MAINTENANCE & RECONSTRUCTION THE OFFICIAL MAGAZINE OF PAVE/X AUGUST/SEPTEMBER 2023 › › › www.ForConstructionPros.com/Pavement ★How to Select the RIGHT ROLLER MEGA MAINTENANCE IN THE CITY OF BROTHERLY LOVE Registration Opens for

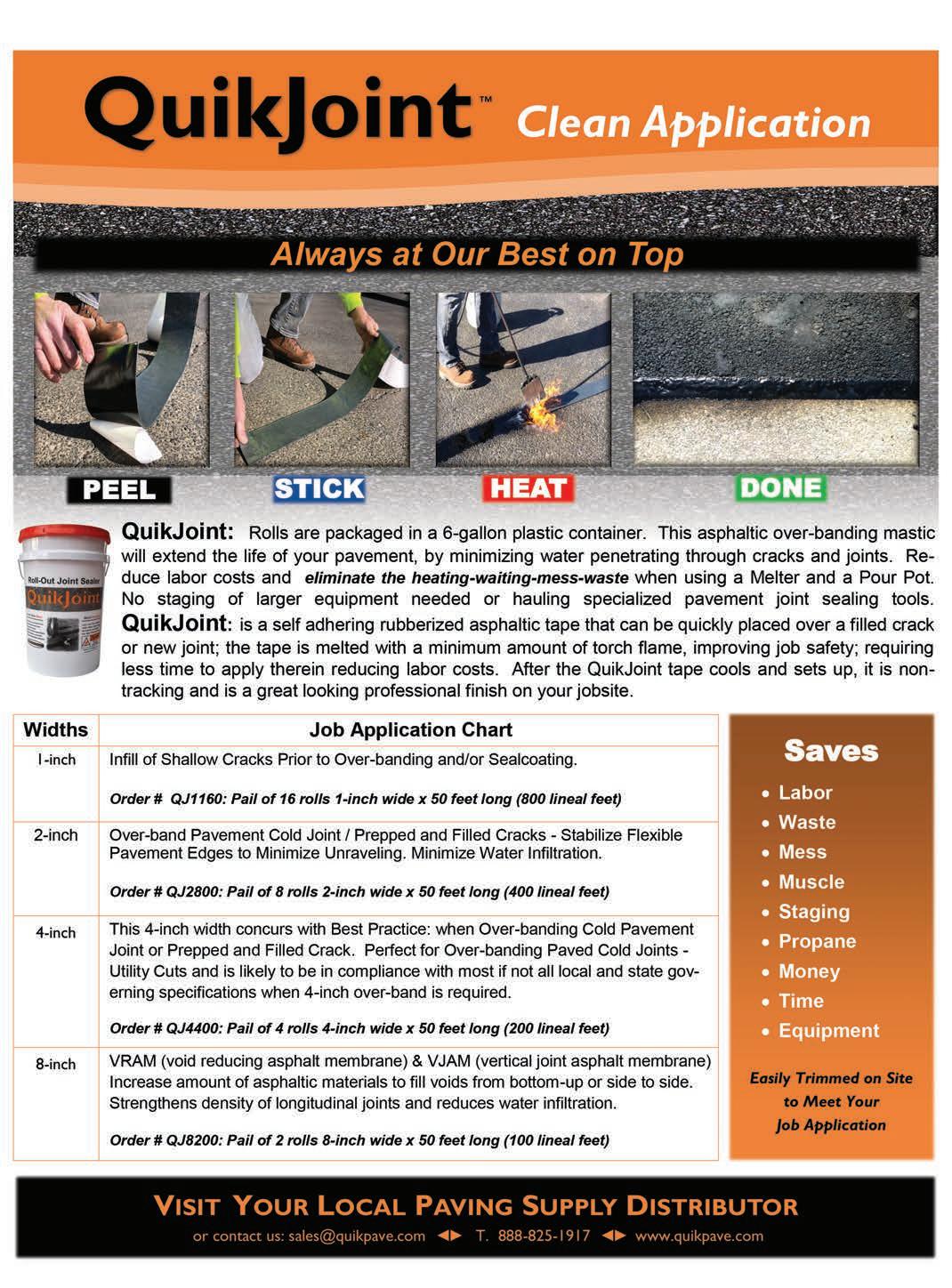

customers expect the best. That’s why Crafco works hard to make sure every batch of our crack sealant exceeds your expectations. At Crafco, we go further. Use the best. We’ll handle the rest. Contact us today! Visit crafco.com/sales Follow us

Your

6

The

9

10

24 The City of Brotherly Love

In the nation’s original capitol, a pair of life-long friends started their business from the ground up, and are now seeing their hard work pay-off in the biggest ways possible.

36 NAPSA

The North American Power Sweeping Association has announced the finalization of a draft revision of the 2018 Power Sweeping Standard. The 2018 version was the first-ever standard for the industry.

36

Using independent sweeping contractors: The advantages and pitfalls. Setting up independent contractors for parking lot sweeping offers advantages for sweeping businesses in terms of flexibility, cost savings, and potential access to specialized skills.

38

42

Part

34

TABLE OF CONTENTS

COVER

August/September 2023 | Issue 6, Volume 36 www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 3 FEATURES

The Benefits of Ground Penetrating Radar Technology in Paving

case study from the Minnesota Department of Transportation.

Educating Customers About Infrared Repair

ON THE COVER A photo taken on the job with All-Out Parking Lots of a CAT AP655F in the “E Lot” at Wells Fargo Arena in Philadelhpia.

STORY

12

A

14

You can greatly expand your opportunities and margins with infrared asphalt repair, but you need to be ready to answer customer questions and demonstrate its advantages.

Compactors and Rollers for All Seasons

have recently released a variety of compactors and rollers, which can be used year-round, if necessary. DEPARTMENTS

SPECIAL REPORT:

16

Manufacturers

Editorial

Hot Mix

After a year in the chair, the editor reflects on learning by doing, and sometimes by making mistakes. 8

the industry.

latest news in

The Product Lane

new products and upgrades.

Select

PAVE/X PULSE

experience!

see a list of

the equipment, education, and more that you won’t want to miss.

Your Business Matters

Registration is NOW OPEN for the hottest, newest pavement

Also,

all

32

your business organized.

Setting up your IT infrastructure keeps

From the Owner’s Desk

of equipment.

Your trailers are an essential piece

WSA

Contractor’s Snapshot

Advanced Asphalt Paving Inc., of Twinsburg, Ohio.

Tailgate Talk

One of a series addressing how to communicate more clearly.

IN EVERY ISSUE

Pavement Profit Center

Classifieds

30

39

VIDEO: Get Ready for the 2023 IGNITE Construction Summit

The content over the course of the 2023 event will be laser-focused on ways business owners can create positive disruption within their companies that will better their business both today and well into the future. The Future is Now at IGNITE 2023.

For more information visit

https://pavemg.com/xm4w6y

Construction Summer Camp Introduces Girls to the Trades

For the past two summers in northeast Ohio, this weeklong camp has partnered with unions and trade associations to teach girls about the various career pathways available to them in the construction industry.

For more informationvisit

https://pavemg.com/pzojvd

Brandon’s First Time On A Paving Job: No Edge Lines, Season 1, Episode 1

In the first episode, our editor visits with a crew in Islip, N.Y., called Royal Pavement Solutions. The two day visit was at a mobile home park, milling and filling the local traffic roads.

For more informationvisit

https://pavemg.com/tk2xdn

information storage or retrieval system, without written permission from the publisher.

PAVEMENT

Subscription policy: Individual subscriptions are available without charge in the U.S. only to pavement maintenance contractors, producers and government employees involved in paving or pavement maintenance; dealers, and distributors of pavement maintenance equipment or materials; and others with similar business activities. Complete the subscription form at www.forconstructionpros. com or use your company letterhead giving all the information requested. Publisher reserves the right to reject nonqualified subscribers. One year subscriptions for nonqualified individuals: $35.00 U.S.A., $60.00 Canada and Mexico, and $85.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Pavement Maintenance & Reconstruction (ISSN 1098-5875), is published eight times per year: January, February, March/April, May, June/ July, August/September, October/November, December by AC Business Media, 201 N. Main St. Ste 350, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI and additional entry offices.

POSTMASTER: Please send change of address to Pavement, PO Box 3605, Northbrook, IL 60065-3605. Printed in the USA.

