Mastering your craft is what separates visionary entrepreneurs from the everyday business class. And for Africa’s packaging, printing, and processing industry, AFRIPACK Expo 2025 proved once again why it’s the region’s premier trade platform.

Hosted in Nairobi from July 2–4, the expo brought together manufacturers, suppliers, innovators, and policymakers all under one roof to tackle our industry’s biggest challenges, sustainability, automation, and supply chain efficiency. Huge thanks to every exhibitor, sponsor, speaker, and attendee who made it such a standout event.

From smart packaging demos to cutting-edge machinery and new recyclable materials, the expo wasn’t just about products, it was about making real connections and sparking ideas.

Small business owners found new sourcing solutions, while global brands shared how they’re customizing their approach for African markets. The biggest takeaway? If you’re not where innovation is happening, you’re already a step behind.

Missed it? Don’t stress. AFRIPACK Expo 2026 is set for July 15–17 at Sarit Expo Centre, Nairobi. Mark your calendar early! The future of packaging in Africa is being shaped right now, and AFRIPACK has a front-row seat.

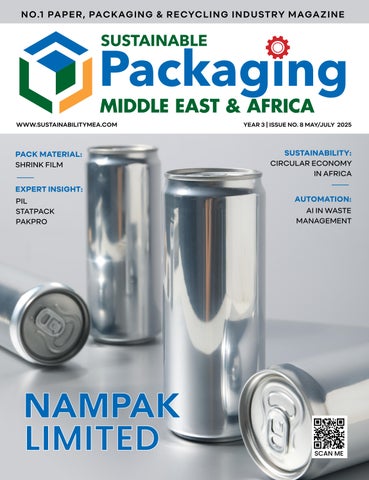

In the meantime, welcome to our eighth issue of Sustainable Packaging Middle East & Africa. We’re kicking things off with a comeback story, Nampak Limited, the can manufacturer that’s slowly regaining ground after tough years and a few strategic exits.

You’ll also get to hear from some incredible voices from the

expo. Adarsh Shah of Statpack Industries shares how they’re building sustainability into their product range, designed with Africa’s needs in mind.

Janet Mbithe from Packaging Industries Ltd walks us through the Barrier Nut Vault, a vacuum-sealed, aluminiumfree pack built for macadamia nuts. It protects quality, cuts carbon, and even extends shelf life to a full year. That’s real impact.

With Kenya now rolling out EPR laws, Bruce Rook from PAKPRO urges companies to lean into Producer Responsibility Organizations (PROs). They offer a full package, education, logistics, reporting, and trusted recycling partners, to help businesses stay compliant and effective.

Over in tech, Mary Wanjira explores how AI is quietly transforming waste management, making it smarter, faster, and greener through predictive maintenance and real-time tracking. It’s one more way technology is helping us move toward a low-carbon future.

Get these and many more, including latest news, innovations, appointments and new packaging designs in the industry.

Got a story to tell or want to contribute? Drop us an email at editor.packaging@fwafrica.net. Let’s keep growing this community and shaping packaging that works for Africa.

Enjoy the read!

Alphonse Okoth Lead Editor FW Africa

Propak West Africa

September 9 – 11, 2025

The Landmark Centre, Lagos, Nigeria https://www.propakwestafrica.com/

Labelexpo Europe 2025 16 – 19 September 2025, Fira Gran Via, Barcelona https://www.labelexpo-europe.com/

FACHPACK

September 23 – 25, 2025

NürnbergMesse exhibition center, Nuremberg, Germany https://www.fachpack.de/en

Tokyo Pack

October 7-10, 2025

Tokyo Big Sight, Tokyo, Japan https://www.japanpack.jp/en/

Shanghai World of Packaging (swop)

November 25 - 27, 2025

Shanghai New International Expo Centre (SNlEC), China

https://www.swop-online.com/en

Africa Dairy Innovation Summit

February 2026

Nairobi, Kenya

https://africadairysummit.com/

AFRIPACK Expo Nigeria & Western Africa

April 14-16, 2026

Lagos, Nigeria https://www.afripackexpo.com/

Africa Food Manufacturing Kenya & Eastern Africa

July 15,17, 2026

Sarit Expo Centre, Nairobi, Kenya https://www.afmass.com/

AFRIPACK Expo Kenya & Eastern Africa

July 15,17, 2026

Sarit Expo Centre, Nairobi, Kenya

https://www.afripackexpo.com/

MIDDLE EAST & AFRICA

Year 3 | Issue No.8 | May - July 2025

FOUNDER & PUBLISHER

Francis Juma

SENIOR EDITOR

Alphonse Okoth

EDITOR

Mary Wanjira

Stephen Kibe

BUSINESS DEVELOPMENT

DIRECTOR

Virginia Nyoro

BUSINESS DEVELOPMENT

ASSOCIATE

Johna Sambai

HEAD OF DESIGN

Clare Ngode

ASSOCIATE DESIGNER

Emmaculate Ouma

ACCOUNTS

Anita Kinyua

Published By: FW Africa

P.O. Box 1874-00621, Nairobi Kenya

Tel: +254725 343932

Email: info@fwafrica.net

Company Website: www.fwafrica.net

We publish some of the most influential magazines and websites in Africa & the Middle East regions. Please visit the websites below for more information about our publications.

Sustainable Packaging Middle East & Africa is published 4 times a year by FW Africa. Reproduction of the whole or any part of the contents without written permission from the editor is prohibited. All information is published in good faith. While care is taken to prevent inaccuracies, the publishers accept no liability for any errors or omissions or for the consequences of any action taken on the basis of information published.

www.foodbusinessmea.com

www.millingmea.com

www.dairybusinessmea.com

www.feedbusinessmea.com

www.healthcaremea.com

www.sustainabilitymea.com

www.hpcmagmea.com

GERMANY – Syntegon has unveiled a next-generation pharmaceutical filling line concept, SynTiso, designed to transform how liquid medications are processed and packaged. Introduced during Pharmatag 2025, the system emphasizes automation, sterility, and efficiency, addressing rising global demand for safe and contamination-free drug manufacturing.

At the core of SynTiso is a gloveless isolator, a significant departure from traditional isolator systems. The design removes the need for manual intervention inside sterile zones, reducing the risk of contamination and improving regulatory compliance, particularly with the EU's Annex 1 guidelines.

“We go one step further,” explains Markus Heinz, Syntegon’s Product Manager. “Robots are kept away from the aseptic core, used only when necessary. This limits particle generation and maintains clean airflow, which is essential in aseptic conditions.”

The line includes real-time germ and particle monitoring, eliminating the need for settle plate exchanges and streamlining cleanroom operations. A standout feature is its contactless, suspended transport system, which simplifies cleaning, minimizes wear, and handles highly potent drugs like oncologics with ease.

The system achieves speeds of up to 600 containers per minute,whether syringes, vials, or cartridges, while enabling 100% in-process control (IPC) for quality assurance. Its modular structure also allows for 50% faster batch changeovers within a smaller physical footprint.

In parallel, Syntegon also introduced the MLD Advanced, a high-speed machine for filling ready-to-use (RTU) syringes. With a 400-unit per minute capacity, it builds on the proven FXS platform, integrating precise, no-touch transport and 100% IPC weighing pre-filling.

For high-value medications, accuracy is critical. “Each drop must be filled and weighed precisely,” says Markus Burkert, Product Manager.

SCZone, Turkey’s URSA partner on US$20M packaging plant

EGYPT - The General Authority for the Suez Canal Economic Zone (SCZone) has signed a major investment deal with Turkish packaging firm UR-SA to build a US$20 million industrial textiles and plastic packaging facility in Qantara West, Egypt.

Spanning 35,000 square meters, the facility will produce industrial and agricultural packaging materials, including Flexible Intermediate Bulk Containers (FIBCs). Notably, 80% of production will be for export, positioning the plant as a key player in regional and international supply chains.

The factory is expected to create 1,000 direct jobs, supporting local families and building industrial skills among youth in the region.

“This is our 23rd project in Qantara West, bringing total investments in the zone to over $643 million,” said SCZone Chairman Waleid Gamal El-Dien. “We’re not just building factories; we’re building futures.”

The facility is aligned with SCZone’s broader strategy to localize industry, boost exports, and integrate value chains. Egypt’s infrastructure and regulatory reforms continue to attract foreign investors seeking efficient market access to Africa, the Middle East, and Europe.

