20 minute read

HIGH PROFILE – BELAZ

FLSmidth looks for sustainable gains

Global mining OEM looks to arm itself to compete in brave new sustainable world

Advertisement

The subtleties behind FLSmidth’s acquisition of thyssenkrupp’s mining business appear to have got lost within the financial community.

The company’s Denmark-listed shares, since announcing the transaction in late July, lost 16% of their value to August 20.

This downward move is hardly surprising when focusing on pure financials: FLSmidth is looking to acquire a company for an enterprise value of $325 million that is only expected to return to profitability two years after financial close.

Yet, this narrow train of thought discounts the well-timed strategy behind the move.

A combination of the two companies will undoubtedly create a leading global mining technology provider with operations from pit to plant. It will also see FLSmidth re-geared towards a mining sector on the up at a time when the cement business it serves is exhibiting flattish demand.

While this won’t be lost on analysts, most of them will only be able to factor in short-term profitability projections into their financial models, meaning, as far as they’re concerned, FLSmidth will be weighed down by the transaction until 2024.

Yet, for FLSmidth and mining, 2024 is practically ‘just around the corner’.

In FLSmidth’s recently released June quarter results it registered an order backlog of DKK16.7 billion ($2.6 billion), the majority of which was associated with mining orders. Of the backlog amount attributable to the mining sector, 16% would not be realised until 2023 and beyond.

This could mean many of the orders FLSmidth registered in the most recent June quarter will only be realised (read: delivered) in 2024, the year thyssenkrupp’s mining business is expected to be back in the black.

This is just one of the subtleties that may have got lost by shareholders fixated on the short term.

The second is how the transaction sets the company up as a mining sustainability leader at a time when the industry is calling out for one.

At the top end of the mining industry, the ability to decarbonise operations is becoming as – if not more – important as returning cash to shareholders. Every tonne of copper extracted and processed, and every ounce of gold mined and refined is likely to come with an associated carbon content/price in future years. The battery materials supply chain tied to the likes of lithium, cobalt and nickel will come under even more scrutiny.

Blockchain-type traceability platforms will mean investors and any interested party can interrogate where the raw materials came from and how they were produced.

These same miners will also be judged on how they use water, with freshwater use being rationalised in many regions where such resources are scarce.

FLSmidth, should the acquisition complete next year, is arming itself to compete in this brave new sustainable world.

The company started this journey all the way back in November 2019 when it announced its MissionZero program at its Capital Markets Day in Copenhagen.

Central to MissionZero is FLSmidth’s focus on enabling its customers in cement and mining to move towards zero emissions operations in 2030.

The OEM planned to do this by leveraging the development of digital and innovative solutions tied to sustainable productivity, offering its customers in the mining sector the technological solutions to manage zero emissions mining processes by 2030 – with a specific focus on water management.

For the latter, dry-stack tailings was the order of the day, with FLSmidth’s EcoTails® solution expected to reduce water costs, tailings dam risks and minimise environmental footprint. The development of the largest filter press plate ever built, the 5 m x 3 m AFP, was a signal of just how confident FLSmidth was on this emerging market trend becoming fully embedded across the globe.

Digital products such as SAGwise™, SmartCyclone™, BulkExpert™ and Advanced Process Control would, in the meantime, allow miners to become that more efficient with every resource (water, energy, etc) they used, again, improving their sustainability credentials.

Close to two years after making the MissionZero declaration, Thomas Schulz, CEO of FLSmidth, says the company has been seeing the program’s effects come through in its order book.

“Actually, this has been translated in orders for a few years already,” he told IM.

“When we look into sustainability, we define it as making productivity improvements. If you don’t adopt these sustainability solutions, you effectively have to pay more to keep operating at the same levels, or you have to stop operating –there is a productivity element to it, and quite a big one.

“For us, as a lifecycle provider, it is important that we offer to our customers at any point in time and any point of our offering, the right solution to make more money. That can be with dry-stacked tailings, tailings management, IPCC (in-pit crushing and conveying) systems, electrification of the pit, reducing emissions or dust, etc.”

Many of these solutions will enable companies to produce the same amount of product, or more, with the same input costs and energy draw, according to Schulz.

