Read them bones. Throw the dice. Is this your card? (Some Vegas magic humor there.) You can do what you want but the upcoming year will always be tough to predict. Ed Sullivan, chief economist and senior vice president of market intelligence for the Portland Cement Assocation presented his updated forecast for the upcoming year during the association’s fall meeting. The TL;DR of it all, the Federal Reserve’s lowering of interest rates coupled with easing inflation should signal a significant retreat in interest rate levels by the end of next year. Additional key points:

• Construction activity is expected to be burdened by oppressively high interest rates. As more rate cuts transpire, construction loan rates are expected to begin to decline mid-2025.

• Mortgage interest rates are expected to decline to 5.5% by mid-2025 and to 5.0% by year-end 2025. This is likely to usher in favorable home affordability and a surge in consumer demand.

• Nonresidential construction will also benefit from lower interest rates. Unfortunately, it will take time to improve occupancy rates and a higher Net Operating Income. These will come as the economy gains momentum next year. Given this, nonresidential is not expected to see recovery until 2026.

• Public construction activity is expected to benefit from increased spending associated with the Bipartisan Infrastructure Law.

Speaking of infrastructure, for concrete paving, “the next five years looks promising,” says Don Weaver, president of Weaver-Bailey Contractors Inc. and incoming chair of the American Concrete Pavement Association Board of Directors. Yet, he holds a realistic level of confidence as compared to what he thought a couple of years ago. Adding, “Companies are plenty busy but margins are down and backlogs not as great. There is ample work out there but greater strain on the entire project schedule from permitting through notice to proceed that comes from additional restrictions in workforce for building departments, inspections and more.”

Looking forward to seeing you all in Las Vegas for the universe of products and equipment that is World of Concrete! Find us at booth C4236.

Thank you.

Get industry news and expert insights delivered straight into your inbox. Stay up to date on the latest happenings across the concrete industry with our e-newsletter, In The Mix. Scan the QR code to subscribe. https://CONC.me/newsletters

ADVISORY BOARD

Kim Basham

KB Engineering Cheyenne, Wyo.

James Baty II Concrete Foundations Association

Mt. Vernon, Iowa

Dennis Purinton Purinton Builders, Inc. East Granby, Conn.

Jim Cuviello Cuviello Concrete Polished | Stained | Crafted Stevensville, Md.

Chris Klemaske

T.B. Penick & Sons, Inc. San Diego, Calif.

EDITORIAL

Editor ........................................................... Jonathan Kozlowski jkozlowski@iron.markets

Managing Editor Gigi Wood gwood@iron.markets

Junior Editor Merina Shriver mshriver@iron.markets

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director Flatworld Solutions

ADVERTISING/SALES

Brand Manager, OEM & Construction Nikki Lawson nlawson@iron.markets

Sales Representative Kaylee Kidd kkidd@iron.markets

IRONMARKETS

Chief Executive Officer Ron Spink

Chief Revenue Officer ....................................... Amy Schwandt VP, Finance Greta Teter VP, Marketing & Audience Development Ronda Hughes VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan

Corporate Director of Sales Jason DeSarle

Brand Director, Construction, OEM & IronPros Sean Dunphy

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

201 N. Main St. Ste 350 Fort Atkinson, WI 53538 (877) 201-3915 | Fax: (847)-291-4816

circ.ConcreteContractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager, OEM & Construction Nikki Lawson nlawson@iron.markets

Published and copyrighted 2024 by IronMarkets.All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

COMMAND Center is a concrete temperature and maturity system used to monitor temperature for thermal control in mass placements and cold weather and for estimating strength in fast-track construction applications. With the latest updates to COMMAND Center Concrete 4 Web, users can use the web portal to create new projects, edit project settings, and share projects with other users. The new version also includes helpful enhancements and an optimized display of the custom-range feature for Android users.

Scan the QR code for more on the Temperature and Maturing System.

https://CONC.me/78mkn0uo

The GRP 480 Rebar Processor features numerous bolt-on wear parts and surfaces for maintenance and jaw protection. The bolt-on, weldable lower tusks work with the weldable, replaceable piercing blades to sort and separate rebar bundles. Additionally, a bolt-on plate on the cutting side of the upper jaw provides a replaceable wear surface and protects the jaw’s parent material. The GRP also features an extra-large pivot group designed to withstand the rigors of daily rebar processing and provide durability. The Rebar Processor features a 24-in. jaw opening with a 26-in. jaw depth and fits up to 48,000-lb. carriers second-member mounted and 90,000-lb. carriers third-member mounted.

Scan the QR code for more information.

https://CONC.me/ags0bs6f

The EnviroMix Impact App is a tool used by the CHRYSO and GCP sales team to optimize the mix design approach and pre-quantify the embodied carbon results of customer’s concrete mixes. The calculator assists in pre-quantification of GWP. The app uses industry average data references for Scope A1 to A3 and allows for product specific environmental product declaration (EPD) data to produce reports for decision making. The EnviroMix Impact App joins the solutions portfolio of the CHRYSO and GCP Curbing CO2 at the Source Program for Sustainability. Through an on-demand EPD program, eco-innovation practices and solutions with a partnered approach, the Curbing CO2 at the Source Program for Sustainability provides concrete producers with products, tools, data, services and collaboration to develop sustainable concrete.

Scan the QR code for more information. https://CONC.me/qywgoz8i

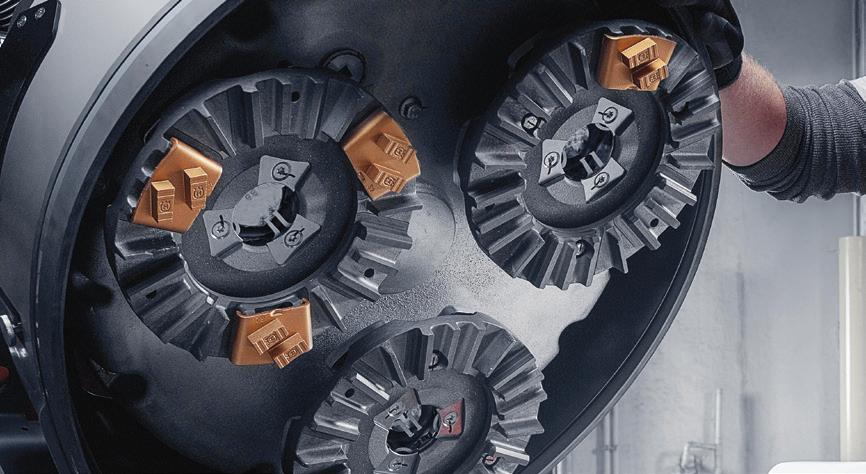

The new range of planetary floor grinders, including diamond tools, dust extractors, floor solutions, is designed to give contractors an easier, more productive workday. From top to bottom, these floor grinders are designed for comfort and efficiency.

• Dual Drive Technology, four-disc technology or conventional three-disc drive

• New ergonomic remote control

• Dustproof/waterproof grinding head and electrical cabinet

• Mist cooler system for longer tool life and higher productivity

• Integrated weights

• EZchange attachment system with improved locking mechanism for tool holder plates

• Standard S-model floor grinders combine reliability with straightforward operation.

Scan the QR code for more information. https://CONC.me/6oq1sihl

EQUIPMENT REDEFINED TRADE FOCUSED SYSTEM WIDE

Even at the foundation, there’s art in the work concrete contractors do. But what happens when an artist decides to step onto the slab and redefine the decorative concrete space?

Anyone active in the decorative concrete industry may very well recognize Rick Lobdell. The multiple awardwinning contractor has been an active member of the American Society of Concrete Contractors (ASCC) since 2013 and joined the board of the Decorative Concrete Council (DCC) a year later. He retired two years ago but continues to share his experience at Surface Koatings Inc. (Surfkoat), one of the main stain manufacturers he used while in business, and an active judge of the DCC Awards. He and his team at Concrete Mystique specialized in custom-designed murals, seals, solid colors, overlays in the $750,000 to $1.5 million house market—everything

except for vertical work.

Anything worthwhile comes through hard work. Though beautiful, the work was grueling often requiring him to lay on the slab for 10 hours a day which left his arms, palms, and elbows stained from color. Though he says that painting a mural on a slab for that long is one the most painful things he’s ever done, the hardest was training somebody else to do what he does and then walk away.

“Considering it’s an art form, you have to have a background in art,” says Lobdell. “There’s not too many artists out there that want to get their hands dirty like I do.” As he figured how to move forward, he retrained his team on the foundations—design, patterns, overlay, stain, seal, etc.

However, it was never just art. “Everybody always thought that all I did was art,” he says. “I would not have made money if I only did art.”

Lobdell started working in the concrete industry 20 years ago. Beforehand, he went to school for computer science and math but graduated with a master’s in painting and a double major in fine art and philosophy. Afterward, he went into construction for a short while and then started his own tile company. Later, he moved to Nashville after marrying and fought hard to find work where he could. He went back to tile. Even taught dancing. But couldn’t find consistent work. “Finally, one day, I went to this interview for Concrete Mystique and they were showing us what we could do,” explains Lobdell. “There was 15-20 people in the interview and they were only hiring one. I’m sitting there, listening to him and I went ‘Hold on…you’re telling me this isn’t tile? I don’t understand how it was concrete.’” They explained that they engraved

the design into the concrete, using grout lines to make it look like tile. Realizing he wouldn’t need to lug boxes of fragile tile and heavy thin-set cement board up flights of stairs but work on the concrete already there he was hooked. He was hired after the two-week trial.

