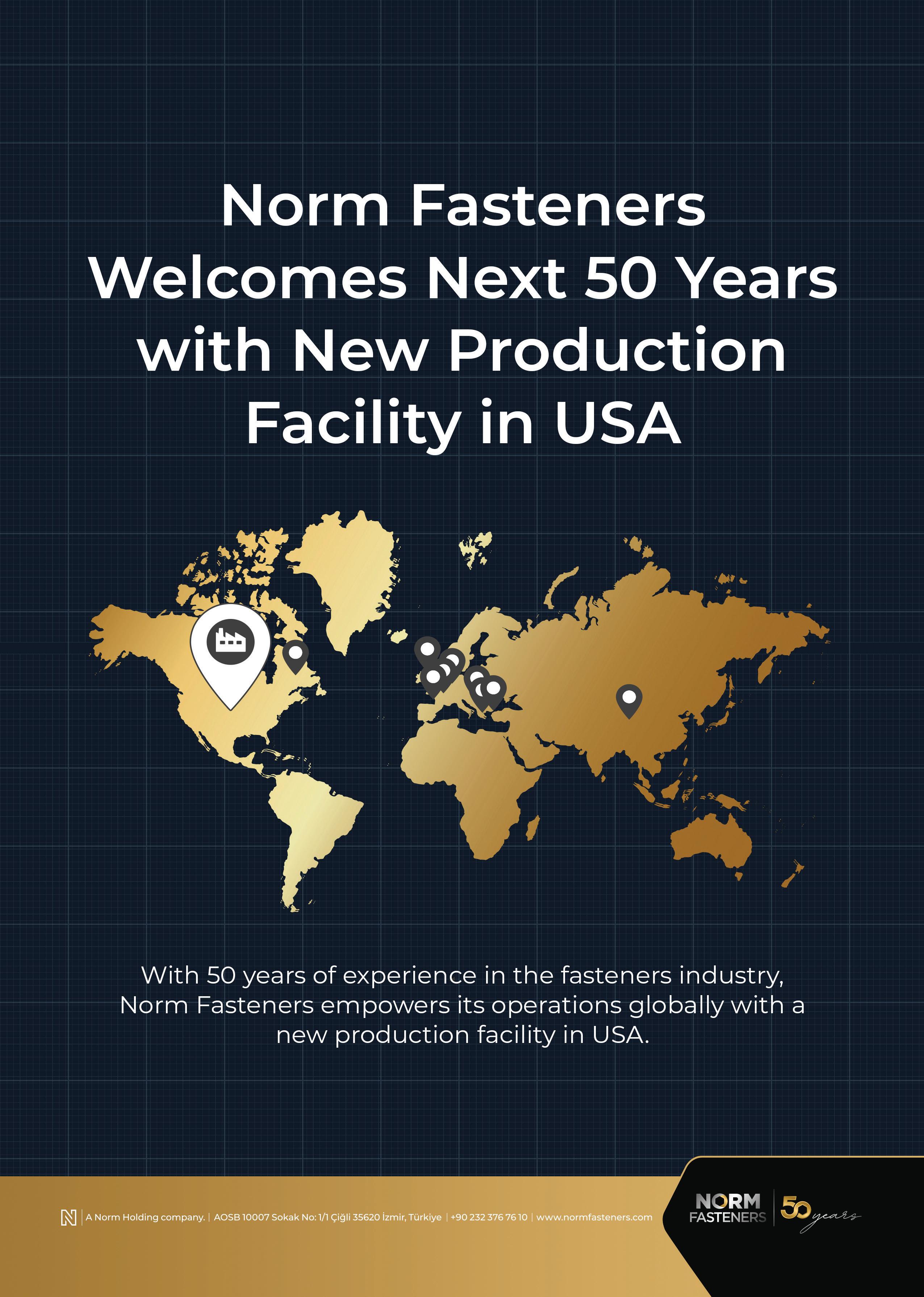

COMPETENT. GROWING.

COMPETENT. GROWING.

Life is full of surprises and the same can be said about the fastener and fixing industry. Recent years have shown that even the most stable supply chains can be impacted by external factors, which are out of any company’s control. Whilst the market might be getting back to some sense of normality, the next anomaly that turns everything upside down is just around the corner. So, what has your company done to add further support to its supply chain?

Alot of companies have taken steps to ensure at least some of its production or suppliers are based close by, with the ability to step up if needed. With that in mind, we have a special Made in eastern Europe feature that showcases some of the companies that can do just that.

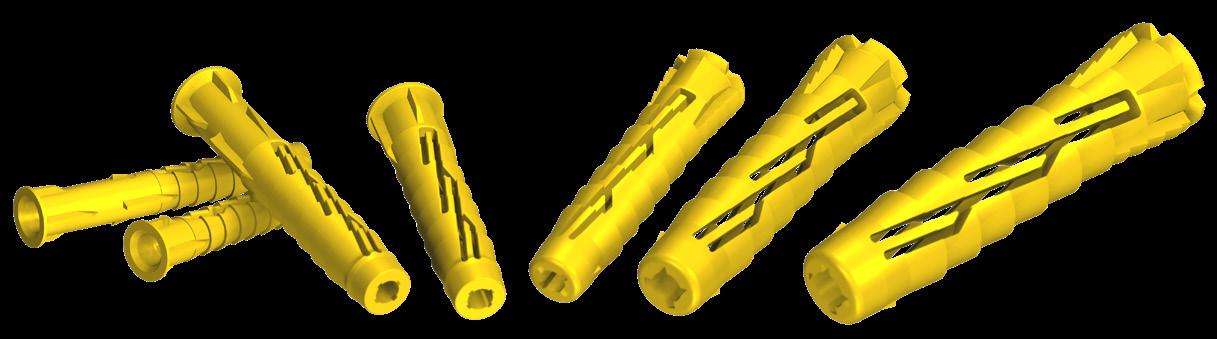

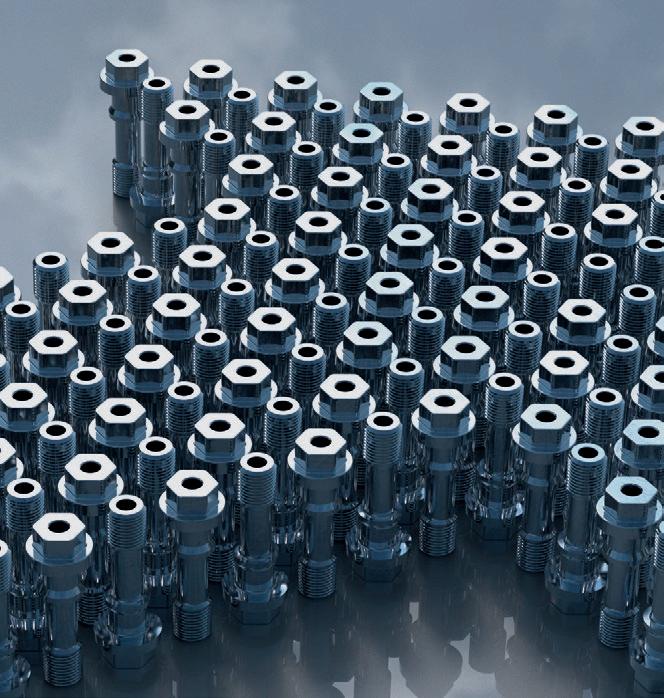

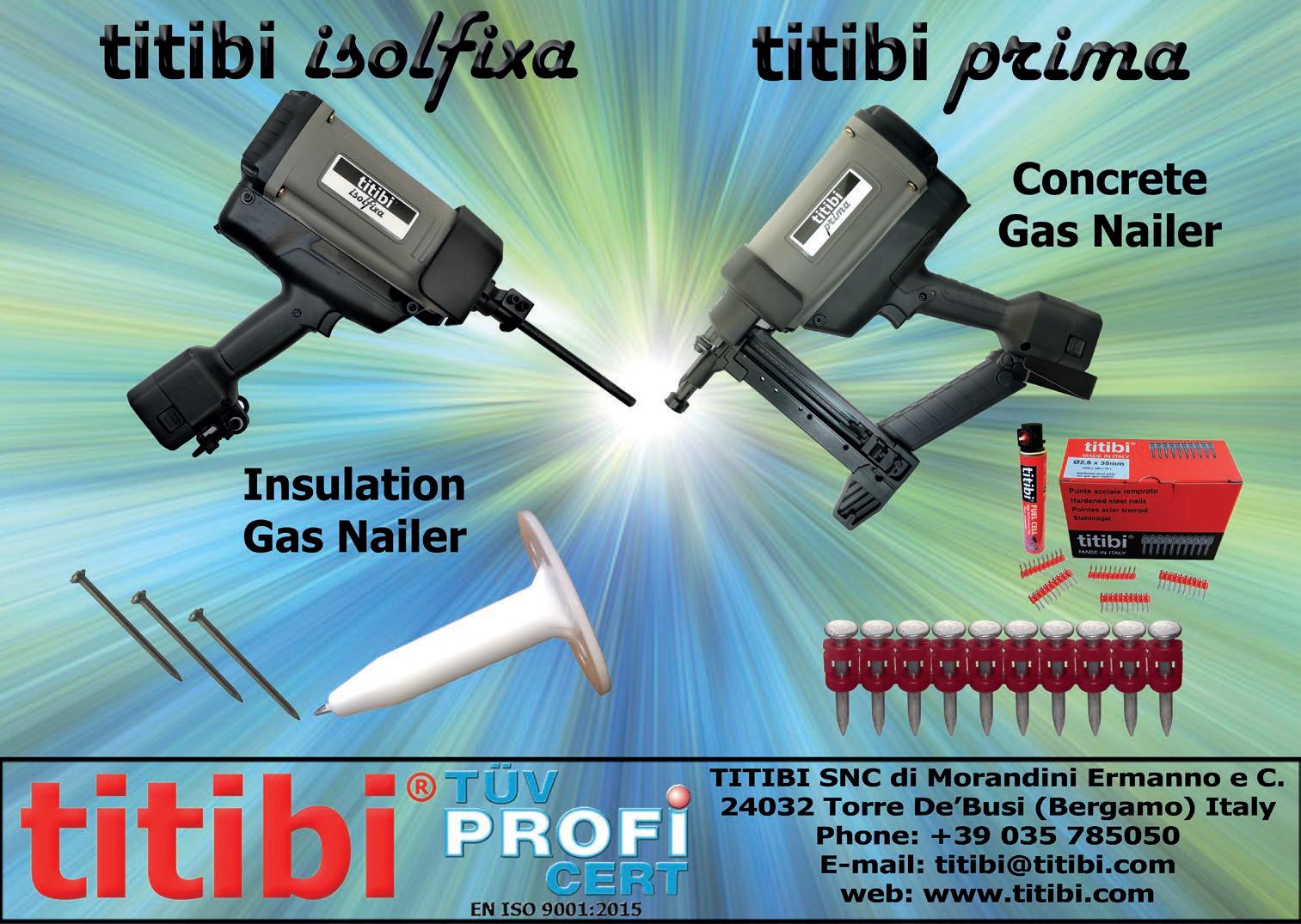

Companies involved within the feature have a wide array of machinery and capabilities that enable them to cover a range of products, including nylon and steel anchors, construction fasteners, screws, wood connectors, bolts, pins, threaded rod, HV and SB bolts, nails, hinges, latches, brackets, garden fittings, self-forming and self-taping screws, rivets, as well as special parts and even heat treatment lines, plus much more.