The UR-SA investment follows similar packaging and textiles projects in the zone. In 2022, a Chinese consortium launched a US$72 million packaging and printing complex in Ain Sokhna. In 2021, Turkish firm Eroğlu Holding established a major garment facility in SCZone, proof of deepening Turkish-Egyptian industrial ties.

With strong logistics connectivity and a clear vision for industrial growth, SCZone is fast becoming a magnet for export-led industries. The UR-SA plant reinforces this momentum, turning strategic partnerships into shared prosperity.

INDIA – In a strategic move to expand its presence in the fastgrowing packaging sector, JK Paper has acquired a 72% stake in Borkar Packaging for US$26.8 million (Rs2.35 billion).

The acquisition comes as the company faces mounting profit challenges, largely due to rising wood prices and cheap imports impacting local margins.

Borkar Packaging, a major supplier to Unilever, Nestlé, and other FMCG giants, operates eight manufacturing facilities across India, including in Goa, Pune, and Kolkata.

It reported a turnover of Rs393.2 crore in FY24, and is well-regarded in the folding cartons segment, used widely in consumer goods, pharmaceuticals, and electronics.

“This acquisition aligns with our long-term vision to offer comprehensive packaging solutions and positions us as a toptier player in folding cartons,” said Harsh Pati Singhania, Chairman and Managing Director of JK Paper.

The deal is particularly timely as JK Paper navigates its eighth straight quarter of profit decline. For the quarter ending June 30, 2025, the company reported a 42% drop in net profit to Rs812.3 million, with wood costs up 9.2% and cheap imports from Indonesia, Chile, and China continuing to pressure margins.

In response to market disruptions, India has initiated antidumping investigations to protect local manufacturers. JK Paper, meanwhile, is considering raising Rs500 crore through non-convertible debentures to support expansion.

Despite financial headwinds, the company continues to invest in sustainable sourcing, with 692,000 acres under farm forestry, aimed at securing future raw materials.

The acquisition of Borkar marks a pivotal step in JK Paper’s strategy to grow its packaging portfolio and lead in a rapidly evolving market.

SOUTH AFRICA - Plastics SA has appointed Samuel Kumbula as its new Sustainability Project Coordinator, reinforcing its commitment to advancing the circular economy and sustainable plastics management in South Africa.

Based in Midrand, Sam brings over eight years of experience in environmental management, with a strong background in community engagement, project implementation, and industry collaboration.

His appointment is expected to strengthen Plastics SA’s grassroots sustainability efforts and foster stronger links between communities and key players in the plastics value chain.

Sam has worked extensively with waste pickers, buy-back centres, and Producer Responsibility Organizations (PROs) in KwaZulu-Natal, equipping him with firsthand knowledge of South Africa’s recycling challenges and opportunities.

A standout project in his career was his leadership of the Transformative Riverine Management Project under the eThekwini Municipality, which covered 24 wards and employed 27 environmental teams.

Under his guidance, 389 individuals, including supervisors and community EnviroChamps, were trained in recycling, river clean-ups, and environmental stewardship.

His international exposure, gained through visits to Germany, Botswana, Malawi, Tanzania, Zambia, and Zimbabwe, has broadened his perspective on waste management systems, adding a global dimension to his local work.

“I’m genuinely excited to join Plastics SA,” Sam shared. “This role aligns perfectly with my values, and I see it as a chance to contribute meaningfully to industry-led environmental action.”

His appointment marks a strategic step in Plastics SA’s mission to build a greener, more circular plastics economy in South Africa.

KENYA - Sky Labels, a key player in East Africa’s labeling sector, is stepping into a new era with the construction of a larger, purpose-built 30,000-square-foot facility in Nairobi, double the size of its current space. The move comes as the company continues to scale to meet rising demand in the region.

Construction began in February 2025 after receiving all necessary approvals. Designed around lean manufacturing principles, the new factory aims to streamline operations and boost efficiency. “This facility is critical to staying competitive,” said Chairman NT Mehta. “Our production team is directly involved in machinery decisions, ensuring we remain at the cutting edge.”

Sky Labels has steadily invested in advanced technology, including the Konica Minolta AccurioLabel 230, the first in East Africa, as well as 6-color and 8-color Multitec flexo presses. A new 6-color press is also on the way. The company offers digital printing for short runs and operates two letterpress

machines. It is also preparing to bring platemaking in-house to further speed up production.

The firm’s 24/7 operation model ensures ultra-fast turnaround times, often delivering labels in just 2–3 days. “We focus on sectors like cosmetics and beverages where brands seek standout designs and specialty materials like semigloss, PP, and tamper-evident substrates,” said Palak Dave, Operations Director.

While sustainable materials remain cost-prohibitive for many small brands, Sky Labels keeps efficiency and ecoconscious practices in focus.

“We combine speed, quality, and value, all while embedding sustainability where possible. That’s the future of labeling,” added Chintan N. Mehta, Head of Business Development.

The company is also enhancing its anti-counterfeiting offerings by sourcing tamper-evident labels from Avery Dennison.

LIBYA - Tetra Pak Egypt Area has partnered with Zulfa, a subsidiary of the Alushibe Group, to launch a US$16 million greenfield project in Benghazi, the first of its kind for Tetra Pak in Libya.

Spanning 140,000 square meters, the state-of-the-art facility is set to begin operations in early 2026, with an initial focus on processing and packaging milk and juice.

The project is designed to boost Libya’s local food manufacturing capabilities and strengthen its food supply chain, bringing much-needed innovation to the region.

The plant will incorporate Tetra Pak’s L3 framework with advanced, fully integrated processing and packaging systems, including modern mixing technology, ultra-high-temperature (UHT) treatment, pasteurization, and three production lines in the first phase.

These technologies are expected to enhance production efficiency, food safety, and product shelf life.

Wael Khoury, Managing Director of Tetra Pak Egypt Area, described the project as a strategic move to unlock highgrowth opportunities in Libya.

“This is more than an investment, it’s a long-term partnership with Zulfa to deliver solutions that are tailored to the Libyan market,” he said.

Hisham Rizk, Sales and Business Development Director,

emphasized that Tetra Pak is not just providing equipment but acting as a strategic partner to transform the local food industry. “Together with Zulfa, we’re addressing Libya’s needs with innovative, sustainable solutions.”

The Benghazi initiative reflects Tetra Pak’s broader ambition to support emerging markets. Earlier this month, the company launched a second aseptic carton material line in Vietnam and is eyeing similar projects to address food security challenges in other developing regions.

Meanwhile, the company has recently achieved the prestigious EcoVadis Platinum rating, positioning it among the top 1% of over 130,000 companies assessed worldwide.

The accolade highlights the company’s commitment to embedding sustainability across its operations, reinforcing its mission to protect food, people, and the planet.

MOROCCO - Nexeo Plastics, a global leader in thermoplastic resin distribution, has officially entered the Moroccan market through a strategic partnership with Azhar Plastics. This move marks a significant milestone in Nexeo’s broader North African growth strategy, reinforcing its commitment to localized service and technical excellence.

Azhar Plastics will now distribute Nexeo’s expansive portfolio of high-performance materials across key industries in Morocco, including automotive, healthcare, electrical, industrial, and packaging. The collaboration blends Nexeo’s global supply chain and material expertise with Azhar’s deeprooted local market knowledge and customer relationships.

Joao Francisco, Commercial Manager for Iberia & North Africa at Nexeo Plastics, described the partnership as a way to “deliver closer, faster, and more efficient service to Moroccan customers,” helping them navigate evolving manufacturing needs with customized solutions.

Rachid Douibi, Managing Director of Azhar Plastics, emphasized that access to Nexeo’s technical resources will enable his team to better serve local manufacturers with materials that meet stringent performance and compliance standards.

Morocco is quickly positioning itself as a key industrial base for North Africa, thanks to its strong infrastructure, strategic location near Europe, and growing demand for high-performance plastics. With local warehousing, color matching, and technical support, Azhar Plastics is well placed to accelerate service delivery and offer tailored solutions to OEMs and converters in the region.

This partnership aligns with Nexeo’s ongoing expansion across EMEA. In recent months, the company has deepened ties with suppliers like Syensqo, LyondellBasell, and Teknor Apex, strengthening its presence in high-value markets.