Sometimes, perseverance truly pays.

Six months later the team in charge left. Within 3 years he found himself the manager of the crews and coming up with new ideas. The company’s specialty was mimicking the look of a 12 x 12-in. tile on concrete and decision-makers were reluctant to change. Finally, even though he’d never done anything like it before, he convinced a job to include a compass rose design. His boss agreed after showing a photo and approved adding $500 for the work. In a week Lobdell came back with an extra $1,000. Finally, in 2007, he purchased the Concrete Mystique.

It was a different industry back then. “When I first started, you had a two-week training class, given a trailer, and you were on your own doing projects. I was engraving. I was doing a pool deck by myself. There is no way I could do that now. Not even close,” says Lobdell. For comparison, under his watch, it required at least 6 months of training before someone was “on their own” at a jobsite.

One of the (many) lessons learned for Lobdell early was that any imperfections in the concrete were going to be seen. Any spills, trowel marks, different sheens, and broom marks, all would be visible if the concrete was only stained and sealed. But, “if you added a tile pattern, all of a sudden all those imperfections become cool tile imperfections. These imperfections become positives to everything in the tile,” he says.

For years he stuck to only acid staining and sealing until a friend convinced him to try epoxy and urethane which eventually took him to be nationally recognized.

The challenge with custom designs, metallic epoxies, or flake garage floors was business. He found that his team only captured those types of jobs once every

two months or so. On the other side of that, they did acid stain, solid colored sealer, or a basic tile pattern often.

Lobdell’s rise to national recognition started in 2011 when he hosted a party when the concrete industry came to his area. Aside from the hand-designed floor (above), he included a collection of his personal paintings. One of the designs featured concentric circles from the center of the room. This required him to calculate a point of reference to figure out the arc and rotate that to find each line.

“You have to be careful. You can follow your lines and relatively cut that

with no problem…but when you switch to doing it on a curve, that changes everything. Trying to do those start and stop points at those intersections while maintaining a curve was grueling,” he says. His process had someone holding center while he transferred the geometric Cartesian coordinates onto the slab with soapstone. The curves were freehanded with an angle grinder and used a Cobra engraver from Engrave-A-Crete for the straight lines.

When consulting with customers, his advice is to sell the design. “My biggest goal is to figure out what you [the customer] want. If I can find something about you, I’ve sold the project no problem,” he says. Case in point, one custom design for a backyard patio featured a specific design inspired by the customer. Lobdell noticed a design in the curtains and pillows during the consultation conversation and offered to use that as a reference for the floor.

“You just have to give that idea and say, ‘What can I do for you?’,” he says.

Interestingly enough, he sketched most designs on paper throughout his career (lower image, page 9)—opting away from utilizing CAD or Photoshop. Other designs were done with a scaled reference picture and then transferred on the slab by hand.

Lobdell explains the patio project: “I had an in-house concrete guy that worked with me. We talked about different

Concrete Mystique’s offerings included pool decks, patios, interior flooring, metallic epoxy, driveways, sidewalks, porches, commercial, and furniture.

surfaces [and] different techniques because I didn’t want just a broom finish. What he figured out was what he called ‘an antique rub.’” He figured out a way to provide a texture with slip resistance without the straight lines of a broom finish. He and his team ended up using this texture on every pour for a decade.

No matter what type of concrete, no contractor works alone. “It is so important to remember that there is a team involved with all of it,” says Lobdell. Fitting they worked out of Nashville, he ran Concrete Mystique as if a band. “Once that sunk in, I started to realize that I need to remember the people that are helping me, are helping me. It might be my idea, but

I can’t do everything by myself. I need a team around me to help me out. His biggest advice for contractors is to become a member of the ASCC. “ASCC is one of the most important things for any contractor to be involved with,” says Lobdell. “You have access to the best of the best when you need help and your manufacturer’s not available—you have a friend to call. You have a hotline to call.”

Retired, Lobdell hosts the Concrete Mystique Podcast. He can be contacted on Facebook at https://www.facebook.com/rick.lobdell.

Featuring commentary by Rick Lobdell and presented by Epoxy Depot, “Epoxy Floor Wars” features teams of competing contractors with challenges on different styles of decorative concrete. Season three will host battles in Florida, Tennessee, Pennsylvania, and Texas in a single elimination tournament with a $50,000 grand prize. The show can be found on YouTube or through EpoxyFloorWars.com.

*At the time of this writing, Concrete Contractor, ForConstructionPros.com or IRONMARKETS has no affiliation with Epoxy Floor Wars.

World of Concrete 2025 features a wide variety of special events, educational sessions, breakfasts/luncheons, and indoor/outdoor exhibits and events. There is bound to be something for everyone. Check out these products on the show floor.

Minnich’s new sprayer is designed to efficiently cover sizable concrete surfaces with ease and accuracy. The Multi-Purpose sprayer is a solution for large scale jobsites requiring application of water-based sealants, curing agents, and detergents. The sprayer mounts to a 55-gal. drum and totes up to 550 gal., offering exceptional flexibility for diverse jobsites such as roads, parking lots, and bridges. Its straightforward setup and operation, including a 1-in. intake hose and adjustable pressure settings, allow users to customize the application for their project needs.

Find Minnich at booth C42237

Wooster Products’ NITEGLOW anti-slip photoluminescent technology provides an illuminated pathway in a darkened environment and sure footing makes them an ideal choice for exit pathways. It combines bright, long lasting photoluminescent epoxy filler with nearly diamond hard aluminum oxide crystals to provides a glow-inthe-dark surface with a high coefficient of friction, even when wet. Available in 3-, 4-, and 6-in. widths, and lengths to 8 1/2 ft., AlumoGrit abrasive cast aluminum structural treads, platforms, and thresholds feature cross-hatching and fluting that are clean and well defined.

Find Wooster at booth N222

MGT America will have on display its line of Soil Compaction products. The line comprises three plate compactors and two rammer compactors, designed for versatility and efficiency. Attendees will have the chance to see the line and attest to its heavy-duty construction, quality manufacturing, and design.

• Self-adjustable clutch

• Handles specially designed to allow compacting soil close to walls

• Increased operator comfort

Find MGT at booth C4205

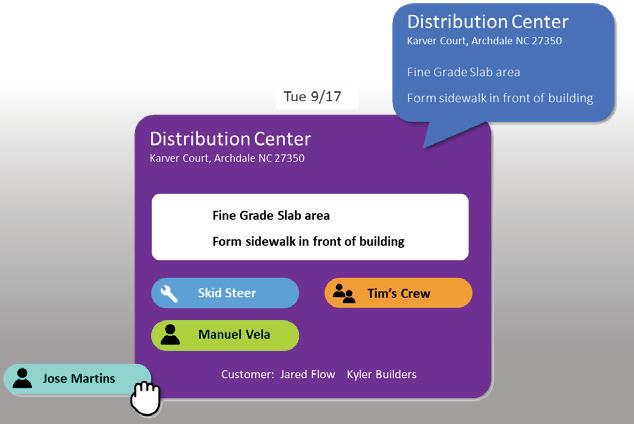

An overabundance of data from construction site equipment can hurt rather than help companies, but FleetWatcher’s advanced telematics platform allows users to manage multiple apps with a single platform. FleetWatcher aggregates the data and allows companies to make real time decisions based on the data. In addition to establishing geo-zones, tracking equipment productivity-versusidle time, tracking driver behavior, determining yield dynamically, thwarting theft, and reporting whether personnel are qualified to operate particular equipment, the company will introduce functionalities like buckets and attachments tracking, fuel burn management, equipment inspection, and more. By taming the “data overload”, this advanced telematics platform brings the connected site closer to reality.

Find FleetWatcher at booth N1773

• PAVE/X, January 27-30, Chattanooga, TN

• Pile Driving Contractors Association Annual Conference, February 4-6, San Antonio, TX

• The Precast Show, February 5-7, Indianapolis, IN

• Decorative Concrete Expo, February 27-28, Canton, OH

• NRMCA Annual Convention, March 4-7, Tucson, AZ

• The American Shotcrete Association Shotcrete Convention & Technology Conference, March 9-11, Savannah, GA

• Concrete Sawing & Drilling Association Annual Conference, March 10-14, San Antonio, TX

• National Stone, Sand, & Gravel Association Annual Convention, March 25-27, St. Lois, MO

• ACI Spring Concrete Convention, March 30-April 2, Toronto, Ontario, Canada

• IEEE-IAS/PCA Cement Conference, May 4-8, Birmingham, AL

• SuperPile, June 18-20, Cleveland, OH

• Concrete Foundations Association Annual Convention, July 18-20, Deadwood, SD

• The American Society of Concrete Contractors Annual Conference, September 10-13, Indianapolis, IN

• National Precast Concrete Association Annual Convention, October 2-4, Grand Rapids, MI

• NRMCA ConcreteWorks, October 10-14, Orlando, FL

• Deep Foundations Institute’s Annual Conference, October 20-23, Nashville, TN

• ACI Fall Concrete Convention, October 26-27, Baltimore, MD

FLAT FLOORS REDUCED LABOR INCREASED PROFITS 24/7 CUSTOMER SUPPORT MADE IN THE USA

Three easy-to-spot testing mistakes that happen during data collection with a walking floor profiler that lower your F-numbers—and how you can better understand the data.

