARCH & INNOVATION

The Future BRH scientific research portfolio is complemented by Responsible Research and Innovation (RRI) work (in partnership with the SYNBIOCHEM Centre) that considers and anticipates possible environmental and societal impacts of biomanufacturing.

This area includes deliberation of ethical, societal, regulatory and policy issues, and research on sustainable industrial systems and collaborative development with stakeholders (business, regulatory, policy and non-government organisations).

Programmes of work also include constructive sustainability assessments and socio-techno economic analysis of target compounds.

The Future BRH funding proposal was supported by over 40 industrial partners from a range of different manufacturing sectors. Their input was crucial in shaping the scope of the Grand Challenge and Platform Research areas. There are two levels of industrial engagement:

CORE PARTNERS Core Partners are companies who are financially contributing to the Future BRH, with both cash and in-kind contributions. In return these Core Partners receive a range of benefits, including:

• A seat on an Industrial Board to shape Future BRH research • Early sight of the outputs of the Grand Challenge and Platform research programmes • Access to platform technologies, equipment and scale-up facilities • Knowledge Exchange opportunities • Confidential research projects

To facilitate these interactions, a Core Partner Agreement allows research outputs to be shared with the Industry Board in confidence. This research is predominantly non-competitive in nature and of interest to multiple sectors. Core Partners can suggest so called ‘Community Projects’ that might benefit the wider biomanufacturing community. More commercially-sensitive research is via Confidential Projects.

Founding Core Partners (at application): Allergan, Almac, Arcinova, Biocatalysts, Biopropane consortium (4 SMEs), BP, Britest, Calysta, CoEBio3 consortium (8 companies), Croda, Dstl, EnginZyme, GSK, Ingenza, Johnson Matthey, Prozomix, Quorn, Shell, Singer, Sphere Fluidics, Unilever.

ASSOCIATE PARTNERS Associate Partners benefit from free of cost networking that is primarily focused on scientific dissemination. The aim is to promote biotechnology to companies who are keen to learn more about biomanufacturing, or are otherwise engaged in collaboration with the Future BRH Hub and Spokes.

Engagement is through direct communication (i.e. regular newsletters), invitation to the annual conference, and free access to knowledge exchange events. Where appropriate, engagement might be though the writing of brief landscaping reports to signpost alternative biomanufacturing approaches. The aspiration is that members at this level will become Core Partners in due course.

Dr. Kirk Malone - Director of Commercialisation