USA – Smurfit Westrock, a global powerhouse in paper-based packaging, has reported an impressive 167.5% surge in net sales for Q2 2025, reaching US$7.94 billion, up from US$2.96 billion in the same period last year.

The growth comes on the heels of the company’s successful merger and a strengthened presence in North and Latin America.

Despite this revenue jump, the company recorded a net loss of US$26 million, reversing from a net income of US$132 million in Q2 2024.

The decline in net income margin, from 4.4% to -0.3%, was largely attributed to restructuring and transaction-related expenses.

Tony Smurfit, President and CEO, remained optimistic, “I am pleased to report a strong second-quarter performance as we continue to deliver in line with our adjusted EBITDA guidance.”

He highlighted robust performance in North America and Latin America, with EMEA and APAC markets showing resilience.

Adjusted EBITDA rose by 152.7% to US$1.21 billion, though the margin slightly decreased to 15.3%. Net cash from operating activities also soared 144.1% to US$829 million, and adjusted free cash flow rose 104.8% to US$387 million,

signaling enhanced liquidity.

In a related update, the company’s Q3 2024 results showed net sales of US$7.7 billion and adjusted EBITDA of US$1.265 billion, with a margin of 16.5%, despite a US$150 million net loss tied to ongoing integration efforts.

For the first half of 2025, net sales hit US$15.59 billion, a 164% increase, while net income climbed 10.2% to US$356 million. The board approved a US\$0.43 per share dividend, reaffirming financial confidence.

Looking ahead, Smurfit Westrock projects Q3 2025 adjusted EBITDA at US$1.3 billion, with full-year expectations ranging between US$5.0 billion and US$5.2 billion, as the company continues investing in sustainability and asset optimization across its 40-country footprint.

1,018 Exhibitors From 35 Participating Countries

MEMBER OF INTERPACK ALLIANCE

EGYPT INTERNATIONAL EXHIBITION CENTER

31,000 Visitors from 143 Visiting Countries

UAE – Abu Dhabi Future Energy Company PJSC – Masdar, one of the world’s foremost renewable energy developers, has divested its stake in the Sharjah Waste-to-Energy plant, signaling a strategic shift in its domestic energy focus.

The move reflects a broader realignment in the UAE’s clean energy and waste management landscape as the country sharpens its path toward Net Zero 2050.

The stake has been acquired by Tadweer Group, a national leader in sustainable waste solutions, pending customary closing conditions.

This acquisition consolidates the Emirates Waste-to-Energy joint venture under Tadweer Group and BEEAH Group, Sharjah’s pioneering force in environmental innovation.

Originally inaugurated in 2022, the Sharjah plant is the first commercial-scale waste-to-energy facility in the Middle East.

With a current capacity to process 300,000 tonnes of nonrecyclable waste annually, it generates 30 megawatts (MW) of electricity.

Expansion plans are already in motion to double both its

output and waste processing capacity, aligning with the UAE’s broader waste diversion and emissions reduction goals.

Masdar CEO Mohamed Jameel Al Ramahi praised the project’s role in the UAE’s energy transition.

“This facility is a testament to the power of partnership in advancing climate action,” he said, reiterating Masdar’s continued global focus on solar, wind, and green hydrogen as it targets 100 GW of clean energy capacity by 2030.

Tadweer Group’s CEO Ali Al Dhaheri noted that the acquisition fits within the company’s strategic priority to scale up domestic impact and expand internationally.

“We are committed to positioning the UAE as a global leader in sustainable waste conversion and energy recovery,” he stated.

BEEAH Group CEO Khaled Al Huraimel also welcomed the transition. “We thank Masdar for their invaluable partnership and look forward to deepening our collaboration with Tadweer to unlock the next chapter of innovation.”

The change in ownership comes at a time of rising momentum in the UAE’s circular economy ambitions.

USA – Sappi North America has completed a landmark US$500 million expansion at its Somerset Mill in Skowhegan, Maine, marking a major milestone in the company’s push toward high-performance, sustainable packaging solutions.

Known as Project Elevate, the initiative focused on upgrading Paper Machine No. 2 (PM2), doubling its capacity to produce approximately 470,000 tonnes of solid bleached sulfate (SBS) paperboard annually. These materials are used in food, beverage, and consumer packaging, an area with growing global demand.

Now delivering commercial-grade products, the revamped facility is expected to reach full production by 2026. According to Sappi North America CEO Michael Haws, “This investment goes beyond machinery; it’s about laying the foundation for long-term innovation and sustainable growth.”

The expansion follows a previous US$200 million upgrade to Paper Machine No. 1 in 2018, further cementing the company’s long-term vision to modernize infrastructure and lead in eco-conscious manufacturing.

Kirk Ross, vice president of manufacturing, noted that the advanced PM2 enables Sappi to “meet growing demand with greater speed, consistency, and responsiveness.”

The project also generated economic benefits for the region, employing 1,000 contractors during construction and supporting 780 permanent jobs at the mill. Sappi is now one of Maine’s largest private employers.

Beyond economic gains, the Somerset Mill’s upgrades reflect a broader environmental mission. The facility treats and returns 93% of the water it uses from the Kennebec River and has earned recognition among the top 4% of companies globally for sustainability by EcoVadis.

“This upgrade strengthens our community and ensures the mill’s vitality for decades to come,” said Blue Keim, managing director of operations.

OMAN – Egypt’s Arab Metals Company ZEINOX and Oman’s OQ Group have signed a strategic partnership to establish a US$2.6 million plastics manufacturing plant in the Sultanate of Oman, reinforcing growing industrial cooperation between Arab nations.

The new factory will operate under Oman’s LADAYN industrial program, which focuses on enhancing local production and export capacity.

It aims to manufacture a range of plastic products for both domestic and regional markets, aligning with Oman’s Vision 2040 goals of economic diversification and industrial localization.

Speaking at the signing ceremony, Oman’s Ambassador to Egypt, Abdullah bin Nasser Al-Rahbi, hailed the initiative as a reflection of deepening diplomatic and commercial relations. “This venture reflects the strong ties that are translating into real industrial progress,” he noted.

Maged El-Zeiny, Chairperson of ZEINOX, emphasized the significance of the project: “It’s a step forward in our strategy to build cross-border partnerships that drive sustainable economic development in the Arab region.”

The plant will contribute to job creation, technology transfer, and broader regional trade, while also strengthening Oman’s role as a manufacturing hub.

It joins 18 other LADAYN-supported projects valued at over US$160 million, largely focused on polymer and materials processing.

OQ Group, leading the LADAYN initiative alongside MADAYN and other government entities, views the project as part of its mission to extend Oman’s polymer value chain and attract specialized capital to fuel a knowledge-based economy.

This collaboration serves as a model for pan-Arab industrial integration, with lasting impact on regional manufacturing and economic resilience.

– Heidelberger Druckmaschinen (Heidelberg) has unveiled the Cartonmaster CX 145, a new large-format sheet-fed offset press tailored for high-volume folding carton production.

This launch marks a significant expansion in Heidelberg’s packaging portfolio, aiming to meet the rising demand in the food, beverage, and consumer goods sectors.

The CX 145, built on the Roland Evolution 900 platform, supports a 105cm x 145cm format and fits between Heidelberg’s Speedmaster presses and the larger Boardmaster.

The press will be fully integrated into Heidelberg’s digital ecosystem, enabling seamless workflow via the Prinect platform and access to real-time performance data through the Heidelberg Customer Portal.

In addition to the press, Heidelberg is offering a complete support suite, sales, training, maintenance, and consumables.

Orders are now open, with the first installation expected in 2026 and a global rollout to follow. Strong demand is anticipated from North America, Europe, and China.

The launch also aligns with Heidelberg’s broader digital transformation. The company has invested heavily in automation, robotics, and AI since 2004.

One key innovation is PAT, an AI-powered consulting tool launched in 2021 to guide printers with workflow recommendations.

Schmedding also announced Prinect Touch Free, an upcoming AI-powered upgrade to Heidelberg’s Prinect software.

The system will autonomously select the most cost-effective printing method, digital or offset, and configure layouts automatically, setting new benchmarks in print automation.

Heidelberg continues to grow its digital services and subscription-based models, linking pricing to actual print volumes.

GHANA – Equatorial Coca-Cola Bottling Company (ECCBC) has reached a major milestone in its African growth strategy by acquiring Voltic (GH) Limited and West African Refreshments Limited (WARL) in Ghana.