The feature underlines that these businesses have been investing in their machinery capabilities and capacity in order to further support existing European customers and become a vital part of new customers’ supply chains.

Alongside this insightful feature, as always, we have several articles that you will just not find anywhere else. Firstly, there is an exclusive interview with Dr Daniel Bossard, CEO of Bossard Group, who discusses how the group works with customers to provide the optimal fastening solutions

Part of the Mack Brooks Group

www.fastenerandfixing.com

Published by

Managing Director Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director Will Lowry will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

Assistant Editor Rebecca England rebecca.england@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe

Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

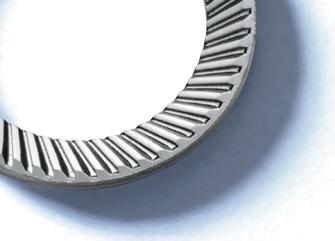

and services. Next up, we have an intriguing article from SCHNORR® GmbH that highlights the growing enquiries it receives for a DIN standard that simply doesn’t exist and how the German manufacturer is trying to educate customers. To add to this, there is another exclusive interview, this time with Johannes Wilfried Huber, senior vice-president for the diamond systems business at Hilti Group, who talks about the crucial role of productivity and process improvements within the construction sector and how Hilti can provide solutions and support.

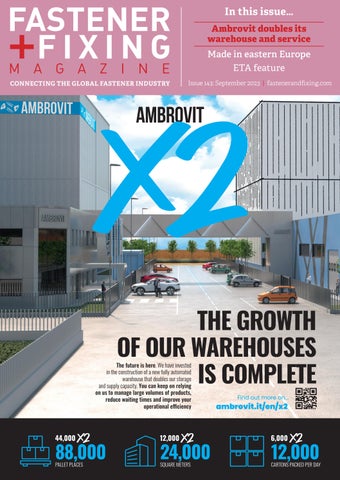

Our Cover Story focuses on Ambrovit Srl and how the Italian leader in fastening systems has doubled its warehouse and service – enabling the company to further raise the bar of efficiency when it comes to the supply of fasteners.

There is still so much more, including an interview with new EIFI President Paolo Pozzi; ECAP and CFE, in separate articles, discuss some of the complications with the impending new Construction Products Regulation, and what it will mean for the construction sector; and SurTec International GmbH explains how it aims to become a single source for matched coating systems; plus an excellent European Technical Assessment feature and Rail application feature. Enjoy.

Fastener + Fixing Magazine is a dedicated, trade–only publication which is circulated freely throughout the European trade.

Disclaimer

The Publisher cannot be held responsible or, in any way, liable for errors or omissions, during input or printing of any material supplied or contained herein although the utmost care is taken to ensure that information contained is accurate and up to date. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or Verulam Media.

Copyright Entire contents copyright © Verulam Media Ltd 2023. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Annual subscription (6 issues) to non–trade and outside EU is €160.00 Verulam Media Limited, Office 121, Ashley Road 134, St Albans AL1 5JR Tel: +44 (0) 1727 743 882

Find us online:

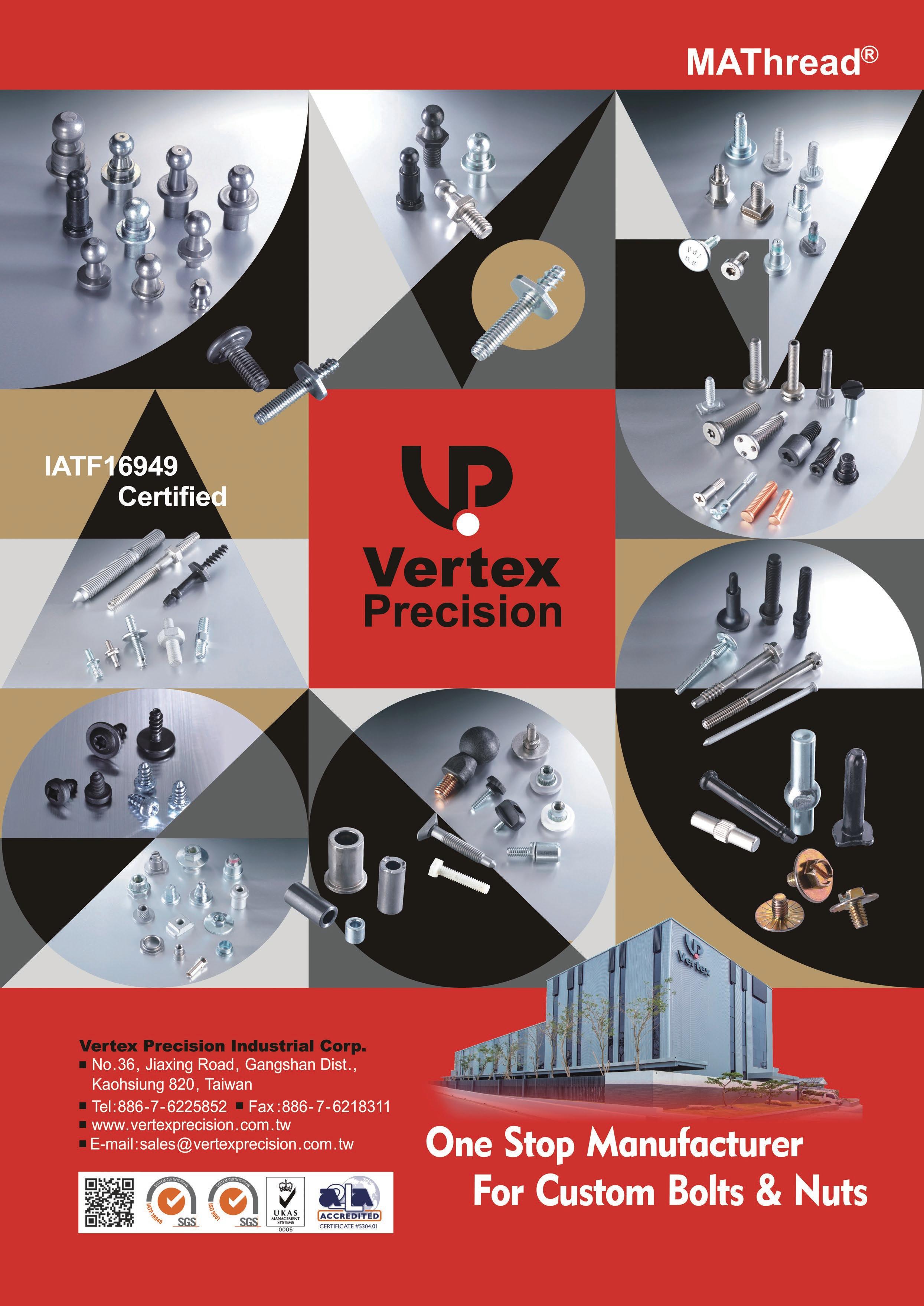

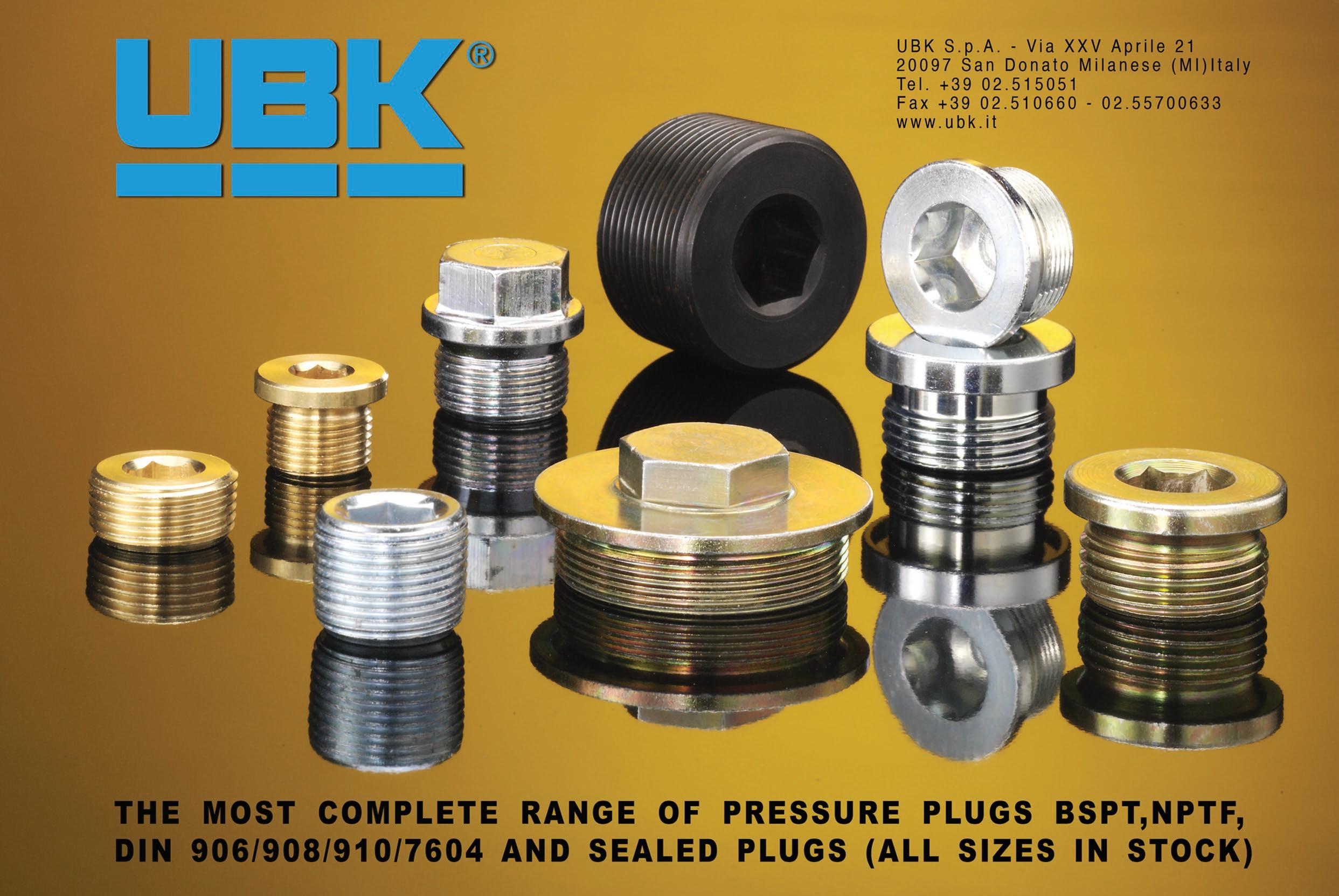

Fit bolts, plugs, knurled thumb screws, square head bolts, flat headed screws, hexagon set screws, brass screws and specials.