ADVISORY BOARD

Agua Trucks Inc ................................................................ Wickenburg, AZ, Scott Duscher

Asphalt Contractors Inc., Union Grove, WI

Robert Kordus

Asphalt Restoration Technology Systems, Orlando, FL Connie Lorenz

Brahney Paving, Hillsborough, NJ

Steven Brahney

Eosso Brothers Paving; Hazlet, NJ Tom Eosso

Maul Paving/Concrete/Sealcoating, PLainfield, IL Chris Maul

Parking Lot Maintenance, Lake St. Louis, MO Todd Bruening

Petra Paving, Hampstead, NH Chris Tammany

Pioneer Paving, Albuquerque, NM ............................................................... Don Rooney

Roberts Traffic, Hollywood, FL .................................................................... Lisa Birchfield

Show Striping Inc. (SSI), Wisconsin Dells, WI

T&N Asphalt Services, Salt Lake City, UT

Amber Showalter

Nick Howell

Young Sealcoating Inc, Lynchburg, VA Steve Young

The Paving Lady Mauro Comuzzi

JMP Excelsior Services Jim Panzenhagen

Sweeping Industry Veteran Gabe Vitale

Flat Nickel Management

Wis-Coat Asphalt Maintenance

Michael Nawa

Marvin Joles

Clear Choice Sealing.................................................................................. Warren Johnson

Jacketta Sweeping Services ..................................................................... Debbie Jacketta

Royal Pavement Solutions

ASSOCIATION REPRESENTATIVES:

Kenneth Roy III

Pavement Coatings Technology Council Brian Riggs, Executive Director

68

4 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

WHAT’S ONLINE

Vol. 36, No. 6 August/September 2023 Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any

-

MOST-MANEUVERABLE

The NON-CDL A4 Storm is uniquely positioned to excel at construction site cleanup where space is limited.

HIGHEST-DUMP

The high-dump AS Twister allows off-loading into the tallest containers and dump trucks.

ILARGEST-CAPACITY

The large capacity A9 Monsoon allows more time sweeping and less time driving to landfills.

A Year of Firsts

Stepping into the pavement maintenance industry, and learning a thing or two about making mistakes.

Ayear ago when I accepted the position as the editor for Pavement Maintenance magazine, I had a very narrow understanding of what this industry was all about. I knew that it was made up of extremely hard working people, and that they reflected the kind of blue collar individuals that I spent the previous fourteen years of my life working with in a steel factory. However, I didn’t grasp this industry right away, or what makes it so special.

Brandon Noel, Editor bNoel@ACBusinessMedia.com 234-600-8983

Over the past several months I’ve had the privilege to travel around to many different states, meet so many men and women who do this work, and see it up close and first hand. The number one thing that has taught me is: Making mistakes is key. Whenever you start a new job, there’s always this sense of energy. You don’t want to mess things up, and have those around you glaring, wondering if they made a mistake in hiring you. That’s definitely how I felt at first. When I’ve traveled to a job site, and been given the chance to drive roller, drive a paver, or especially the time I got to match -- I was totally stressed out about making a mistake. made them, every time.

The important lesson I took away from teach mistake made, was that there were important reasons for those mistakes, and I really couldn’t have learned them without messing it up in the first place. Each crew I’ve been with has had the same response to my errors, whether it was the time I stepped right on freshly laid mat, or when I mashed the hell out of a seam, or when took off with the paver moving too fast. They all said, “We can fix it, don’t worry, this is how we all learn.”

It’s so important that we all keep that perspective, whether we are out on the job site, in the office, or out trying to make new sales. You’re going to make mistakes, and in a lot of cases, you’ve got to make those mistakes in order to learn what you couldn’t have known. For business owners and foremen, it’s important to foster the right environment for your new hires and help. If the environment is too punishing, you might just run off a potentially good hire because they didn’t feel like they stood a chance.

I appreciate this industry, and the people who are in it, more and more every day. I love this job, and I love getting to meet and engage with all of you doing the real hard work out there. Hopefully soon, if we haven’t met yet, I will get to see you at things like the IGNITE conference in December, or PAVE/X next summer! If you’re there, make sure to come say hello! See you on the road.

EDITORIAL Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Jessica Lombardo jlombardo@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction

Technology, IRONPROS ................................ Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Sales Representative Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative ....................................................Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative ..................................................Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction................................ Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo Data Axle (518) 339 4511 bart.piccirillo@infogroup.com

REPRINT SERVICES

Sales Representative Tadashi Soma (800) 538-5544 ext. 1267 tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@PAVEMENTMAINTENANCE

6 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t EDITORIAL PAVEMENT @PAVEMENTMAGAZINE @PAVEMENTMAGAZINE @PAVEMENTMAGAZINE

WWW.FORCONSTRUCTIONPROS.COM/PAVEMENT Published by AC BUSINESS MEDIA 201 N. Main St. Ste 350, Fort Atkinson, WI 53538 (800) 538-5544 www.ACBusinessMedia.com

Brandon Noel

RAISING THE STANDARD

weilerproducts.com Since its introduction, the Weiler P385 has set the standard for commercial pavers. The P385C raises that standard.

Increase to 120 hp with the Cat® C3.6 Tier 4F/Stage V engine. Variable speed and reversible conveyors and augers and a 25% increase in tunnel height provide optimal material output. Modular conveyor drive and sealed chain case increase feeder system reliability and life. Enhanced heat system performance with direct-drive hydraulic generator and elimination of GFCI breakers.

1-800-STRIPER Set to Paint the Town

On May 1, the newest 1-800-STRIPER franchise rolled out in southeast Jacksonville, Fla., bringing business and property owners an affordable way to restore commercial and industrial parking lots – as well as plenty of other paved areas.

1-800-STRIPER was founded more than 20 years ago on the belief that businesses don’t need to spend a fortune on parking lot repairs and maintenance to make a good impression. Sometimes, a fresh set of lines is all that’s needed.

The striping company offers customized layouts for parking lots and paved areas, ensuring ADA compliance, safety, and proper traffic flow. In addition, they provide layout and line painting for sports courts, interior markings for parking garages and factories, and temporary solutions for special events. construction sites.

RDO Equipment Co. Becomes the Exclusive Topcon Intelligent Paving Dealer in Texas

RDO Equipment Co. has been awarded a Topcon Intelligent Paving Solutions contract and will be a direct dealer of Topcon’s Intelligent Paving Suite of products in all eight Texas stores.

“During the last three years, asphalt and paving jobs have significantly increased,” said Senior Vice President of Texas Construction Cory Kosse. “Innovations in paving technology help our customers manage tighter agency specifications, smaller bid margins and an ever-changing workforce.”

The RDO team in Texas joins

A round-up of recent news, moves and events impacting the pavement maintenance industry

For more information visit https://pavemg.com/mz1q1r

HYUNDAI LAUNCHES DEDICATED COMPACT EQUIPMENT SALES AND SUPPORT TEAM IN NORTH AMERICA

Following the introduction of skid steer and compact track loaders, along with updates across its compact excavator lineup earlier this year at CONEXPO-CON/AGG, Hyundai Construction Equipment North America has announced the formation of a new team dedicated to Hyundai compact equipment sales and support.

Hyundai has hired Jeff Pate as vice president of Compact Equipment Sales, reporting to Mike Ross, senior VP of HD Hyundai CE North America. “Jeff is a proven, dynamic and passionate leader, with 20-plus years in dealer and channel development, market intelligence, and strategic planning, including more than 10 years’ experience in the compact equipment sector,” Ross said.

Reporting directly to Pate are four new team members, each of whom will be responsible for sales and dealer development in distinct regions covering the United States and Canada.

Dale McLemore, an industry veteran with 35 years’ experience in compact equipment, is joining the company as senior dealer development and national accounts manager for compact equipment covering the southeastern region. Brian Slavinski brings 12 years of experience to his role as district manager for the northeastern United States and eastern Canada, including extensive knowledge of the equipment industry from both the retail and manufacturing side.

those in the Midwest and Southwest, providing customers with expertise and Topcon’s Intelligent Paving Suite of products, including intelligent compaction for rollers, Topcon’s industry exclusive road scanning technology RD-M1 and machine control solutions for mills and pavers. These machines and equipment technology improve roadbuilding accuracy and consistency for American road builders.

Across the country, RDO has been partnering with customers in the Intelligent Paving market for over eight years.

“We are looking forward to expanding our partnerships with road builders in Texas for Topcon’s Intelligent Paving solutions,” said Senior Vice President of Technology and Innovation Adam Gilbertson. “These new methods improve

the construction process on many levels and result in a smoother, safer road and extends the life of the surface making better use of our nation’s infrastructure investments.”