The acquisition, involving Coca-Cola Beverages Africa (CCBA) and The Coca-Cola Company, hands ECCBC full control over the production, packaging, distribution, and sales of Coca-Cola, Fanta, Sprite, and Voltic mineral water in Ghana. This move solidifies ECCBC’s footprint in West Africa and positions it to better serve a growing population of over 34 million.

“We are thrilled to acquire Voltic, a cornerstone of Ghana’s bottled water sector, and WARL,” said Alfonso Bosch, CEO of ECCBC. “This move underscores our long-term commitment to Africa and allows us to build on Voltic’s legacy of excellence.”

The deal, announced on July 8, 2025, is subject to regulatory approval and is expected to enhance ECCBC’s

integrated beverage platform while unlocking greater value for consumers, suppliers, and partners in Ghana’s US$1.5 billion non-alcoholic beverage market.

Sunil Gupta, CEO of CCBA, said the transaction will allow CCBA to focus more intently on high-growth markets in Southern and East Africa.

The Coca-Cola system, including bottlers like ECCBC, contributed US$10.4 billion to Africa’s economy in 2024 and supported over one million jobs, according to data presented at the 2025 U.S.-Africa Business Summit.

Luisa Ortega, President of The Coca-Cola Company’s Africa unit, noted: “Our partnerships with local bottlers like ECCBC drive sustainable growth and community development across the continent.”

This acquisition follows Coca-Cola and Voltic’s 2023 brand refresh, which introduced a sleek 750ml premium bottle under the campaign "Own Your Richness."

KENYA – The UN Global Compact Network Kenya (GCNK), part of the world’s largest corporate sustainability initiative, has appointed sustainability advocate Mary-Ann Musangi to its Board of Directors. The move is seen as a strategic step to strengthen leadership and deepen private sector engagement in responsible business practices.

Mary-Ann, known for her work in environmental and social impact initiatives, expressed gratitude and resolve.

“I am deeply humbled and honoured to join the board of GCNK, a platform that champions responsible business and accelerates progress toward the Sustainable Development Goals (SDGs),” she said.

“This role comes at a time when the private sector must reimagine itself, not just as a driver of profit, but as a steward of people and the planet.”

GCNK plays a pivotal role in guiding Kenyan businesses on sustainability through training, advocacy, and aligning corporate actions with the UN’s 2030 Agenda. The organization promotes ethical principles in human rights, labour, environment, and anticorruption, and supports platforms like the Africa Business Leaders Coalition (ABLC) and SDG Pioneer Awards.

Mary-Ann’s appointment aligns with GCNK’s broader mission to scale impact and foster inclusive leadership within Kenya’s business community.

“I look forward to working with fellow board members and changemakers to build bold partnerships, deepen corporate engagement, and ensure responsible business becomes the norm, not the exception,” she added.

Her leadership is expected to bring strategic insight and renewed momentum as the board navigates Kenya’s rapidly evolving corporate landscape.

“Here’s to purpose-driven leadership, shared prosperity, and leaving no one behind. Together, let’s keep building better,” she concluded.

With Musangi on board, GCNK reinforces its commitment to ethical, sustainable, and inclusive business practices across the region.

CZECH REPUBLIC - Mondi, a global leader in sustainable packaging, has launched a state-of-the-art paper machine at its Štětí mill in the Czech Republic, following a €400 million (US$454 million) investment.

Commissioned in December 2024, the machine is already delivering high-performance kraft paper that meets growing global demand for paper-based flexible packaging.

“This is a major achievement for our team,” said Roman Senecky, COO of Kraft Paper at Mondi. “We delivered the project on time and within budget, and the paper quality has exceeded expectations.”

The new machine strengthens Mondi’s vertically integrated Paper Bags business and supports the company’s broader kraft paper portfolio, producing a wide range of grades, from high strength to high porosity, used in applications like construction sacks and industrial bags.

More than just a production upgrade, the project marks a key milestone in Mondi’s sustainability journey.

It supports the company’s Action Plan 2030 (MAP2030),

which commits to making all packaging solutions reusable, recyclable, or compostable.

By expanding capacity and efficiency, the Štětí investment enables Mondi to better support customers shifting to more sustainable packaging alternatives.

In parallel, Mondi has also started up a recycled containerboard machine at its Duino mill in Italy. Once fully operational, the facility will produce 420,000 tonnes of highquality containerboard annually using 100% recovered fibre. This material is especially suited for lightweight corrugated packaging used in fast-growing markets like eCommerce and FMCG.

Duino joins a network of integrated Mondi mills across Europe, including sites in Poland, Slovakia, Austria, and the UK, solidifying the company’s role as a reliable producer of both recycled and virgin containerboard, and reinforcing its commitment to circularity and innovation in sustainable packaging.

consumer demand while creating value across the supply chain, from our suppliers to communities,” said Moses Lubisi, Manufacturing and Technical Director at Coca-Cola Beverages South Africa.

CCBA CEO Sunil Gupta added that this investment is part of the company’s broader growth strategy across Africa.

“It reflects our focus on innovation, operational efficiency, and quality,” he said.

The announcement follows a US$14.9 million upgrade at Coca-Cola Beverages Malawi Limited (CCBM), another CCBA subsidiary.

SOUTH AFRICA - Coca-Cola Beverages Africa (CCBA) has invested R365 million (US$20.33 million) in a state-of-theart high-speed bottling line at its Midrand facility in South Africa, a move aimed at enhancing production capacity and supporting local manufacturing.

The new line, the first of its kind in the country, can produce up to 72,000 bottles per hour. It will initially focus on the hydration category, producing Bonaqua Pump Still (750ml) and Powerade (500ml) in new sports cap bottles.

It will also handle Bonaqua Still (330ml and 500ml) and the new Powerade Springboks Edition.

“This investment strengthens our ability to meet rising

The new line in Malawi supports production of CocaCola beverages and the local favorite Sobo, with a capacity of 19,200 bottles per hour in sizes ranging from 300ml to 2 litres.

Additionally, Coca-Cola Beverages Africa in Mozambique has been recognized for the fourth year in a row as an Elite Employer by Tempus Global Group, the local representative of Alexander Forbes in Mozambique.

This recognition is based on measurable data from the National Employee Benefits and Human Capital Management Survey, which assesses the perspective of HR professionals across five key pillars of the Employee Value Proposition (EVP).

Shanghai World of Packaging 2025 opens doors to the Asian packaging market

There is a vital port of call for those seeking to gain a foothold in Asia: the Shanghai World of Packaging (swop). This is the ideal meetingpoint for all those looking to make their entry into one of the world’s most exciting areas of economic activity. Once again, in November, swop – the central hub of the Asian packaging industry – will provide firstclass conditions for market entry, doing business and targeted exchange.

The international processing & packaging industry is set to convene at swop – an event organised by the interpack alliance – in the Shanghai New International Expo Centre between 25 and 27 November 2025. In excess of 950 exhibitors and more than 40,000 visiting

professionals from over 100 countries are anticipated – providing ideal conditions for entering into direct dialogue with decisionmakers from key industries such as food, pharma, cosmetics and consumer goods, and for securing a position in the dynamic economic region in and around China.

The trade fair not only provides the bigger picture concerning the industry’s entire supply chain, but also brings together current trends, technological developments and market segments under one roof. In addition, as a member of the interpack alliance, swop benefits from the global network’s international coverage and excellent industry representation – which is a clear competitive advantage for all participants with an eye to the Asian market.

“Person-to-person contact is of vital importance for business relationships in China. If you’re not doing business locally, you can’t do business here at all. We are happy to report that swop is developing into a ‘must-attend’ event in the Chinese processing & packaging market more and more each year,” emphasises Thomas Dohse, Director of interpack. Feedback from the previous year also demonstrates that the concept is working: 98 percent of exhibitors and 95 percent of visitors declared their all-round satisfaction with their trade fair participation in 2024.

Particular added value for international exhibitors is provided by the “International Pavilion” – an all-inclusive offering by the interpack alliance that combines the best possible trade fair presence with high visibility. What’s more, exhibitors in the Pavilion benefit from targeted visitor routes that lead important purchasers straight to their booths. This provides the ideal basis for generating qualified contacts and tapping into new markets.

