company profile

CONCRETE SOLUTIONS

From The CEO

Since its establishment in 2015, 3S Ready Mix has achieved excellent progress in the market.

Through the years, 3S Ready Mix has delivered its integrated concrete services to many projects & companies in Egypt.

3S Ready Mix has been a trusted subsidiary company to Hassan Allam Holding, since its establishment in 2015. The company has since charted a steady course, delivering both economic and intrinsic value to our stakeholders, in the process building a portfolio that features some of the most iconic projects in Egypt.

Throughout this rapid growth, 3S Ready Mix continues to be have commitment towards our customer and support them to achieve their requirements with best quality on due time.

Being part of a great Group like Hassan Allam Holdings is central to 3S Ready Mix ‘s philosophy, that workplace safety is just as important to 3S Ready Mix, as seeking mature talent, developing best practices and utilizing the most modern technologies to deliver on our commitments.

3S Ready Mix is committed to help our partners realize their vision with efficiency in a brave new world, where no ambition is too ambitious, and where partnership means much more than a signature or a contract.

3S Ready Mix is here to help manage your vision for a better future.

MOHAMED EL DAGHASHY

Mohamed El Daghashy

1 – House Keeping

3 – Isolation Procedures

5 – Working at heights

6 – Confined spaces

7 – Safety inductions & Trainings

1 - Standard Operating ProceduresTraining (SOPS Training)

- Drivers - Maintenance team

- Plant operators - QC technicians

- Pump operators

2 - Safety Campaigns

- Safety driving - Management

- Safety tours - participation

3 - Safety indicators

- LTIs - TRIs - Fatalities

1 - Aggregates

Which is made up of roughly 60% to 75% of ready-mix concrete’s volume, are obtained from quarries and aggregate banks.

2 - Additives

Are solid or liquid chemical substances that can be added to ready-mix concrete before or during preparation. Most commonly used additives either Improve a hardened concrete’s durability or reduce a concrete’s water content in an effort to shorten setting times.

3 - Water

This is the Mix’s vital fluid, Which sets of a chemical reaction when it comes into contact with the cement.

No other material rivals cement’s importance in the mix; It’s the ingredient that gives concrete its resistance. Although types II and IV are also employed, the most widely used cements are gray Portland type I and Pozzolana Portland type C2We used in our projects OPC , SRC , Type II , CEM III

During the mixing phase the different components come together to produce a uniform mass of concrete. Mixing time is registered from the moment material and water are poured into the cement mixer, and it begins rotating. While transporting concrete to a site, the cement mixer never stops revolving at a speed of two to six rotations / minute.

In a high hazard industry like construction, safety is an investment that provides real benefits. A safe work environment helps to keep skilled employees on the job and projects on track by reducing accidents that result in injuries and schedule delaysQ, while also reducing the risks of litigation and regulatory action.

Our top priority is customer satisfaction. Our team is very keen to providing customers with a unique level of service.

We provide the required services that exceed their expectations.

We offer you expert support and answer any questions or concerns you might have.

We also appreciate any feedback you’d like to give. It’s only through close relationships and ongoing dialogue with our customers that we’re able to better.

Grading (sieve analysis)

% passing sieve No.200

Moisture content

Unit weight and voids in aggregates

Clay lumps and friable particles

Specific gravity &absorption.

Resistance to abrasion using Los angles machine.

Potential reactivity.

ASTM C 136

ASTM C 117

ASTM C 566

ASTM C 29

ASTM C 142

ASTM C 127

ASTM C 131

ASTM C 289

ASTM D 4791

Flakiness and elongated particles. E . C for R.C

Chemical analysis(Chloride Sulfate). Structure limits

Once per day

Once per week

Once per month or when source change

Grading (sieve analysis)

% passing sieve No.200

Moisture content

Unit weight and voids in aggregates

Clay lumps and friable particles

Specific gravity &absorption.

Potential reactivity.

Organic impurities.

Chemical analysis(Chloride Sulfate).

