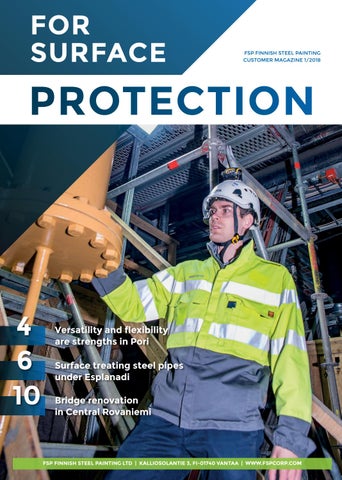

FOR SURFACE

FSP FINNISH STEEL PAINTING CUSTOMER MAGAZINE 1/2018

PROTECTION

4 6 10

Versatility and flexibility are strengths in Pori Surface treating steel pipes under Esplanadi Bridge renovation in Central Rovaniemi

FSP FINNISH STEEL PAINTING LTD | KALLIOSOLANTIE 3, FI-01740 VANTAA | WWW.FSPCORP.COM