National Ready Mixed Concrete Association

“Area doesn’t meet surface profile tolerances”, is not what you want to see on an FF/FL report as a commercial concrete flooring contra or. The moment a test agency submits a failing report, things get serious, and people are looking for answers.

While bad service, mix issues, and equipment problems are the usual suspects, few people question the test itself. That’s especially true when the results are put together in a well-formatted, official-looking, report that just has an unquestionable air of authenticity about it.

In this article, I’d like to cover three easy-to-spot testing mistakes that happen during data collection

with a walking floor profiler that can be identified at a glance and greatly affect your run scores. As a concrete contractor or testing agency, your ability to detect these mistakes can be of great value, especially if the mistake makes the difference between a passing or failing score on a floor.

(continued on page 17 )

If you’re a testing agency reading this, and you’re not doing this already, train your technicians to check for these issues before handing over the report to the client. Include the profile graphs without being asked for them, and make sure you do a good job of documenting where you take your runs so they can be easily located should the results ever come into question.

If you see you’ve made a mistake, or suspect your profiler malfunctioned, own it and remedy the issue. An erroneously failing report has far-reaching implications that could create a lot of needless headaches, costs, and delays for the concrete contractor and your client. If you’re already doing this, keep up the great work. These extra steps set you apart and you’d do well to market that to future clients.

• A reading was taken in the air.

• Accidentally measuring an object stuck to the floor.

• Bad calibration/something stuck to the footpad.

The first step to seeing these is to get your hands on the profile graphs (or plot). Every profiler on the market can produce these graphs. They may look slightly different, but they all display the same information in nearly the same way. The question is, whether or not the test agency provided them with the report. It would be best if pre-pour, the testing agency is informed that you want these graphs included with every report produced for that project. If you know how to read them, they can tell you a lot about screed settings, forming, and even laser issues (which may be an article for another time). For now, let’s get back to the three issues and how to see them on the profile graphs.

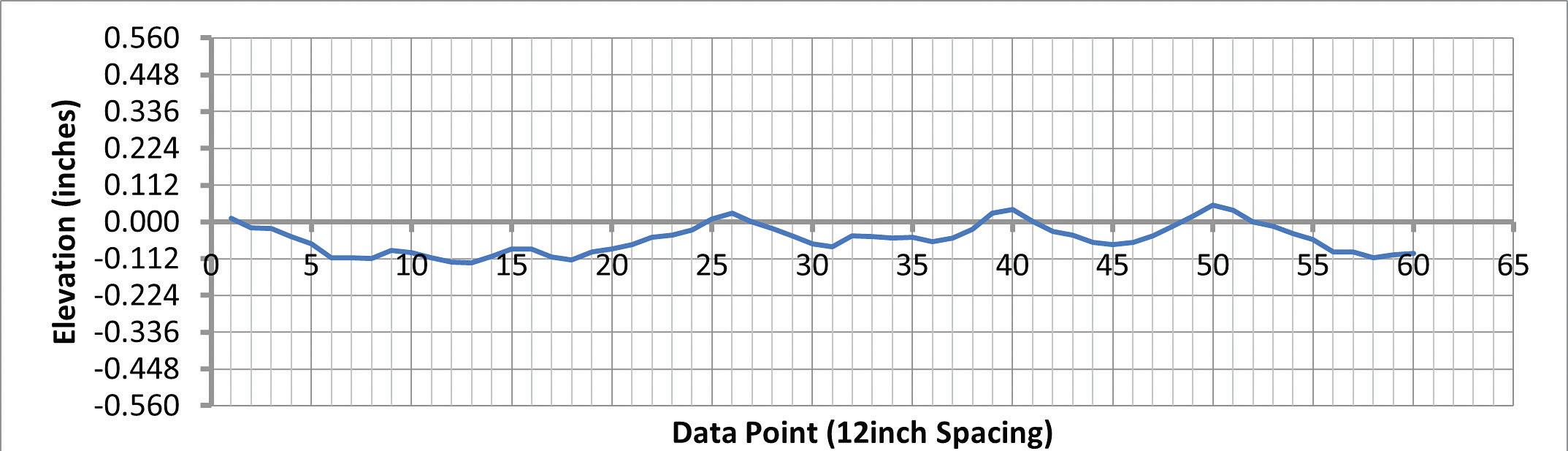

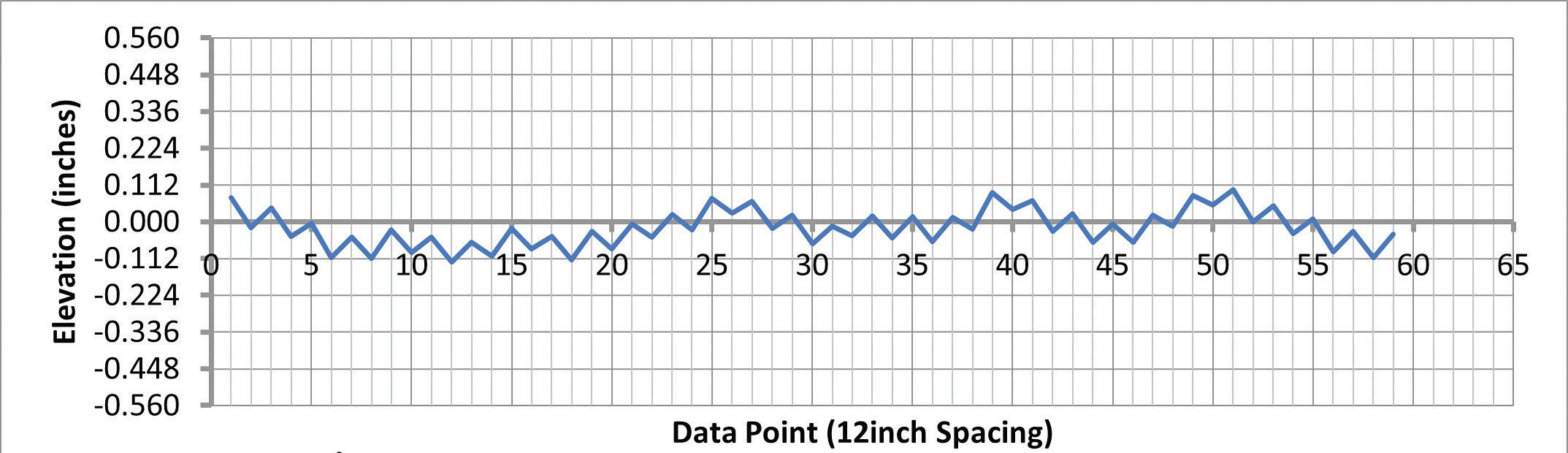

To see them you first need to understand what a profile graph is and how to read it. Profile Graph 1 (page 16) is a profile graph from a real run on a real floor taken with a walking profiler.

For each step taken with the profiler, an angle is captured and translated into an elevation reading. That is then plotted on a graph. As you walk the profiler, captured data creates a profile of the actual floor, hence the name “floor profiler.” In this example (profile graph 1), 60 readings were taken. The distance is plotted along the X-axis. The spacing on the footpads on the profiler was 12 in. which can provide us the total length of the run, 60 ft. The elevation reading for each step is plotted on the Y-axis. Runs always start from zero and then elevation is added or subtracted to the subsequent reading. In summary, the entire run of measurements fell within a 0.174-in. envelope. (Which is around 3/16 in. for those who are

like me and have a hard time with decimals.)

Couple that with the FF/FL score reported for this run of FF 65.5 and FL 64.74, you will be able to better understand everything you need to know to quickly identify the three issues. (For brevity’s sake,

we’ll not be covering how FF/FL is calculated using this information in this article).

Whenever you see a profile plot that has a ledge that steps up in

one reading (sharp line up within one reading per 12 in.) as seen in profile graph 2 (page 16) at the 30 mark data point, it’s likely a false reading that was taken in the air. This happens when the profiler collects a reading before its footpad is in contact with the ground. Another way to create a profile like this is if the operator literally stepped up onto a higher surface with the profiler at this point in the floor. Either way, you have a problem.

To show the impact of this, we added 0.25 in. to one single point using the same data from the baseline data run seen in Profile Graph 1. Remember the baseline run measured FF 65.5 and FL 65.74. That same run with just a 0.25-in. reading in the air has now dropped the score to FF 28.1 FL 30.13. This one mistake cut your score in half for that run.

If you ever have a sharp up and down spike in a graph for one reading it means that the profiler foot was actually on something when two readings were taken. To create this, the profiler takes a reading as it steps onto an object and then when it steps off. Something stuck to the floor or footpad for a single reading can cause this. If you ever see it on a graph, simply ask the testing agency to take you to the location of the floor where they took this measurement and show you the object they stepped up on.

For this example (see profile graph 3,page 16, note the spike at the 30 mark data point), using the baseline run again but added a 0.25-in. step up and a 0.25-in. step down. The rest of the data was the same. The run now drops to a score of FF 17.7 and FL 53.18.

Trust me this can happen. Especially if a profiler was walked or rolled through debris on the floor. For example, a contractor sent a video of someone rolling a profiler directly through a pile of dust left from saw cutting.

Pro Tip:

Go on Amazon or Harbor Freight and get yourself a pair of cheap digital calipers. You can quickly set it to 0.174 in. to physically see what that looks like in fractions of an inch, and for future reports where you are trying to figure out just how big a bump is.