Intelligent Paving Product Manager Tony Carden at RDO noted that new states are adding intelligent compaction and thermal profiling requirements to jobs every year, so government officials can prove an investment into vital roads and bridges will last.

RDO customers in Texas can now leverage the total resources of the RDO technology team and its support network across all eight states where RDO Equipment Co. supports construction customers. The team includes more than 100 leading construction technology experts.

8 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

1 3 5

Wacker Neuson RD 27 Series

Wacker Neuson

The redesigned RD 27 2.5-ton double drum vibratory roller incorporates a multi-functional lever that contains buttons for all vibration options, water on/off and even the horn.

• Features a tapered front frame for optimal visibility to the front drum and ergonomically designed operator’s station with easy-to-read dashboard and control panel

• 5,470-lb. RD 27-100 comes with a 39.4-in. drum width and and produces a low/high total centrifugal force of 15,589/16,860 lbs.

• 5,950-lb. RD 27-120 has a 47.2-in. drum width and produces 15,285/20,232 lbs. of low/high centrifugal force

• Single or dual drum vibration

StaCool Vest Core Body Cooling System

StaCool Industries

The StaCool Vest Core Body Cooling System features micro-thin, highly breathable materials that are easy to care for and provide wearers enhanced cooling comfort without compromising mobility.

• Models can be worn over or under normal clothing and are available to suit any style, preference and application

• ThermoPaks in front and back provide hours of cooling with a spare set of ThermoPaks included

• Help maintain a consistent core body temperature

• Thermal barrier built in to ensure wearer does not get too cold

Infinity Lube Tar-minator

The Fuel Ox

An industrial strength, plant-based asphalt and tar remover designed to clean and protect truck beds, rims, shovels and rakes.

Tar-minator, fortified with Infinity Lube HDI 2500, is completely unique in the marketplace. It treats the metal directly through a microscopic chemical reaction, making the metal less susceptible to reattachment of asphalt and other tars and adhesives, making subsequent cleanups much easier – if not completely unnecessary.

To activate Tar-minator to treat metal, unpainted surfaces, it is best to lightly scrub the surface with a wire brush or 0000 steel wool first. This will help initiate the chemical reaction between the HDI-2500.

2 4 6

Case SR240 and SV280 Tier 4

Final Skid Steers

Case Construction Equipment - CNH

The 7,400-lb. SR240 and 8,090-lb. SV280 Tier 4 Final large-frame skid steers feature a 74-hp Tier 4 Final engine with a maintenancefree particulate matter catalyst solution.

• Deliver 232 ft.-lbs. of torque, a bucket breakout force of up to 8,680 lbs. and standard (24.2 gpm) and high-flow auxiliary (33.2 gpm) hydraulics

• Offer rated operating capacities of 2,400 (SR240) and 2,800 lbs. (SV280)

• 360° visibility with a cab-forward design, skylight and ultranarrow wide side screens

Komatsu Upgraded PC130LC-11 Mid-Size Excavator

Komatsu

Komatsu has released the upgraded PC130LC-11 excavator with a longer undercarriage design. The excavator also features increased lifting capacity by up to 20% compared to the previous model. This 97.2-hp tail swing excavator offers a combination of lightweight power and agility on construction sites. Operating weight is 28,440-29,101 lbs and bucket capacity is 0.34-0.78 cubic yards. The PC130LC-11 uses up to 12% less fuel than the previous model (PC130-8). The Komatsu diesel oxidation catalyst (KDOC) helps reduce particulate matter by using passive regeneration over 98% of the time.

DEVELON DX42-7 Mini Excavator DEVELON

With 47 net hp and a conventional tail swing configuration, this 4-metric-ton model is designed for navigating tight, congested jobsites and urban areas.

Part of the next-generation -7 Series mini excavator lineup, the DX42-7 offers fast cycle times, torque-limiting piston pumps that respond to load demands and a large counterweight for balance and durability. Its maximum digging depth is 11 ft., 5 in. and maximum digging reach (ground) is 18 ft., 3 in. Its maximum loading height is 2 ft., 6 in. and its travel speed is 2.1 – 3.1 mph. The DX42-7comes equipped with a standard thumb-ready arm, quick-coupler-ready design and lever pattern control.

Buyers Guide at ForConstructionPros.com

Get fast, relevant product information in the

www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 9

BY BRANDON NOEL, Editor

★Registration Now Open for PAVE/X 2024

The inaugural event, Jan. 30 - Feb. 1 in San Antonio, features education, live equipment demos and tradeshow floor.

PAVE/X, The Pavement Experience, has officially opened registration for the 2024 event. It will take place Jan. 30-Feb. 1, 2024 at the Henry B. Gonzalez Convention Center in San Antonio, Texas. The first-ever event will feature more than 60 hours of conference sessions and attendees can now register for classes to improve their skills.

“We really wanted the PAVE/X difference to begin with a robust educational program that is unlike any other learning experience in the market,” Jessica Lombardo, conference manager of PAVE/X said. “This industry is full of experts and PAVE/X will provide enhanced opportunities for our industry to expand their knowledge, no matter what level they are at in their careers. Some of the most experienced leaders in the industry are joining us at PAVE/X to bring next level education on running a business, enhancing your performance, mastering new technology and so much more.”

The educational program will feature five tracks: Paving, Striping, Sweeping, Sealcoating and Business Management.

Some of the brand new content sessions coming to PAVE/X include:

• The Game Plan: Planning Your

Paving Project for Success by Kenny Roy, Royal Pavement Solutions

• Planning & Building Specialty Paving Projects by Wayne Jones, Asphalt Institute

• Understanding Density & Rolling Patterns by John Ball, Top Quality Paving

• Break Through the Ceiling: How to Grow Your Striping Business by Cam Roberts, Laser Pavement Solutions

• A Hands-On Approach to Learning Striping Technologies by Chad Jung, Superior Striping

• The Master Class: Mastering the Art of Precision Striping by Mark Estrada, Marathon Pavement Solutions

• Starting Your Sealcoating Business from the Ground Up by Steve Young, Young Sealcoating

• Everything You Need to Know About Owning a Mill by Tom Eosso, Eosso Brothers Paving

• How to Succeed with Asphalt Emulsion Sealers & How to Prepare for Future Material Needs by Steve Brahney, Brahney Asphalt

• If Cost Is the Issue, What’s Your Solution? by Brad Humphrey, Pinnacle Development Group

• Full Contact Business Management by Mauro Comuzzi, The Paving Lady

• Pivot 101: Your Guide to Successful Business Planning in a Changing Market & Pivot 201: Strategies to Identify & Execute Future Business Growth by Guy Gruenberg, Grow Consulting

The program will also feature a panel discussion with industry experts and

manufacturer representatives that will provide attendees a more interactive path to learn about pressing business questions such as “What Do I Need to Know About a Concrete Business” and “How to Incorporate Machine Control to Save BIG Money.”

“These panel discussions are a great way for attendees to be able to participate in a discussion where they can learn firsthand the ins and outs of adding a service or growing their business,” Lombardo said. “These conversations give attendees more of an opportunity to connect with speakers and ask questions during the session, allowing for a different level of education that they may be used to and we’re excited to be able to facilitate that with PAVE/X.”

In addition, the exclusive sweeping track at PAVE/X is tailored to the needs of sweeping professionals and will include the Sweepers Roundtable, North American Power Sweeping Association (NAPSA) Best Practices Workshop and NAPSA keynote event, which will all be discounted for NAPSA members.

“We are pleased to be partnering with the NAPSA on education,” Lombardo said. “We are crafting this content with purpose and care, knowing how important each and every session will be to helping contractors strengthen their skills and their businesses.”

To learn more, visit www.pavexshow. com and register at https://events.american-tradeshow.com/pavex2024.

For more information visit https://pavemg.com/vwl6i0

10 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

YOUR PARTNER ON THE ROAD AHEAD

What does that mean? It means that we are determined to support you in your journey towards greater profitability, safety and environmental stewardship. It means that we will help you forge new paths, shape key trends and offer new solutions to support you on that journey. And it means we will be with you for every step of that journey through application consultancy, personalized trainings; across numerous geographic territories and around the clock.

Tell us where you’re going and we will help you get there.

800-651-0033

The Benefits of Ground Penetrating Radar Technology in Paving

A Case Study from the Minnesota Department of Transportation.

