Our fragile planet is at catastrophic risk from waste plastic, with numerous quantities ruining our bountiful oceans, endangering marine life, human health and ecosystems. Harmful chemicals such as bisphenol A (BPA) and phthalates in plastic can cause havoc in soil chemistry and landfill groundwater. Abacus Flooring Solutions is a multi-award-winning specialistflooring manufacturer from Coalville, Leicestershire that has come up with a landmark innovation. By using waste plastic (that would otherwise go to landfill) in industrial resin flooring, the East Midlands based company has revolutionised the flooring industry.

The groundbreaking patented innovation is named ‘Abaplas’ and is the brainchild of Managing Director, Nick Megson. It is the first exclusive design in the world of its kind, providing a wholly sustainable, eco-friendly flooring method. Established in 2020, the company designs, manufactures and installs resin flooring for a wide range of industries from industrial, commercial to healthcare. With a dedicated aftercare service, customers benefit from an annual follow-up site visit for cleaning advice and slip testing. Furthermore, the sister company: Abaplas Recycling Limited treats all the plastic recycling for Abacus resin flooring products and initiates the sales of treated plastic for use by other product manufacturers.

We caught up Nick Megson, Managing Director to find out more about this awardwinning company,

“Our products are intrinsically more environmentally friendly than any other flooring product on the market: there is currently no competitor offering a resin flooring that entirely replaces harmful silica sand with 100% recycled waste plastic.” “Resin flooring, along with many other industrial products, has traditionally been manufactured using silica sand, which is a dangerous and potentially carcinogenic substance when inhaled.” “Abaplas instead contains non-harmful recycled waste plastic, which is ground down to a white powder. The process will vastly reduce the volume of waste plastic ending up in landfill or the world’s oceans.”

“The world’s first resin flooring using 100% recycled plastic was installed by Abacus in the enormous VIP Visitor Centre auditorium at JCB’s global headquarters in Staffordshire, UK.” The future looks bright for this flagship company as it sets a new benchmark for sustainable usage of plastic waste in flooring for years to come, “It is expected that Abaplas Recycling Limited will grow exponentially over the next few years as more clients specify Abacus’s 100% recycled waste plastic flooring. Rapid growth is also expected as Nick’s unique process becomes adapted for use in a much broader range of flooring, construction and industrial products,” concludes Nick.

For more information on Abaplas, please see the website below:

T 01530 432790

nick@abacusflooringsolutions.co.uk

www.abacusflooringsolutions.co.uk

Hi-tech fabrics, functionality and fit are the hallmarks of this market-leading working clothes range.

For discerning professional tradesmen and women, trousers that deliver maximum functionality, comfort, protection and mobility are key factors in their brand choices.

That’s why the sustainable, streetsmart, body-mapping features of Snickers Workwear Work Trousers make them the clothes of choice for those who want to work at their best.

https://www.snickersworkwear.com/ list/product-guide/trousers-made-to-fit

The AllroundWork trousers suit any kind of work in any trade. FlexiWork trousers deliver superior freedom of movement. While LiteWork trousers keep you cool, dry and ventilated.

Then there’s RuffWork trousers, reinforced and tough for the roughest

work on site. ProtecWork protective wear for hazardous environments and certified High-Vis trousers when personal visibility on site is a priority. work environments.

Snickers Workwear Trousers also deliver certified protection with the patented KneeGuard® system and CORDURA® reinforcement for greater flexibility, comfort and durability.

All in all, this is what makes them the optimal choice for craftsmen and women who need to get every job done comfortably, efficiently and sustainably on site.

www.snickersworkwear.com

Handheld fibre laser welding technology is new to the UK welding industry, offering excellent welding performance, improving production efficiency and reducing operational costs. Up to 4 times faster than traditional welding methods, it offers high precision and neat welding seams on various materials. The Weld Star – Max Photonics system advanced air-cooling with self-adaptive fans ensures long-term stability and a neat, compact design. It is lightweight and ergonomically designed welding torch offers comfort and manoeuvrability to the user at only 680 grams and guarantees multiple safety precautions for welding operations.

A full colour 7-inch graphical user interface with synergic set up and the possibility to save up to 32 stored jobs offers easy set up and high repeatability to the user. Shooting mode offers controllable and repeatable tack welding and single sided spot welding, whilst pulse mode offers aesthetically pleasing welds similar to that of traditional TIG welding methods.

Quick training times with the laser process gives employers the opportunity to up-skill workers and increase production.

Laser safety is a big factor with this process being a Class 4 appliance. As such, it is imperative that the guidance is followed and this equipment is operated within a suitably approved class 4 enclosure. Wilkinson Star can offer a full package solution in compliance with EN 60825-4.

Machines come with a 2 year warranty and torches a 12 month warranty.

www.wilkinsonstar247.com/ laser-welding

Available through Wilkinson Star’s authorised network of distributors

We are MacClancy and Sons Ltd, a family run business, providing your industry with the best Explosion Protection equipment for the best price.

We offer high-quality Explosion Protection equipment from our wide range of Vent Panels, Flameless Vents and Isolation Valves as well as Sensors, Environmental and Safety Protection.

The products we provide are competitively priced thanks to our exclusive contract to supply the UK with VigilEx® Safety Protection equipment. Everything we supply is fully ATEX, NFPA and EN certified for all types of combustible dust up to 250Kst. Rest assured that our manufacturing partners

STiF are leading the way in safety protection, improving certification testing with European Notified Body INERIS to reflect real world conditions and improve the latest EN Standards.

Detailed information on VigilEx® equipment and accessories can be found attached to this email and certification and technical drawings are available, free of charge, online at Vigilexuk. com.

Oliver Hydcovalves, established in 2021, is dedicated to supporting clients and end users in their pursuit of sustainable and environmentally friendly practices. As part of the renowned Oliver Valve family of companies, we draw upon over 40 years of manufacturing expertise, enjoying a strong global reputation and recognition on many Approved Vendor Lists (AVLs).

Over the past two years, Oliver Hydcovalves has allocated significant resources to extensive research, aiming to understand the unique effects of hydrogen on various materials. With the advantage of an in-house metallurgy department and a state-ofthe-art research and development facility, we have successfully refined and redesigned "conventional" valves, making them well-suited for hydrogen fueling applications.

Hydrogen, being a volatile gas, presents substantial risks, especially to the integrity of materials. Consequently, selecting the appropriate materials is crucial to ensure optimal valve performance. Hydrogen embrittlement, a phenomenon where hydrogen atoms infiltrate the metal lattice, resulting

products through a range of tests to simulate them in service conditions to prove product performance.

At Oliver Hydcovalves, we prioritize safety and exceptional performance in hydrogen applications. Our meticulous material selection process, combined with our innovative sealing technologies, guarantees reliable operation and safeguards against potential risks. We take pride in delivering valve solutions specifically tailored to meet the unique challenges presented by hydrogen applications, and in particular for hydrogen fuel stations.

in brittleness and eventual cracking, poses significant safety hazards and environmental risks, particularly in critical components like valves.

While the visual changes we have made may appear subtle, they were deliberate decisions aimed at maintaining visual familiarity with valves that have been in the field for many years. Our goal is to ensure that our product reputation remains recognisable and, consequently, trusted by our clients.

Oliver Hydcovalves has worked closely with the well-renowned third-party testing body TUV, to type test our Hydcovalves products with 99.9% hydrogen. In fact, Oliver's was the first valve manufacturer to successfully qualify a valve at TUV with hydrogen. Additionally, our collaboration with Dupont has led to the development of a patented sealing technology widely recognized as industry-leading for fugitive emission control.

A common question we receive is, "What is the difference between a 'conventional valve' and a valve suitable for hydrogen?”

The key distinctions between a standard

With our extensive experience and expertise in the hydrogen industry, we are proud to have a robust reference list of successful hydrogen projects that we’ve supported such as, hydrogen transport and hydrogen gas pipeline. These projects serve as tangible evidence of our commitment to delivering reliable valve solutions and our ability to meet the unique requirements of diverse hydrogen applications.

Our valve products have been meticulously designed with hydrogen and carbon capture technology to cater to a wide range of applications. Whether you are involved in hydrogen transportation and refueling, purification, storage, blending, fuel cells and electrolysers, or heating and cooling systems, we have the right valve solution to meet your specific needs.

If you have any further inquiries or require additional information, please do not hesitate to reach out to us. We are committed to providing you with the highest level of expertise and assistance.

www.valves.co.uk

In this issue of Industry Update, we are celebrating Delta Logic Automatisierungstechnik GmbH as our automation technology Company of the Month.

Delta Logic is a leading software and hardware specialist in automation technology to Siemens controller customers from a wide range of industries, such as: automotive, food, mechanical and plant engineering, energy, chemicals and metal processing.

Based in Schwäbisch Gmünd, in the South of Germany, the company recently celebrated its thirtieth anniversary. The company focuses on software development for PC-PLC communication, namely as a technology leader in the Siemens environment. This incorporates communication with PLCs such as S5 and S7, as well as LOGO! and machine tool controllers such as SINUMERIK and SINUMERIK One.