Simply put, one side of the profiler is reading higher than it should be. This can be due to a bad calibration or something physically stuck to one foot for the run. In either case, it creates a “sawtooth” pattern (see profile graph 4, above) in the readings on a walking profiler. Adding 0.0625 in. (1/16 in.) to one side does to the baseline run measurements now scores an FF 11.4 and FL 65.74.

When you know what to look for these issues stick out like a sore thumb. As a concrete contractor, it’s always in your best interest to ask for the profile graphs and to start looking for them. It could mean the difference between passing or failing.

Bill Arpin is the co-founder of CREWCONSOLE.

Scan the QR code for more in Coatings & Sealants https://CONC.me/coatings-sealants

Pecora’s

The rapid installing, low-cost Crack Stitch is ideal for projects with small to mid-sized cracks and has a tensile strength of over 6,000 lbs. It installs just below the surface of the substrate, making it easy to hide behind a coating (which can be installed shortly after the stitches are installed). The Crack Stitch can be installed using an epoxy or cementitious mix. It’s made utilizing pre-cured Carbon Fiber with a Kevlar cross thread, which creates the patented open grid design allowing for the adhesive material to form rivets, resulting in a mechanical bond from end to end. This technology, called Reinforcement Grid Technology, or ReGrid, is the same that Fortress uses in its ICC-certified wall reinforcement system, InvisiBeam.

Coval Technologies has announced the release of Coval Matting Agent which is to be added to the gloss finish of Coval coatings to create a satin or matte finish. Previously, Coval coatings were packaged as gloss, satin or matte finish. Now only the gloss finish will be sold, with the Coval Matting Agent added according to the finish desired. Packaged in sizes of 15.4g for a 1-gal. unit and 77g for a 5-gal. unit, the Coval coatings to which Coval Matting Agent can be added are Coval Concrete, Coval Ultimate Top Coat and Coval Vinyl. The matting agent can be combined with a portion of the Coval coating in a mixing container using a paddle paint mixer with a low-speed handheld drill. Then, the remaining 1- or 5-gal. pail of Coval is slowly added to the container and thoroughly mixed. A good dispersion of Coval Matting Agent is required for performance.

Pecora Corp. added to its Traffic Coatings and Sealants line with Pecora-Deck HB1100-SA. The product is an aggregate, single-coat application, polyurethane waterproofing and traffic bearing coating. Pecora-Deck HB1100-SA is a two-competent, self-leveling, fast curing, UV and weather resistant, low VOC, polyurethane traffic coating system designed for use in both exterior and interior applications exposed to pedestrian and vehicular traffic. This coating is applied as a one-step traffic coating system that includes an integral aggregate and functions as both a waterproofing and traffic bearing deck coating system. Fortress Crack Stitch

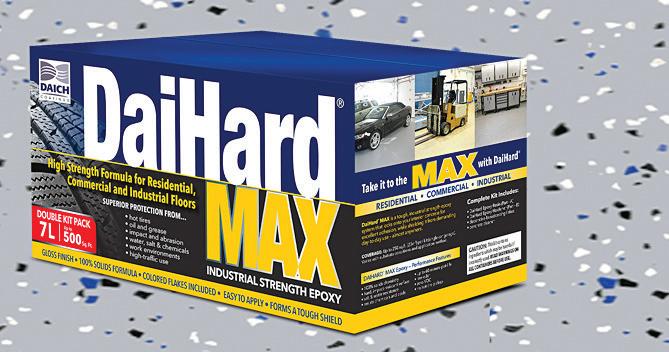

DaiHard MAX Industrial Strength Epoxy Floor Coating Double Kit offers expanded options for providing finishes to interior concrete floors. For individuals looking to finish off a large garage or basement floor, each gallon of the epoxy covers 250 sq. ft. of space. The DaiHard MAX Double kit comes in gray or tan—and a clear option. With two cans of the epoxy in the kit, contractors can cover up to 500 sq. ft. of space. Decorative vinyl flakes are included in the kit, which may be sprinkled onto the wet surface in a uniform layer to create a slip-resistant floor. Because Daich Coatings has received requests from consumers looking for a high gloss look on floors, the DaiHard MAX Double kit is also available with one gallon of grey or tan and one gallon of clear epoxy. To achieve a showroom-shine finish, individuals would first put down the colored option. Then, after an appropriate amount of drying time, they would add the clear coat. The decorative non-slip flakes are still an option to add. The tough, industrial strength 100% solid epoxy floor coating in all versions of the DaiHard MAX kits offer resistance to hot tires, chemicals and daily wear.

Decorative concrete has become a staple for both residential and commercial construction, thanks to its strength, versatility and aesthetic possibilities. However, like all surfaces, it is subject to wear and tear from the elements, foot traffic and the passage of time.

For contractors, revitalizing these surfaces without resorting to full replacements is key to maintaining client satisfaction and staying within project budgets. Fortunately, there are a range of cost-effective techniques—such as polishable overlays, sprayable toppings and other resurfacing methods—that can restore decorative concrete to its former glory.

Over time, decorative concrete surfaces naturally deteriorate due to a variety of environmental and physical factors. Concrete is subject to expansion and contraction as it faces temperature fluctuations, leading to common issues like cracking and spalling. This process is exacerbated in areas with freeze-thaw cycles, where moisture can enter cracks and expand as it freezes, further damaging the surface. Heavy foot or vehicle traffic also contributes to surface erosion, particularly on outdoor concrete

slabs, where decorative patterns can wear down over time.

In addition to physical damage, prolonged exposure to UV rays can cause fading or discoloration, making once-vibrant decorative surfaces appear dull and worn. For many property owners, this deterioration can reduce the aesthetic value of their concrete. Moreover, as design trends shift, older concrete finishes may appear outdated, prompting the need for revitalization to align with modern styles. Beyond aesthetics, addressing these issues promptly ensures that minor damage does not worsen, preserving both the visual appeal and structural integrity of the surface.

Full replacement of concrete surfaces is not only expensive but also environmentally impactful. Tearing out old concrete, hauling it away, and repouring a new slab contributes to significant waste generation and carbon emissions, as concrete production is responsible for approximately 8% of global CO2 emissions. Resurfacing offers a sustainable alternative that reduces environmental impact by minimizing waste and avoiding the need for new raw materials. By applying new layers or coatings over existing surfaces, contractors can achieve the same effect as a replacement while simultaneously lowering labor, material

and disposal costs. This eco-friendly approach is further supported by the use of low-VOC formulations in modern resurfacing products—making it a sustainable solution for property owners and contractors alike.

Polishable overlays provide an excellent solution for revitalizing decorative concrete surfaces, particularly when the underlying slab remains structurally sound but the surface has worn or become damaged. These overlays are made from a combination of cementitious materials, polymers, and aggregates, which are applied over the existing surface to create a new layer

that can be polished to a high-gloss finish. This technique offers significant aesthetic flexibility, allowing contractors to customize the surface by adding color, decorative aggregates or even metallic pigments. These enhancements can create finishes that mimic premium materials such as natural stone or terrazzo, offering clients a luxurious look at a fraction of the cost.

In terms of durability, polishable overlays are known for their wear resistance. Once polished, the concrete surface becomes more dense and resistant to stains, moisture penetration, and daily wear and tear. This makes polishable overlays ideal for high-traffic areas in both residential and commercial applications, where longevity and maintenance ease are critical.

The process also saves significant time. After application, the overlay can be polished within a short period, reducing overall project downtime and allowing clients to return to using their space more quickly. From a cost perspective, polishable overlays offer a much more affordable alternative to complete slab replacement. Contractors save on labor, material, and disposal costs, all while delivering a high-end, modern look to revitalized concrete surfaces.

AN EFFICIENT SOLUTION

Sprayable toppings offer another effective and efficient method for restoring decorative concrete surfaces, particularly those with minor surface imperfections such as light spalling, staining, or discoloration. These toppings are typically made from polymer-modified cementitious materials that are sprayed directly onto the existing surface using specialized equipment. This method allows for rapid application, especially over large areas—making it a time-saving solution compared to more laborintensive resurfacing techniques.

Sprayable toppings are highly versatile, allowing contractors to create a variety of finishes depending on the project’s needs. They can produce smooth, uniform coatings or textured, slip-resistant surfaces, which are ideal for exterior walkways, pool decks, or driveways. The ability to tint or

Applying a cementitious microtopping to properly prepared concrete will create a smooth, durable, and aesthetically versatile surface.

A spray-applied topping resurfacer can rejuvenate worn stamped concrete by filling imperfections, restoring color, and providing a durable, fresh finish that enhances the original design.

stain the topping also adds to its versatility, enabling contractors to match the client’s desired color scheme or update the aesthetic to align with modern trends. In addition to its speed and design flexibility, sprayable toppings are a costeffective option. The process eliminates the need for extensive demolition, repair, or replacement of the existing slab,

significantly reducing labor and material costs. Furthermore, sprayable toppings generally require minimal surface preparation, which further streamlines the project. Typically, light cleaning and addressing major cracks or damage is sufficient before the application, allowing contractors to achieve professional results quickly and affordably.

In addition to polishable overlays and sprayable toppings, contractors have several other cost-effective methods at their disposal to rejuvenate decorative concrete surfaces.

One such method is staining and recoloring. Over time, decorative concrete can lose its vibrancy due to UV exposure and general wear. To bring these surfaces back to life, acid-based or water-based stains can be applied to penetrate the concrete and produce rich, deep colors that enhance the aesthetic appeal. Stains are particularly ideal for highlighting textures, bringing out the unique characteristics of the surface, and providing a new look without the need for extensive resurfacing. They are often paired with other resurfacing methods like overlays or microtoppings to create a cohesive and modern design.