When it comes to asphalt, measuring pavement density is key to building longer-lasting surfaces. Contractors must ensure pavement is compacted enough to ensure long-term health. Identifying the percentage of air voids in the overall placed mix is the accepted measure of evaluating this key factor to integrity. The current industry standard for measuring compaction and air voids are point-by-point techniques, such as: coring or using a nuclear density gauge, but up-and-coming Ground Penetrating Radar (GPR) technology could provide an alternative.

THE TROUBLE WITH POINTBY-POINT TECHNIQUES

With these techniques, inspectors measure random sample locations of the pavement, extrapolating data to the entire road. However, this technique does not cover a large area and could miss problem areas. You could be at a location that is well within passing density, then move just a few feet away on the pavement and observe a failing density. Coring is currently the golden standard for assessing pavement health, but it has further issues. This destructive method tests for air voids at the cost of pavement integrity. Sometimes additional resources and road closures are needed to fill in these cored areas. Besides being destructive, this method also lacks realtime data, but rather requires a lengthy and costly process of sending out the

cores to be analyzed. Nuclear gauge testing, another point-by-point method, requires certificates for safety and operation.

GPR is a non-destructive method for analyzing pavement. The technique of using dielectric constant to relate to asphalt density has been around since at least the 1990s, but up until recently, the technology wasn’t precise enough to be able to use it for deployment on actual roads.

MNDOT’S STUDIES UPHOLD THE VALUE OF GPR IN PAVING

In 2020, the Minnesota Department of Transportation (MnDOT) joined a group of states and the FHWA to create a fund to experiment with GPR technology to improve asphalt pavement density. MnDOT focused specifically on deploying continuous asphalt pavement compaction technology. Through this project, MnDOT collaborated with researchers, foremen, and contractors in a unique and iterative process. MnDOT familiarized contractors with the technology so they understood the information it provides. Contractors also provide feedback on the protocols in development, with the ultimate goal of rolling out GPR as a quality assurance tool in Minnesota.

There are many contractors already doing everything they can to try to get consistently good density and are looking for any sort of information that can help them continue to improve. They’ve been very receptive to trial data collection on their projects, and we’ve had multiple contractors using the information from the GPR technology to improve their compaction operations. The process

thus far demonstrates the effectiveness of GPR.

For example, a MnDOT team recently tested the technology on a highway echelon paving project. Two asphalt pavers were simultaneously paving both lanes of a two-lane highway, which allows for good compaction at the longitudinal joint, or the area between those two lanes, since the compaction occurs while both lanes were hot. However, MnDOT was able to use a density profiling system to identify a problem less than a foot away. They noted periodic lower densities along one side of the joint, for 100-to-200 foot stretches. The MnDOT team collaborated with the contractor in real-time to brainstorm. The team identified what was causing the lower densities and made the necessary changes to ensure adequate density.

GPR IN THE FUTURE OF PAVING

These MnDOT projects have demonstrated the potential of GPR technology. The advent of the use of intelligent construction technologies in day-to-day work is occurring at MnDOT and other partners. The expansion of these technologies could benefit other states and countries as more and more information of the paving process becomes available. Work to date shows that longer-lasting road integrity through improved density is on the horizon if this technology is adequately implemented.

Kyle Hoegh, research engineer, Minnesota Department of Transportation.

For more information visit https://pavemg.com/e6dfes

AdobeStock_389731149 TECHNOLOGY UPDATE 12 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

Educating Customers About INFRARED REPAIR

If you want to grow your pavement maintenance business, using infrared (IR) asphalt repair technology is an excellent and powerful tool to add to the other offerings you have for customers, especially when paired with an asphalt hot-box. For contractors the benefits of increasing IR business are:

• Speed: Infrared and hotbox patches can be completed in as little as 15 minutes, start-to-finish.

• Efficiency: Two-person crews, no heavy machinery, low work-zone footprint.

• Margins: Above average profit margins when effectively implementing IR solutions. However, there are many property managers and other potential clients that are unfamiliar with IR, and others still, who might have misconceptions about how it works or its effectiveness.

Zach Young, the chief operating officer at Potholes Heroes, a pavement patching and repair contractor based out of southern Florida, has run into this time and time again. Young described getting pushback from other contractors in the industry in addition to misinformed clients or clients who had a prior negative experience with IR that wasn’t implemented correctly.

“I was in the Nashville airport, talking to a guy and he just straight up told

me that infrared isn’t as good,” Young recounted the anecdote from a time before he got involved with IR himself. “A guy told me that it takes too much time and that it doesn’t last as long. It had the opposite effect on me, though. It just made me want to know more. I’m kind of contrarian that way. I’ve got to find out for myself, and I did.” That personal investigation led Young and Potholes Heroes to grow into a hugely successful pavement repair and maintenance network, which has spread nearly statewide, doing nothing but pothole repair.

If you’re trying to grow your business, however, you have to do for your customers what Young sought out for himself. Where he too the time to seek out answers and educate himself on the power of infrared, you have to step in, know the facts, and be able to educate clients on just how powerful IR solutions can be for their property liabilities.

STEP ONE: IDENTIFY OPPORTUNITY

The first step in expanding your business with infrared solutions requires you to be proactive in situations with clients and prospectives. Don’t wait for customers to seek out infrared, but instead,

initiate contact points when you identify potential properties, liabilities, or other appropriate situations that IR can be best taken advantage of. In order to do that, first of all, you have to at least know the basics.

“First things first, you have to make the customer ask that question: what is infrared?” said Young. ‘We get to that point, by offering them an alternative, arguably superior method. You tell them that you can fix their problem with infrared technology, initiating the conversation about it from your side.” There are really only two questions they might initially ask in this conversation. One might be that they’ve heard

SPECIAL REPORT | BY BRANDON NOEL, Editor 14 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

Greatly expand your opportunities and margins with infrared asphalt repair, but be ready to answer customer questions and demonstrate its advantages.

Provided by Pothole Heroes

infrared doesn’t work, and the second could be that they’ve never even heard of it. Both are good for you in step 2.

For those who already own a pavement maintenance business, and offer sealcoating, paving, striping, and/ or sweeping; another part of expaning opportunities for IR comes with teaching your crews to spot liabilities and trouble spots when they are on site for other work. Once new opportunities hare identified, step two comes into play.

STEP TWO: EDUCATE CUSTOMERS

Opportunity plus education is the secret formula for selling your infrared services. Any damaged areas of asphalt in a parking lot can be fixed using infra-

up, and god-forbid you have to drag in a saw and kick up a bunch of dust, and make a huge mess. You explain that you can bring in an infrared machine and a hot box, take 15 minutes, with minimal environmental and traffic disturbance, and have their problem solved like you were never there.”

Even in cold northern climates this scenario is possible, as the hot-box units are capable of heating stored or reclaimed asphalt into usable material for permanent patches. Even though Young lives in sunny Florida now, he is originally from Ohio, and said, “Up there, they use cold patch until the spring and then come back and repair the hole again. However, with these tools you can reclaim asphalt in January when it’s zero degrees outside and make a permanent repair.”

Not only can the smaller Hot Boxes keep short runs of asphalt warm for quick patching jobs, but they can heatup bulk stored asphalt long after the fact. This means a crew could stay busy through the usual off-season as much as they wanted. There’s no shortage of damage done to roads or parking lots in the winter, often by snow plows.

As the customer sees, day-in and day-out, how seamlessly IR patches blend into the original asphalt surrounding it, and how durable it is, they become an advocate for IR all on their own. How you take advantage of this depends on your level of engagement after the fact. Asking for referrals can be challenging, but you should never hesitate when it comes to infrared repair referrals. You can always stand on the quality of the work, the longevity of the patch, the speed of repair, and the low level of traffic disruption.

red, but there are some places better suited than others. Pairing those with the education is where a potential/lead suddenly becomes a paying client. One such scenario is the high traffic areas, for property managers who can’t afford a lot of disruption.

“The place where it wins is like to drive lane of a restaurant and McDonald’s at lunchtime,” Young said. “or a situation where after-hours fixes aren’t a viable option for the customer. For instance, it could be at the entrance of a big-box retailer at Christmas time on Black Friday, the most inopportune time and place. Suddenly, a liability opens

Contractors who can work in those freezing conditions are able to charge a premium for their services, which are of a much higher quality and durability than a traditional cold-patch. It’s estimated that, on average, a contractor could pay for a 2-ton Hot Box with the savings from lost asphalt in as short four to six weeks.