Furthermore, the German powerhouse supports symbolic communication as well as online and offline access to TIA Portal projects and communication adapters for S5 and S7, supplementing the portfolio with remote maintenance (VPN router, VPN portal and accessories), as well as other hardware, such as a Profibus tester.

We spoke to Barbara Hönle: Marketing Director for a further insight into this market-leading company,

“We are a technology leader, as demonstrated through our highlighted product: our communication library ACCON-AGLink. This offers a wide range of possibilities, with an unbeatable scope: it supports a wide range of operating systems, programming languages and communication channels.”

ACCON-AGLink offers functionality for data access, diagnostics and time synchronisation and is compatible with a whole host of controllers, operating systems and programming languages. ACCONAGLink is a super-charged communication library for streamlined PC-PLC data exchange, for S7-200, S7-1200, S7-1500, S7-300, S7-400, S7-400H, LOGO! 0BA7 and 0BA8, S5 PLCs and SINUMERIK controllers. The library supports all widely used programming languages via DLL, or shared object and Java and is available for Windows, Windows CE, Linux and Linux

Embedded. It also offers support for other operating systems like Solaris, 0S9000 and VxWorks on request.

ACCON-AGLink was precision-designed for mastering protocols, through its high useability and functionality, across differing controllers, communication pathways and operating systems, with varying programming languages.

“In addition, with our ACCON-OPC-Server UA we offer an OPC UA server, where Siemens PLCs and machine tool controllers can be accessed extremely easily. This makes it possible to access a wide variety of controllers and controller generations within an OPC project without changing the Siemens components or projects with an OPC UA server that is certified by the OPC Foundation.”

"Our popular S7 programming adapter: the ACCON-

NetLink-PRO compact is a great addition to use our hightech software in combination with older S7 controllers. We also offer other adapters for S7 and S5 PLCs which make it easy to access those PLCs directly from a PC or to add them to the local network," adds Barbara.

Another great tool is the datalogger ACOON-EasyLog: a fast and unbeatable modular datalogger for PLC data, providing time-controlled or event-driven data functionality, from differing input and output sources. ACOON-EasyLog can access the data from Siemens controllers with or without TIA. Users can monitor and save PLC process data as CSV file or alternatively in a SQL database.

Looking to the future, Delta Logic is poised to maintain its market-leading position,

“We intend to keep the ball rolling and delivering great products and service for our customers, further expanding technology leadership. We have redesigned our website, in lieu of our 30th anniversary celebrations, to streamline customers’ digital experiences,” concludes Barbara.

For further information, see the website below: www.deltalogic.de

Bradshaw, the UK’s leading manufacturer of industrial electric vehicles, found themselves at the forefront of the recent RTX Expo at Stoneleigh’s NAEC where their Club Car Tempos and Carryalls helped to ferry exhibitors and visitors throughout the show.

The event, which took place between 28th and 30th June, successfully championed the road haulage sector over the course of three days by bringing together the latest trucks, trailers, tankers and everything in between into one far-reaching show.

Along with the fleet of all-electric three Tempos and two Carryalls, Bradshaw was also proudly exhibiting its G2 and G4 Goupil utility vehicles, which enable businesses and organisations to make their last-mile distribution and overall operational needs more sustainable and environmentally friendly.

Priding themselves on their bespoke offering, the Goupil vehicles can be equipped with lead acid or lithium batteries and can each be tailored directly to the customer’s requirements – which is furthermore

complemented through their newly formed relationship with vehicle conversion and racking specialists, Bott – who fitted out a G2 box van with their market leading racking systems.

An all-electric compact road utility vehicle, the G2 range offers an ideal solution for customers who have multiple sites which are connected by public highway. Available with pick-up, cage and van bodies, the G2 has been expertly designed to transport payloads of up to 600kg, while retaining small and compact size for convenience of use.

With an operational range of between 27 to 62 miles the G2 range has a payload of between 415 to 533kg and 78 to 596kg depending on the chosen model.

This year Bradshaw also exhibited a G4 at the bustling show, this time with an innovative offering; a combi pickup with a 200 litre pressure washer fitted with a demountable hill tip salt spreader provided by Peacocks Salt – ultimately showcasing the versatility of the vehicle and its many applications and uses. There was also a G4 cage tipper exhibited on the stand

which comes with all the same features as the pick-up model but with the added feature of a hydraulic tipping body that can be controlled from outside the vehicle.

With an operational range of 68 miles and a maximum speed of 31mph, the G4 range can be equipped with an array of body types to cater to the customer’s specific requirements and feature a safe and secure cabin and both left and right hand drive options. The G4 road vehicles on offer also include pick-ups, vans and waste collectors, all designed to transport people and equipment for a variety of different applications.

Ramsy Labassi, Marketing Manager at Bradshaw Electric Vehicles, commented, “It was fantastic to see our Club Car Tempos and Carryalls play a role in ensuring that the RTX Expo ran smoothly by ensuring visitors and attendees alike got from A to B seamlessly.

“We were also delighted to exhibit once again for the second year running and showcase our versatile Goupil vehicles – the G2 which featured our bespoke fitouts provided by Bott as well as the G4 tipper and a combi pickup with a 200 litre pressure washer fitted with a demountable hill tip salt spreader provided by Peacocks Salt.

“With environmental sustainability at the top of the industry’s agenda, especially with Net Zero etching ever closer, we were delighted to be on hand to discuss the benefits and versatility of our Goupil range to businesses and organisations who were actively looking to make the all-important switch to electric.”

enquiries@bradshawev.com

www.bradshawev.com

Bradshaw will be exhibiting their range of versatile electric vehicles at the show, which is due to take place at Birmingham’s NEC between 13th-14th September.

RWM will once again provide participants and visitors alike with a platform to engage in critical discussions, as well as offering an exciting opportunity to explore ground-breaking green technologies, which will be showcased throughout the two-day event.

The show will take centre stage as a part of the Environmental Services & Solutions Expo – which acts as one of Europe’s most prominent events dedicated to the environmental services sector.

Bradshaw’s range of Goupil Electric Utility Vehicles will be on display at the event, along with their T700/T400 and PT-400 tow tractors as well as their road legal bin trailer.

The Goupil vehicles can be equipped with lead acid or lithium batteries and can each be tailored directly to the customer’s requirements – which is furthermore complemented through their newly formed relationship with vehicle conversion and racking specialists, Bott – who fitted out a G2 box van vehicle with their market leading racking systems.

The G2 box van vehicle will be centre stage on the Bradshaw stand where visitors will learn more about how it offers an ideal solution for customers who have multiple sites which are connected by public highway. Available with pick-up, cage and van bodies, the all-electric compact road utility vehicle has been expertly designed to transport payloads of up to 600kg, while retaining a small and compact size for convenience of use.

With an operational range of between 27 to 62 miles the G2 vehicle range has a payload of between 415 to 533kg and 78

to 596kg depending on the chosen model.

This year, Bradshaw will also showcase a Goupil G4 at the show with an innovative offering; a combi pickup with a 200 litre presser washer and demountable hill tip salt spreader provided by Peacocks Salt – further showcasing the versatility of the Goupil range and its many applications and uses. There will also be a G4 cage tipper exhibited on the stand, which comes with all the same features as the pick-up model but with the added feature of a hydraulic tipping body that can be controlled from outside the vehicle.

The G4 road vehicles on offer include pick-ups, vans and waste collectors, all designed to transport people and equipment for a variety of different applications. With an operational range of 68 miles and maximum speed of 31mph, the G4s can be equipped with an array of body types to cater to the customer’s specific requirements, and feature a safe and secure cabin as well as both left and right hand drive options.

With ten different variations to choose from, the G4’s greater payload offers an ideal electric vehicle for many stop-start and last mile applications and is ideally suited to operate within low-emission zones, while still delivering optimal performance and low vehicle operating costs.

Bradshaw’s T700, which is expertly designed for exceptional manoeuvrability, will also be on show at the event. The three-wheel tow tractor provides users with a seventonne tow capacity as well as a 200kg payload while still seamlessly delivering consistent performance for daily operators over medium distances.

Launching at RWM is the T400 four-tonne tow tractor. With AC drive, hydraulic steering and four wheels the T400 delivers stability and manoeuvrability for daily operations over short to medium distances. Available with or without cab the T400 is ideal for all waste collection – both indoors and outdoors.

Also on Bradshaw’s stand at RWM will be the electric vehicle manufacturer’s popular PT400, which offers a 500kg payload and can maintain complete control up and down slopes eliminating any need for manual handling, keeping operators safe, and maximising productivity. The PT400 is also designed to effortlessly tow loads of up to 4,000kg.

The company’s tow tractors and trailers can help play a pivotal role in waste management operations and refuse collection, especially when towing 1100-litre road legal wheelie bins – which attendees will also be able to see firsthand on Bradshaw’s stand.