Microtoppings are another valuable technique for addressing surfaces with minor imperfections. These ultra-thin layers of polymer-modified cement are designed to be applied over existing concrete to create a smooth, uniform finish. With a thickness typically no more than 1/16 of an inch, microtoppings are perfect for resurfacing areas that need light touchups or to modernize worn-out concrete. Contractors can choose to create sleek, polished finishes or introduce texture to add depth and interest. The flexibility of microtoppings allows for creativity while being cost efficient, as the process uses minimal material and can be completed relatively quickly.

Stamped overlay systems are yet another technique used to restore or update decorative concrete. Over time, stamped patterns can wear down due to traffic or weather exposure, losing the sharpness and definition that once made them stand out. Stamped overlays can replicate the appearance of new stamped concrete without the need for tearing out and replacing the existing slab. This process involves applying a fresh layer of polymer-modified concrete and imprinting it with decorative patterns. Contractors can also use stamped overlays to introduce entirely new designs, offering clients the chance to refresh their

Cementitious decorative toppings can refresh unsightly concrete surfaces and provide a rich-looking, durable overlay.

spaces without the expense and disruption of a full replacement. Stamped overlays not only restore aesthetics but also improve the durability of the surface, making it more resistant to wear and environmental factors.

Once decorative concrete has been revitalized, proper maintenance is essential to preserve its appearance and durability. Applying a high-quality sealer helps to protect the surface from moisture, stains, and wear. Regular cleaning and resealing, based on traffic levels, will further extend the life of the revitalized concrete and safeguard a client’s investment.

All in all, revitalizing decorative concrete surfaces doesn’t have to be costly or time-consuming. With techniques like polishable overlays, sprayable toppings, and a range of resurfacing solutions, contractors can transform worn or outdated concrete into modern, functional designs. These cost-effective methods enhance the aesthetic and structural integrity of a concrete surface while contributing to sustainable construction practices and keeping project budgets in check.

Rich Cofoid is a senior product and marketing manager at Euclid Chemical for the Increte line of decorative concrete products.

Introducing the Simpson Strong-Tie ® MASOZ™ mudsill anchor for residential construction. Ideal for factory-built, sheathed wall panels, this connector gives you a smarter way to build than traditional methods. The MASOZ has strategic nail hole placements and raised embossments, making it easy to secure wall panels in seconds with a pneumatic nailer. Installers no longer have to deal with misaligned cast-in-place anchor bolts or post-installed anchors. The MASOZ mudsill anchor offers fast, accurate installation, code-listed loads and a lower installed cost. Like all of our mudsill anchors, the MASOZ is widely available and backed by expert service and support.

Learn more about the MASOZ mudsill anchor at go.strongtie.com/masoz or call (800) 999-5099.

Introduced commercially in the 1970s for the Canadian logging industry, let’s look at where roller-compacted concrete stands today.

Infrastructure is an obligation and an opportunity. It’s an obligation because we can’t live without it and an opportunity since there is always room for improvement. Of the many forms of infrastructure, paved surfaces—roads, bridges, parking lots, industrial yards—might be the least likely place to look for opportunity until you consider that low-maintenance longevity is almost always a top priority for the infrastru ure investor. When it comes to durability, ease of maintenance, and uniformity of finished product, concrete is hard to beat. Yet our insistence on innovation persists.

“The majority of the paved surfaces in the world are asphalt, followed by conventional concrete,” begins Greg Halsted, Senior Director of Local Paving at the National Ready Mixed Concrete Association (NRMCA). Halsted has 39 years of heavy civil infrastructure experience across a career that includes roles with the Georgia Department of Transportation, the Portland Cement Association, and the Concrete Reinforcing Steel Institute before joining the NRMCA in 2023. Founded in 1930, the NRMCA supports the expansion and improvement of the ready-mixed concrete industry through leadership, advocacy, workforce development, and concrete technology advancements. “As a pavement engineer, I like the idea of coming up with pavement solutions that

address specific situational needs while also being very durable and sustainable. Roller-compacted concrete (RCC) is now widely accepted and gaining ground on asphalt in the paving world and rightfully so.”

RCC uses the same basic ingredients as conventional concrete—cement, water, and aggregates—but does so in a drier mix more like damp aggregate than a slurry. RCC can also contain supplementary cementitious materials such as fly ash and slag cement as well as chemical admixtures that enhance the material’s fresh and hardened properties.

“RCC is a zero-slump – some even say a negative-slump – concrete

that is consolidated by compacting it with vibratory rollers similar to paving asphalt,” says Halsted. “It is placed quickly because of its high production rates and the absence of formwork and reinforcing steel. It requires a lot less labor, as well as fewer types of equipment and materials to lay down. RCC’s durability is basically identical to conventional concrete. So, having it last for 40 to 60 years with minimal maintenance would not be uncommon.”

RCC was introduced commercially in the 1970s when the Canadian logging industry started engaging in environmentally cleaner, land-based log sorting methods requiring ultra-strong pavement

to stand up to massive loads and specialized equipment. In a sense, RCC is the best of both worlds - the durability of concrete with asphalt’s ease of application. However, as Halsted points out, placement requires precise experience, specialized equipment, and ingrained attention to detail.

“People often ask if RCC is hard to place. My honest answer is ‘Not for people who know what they are doing,” Halsted says. Paving RCC involves placing equipment and techniques similar to those involved in paving asphalt, which helps to make RCC very competitive on a first-cost basis in many markets. Factoring in its durability and minimal maintenance requirements, RCC is the lower-cost paving material over its service life. Whereas much of the world is paved in asphalt, affording opportunities to many contractors of varying expertise, little of the world is paved in RCC. Best

practices demand RCC-specific equipment and expertise in both concrete and asphalt paving.

Bridging the gap between progress and process, Halsted is joined in this conversation by Corey Zollinger,

Chairman of the RCC Pavement Council, a volunteer-led industry trade association founded in 2014. A civil engineer by training, Zollinger and the Council are concentrating on increasing RCC’s market share by growing workforce expertise.

“The most critical element in the decision to use RCC is hiring a contractor who has the equipment, experience, and knowledgeable personnel this material requires,” says Zollinger. The Council’s members include contractors, engineers, and equipment and material suppliers. Membership tiers include Contractors, Contractors-in-Training, Associates, and Allies. “The biggest challenge with RCC is the learning curve. Our Contractor-in-Training program is open to businesses that have five RCC projects or less or may not have all the equipment or personnel in-house.”

Zollinger advises any pavement or concrete contractors thinking of adding RCC to their arsenal to join the Council and take advantage of the training, experience, and network of resources required to make RCC operationally efficient.

“There is no learning on the job. If

Once used almost exclusively in low-speed, high-traffic, and heavy-load areas, today’s RCC pavements are well suited for highways, streets, roads, parking lots, airports, and even small-scale placements only a few feet wide.

• RCC pavements are now jointed the same way conventional concrete pavements are to prevent internal restraint and enhance performance.

• Equipment manufacturers are now making equipment specifically designed for paving RCC rather than asphalt.

• Surfacing admixtures and troweling now produce an RCC surface comparable to conventional concrete.

• RCC design methodology can now determine the best pavement thickness for performance and durability.

• Several aggregate gradation ranges now exist to produce RCC mixes that deliver specific strengths and surface textures.

• RCC pavements now commonly incorporate blended cements.

• RCC is recognized for having a low carbon footprint, long lifecycle, minimal maintenance, high use of supplementary cementitious materials, and is recyclable.

• RCC pavements now benefit from chemical admixtures like water reducers, retarders, and accelerators that enhance long-term performance.

• Engineers now understand RCC as a reliable, useful third option to conventional concrete and asphalt pavements almost anywhere.

you are new to this, it is going to take an investment. That’s not only money but your brain and your heart too,” says Zollinger, the son of a concrete pavement professor who cut his teeth in the industry as a soils lab technician. “RCC is not a forgiving material. As a no-slump concrete, there is no top-to-bottom movement. You must pay close attention to the mix design in production and placement requires high-density compaction pavers and vibratory rollers. RCC is compacted to a natural finish that looks like asphalt. It can be power-troweled or given a broom finish if desired. It is then sprayed with a curing compound that allows the concrete to maintain water content while it gains strength at an appropriate rate.”

Operationally, RCC’s advantage over conventional concrete is the speed of placement. Without formwork and reinforcing steel as part of the equation, pavers need little more than a string line to follow to lay down the surface. Because of RCC’s density, contractors can allow light traffic to cross it relatively soon after it is placed, meaning homeowners can access their driveways during construction.

“RCC will achieve 2,500 psi or more in three days, and it can be opened to traffic shortly after placement,” says Zollinger of a benefit that increases RCC’s appeal as a municipal roadway in urban areas. “We have seen instances where a major intersection was being paved at 10:30 in the morning and opened to traffic by 5 o’clock.”

As a trade association, the RCC Pavement Council strives to provide the leadership, resources, and direction the industry needs. As such, Zollinger and his colleagues are developing an amalgamated Environmental Product Declaration (EPD) based on member data from across a wide range of industry averages.

“Among pavements, due to the much lower cementitious content, RCC is less carbon intensive than either conventional concrete or asphalt,” finishes Zollinger. “Using sustainable building materials is important for owners. The

EPD will demonstrate RCC’s sustainable advantages over conventional concrete or asphalt.”