90

Würth Group remains on course for growth, albeit at a much slower pace than in the previous two years, with the company reporting sales of €10.5 billion in the first half of 2023 – corresponding to an increase of 5.9% compared to the same period last year. Adjusted for currencies, this is equivalent to 6.6%.

For the first half of 2023 the operating result of Würth Group amounted to €680 million, which is slightly below the same period last year (2022: €720 million). Apart from higher personnel expenses, this development is due to increased costs for mobility and maintenance, as well as the ongoing price pressure.

Robert Friedmann, chairman of the central management board of Würth Group, commented: “After two years of record sales and operating result, the economic slowdown is becoming apparent.”

However, after almost three years of the Covid-19 pandemic and related supply chain problems, the supply situation is improving for the Group. Although, at the same time, interest rates remain at a high level, which, in turn, hampers the demand in the construction industry. Geopolitical challenges such as the smouldering conflict between China, Taiwan and the USA, as well as the war in Ukraine, and the associated high energy prices, has influenced the economic growth in Germany. “Against this backdrop, we are very satisfied with the development in the first half of 2023,” emphasised Robert.

The companies of the Würth Group in Germany generated sales of €4.2 billion and, with almost double-digit growth (+9.6%), reported a positive development overall. Well established companies of the Würth Group, such as Würth Industrie Service,

tool distributor HAHN+KOLB and electrical wholesaler FEGA & Schmitt have made a decisive contribution to this successful result, which was achieved without acquisitions. Adolf Würth GmbH & Co KG, the largest individual company in the Würth Group, generated sales of €1.5 billion including intra-group sales.

The Würth Group companies abroad generated sales of €6.3 billion, which was a 3.5% growth compared to the same period in 2022. Growth drivers were the companies in southern and eastern Europe.

Whilst it is difficult to predict how the many conflict hotspots and their consequences, such as high energy prices, will affect Würth Group, Robert Friedmann was still optimistic about opportunities within the market. “On a positive note, the transport markets have clearly recovered and the Covid-19 pandemic is not as prevalent as before. In general, it can be said that supply chains have stabilised significantly again, which means that availability has almost reached the pre-crisis level. Procurement prices, which are still well above the pre-crisis level, however remain problematic. Provided conditions do not deteriorate drastically, we expect mid-single-digit sales growth and a slight decline in operating result.”

Bossard Group has reported that the first half of 2023 was marked by a heterogeneous development in demand in its three market regions. Gratifying growth in America contrasted with the economic slowdown in Europe and in Asia, especially in China. Overall, Bossard’s sales, as well as EBIT and net income, fell slightly compared to last year’s records.

Bossard’s sales in the first half of 2023 declined by 1.5% to CHF 577 million (2022: CHF 586 million), while growth in local currency was 3.1%. Organic growth amounted to 1.2% and net income fell by 16.7% to CHF 49.9 million (2022: CHF 59.9 million).

The challenges for Bossard have shifted in the last six months. With the lifting of the strict Covid-19 restrictions in China, demand started to normalise in the consumer goods and electronics industries, as well as in medical technology – the industry sectors that benefited from the pandemic. At the same time, decreasing demand and shorter delivery times during the second quarter led to a normalisation in the procurement market.

In Europe, Bossard recorded a decrease in sales of 3.2% (in local currency: +0.4%) to CHF 321.2 million (2022: CHF 331.7 million). This result is the consequence of the economic slowdown and normalisation of demand. In an environment marked by a shortage of skilled labour and inflation, Bossard’s Smart Factory services drew even more attention from customers.

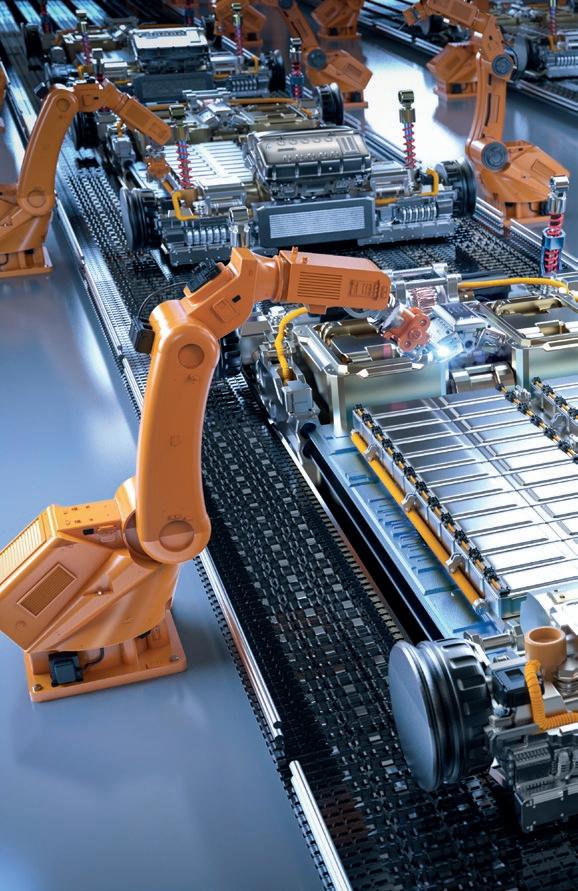

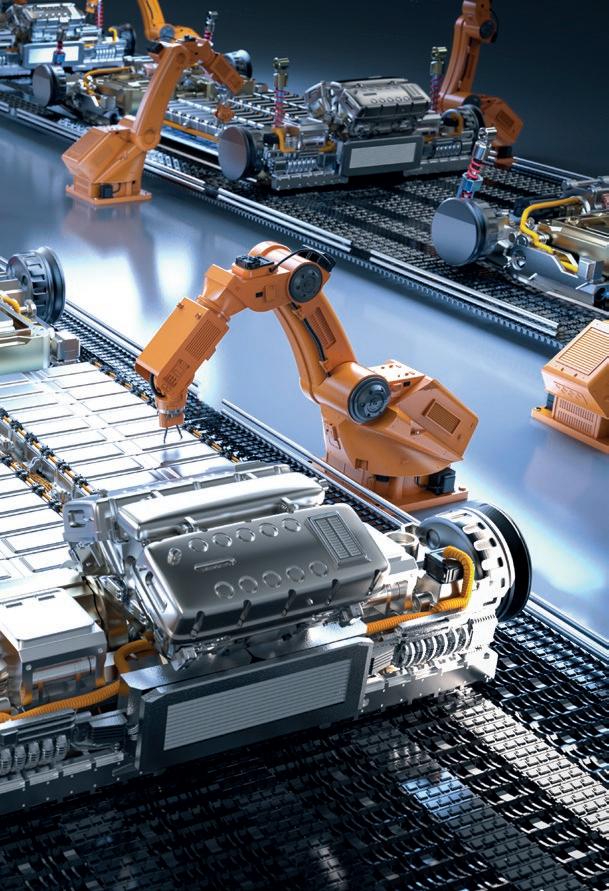

In America, Bossard again posted solid and broad-based growth in the first half of the year, although it began to slow down towards the end of that period. Sales increased by 9.9% (in local currency: +13.8%) to CHF 161.6 million. Organic growth in local currency amounted to 6.4%. The Group’s expertise in the electromobility sector, built up over the last several years, has led to further expansion of its customer base.

Owing to the uncertain economic environment, geopolitical tensions, and increasing trade conflicts, Bossard believes the outlook for the rest of the year remains marked by uncertainty and risk. Based on observations of current developments, Bossard expects moderate economic demand in the second half of 2023. This expectation is also based on its customers’ continued inventory reductions and, in a best case scenario, stable purchase prices. Notwithstanding the above, the consistent implementation of Strategy 200 in the first half of the year has further improved conditions for sustainable, profitable growth and Bossard views the future with optimism.

NORMA Group grew slightly and improved its profitability in the second quarter of 2023. A marked increase in demand from the automotive industry and targeted price management were key growth drivers, more than compensating for lower demand in the water management sector.

Figures showed that NORMA Group sales were up 1.9% over Q2 of 2022 to €324 million (Q2 2022: €317.9 million). Organically, the company grew by 4% from April to June 2023. Negative currency effects in connection with the US dollar reduced sales growth by 2%. Net operating cash flow was €31.9 million in the second quarter of 2023, an improvement compared with the same quarter last year (Q2 2022: €26.4 million).

Guido Grandi, CEO at NORMA Group, commented: “We delivered a successful second quarter and launched the first initiatives from our ‘Step Up’ growth programme. We improved our profitability both versus the prior year quarter and compared to the first quarter of 2023. We also managed to cushion the impact of inflation. Our global presence and broad-based portfolio of joining technology for vehicles, water management, mechanical engineering, and other industries, make us extremely robust –and that is proving beneficial in what is currently a sluggish overall economic environment.”

In the EMEA region, the growth trend experienced in the first quarter of 2023 continued. Sales in the second quarter of 2023 showed a significant increase of 12.4% over the prior year to

€136.6 million (Q2 2022: €121.6 million). Negative currency effects reduced growth marginally by 0.3%. The strong organic growth of 12.7% is primarily attributable to a strong recovery in the automotive industry and an upturn in demand for joining solutions for all types of passenger cars. Sales also increased in the area of industry applications.

In the Americas region, sales in the second quarter of 2023 fell by 6.9% year-on-year to €144.5 million (Q2 2022: €155.3 million). Organically, sales decreased by 5.2%; currency effects reduced sales by an additional -1.8%. Sales of joining technology for cars and commercial vehicles were lower following a strong prior year quarter. Business with water management products was also lower following a very strong prior year quarter, but improved compared to the first three months of 2023.

In the Asia-Pacific region, sales grew by 4.5% year-on-year to €42.9 million in the second quarter (Q2 2022: €41.1 million). Organically, sales showed strong growth of 12.5%; negative currency effects reduced sales growth by 8.1%. Demand for joining technology from Chinese automotive manufacturers in particular increased compared with the lockdown quarter of the previous year – leading to higher business volumes in the region. By contrast, sales of standard joining technology for water management and industry applications were lower than in the prior year period.

SFS Group reported sales of CHF 1.58 billion (€1.65 billion) for the first half of 2023, along with a renewed strong sales growth of 29.2% – driven by the inclusion of Hoffmann. At CHF 189.9 million, operating profit (EBIT) rose by 16.6% year-on-year.

Whilst SFS Group benefited from opportunities arising from its broad positioning across different end markets and regions, it still felt the impact of challenging regional and global developments. Business in the first half of 2023 clearly reflects this by a mixed performance and effects from de-stocking.

Consolidation effects led to growth of 32.7%, stemming from the inclusion of Hoffmann as of 1st May 2022. Currency effects reduced sales growth by 4.3%. On a like-for-like basis, a slight organic growth of 0.8% was achieved.