ASTM C 117

ASTM C 136 Once per day

ASTM C 566

ASTM C 29 Once per week

ASTM C 142

ASTM C 289

ASTM C 40

ASTM C 128 - Once per month or when source change

E . C for R.C Structure limits

Time of setting by vicat apparatus. ASTM C 191

Fineteness (by Blain) apparatus ASTM C 204

Compressive strength ASTM C 109

Physical Analysis Once every month

Chemical analysis

Chemical analysis C3A content

Total alkali, SO3 ASTM C 114

Density

PH ASTM C 494

Chloride content

Solid content

ASTM C 494

One test each delivered

Once every month & when source change

Chemical analysis (Chloride –Sulfate T.D.S –pH)

E.C for RC Structures limits or project specs

Once every month

Visual inspection Every Truck Temperature 50/1m3 or 1/mix

Slump test ASTM C143 50/1m3 or 1/mix

Concrete cubes

Hardened Concrete density

Hardened Concrete Comp. strength

BS 1881 – Part 108

One set (6cubes) for every recipe/day or 1Set/100m3

BS 1881 – Part 114 at 7 days 3 cubes, at 28 days 3cubes

BS 1881 – Part 115 at 7 days 3 cubes, at 28 days 3cubes

Digital Compressive Strength 2000KN

For Cubes up to 150mm

Stainless Steel slump with accessories

Cubes 150*150*150mm (local) New

Air Meter type B

Tapes 2ms (local)

Digital Thermometers 50- to 150 with cable not probe

Dial Thermometers 0 to 60

Glass Thermometers 0 to 110 (local)

Digital or automatics scale 30Kg capacity , 5gm acc.

Digital scale 6Kg capacity, 0.1gm accuracy

Modar Mixer for Cement tests

Setting time apparatus (Vicat)

ITEM

ITEM

Crushing Value apparatus with accessories

3liters unit weight

Sample splitter

Cover & Pan

Pycnometer

Glass measuring cylinders 25

Glass measuring cylinders 100ml

Glass measuring cylinders 500ml

Glass measuring cylinders 1000ml

Glass Bakers 100ml

Glass Bakers 600ml

ITEM

Stoppered volumetric flask 1000ml

Scoops 1000ml

Aluminum pan Small

Aluminum pan Medium

Aluminum pan Large

Aluminum dish 200mm diameter

Hot plate

Dry oven 125liters

Brass brush

Steel brush

Rectangular trowel

Computer and printer

General purpose tool kit

Tamping rod for cubes

Is a composite material composed of coarse aggregate bonded together with a fluid cement which hardens over time.

Most concretes used are limebased concretes such as Portland cement concrete or concretes made with other hydraulic cements, such as cementfondue. However, road surfaces are also a type of concrete, asphalt concrete, where the cement material is bitumen, and polymer concretes are sometimes used where the cementing material is a polymer.

Mortars are used in masonry for joining stones, bricks, blocks etc. and plasters are used for rendering on the outside and inside of walls. The differences between mortar & plaster lie in the capacity of plasters to take better finish, which depend on a very large extent of the type of sand used in the mix. For plasters we use finer sand.

However the term mortar is also used loosely to refer to both plasters and mortar.

Is a low cost solution for an untracked section designed of concrete members. Uses steel fiber reinforcement in concrete to enhance the ability of structural members in order to carry significant stresses.

The use of fibers increases the toughness of concrete under any type of loads.

Fibers in concrete has the ability to absorb more energy.

Concrete which, through the use of high‐early‐strength cement or admixtures, is capable of attaining specified strength at an earlier age than normal concrete.

Self‐compacting concrete (SCC) is a flowing concrete mixture that is able to consolidate under its own weight. The highly fluid nature of SCC makes it suitable for placing in difficult conditions and in sections with congested reinforcement. Use of SCC can also help minimize hearing‐related damages on the worksite that are induced by vibration of concrete.

Another advantage of SCC is that the time required to place large sections is considerably reduced.

Is a concrete containing fibrous material which increases its structural integrity. It contains short discrete fibers that are uniformly distributed and randomly oriented.

Type of concrete which includes an expanding agent in that increases the volume of the mixture while giving additional qualities such as nailbility and lessened deadweight.

Slip form is a method of construction in which concrete is poured into the top of a continuously moving formwork.

As the concrete is poured, the formwork is raised vertically at a speed which allows the concrete to harden before it is free from the formwork at the bottom.

Successful slip form depends on the delivery of a high-performance concrete with uniform and predictable properties.