Halsted agrees and stresses the importance of choosing the right pavement for functional needs and specific conditions.

“At this point, owners developing projects involving pavement should think of RCC pavement as an option along with asphalt and conventional concrete,” he says. “For example, an industrial lot requiring 14 in. of asphalt may only require 8 in. of RCC. That’s a big difference. When you consider the longevity of the pavement, RCC is far superior in the cost/benefit analysis.”

As for detractors, beyond some first costs and the need for highly experienced RCC contractors, the main knock against RCC pavement to this point has been surface smoothness.

“Fifteen years ago, RCC wasn’t being paved to the same level of smoothness as conventional concrete,” continues

Halsted who is the Chair of the American Concrete Institute’s Committee 327 to update the Guide to Roller Compacted Concrete Pavements. Meant to provide owners, contractors, material suppliers, and others with a thorough introduction to RCC, the Committee is working on documenting key changes in RCC science since the Guide’s original 2015 release (see sidebar, page 29). “For quite a long time now, RCC has been used to pave surfaces that support high traffic and heavy loads. With innovations in aggregate mixtures, compaction equipment, and additives, RCC is being used for DOT projects, regular parking lots, municipal roads, and even small applications like a golf course cart path. Just like any quality building material, RCC has gotten better over time.”

Sean O’Keefe is a freelancer specializing in design and construction.

Built to exceed your expectations and outperform the competition. With results in mind, our vibrators are engineered for control and durability, ensuring a smooth and flawless pour every time. With more control over your results and a longer lifespan than other options on the market, our flex shaft concrete vibrators are the perfect choice for the professional looking to take their work to the next level.

The basics on how to catch an edge.

Like anything with concrete work, catching an edge starts with timing. Find that goldilocks point of time between it setting up enough to work and too hard. You want some stiffness with a little bit of integrity. Typically, the rule of thumb here is that the indentation of the knee board should not exceed 1/8 to 1/4 of an inch.

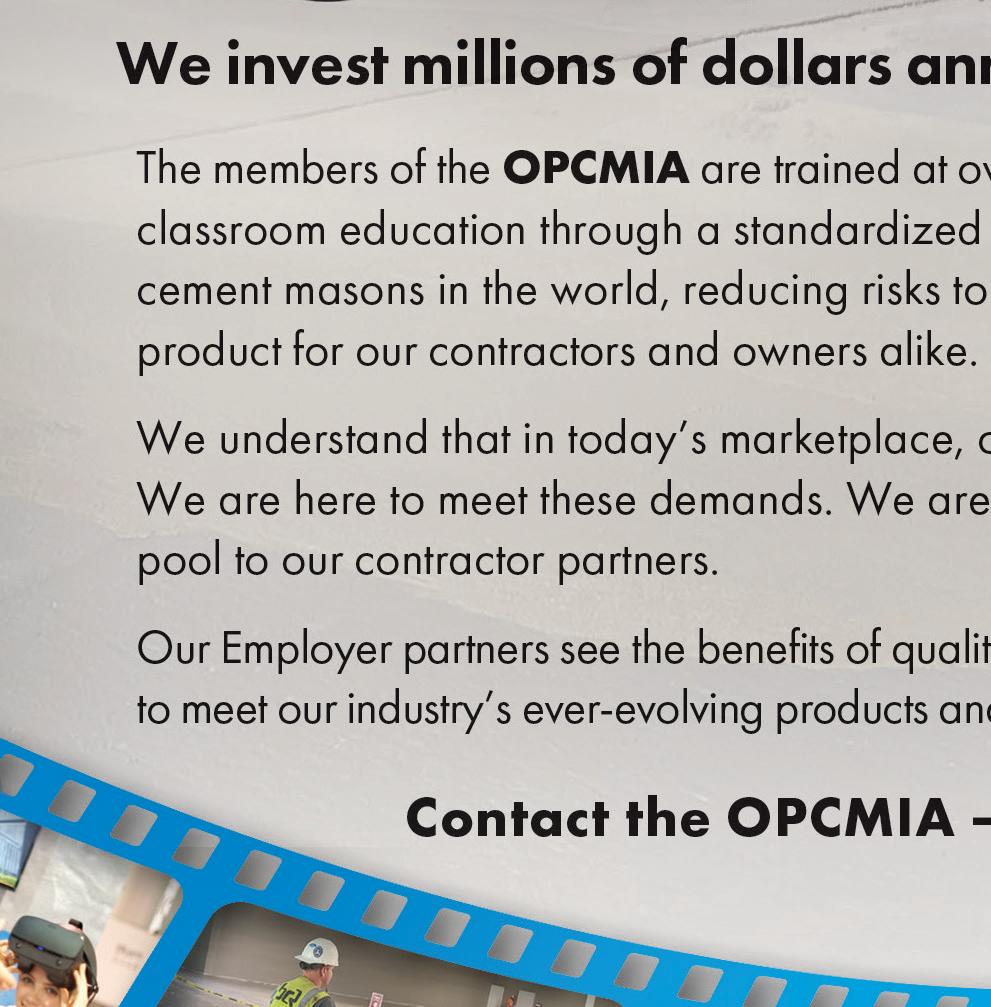

The radius of edges are determined by the radius of your edger. For the new talent on your team, Nick Demonte, ITF cement mason coordinator from the Operative Plasterers’ & Cement Masons’ International Association (OPCMIA) suggests starting beginners with the wider 6-in. edger. “For beginners, we want them to use the wider edger to learn what the flatness of an edge is,” he says. Similar to training people on using a float, it all about how to control the tool along with the stiffness of the concrete.

Consider the weight of the tool. It’s possible to edge if the concrete is super wet but makes it more difficult. Too wet requires you to hold the tool up to stop

the edger from sinking in; some stiffness in the concrete will help keep the tool flat. Holding the angle of the tool too high will take paste away, think more around 5-10 degrees, enough so that the front of the tool doesn’t “dig” back into the concrete.

Consider your body position. It’s common to work on the ground close to the slab on your knees but Demonte prefers to work from his feet and recommends standing. “You can cover more ground by standing up,” he says. “You hold your stance a little wider. The wider your stance will help preserve your back.” Always work in one pass—an arm’s length from one side to the other. Practicing this technique will be key as your technique shouldn’t change. A practiced technique will be how you gain speed and work the concrete faster.

“There’s different techniques for different types of edging,” says Demonte. A finished floor is a different story. For catching a regular edge, widening your stance should make it easier to bend over and work the trowel at an arm’s length.

A line should indent on the outside part of the edge of the concrete (away from you) as the edger coasts over the concrete. This indentation tells you whether you dug in or just touching the surface. Follow using your float to take away the line without closing the edge. This will also help you stay flat. Reposition and continue using the same technique until the slab has been completely edged.

“One of the biggest misconceptions that people make is when there’s a big aggregate and go and take that rock away,” notes Demonte. “Now you have to fill that hole. The biggest mistake people make is they push down on the edger to fill that hole. Now, what they’ve done is haven’t made a flat edge, they’ve made a low area by the form.”

Having the knowledge on when to start the edging process comes with experience.

Oh, and remember to clean your tools and properly store them away.

Curb Roller Lynx Modular Roller Screed

The Lynx Screed has a modular design featuring a series of linkable screed pipes that can accommodate concrete pours in varying widths from 3-22 ft.

• Available in a package consisting of three 7-ft. pipes, or a package containing a 5-, 7- and 9-ft. pipe

• Can be customized to include any 3-, 5-, 7and 9-ft. length combination up to 22 ft.

• Pipes aligned and connected with three separate bolts and a centering ring for quick, easy installation

• Setup completed by bolting drive and static heads to the assembled pipe’s ends and connecting to the electric Eel Screed or battery-powered Batt Screed

Ligchine’s SCREEDSAVER ULTRA PLUS

Scan the QR code for more in Screeds https://CONC.me/screeds

Somero S-940E Electric Laser Screed

Born with a long reach and a wide pass, the Ligchine SCREEDSAVER ULTRA PLUS was built to screed more and screed faster. Complete with an ultra heavy-duty boom reaching 20 ft. with an Ultra Performance 14 ft. 6 in. screed head. Powering the ULTRA PLUS is a 45-horsepower Kubota turbocharged diesel engine. For increased maneuverability and traction, the ULTRA PLUS includes selectable four-wheel drive with a 2-speed drive range and four-wheel independent steering. The ULTRA PLUS features a high-tech elevated operator’s platform, including a captain’s seat, twin joystick controls, and a 7 in. touchscreen control panel which also serves as a display for the SCREEDVIEW camera system.

as a solution for projects requiring reduced noise pollution or zero emissions. An 11-ft. wide screed head covers large areas during use. Weighing 1,950 lbs., it features 4-wheel drive with hydraulic motors for performance on worksites. This machine is powered by three, 7 kwh lithium-ion batteries at 48V. The S-940E provides eight hours of runtime and can cover up to 35,000 sq. ft. per full charge. A full charge takes about four hours using a 240V outlet or 10 hours using a 120V outlet. Optional features include a rotating head dolly, high float tires, spare hose kit, hydraulic fittings kit, tripod kit, column clamp, spare tire or wheel assembly and spare auger kit.

DEWALT POWERSHIFT Walk-Behind Screed

DEWALT’s POWERSHIFT is an electrified equipment system for concrete jobsites. Designed to meet the needs of concrete professionals, the electrified line will allow users to transition away from gas-powered equipment. The DEWALT POWERSHIFT Screed has the power to break a cold joint and adapts to the three most common bar/board styles. The POWERSHIFT line is now available across North America and was recently recognized at TIME magazine’s “Best Inventions of 2024.”