Profitability was impacted by a mixture of factors, including uneven capacity utilisation from new programme ‘ramp ups’ and partially increased cost basis. The Distribution & Logistics segment developed positively and contributed significantly to the increase in operating profit.

To guarantee a strong customer focus and better leverage cross-selling potentials, as well as both operational and application oriented synergies, the current Automotive and

Industrial divisions are being complemented with the respective end market specific business areas of the Riveting division. This change will be implemented within the organisation as of 1 st January 2024. The growth and profitability targets of the EC and FS segments will remain unchanged.

Looking forward, SFS Group has updated its outlook on the 2023 financial year and expects sales of between CHF 3.1 billion and CHF 3.3 billion, including the first time consolidation of Hoffmann for the full year. This corresponds to an expected sales growth on a like-for-like basis along the mid-term guidance of 3% – 6%. For the SFS Group as a whole, an EBIT margin of around 12% is expected, at the lower end of the mid-term guidance of 12% – 15%. The outlook is based on the assumption that there will be no significant deterioration in the underlying economic conditions or geopolitical, energy or pandemic related restrictions.

Thanks to a warehouse of products so vast that it could go around the moon twice, we are able to push ourselves far away from home, reaching more than 50 countries in the world.

THE GROWTH OF OUR WAREHOUSES IS COMPLETE Find out more on... ambrovit.it/en/x2

After 10 years with the company, working alongside her father Stefan Bülte, Fanny Bülte has officially taken over the reins of Bülte Group.

Bülte Group has been a family business since it was founded in 1956 by Norbert Bülte –who, after 8 years’ experience in the polyamide parts industry, decided to set-up his own assembly parts and fasteners company, with offices in Lüdinghausen, in north Rhine-Westphalia, Germany.

In collaboration with companies in the sector, and specialists, Norbert Bülte invented the Bülte polyamide safety/sealing washer. In 1979, he was joined by his son, Stefan Bülte, who contributed to the company’s international development and set up Bülte Plastiques in France in 1986.

In 2013, Fanny Bülte, granddaughter of the founder and daughter of the CEO, joined the family business and modernised its working and marketing methods. In particular, Fanny was behind the digitisation of processes and the communication strategy.

Now the head of the company, following her father’s retirement, Fanny Bülte is determined to preserve the family heritage and perpetuate the values and expertise that have been the company’s strength for almost 70 years. The company will also continue to preserve its culture of customer proximity, thanks to its team of international experts.

Fanny concludes: “We will continue the family culture of the company, while remaining attentive to the environmental and social challenges of production, such as the climate emergency; the rational consumption of raw materials; the decarbonisation of the industry; and the need for more responsible management and governance.”

www.bulte.com

Hilti Group has recently announced its intent to acquire 4PS Group, which specialises in providing business management (ERP) solutions for the construction industry. Through this acquisition, Hilti hopes to expand its software portfolio and help drive the digital transformation of the construction industry.

Founded in 2000 in the Netherlands, 4PS is a leading player in its domestic market and has expanded its presence to include the UK, Belgium and Germany. With over 70,000 daily users in the building construction, civil engineering and installation sectors, 4PS has gained a strong reputation. With this acquisition, the 4PS solution will allow Hilti to expand its software offering beyond the ON!Track and Fieldwire solutions already available in the company’s portfolio.

Both parties have signed the acquisition agreements, subject to approval by oversight authorities. Hilti states it is committed to retaining the more than 350 existing team members, including management, in their current roles, where they will continue to develop new solutions. The shareholders of the company, Wim Jansen, André Overeem, and Martin Westerink, will remain on the board of directors to support the integration in the coming years.

“As a company that closely works with customers, and with a focus on supporting the digital transformation of the construction industry, 4PS Group is a perfect fit for Hilti. We also share the conviction that there is enormous productivity potential for construction companies in optimised business processes,” explains Thomas Hillbrand, member of the Hilti executive board. “Construction projects are complex and administrative tasks take up a large amount of time. All the more reason for us to digitalise processes and make information easily and quickly available.”

“We are looking forward to joining forces with Hilti,” says Johan Bakker, director sales & marketing at 4PS Group. “Like Hilti, we understand our customers’ challenges and offer direct advice and support in implementing our innovative software solutions. It is an important next step to be able to take a leading role in the European market.”

“Our customers, partners and employees will benefit from this acquisition. By integrating our services and Cloud solutions into Hilti’s portfolio, we can together fully focus on becoming the trusted digitalisation partner for the construction industry,” adds Paula Middelkoop, director product & development at 4PS Group.

Bulten Group has reported net sales amounted to SEK 1.41 billion (€118.4 million) for Q2 of 2023, an increase of 40.8% on the same period the previous year (Q2 of 2022: SEK 1.006 billion). Adjusted operating earnings totalled SEK 58 million, equating to an adjusted operating margin of 4%.

Bulten highlights that its operating earnings have been charged with transaction costs of SEK 8 million –attributable to the acquisition of Exim & Mfr Holdings Pte Ltd (for more read page 16). The corresponding quarter of the previous year was adjusted by approximately SEK 10 million, related to winding-up costs for Bulten’s operation in Russia.

“Demand has been strong over the past quarter. High sales volumes combined with the product mix, however, forced extraordinary measures that had a negative impact on operating profit. Shortly after the end of the quarter we signed an agreement to acquire Singapore-based Exim, which will provide a good platform for Bulten to grow in new sectors,” reported Anders Nyström, president and CEO at Bulten Group.

PEM® Europe, a leading provider of self-clinching fasteners and precision engineered components, has announced a new distribution partnership with Rivit Srl, which will enable the Italian distributor to offer PEM® Europe’s range of self-clinching fasteners and Haeger ® insertion presses to its customers throughout Italy.

Mary Ann Fleming, president at PEM® Europe, commented: “We are excited to announce Rivit as an authorised distributor and bring our range of PEM® self-clinching fasteners and Haeger ® machines to a wider audience throughout Europe.”

Gerard Quaid, vice-president of sales and marketing EMEA at PEM® Europe, added: “Rivit’s extensive experience in the distribution of fasteners and industrial supplies, combined with our precision engineered products, will provide customers with the fastening solutions they need to succeed.”

PEM® self-clinching fasteners provide a reliable and cost-effective solution for attaching components to thin sheets of metal and other materials, including PC boards. They are widely used in the automotive electronics, consumer electronics, medical, and telecom industries. Haeger ® insertion presses provide automated and high-speed insertion of PEM® fasteners, making them ideal for high volume production environments.

“We are thrilled to partner with PEM® and offer their range of self-clinching fasteners and Haeger ® insertion presses to our customers,” said Francesco Montanari, assistant director at Rivit (pictured). “We believe that this partnership will enhance our offering and help us better serve our customers’ needs.”

Rivit has been serving the European market for over 40 years and is committed to offering its customers the best products and services. It believes this partnership with PEM® Europe reinforces that commitment and ensures the company continues providing customers with a reliable and efficient solution for their fastening needs.

Bulten Group has announced that the acquisition of Exim & Mfr Holdings Pte Ltd has been completed. Closing of the transaction follows the announcement in July that Bulten had signed an agreement to acquire Exim for a purchase sum of approximately SG$66.3 million (€45.3 million) on a cash-free and debt-free basis.

Established in 1982 and based in Singapore, Exim distributes fasteners and other c-parts, along with related services from more than 1,800 manufacturers and suppliers for American, European, Indian and Japanese companies operating in Asia. The company has more than 1,000 customers in a range of sectors including telecom, electronics, energy, medical technology, aviation, and other industrial manufacturing. Exim has approximately 140 employees in Singapore, India, Indonesia, Malaysia, Thailand, the Philippines, and Vietnam, and annual sales of about SG$40 million.

“I am delighted that we now have completed the acquisition of Exim. It is an important milestone as we are now broadening our business within the distribution chain and thereby creating future opportunities for us to grow within new customer groups,” commented Anders Nyström, president and CEO of Bulten Group.

Felix Lian, newly appointed managing director of Exim, will be responsible for leading and developing the company further.

Italian industrial clamp and cabling solutions innovator, Clamp Srl, is celebrating its 40 th anniversary after four decades of excellence in the European industrial clamp market.

Clamp Srl has made remarkable strides during this time in manufacturing and engineering, earning a well deserved reputation for quality and reliability, innovation and craftsmanship.

“Since our 1983 inception, we have been at the forefront of technological advancements, consistently pushing boundaries and revolutionising various sectors,” stated the company proudly. “From precision engineering to sophisticated manufacturing processes, we have displayed our expertise across diverse industries, including automotive, aerospace and energy. By consistently embracing innovative technologies and fostering a culture of creativity, we have not only stayed relevant, but have thrived as a leader in a competitive market.”

One of the cornerstones of Clamp Srl’s success has been its unwavering commitment to delivering superior quality products and exceptional customer service. Throughout its 40 year journey, it has prioritised customer satisfaction, tailoring its solutions to meet specific requirements. This customer-centric approach has cultivated strong relationships with clients throughout Italy and Europe.

“As we celebrate our remarkable 40 year milestone, the team is setting its sights on the future with confidence. Together with Tridon Europe and Ideal Tridon Group, we remain dedicated to innovation, service and continuing to exceed customer expectations,” concluded Clamp Srl.