STEP THREE: THE REFERRAL PIPELINE

Whether you’ve introduced a new client to the power of infrared, or you provided education to a dubious prospect, where you truly make your money is in step three. If you’ve done your part correctly, having identified liabilities or jobs where IR outperforms other solutions, and you’ve correctly implemented the technique, then this part can really take care of itself.

This is why educating your customer is so important, because an educated customer will educate someone else. “There’s nothing anybody likes more than to tell someone something they know, that the other person doesn’t,” said Zack. “When anybody asks that property manager how that pot hole got filled in so quickly, so seamlessly, they won’t hesitate to turn around and talk about infrared and how easy it was. When they’re proud of it, they’ll be proud to tell someone.”

In the case of infrared patches, which don’t leave behind obvious saw cut lines and edges, the visual esthetic appeal is something every customer you service will be excited to point out.

For more information visit http://asphalt.com/kk3fi1

www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 15

COMPACTORS AND ROLLERS for All Seasons

As the asphalt and pavement maintenance industry continues to utilize more and more zero-emission products, Wacker Neuson has recently responded by introducing a wide array of single-direction, batterypowered plate compactors.

Known as the APS series, the compactors are available in various plate widths, ranging from 13.8 to 19.7 inches. Offering the same performance capabilities as typical gasoline-powered models, one of the series’ plate compactors was released this year: the APU3050e.

Providing users continuous forward and reverse compaction, the plate compactor utilizes an easy-to-use, interchangeable lithium-ion battery system (similar to the other APS plate compactors that have previously been released), while also offering operators quiet, zero-emission operation capacities.

In the meantime, the manufacturer has released newer models of its gasoline, single-direction plate compactors, too: the BPS series. Each of the series’ models have enhanced base plate designs, which allow operators to effortlessly handle them on soil, as well as fresh asphalt. Providing a centrifugal force that ranges from 2,248 to 4,496 pounds, along with an option to utilize a Briggs and Stratton or a Honda engine, the BPS series has base plates available in 13.8-inch, 15.5-inch and 19.7-inch widths.

“Every model’s base plate has angular

BOMAG Americas, Inc.’s BPR45/45 provides operators an 8.4 hp Honda GX270 engine and 10,116 pounds of centrifugal force.

side edges too, leading to smooth, clean asphalt finishes along curbs and obstructions,” said Luke Sevcik, product application and training specialist, Wacker Neuson. “All models come with—or without—a large-capacity water tank for asphalt applications. The water system includes a large rotary knob that regulates water flow, while each model’s sprinkling system disperses water across the entire plate, ensuring asphalt doesn’t stick to it.”

Aside from being environmentally friendly, the plate compactors can also be utilized near curbs, as well as in tight areas. In addition, they require minimal maintenance, enabling them to have long lifespans.

CONTRACTOR’S CHOICE 16 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

Manufacturers have recently released a variety of compactors and rollers, which can be used year-round, if necessary.

“For example, each battery-powered plate compactor is essentially maintenance-free, due to its direct drive, which doesn’t have any V-belts, while offering lubricated bearings that are built to last,” Sevcik added. “Meanwhile, the gasoline-powered plate compactors provide operators a rugged V-belt, along with bearings that have lifetime lubrication, leading to a significant reduction in maintenance.”

COMPACTORS ENHANCE OPERATORS’ PRODUCTIVITY

Recently, Volvo Construction Equipment began to accept reservations for its DD25 Electric asphalt compactor, its latest compactor offering. A zeroexhaust solution, the compactor can be utilized for small-scale compaction projects like driveways, parking lots and street repairs, due to its size. Featuring 32 hp (24 kW) of available power—30% more than its previously released, conventional counterpart—the DD25 is also more responsive than the manufacturer’s other compactors, with regards to its speed and vibrations.

As a result of its component sizes, the compactor performs better on grade, as well as at high elevations, when compared to diesel machines.

“While working in an urban or noise- and fume-sensitive area, the DD25 is an ideal solution, as it provides a cleaner work environment for operators, site teams, and passers-by,” said Mark Eckert, product manager, compactors, Compact Assist, Volvo Construction Equipment. “Whenever operators travel or operate with the drums off, the DD25 is very quiet, too.”

Unlike the DD128C, a diesel, vibratory compactor the DD25 doesn’t require as much time to warm up, prior

to being utilized, as a compactor with a diesel engine does.

“The DD128C offers operators the asphalt and pavement maintenance industry’s highest frequency though: 4,800 vpm,” Eckert noted. “And its front drum is 79 inches wide with chamfer and radii drum edges, while its rear, 55-inch drum has auto-reversing eccentrics that ensure eccentric rotation in whichever direction it’s traveling, leading to smoothness.”

The DD128C is equipped with an automatic drum wetting system, which provides speed-dependent water flow, in order to reduce their water usage, as all coverage is uniform. Additionally, it has an eight amplitude eccentric system—the widest range of amplitudes (0.0003 to 0.03 inches) on the market—leading to high versatility, whether operators need to conduct ultra-thin or deep lifts.

Designed for base preparation and asphalt finishes, Wacker Neuson’s RD12, a 1.2-ton tandem vibratory roller, offers operators high visibility, along with curb clearance and service access.

www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 17

Wacker Neuson’s APS series of single-direction, battery-powered plate compactors are available in various plate widths, ranging from 13.8 to 19.7 inches.

“Due to our patented technology that can detect amplitude settings, the compactor’s vibration frequency is automatically adjusted to the highest vpm available, regarding its amplitude setting,” Eckert added. “Consequently, operators can achieve high rolling speeds and productivity—without any compromise.”

“We want to keep their maintenance costs down, ensure their uptime is as high as possible and offer machines they can use for years to come,” said Daniel Margrave, product training and marketing manager, Sakai America, Inc. “Our PC600 and PC800 plate compactors help small project contractors achieve these goals, among others.”

Very lightweight, relative to force, each plate compactor has abrasionresistant steel plates, a quick-release water tank, shock isolation and a water spray system. Aside from their sizes—as the PC600 has an operating weight of 159 pounds, while the PC800 has an operating weight of 225 pounds—the plate compactors have one other key difference: the PC600 has a foldable handle, while the PC800 has a reversible handle.

“Powered by Honda GX120 engines that have two-year warranties, the plate compactors can be utilized during any season, as well as in any climate,” Margrave added. “And, while using them whenever they’re comfortable with laying asphalt, operators will never have to be concerned about long-term downtime or excessive maintenance either.”

BPR45/45 and the BPR60/65 provide operators ease of service, high performance and reliability long term.”

He added, “Although both of the gas reversible plate compactors were designed for year-round operation, operators must remember that there are situations in which diesel reversible plate compactors may be more ideal options in colder temperatures. With this in mind, BOMAG Americas, Inc. has diesel reversible plate compactors that complement the gas reversible offerings and can perform in any climate, too.”

COMPACT ROLLERS FOR VARIOUS APPLICATIONS

PLATE COMPACTORS ARE DURABLE AND DEPENDABLE

With regards to its compaction equipment, Sakai America, Inc. hasn’t released any new light compaction equipment this year, as it has only updated its offerings’ colors. Striving for simplicity and focused on maintaining its reputation for dependability and durability, Sakai America, Inc. is also determined to continue to provide small project contractors a variety of benefits.

On the other hand, BOMAG Americas, Inc. offers operators two plate compactors: the BPR45/45 gas reversible plate compactor and the BPR60/65 gas reversible plate compactor. The BPR45/45 provides operators an 8.4 hp Honda GX270 engine, 10,116 pounds of centrifugal force, a working width of 21.7 inches and an operating weight of 750 pounds. In the meantime, the BPR60/65 offers operators an 11.7 hp Honda GX390 engine, along with 13,500 pounds of centrifugal force. Furthermore, it has a working width of 25.6 inches and an operating weight of 1,000 pounds.

“So many of our U.S.-based customers were moving from diesel reversible plate compactors to gas, leading us to deliver these two gas reversible plate compactors,” said David Dennison, territory sales manager, Midwest, BOMAG Americas, Inc. “Just like our diesel reversible plate compactors, the

Aside from its APS and BPS plate compactor series, Wacker Neuson has also released a redesigned version of its RD12 ride-on roller. Designed for base preparation and asphalt finishes, the 1.2-ton tandem vibratory roller offers operators high visibility, along with curb clearance and service access. Ideal for residential and commercial construction, concerning asphalt and subbase soil compaction of driveways, nature trails, parking lots and secondary roads, the ride-on roller can be maneuvered in tight areas as well, due to its compact dimensions. Moreover, as a result of its design, the RD12 provides operators views of the entire drum edge as they approach obstacles and walls, leading to higher productivity.