Vanse Screeds West YZ40-4E Screed

Vanse Screeds West’s YZ40-4E is a powerful screed designed to meet the demands of concrete professionals, powered by a Yanmar 4-cyl. engine, delivering 83 hp during use.

• Fuel: Diesel, with a 37-gal. fuel tank

• Mobility: Equipped with four-wheel, twowheel and crab-crawl drive modes for maneuverability

• Performance: Capable of a working speed of 258.33 sq. ft. per minute

• Reach: Features a 20-ft. boom and a 13-ft. head with 360-degree rotation for coverage

• Screed Swing Angle: 120-degree swing angle for operational flexibility

• Weight: 18,739 lbs. for stability and durability on the jobsite

MARSHALLTOWN

Speed Striker 2.0

Power Screed

Powered by a four-stroke Honda GX35 gasoline engine, the screed helps generate a strong slab by vibrating over the concrete. Customers can choose to purchase the Speed Striker 2.0 without a blade or with a 4.5-ft. blade. Forward mounting with 9-in. hole spacing caters to installation with various power screed blades. Equipped with grips for stability, operators can adjust the height of the handle to meet their height and reach requirements. The throttle lever does not require constant contact during use, allowing individuals to position the unit smoothly. An accessible bolton kickstand is available to keep the machine in an upright position on standby.

www.ebay.com/heavyequipment

Traditionally, the concrete industry has been slow to adopt technology into its workflow, but today’s contractors have solutions that improve and streamline workflows, help to mitigate risks, and promote efficiencies at the jobsite and in the office. As the industry is challenged with a skilled labor shortage, technology innovations have stepped up to help. The labor challenge will likely not disappear overnight—if contractors want to grow, they’ll have to figure out how to do so with technology.

Here are 4 ways concrete contractors are taking advantage of technology.

Laser scanning has been helping contractors be more intelligence with their concrete. For example, being able to do a floor flatness / floor levelness in the field before the concrete is dry with progressive scanning as part of that intelligence. One case study featured the placement of a concrete foundation and discovered that the construction

company experienced a 2,000% ROI with the use of 3D progressive scanning throughout the project. This also aided in mitigating mistakes.

It could be argued that the major adoption of technology can be attributed toward cloud computing. When everything resided in a desktop, upgrading the hardware in 30 plants or 100 concrete trucks would be a hassle and costly. Cloud-based solutions made it better for integrating platforms and connecting devices.

Today’s smartphone technologies have gotten advanced enough that augmented reality combined with the data from CAD and BIM can provide them a digital way to confirm various elements of the project—let alone aid in estimation. Software planning tools help manage material workflows and assist in more intelligently scheduling activities in coordination with supply chains. The modern digital workflow also aids in getting bid documents to accounting to the guys in the field and back again.

Telematics dispatch software helps transmit information from the field to the office in real-time. Combined with AI, these solutions can help managers make better business decisions for the projects on the docket.

In a way, the integration of cameras on the jobsite has impacted the jobsite’s workflow as well. Modern cameras now allow contractors to better manage access control, monitor pours for oversight and quality control, as well as aid in identifying where processes can be improved. Some use-cases include:

• Using cameras and AI to automatically keep track of vehicles entering and exiting the site in real time, providing data to the project team regarding traffic management on site and even dwell times.

• Live monitoring of pours allows remote teams to provide some oversight for quality control and look for process improvements.

• Future use-cases may include using cameras and AI to benchmark and document progress.

(continued on page 39)

-

NOTEWORTHY FEATURES:

Over 120 industry-leading Manufacturers & Suppliers from the Paving & Pavement Industry

Robust Educational Program Featuring Tracks on Paving, Striping, Sweeping, Sealcoating, Business Management & More!

Fast-Paced Demonstration Showcase with Enhanced Hands-On Opportunities

Unlimited Networking Opportunities Including the Pre-and Post-Show Parties!

There’s only one place you’ll find the heavy hitters of concrete and masonry this January: Vegas, baby — at World of Concrete 2025, the largest and only annual international event dedicated to your business. Be here to mix with industry giants. Get your hands on the latest technologies revolutionizing safety, performance and speed. And learn what it takes to not only claim a piece of our industry’s massive projected growth but dominate the field. Join the power players of concrete and masonry.

EXHIBITS: JANUARY 21-23, 2025

EDUCATION: JANUARY 20-23 LAS VEGAS CONVENTION CENTER

Whether at the plant or drum/volumetric truck, technology has given operators a lot more control of the mix. Integrating computerized information and digital operation allows the control to produce the concrete to the mix design and amount needed. AIbased systems at the ready-mix plant help precasters and concrete producers optimize their mix designs—affecting the quality of both the concrete and delivery logistics so trucks show up to the jobsite on-time.

Undeniably, electrification has driven a lot of change for contractors and the construction industry, steering contractors from gas-based equipment to battery-powered platforms. In turn,

this move has also increased construction projects like infrastructure and the development of solar fields.

Technology has also impacted safety by tracking the metrics of tools and equipment. Manufacturers are noticing the shift that contractors are willing to invest in solutions that improve the ergonomics and health of their workers. These manufacturers aren’t using machine learning for the sake of it, they’re using test data to impact the productivity of both the worker with better tools and the jobsite.

Consider the introduction of the laser screed. Where once a 20,000 sq.ft. parking lot would need 12 workers all day, a laser screed could allow a contractor to need half that plus finishers. The other workers can then be productive on a separate job.

Technology has a limitless potential for innovation. That’s the point of it. The few mentioned here represent just a very small view of how technology has changed the jobsite both large and small.

Editor’s Note: Thank you to Danielle Proctor, President and CEO of Advanced Construction Robotics; Patrick Weber, Vice President at Advanced Construction Robotics; Michael Fletcher, Vice President of Sales and Marketing at AICrete; Mark Rinehart, Vice President of Sales and Marketing at Cemen Tech; Aaron Stallbaumer, President of Stallbaumer Contracting and Stallbaumer Concrete Industries; Brianne Stewart, Group Product Manager at Milwaukee Tool; Nathan Patton, Product Marketing Manager in the Field Systems Organization at Trimble; and David Gaw, Chief Strategy Officer & Founder of Sensera Systems in the development of this brief.

Recruiting and retaining skilled workers is crucial as labor shortages continue to challenge the construction industry. While there’s no shortage of gimmicks and quick fixes out there, the real solution begins with being a great employer.

That’s why Equipment Today, Asphalt Contractor, Concrete Contractor, Pavement Maintenance & Reconstruction, and ForConstructionPros.com hosted the Best Contractors to Work For recognition program. This program goes beyond surface-level strategies, offering a comprehensive, research-based analysis of a company’s workplace culture, benefits, and employee satisfaction.

To be considered, employers needed to register, while employees filled out surveys about what it’s like to work for their boss. Entry forms and surveys were handled by the Best Companies Group, who analyzed the data and provided an actionable insights report that companies can use to improve employee recruitment and retention.

Want to be considered for the 2025 Best Contractors to Work For?

Please contact Emily Leising at: ELeising@Iron.Markets

★ After a few months of tallying and analysis, the results are in! Congratulations to the 2024 Best Contractors to Work For in Construction award winners:

Winners include, in alphabetical order (company name, number of employees, headquarters):

A & A Paving Contractors, Inc., 16 Roselle, IL

AGUA TRUCKS LLC, 30 El Mirage, AZ

K-Five Construction Corporation, 114

Westmont, IL

Reed Construction, 61 Chicago, IL

Robbins Construction Group, 30 North Charleston, SC

C.W. Driver Companies, 323 Pasadena, CA

CF Evans Construction LLC, 128 Orangeburg, SC

D.A. Sullivan & Sons, Inc., 50 Northampton, MA

Diamond Surface, Inc., 101 Rogers, MN

Fessler & Bowman, Inc, 775 Holly, MI

Fite Building Company, 141 Decatur, AL

Four Seasons Kanga Roof, 63 Roseville, MI

Hayner Hoyt Corporation, 114 Syracuse, NY

Kent Design Build, 85 Mandeville, LA

KNL Industries Inc., 58 Canby, OR

Landis Construction Corporation, LLC, 68 New Orleans, LA

McHugh Concrete Construction, Inc., 38 Chicago, IL

Millstone Weber, LLC., 326 Saint Charles, MO

Morrey’s Contracting, 45 Detroit, MI

MYCO Mechanical, Inc., 207 Telford, PA

Palmetto Sitework Services, 46 Orangeburg, SC

Precision Concrete Construction, Inc, 614 Alpharetta, GA

Stevens Construction Inc., 65 Fort Myers, FL

Stronghold Engineering, Inc., 147 Perris, CA

Supersealers Asphalt Maintenance INC DBA Black Eart Pavement, 59 Delafield, WI

T&K Asphalt Services, Inc., 135 Whitman, MA

The Garrett Companies, 300 Franklin, TN

The Pavement Group, 29 Wexford, PA

Wm Winkler Company, 49 Newman Lake, WA

Please join us in congratulating these leading employers!

A LOT OF FACTORS GO INTO THE PRICE OF YOUR WORK. ARE THEY REFLECTED ACCURATELY IN YOUR ESTIMATES?