Coping with further restrictions on the industry’s access to freshwater will require more than step-change initiatives, and that is why the company is working on how its equipment can use “different types of water” and technologies that use less freshwater to ensure operations can abide by incoming legislation.

The company has been working on providing these zero-emission and resource-efficient

Heavy-duty overland conveyors are just one of the solutions thyssenkrupp mining will bring to the FLSmidth business

solutions since 2019 to enable its customers to become sustainable operators by 2030.

“For many people, that sounds very long,” Schulz said. “In the mining industry, it’s not.”

Factor in the two-to-three years to build a pilot plant to prove such technology, two-to-three years to get a full-scale plant approved and the associated construction time, and a decade has passed.

Sustainability represents the ‘long game’ for mining OEMs, and technology is the key to achieving that sustainability, Schulz said.

Which brings us back to the thyssenkrupp mining business acquisition.

One of the big pillars

FLSmidth, in adding thyssenkrupp mining to its portfolio, is providing a whole host of decarbonised options for its mining customers to consider in their own sustainability drive.

It is adding mine planning expertise to its portfolio, ensuring that the IPCC and continuous surface mining technologies it puts forward are optimised for the operation at hand. These technologies are further complemented by semicontinuous and mobile crushing options from thyssenkrupp mining, adapted to the pit profile at hand.

Heavy-duty overland conveyors from thyssenkrupp mining complement other bulk handling solutions FLSmidth might be providing at stockyards or ports to reduce truck haulage and shift the transport dynamic to ‘green’ grid power.

Then, when it comes to comminution, a crushing (including primary jaw crushers) and screening portfolio, plus smaller milling options and expertise in high pressure grinding rolls (HPGRs) through the globally renowned Polysius business, is bolted onto FLSmidth’s own crushing and grinding (including vertical roll milling technology) portfolio. This puts the combined offering up there with any global OEM around, while also providing the potential ‘dry grinding’ technologies the industry has been on the lookout for.

All these solutions come with sustainability benefits that can be felt throughout the mining value chain.

They also provide options and flexibility to an industry that cannot just suddenly retire a fleet of ultra-class haul trucks at a deep open-pit operation in favour of a fixed IPCC solution, or build a new process plant fitted with HPGRs to replace a typical SAG and ball mill grinding circuit. Schulz said as much to IM.

“One of the big pillars of the whole acquisition lies in sustainability,” he said. “Normally, the process plants where we play big are all electrified, so if the energy resource coming into these plants is a green one, the process is already sustainable.

“When we look into the pit, in-pit crushing and transporting of material is where we can focus a lot.

“I’m not saying you can replace every truck, but some of the surface mines and the ones underground can be made significantly more continuous and sustainable from a transport perspective.

“thyssenkrupp is leading in that. They are quite big in the pit; we are quite big in the processing plant. Both, together, are complementary.

“If we can integrate the offering – and we will do – and make it more sustainable, that is a big step towards the 2030 MissionZero target.”

This increased spread of solutions will also provide FLSmidth with more opportunities to refine the entire flowsheet, providing further sustainability benefits to its customers.

“When we design solutions, or offer replacement equipment or a new process, we can now rely on expanded competences to look at what the best overall system for the entire flowsheet is,” Schulz said. “For instance, if we change the gyratory on a mine site and then look into the pit, we know how to size the equipment in the pit and the concentrator upstream.”

This increasing flowsheet focus must be complemented by an aftermarket approach that ensures the process remains efficient and sustainable throughout a product’s, solution’s or mine’s lifetime.

This was one of the obvious disparities between the two companies when the announcement was made in late July. It is also one of the biggest opportunities that comes with the planned transaction, according to FLSmidth. Whereas capital business represented 37% of mining revenue in 2020 for FLSmidth, it was 66% of revenue for thyssenkrupp’s mining business. Services represented 63% and 34% of the two businesses’ 2020 revenue total, respectively. Schulz has seen such a contrast – and opportunity – before, referencing his arrival at FLSmidth in 2013.

“When I came here to FLSmidth, it was actually quite similar,” he said. “I was at Sandvik for 16 years where the aftermarket was actually seen as the most important. They realised the importance of the customer relationship: the capital equipment sales team may meet the customer for a few hours per year, but the service technician has that interaction over weeks and months in terms of aftermarket.”

