LABORATORY TESTS

IN-HOUSE TESTING CAPABILITIES AT FIBERPARTNER

At Fiberpartner, we understand that precision and reliability are essential in your fiber applications. That is why we have built our in-house laboratory - to provide you with accurate testing solutions that help you optimize quality, efficiency, and performance.

With our advanced testing capabilities, you gain valuable insights into the properties of your fibers, ensuring they meet your exact requirements. We offer:

Elongation Break & Tensile Strength

Helping you assess fiber durability and mechanical performance.

Fiber Physical Observation

Giving you a detailed view of structural integrity and surface characteristics.

Oil Extraction & Polymer Melting Point

Providing insights into material composition and thermal behavior.

Carding Effect & Linear Thickness

Supporting you in evaluating fiber processing and uniformity.

Moisture Value & Crimps

Helping you determine retention properties and structural resilience.

Color Assessment

Ensuring your fibers maintain consistent appearance.

Washing/Drying Test

Verifying fiber stability under real-use conditions.

Cross Section Analysis

Offering you a microscopic look at fiber morphology.

Fiber Compression & Recovery

Measuring elasticity and resilience for your applications.

By choosing our lab services, you gain a partner who helps you enhance product consistency, verify compliance, and explore new possibilities in fiber performance.

Get in touch to learn more about how we can support your business.

Fiberpartner In-House Testing Capabilities

Elongation break (%)

Standard: ISO 5079

The elongation at break test measures how much a fiber or yarn can stretch before it breaks, expressed as a percentage of its original length. This test provides critical data on the material’s flexibility and durability under tension.

Tensile strength (g/den)

Standard: ISO 5079

The tensile strength test measures the force required to break a fiber, expressed in grams per denier (g/den), which relates the strength to the fiber’s linear density. It reflects the material’s ability to withstand tension before failure.