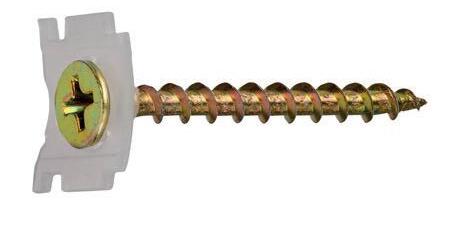

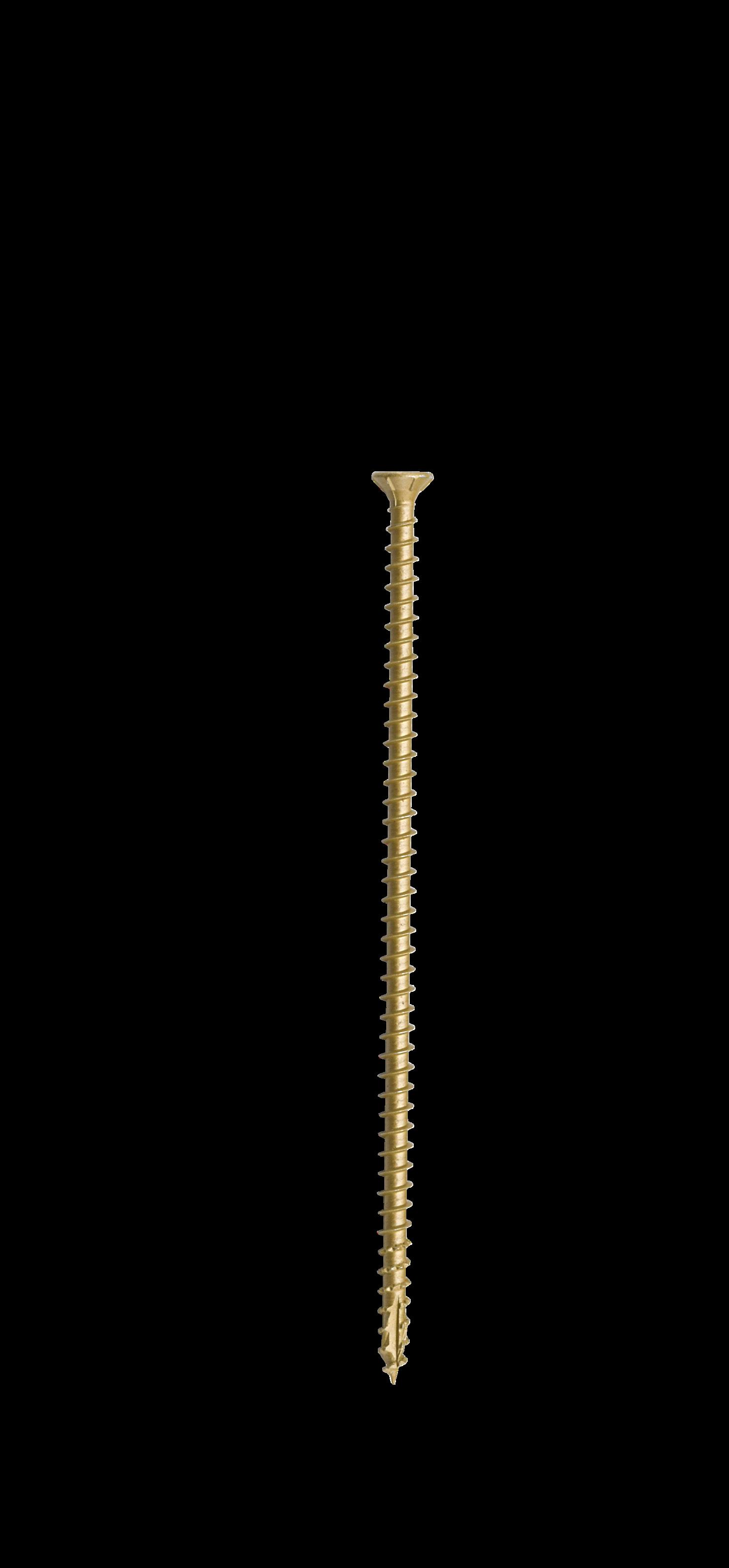

Bugle Head Fine Thread Black Phosphate

Diameters: 3.5-4.8mm

Lengths: 25-100mm

Bugle Head Fine Thread BZP

Diameters: 3.5-4.2mm

Lengths: 25-75mm

Bugle Head Coarse Thread Black Phosphate

Diameters: 3.5-4.8mm

Lengths: 32-50mm

Bugle Head Self-Drilling ZYP

Diameters: 3.5-4.2mm

Lengths: 25-75mm

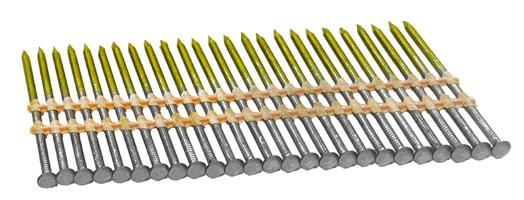

Collated Bugle Head Fine Thread Black Phosphate

Diameters: 3.5-3.9mm

Lengths: 25-55mm

Collated Bugle Head

Coarse Thread ZYP

Diameters: 3.9mm

Lengths: 38mm

Wafer Head BZP

Diameters: 4.2mm

Lengths: 14mm

Bugle Head Fine Thread ZYP

Diameters: 3.5-4.2mm

Lengths: 25-75mm

Bugle Head Self-Drilling BZP

Diameters: 3.5-4.2mm

Lengths: 25-75mm

Collated Bugle Head Coarse Thread Black Phosphate

Diameters: 3.5-4.2mm

Lengths: 25-75mm

Collated Bugle Head Fine Thread BZP

Diameters: 3.5mm

Lengths: 25-55mm

Wafer Head ZYP

Diameters: 4.2mm

Lengths: 14mm

Collated Bugle Head Fine Self-Drilling BZP

Diameters: 3.5mm

Lengths: 35-45mm

Wafer Head Self-Drilling BZP

Diameters: 4.2mm

Lengths: 13mm

Wafer Head Self-Drilling ZYP

Diameters: 4.2mm

Lengths: 13mm

Berner Group has carried out a survey of over 1,227 decision makers within the wood, stone, metal processing and installation technology sectors in a cross-nation barometer, which shows that whilst the outlook for the building trade is certainly not brilliant at the moment, many companies are not dissatisfied with the business year to date.

Thomas Eikel, head of segment management construction at BERNER Group, explains: The start to 2023 has been solid and has cooled off less dramatically for most trades than was feared in the second half of 2022.” Due to the generally challenging framework conditions, including shortage of skilled workers, interest rate increases, and persistent inflation, 10% of construction professional who were surveyed in 2022 had assumed that business would be ‘worse’ or even ‘significantly worse’ in the first of half of 2023. In fact, only 5% have now confirmed that this has come true, where more than 15% of professionals said that business was better than expected.

In the country ranking, Italy in particular stood out. “The mood of Italian companies is still at a high-level compared to other European countries,” points out Thomas Eikel. This is mainly due to the fact that order books are shrinking, as is the case everywhere, but are still full as a result of the Italian government’s ‘super bonus’ subsidy programme. “Despite many uncertainties, just 5% of the Italian companies, and thus fewer than in any other of the markets we surveyed, expected their order situation to deteriorate in the first half of the year. With the exception of the installation sector and metalworking trades, the reality then looked even better in the end,” highlights Thomas. More than 25% of the respondents said that their business had developed more positively than expected in the first half of the year.

“In Germany and Austria, there are significantly fewer orders coming in and people are drawing on their existing stock,” reports Thomas. “However, around 10% of construction professionals predicted the first half of the year to be significantly weaker than they assess it from today’s perspective. The situation in both markets is basically similar. However, if we carry out a more detailed analysis of the data, quite interesting deviations are discernible. In contrast to Germany, construction professionals in Austria were very cautiously optimistic.”

Differentiated according to trades, the following picture also emerges for the construction industry:

Wood: In the last sector barometer in the second half of 2022, around 11% of companies with a focus on wood (window construction, carpenters, joiners, roofers) expected a weaker

order situation in the first half of 2023. In the current survey, by contrast, only 6% now said this had occurred. 13% said that their order situation had developed more positively than in the previous period. The front runner is Italy, where 23% of the corresponding companies said that their business was better. Stone: In the last sector barometer in the second half of 2022, around 9% of companies with a focus on building construction expected a weaker order situation in the first half of 2023. In the current survey, on the other hand, only 5% now said this had occurred. More than 16% said that their order situation had developed more positively. The pole position here also goes to Italy (30%).

Metal: In the last sector barometer in the second half of 2022, around 10% of companies with a focus on metal (metal construction and SHK/installation technology) expected a weaker order situation in the first half of 2023. In the current survey, on the other hand, only 5% of respondents now said this had occurred. More than 16% said that their order situation had developed more positively. Italy and France share the top position; in both countries, more than 20% of the respective companies confirmed a better business trend.

The question of how business will develop in the coming six months is assessed differently depending on the country and the trade. “We do not see a uniform picture here,” says Thomas. “There are many fluctuations in the sentiment index, which are influenced by a wide variety of factors – both positive and negative. For example, the trades that contribute directly or indirectly to the energy efficient refurbishment of buildings and climate change are currently the drivers of a more confident outlook, whilst the stone building contractors tend to be more pessimistic because they are particularly attached to new construction and are also feeling the cooled demand before everyone else.”

He concludes: “In total, the future expectations of companies in the European building trade are about 4 percentage points lower than in 2021, the Covid-19 catch up year in the sector. With the exception of June, which showed a downward trend in all countries and trades, construction professionals were at least somewhat more optimistic than they were six months ago.”

US-based Martin Fastening Solutions has announced the sudden and unexpected passing of its executive vice-president of fastening solutions – Marc Strandquist.

Aseasoned global executive leader, Marc brought to Martin more than 35 years of valuable experience in the C-class component industry, overseeing companies across Europe, South America and North America.

In his illustrious career, he held executive positions for over 24 years, driving value for parent organisations, from smaller entities with annual sales of US$40 million to US$50 million to industry giants such as Würth Industry North America and Optimas Solutions – with sales of US$850 million and US$650 million respectively.

Marc had recently joined the Martin family in January 2023, operating out of the Jackson, TN, location. “In the short time he was with us,” said Douglas Ruggles, co-CEO at Martin Fastening Solutions, “his impact was significant, enhancing the strategy and operations of our Fastening Solutions division. His passion, dedication and invaluable insights will be deeply missed by both colleagues at Martin and professionals in the broader fastening industry.”

Located in Barcelona, Spain, Proton Fasteners is a company dedicated to the supply of a wide range of products, including high strength bolts and screws – providing quality products with a first-class service.

Proton Fasteners has looked to develop its infrastructure, services/ products, customers and sales area – both nationally and internationally – year-on-year, using the experience and knowledge of its team to grow and continue to meet the needs of its customers.

The company is able to supply a range of products, including hex bolts, structural bolts, nuts, washers, thread rods, studs bolts and screws and pins, which are available in a variety of materials, such as steel (8.8, 10.9 and 12.9), stainless steel (A2 and A4), duplex, super duplex and brass – in sizes from M2 to M80 and in lengths from 4mm to 1,000mm.

“In order to meet the needs of our customers, we have looked to invest in expanding our product range, with recent additions including structural bolts and hex bolts in Class 10.9,” reports Proton Fasteners. “We always ensure our products are to the relevant DIN and ISO standards, according to the needs of the different sectors, and we only work with factories qualified by our quality department.”

Through its collaborating factories, Proton Fasteners is also able to guarantee the quality of its products and can work with customers in improving projects and providing ideal solutions. “Thanks to our direct personalised customer support, as well as our ability to offer products in all types of materials, we can offer full support to our customers and grow alongside them,” underlines the business.

Due to its recent success, the company has looked to expand its capabilities with further investment in material stock, additional employees and a new warehouse. “Our business plan is to develop our sales across Europe and North America,” states Proton Fasteners. “We have a presence in countries such as in Spain, Portugal, France, and México, and have developed our online store to include different languages – so we can provide an even better service to our international customers.”

www.protonsl.com

Belgian manufacturer of threaded rods, Bodegraven Metaal, has opened a new entity, Bomet UK, in the West Midlands, to supply threaded bar to UK customers in a move to overcome the challenges, beauracracy and costs associated with BREXIT’s impact on its business.