“The RD12 benefits practically every contractor, whether they oversee small or large projects, in virtually any season, as it’s a multipurpose machine that can compact a variety of applications, including turf rolling,” Sevcik emphasized. “In hot locations, its tank should be drained daily though, in order to avoid bacterial growth and any potential clogging of its water distribution system. Conversely, it should also be drained and have an environmentally friendly, anti-freeze material run through it if operators decide not to use it during the winter.”

Meanwhile, Volvo Construction Equipment provides two combination rollers, the CR30 and CR35, which

18 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t CONTRACTOR’S CHOICE

Luke Sevcik, Wacker Neuson

Daniel Margrave, product training and marketing manager, Sakai America

Mark Eckert, Volvo Construction Equipment NA

© 2023 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. Introducing Cat® SDX Screed Plate System: Featuring smoother surfaces, higher densities and a hardware-free fastening system that cuts plate replacement time by 80% and twice the durability of conventional screeds. Visit cat.com/SDXScreed to learn more. PURSUE HIGHER STANDARDS

can be utilized for smaller projects like driveways, patchworks, pathways and road shoulders. Featuring a drum on its front side, along with high-frequency vibration, each of the rollers also has four rear-mounted pneumatic tires, which manipulate any compacted material, thereby improving surface texture, while decreasing water intrusion, too.

“The combination of these two compaction methods will help operators produce dense, high-quality mat surfaces,” Eckert said. “And, of equal importance, due to their smaller sizes, the CR30 and CR35 will reduce operators’ fuel consumption as well.”

Offering operators two other options as they conduct small asphalt projects, Sakai America has developed the CR271 35.5-inch roller and the SW354 47-inch roller. Utilizing a 20.8 hp Honda GX630R engine, the CR271, which has an operating weight of 3,245 pounds and a vibration frequency of 4,000 vpm, doesn’t require any diesel after-treatment. Additionally, the roller—featuring 35.5-inch x 22-inch drums—doesn’t feature any complicated electronics either. Hence, operators can focus on other tasks, aside from electronic maintenance, resulting in higher productivity.

“The SW354 has a completely mechanical engine too—a Kubota D1703 T4 Final engine, which eliminates any necessity for a diesel particulate filter, diesel exhaust fluid or an engine control unit—ensuring that maintenance is as effortless as possible,” Margrave noted. “Therefore, operators will never have to worry about the downtime and costs that are associated with some rollers’ diesel engines.”

Although Sakai America hasn’t released any new asphalt rollers this year, it has launched Guardman variants throughout the last few months. Using millimeter radar or 3D-LiDAR (light detection and ranging), depending on whichever roller model operators prefer to utilize, Guardman detects and, most importantly, automatically brakes for equipment, objects and personnel that

are behind asphalt rollers. As a result, product damage and injuries will decline.

“Of note, rollers equipped with Guardman are factory-built only, so retrofitting isn’t possible, as their hydraulic pumps, along with many other components, were re-engineered specifically for automatic braking,” Margrave added. “In turn, operators likely won’t have to repair or replace their rollers down the road, which will reduce their expenditures long term.”

ROLLERS FOR SEVERAL PURPOSES AND PREFERENCES

In recent months, BOMAG Americas, Inc. has released BW120 SLC combination rollers, which have a 24.8 hp Kubota engine, an operating weight of 5,070 pounds and a working width of 47.2 inches. Featuring a steel vibratory drum in its frontside, along with four pneumatic tires in its rear, each roller also utilizes the manufacturer’s BOMAG ECONOMIZER.

“By using the BOMAG ECONOMIZER, operators will have an ‘eye for compaction’, so to speak,” Dennison said. “After all, the onboard material stiffness indicator, located on rollers’ dashes, will signal, via a light, the various stages of material compaction stiffness, enabling operators to know exactly which stage they’re in, regarding each of their asphalt projects.”

Tim Kowalski, application support manager, Hamm, Wirtgen America, on the other hand, is preparing for new innovations, including several roller models that can be utilized efficiently on varying asphalt mixes and soil types. Two of its latest products are the HD10e and HD12e electric rollers, each of which are available in eight different models, including OT (oscillation, tires), VO (vibration, oscillation), VT (vibration, tires) and VV (vibration, vibration). In addition, it has released the HD+120i VIO-2 HF machine.

“It has taken our soil rollers’ VIO drum design and implemented it into an asphalt roller, which is capable of running dual vibration with both

of its drums—in a high frequency of 4,020 vpm,” Kowalski explained. “Both drums can be used in oscillation or a combination of vibration and oscillation, too.”

He added, “Furthermore, in automatic mode, operators can have the roller’s front drum in vibration and its rear drum in oscillation, while driving forward. Upon driving in reverse, the roller’s drums can switch, as its rear drum vibrates and its front drum uses oscillation, an advantage for operators that have many options, regarding compacting.”

Additionally, Wirtgen America has released its HP 100i, a nine-tire, articulated, pneumatic roller that’s based off of the manufacturer’s HD+ 70i frame. Offering a weight of 6 tons, which can be ballasted to 8 or 10 tons, if necessary, the roller has primarily been designed for chip seal purposes. Yet, it can also be utilized for smaller asphalt projects, due to its water and scrapper system.

Finally, the manufacturer has unveiled redesigned HC soil rollers as well. The HC 100i to 160i models feature John Deere engines that decrease noise levels by up to 20%, when compared to previously released versions, while the HC 180i to 250i models still have DEUTZ engines, along with 30% more cab space than past versions. At the same time, each HC 120i to 250i model has a seat that rotates to more than 70 degrees in one direction and 30 degrees in the other direction.

“Without question, the future of rollers is bright, as evidenced by our latest offerings,” Kowalski concluded. “Now is the time for operators to purchase their next roller, as they prepare to conduct their upcoming asphalt and pavement maintenance projects.”

For more information visit https://pavemg.com/ckaq9p

20 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t CONTRACTOR’S CHOICE

Chris Lewis is a freelance writer for Pavement Maintenance magazine

WE’RE HERE TO HELP! North Branch, MI 800-492-1757 sales@kminternational.com Common Infrared Uses Benefits of Using IR Pictured: KM 4-40 Infrared Recycler 1/3 The Time and Costs of Tradtional R&R Seamless, Thermally Bonded Repair READY TO TAKE YOUR BUSINESS TO THE NEXT LEVEL? LET KM HELP! Pothole Repair Oil Spots Paving Mistakes Storm Drain Damage Thermoplastic Installs Trip Hazards And Much More! Ability To Extend Working Season Generate $4-5K in revenue a day

JANUARY 30 - FEBRUARY 1, 2024

Henry B. Gonzalez Convention Center - San Antonio, TX

You are invited to the inaugural immersive tradeshow, PAVE/X! And, we are excited to announce that OVER 45 industry-leading manufacturers and suppliers from across the paving and pavement maintenance industry will be in San Antonio for this NEW event.

The event will feature a robust educational program with FIVE TRACKS: a fast-paced demonstration showcase, and unlimited networking opportunities.

Paving, Striping, Sweeping, Sealcoating & Business Management,

We saw a distinct need in the market to evolve what an in-person event could mean to the industry. PAVE/X is already a reflection of that. As such, the experience significantly differs from other trade shows and conferences that serve paving and pavement maintenance contractors. Our goal with this event is to guide contractors towards deeper buyer insights as they make important purchasing decisions by utilizing high-quality curated education, live equipment demonstrations and networking opportunities that connect the right buyers and sellers, while maximizing the entire experience of both attendees and event supporters.

– Amy Schwandt, Chief Revenue Officer, ACBM

– Amy Schwandt, Chief Revenue Officer, ACBM

BROUGHT TO YOU BY FOR MORE INFORMATION, VISIT: PAVEXSHOW.COM

FOR THE EVENT

OPEN!

REGISTRATION

OF THE YEAR IS NOW

“ ”

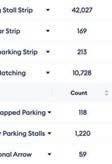

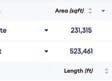

The City of Brotherly Love

The Philadelphia Sports Complex is where the NBA’s 76ers, NHL Flyers, MLB Phillies, and NFL Eagles all call home. One gigantic asphalt playground for all the city’s major sport fans. All-Out Parking Lots first started doing sealcoat work in some of the surrounding lots about 10 years ago. That was a job that they say came about from what literally amounted to a cold call, and, year-by-year they’ve earned larger and more complex maintenance work with the popular city destination.