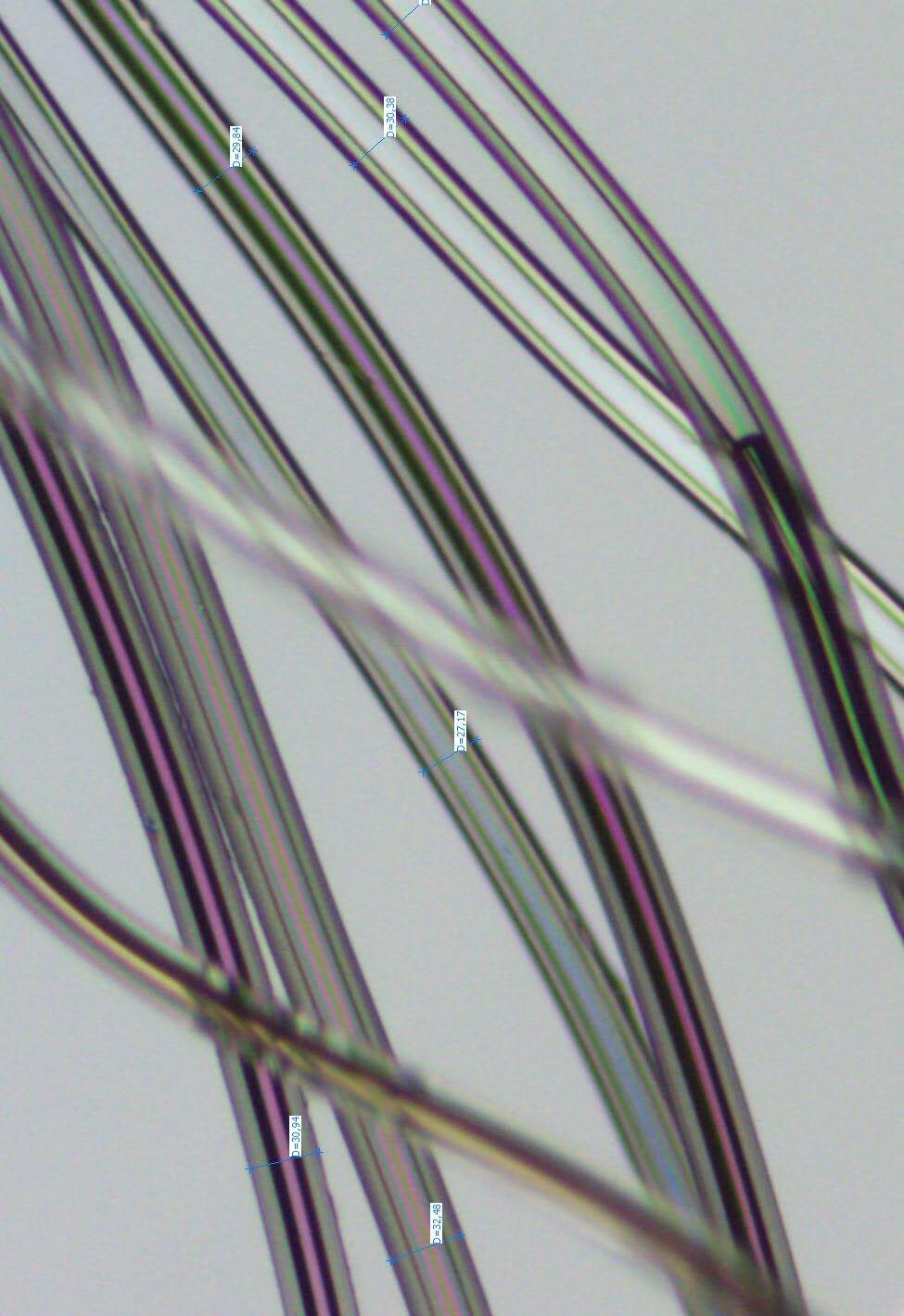

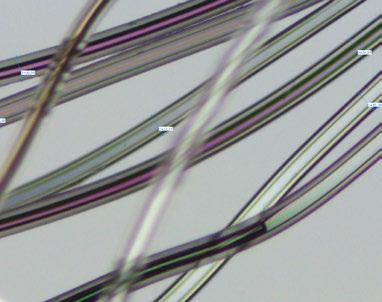

Fiber physical observation

Fiber physical observation visually evaluates external characteristics like shape, texture, color, and uniformity. This qualitative assessment offers insights into fiber quality and suitability for specific applications while helping identify fiber type, detect irregularities, and ensure consistency before quantitative testing.

Oil extraction (%)

The oil extraction test determines the percentage of oil or finish on fibers, which affects processing performance and end-use. It ensures the correct amount of lubricant is applied to improve handling, reduce friction, and enhance manufacturing efficiency, such as in spinning or weaving.

Polymer Melting point (ºC)

The test identifies the temperature at which a fiber’s polymer transitions from solid to liquid, providing insights into its thermal behavior. This information is crucial for evaluating heat resistance, processing conditions, and suitability for specific applications.

Carding Effect

The test evaluates how effectively fibers are straightened, separated, and cleaned during the carding process. It assesses fiber quality, evenness, and impurity removal to ensure readiness for subsequent steps like spinning or producing nonwoven materials. This ensures efficient processing and consistent product quality in textile manufacturing.

Length (mm)

The fiber length test measures fiber length, typically in millimeters (mm), to assess performance in manufacturing and suitability for various applications. Fiber length influences the strength, uniformity, and quality of yarns and fabrics, directly impacting their performance and end-use.

Colour assessment

The color assessment of fibers evaluates consistency, appearance, and quality to ensure they meet design and usage standards. This process reduces defects, ensures uniformity, and aligns with customer or industry requirements for visual appeal and product consistency.

Crimps (N/25 mm)

The crimps test evaluates a fiber’s natural waviness, measured in crimps per millimeter (N/mm). This property influences elasticity, bulk, and performance, affecting fiber cohesion, stretchability, and processing behavior. It is critical for applications requiring specific mechanical or aesthetic qualities, such as fabrics and nonwoven products.

Washing /Drying test

ISO 6330

The washing and drying test assesses a fiber’s durability, appearance, and performance after standard cycles defined by ISO 6330. It verifies compliance with quality and resilience standards for home textiles and furnishings by simulating real-life usage conditions.

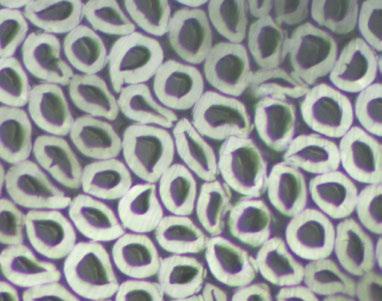

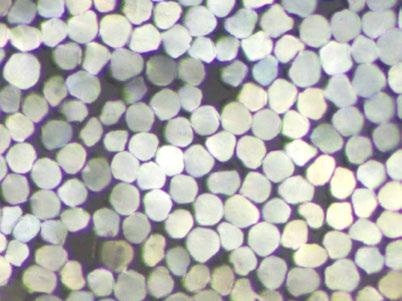

Cross section

The cross-section test analyzes the shape and area of a fiber’s crosssection, which affects its mechanical properties,, and overall performance. This test is crucial for understanding fiber behavior in applications like textiles, filtration, and composites.

Linear Thickness (d.tex)

The linear thickness test measures fiber mass per unit length in decitex (d.tex), with one d.tex equal to the mass in grams of 10,000 meters. It indicates fiber fineness or coarseness and ensures consistent quality for textile applications..

Fiber Compression/ Recovery (mm) / (%)

This test measures a fiber’s ability to compress under pressure and recover its shape once the pressure is removed, with recovery expressed as a percentage (%). This property is vital for assessing resilience and durability, ensuring fibers meet standards for comfort, longevity, and structural integrity in cushioning, upholstery, and home textiles.

Moister Value (%)

The moisture value test determines the percentage of water in fibers, impacting their weight, processing behavior, and physical properties. It reflects the fiber’s capacity to absorb and retain moisture, influencing strength, elasticity, and comfort, ensuring quality and suitability for specific applications

Selahattin Onur

Signe Rose Steffensen QC Enginner srs@fiberpartner.com

Fiberpartner is a Danish advisor and supplier of textile fibers. We understand the urgent need to transform polyester production and consumption for a more sustainable future. With our 40 years of experience, we’re committed to driving change through strategic partnerships and innovative technology and solutions, including recycled and biodegradable polyester solutions. Join us in reshaping the polyester industry for a better tomorrow. Feel free to