KOCH Pac-Systeme is one example of those that will be in attendance: “We’re looking forward to taking part at swop in Shanghai again in 2025! At the trade fair, we’ll be presenting our comprehensive solutions: from standard machine designs

via modular machines to tailored solutions. And pride of place always goes to the comprehensive consulting services provided by our Packaging Competence Center,” explains Darren Ding, Sales Manager China at KOCH Pac-Systeme.

With a diverse accompanying programme, swop 2025 once again delivers a strong impetus for the packaging industry’s ongoing development in China. Current market trends, technological innovations and international industry dialogue are at the focus. Alongside proven formats such as the Smart Packaging Zone and Green Power Zone, the successful “Food Processing and Intelligent Manufacturing Zone”, in particular, will be undergoing further expansion – a special show put on in partnership with the Chinese Institute of Food Science and Technology (CIFST), concentrating on forward-looking technologies for food processing and smart manufacturing.

The SAVE FOOD Forum will also be taking place again, a joint project by interpack, Messe Düsseldorf, FAO China, UNIDO and the World Packaging Organization (WPO). The

forum focuses on the role of packaging in the fight against food loss and food waste.

One highlight this year, once again, is the “Women in Packaging” forum. It pays tribute to women’s contribution in an industry undergoing changes, creates visibility and promotes international dialogue on equity, leadership and diversity in the packaging industry.

More information on swop 2025 is available at https:// www.swop-online.com/en/

The Shanghai World of Packaging is jointly organised by Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd. and is part of the interpack alliance portfolio. The next swop will take place from 25 until 27 November 2025 in the Shanghai New International Expo Centre (SNIEC).

For more information on exhibiting opportunities, please contact the interpack team (Ivania Portillo-Elzer, Portilloi@ messe-duesseldorf.de)

Nigeria’s Meptico has launched its Domo Strawberry Flavour Instant Dairy Whipped Chantilly Cream in two sachets, each held inside a compact 72 g folded carton. The carton features bright, strawberry-themed visuals and product preparation instructions for convenience. Inside, the sealed foil sachets ensure freshness and protection from moisture, making the product shelf-stable and easy to store or display.

Smirnoff Ice Pine Twist Spirit Cooler

Diageo South Africa has launched Smirnoff Ice Pine Twist Spirit Cooler in a new 440 ml recyclable aluminum can, replacing the previous bottle packaging. The cans are fully recyclable and part of Diageo’s effort to expand sustainable packaging for its RTD (ready-to-drink) range in South Africa.

This move aligns with broader trends in the Smirnoff Ice global strategy, which include switching from bottles to cans as RTDs gain traction in convenience-store markets and sustainability becomes more important.

Personal care brand, Wild, in collaboration with Design and innovation agency Morrama has introduced a refillable roll-on deodorant with plastic free refills. The 50ml refill is made from Vivomer – a compostable material already used in Wild’s shower gel range that breaks down completely in soil within a year.

Made from a combination of anodised aluminium and 50% post-consumer recycled plastic, the rounded edged silhouette of the roll-on is designed to fit nicely in hand.

Pernod Ricard’s vodka brand Absolut, in partnership with Blue Ocean Closures, has unveiled a paper-based cap and bottle, reportedly marking an industry first as part of its vision for fully biobased packaging.

The paper-based bottle prototype made from 57% paper and 43% recycled plastic, designed to reduce carbon emissions while maintaining product integrity.

It is sealed with a sustainably sourced, recyclable paper-based cap, made of more than 95% Forest Stewardship Council-certified fibres with a thin plastic top-seal barrier.

Aptar Closures is set to unveil its new tamper-evident, recyclable sports beverage closures at Drinktec 2025, in September.

The NexTE 29.25 Sport Closure sports a sleek, streamlined flip-top design ideal for sports beverages across ambient and dry aseptic fills.

The cap features a visible, non-detachable tamper-evident band that flexes back to enable smooth, one-hand opening without detaching, ensuring regulatory compliance while preserving user convenience and safety.

Japanese IL Group has introduced its innovative Light Protect Pack, a cutting-edge labeling solution designed to safeguard light-sensitive pharmaceuticals. This advanced label blocks harmful light at wavelengths as low as 380 nanometers, ensuring the stability and efficacy of photosensitive medications from packaging to administration. In addition, it is compatible with both glass and plastic vials and syringes, enabling visual inspection during reconstitution while maintaining robust protection against photodegradation.

Africa's Packaging Powerhouse Charts a Leaner, Smarter Future

BY ALPHONSE OKOTH

Nampak Limited, Africa's largest diversified packaging manufacturer, has a rich heritage dating back to 1918 when John Herzberg started a box-making venture in Cape Town. Over the decades, the company evolved through strategic mergers, most notably in 1968 when the National Amalgamated Packaging group (Nampak) was officially formed through the union of key packaging players.

Listed on the Johannesburg Stock Exchange in 1969, Nampak quickly cemented its position as a major packaging supplier to South African industries. Acquisitions such as Metal Box South Africa and Malbak in the 1980s and early 2000s significantly expanded its portfolio, enabling it to tap into international markets.

Over the years, the company has established operations or expanded its footprint in countries including Angola, Nigeria, Kenya, Zambia, Malawi, Zimbabwe, and Ethiopia, as well as select European markets. These strategic expansions have allowed Nampak to build a robust pan-African presence that supports its vision of being the continent’s leading packaging partner.

Nampak’s evolution from a broad-based packaging conglomerate into a focused specialist is emblematic of the shifting dynamics within the global and African packaging industry. In its earlier years, the company managed operations across a wide array of materials, glass, paper, metals, and plastics, serving diverse markets. However, in the face of sustained financial pressures, rising operational costs, and market fragmentation, Nampak adopted a strategic overhaul beginning in 2014.

This transformation involved the deliberate divestment of non-core or underperforming business units. The company exited its glass manufacturing business due to high energy costs and maintenance issues, sold its recycling and flexible packaging divisions, and later offloaded its liquid cartons operations in South Africa, Zambia, and Malawi.

Most recently, Nampak sold its Industrial & Commercial Solutions (I&CS) division and divested from its operations in Kenya, Nigeria, and Zimbabwe, markets that were either underperforming or misaligned with the company’s future growth strategy.

Today, Nampak’s operations are centered on its core strengths in metal and plastic packaging, particularly for the beverage and food sectors. This renewed focus aligns with fastgrowing consumer segments across Africa. The company has streamlined its footprint to concentrate resources in strategic hubs such as South Africa, Angola, and Ethiopia, while maintaining a commercial presence in countries like Malawi and Zambia.

This leaner structure has allowed Nampak to allocate capital more efficiently, improve margins, and better position itself for long-term, sustainable growth within Africa’s evolving packaging landscape.

Today, Nampak operates through its primary divisions: Bevcan

and DivFood. Bevcan manufactures aluminium beverage cans, with major operations in South Africa and Angola. DivFood specializes in three-piece food cans, aerosols, closures, drums, and metal containers.

On the plastics front, Nampak produces lightweight PET bottles and closures for the beverage industry. Though the company has exited the glass and paper-based packaging segments, its remaining portfolio is firmly aligned with highdemand, scalable segments of the packaging sector.

Nampak’s financial journey has been challenging in recent years, largely due to high debt levels, currency devaluations, and operational inefficiencies in some African markets. However, recent results signal a turnaround. In the first half of 2025, Nampak reported a revenue increase of 11% to R5.7 billion (US$321.86m) and an EBITDA of R1.1 billion (US$62.11m).

Most impressively, the company posted a net profit of R3 billion (US$169.40m), a significant swing from the previous year’s loss. The group reduced its net debt by over 33% to R3.1 billion (US$175.04m), supported by the sale of operations in Nigeria, Kenya, and Zimbabwe.

Under outgoing CEO Phildon Roux, who will step down in September 2025, Nampak has pursued an aggressive

strategy to improve margins, reduce debt, and exit non-core markets. A clear pivot toward sustainable profitability and regional consolidation has marked his tenure. The incoming leadership is expected to build on this foundation, with a continued focus on growing metal and plastic packaging segments across high-demand African economies.

With operations spanning multiple African countries, including Angola, Malawi, and previously Zimbabwe and Kenya, Nampak has demonstrated resilience amid macroeconomic headwinds. For instance, Nampak Zimbabwe invested in new generators and an eight-colour printer to modernize its facilities, improving both efficiency and profitability.