Ramsy Labassi, Marketing Manager at Bradshaw Electric Vehicles commented, “We are very excited to be exhibiting at the upcoming RWM EXPO next month, where we will be proudly showcasing our versatile G2 and G4 Goupil vehicles, range of tow tractors as well as our bin trailer.”

“With many organisations, businesses and local authorities placing greater emphasis on environmental sustainability, electric utility vehicles such as those being showcased at the event offer operators with the prospect of not only vastly improving their environmental footprint, but also enhancing their operational performance and lowering their vehicle operating costs as well.”

“As with all of our vehicles, each can be tailored to the customer’s individual requirements relative to their usage.”

“We are looking forward to showcasing our diverse range of vehicles on our stand as well as demonstrating Bradshaw’s value-added and bespoke offering to visitors at RWM – especially in line with the show’s aim of showcasing how businesses, such as Bradshaw, are driving positive environmental change through sustainable resource management.”

www.bradshawev.com

With over 15 years of experience in flexo printing, BEMA BV has built a reputation for delivering exceptional packaging solutions. Early on, the company recognized the superior quality and brightness of Resino’s printing ink, which met their stringent standards. This partnership laid the foundation for an efficient and effective production process. As the volume of orders grew over the years, BEMA BV found that Resino's fast delivery and high-quality inks not only allowed them to meet their customers' needs but also led them to an environmentally friendly, cost-efficient printing process.

The journey towards LED Curing Systems

BEMA BV was not content with their achievements and sought continuous improvements in their production efficiency and product quality. The printing department, operating 24/7, played a critical role in the production of printed casings. Through careful monitoring, they identified a bottleneck in their UV-curing systems, which limited their production capacity. To address this issue, BEMA BV made the decision to invest in a new curing system.

At the time of this decision, the company faced additional challenges, including the impact of the COVID-19 pandemic and the ongoing Ukrainian war. These factors led to increased energy prices, making it essential for BEMA BV to explore alternative options for reducing their energy consumption and overall production costs. In their pursuit of a more sustainable solution, they became aware of Resino’s ongoing development of an LED curing system paired with LED inks for printing on sausage casings and food packaging.

Recognizing the potential benefits of this innovative system, BEMA BV and Resino collaborated on a series of tests in BEMA BV's production facility. The results were promising, and the LED system with LED inks proved to be just the right solution for their needs. This breakthrough not only significantly reduced their energy consumption but also enhanced production speeds. Furthermore, the adoption of the LED curing system aligned perfectly with BEMA BV's commitment to environmental sustainability.

Tom De Booij, Change Manager at BEMA BV describes the successful outcomes: “Due to the curing of the LED inks with LED lamps our energy consumption has decreased by over 40% on this machine, our production speeds have doubled, and the quality and colors of our prints have significantly improved due to better ink curing”.

BEMA BV is currently running with 1 LED system in their printing facility and has been working with LED inks for over 3 months. For that reason, BEMA BV recently made the decision to implement the LED system on their other printing machines as well, enabling them to work exclusively with LED inks and

further enhance their production efficiency.

“One of our long-term goals is that our production facility is production for 100% on self-generated energy. By reducing the energy consumption of our printing machine with 40%, this contributes a lot!”

Tom de Booij,Change Manager at BEMA BV

For Bema BV’s customers, a consistent product quality and food safety were the most important things, assuring that their products were food-safe and had no negative side effects in their production processes. The LED system underwent rigorous internal testing with LED inks before production runs for customers and clients. New migration tests were conducted to ensure that

environmentally friendly manner which frames Resino’s objective.

“Our aim is to help more printers to switch to UV LED – thereby heading towards a more sustainable environment and a healthier work environment”

KristianKarlsen, R&D Director at Resino Inks.

For more information, see below. www.resino.dk

The new Rebo SMS R1 is a revolution in industrial label printing technology, with the latest advanced touchscreen technology, offering precision-printing at 300DPI. This in-house sign and label production technology is ideally suited across a range of industries from engineering, HVAC, alternative energy markets, plant processing, facilities management, manufacturing, R&D, scientific/analytical processing and many more applications.

It has been expertly designed for the following bespoke applications:

t LO/TO labelling and tags

t maintenance labelling

t Health and Safety

t cable and wire marking

t pipe identification

t tank and valve identification

t part of product labelling

t shutdown/Turnaround labelling

t prototype labelling

t plant and equipment labelling

The Dutch company Rebo B.V. is at the forefront of industrial printing ergonomics and this latest addition to the family: Rebo SMS R1 guides users through the operations step-by-step for flawless sign and label production, every time. The slide-in cassette and automatic tape load functionality, makes changing materials a walk in the park!

The new innovation is capable of fast in-house product labelling, using a wide range of 14 sharp colours and amazingly, in any shape you desire. As a fully-functional desktop product and with excellent USB/Network connectivity, you can say goodbye to outdated, cumbersome machinery. It is compatible with almost all everyday software, including design software like Adobe/CAD or Rebo recommended label software.

With fast, accurate functionality, and a small footprint the SMS R1 will slot right into any work environment effortlessly.

Label stock holding is now obsolete- introducing the SMS R1, stocks of multiple size labels are no longer required and as it uses one width of material, all cutting to dimensions are seamlessly carried out. This compact, next-generational machinery is faster

– on-demand – and lower cost than external label printing companies, without any of the inconvenient proofing delays!

The capabilities of the SMS R1 are endless: powered by the latest thermal transfer printing technology, the SMS R1 has a full production speed of 100mm/s. The meticulous, accurate printing process produces unmatched print and cut lengths and the touchscreen makes this the most user-friendly print & cut system yet!

Ultra versatile print technology

The SMS R1 offers flexibility across a spectrum of printing needs, with its in-built durability. These include the following materials:

t glow-in-the-dark

t reflective

t hologram

t five and ten-year outdoor vinyl

t metallised polyester

t long-life polyester

t hi-visibility

Across a broad range of applications, the SMS R1 can bring sign and label production to life, with cutting-edge technology.

Bespoke, specialist printing every time

The SMS R1 is the master of unique, customised ‘one-offs’ and built for specialist, low volume production runs. Designed to take the headache out of industry-standard, professional-looking prototype label sets, this is the perfect addition to in-house industrial printing technology. Rebo offer unparalleled pictogram library images (over 5,000), fully compliant with ISO/NEN and all certified bodies.

Next-generational level of productivity

Designed to seamlessly deliver small labels in long runs of over ten metres, mixed label sizes and styles, accurately cut into batches- the fully-equipped SMS R1 is ready to take your printing to the next level. The maximum length of any print job is now an astonishing 12 metres, making long or large productions effortless and second-nature.

Time to go in-house: forget external printing companies

If you’ve always thought that in-house sign and

label production was a luxury beyond reach, the SMS R1 is a game-changer. From MRO, manufacturing, to process industry, more and more companies are taking the leap and enjoying the benefits of the SMS R1. This investment provides huge returns on flexibility and customisation, with just-intime labelling always keeping material stock to a minimum, giving peace of mind day in, day out. That’s not all- due to the additional ribbon saving feature, there is no ribbon loss during printing and can save companies up to 40% on current supply costs. Furthermore, the tape rolls are longer, allowing you to produce more for less and with an extra laminate function, extra label protection can easily be added.

The age of sustainability and H&S: circular economy to REACH

With the onus on the UK Government's 2050 netzero target and a huge push towards recycling on large, industrial scales, the SMS R1 comes with fully recyclable material and no nasties: no toxic solvents, plasticisers and is fully REACH- compliant. The Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) European regulation was set up to protect human health and the wider environment from the unlawful usage of chemicals and pertains to all chemical substances manufactured, imported and placed within the European Community. For UK companies looking to contribute to the circular economy and simultaneously meet European-wide H&S guidelines, then the SMS R1 is the perfect investment for your company. The complete printing process occurs internally within the printer, negating all concerns around dust, dirt or grease, making this a H&S dream all round.

With an ever-increasing network, Rebo now has well-established distribution across the UK, Europe, Asia and the Middle-East. The expert Rebo-team are happy to offer on-site demonstrations of the SMS R1 to all interested parties.

Find out more about how the SMS R1 can add value to your manufacturing today through cost savings and greater flexibility.

T +31 35 601 69 41

clinton@rebo.nl

www.rebo.nl/en/sms-r1-multicolour-printer/

Introducing the new SMS R1 -

desktop ‘colour and cut’ sign and labelling system

Free from shareholders and owners, EEMUA is the industrial engineering community’s not-for-profit association that invests all its revenue into sharing practical guidance resources, events, training, and more ~ all developed ‘for industry, by industry’ and proven by engineers in everyday use over more than 70 years for efficient and safe industrial engineering.

Offering blended, live online, classroom, e-learning, and in-house options, with multiple language choices throughout each year and certification up to 5 years, EEMUA’s courses cover: Mechanical Integrity; Storage Tanks; Electrical, Instrumentation, Cyber Security, and Control; Subsea Engineering; and more.

As well as training, EEMUA incorporates the experts’ guidance in publications, checklists and industry events.