He also recognises the cultural shift needed to capture many of the profitable aftermarket dollars that the company is forecasting with the planned acquisition.

“The culture in project service companies is you are the hero if you come to the table with the next big project,” he said. “In product service companies, you are the hero if you come with the next big profit.

“You need both – we need profit, and our customers need profit to invest, while you need the projects to spur these aftermarket opportunities.

“We calculated what the aftermarket potential of the thyssenkrupp mining business is and understood it was not covered as they were all looking for the next big project, which we understand.

“But this is not what we will accept in the future. We have to have a strong aftermarket and strong customer link.”

Which all comes back to MissionZero.

“If you focus on MissionZero, then you invest there where you can impact MissionZero. Wherever you have aftermarket, you impact MissionZero. Where you don’t have aftermarket, you don’t impact MissionZero.”

At the same time, Schulz is not losing sight of the company’s end goal with all the business it coordinates in the mining sector.

“Whatever we do with the customer, they have to be more efficient, more productive and make more money.”

It just so happens that in doing this, the mining sector will become that much more sustainable. IM

“For us, as a lifecycle provider, it is important that we offer to our customers at any point in time and any point of our offering, the right solution to make more money,” Thomas Schulz says

BELAZ-7558E all electric batterypowered mining dump truck with payload capacity of 90 t Mine haulage robots

Mining truck innovation

Paul Moore caught up with Belarussian mining truck major BELAZ, which outlines here its current and future roadmap for mining haul truck technology

Battery-powered dump trucks, diesel trolleys, mining shuttle robots, unmanned technologies, robotic control systems, artificial intelligence, "smart" quarries for mining - all these are not fantastical concepts of the future, but the realities of a new era of technology, which is rapidly advancing. Following world trends and working towards the future, BELAZ is intensively introducing innovative technologies into its products, thereby helping to define the direction for the future development of open-pit mining equipment.

Each innovation developed and applied in the new equipment of the BELAZ enterprise is designed to improve reliability and safety, provide more comfortable conditions for the driver, and make the operation of the machines more costeffective. Electronics, "smart" technologies and other sensors and devices are being actively introduced into the structure of BELAZ equipment, which greatly facilitate more efficient operation and maintenance.

Striving to improve quality and efficiency, reduce operating costs, and improve the reliability, safety and environmental friendliness of mining dump trucks are the main driving forces behind BELAZ's innovations. And today the enterprise is already ready to deliver many of these modern machines, which will be discussed in this review.

Expanding of AC range

Firstly, OJSC “BELAZ” is first expanding production of its most in demand dump trucks with AC electric drive. The mining dump truck series BELAZ-7558 with payload capacity of 90 t has expanded with the production of the following three variants: the BELAZ-7558F, BELAZ7558C and BELAZ-7558D. The new 180 t dump truck, the BELAZ-75182, is equipped with a stateof-the-art AC electric drive system by Wabtec and has been manufactured delivered to customers. The product line of 240 t dump trucks has been reinforced with the manufacture of the new mining dump truck BELAZ-7531B which is equipped with a new efficient liquid cooling system for the AC electric drive control cabinet.