Despite a 17% dip in revenue in Zimbabwe in H1 2025, the operation remained profitable. This adaptability showcases Nampak’s strategy of optimizing regional operations while divesting from non-performing or non-core assets.

Nampak’s latest investments align closely with its strategic priorities, enhancing operational efficiency, reducing debt, and focusing on high-growth segments. Between 2022 and 2023, the company upgraded one of its beverage can production

lines using funds raised from its rights offer.

This modernization boosted both capacity and performance, addressing the growing demand for canned beverages in key markets. As noted in its 2023 integrated report, “The proceeds from the rights offer enabled us to strengthen our manufacturing base and improve our financial stability.”

In 2023, Nampak also sold its crate manufacturing equipment to Mpact for R40 million, generating a profit of R35.5 million that directly supported debt reduction. According to Nampak, “These non-core disposals are part of our broader commitment to unlocking value and simplifying the business.”

To ensure quality and competitiveness, Nampak has continued to invest in operational enhancements across its facilities in 11 African countries. With over 5,000 employees, the company is leveraging regional talent and technology upgrades to drive consistent performance.

In early 2024, Nampak sold its liquid cartons businesses

TODAY, NAMPAK’S OPERATIONS ARE CENTERED ON ITS CORE STRENGTHS IN METAL AND PLASTIC PACKAGING, PARTICULARLY FOR THE BEVERAGE AND FOOD SECTORS.

in South Africa, Zambia, and Malawi for R450 million. Later that year, it exited its I&CS division and sold its 51% stake in Nampak Zimbabwe for US$25 million. In early 2025, Kenya’s Metal Cans & Closures acquired Nampak’s local plant and inventory, marking another major divestiture.

These sales were part of a multi-year restructuring program designed to reduce debt and reallocate capital toward highmargin growth areas. As the company stated in its 2024 strategic update, “Proceeds from these transactions are being redeployed to strengthen our core divisions and streamline our operating footprint.”

As sustainability takes center stage in the global packaging industry, Nampak has positioned itself to lead on the continent. The company has ramped up its investments in environmentally responsible practices, with a focus on lightweighting, recyclability, and energy efficiency. In South Africa, over 80% of aluminium beverage cans are now recycled, a feat attributed in part to Nampak’s material choices and partnerships with local recycling networks.

Additionally, Nampak has begun integrating solar energy at some of its key production sites. For example, a pilot solar project in one of its South African facilities has reduced reliance on grid electricity and cut carbon emissions. The company has also rolled out energy-efficient compressors and water-reduction systems in its plastics division, resulting in meaningful cuts in energy and water usage.

More recently, Nampak has focused on redesigning its products to use fewer raw materials through lightweighting initiatives, which reduce plastic and metal content without compromising strength or performance. These innovations not only reduce environmental impact but also lower production costs. Further, Nampak has continued investing in closed-loop systems and extended producer responsibility

(EPR) schemes, particularly in its South African operations, where regulatory and consumer expectations around circularity are rising.

“We are embedding sustainability into our operations not just to meet regulatory expectations, but to ensure long-term viability and reduce our environmental footprint,” the company noted in its 2024 Environmental, Social and Governance (ESG) report. These investments underscore Nampak’s belief that sustainable packaging is not only good for the planet but also a competitive advantage in an increasingly eco-conscious marketplace.

321.86M NAMPAK'S REVENUE IN H1 OF 2025

Beyond its operational footprint and environmental efforts, Nampak is equally committed to social sustainability through investment in people and communities. With over 5,000 employees across 11 African countries, the company places a strong emphasis on developing regional talent and nurturing inclusive workplaces. The company has implemented several training and mentorship programs aimed at upskilling its workforce, particularly in technical fields such as mechanical engineering, quality control, and sustainable manufacturing practices.

In South Africa, Nampak has established learnership and apprenticeship programs that combine classroom training with hands-on factory experience, providing young people with

practical skills and pathways to employment. Through partnerships with local technical institutions, the company also supports bursaries and internship placements, actively contributing to capacity building in the manufacturing and packaging sectors.

Community engagement is another key pillar of Nampak’s sustainability agenda. The company supports various local development initiatives, including school refurbishment projects, food relief drives, and clean-up campaigns in areas surrounding its production plants. By integrating socio-economic upliftment into its business model, Nampak not only fosters goodwill but also reinforces the social license to operate in diverse and sometimes challenging markets.

These people-first initiatives reflect the company’s broader ESG strategy: sustainability is not just about reducing emissions, it’s about building inclusive, resilient communities that can grow alongside Nampak’s success.

With its extensive African footprint, leaner structure, and a renewed focus on high-margin segments, Nampak is well-positioned for future growth. Its divestiture strategy has not only stabilized its finances but also reoriented its operational focus toward scalable, sustainable solutions. As it continues to invest in innovation, regional capacity, and sustainability, Nampak is poised to retain its leadership position in Africa’s packaging landscape for years to come. SPMEA

BY ALPHONSE OKOTH

Picture this: you’re at the grocery store, grabbing a pack of bottled water or admiring a neatly wrapped tray of fresh strawberries. Ever wonder what keeps those products snug, secure, and looking oh-so-appealing on the shelf? Enter shrink films, those magical plastic wraps that shrink tightly around products when heated, creating a protective, eye-catching package.

These films are the unsung heroes of packaging, blending practicality with pizzazz. From keeping your food fresh to safeguarding pricey electronics, shrink films are everywhere. And the numbers back up: the global shrink films market was worth US$4.7 billion in 2021 and is expected to hit US$8.0 billion by 2031, growing at a steady 5.4% annually.

Another estimate pegs the market at US$18 billion in 2024, soaring to US$29.2 billion by 2032. Let’s dive into where shrink films shine, the cool innovations driving them forward, and the data that shows why they’re a big deal.

The shrink film market is booming, and the data proves it. The global shrink packaging market valued at US$11.61 billion in 2024 is projected to be worth US$18.85 billion by 2032, exhibiting

a CAGR of 6.32% during the forecast period, according to Fortune Business Insights. Meanwhile, the broader shrink packaging market, encompassing films and related formats, was valued at US$12.3 billion in 2024 and could climb to US$26.2 billion by 2034, with a 7.8% annual growth.

Regionally, Asia-Pacific leads with a commanding 35% market share. This growth is fueled by rapid industrialization and expanding consumer markets in countries like China and India. North America and Europe each hold 25%, driven largely by a surge in e-commerce and regulatory shifts pushing brands toward more sustainable packaging solutions.

Sustainability is a pivotal force. In 2023, over 200 companies received eco-certifications for their shrink film offerings. With 65% of global consumers prioritizing eco-friendly packaging, the recyclable shrink film segment is forecasted to grow at 5.65% annually through 2034.

Food and beverage: The big player If you’ve ever grabbed a six-pack of soda or a tray of chicken

from the supermarket, you’ve seen shrink films in action. The food and beverage industry is the heavyweight champion of shrink film use, gobbling up a massive chunk of the market. In 2021, beverages alone accounted for 32.3% of the global shrink film market, according to InsightAce Analytic.

Why? Because shrink films are perfect for keeping food fresh, safe from germs, and looking good. They wrap everything from meat and cheese to frozen pizzas and bakery treats, shielding them from moisture and dust while extending shelf life.

For drinks, shrink films are the go-to for bundling bottles or cans into multipacks. Think about those 24-packs of water you lug home, shrink films keep them together without breaking the bank. The beverage multipack market was valued at US$3.02 billion in and is expected to hit US$4.75 billion by the year 2034 at an 4.8% CAGR during the forecast period, reports InsightAce Analytic.

Plus, high-clarity shrink films let you see the product inside, which is a game-changer for things like fresh produce or fancy bottled drinks. They’re also used to wrap pallets of food for shipping, keeping everything stable during those bumpy truck

rides.

In the world of medicines and medical devices, shrink films are like a trusty bodyguard. They provide tamper-evident seals and sterile protection, which is critical for keeping drugs and equipment safe. In 2023, the pharmaceutical sector made up about 15% of the recyclable shrink film market. These films block moisture and physical damage, ensuring your pills or medical tools stay in top shape from factory to pharmacy.

What’s really cool is how shrink films are getting smarter. Some now come with QR codes or RFID tags, letting companies track products or fight counterfeiting. Imagine scanning a QR code on your medicine bottle to confirm it’s the real deal, that’s the kind of innovation shrink films are bringing to healthcare.