Open to all, EEMUA’s next events include:

EEMUA Pressure Systems Seminar – Live Online – 7 September 2023 – 12:00 - 15:45 UK time – covering: Inspection and Monitoring of Pressure Equipment; Vibration Risk on Process Piping – Risk Identification and integrity management; How Risk Based Inspection (RBI) can go wrong; Low Cycle Fatigue Analysis of a Knock-Out Drum Case Study; Integrity Management of High-Pressure Systems; and more.

EEMUA Inspection Seminar - Non-Conventional Techniques – 28 September 2023 –09:00 – 16:00 UK time – at The Aberdeen Altens Hotel, UK – covering: Monitoring of vessels and pipelines using guided waves; Non-electrical inspection in hazardous areas; Remote inspection; Inspecting with AE – ammonia storage tanks to hydrogen bullets; Rapid detection and localisation of active defects; Digital transformation and optimization; Eddy current arrays and digital image correlation; Laser scanning for innovative analysis; Replication metallography; professional networking and more.

EEMUA Storage Tanks Seminar – 30 November 2023 – Rotterdam, NL – 09:00-16:15

Rotterdam, NL time – covering: Regulatory View; Current research projects relating to tank storage; Gas Storage; EEMUA Publications “Speed Dating” Part 1; EEMUA Publications “Panel Session” Part 2; Mothballing of Storage Tanks; Guidance for statistical analysis for tank floor inspection (New EEMUA Publication); professional networking and more.

Find more information on EEMUA Events and other resources at www.eemua.org, or ‘phone +44 (0) 20 7488 0801, or ask@eemua.org to make EEMUA’s many resources work best for you and your team.

In this issue of industry update, we are pleased to announce Incremental Engineering Ltd as our Industrial 3D Printing Company of the Month.

Having years of prior experience in designing and manufacturing industrial and laboratory equipment, Incremental is well respected by its customers and takes great pride in guiding them in the effective implementation of additive manufacturing into their supply chain.

Incremental Engineering Ltd has the capabilities to make robust Nylon parts for industry, acting as a gateway provider for OEMs into additive manufacturing.

Jerry Sutton established the business in 2018. He explained further the most common applications of Incrementals services.

“Our services are generally used to bridge a gap; a gap which may take various forms including the following:

Production: this is ongoing low to mid volume production or bridge production to Injection moulding. The tipping point between print and injection moulding is variable and sometimes quite complex. The obvious costs are quite easy to compare, the cost of tooling with cheaper parts compared to slightly higher printed part costs. The less obvious measure is related to stock holding and availability. Incremental tend to print the number of parts that customers require within a few days, not the number of parts to make an IM production run viable. This

reduces our customer’s stock holding costs to near zero.

Assembly Reduction: increased complexity of printed parts over traditionally machined or moulded parts can reduce the amount and cost of assembly.

Fast supply: turnaround times can be as low as 24 hours, even for complex parts; and Prototype Evaluation.”

Working across a broad range of sectors, the company specialises in Contract Manufacturing that includes any of the following applications: scientific instruments, automotive parts, aerospace, consumer products, and general industrial parts.

“One of the many benefits of our service is that Incremental forms lasting relationships with our clients and their models. As consistency is king for production, working with the same bureau brings real advantages rather than working with random online providers. We can nest builds of parts for customers and print exactly the same build for them on exactly the same printer each time they need a set of parts. When working with online bureaus the parts will be nested in the most economical way with all the other jobs, rather than in the best way for the parts. Whilst our approach may not make for the cheapest parts available, it does

in the long run make economic sense as there are less / no rejections and a consistency in production” added Jerry.

Incremental is one of few bureaus in the UK to run Vapour polishing of parts and this allows a near injection moulding finish to be achieved. Furthermore, Incremental is also the only bureau in the UK to offer full colour production parts too.

“We host the only HP MJF 580 colour printer available to industry. This printer creates fully coloured robust parts that can be used, not just looked at. Combined with Vapour polishing the results are stunning. If you want a part made with a wood grain, marble, technicolour swirls, or if you just want text embedded to aid assembly, it can be achieved!” said Jerry.

The future looks bright for Incremental as it continues its growth trajectory in a controlled and positive manner. Using a measured approach to growth by only taking on a certain number of production customers that appreciate the quality of product that can be achieved, Jerry and his team are on track for a very successful future.

For more information, see below.

T 01256 533838

www.incrementalengineering.com

DCON Safety Consultants Limited offers leading health and safety consultancy and construction statute advice services. The company prioritises and specialises in the highest levels of informed and intelligent advice, senior project resource allocation and compliance assurance. Informed by industry expertise, DCON Safety Consultants Limited knows that every project has potential risks, no matter what its potential benefits, so its team of highly experienced construction professionals helps to ensure clients’ statutory conformity.

Upon gaining understanding of the specific needs, goals and desires of each client and their project, DCON Safety Consultants Limited is dedicated to implementing a design and construction management plan that will meet or exceed these requirements. And, DCON Safety Consultants Limited ensures that there is honesty, integrity, trust and professionalism underpinning every project. Moreover, the company’s services are centred on three delivery principles:

t Maximising Quality: The company implements proven health, safety and wellbeing strategies to help clients achieve high quality and cost-effective work commensurate with the design of their projects.

t Minimising Risk: The company effectively manages design and delivery risk on projects to match each client’s desired risk level profile.

t Managing Compliance: The company relies on its extensive background working on a wide variety of projects to assist clients in developing, monitoring and maintaining compliance performance.

This excellent service would not be possible without the leadership of Diarmuid Condon, a construction industry leader who brings unique perspectives to encourage, support and mentor the abilities of his colleagues. As a construction professional with a surveying background and experience spanning two decades, Diarmuid is emblematic

of DCON Safety Consultants Limited’s commitment to providing outstanding services to clients. Diarmuid has contributed his invaluable expertise to over 400 projects over 20 years, with a client list including public sector departments, corporate owners, real estate developers, main contractors, design professionals and infrastructural bodies. With this incredible portfolio, Diarmuid is helping DCON Safety Consultants Limited to become a leader in health and safety consultancy across the construction industry.

Key to DCON Safety Consultants Limited’s services is working as a Project Supervisor for the Design Process and CDM Advisor in various sectors across the Irish construction market. No project is too simple or too complex for the company’s construction safety consultants, all of whom are construction professionals with an average of 20 years’ experience in the built environment. The ability to maximise this knowledge and skillset means DCON Safety Consultants Limited can generate distinctive and innovative ideas from traditional PSDP service inputs and outputs.

Additionally, DCON Safety Consultants Limited offers planning compliance assurance services. The ability to strategically support a positive planning decision is exclusive to the company. Its Draft Construction Management Plans (DCMP) inform the overall planning, coordination and control of a project from the beginning of construction to completion. The DCMP also safeguards the obligation placed upon a client to produce a safe, functional and financially viable project.

DCON Safety Consultants Limited also provides its main contractor clients with intelligent, practical, and reasonable physical site safety advice to support compliance and good practice adherence. Behavioural safety outcomes inform how the company approaches each solution with the contractor and their supply chain, identifying opportunities for improvement.

To complement this, DCON Safety Consultants Limited can also help with clients’ health and safety strategy. Its holistic and integrated approach can help unlock substantial benefits for clients by providing a structured, objective and SMART framework for full optimisation through the creation of an environment that embraces health, safety and wellbeing.

This means DCON Safety Consultants Limited helps clients to improve their health, safety and environmental performance; enhance staff satisfaction thanks to improved performance; improve risk management and corporate governance with a clear audit trail; gain confidence from long-term planning, better sustainability and performance; and improve overall corporate reputation, including greater staff satisfaction and a more efficient procurement and supply chain.

Finally, DCON Safety Consultants Limited can offer a safety expert witness service, which is headed by Diarmuid himself. He has extensively supported safetyrelated matters, and is a certified and competent safety professional who will work with clients to identify exactly what kind of safety expert is needed. Then, he will use an extensive network of contacts to recruit the right person to protect clients’ interests.

DCON Safety Consultants Limited’s fantastic service offering and proven track record of offering leading health and safety consultancy services makes the company a worthy winner of our Commitment to Excellence award. Such achievements are proof that DCON Safety Consultants Limited is well-placed to help ensure your safety, health and wellbeing and make your project possible.

If you are interested in finding out more information on DCON Safety Consultants Limited’s full range of excellent services, head to the website or get in touch directly using the contact details below.

T +353 (0)1 611 1556 diarmuid.condon@dconsafety.com www.dconsafety.com

We prioritise and specialise in the highest levels of informed & intelligent advice, senior project resource allocation and compliance assurance. We know that every project with potential benefits also has potential risks with the art of planning centring on the co-ordination of these two zones of uncertainty. Our team of highly experienced construction professionals consistently ensures each client’s best interest and statutory conformity.

Wuppertal, 27 July 2023.

Schmersal is launching two new versions of its Safety Fieldbox. This means that the box can not only be integrated into systems with PROFINET/PROFIsafe as before, but is now also be available for the EtherNet/IP with CIP Safety and EtherCAT with FSoE bus systems.