The Belgian company had a previous UK production unit in Willenhall, which it closed in 2007. “Since BREXIT, transport costs to the UK have risen enormously,” states Bodegraven Metaal. “Due to the extra import and export charges, but also due to the disappearance of many transporters who, because of known start-up problems, chose not to ship to the UK anymore.”

Due to these challenges, Bodegraven Metaal decided to set up Bomet UK and ship its threaded rods (DIN976-1), which are 60° thread angle, directly to the UK subsidiary – meaning that customers can now buy their studding from an English supplier, saving them a lot of time and cost.

“Bomet UK was actually opened earlier this year, but is now ready to meet the sector’s demands from its new branch in the West Midlands,” explains Bodegraven Metaal. “We have also invested in new cutting machines in Belgium, which means that special lengths can be delivered quickly and inexpensively to the company’s warehouse in Birmingham.”

Bomet UK works together with Paul Ponsonby Warehouse, located on the M6 north of Birmingham, to handle orders.

Jergens Inc, a US-based global manufacturer of workholding, lifting, and specialty fasteners, has appointed a new commercial business director for Europe, Spencer Wills, as the company looks to further expand its customer base and support in the UK and Europe.

Although Jergens, with its headquarters in Cleveland, Ohio, has had a strong reputation in Europe for many years, this is the first time the company has employed directly in the UK and within proximity to the EU. The initiative has two aims, the first to develop and expand a distribution network for workholding solutions, specialty fasteners and lifting solution product groups – with a focus on high-level competencies and experience within target market sectors. The second, to increase support for major OEMSs and end users within the aerospace, defence, motorsport, marine, oil and gas, as well as general industry sectors – where high-quality and strict standards, such as ISO 9001:2015 and AS9100, are requirements.

Scott Halfhill, international director at Jergens, said: “It’s a necessary and strategic move for further growth and support, and one that we have been exploring for several months.” He added that Wills had the experience, both technically and commercially, to establish Jergens in the European market. For his part, Wills said, of the company’s UK and European customer base, that: “As we have customer relationships here, we feel it is a must to have a local presence – with technical and commercial support and available products – within the EU to meet growing needs.”

The FIN Fastener Stock Index (FINdex) continued to improve in the second quarter of 2023, rising 6.1% compared to a 5.2% increase by an index of related industrial stocks.

Double-digit gains were widespread among fastener businesses in Q2 despite an uneven economic performance that caused share value declines for four FINdex companies.

Park-Ohio Holding Corporation achieved the highest percentage gain during Q2, rising 58.3% during the period after recording a 1.2% stock value decline in the opening quarter of the year.

Other FINdex companies achieving stock increases of 10% or more during Q2 included Carpenter Technology (up 25.4%), Grainger (up 14.3%), Howmet Aerospace (up 17%), MSC Industrial (up 13.1%), Simpson Manufacturing (up 26.3%) and Stanley Black and Decker (up 16.3%). FINdex companies losing share value during Q2 included Chicago Rivet (down 13.4%),

Dorman Products (down 8.6%), Tree Island Steel (down 1.9%) and TriMas Corporation (down 1.3%).

During the first six months of 2023, the FINdex grew 24.2%, more than doubling gains by an index of related industrial stocks. Three FINdex companies achieved 50% or more in share increases during the period.

Simpson Manufacturing topped the list with a 56.2% gain in stock price during the period, followed by Park Ohio (up 55.3%) and Carpenter Technology (up 52%).

FINdex companies losing share value during the first half of 2023 included Chicago Rivet (down 10%), Dorman Products (down 2.5%) and TriMas Corporation (down 0.09%).

The FINdex rebounded in the opening quarter of 2023, jumping 17.2% after losing 11.5% of its value during 2022.

ITW reported revenue rose 2% to US$4.1 billion (€3.79 billion) in the second quarter of 2023, boosted by 3% organic revenue growth and dragged down by divestitures. Operating income grew 9% to a record US$1.01 billion, while operating margin improved 170 basis points to 24.8%.

CEO E. Scott Santi stated: “Organic growth was three percent, as resilient demand in many of ITW’s industrial end markets was partially offset by inventory reduction efforts by our end customers and channel partners in response to stabilizing supply chain performance, which we estimate to have impacted organic growth by 1% to 1.5% in the quarter.”

He added: “While customer and channel inventory normalization will continue to be a factor for the next several quarters, we expect stable underlying demand and continued strong margin and profitability performance through the balance of the year.”

Automotive OEM revenue, including fasteners, increased 16.2% to US$826 million in Q2, with operating income of US$139 million and operating margin of 16.8%. Six month Automotive OEM revenue totaled US$1.62 billion, with operating income of US$267 million and operating margin of 16.4%.

Construction Products revenue, including fasteners, declined 6.8% to US$526 million in Q2, with operating income of US$154 million and operating margin of 29.3%. Six month Construction Products revenue totaled US$1.05 billion, with operating income of US$299 million and operating margin of 28.4%.

Blue Ribbon Fastener (BRF) has implemented a new wireless warehouse system that integrates with the company’s proprietary warehouse picking processes to maximize productivity and reduce costs.

Located in Shandong Province, the 1.6 million square foot factory – complete with automated production workshops and an 86,000 square foot smart warehouse –will manufacture products for the electronics, automotive, medical, equipment manufacturing and aerospace industries.

By introducing the new wireless warehouse system, the Skokie, IL-based full service distributor gets ever closer to creating a fully digitized Class-C component distribution workflow.

“Today’s buyers expect a fully digitized experience when ordering fasteners,” said Ben Lussier, vice-president at Blue Ribbon Fastener. “This new system allows for more efficient

inventory management, a paperless picking process, and reduced possibility of human error. It’s a win-win operational upgrade that will help us keep costs down as we grow, and pass savings on to our customers.”

Built by Computer Insights Inc, the wireless warehouse system digitizes warehouse picking by combining barcode technology, wireless networking and handheld wireless scanners.

Founded in 1985, BRF supplies fasteners and hardware to North American OEMs out of Chicago.

BlueRibbonFastener.com

Fastenal Co has entered into a scrap supply agreement with composite decking manufacturer Trex to repurpose plastic into outdoor building products. The entire portfolio of Trex composite decking is made from 95% recycled and reclaimed materials, including a mix of polyethylene (PE) film and industrial wood scrap.

Through the partnership, Fastenal is collecting used PE film in its distribution centers, branches, and onsite locations, and shipping it to Trex. PE film (known as pallet wrap) is used by Fastenal and its suppliers to secure boxes and other packaging to pallets for shipment. “Pallet wrap is vital to our daily operations, but once the product is unwrapped, we have no use for it,” says Dave Olson, director of EHS & sustainability for Fastenal. “Working with Trex to turn all that potential waste into sustainable outdoor building products is a win for both organizations.”

To support the program, Fastenal has invested more than US$300,000 (€277,480) in equipment and infrastructure in its US distribution centers to efficiently bale and consolidate used PE film for recycling by Trex. In the first year of the program, Fastenal expects to divert an estimated 600,000 pounds (272,155kg) of plastic from landfills – through material collected within its distribution centers (where a high volume of pallet wrap is received as part of inbound shipments from suppliers).

In addition, more than 2,500 US Fastenal branches and on-site locations can participate by using Fastenal’s regular truck routes to back-haul used material to the nearest distribution center for baling, consolidation and shipment to Trex.

Each year, Winchester, VA-based Trex repurposes in excess of one billion pounds of reclaimed materials, including approximately 400 million pounds of plastic film – making it one of the largest recyclers of PE film in North America.

Howmet Aerospace reported Fastening Systems revenue rose 19% to US$329 million (€304.3 million) in the second quarter of 2023, boosted by growth in the commercial aerospace, defense aerospace, industrial and commercial transportation markets.

Fastening Systems adjusted EBITDA gained 14% to US$64 million on volume. Segment adjusted EBITDA margin decreased approximately 70 basis points to 19.5%. During Q2, the fastener segment added approximately 215 net headcount and approximately 430 net headcount in the first half 2023. Fastening Systems’ capital expenditures during the quarter dropped 44% to US$5 million from the previous quarter.

Consolidated Howmet Aerospace Q2 revenue rose 18% to US$1.65 billion, driven by a 23% jump in commercial aerospace. Net income improved 31% to US$93 million.

“The outlook for Howmet Aerospace continues to be strong and supported by the extraordinary backlog of commercial aircraft orders at Airbus and Boeing,” states CEO John Plant. “Our key defense aerospace and industrial end markets continue to be solid, while the commercial transportation end market remains healthy.”

Headquartered in Pittsburgh, Howmet Aerospace’s primary businesses focus on jet engine components, aerospace fastening systems and titanium structural parts for aerospace and defense applications, as well as forged wheels for commercial transportation.

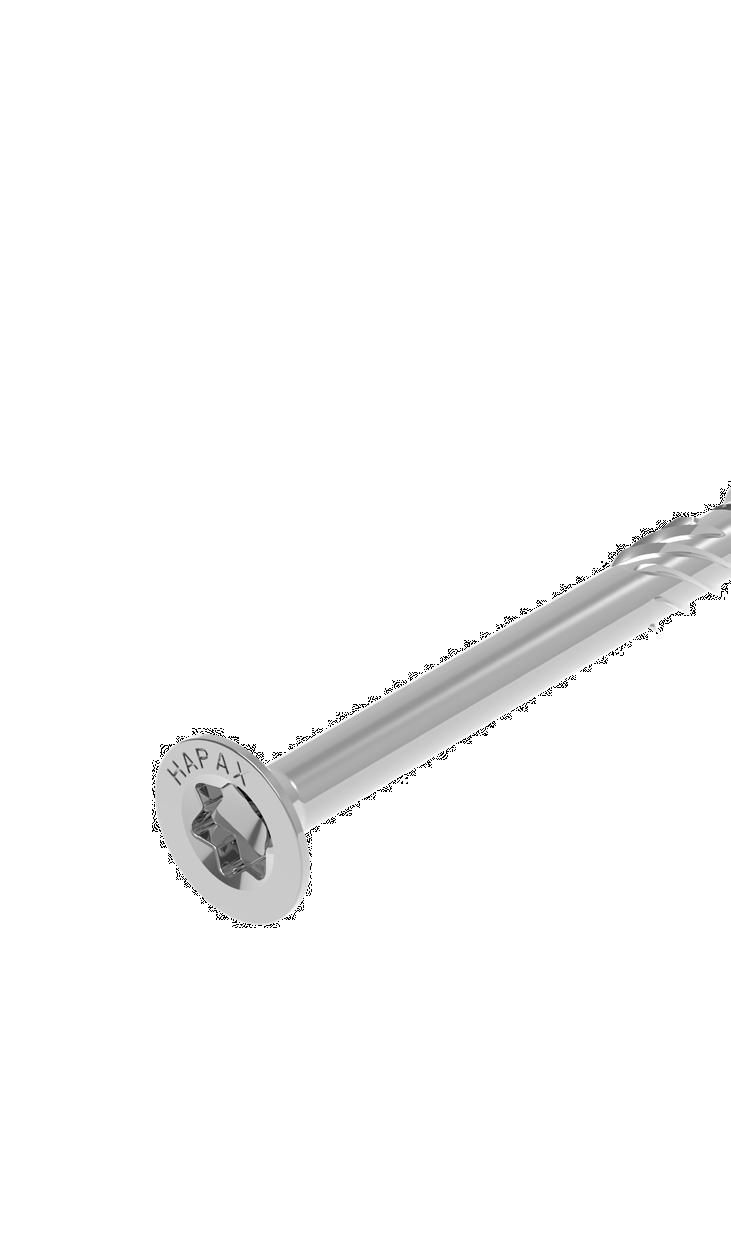

In a monumental stride towards excellence, Schmid Schrauben has achieved a significant milestone by receiving ICC certification for its RAPID line of screws.