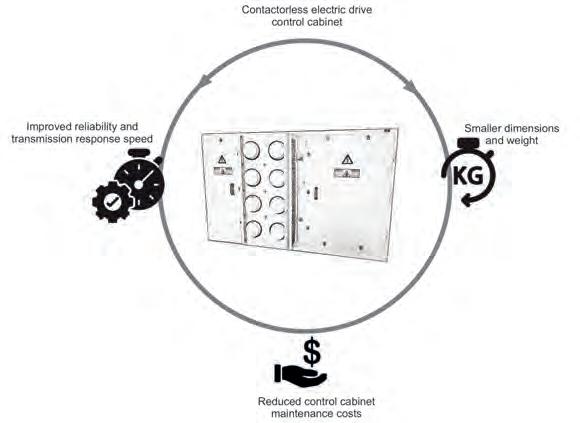

Pre-commissioning of the world’s largest mining dump truck, the BELAZ-75711, with a payload capacity of 450 t is also underway. BELAZ is constantly trying to improve its own designs and solutions applied in traction electric drive control systems. One example is the development and application of a non-contactor control system for a traction electric drive in dump trucks with an AC-DC transmission, which, as a result, increased the reliability of the unit and, as a result, the efficiency of the dump truck as a whole. Currently, this design is undergoing a set of operational tests on mining dump trucks with payload capacity of 130 and 220 t. Mining is being conducted in increasingly difficult and sometimes dangerous working conditions and in remote areas. Temperatures from -50°C to +50°C, depending on climatic zones, gas pollution, dust and sometimes increased background radiation are present challenges. In such conditions, the human factor unwittingly becomes the reason for a decrease in work efficiency. And here “smart” dump trucks from BELAZ can come to the rescue, as they can already work without a driver in the cab. A multitonne unmanned vehicle doesn’t required clean air, good visibility and lunch breaks. It performs all the necessary operations optimally and precisely.

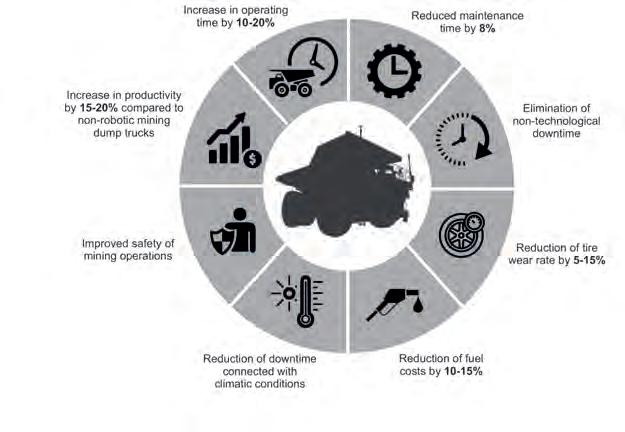

Work on the creation of the first robotic mining truck at BELAZ started back in 2009. Today, the first 130 t autonomous mining dump trucks of model BELAZ-7513R equipped with intelligent control systems have already proven themselves as high-performance trucks in the real operating conditions of Chernogorskiy open-pit coal mine in Khakassia, Russian Federation, where they transport overburden, moving along a dedicated road section of the open-pit with a length of 1,350 m.

The next step for BELAZ in the direction of expanding the range of manufactured robotic equipment is the production of a batch of mining dump trucks of model BELAZ-7558R with a payload capacity of 90 t, as well as the wheel loader BELAZ-7528D with remote control.

Robotic truck design features

The new BELAZ robotic mining dump trucks have a number of fundamental features that distinguish them favourably from earlier models due to the introduction of intelligent control systems for a new generation robotic mining dump truck. The intelligent system significantly improves the operational performance of the truck: xn Provides optimal parameters of movement xn Increases the time of using equipment due to

the absence of shift changes and lunch breaks xn Allows you to work in conditions of limited visibility and gas pollution xn At the same time, the use of robots in the mining industry significantly reduces the influence of the human factor, especially in places potentially dangerous to life (for example, uranium mines).

Today, for high-quality and smooth operation of robotic machines, the design of the main units of the dump truck has also been adapted: xn Developed a steering and braking system using hydraulic proportional valves, which are ideal for digital programmable systems. This made it possible, together with modern navigation systems, to achieve high positioning accuracy while driving, repeatability of the optimal route and fuel economy xn All the electronic systems of the machines involved in the mining process are united into one intelligent network, which makes it possible to generate detailed reports on the functioning of robotic equipment for assessing and adjusting work plans and transportation schedules, and service services receive up-todate information on the state of the components and systems of the robot, on the basis of which decisions are made on the planning of their maintenance xn In order to increase the speed and improve the quality of the transmitted video image and other information, the robot was tested with a new generation 5G GSM network.

One of the most important aspects requiring special attention in the operation of robotic dump trucks is the issue of safety. For this, the trucks are equipped with video cameras, radar and LiDAR which allow the truck to objectively determine possible obstacles while driving and, using an intelligent algorithm, make a decision to bypass them or stop. All the main components of the vehicle have redundant control systems that come into operation when the main system fails.

The unique anti-lock and traction control systems developed at BELAZ, as well as the improved algorithms for controlling the electromechanical transmission, improve the safety of the robotic truck’s movement when the road situation deteriorates in the event of rain, snowfall and other unfavourable weather conditions. In case of unforeseen situations, the remote control of the dump truck can be taken over by the operator located in the control room.