The benefit: the designer can now plan the safety functions of a machine in a project regardless of the fieldbus system that is used, as the three versions together cover the most commonly used control systems worldwide.

The Safety Fieldbox from Schmersal enables flexible safety solutions, fail-safe and fast installation and maximum process transparency. It also enables easy connection of up to eight safety switchgear devices with plug and play. Universal device interfaces for eight-pin M12 connectors allow a wide range of different safety switchgear devices to be connected, including electronic and electromechanical solenoid interlocks, sensors, control panels, light curtains and switches.

Unique features of the Safety Fieldbox from Schmersal include the need for just a single M12 slot for solenoid interlocks and safety light curtains and the connection of control panels with EMERGENCY STOP function and up to three non-safe command and signalling devices.

Connecting safety devices via the Safety Fieldbox also helps to save costs, as up to eight devices can be connected to a single Fieldbox, which is much more cost-effective than equipping each individual device with a bus interface.

An integrated digital input on each device slot allows the diagnostic signals of all connected safety devices to be evaluated. This means that safety-related and operational signals, such as those required for diagnostic purposes, can be collected and transmitted. The user can use this information to detect irregularities, e.g. a safety guard that has been moved, and enable prompt intervention if service is deemed necessary. This helps to improve

system availability and minimise the risk of downtime. Users can also benefit from greatly simplified, and therefore more cost-effective, wiring of safety devices.

www.schmersal.co.uk

As surgical instrument manufacturers pursue greater throughput while facing increased labor costs, automating the medical instrument manufacturing process has become a necessity. However, integrating automation into the gundrilling process for drilling deep holes in extremely precise surgical instruments in lights-out operation is a major engineering challenge requiring more than simply pairing a robot with a deep-hole drilling machine.

The right machine, tools and process must all come together to create small holes with extreme precision in difficult-to-machine materials such as titanium and surgical stainless steel. More importantly, the entire system must flow from a unified concept where the whole is greater than the sum of its parts.

To meet these challenges, UNISIG developed its UNE6-2i-750-CR dual independent spindle gundrilling machine. The UNE6-2i is capable of gundrilling hole diameters ranging from 0.8 – 6 mm in part lengths measuring up to 30 inches with depth-to-diameter ratios from 20:1 to more than 100:1. The machine has a maximum combined drilling speed of 28,000 rpm and a 3,000 psi (207) bar programmable flow-based coolant system with dedicated pumps for each spindle to ensure precise coolant pressure control.

Automating hundreds of cycles of precision manufacturing, however, is not possible unless the overall operation is considered from the outset. Surgical instrument manufacturing is a sequential process: parts must be loaded into the machine in a particular way for specific operations that happen in a specific order.

Workpiece length, shape and configuration determine where it is gripped by the robot when loaded into a machine, moved from spindle to spindle for drilling, residual cutting fluid removed, and returned to the pallet. Where a part is gripped impacts where it is clamped for drilling to ensure accuracy. Every variable along the process chain must be considered and accounted for, and the calculus is detailed and complicated.

Then there are unique customer needs and requirements. The equipment and process must accommodate a variety of part families and hundreds of parts to increase runtime and efficiency. Operators must be able to change over part types and programming without calling in an automation specialist, and the entire process must be controlled from a central interface. Add to the mix that everything must be packaged in as small a footprint as possible, and the scope of

the engineering challenge comes into focus.

UNISIG’s approach to solving these problems, however, results in targeted automation that enhances the existing benefits of gundrilling, ensuring a solid foundation for reliable process-wide automation.

At its core, the automated UNE6-2i is a purpose-built machine with automation embedded in its design, not added as an afterthought. Flexibility and adaptability are maximized by a harmonious, interdependent mechanical, software and operational planning scheme.

To meet size constraints, a 6-axis robot was embedded in the machine with a pallet system on the backside of the machine, allowing easy operator access from the front to setup the machine without compromising ergonomics. The configuration enables quick setup changes between prototype and proving operations and full production runs.

The robot automatically repositions the workpiece from the front of the first spindle into the rear of the second spindle without operator input. The process of drilling a part from both ends in a single-piece flow is unique to UNISIG. Workpieces with enlarged features on one side are loaded from the rear of the collet, solving a common problem in gundrilling medical surgical instruments with full automation.

Control of the UNE6-2i and a computer are consolidated into the Human Machine Interface (HMI), a menu-driven touch screen system for easy, intuitive operation. Training and operator engagement with the system is significantly reduced due to user-friendly UNISIG controller menus and prompts.

UNISIG’s comprehensive and integrated approach to automating medical part manufacturing is a vison that sets it apart in the industry. It’s more than drilling the impossible hole. It’s a commitment to understanding and to the research that drives continuous improvement and innovation for automated part production at its full potential.

Further information on all machines and the complete UNISIG machine program is available at: www.unisig.com or follow the company on LinkedIn and Twitter (@UNISIG). You will also meet us at the EMO 2023 show in Hannover, Germany, from 18.–23. September.

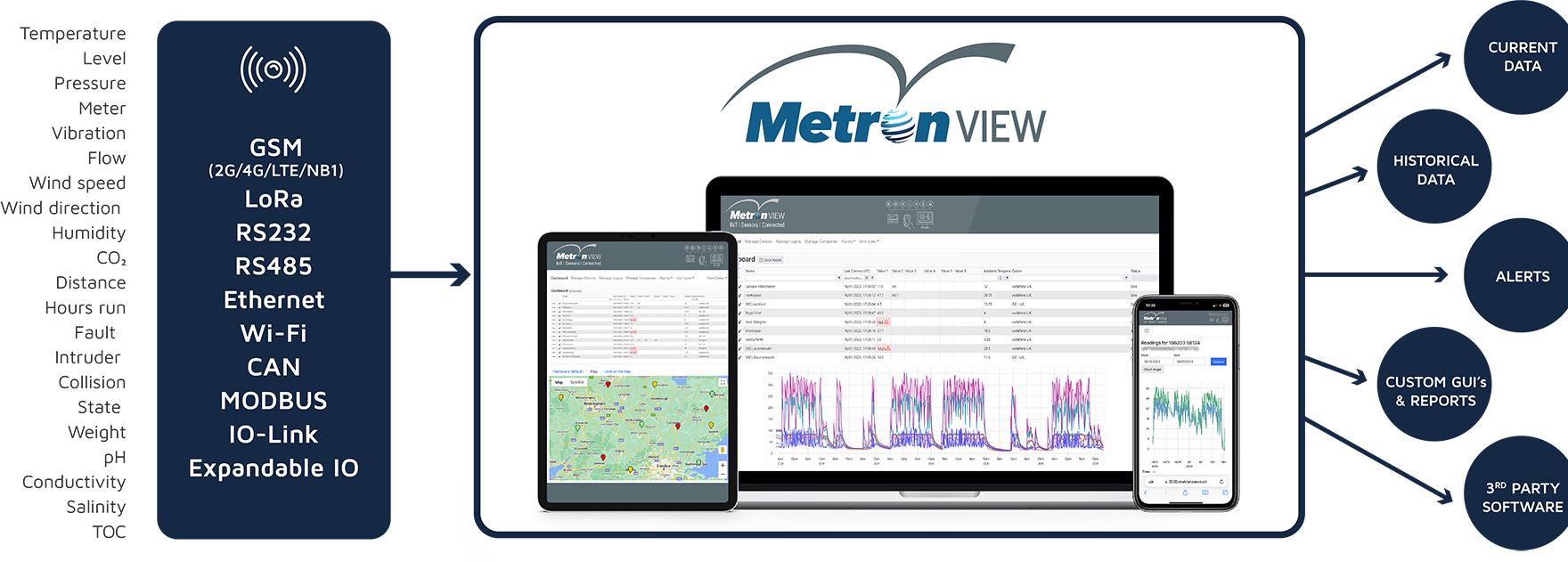

Industry Update is delighted to announce PowTechnology as the winners of our Company of The Year in the Industry 4.0 Industry Sector! Congratulations!

PowTechnology really stood out to our board of directors and editors as a highly innovative company, leading the way in a cutting-edge industrial sector.

Not only does PowTechnology boast over 30 years’ experience in sensing and communications, but they have built on that heritage, embracing new technologies, developing them and incorporating them into their versatile offering.

A glance at their case studies page clearly demonstrates that their robust, innovative IIoT solutions helps customers

lower costs, prevent breakdown, maximise resource, comply with legislation, introduce new revenue streams and differentiate their service.

Industry Update took the opportunity to speak to PowTechnology CEO, Dave Oakes, who’s career in sensing, instrumentation and communications spans over 30 years.

“Firstly, I am extremely proud, to accept this award, on behalf of the whole PowTechnology team… and it really is a great team!

This award is especially meaningful, as this is our first year operating as PowTechnology! The name change was the icing on the cake, consolidating an exciting period of growth, restructure, investment and diversification.