This certification not only solidifies Schmid Schrauben’s position as one of the industry’s leaders but also underlines its unwavering commitment to quality, innovation and safety in the world of construction and woodworking. For over a century, Schmid Schrauben has been at the forefront of driving innovation in timber screw technology. From its humble origins rooted in traditional craftsmanship to its present day state of the art manufacturing facilities, the company has consistently pushed the boundaries of what is possible in fastener solutions. The ICC certification serves as a testament to Schmid Schrauben’s relentless pursuit of excellence and its dedication to meeting the highest standards of performance and reliability.

With ICC certification in hand, Schmid Schrauben has positioned itself well for the boom of timber construction in North America that it says is beginning to take shape. “The certification serves as a symbol of our commitment to advancing the construction and woodworking industries through innovative and reliable fastener solutions,” states Schmid Schrauben. “Whether it’s a towering skyscraper, a resilient wooden bridge, or a finely crafted piece of furniture, Schmid Schrauben’s ICC certified screws will continue to play a pivotal role in shaping the landscape of modern construction.”

Fastener World Magazine has compiled the revenues and growth of major Taiwanese fastener companies and published the following table of results:

With the war between Russia and Ukraine still ongoing, and the fastener industry in Taiwan having hit relatively low levels in terms of orders received during the same timeframe, Taiwanese business owners have become very concerned about future wire rod prices, as well as global market developments.

With such concerns in mind, leaders from these businesses converged in early June on the large port of Kaohsiung for a conference with Taiwan CSC (China Steel Corporation), the nation’s largest steel mill.

In terms of statistics on wire rod, the conference highlighted that in the first four months of 2023, Taiwan’s imports of high, medium and low carbon steel fell significantly in weight by 41%, 34% and 19%, respectively. In the same period, Taiwan imported the largest proportion of wire rods from Indonesia, accounting for 48%, followed by South Korea and Vietnam, each accounting for 17%. The main types of steel imported were low carbon steel and alloy steel, accounting for 50% and 35%, respectively.

In terms of fastener prices, Taiwan’s exports of screws, bolts and nuts in the first four months of 2023 amounted to 440,000 tonnes, down 25% year-on-year, with an average unit price of US$3.88 per kilogram, up 4.4%. In the same period, Taiwan’s top five export destinations for these products were the USA, Germany, the Netherlands, Japan, and Canada, of which only the weight of exports to the Netherlands had slight growth, while exports to the other four countries had a more than 20% decrease.

Taiwan’s export weight and price of several fastener types Jan – Apr of 2023 (Source: TIFI)

Taiwan’s export weight of screws, bolts and nuts Jan – Apr of 2023 (Source: TIFI)

Taiwan CSC explained that the decline in the number of orders from overseas is due to the global macro-environment. Fastener inventory in overseas countries remains high and thus the demand for Taiwanese fasteners has decreased. Taiwan CSC suggested focusing on energy saving and carbon reduction activities while there are less orders. This sentiment was echoed by the chairman of the Taiwan Industrial Fasteners Institute, Mr Tu-Chin Tsai, with a message to business owners that the EU carbon tax will soon affect the fastener industry in Taiwan, so it is time to prepare in order to be able to receive orders when the tide of carbon tax sweeps in.

Ming Tang (Weng Yang) Machinery, a Taiwanese specialist manufacturer of bolt parts formers, has been at the forefront of R&D in its sector for nearly 45 years and is committed to improving machine stability and operational efficiency – with its latest development a centrifugal feeder to replace the conventional vibration feeders.

Ming Tang explains that conventional vibration feeders using vibratory/vibrating plates are prone to many problems, including the noise they emit and potential damage to product surfaces. However, by using centrifugal alignment for the feeder it can significantly reduce noise, as well as prevent the coatings from peeling off the feeder and/or damage to the plating layer.

Ming Tang’s centrifugal device is made of stainless steel, which is highly resistant to wear and rust and is durable, having been coated with 10mm thick PU oil. The design of the

by Abhijat Sanghvi, president,centrifugal structure also includes a removable inner tray, which can be easily removed by maintenance personnel to clean up chips and oil stains, saving time and effort.

Ming Tang points out that its centrifugal feeder consumes just one tenth of the power compared to a conventional vibratory plate; is suitable for long screws; and its feed speed can be adjusted via a frequency converter. The company is continuously improving and upgrading its centrifugal feeders and expects to launch larger and more powerful models in the future.

AssociationThe Indian Government has implemented mandatory quality norms for nuts, bolts, and fasteners, to elevate local manufacturing and shield consumers from sub-par goods.

The Department for Promotion of Industry and Internal Trade (DPIIT) issued a notification on 21 st July, announcing the ‘Bolts, Nuts and Fasteners (Quality Control) Order, 2023’. This order places a firm requirement: ‘Unless they bear the Bureau of Indian Standards (BIS) mark, these products can’t be manufactured, sold, traded, imported, or even stocked, and non-compliance with BIS certification is no light matter; it could mean imprisonment and hefty fines’.

The Quality Control Order 2023 is set to be effective six months from the date of publication of the notification and aims to fortify India’s quality ecosystem; prioritise consumer health and safety; and stimulate the growth of domestic micro and small industries. The order accommodates certain relaxations to ensure a smooth transition and uphold the ease of doing business in the country. Exemptions have been granted for domestically manufactured goods meant for export; items imported as part of finished products or components; and imports by domestic manufacturers for producing goods intended for export.

Sundram Fasteners Ltd has displayed a remarkable performance, outperforming the Nifty50 index with a striking 47% year-on-year return. Analysts are now pointing towards a potential 10% – 22% upside for the stock, supported by a consensus view from most brokerages.

Producing a diverse range of critical components, including fasteners, powertrain components, and more, the company boasts a well-rounded revenue mix of domestic OEMs, aftermarket, and exports, at 52%, 13%, and 35%, respectively.

With a positive outlook from both technical and fundamental viewpoints, the momentum for Sundram Fasteners stock seems to be riding high, capturing the attention of investors and analysts alike.

Indian aerospace suppliers are poised to benefit from a surge in orders for jets placed by major carriers Air India and IndiGo, boosting domestic parts manufacturing and aircraft repairs.

The increasing air traffic; efforts to diversify sourcing away from China; and substantial orders for almost 1,000 jets; have solidified India’s significance in the aerospace market.

Small and medium suppliers are attempting to capitalise on the demand for locally supplied parts, but they urge that the government provides more help to boost manufacturing.

The expansion of India’s civil aviation industry is predicted to boost maintenance and overhaul activity. Deloitte expects the industry to grow from US$1.7 billion in 2021 to US$4 billion in 2031. While the civil aviation ministry acknowledges the positive impact of these orders on aerospace manufacturing, local production requirements cannot be mandated as they are in defense deals.

The growing fleet of aircraft in India underscores the need for enhanced maintenance services, prompting suppliers to seek proximity to customers. Indian companies like PTC Industries aim to meet global demand for alternate sources of Russian made titanium and Chinese production.

SUNCO will run a booth at IFE in October.

Booth No. is 1876.

Metalurgica FEY S.A, a leading Brazilian fastener manufacturer, has reinforced its market positioning and adopted a new visual identity through a branding innovation.

One of the most important fastener manufacturers in South America, and a global international fastener supplier, the FEY portfolio of products includes bolts, screws, nuts, and similar items, which are provided to industries such as agricultural and road machineries, as well as the automotive sector.

FEY has an annual revenue of R$500 million, 8% of which come from exports, and has a production capacity of 3,200 tonnes per month – with more than 750 employees. In addition to the already consolidated portfolio, it also develops tailor-made projects, especially for customers such as large car manufacturers and agricultural equipment. FEY is also present in the distribution area, in the aftermarket and other sales channels.

Now almost totally under management of the second family generation, and with a focus on the future – especially its overseas operations, the company announced in July the conclusion of a branding process. “The new branding process was not just about updating the company’s visual identity. It was about going beyond this and translating what we believe, and the steps we are going to take to help the business move forward,” explained Bruno Maia, marketing and new business manager at FEY. “This means

seeking solutions together, through both cold and hot forming processes, to achieve formidable results. The brand adaptability, with a presence already in several countries, means we are able to achieve the Portguese slogan: ‘Dando forma ao que o mundo precisa’, which translates as ‘shaping what the world needs’.”

The branding reinforcement work is part of a series of investments that FEY has been carrying out over the last four years, which add up to more than R$80 million (€15 million) and includes areas of technology and people preparation.

Another area that the company intends to strengthen in its market positioning are the three factors that

mark its performance – sustainable development, innovation movement and strength of the brand.

For sustainable development, FEY is already a partner of the UN (United Nations Organisation) and signatory of the ODS Movement (Sustainable Development Goals). When it comes to its innovation movement, the company is reinforced with development and its own laboratory, which enables it to create products and verticalised production. Finally, the strength of the brand is characterised by being a family business, reinforced by a complement of professional leaders, investment in technology and sustainable growth.

After finishing the first half of 2023, Brazilian exports and imports of fasteners – bolts, screws, nuts and other types of fasteners –have fallen in both value and volume when compared to the same period in 2022.

First

For H1 of 2023 the export value of fasteners was US$86.33 million, down 3% when compared to the US$89.05 million in 2022. Export volumes were also down 24.17% with 15,110 tonnes of fasteners exported in H1 2023, compared to 19,929 tonnes in 2022. When it comes to imports for the first half of the year, the value of fastener imports reached US$498.21 million, which is 2.88% down on the US$513 million achieved in 2022. However, this could partly be down to the fall of the US dollar against the Brazilian Real.

The Brazilian fastener industry is hoping for things to improve within the second half of the year, especially with a probably drop in interest rate from the Banco Central do Brasil (the Brazilian Central Bank), which is currently at 13.65%.