As native sons of Philly, Marco Menna and Kevin McGarvey’s history isn’t just rooted in the area in general, but they have “business” ties going back to the high-profile jobsite location where they milled, paved, sealed, and patched over the course of two weeks.

“Our first business venture here was a while before that, though,” said McGarvey. “When we were in high school we had this hot shot idea to sell t-shirts outside a big concert, so we dropped $400 on a box of knock-off Kenny Chesney merch.”

Menna interjected, “To a highschooler, that was like an insane amount of money, but we thought we were going to walk away rich.” Their entrepreneurial spirit was not appreciated at this stage in their career. “Within five minutes, security pulled up to us, confiscated all our merchandise, and kicked us out.”

At this point it’s fair to say that, after a decade of a continually expanding list of maintenance projects with the complex, that initial loss has been made back many times over. The work they’re doing this year is massive.

ON THE JOB | BY BRANDON NOEL, Editor 24 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

In the nation’s original capitol — Philadelphia — a pair of life-long friends started their business from the ground up, and are now seeing a big payoff.

Brandon Noel

THE SCOPE OF THE WORK

The Philadelphia Sports Complex is a sprawling center for fandom and entertainment in the city. It’s located within walking distance to some nearby neighborhoods, but for those driving in for a visit, there’s plenty of parking space. With nearly 10 million square feet of blacktop, it’s a big job to keep it all serviced and safe.

“For this particular job, we’re doing 500,000 square feet of sealcoating, crack sealing, and line striping,” said McGarvey as we walked from one patch job being completed, past the Phillies stadium, and toward where the bulk milling job was underway.

“We are also doing 200,000 square feet of milling and paving,” he continued. “In addition to all that, we have just over 2,000 square feet of excavating and patching. That’s the whole project.”

The timing of when to conduct this body of work was important, and the first two weeks of June were perfect. Despite the city’s disappointment when the 76ers were eliminated from the NBA playoffs, it signaled the start for All Out’s crews, and they had to be ready to go. The scheduling is a matter of calculated coordination.

“For a very brief period, there’s a lot fewer events, and we are taking full advantage of that. But we still have to plan the job out as efficiently as possible,” said McGarvey. “Right now the Phillies have one week of consecutive away games and travel. For their main parking area, this phase is all crack sealing. Then they’ll be home for a week, and we’ll pause the work until the following week where they’re gone again. That’s when we will tackle sealcoating and re-striping for that area.”

Marco took me over to where a squad of their crack sealers were gradually winding their way over a spider-web like network. Each worker had a combo

melter/applicator box on wheels. It was the first actual thing on this visit that I got to take a “crack” at (pun intended). The biggest takeaway from that, for me, was that it looks a lot easier than it is.

I struggled to keep the balance of melted material within the applicator squeegee and stay in-line with the depth and direction of the pavement cracks. A great example of the saying, “There’s no such thing as ‘unskilled’ labor.” Because there’s a huge gap between how fast the All Out crew members were hustling, and the stop-and-go method I brought to the scene.

THE MILL AND THE FILL

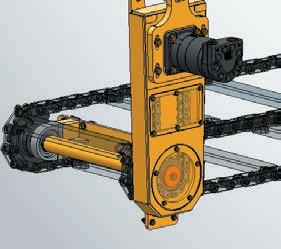

E Lot (the executor lot) at Wells Fargo Arena is where the biggest work took place. All-Out’s 7-foot Wirtgen mill churned out a full tri-axle load every two and a half minutes. The team took up 3 1/2 inches of depth, but below that the base contains an extra ingredient they had carefully avoid.

“It’s called a geotextile fabric,” said Pedro Bermudez, a project manager and pavement advisor for All-Out Parking Lots. “The base on any pavement surfacev is 80% of the strength. That makes this material ideal for roadways and big traffic areas. It comes in really

www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 25

All photos: ACBM Staff

large rolls, tacks the existing surface, and then it rolls out. Then they can pave right over top of it.”

I picked up a small scrap of the material that was kicked up during a milling pass. It felt a lot like a roofing shingle, except thinner and more flexible. “Little pieces like this aren’t going to effect the mill, but if you were to run the whole thing up, constantly, it would slow down the process.”

When it comes down to the paving, the crew brought in a highway class CAT AP655F (as shown on the cover of the issue), laying down 2 1/2 inches of compacted base layer, and 1 1/2 inches compacted of top course, in two lifts. A total of 200,000 square feet, or 3,200 ton of asphalt. The goal was to reach 4 inches after compaction.

To ensure that the quality of the mat met spec, they had a nuclear density tester, and a specialist to utilize it on site, taking measurements as the work progressed. The sensitive tool uses gamma rays to bounce through the mat, measuring air holes, and gives the crew a sense of how many more passes are needed to reach peak compaction.

PATCHING BUSTED DRAINAGE

On the second day of the jobsite visit,

rain was a very present threat to the day’s work. An old catch basin was needed to be removed, the new one put in, and the area around it repaved.

“This is the kind of work, when you come in and assess the project for a client, that you find and that identify the major liabilities for the client,” said Menna, and pointed to the exposed underside of the concrete basin as it was removed by mini-excavator. “You can see how it’s just crumbling underneath. If that were to collapse, that becomes a serious liability issue.”

In order to try and get ahead of the weather, I tagged along with Jeffery “JP” Parris to the asphalt plant to fill up AllOut’s asphalt hot-box. JP had personality by the truck load, and wasn’t shy in sharing some of his three decades of

knowledge and experience. In fact, when we reached the plant we were given a small tour of the facility by someone he had worked with years before.

The real fun for me was when we returned to the catch basin, and was put behind the “wheel” of a small plate compactor. After they installed the new basin, rain just started to fall lightly over the site. Everyone grabbed shovels and started spreading the hot asphalt as quickly as possible. Even Operations Manager Javier Valdez jumped in.

“I started out on the shovel, so I know what that’s like,” he told me later. “All the time, guys will say to me, ‘Why are you doing this or that? You are the foreman, you don’t have to do it.’ And honestly, sometimes I do it just because I don’t want to be bored,” Valdez laughed. “But seriously, it’s important to me to show my guys that I know what the work is, what it takes, and we are all on the same team.”

Not too long after, I was asking him for help as I tried to effectively use the plate compactor. I approached it like a lawnmower, but it was definitely piloting me more than I was piloting it.

It’s a strange thing to balance when you’re out there on a job like this, and it

26 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t ON THE JOB

The team took up 3 ½ inches of depth at the jobsite.

At Wells Fargo Arena, AllOut’s 7-ft. Wirtgen mill churned out a full tri-axle load every few minutes.

BUILDING AMERICA ONE ROAD AT A TIME

LEARN MORE AT WWW.LEEBOY.COM

crossed my mind multiple times while I was there. Everyone watching me knows what they’re doing, and I came to learn, but at the same time you don’t want anyone to think that’s it’s just for “show.”

When I come to a jobsite, I want everyone to know I’m there because I respect the work. That’s first and foremost. I might make jokes at my own expense, but I don’t think the work is a joke in the slightest. I’m thankful for people like Javier, Pedro, and JP, who took the time to show me these things hands-on.

GROWING A COMPANY NEEDS RELATIONSHIPS (AND MONEY)

It’s a cliché to say it, but it still takes money to make money. And for All Out Parking Lots, their growth over the past 10 years has meant an increasing amount of resources needed. While

visiting with them for the Philly Sports Complex job, I learned something that won’t come as a surprise to any contractor reading this story. They don’t get paid when the job is completed, not usually, and the larger

the corporate entity they deal with, sometimes, the larger the gap between completion and payment.

“It’s just literally the cost of doing business at this level, and with these types of customers,” Menna said. “We have to build that into all of our job costing, how long we might have to float the money for one job, and the interest loss on that float period. It has to be taken into consideration or that’s just a loss then for us.”

Some large national corporations and chains that All Out does business with only pay out on contract work like theirs three to four times a year. With so many moving parts, and internal processes that take many months to move through, it takes a long time no matter how you slice things.

“If you’re a mid-level size operation, and you want to someday move to this

Prevent surface water penetration into underlying layers of any tra c grade surface with Pecora’s silicone and urethane tra c sealants. 322FC Pecora Sealant Solutions REDUCE PAVEMENT DETERIORATION Fast Cure Tra c Silicone 300SL Self-Leveling Pavement Joint Sealant 301NS Non-Sag Highway & Pavement Joint Sealant 28 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t ON THE JOB

tier of work, you can’t do it alone,” said McGarvey. And what he’s talking about isn’t just having a strong business partner, staff, and management team. He’s talking about having a strong business relationship with your bank.