PowTechnology’s solutions are known by many terms, including Industry4.0 (I4.0), the Industrial Internet of Things (IIoT), digital transformation, remote monitoring, big data, smart factories and many more. Whatever term you use, reliable, timely data has been proven time and again to improve decision-making and organisational success.

This time last year, we were all still emerging from COVID-related business challenges. Whilst we can’t say that everything is back to business as usual, COVID did highlight the benefits of remote monitoring to many historically-cautious industrial sectors.

Pre-COVID we encountered reluctance in some industries to embrace the IIoT due to perceived entry costs and payback time. PowTechnology has been exceptionally well-placed to counter these concerns. Our digital transformation kit is user-friendly, proven, affordable and, importantly, it has been designed to be modular and highly scalable.

over the past year as we do more custom development and integration work!”

This in-house expertise and early adoption of new technologies has led to the development of versatile, modular, digital transformation ‘building blocks’, collectively known as Metron Intelligence.

GreenChem, one of Europe’s largest

huge advantage is the ability to remotely configure units to accommodate over 40 tank designs.

PowTechnology’s standard kit helps GreenChem schedule efficient distribution to minimise fuel costs and environmental impact, whilst ensuring that thousands of customers always have product.

In the words of Guy Flochlay, GreenChem CEO, “As one of Europe’s largest AdBlue distributors, GreenChem rely upon efficient logistics.

PowTechnology’s dependable and robust remote tank level monitoring solution supports that and helps us deliver exceptional customer service. PowTechnology have been our telemetry partner for over a decade, because their solutions are exceptionally well-proven in many countries and we are fully supported technically and commercially.”

Dave Oakes went on to explain, “PowTechnology has invested heavily in R&D, collaborating with academia to embrace emerging technologies and enjoying the diverse skill set of a rapidly-expanding internal Development Team.”

Rachel Crowther, PowTechnology CTO, added “The Industrial Internet of Things is ever more relevant to combat cost of living issues. With energy bills and raw material pricing eating into margins, people are actively seeking new solutions to help reduce costs and improve productivity.

PowTechnology can help, putting together new solutions, which integrate systems from a variety of vendors, sprinkling our own magic over the result and giving extra value to our customers. Our development team has tripled

That, in turn, gives PowTechnology a unique agility! We can often develop sector and application-specific IIoT solutions, based on these existing building blocks, with minimal development costs. We can create proofs of concept within a few months, where others may have taken years.

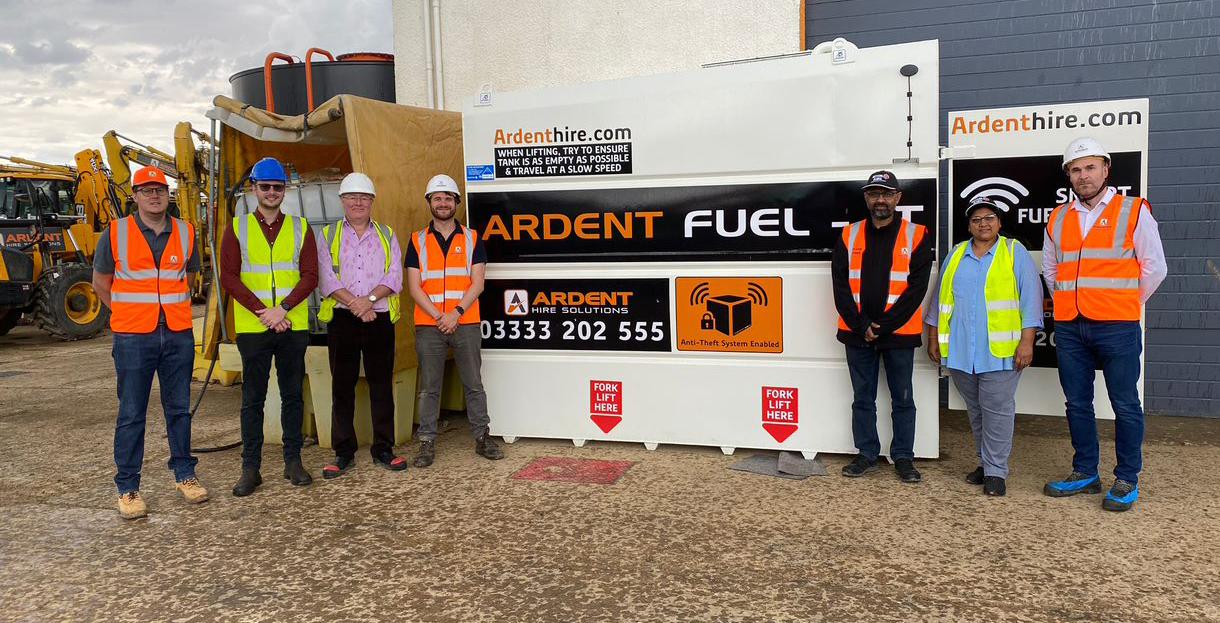

A fantastic example is our collaborative partnership with Ardent Hire Solutions, resulting in the recently launched Fuel-IT smart fuel tanks, which collect level, flow, dispersal and GPS location data. (https://www.ardenthire.com/).

Ardent is a multi-category rental equipment specialist that differentiates itself through digitalisation, sustainability and spectacular customer service. It manages over 7000 assets, via 10 depots across the UK, using their own multi award winning Site Manager software, which tracks asset performance and alerts sites of safety and productivity events based on telematics data.

Kit is often hired to construction sites. In April 2022, it became illegal to use low tax red diesel on construction sites. White diesel is heavily taxed and can be used by anyone. This meant site fuel would be more expensive and at greater risk of theft.

Ardent is a data-driven business. To accommodate the upcoming change in fuel regulations, they recognised the value of monitoring data from on-site fuel tanks and integrating it into Site Manager, to enhance security.

Ardent reviewed the market for a partner with the flexibility to realise both the functionality and integration elements of their vision. A PowTechnology customer recommended us!

Our IIoT Solution Architects helped Ardent define their project scope and our Development Team produced a proof of concept within 6 months of our first contact.

Feedback on that prototype helped us refine functionality and aesthetics, as well as modify the design for ease of manufacture and maintenance. PowTechnology have also provided full installation and usage training to a range of Ardent personnel.

As well as monitoring level to automate fuel ordering, plan fuel deliveries and avoid run-outs, the Fuel-IT tanks offer authorised dispersals, where users identify themselves and the asset being fuelled. Authorised users can see data on any web-enabled device.

Now Ardent are rolling out a proven, market-leading IIoT solution, which helps their customers streamline operations, reduce costs, improve health and safety and increase sustainability on site.

As Jeremy Fish, Ardent CEO told us, “Ardent’s solutions are transformative, differentiated and vital for ensuring safety and productivity on projects involving our equipment.

We needed a partner with the expertise to achieve our vision, the agility to respond quickly to our commercial challenge and the infrastructure to provide exceptional technical support. PowTechnology has been an excellent choice on all counts!

Fuel-IT smart fuel tanks are the UK’s most sophisticated tanks, enhancing our brand and reputation and our customers are delighted! I would have no hesitation in recommending PowTechnology as an IIoT development partner.”

Whether our customers need a ‘plug n play’ or a bespoke solution, our technology is fit to purpose and with controlled whole of life project costs and comprehensive technical support.

Over 100,000 IoT devices have been manufactured and supplied by PowTechnology. They deliver data on level, flow, temperature, pressure, vibration, humidity and more.

Our technology has helped customers respond to organisational challenges within factory automation, fuel management, lubricants, utilities, power, transport, waste management, environment, chemicals, flood protection, construction, security, agriculture, bulk liquid and gas distribution and pumping.

Our case studies page bears testament to our wealth of sector and application knowledge, with over thirty case studies. They include household names and multinationals, such as United Utilities, Royal Mail, Environment Agency, RSPB, Cemex, Fuchs Lubricants and Speedy. If you haven’t visited, then please take a look.

Dave Oakes concluded, “PowTechnology is on track for our best year ever. These are exciting times! We continue to expand, most recently within our Sales and Production Departments and we have new some amazing new technology and a really special partnership to announce very soon.”

As always, we welcome your application enquiries and will do our very best to offer a reliable, fit-to-purpose IIoT solution together with user-friendly installation and outstanding technical support.

What can PowTechnology do for you?

+44 (0) 1827 310666

sales@powtechnology.com

www.powtechnology.com

Lab Innovations is the UK’s leading annual exhibition for the entire laboratory industry and will take place on the 1st and 2nd of November 2023, at the NEC in Birmingham.

At the show, the industry will meet to showcase the latest products and innovations to the UK’s leading lab professionals, suppliers and manufacturers. Lab professionals across all sectors will be able to discover sustainable lab initiatives, secure the latest technology, attend free conferences to earn CPD points and explore new ways to ensure their labs are future-proofed.

Supported by some of the UK’s top science institutions, over 190 industry leading suppliers and manufacturers will be exhibiting cuttingedge technologies this year from all over the world such as Bio Molecular Systems, CEM Microwave Technology, Air Products, Huber UK Temperature Control Ltd, and many more.