Consumer goods and electronics: Style meets strength

From shiny bottles of shampoo to the latest

smartphones, shrink films make consumer goods and electronics look good while keeping them safe. In cosmetics and household products, these films offer crystal-clear packaging that shows off the product inside, making it pop on store shelves.

For electronics, shrink films protect pricey gadgets from scratches and bumps during shipping. Cross-linked polyolefin films, which are extra tough and clear, are perfect for heavier or high-end items like laptops or luxury skincare products.

Sustainability is also a big deal here. More than 65% of shoppers want eco-friendly packaging, and companies are listening, rolling out recyclable shrink films to meet that demand. It’s a win-win: great protection and a nod to the planet.

If you’ve ordered anything online lately, you know how important it is for packages to arrive in one piece. That’s where shrink films come in. The e-commerce boom has fueled demand

IN NUMBERS

1.67B

US$ MARKET PROJECTION OF RECYCLABLE SHRINK FILM BY 2034

for these films, especially for secondary packaging (think wrapping multiple items together) and tertiary packaging (like pallet wrapping).

They’re lightweight, cheap, and keep products safe from rain, dust, or rough handling. In 2024, the U.S. shrink packaging market held a 25% share of the global market, thanks to the massive growth of online shopping and retail.

Shrink films also help brands stand out in the crowded e-commerce space. Promotional multipacks wrapped in colorful, printed shrink films catch the eye, whether they’re sitting in a warehouse or on your doorstep.

The shrink film industry isn’t just resting on its laurels, it’s buzzing with innovations that make packaging stronger, greener, and smarter. From new materials to high-tech features, here’s what’s shaking things up.

Back in the day, polyvinyl chloride (PVC) was the star of shrink films because it was cheap and easy to use. But PVC has a dark side, it releases toxic chlorine when heated or disposed of, which isn’t great for the environment. Enter polyolefin (POF) and polyethylene (PE), the new kids on the block.

Polyolefin is chlorine-free, super clear, and versatile, making it a favorite for food, cosmetics, and more. Crosslinked polyolefin takes it up a notch with extra strength and puncture resistance, perfect for premium products.

Polyethylene, especially low-density (LDPE) and linear low-density (LLDPE) versions, is stealing the spotlight for its recyclability. It’s strong enough for heavy items like beverage multipacks and plays nice with recycling systems. The polyethylene segment is expected to hit US$10 billion by 2034, thanks to its wide range of uses and eco-friendly edge.

Let’s face it, plastic waste is a problem, and consumers are pushing for change. The shrink film industry is stepping up with sustainable options like biodegradable and compostable films. In 2023, over 200 new biodegradable shrink films hit the market, designed to break down naturally and reduce landfill waste.

Big players like Amcor are leading the charge with recycleready films like AmPrima, which meet strict recycling standards. In June 2024, Dow teamed up with RKW to launch REVOLOOP, a recycled plastic resin for shrink films that’s all about closing the loop on waste.

The recyclable shrink film market is on fire, growing from US$961.42 million in 2024 to a projected US$1.67 billion by 2034, with a 5.65% annual growth rate. Events like Packaging Innovations in February 2024 showcased compostable shrink films, especially for food and beverage packaging, proving that green is the way to go.

Shrink films are getting a high-tech makeover. Imagine a shrink-wrapped product with a QR code you can scan to learn about its ingredients or verify its authenticity. Or an RFID tag that tracks a package from factory to store. These smart features are popping up in pharmaceuticals and high-value goods, making packaging more secure and interactive.

In 2023, shrink films with barrier properties helped extend the shelf life of over 100 million food items by blocking oxygen. Multi-layer films, which combine different plastics for

extra strength and protection, are also gaining traction.

The way shrink films are applied is getting a tech upgrade, too. Robotic automation has boosted productivity by 30% in 1,500 factories worldwide, making packaging lines faster and more efficient. Energy-saving shrink tunnels are cutting power use by 25% for 800 manufacturers, saving money and the planet.

In Germany, two robotics labs are working with shrink film makers to sync packaging with automated warehouses, streamlining the whole process. And get this, augmented reality (AR) is helping 500 factories maintain their equipment remotely, reducing downtime and keeping things running smoothly.

Shrink films aren’t perfect. Recycling infrastructure for plastics

regulations cracking down on single-use plastics are forcing companies to rethink their approach.

But the future looks bright. With bio-based films, smart packaging, and automation on the rise, shrink films are evolving fast. Over 150 mergers in the packaging industry in 2023 show companies are teaming up to innovate. Emerging markets like Brazil and Mexico are also heating up, driven by urban growth and retail expansion.

Shrink films are the rock stars of packaging, keeping products safe, fresh, and stylish across industries like food, pharmaceuticals, consumer goods, electronics, and e-commerce. From eco-friendly biodegradable films to hightech QR codes and robotic packaging lines, the industry is buzzing with innovation.

With a market set to soar to nearly US$30 billion by 2032 and a growing focus on sustainability, shrink films are here to

70,000m2

40,000+

BY STEPHEN KIBE

As global and regional industries shift towards environmentally responsible practices, Packaging Industries Limited (PIL) is positioning itself at the forefront of sustainable packaging innovation. At the conclude AFRIPAK EXPO, Janet Mbithe, Technical Sales Representative at PIL, shares her expert insights on how the company is not only responding to market trends, but actively shaping the future of eco-conscious packaging in East Africa.

According to Janet, PIL’s sustainability journey is rooted in a practical, solution-driven approach. “At PIL, we’re not just talking about sustainability, we’re engineering it into every layer of our packaging innovations,” she says. From materials science to manufacturing practices, PIL’s focus is on reducing environmental impact without compromising functionality or product protection.

At the expo PIL unveiled a range of sustainable packaging innovations tailored to address the needs of East Africa’s growing food sector. One of the most talked-about solutions was the Barrier Nut Vault, an aluminium-free, vacuum-sealed pack explicitly designed for macadamia nuts.

“Traditional nut packaging relies on aluminium, which is resource-intensive and difficult to recycle,” Janet explains.

“Our Barrier Nut Vault uses high-barrier plastic films to achieve the same protective qualities while significantly lowering the pack’s carbon footprint. It also extends shelf life to up to a year, helping reduce food waste.”

This innovation earned industry recognition not just for its environmental credentials but also for its impact on value chains. Exporters of macadamia and other nuts can now adopt packaging that aligns with international sustainability standards, crucial for accessing premium markets in Europe and North America.

Beyond nuts, PIL is developing lighterweight milk pouches, hermetic grain and legume bags, and silage bags that serve the agricultural and dairy sectors. These products are engineered to use less raw material, reduce transport costs, and ensure superior food protection, all while meeting recyclability and reuse criteria.

“Our design philosophy balances three pillars: functionality, affordability, and sustainability,” says Janet. “Whether it’s a bag for animal feed or a pouch for flour, our aim is to make ecoconscious packaging accessible to manufacturers of all sizes.”

Modern packaging is no longer just about containment and branding, it’s also about usability, lifecycle, and waste reduction. Janet points out that many of PIL’s recent developments focus on multi-use and repurposable packaging.

“We’re developing packaging that consumers can reuse directly, like warming food in the same pouch it was purchased in, or resealing dry foods to maintain freshness,” she says. “It’s a subtle but powerful shift. We’re extending the utility of the pack beyond its first use, thereby keeping it in circulation for longer and reducing overall waste.”

Such features also increase consumer engagement with the product and brand, an added value for manufacturers looking to differentiate themselves in competitive markets. “Today’s packaging must not only perform technically but also enhance the consumer’s experience. That’s where smart, sustainable design comes in.”

With the Kenya Extended Producer Responsibility Organization (KEPRO) driving regulatory oversight for packaging waste,

manufacturers must take active steps to align with national waste management goals.

“Sustainability isn’t just an option anymore, it’s a legal and ethical imperative,” Janet emphasizes. “We advise our clients to register with Producer Responsibility Organizations like KEPRO Kenya and choose packaging formats that support recycling and biodegradability. It’s not about ticking a box. It’s about joining a broader movement toward responsible production.”

PIL’s internal processes reflect the same commitment. The company continuously invests in material R&D, efficient production methods, and partnerships with waste recovery networks to close the loop on packaging lifecycles.

As packaging landscape in East Africa that is inclusive, circular, and innovation-driven, Janet believes that companies like PIL have a central role to play, not just as suppliers but as changemakers in the push for a more sustainable future.