In the future, BELAZ is ready to expand the number of models of dump trucks designed for autonomous operation. Intelligent equipment tested on mining dump trucks of the BELAZ-7513 and BELAZ-7558 series can be installed on all machines of extra heavy lifting capacity - 90, 180, 220, 240, 290 and 360 t. This will allow the mining companies and partners of BELAZ who already know the performance of Belarussian mining equipment and use it in their operations, to reduce the cost of mining operations further due to increased productivity.

Gas powered dump trucks

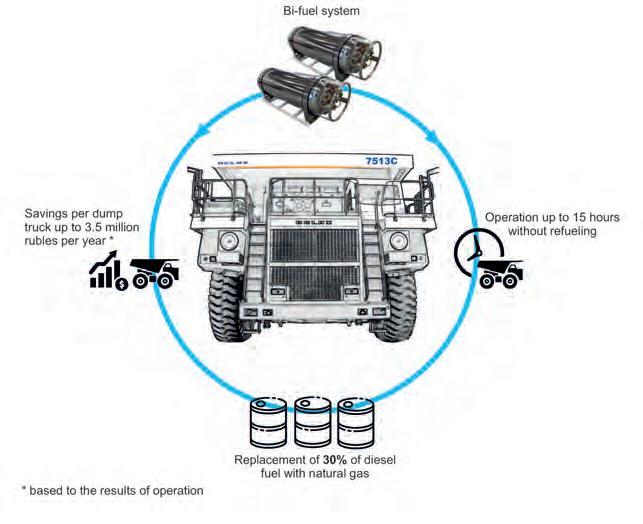

Meeting the interests of mining companies and satisfying the growing demands of consumers, BELAZ is implementing several breakthrough projects in the segment of open-pit vehicles running on LNG. The interest in it from the mining companies has been growing fast. After all, the technology that uses liquefied natural gas as a motor fuel allows not only saving of money, but also improves the environmental situation in high diesel consuming mines.

The work on the gasification of mining equipment is being carried out in two directions: gas-diesel and pure gas vehicles. In particular, BELAZ specialists are working on the development and production of a 90 t dump truck powered by an all gas-fuelled engine. Today, the company has also assembled a dump truck with a payload capacity of 136 t which is powered by a gas-diesel engine based on the Cummins KTA 50C diesel engine.

Meanwhile, another BELAZ gas mining truck development, the BELAZ-75476 mining dump truck, having passed operational tests in the Arkhangelsk region in the diamond mining open pit of Alrosa’s Lomonosov GOK, was converted to

use compressed natural gas. The machine is continuing its work with Alrosa. BELAZ also emphasises that all developments are carried out on the basis of marketing research and in close cooperation with potential consumers of the product.

Diesel trolley and electric vehicles

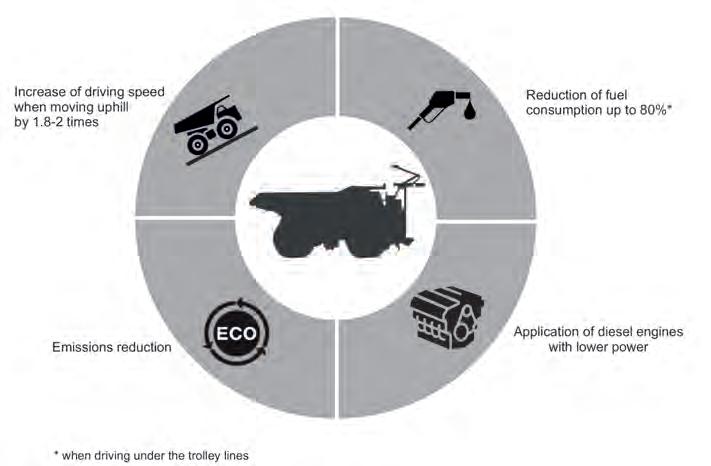

Diesel trolley assist mining trucks are another promising direction for BELAZ in line with global trends in the use of alternative energy sources in mining equipment. The use of open-pit vehicles of this trolley type represents an effective solution for mining transport operations, since it can increase the speed of the dump truck on the upramp by 1.8-2 times, which in turn will make it possible to increase productivity and increase the volume of traffic. Along the way, fuel consumption will be reduced by up to 80%, emissions into the environment will be significantly reduced and the ecological situation in the mine and adjacent areas will be improved. The transition to diesel