Lab Innovations offers the perfect opportunity to discover innovation and sustainability for the future of the laboratory industry. As the UK’s only trade exhibition for the entire laboratory industry it will once again be showcasing the newest technologies and businesses that are key to powering the future business of science.

Over 4,000 laboratory professionals are expected to attend the show alongside over 50 expert speakers who will be discussing and demonstrating the current trends, present challenges and future solutions in laboratories.

To support the free to attend conference, Lab Innovations will stage a number of networking events that will include Business Matchmaking, a Networking Lounge that will provide drinks and a place to wind down and connect, as well as the Sustainable Laboratory where you can discover environmentally friendly products and cutting-edge case studies of sustainable initiatives in the lab. Andy Evans of Green Light

Laboratories will host tours on his stand and speak in the Insights and Innovation Theatre also.

Lab Innovations will be co-located with Advanced Engineering; therefore one badge will allow you to attend two shows. Scientific Laboratory Supplies (SLS) is the official Laboratory Equipment Distributor for Lab Innovations, and this year the new SLS Pavilion will be the platform for 12 key supply partners along with four important focus areas for SLS.

For more information visit the website below. www.lab-innovations.com

Containment Technology Services – CTS Europe – specialises in the containment of airborne particles often present when handling drug compounds within the laboratory, and has many years of experience in the supply of proven containment solutions.

CTS have focused on the production of custom laboratory containment which has progressively led to the development of a solid range of laboratory safety enclosures. From specialist powder weighing enclosures to automation enclosures, climatically controlled enclosures

systems and to complete enclosed laboratory processes.

Our latest development is the SafetyBox™ HEPA Filtered Glovebox specifically design to provide a safe handling environment for high hazard drug products. This product is unique in that it is constructed with fully radius internal edges for cleanability which is something previously only available with a fully stainless steel fabrication.

Contact us on

+442393 695521

sales@containment-technology.co.uk

www.containment-technology.co.uk

Founded in 1988, Techcomp Instruments Ltd is a laboratory instrumentation group with UK headquarters in Livingston, Scotland. We specialise in three core technologies: Molecular Spectroscopy, Chromatography and General Laboratory Instrumentation.

Techcomp Lab Products division designs, develops, manufactures, and distributes quality laboratory products.

Our Lab Products division includes Precisa, Froilabo, Edinburgh Sensors and Dynamica:

t Balances and Moisture & Ash Analysers, by Precisa

t Gas Analysis Solutions by Edinburgh Sensors

t Temperature Control Solutions & Cryogenic Storage Systems by Froilabo

t Benchtop Centrifuge Solutions and ELISA by Dynamica

This November, we are exhibiting for the first time as Techcomp Lab Products at Lab Innovations. We aim to provide our clients and customers, both existing and new, the perfect solution for all their laboratory equipment needs.

This September, we are delighted to launch two new products in the Techcomp Lab Products division: the Series 530 Moisture Analyser by Precisa the Velocity 17Pro by Dynamica.

Our Precisa products are Swiss design and innovation with over 45 years of knowledge and experience leading to Moisture Analyzers, which are innovative, research-led, and laboratory-ready.

Our Dynamica High-Speed Centrifuges are low noise and stable. Our Dynamica centrifuges allow you to separate your biological sample without disturbing the peace.

Come and meet the Techcomp Lab Products team at Lab Innovations.: STAND G51

Louise Milne: Sales Manager - Lab Products

1 Bain Square, Kirkton Campus, EH54 7DQ, UK

+44 (0)7545 654 715 | (0)1506 425 300 techcomp-instruments.com

We are LAUDA – the world market leader for precise temperatures. Our temperature control devices and systems are at the heart of important applications and hence make a contribution to a better future. As a fullservice provider, we guarantee the optimum temperature in research, production and quality control. We are the reliable partner for hydrogen, chemical, pharmaceuticals, biotech, semiconductors and medical technology. With competent advice and innovative solutions, we have been inspiring our customer every day for over 65 years – worldwide.

Our Hydro Water Baths boast reliability whilst being virtually maintenance free, and are built for continuous operation in the laboratory. A further reliable partner for applications in the lab is our Varioshake Shaker; extremely user-friendly, robust and durable. The LAUDA Puridest will provide ultra-pure, low-gas, sterile and pyrogen-free distillate. All of our products set impressive standards with their compact design, user-friendliness and performance.

Don’t just take our word for it – come and see us at Lab Innovations ’23 to discuss the full spectrum of your temperature and laboratory needs with our expert team.

We look forward to seeing you!

Stand Number: M92

Contact Details:

info@lauda-technology.co.uk

+44 (0)1780 243 118

LAUDA Technology Ltd, Unit 12, Tinwell Business Park, Tinwell, Stamford, PE9 3UN

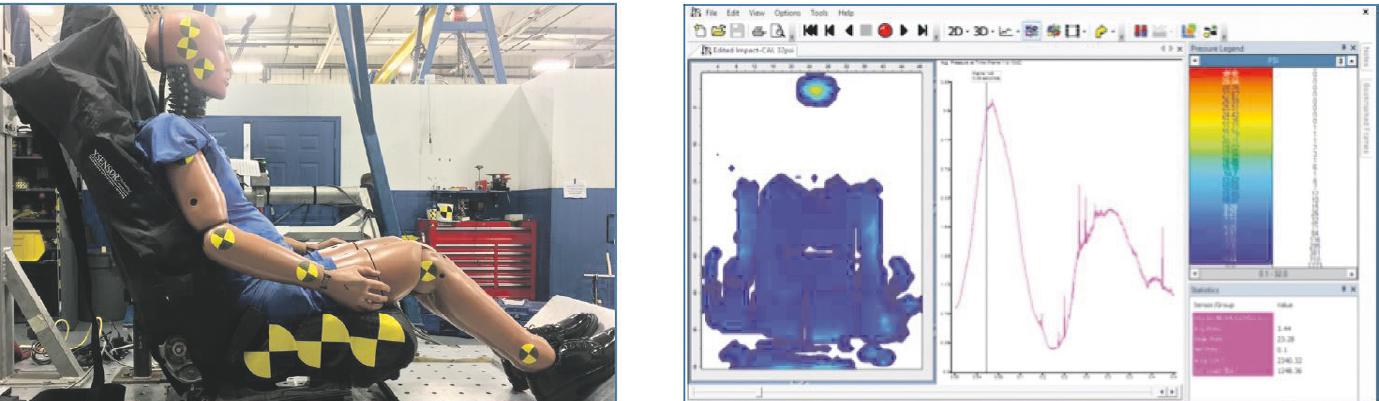

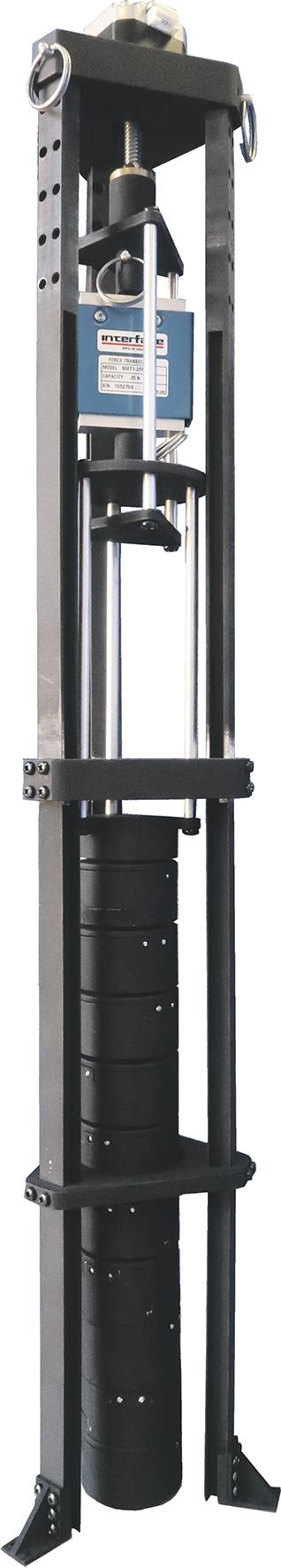

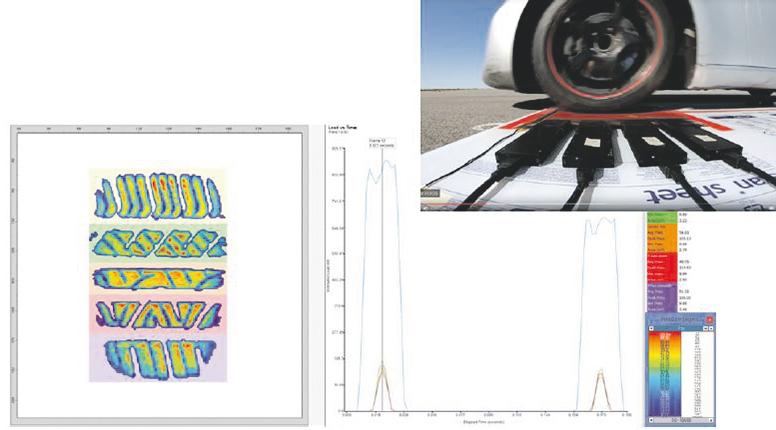

The team at Interface Face Measurements is once again looking forward to exhibiting at the Advanced Engineering show on the 1st and 2nd of November. There is always an air of anticipation as we prepare to meet new and existing customers, discuss their latest projects and find out how we can help.