“We want to be more than a packaging company,” she says. “We want to be a sustainability partner, helping businesses of all sizes meet their environmental goals, serve their communities, and grow in a way that respects the planet.”

BY STEPHEN KIBE

Statpack Industries is emerging as a leader in East Africa’s drive for smarter, more sustainable packaging. At the heart of this transformation is Adarsh Shah, Team Leader of Product Research and Development at Statpack, who is helping shape the company’s innovation pipeline to meet both environmental and operational demands.

Speaking at the recent AFRIPAK Expo, Adarsh shared insights into how Statpack is embedding sustainability into its packaging technologies, without compromising performance or affordability. “We’re engineering solutions that reduce waste, extend product shelf life, and meet global packaging regulations, especially for exporters targeting high-standard markets.”

At the expo, Statpack showcased a range of packaging products designed with a clear sustainability focus. One standout innovation was the StatWrap Cling Film, now redesigned with a built-in cutter. “It’s a small but

impactful upgrade,” Adarsh explained. “By integrating the cutter, we reduce material waste, improve usability in fastpaced kitchen environments, and support cleaner handling, key for food processors and retailers alike.”

Also on display were barrier-coated and vacuum packaging films that significantly reduce oxygen ingress, extending shelf life for meats, dairy, and ready-to-eat meals. “These solutions are vital in cutting food spoilage, especially in hot and humid climates,” he noted. “Less spoilage means less food waste, which is a win both economically and environmentally.”

Adarsh also highlighted digitally printed laminate pouches, a cost-effective option particularly attractive to small and medium-sized enterprises (SMEs). These pouches eliminate the need for traditional printing plates or cylinders, making customization easier, faster, and more economical. “This is about democratizing access to high-quality, sustainable packaging,” he said. “Even startups can now launch products with packaging that looks professional, performs well, and aligns with eco-conscious values.”

Other key products showcased included shrink sleeve labels, greaseproof poly-coated papers for the bakery and fastfood sectors, and entry-level Form-Fill-Seal (FFS) machines that support production automation. “FFS machines are essential for improving hygiene, reducing human contact, and helping businesses scale without exponentially increasing labour costs,” Adarsh added.

What sets Statpack apart, according to Adarsh, is its holistic integration of sustainability across the value chain. The company offers eco-friendly barrier-coated films and paperbased materials that meet stringent export requirements in the U.S. and Europe, regions where environmental compliance is no longer optional.

“These solutions not only preserve freshness but also satisfy recyclability or compostability standards abroad,” he noted. “They’re designed to help food exporters avoid noncompliance fines and access premium markets.”

Statpack's sustainability focus is underpinned by rigorous quality standards. Certified under ISO and BRC (British Retail Consortium) protocols, the company ensures that every package meets high-performance and safety benchmarks. “From vehicle inspections and secure transport to tamper-evident features, we’ve embedded traceability and accountability into every step,” said Adarsh.

This level of quality assurance is crucial for food manufacturers aiming to build trust in both domestic and international markets. “It’s no longer enough to be green, you must also be reliable,” he emphasized.

Beyond manufacturing, Adarsh believes the industry has a critical role to play in closing the knowledge gap around sustainable packaging. “There’s still a lot of confusion, especially among smaller players, about which materials are food-safe, compliant, or environmentally suitable,” he observed.

That’s why Statpack is doubling down on its role as both a supplier and educator. “We take time to consult with clients, explain regulations, and recommend the right packaging for each product and market. Our mission is to build a more informed ecosystem, where good intentions are backed by the right technical solutions.”

He urges industry stakeholders to champion smarter packaging choices, not just through product offerings but through open dialogue. “Whether it's proper material selection or training on equipment usage, we must work together to build a future where sustainability is second nature, not an afterthought.”

For Adarsh and the Statpack team, the vision of sustainability goes beyond product launches, it’s about creating a circular packaging economy in East Africa. This includes investing in recyclable materials, supporting material recovery partnerships, and exploring biodegradable and compostable alternatives tailored to regional waste management capabilities.

“East Africa has unique challenges, limited infrastructure for recycling, informal economies, and high climate variability,” he noted. “Our solutions must be practical, scalable, and resilient in this context.”

That’s why Statpack is continually refining its technologies to perform in real-world conditions, balancing cost, durability, and environmental impact. “It’s not just about ticking the green box,” Adarsh concluded. “It’s about building systems that are smarter, cleaner, and built to last.” SPMEA

BY STEPHEN KIBE

As Kenya intensifies its efforts to combat plastic pollution and transition toward a circular economy, Extended Producer Responsibility (EPR) has become a defining pillar of environmental policy. EPR regulations place the burden of post-consumer waste management squarely on producers, tasking them with the collection, recycling, and repurposing of materials once their products reach end-of-life.

At the forefront of helping businesses navigate this evolving landscape is PAKPRO, a leading Producer Responsibility Organization (PRO).

During the recent AFRIPAK Expo, Bruce Rook, Membership Assistant at PAKPRO, shared his expert insights into how the organization is not only supporting compliance but also driving a culture of sustainability through practical, scalable solutions.

“PAKPRO’s core role is to turn EPR from a regulatory obligation into a strategic advantage,” says Rook. With its roots going back to 1979 and operations in over 45 countries, PAKPRO brings

global expertise to Kenya’s local waste management challenges. The organization facilitates responsible waste collection and ensures it is channelled to certified recyclers, thereby minimizing illegal dumping, reducing landfill volumes, and closing the loop in packaging lifecycles.

“At its heart, EPR is about accountability, producers must be responsible for what they put into the market,” Rook explains. “PAKPRO offers the systems, partnerships, and monitoring tools to make that responsibility manageable and impactful.”

PAKPRO also acts as a liaison between businesses and regulators, simplifying the often-complex terrain of environmental compliance. For companies struggling to keep up with evolving legislation, PAKPRO provides a turnkey solution: education, logistics, reporting, and verified recycling partnerships all in one ecosystem.

PAKPRO’s track record speaks for itself. Since 2018, the organization has successfully facilitated the recycling of over 58,000 tons of post-consumer packaging waste, equivalent in weight to around 58,000 cars. This figure not only reflects an impressive operational footprint but also demonstrates the potential for voluntary industry collaboration to achieve realworld environmental outcomes.

Rook emphasizes that members of PAKPRO benefit far beyond compliance. “We’re building a community where members gain access to exclusive programs, such as buyback initiatives and partnerships with vetted packaging suppliers and waste handlers,” he says. “It’s not just about ticking the EPR box, it’s about reshaping business models to align with sustainability principles.”

The upcoming buyback programs are especially promising, designed to incentivize participation by making recovery both economically viable and operationally seamless. Members are also given priority access to updates, training resources, and networking opportunities via PAKPRO’s growing digital platforms.

One of the most important aspects of PAKPRO’s mission is its focus on small and medium-sized manufacturers (SMEs). Often resource-constrained and underserved, SMEs face significant barriers to EPR compliance, ranging from lack of information to the cost of integrating new systems.

“PAKPRO levels the playing field,” Rook affirms. “Our services are tailored to be accessible for SMEs, ensuring that smaller players are not left behind in the sustainability transition.”

Membership opens doors to affordable waste management, simplified regulatory navigation, and a network of packaging experts and recyclers. It also enables SMEs to participate in events such as AFRIPAK and other expos, where they can gain insights, forge partnerships, and showcase their own sustainable initiatives.

Importantly, PAKPRO’s easy onboarding process, whether through its website or direct outreach, ensures that businesses can begin their sustainability journey without getting bogged down in red tape.

For Bruce Rook, PAKPRO represents more than just a compliance platform, it is a catalyst for change. “We’re urging businesses to think beyond the legal requirements,” he says. “Joining PAKPRO is a declaration of intent, to do better by the planet, to design for circularity, and to build resilience through sustainability.”

Through upcoming awareness campaigns and its proactive social media presence, PAKPRO is equipping members with the tools and information needed to make environmentally sound decisions. These include early access to waste reduction programs, recycling updates, and training opportunities designed to embed sustainability into day-to-day operations.

Rook’s closing message is clear: “Sustainability is no longer optional. It’s a shared responsibility, and with the right partners, it’s entirely achievable. PAKPRO is here to make that journey possible, practical, and profitable for all.”

BY ALPHONSE OKOTH