The essential slip form properties of the fresh concrete can be defined as the following;

• Slump (or workability)

• Setting time (at all times tailored to the intended lifting rate)

• Stability (absence of segregation)

Watertight designed to protect a structure from water ingress or to retain water within a structure, Watertight admixture reacts with the cement hydration process to form a hydrophobic ingredient to reduce the capillary suction and prevent the ingress of potentially deleterious soluble material, resulting in concrete with enhanced durability. Watertight concrete is used to water tank, pool and Basement.

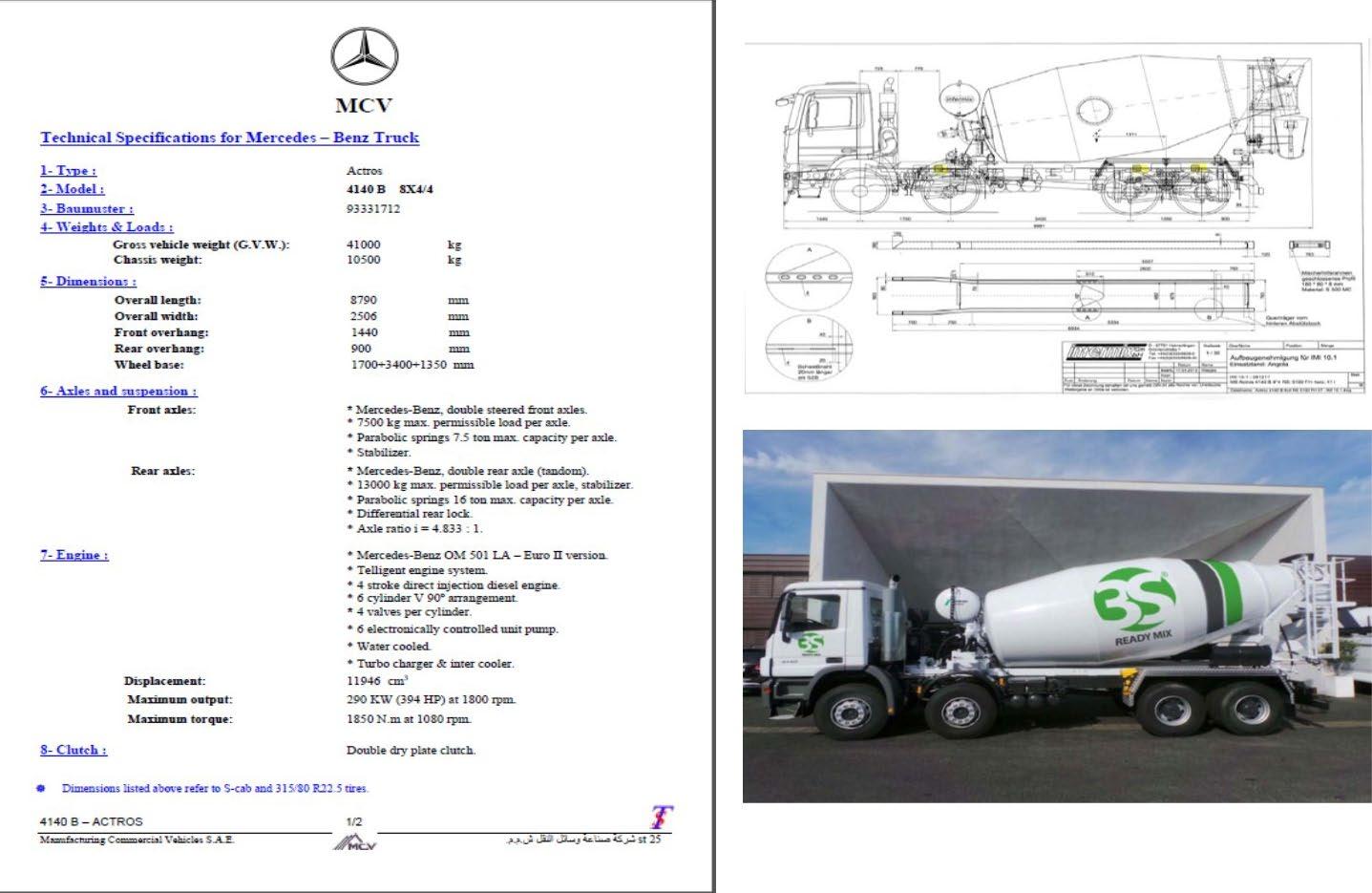

Mercedes Benz Actros 4041 / Truck mixer size 10m3

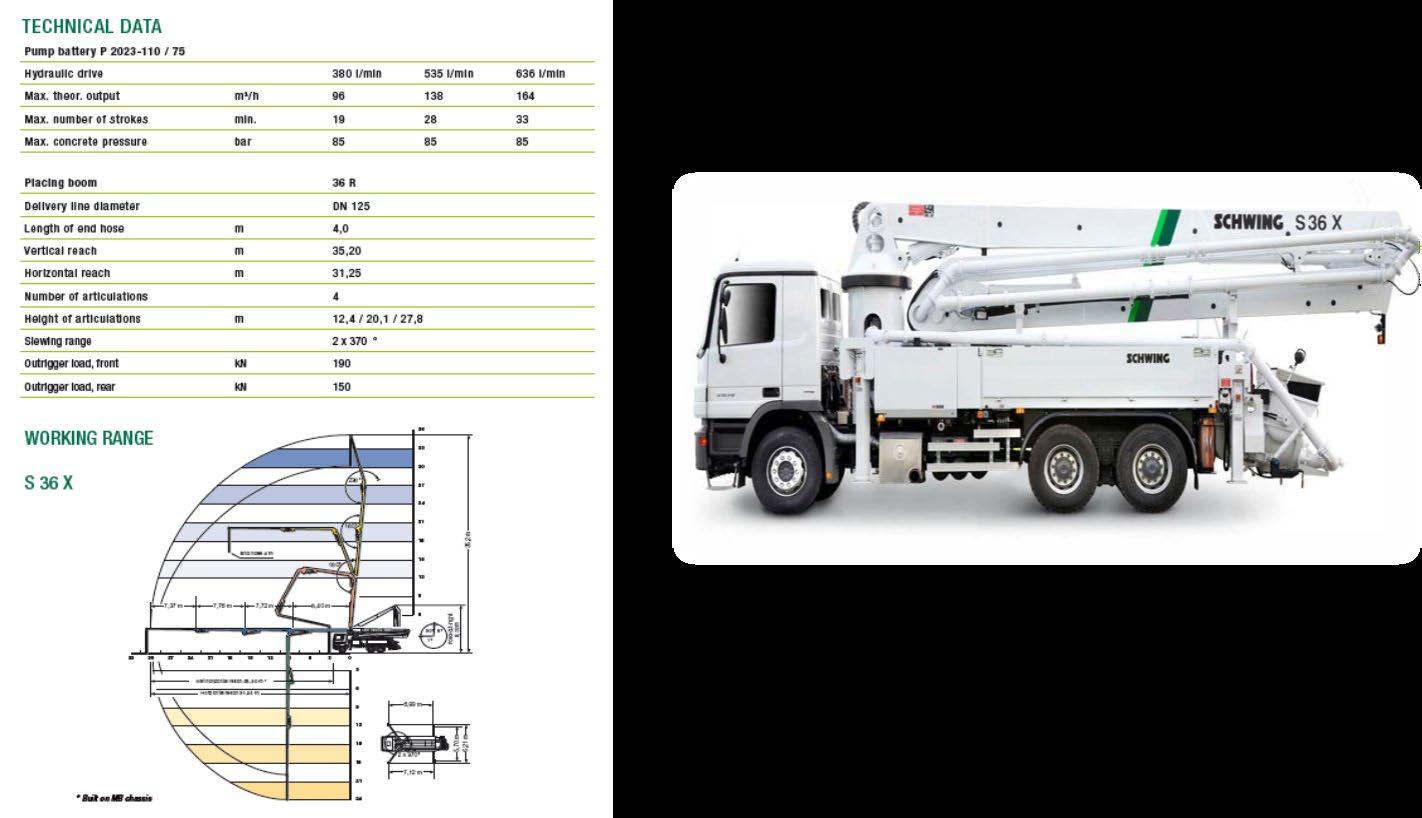

SCHWING–Truck Mounted 36 X Mobile pump

SCHWING–Truck Mounted S 47 SX Mobile pump

Address : 78 El-Moltaka El-Araby St., Ground Floor, Sheraton, Heliopolis, Cairo, Egypt

Telephone : +2 (02) 20644034

+2 (02) 20644092

+2 (02) 20644091