We will be displaying our range of Load Cells, Torque transducers, pressure mapping sensors and systems.

The Advanced Engineering Show is also a great venue to launch new products and we have a new Hydrogen Gas certified sensor from German manufacturer DDM. The PV22-H2 is for anyone conducting research into using Hydrogen Gas as a fuel. Its small form factor makes it ideal for applications where space is tight.

We are also pleased to be displaying what we believe to be a world-first. Our US partner GP50 has developed the first pressure sensor compatible for use with liquid Hydrogen. The GP50 311AI has been tested by NASA at liquid helium temperatures (-269 Deg C). This sensor is ideal for research into liquid Hydrogen storage and transfer.

We

Withnell Sensors are temperature and humidity specialists who are proud to support the life science, research laboratory and advanced engineering industries. We are pleased to showcase our products and services at the upcoming Lab Innovations show including a variety of data loggers for controlled monitoring and validation. We also offer a full range of temperature controlled units such as medical fridges and freezers, incubators, ovens and test chambers. We can also plan, design and build custom refrigeration units tailored towards your business, application, or space.

Our services include UKAS accredited temperature and humidity calibration, temperature mapping and on-going maintenance and validation.

Our team of UK based engineers are available to offer support and advice on projects of all sizes. We aren’t a manufacturer but we represent some of the world’s leading brands which means we can put your needs first and offer you the most suitable solution. As well as this impartial support we are always on-hand to deliver on-going help whenever it is needed.

Stop by our stand, visit our website or speak to a member of our team about your temperature and humidity needs.

Lab Innovations stand number: F21

www.withnellsensors.co.uk

01254 831375

Based in Sheffield since our inception in 2003, we are a stockist and distributor of high specification Stainless Steel, Nickel Alloys and Super Alloys to UK, European, and Worldwide markets for Oil and Gas, Petro-Chemical, Power Generation, Marine / Sub Sea, Motorsport and Aerospace and Nuclear.

We specialise in round bar from 12.7mm diameter to 304.8mm diameter and beyond in certain grades. Our Aerospace department also specialises in the supply of hoses, ground support equipment, aerospace power accessories and overhaul services.

We have held ISO 9001 since 2005, gained our

AS9120 Aerospace certification in 2019 and all the material we sell is from US or European mills with full traceability and complete certification.

We have a vast amount of knowledge in the metals arena and work confidently in accordance’s with ever exacting customer specifications. In addition, full testing can be undertaken (mechanical, metallurgical and non-destructive), if necessary, under third-party witness with the intent of EN 10204-3.2.

We offer over the the phone quotations if required and next day dispatch of our bar stock and products as standard. Over 40% of our sales are to export markets and we have in house expertise in export.

Fidgeon Limited boasts nearly five decades of experience as a trusted supplier in the field of Non-Destructive Testing (NDT). Since its establishment in 1975, Fidgeon has been a reliable partner for various NDT industries, including but not limited to, aerospace, oil, and gas, automotive, and defence. The company's primary focus is to meet the diverse needs of its customers by sourcing a wide range of NDT equipment and consumables. This year marks an exciting milestone as Fidgeon Limited participates in the Advanced Engineering Exhibition for the very first time. The company will proudly showcase innovative equipment from leading manufacturers that it has the privilege to support.

If you're eager to delve into a variety of NDT techniques, we invite you to visit us at stand number F145. Here, we will be providing demonstrations of cutting-edge X-ray Diffraction, Barkhausen Noise, Film Digitisation, and Eddy Current equipment. These technologies, crafted by renowned NDT specialists, exemplify the forefront of the industry's capabilities. Our presence at the exhibition underscores our dedication to staying current with the latest advancements and offering the best solutions to our customers.

We look forward to seeing you all at the exhibition in November!

At European Springs & Pressings Ltd we are proud of the way we work with our clients to provide bespoke parts and solutions for their manufacturing processes, and have enjoyed building our profile at exhibitions and across print and social media outlets. At European Springs & Pressings Ltd we understand that the needs of our clients vary from job to job, therefore we endeavour to work with them to overcome all their manufacturing challenges.

No two jobs are the same; similar products often require the use of different materials, treatments, variable tolerances or specific heat resistance. This is why we invest in the latest technology, qualified toolmakers and engineers to ensure that

At Monmouth Scientific environmentally responsible recirculating technology is the core of our expertise.

A UK Market Leader in Clean Air Solutions, we create clean environments to help scientists, engineers, and technicians to work safely & effectively. Our specialised Fume Cupboard, Laminar Flow, Biological Safety, Powder Containment, and ISO Class Cleanroom solutions provide the best protection and performance for your personnel.

Complete Project Management from initial enquiry through to installation and continuing maintenance and support, means minimal disruption that allows you to work effectively in a safe environment.

Combing Safety & Sustainability at Lab InnovationsIntroducing the Circulaire® Hybrid Fume Cupboard

Visit us on Stand K50 as we proudly unveil the Circulaire® Hybrid Fume Cupboard. A revolutionary combination of modern clean air technologies and traditional fume cupboards that sets new standards for safety and sustainability in laboratory, research, and manufacturing facilities.

we design and produce the very best bespoke stampings, springs and wire forms.

The company has a dedicated team of reliable engineers that work with you to ensure the right product is chosen at the most economic price. After initial engagement, European Springs & Pressings Ltd will help design a product that is fit for function achieving all technical and quality requirements. These aspects also take into account the repeatability of manufacture including tolerances, the product life, the ease of production assembly and the most economic method of manufacture.

For more information, see below.

www.europeansprings.com

The highly energy efficient Fume Cupboard, features Partial Airflow Recirculation technology, cutting emissions by returning 60% of the air, free of contaminants, to the working chamber and exhausting 40% clean and filtered air to the outside atmosphere.

Join Monmouth Scientific on Stand K50 to find out how our market leading clean air solutions can be the difference for you.

www.monmouthscientific.co.uk

‘I am very impressed with Relyence platforms and its capabilities, and I am impressed with its features and how convenient it is to use for Reliability Prediction.’

With client testimonials like this, it’s no wonder Relyence UK Limited is one of the most anticipated exhibitors at this year’s Advanced Engineering Expo 2023. If you’re looking for new ways to design reliable products, better processes, and create safer operating environments, Relyence UK Limited offers an integrated platform that enables you to mix and match its reliability software tools in any combination you require.

Relyence Corporation is committed to continually working on product development, new capabilities, feature enhancement, as well as always improving its tools. Offering global access, it’s portfolio of software is built for teams, is user friendly, and is considered as the most powerful reliability and risk management software in the industry.

The company is expected to showcase a number of products at the 2023 Exhibition designed to help

Sympatec develops, manufactures, sells, services and supports an innovative range of best instruments for particle size and shape analysis in laboratory and process for customers worldwide.

With continuous innovations in the technological fields of laser diffraction, dynamic image analysis, ultrasonic extinction and dynamic light scattering, Sympatec makes a prominent contribution to the development, production and quality control of most challenging particulate systems.

Typical applications cover dry powders and granules, fibres, suspensions, emulsions, gels, sprays and inhalants within a size range from 0.5 nm to 34,000 μm. Modular instruments show great versatility

clients with the following;

More information, see below.

T 0121 794 2030 info@relyence.co.uk

www.relyence.co.uk

and can be adapted to the specific task within your laboratory.

Moreover, all instruments reliably deliver most accurate, reproducible and comparable results at shortest measuring times.

uk@sympatec.com

www.sympatec.com

T +44 161 763 5757

MManufacturing composite products requires a perfect vacuum integrity before treatment. Any leak in a bag can compromise the final product quality and will require additional repair time. However, the actual methods in use are tedious, time-consuming and heavily user dependent. These can lead to missed leaks, being a source of defects after treatment.

Distran presents a new technology: ultrasound imaging, providing a clear pinpointing of

leaks. Operators now pinpoint vacuum leaks 10x faster than before and at a distance, significantly improving the overall process efficiency. The camera triangulates the vacuum leak’s position vacuum in real-time and overlays it on a wide-angle optical image. Anyone can conduct comprehensive and reliable leak inspections. After reinstating the sealing integrity, tightness can immediately be controlled.

This technology is currently successfully applied by industrial leaders within a variety of applications such as renewables, boating, aerospace, etc. Come by our booth or visit our website to know how Distran

supports its clients in improving their processes by reducing inspection times while increasing inspections’ reliability.

Contact:

Hermann Préchoux

T +33 7 88 24 27 31

Hermann.Prechoux@Distran.fr www.distran.swiss