You can create a skate park, swimming pool, or a school with it, from airports to apartments and high rises to our homes, concrete is the quintessential element supporting our civilization. Concrete is in high demand, yet few people understand it is extremely demanding work, most people outside our industry struggle to comprehend the price we pay to place concrete.

If we negotiate from an insecure stance we jeopardize our earnings; only when you are profitable will your business continue running. A lot more goes into preparing our estimates than measuring man-hours and materials, there are a multitude of factors and challenges unwritten in our budget that affect the placement of concrete.

As you prepare your estimates you have to factor in accommodating conflicting schedules between several other trades working on the same project, like excavators or plumbers, as well the concrete plant and onsite testers. You need to appreciate the

value of your crew’s abilities and the brute physical stamina required to form and place concrete. Consider the cost of the stress of managing others’ expectations as well. There are issues like difficult terrain to overcome and equipment expenses such as pumps or conveyors to consider.

Concrete doesn’t ship from the plant with a pause button—once that drum spins at the batch plant, the clock is ticking and the margin of error is slim for those who take the risk of taming concrete. Concrete uniquely has an immediacy intrinsically woven into it, it is pliable enough as it comes down the chute that a toddler can manipulate the material, it starts with fluidity but it sets up within a very brief time becoming absolutely solidified. Knowing how and when to shape it and finish it takes years of tactile experience and knowledge, and few people have entered in and mastered our trade.

Being able to brace a foundation, vibrate it and avoid blowouts while keeping the wall plumb or having the ability to evaluate a slab and gauge

the surface-level moisture with just a glance and knowing what steps are next, to feeling the surface pressure with a simple touch, knowing when the slab will support either knee-boards or troweling machines, knowing how to tie in a cold-joint from separate loads or when to get on a slab a little early so the timing works out so you don’t lose the slab all require a precise expertise. These can’t be learned from watching a video, these specialized hard-learned lessons only come from years of hands-on experience.

To be able to see concrete changing physically in real-time, and to feel the transformation of the concrete that’s been placed so that you know how to properly work it with the right tool at the right time it is an underappreciated art by people who can rarely conceptualize the process of properly placing the concrete. These talents are valuable, nearly priceless.

On top of that, placing concrete requires insights into how weather interferes with and impacts curing times. Adapting to the seasons, switching additives, and proper

Simpson Strong-Tie equips you for success at every stage of tilt-wall construction. From panel formwork, erection and bracing to structural and roof framing, decking and interior finishing, our code-approved connectors, mechanical anchors, adhesives and fastening systems keep you moving ahead. Builders also rely on our onsite training, service and technical support, plus web apps and calculators that simplify and streamline project management. Our nationwide distribution network ensures that products are readily available for jobsite delivery when and where you need them. Altogether, it’s a total solution designed to elevate performance. So you can take your operation to new heights. To learn more, visit go.strongtie.com/tiltwall or call (800 ) 999-5099.

@aboutmomentsimages - stock.adobe.com

planning are all necessary to place concrete successfully year-round. These factors all add up at the end of the day. Are they reflected accurately in your estimates?

Beyond these challenges, we also need a level of people skills as well. For insights into who will make from those who won’t, no one interacts with a greater spectrum of concrete contractors than a ready-mix dispatcher. In Northeast Tennessee, Randy Jenkins with Summers-Taylor Inc. thinks, “There are a lot of things that separate successful finishers from those who don’t make it but through the eyes of a dispatcher: A successful finisher will develop and maintain a good working relationship with the ready mix suppliers in their area (sales, plant managers, drivers, and most importantly dispatchers). They will have access to a whole host of knowledge and experience [once they demonstrate this] dispatch and sales can recommend them to potential customers.”

Scott Enger, owner-operator of Concrete Pumping Services of Eastern Idaho Inc., has worked in concrete continuously for 41 years. Once the general manager of 20-plus concrete pumps in the San Francisco North Bay Area he eventually became the ready mix operations and plant manager as well. His perspective on this topic: “From my experience, the most successful contractors I’ve dealt with were the ones that gave up the most details of what they expected and asked the most questions of me. In concrete, communication is King, so being on the same page with everybody who is directly involved with me on a project is paramount. The most successful contractors I deal with do exactly what they say they’re going to do and when they say they’re going to do it. My advice is always keep your word and treat each and every customer like they’re your only customer. It’s very hard to attain a new customer, so customer retention

“A successful finisher will develop and maintain a good working relationship with the ready mix suppliers in their area.”

— Randy Jenkins, Summers-Taylor Inc.

needs to be the focus. Keep that phone ringing!”

Whenever you experience periodic pushback on your prices and you wonder how to best communicate the rationale behind your rates, or simply to feel more confident in setting your rates, perhaps some of the ideas shared here will help influence you. A common mistake is dropping your prices to be competitive, but lowering your prices might compromise your company instead. The fear is if you charge too much you’ll lose their business, but the reality is if you charge too little you will lose your business.

Add up everything that goes into the mix of placing concrete and consider charging more and paying your people more, that way you attract the best possible team. From our gas stations to grocery stores, from the hospitals to our homes, our civilization depends on concrete. Know your worth, because the stress of overcoming our obstacles, the risks we take, and the talent required to place concrete is too valuable to give it away.

Craig Cottongim is a second-generation concrete contractor, he writes about the concrete industry and leadership.

INTEGRAL AGGREGATE, SINGLE-COAT APPLICATION, POLYURETHANE WATERPROOFING & TRAFFIC BEARING COATING

Pecora-Deck HB1100-SA is a two-component, self-leveling, fast curing, UV and weather resistant, low VOC, polyurethane traffic coating system specifically designed for use in both exterior and interior applications exposed to pedestrian and vehicular traffic.

This coating is applied as a one-step traffic coating system that includes an integral aggregate and functions as both a waterproofing and traffic bearing deck coating system.

Milwaukee Tool’s MX FUEL™ REDLITHIUM™ FORGE™ lineup of batteries are the most powerful, fastest charging, and longest-life batteries. Available in XC8.0 and HD12.0 options, the MX FUEL™ REDLITHIUM™ FORGE™ XC8.0 provides up to 33% more runtime in a lighter weight design, while the MX FUEL™ REDLITHIUM™ FORGE™ HD12.0 delivers 2x more runtime of the MX FUEL™ REDLITHIUM™ XC406, making it ideal for high-demand, long duration applications. Both packs feature COOL-CYCLE™ Active Cooling which provides high-speed cooling for less downtime to get the user back to work faster than ever before. COOLCYCLE™ works with MX FUEL™ batteries and chargers that have COOL-CYCLE™ capability. These battery packs provide the longest life for the most recharges and best performance over their lifespan. When paired with the MX FUEL™ Super Charger, the charger offers up to 2X faster charging. Both the battery and charger include REDLINK™ Intelligence, which communicates cell voltage, temperature, and charge status to optimize performance compatibility.

Oztec is proud to introduce the newest edition to its industry leading backpack vibrators.

The New BP-45 adds a powerful 2HP option, capable of running vibrator heads up to 2” in diameter, in a lightweight configuration. This backpack maintains Oztec’s Job-Proven Rugged design. Built to withstand the demands of concrete construction sites with a sturdy steel frame, dependable Honda engines, fully adjustable padding system and the highest quality components, all designed for easy maintenance and long life.

The BP-45 is an option between Oztec’s lightest weight model, the BP-35, and Oztec’s most powerful option, the BP-50a. As with all of Oztec’s power units, the BP-45 includes our patented Quick Disconnect for easy interchangeability with Oztec flexible shafts and vibrator heads.

In December of 2019 Oztec Industries, Inc. reintroduced its 1-1/8” & 1-1/2” RubberHeads®. Both of these heads are available with an optional rubber coated extension piece. With Oztec extension pieces, you can greatly reduce the chance of the vibrator head becoming entangled in the rebar. These heads were originally designed to meet the needs of the construction of the Hood Canal Floating Bridge in Washington State, where over 30,000 cubic yards of concrete were poured in heavily congested rebar without a single head getting entangled in the rebar.

Oztec RubberHeads®, ranging in size from 1-1/8” to 2-3/4”, not only protect epoxy coated rebar and delicate form faces, but also produce better consolidated concrete and are job proven to be more efficient and effective than any other vibrator head on the market!

Oztec Industries, Inc.

65 Channel Drive · Port Washington, NY 11050

1-800-533-9055 - 516-883-8857 - Fax 516-883-7857 www.oztec.com

Brokk Inc. | 1-360-794-1277 info@brokkinc.com | www.brokk.com/us Distributed

PoreShield is a revolutionary bio-based concrete protectant that absorbs below the surface, blocking salt and moisture damage for 10+years. Get the next generation of concrete protection with PoreShield –the safe, durable and costeffective treatment for all types of concrete.

PoreShield.com

Minnich Manufacturing, the leading manufacturer of concrete dowel pin drills, concrete vibrators and vibrator monitoring systems, is dedicated to helping concrete contractors maximize efficiency.

Minnich’s Stinger and Controlled Speed Vibrator (CSV) are just two examples of how the company’s concrete innovations serve customers.

The light yet rugged Stinger electric flex shaft concrete vibrator is a 14.5-pound double-insulated universal motor that can drive the full line of Minnich vibrator shafts and heads from ¾ inch to 2 ½ inches.

The CSV enables contractors to communicate using their cell phone’s Bluetooth to select set speeds of vibrations per minute (VPM) in coordination with the concrete slump being poured. Minnich will continue to bring products to the industry that support the findings of concrete research facilities across the country.