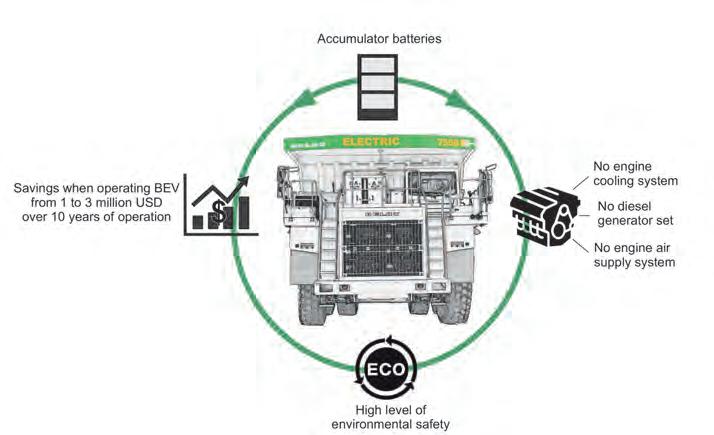

trolley cars will also allow the use of diesel engines of lower power rating.There are two different projects being developed by BELAZ specialists in this direction plus an all electric battery truck: xn Diesel-trolley truck: mining dump truck that uses an external source of electricity as power supply on a certain section of open-pit mine haul road, thereby increasing the speed of the vehicle and diesel fuel savings xn Electric trolley truck: mining dump truck that uses an external source of energy from trolley power lines and switches to on-board batteries at loading and dumping areas. xn All-electric truck: electric dump truck using traction accumulator battery pack as a power source

Development of the first two types of trolley mining dump trucks is already in full swing. For equipment testing and adjustment a contact trolley line with a total length of more than half a kilometre was installed at the Zhodino factory testing grounds with a traction electric substation. The first diesel trolley truck BELAZ-7530E with payload capacity of 220 t was assembled, and a control system was developed.

Also, in 2021, BELAZ specialists released a completely new type of all electric open-pit mining truck powered by BELAZ-7558E batteries with a carrying capacity of 90 t. This development opens a new direction in the production of "green" dump trucks completely free from harmful emissions. The use of electric dump trucks will allow mining enterprises to save money due to the difference in prices for fuel and electricity, service costs and fuel and lubricants. The battery-powered engine provides the best cost of transportation of minerals and a high level of ecology in the field.

According to preliminary estimates, savings when using a battery-powered vehicle compared to a serial BELAZ dump truck for 10 years can range from $1 million to 3 million US dollars (depending on the region of operation).

Intelligent mines

The rapid development of electronics and IT related technologies has affected all areas of activity, including mining and mechanical engineering. Thanks to this, BELAZ continues work on the development of a unified monitoring system, analysis of predictive analytics and dispatching data, united into a unified intelligent mining transport management system.

With the help of this system, the management of the mining enterprise, service services in real time receive complete information about the work of the mine. The technology is even more effective when managing a fleet of robotic equipment. In this case, the number of people involved in the work is reduced to a minimum, and the main mining activity is performed by the smart mine system.

In 2021, tests of the robotic industrial complex of BELAZ were conducted, including robotic mining dump trucks BELAZ-7558R with a carrying capacity of 90 t and a front loader with a remote control system BELAZ-7825D with a bucket volume of 12 cubic metres. This was done as part of an intelligent quarry system, implemented in a section of Granit’s Sitnitskoye quarry in Belarus.

Today, for the operation of an intelligent mine system at Sitnitskoye, a modern relocatable control and dispatching centre has been erected, and a new comms network and electrical infrastructure have been installed, including 48 poles for which more than 4 km of cables were laid. The equipment that provides 5G network coverage of the mine site for controlling a robotic mining complex was mounted on 3 poles. BELAZ specialists carried out testing and debugging of the server and network equipment for collecting, accumulating and transmitting data. A video surveillance and access control system has also been deployed on the premises. IM