“Your bank might not understand our industry, how it operates, the flow of finances,” he said. “What we’ve done with our financial institution is to bring our books in, show them what’s out there, what’s coming in, and we’ve shown over the course of our time working with them, a strong level of consistency.”

That’s not something you can build overnight. While, at first, they wouldn’t

keep getting asked to do more and more of the work there.

The real foundation of All Out Parking Lots comes from something even deeper. “Friendship,” said McGarvey.

“That’s what we are built on, and that’s why I think we’ve been able to create a successful business together. Marco

and I have been friends since the sixth grade.”

That friendship and partnership continues to bear fruit today in the city of brotherly love.

For more information visit https://pavemg.com/mz1q1r

have been able to float these kinds of jobs, according to Menna, it’s not unusual for them to have $1 million out there.

“This is why accurate job costing become so important, because when you’re dealing with a credit line, and even relatively low interest rates on that kind of money, you don’t want to be off,” he said.

It all ties back into their company ethos, as well as the culture of the city where they’re not only from, but the city they decided to stay in, put down roots, and build their business. They’re meticulous, and it showed on the way they managed the work and the phasing for the Sports Complex. It’s why they

PERFECT BLEND OF SEALCOATINGS Meets Applicable Specifications for Component Sealcoatings. Professionals Choice for Performance and Durability. Developed With Performance and Eco-Friendliness in Mind. No Change in Application, Storage and Handling. www.starseal.com 800-759-1912 Call or “click” today to contact a plant near you ! EXPERTS IN SEALCOATINGS WORKING T OGETHER The ULTIMATE PROTECTION The The Ultimate Protection www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 29

ASPHALT PAVEMENT SEALER

Aerial images of the jobsite in Philadelphia.

Brandon Noel

30 PAVEMENT MAINTENANCE & RECONSTRUCTION www.ForConstructionPros.com/Pavemen t PAVEMENT PROFIT CENTER Family-owned and operated since 1975. Trust our industry experts to help you grow your business and optimize your time and e orts. QUALITY YOU NEED. SERVICE YOU DESERVE. 800.543.7077 www.neyra.com PAVEMENT SEALERS | ADDITIVES & PRIMERS | CRACK SEALANTS & PATCHING SPORTS SURFACING | MARKING PAINT | TOOLS, SUPPLIES & EQUIPMENT “CUSTOMER FIRST” FOCUS INDUSTRY LEADING INNOVATION EXCEPTIONAL CUSTOMER SERVICE PREMIUM PRODUCT QUALITY

EZ Liner and Arrow have joined forces to mark a new era in surface prep and pavement marking application. From in-stock Latex ValuLiners, custom-built Paint, Epoxy and Thermoplastic Stripers to Grinder and Rumble

equipment -

www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 31 Cascade: 110 gallon capacity Contact us today! (800) 373-4016 Latex Paint Epoxy Thermoplastic Contract #080521-EZL Rumble StripGrinder (800) 373-4016 • sales@ezliner.com • ezliner.com EZ Liner and Arrow are a liates of VTS. We are Road-Tested. Surface Prep, Latex Striping, Thermoplastic.

you get a complete line of quality

at

exceptional value. Available Now! Contact Tadashi Soma Print and Digital Advertising | 920-542-1267 | tsoma@ACBusinessMedia.com

trucks,

an

Setting Up Your IT Infrastructure Keeps Your Business Organized

It’s important you don’t get bogged down because your business systems are sloppy. Organization starts with your IT infrastructure.

An organized business is a productive business. When you’re scaling, things get hectic. You’re wearing multiple hats–growing sales, servicing customers, sending out invoices, paying bills, keeping your employees happy–you’re juggling a lot. It’s important that you don’t get bogged down because you’re unorganized. Organization starts with your IT infrastructure.

First – digitize your documentation. Stop printing paperwork. The more digital your business is, the more efficient you’ll be. When a customer calls while you’re at a jobsite, you won’t have to wait until you’re back in the office to find their agreement and answer their question. When a vendor calls to ask about payment, you’ll be able to pull up a copy of their bill to discuss. If you’re not yet paperless, start today. Don’t worry about your historical documentation, just start with anything new that comes in and don’t go back!

Two key components to your IT infrastructure in a paperless environment are folder structure and naming conventions. You want to get these two things right to avoid frustration in the future.

IT FOLDER STRUCTURE

First, set up a shared document environment. Regardless of whether you choose Google Drive, Microsoft SharePoint, or some other document storage platform, you want to make sure everyone who may need access to your files has it. You can set up security profiles so that certain folders or files are locked down or only available to certain team members, but you will streamline your operations if you are able to share files across your team. Organize folders so that you will know where to find files. You want to set up your IT folder structure to align with your functional areas. Ensure all documentation gets filed in the appropriate folder as soon as received, completed, etc. Educate your team to keep all documents in these shared folders so that everyone can find what they need at any stage of the work.

Example folder structures:

• Administraton

- Admin Procedures

- Accounting

- Facilities

- HR-people

- IT

• Operations

- Operation Procedures

- Projects

- Scheduling

• Sales and Marketing

- Sales & Marketing Procedures

- Marketing

-Sales

NAMING CONVENTIONS

Once you have determined the appropriate file structure for your business, it is important to determine how you’re going to name files. It is easy to find documents when you are in a paperless environment, but only if you name them in a way that you can do so.

Set standard naming conventions so that everyone in your company names files the same way. This helps you easily find what you need, when you need it.

First, determine the structure you’ll use for your naming conventions. Start with a standard for the header. For example, you may choose to do all capital letters for your header or start with a number or abbreviation. The header will be different based on what type of file you’re naming, but the structure should be consistent across each type of file. For example, you might use CAPITALLETTERS as your header, where CAPITALLETTERS is the type

YOUR BUSINESS MATTERS 32 PAVEMENT MAINTENANCE & RECONSTRUCTION | August/September 2023 | www.ForConstructionPros.com/Pavemen t

AdobeStock_516188921

of document you’re saving, such as CUSTOMERAGREEMENT.

After you’ve determined your header, it’s good to add a date to your file name. This helps you to differentiate files, for example, a customer agreement for a 2020 project versus a 2023 project. Make sure everyone is consistent with the date format being used. For example – MM.DD.YY or MM.YYYY. This will help files align and also tell you if a document is related to a specific date or maybe a period of time.

After the date, add the customer name/vendor name/company name. This tells you who the document relates to.

For example: CUSTOMERAGREEMENT –05.23.23 – ABC Company.

And, finally, you’ll want to include any additional information that will help you to distinguish the document. This is especially helpful if you sign multiple agreements with customers or have multiple insurance policies, etc.

For example: CUSTOMERAGREEMENT –05.23.23 – ABC Company (12345 Driveway).

Standard File Type Examples:

• CUSTOMERAGREEMENT –MM.DD.YY – Customer Name (Office Parking Lot)

• VENDORUPDATE – MM.DD. YY – Vendor Name (Payment address change)

• DEPOSIT – MM.DD.YY – Bank

Account Name

• PMTCC – MM.DD.YY – Vendor

Name (cc x1234)

• MONTHLYP&L – MM.YYYY –

Company Name

• POLICY – MM.DD.YY – MM.DD. YY – Travelers (Workers Comp) Having a good folder structure and standardized naming conventions will save you time and headache, allowing your business to operate more effectively.

Shauna Huntington is founder and CEO of Fortiviti; and creator, The Small Business Bootcamp (smallbusinessbootcamp.com)

For more information visit https://pavemg.com/9zys7k

www.ForConstructionPros.com/Pavemen t | August/September 2023 | PAVEMENT MAINTENANCE & RECONSTRUCTION 33

FROM THE OWNER’S DESK

BY NICK HOWELL

Your Trailers are an Essential Piece of Equipment

Why – and how – to become a trailer maintenance master!

If you’re working construction, you probably have a trailer. In fact, our first purchase was a trailer to haul striping equipment – even before we bought a striping machine! Regardless of how many trailers you have, it will be worth your time and investment to become a “trailer maintenance master.”

As you grow, so will your fleet. At our company we are at a point we have so many trailers it’s near impossible to keep track. But we put in place a system that enables us to keep track of them and to maintain them, as well.

Trailer maintenance shuold be at the top of every contractor’s “to-do” list because your paver rigs won’t do you any good if you can’t haul them to the jobsite. But for many contractors, trailer maintenance isn’t even on the radar!