SERVICING YOUR GLOBAL NEEDS WIDE STOCK AVAILABLE ENGINEERING SUPPORT DELIVERED ON TIME

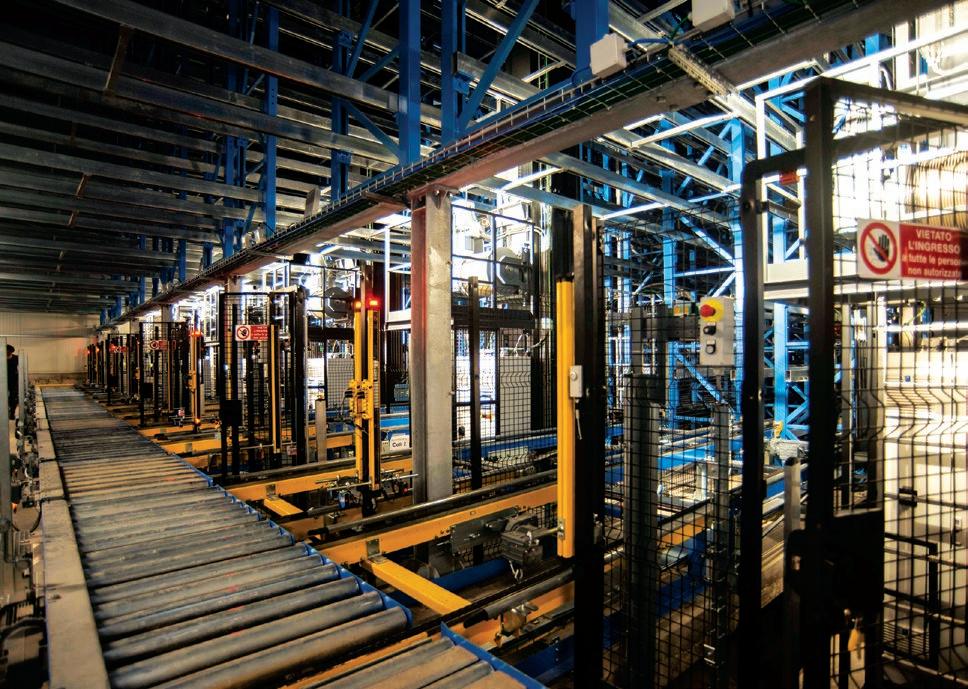

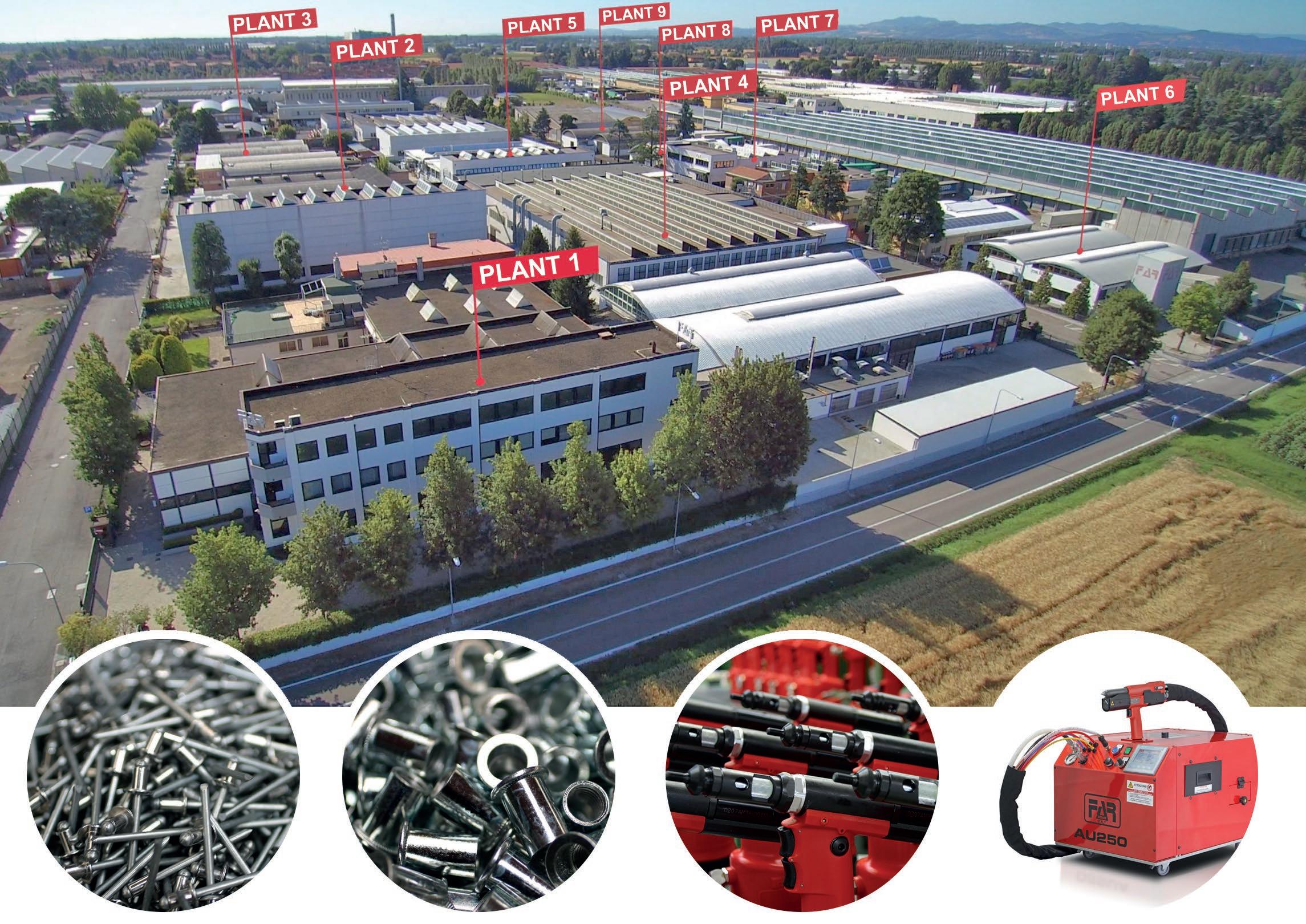

At Ambrovit, the future is already here, thanks to the company’s latest investments in quality, logistics and service. All distinctive features that differentiate Ambrovit from its competitors in Italy and Europe – with the investment including the doubling of its automated warehouse.

Founded in 1997 by the initiative of two entrepreneurs from the fastener industry, Ambrovit SpA has become a leader in fastening systems and the ideal partner for both industry and distribution. The recent doubling of the warehouse enables the company to further raise the bar of efficiency in the supply chain, as well as in the management of large volumes of products – whilst also reducing waiting

times and consequently improving the operational efficiency of its customers.

Today, Ambrovit’s automated warehouses in Garlasco occupy a total area of 24,000m 2 and boast numbers that speak for themselves. The new warehouse is 104 meters long, 40 meters wide, and 28 meters high, and is interconnected to the existing warehouse thanks to a 26 meter long connecting bridge, which guarantees maximum integration in the handling of products.

The company has completed the enhancement of the fully automated warehouse, which doubles the storage capacity and offer in fixings.”

“Thanks to the investment in the new automated warehouse, and the doubling of our storage capabilities, we are able to focus on new markets and new segments in the world of fasteners,” emphasises Mattia Sozzè, quality manager at Ambrovit.

Through this investment, Ambrovit has been able to significantly grow its storage capacity, with an increase that, including automatic warehouses, as well as operational and logistics units, is close to 100,000 pallet places – guaranteeing prompt delivery in 24/48 hours. “As a business we currently ship approximately 2,500 tonnes every month, whilst being able to increasingly meet customer needs,” highlights Mattia.

The logistics centre is a fully automated facility, managed by 16 stacker cranes for the storage and monitoring of palletised products. This results in picking activities, and operational flows, also increasing to new levels. “Ambrovit is a young company

that pays great attention to future projects, in particular technological evolution,” continues Mattia. “Thanks to the original foresight of the business to include logistics in a fully automated environment, we have been able to continue on this path of efficiency and improvement of automation processes,

and the new warehouse is another significant step forward.”

Mattia continues: “Quickly-achieved, operational excellence goals, which will push the company towards a path of renewed visibility, will be revealed in the coming months.”

www.ambrovit.it

Thanks to this latest development, Ambrovit intends to focus on new markets and new segments in the world of fasteners to respond to new customer target markets.”

Bossard Group is a company steeped in history and has established itself as a global leader within fastening technology. Here we speak to CEO Daniel Bossard about how the business is able to work with its customers to provide the optimal fastening solutions and services.

Bossard is known for its ability to work in partnership with its customers – providing bespoke answers to meet specialised requirements. Why has Bossard decided to take this solution-orientated approach and how does it work in practice?

“Our aim is to reduce the total cost of ownership for our customers. To do this, our engineers work with customers’ R&D departments to design the optimal products and assortments. In addition, our Smart Factory Logistics system enables us to partner with customers to set-up the most optimal, predominately automatic, C-parts management systems. By combining all of this into one service we can typically save customers between 30% and 40% of their total assembly costs.

At Bossard we do not look to stock commodity fasteners and provide standard services. Instead, we supply customised solutions and offer savings through our engineering and logistics capabilities. By doing this, we create stronger relationships with customers, we add more value and we help them reduce total costs.

A prime example is one of our key customers in the railway industry, for whom we are a strategic development partner and have set-up numerous Smart Factory Logistics systems in their global plants. Recently, we were even invited to be part of the set-up for a new plant in Johannesburg, South Africa. We were able to support them in planning the layout for C-parts management flow throughout the factory, which again helped them save considerable total costs, as well as optimise the entire production process.

This is just one example of how we can collaborate with customers, not just by providing products but supporting them

on selecting the correct products and the most enhanced logistics set-up. To do this, rather than speaking to a buyer, who is going to rightly be focused on getting the lowest price possible, we talk to managers, logistics, production, and engineering, and focus on the holistic point of view, by concentrating on total costs and finding the best solution to meet the requirements – whether it is an innovative or smart product. By doing this more and more, we can create longer lasting partnerships and add real value to customers. Our experience and knowledge in this type of service enables us to stand out from competitors and truly add value and step away from the low cost commodity product side of the business.”

What is Bossard’s current business strategy? What targets has the Group set for itself? How do you see the geographic and industry specific markets growing in the future?

“We have set a target for 2031, which is when Bossard will turn 200 years old, to bring proven productivity and

At Bossard we do not look to stock commodity fasteners and provide standard services. Instead, we supply customised solutions and offer savings through our engineering and logistics capabilities.”

HEICO-TEC®

Tensioning Systems

The best value to secure and tighten bolted joints WWW.HEICO-GROUP.COM

HEICO-LOCK®

Wedge Locking Systems

The approved system for bolt securing

Easy, fast and reliable assembly of large bolted joints

sustainability to every assembly operation in the world. Now that sounds a bit bold, but it’s what we are aiming to do. In numbers, this means growing sales organically 5% year-on-year, at an EBIT margin of 12% – 15% in the medium term – following a phase of increased investments.

To do this, we have four fields of strategic initiatives that will help us to achieve our targets. The first is a cultural transformation, which in essence means less hierarchy and more empowerment and coaching. Plus, the notion of how we attract new talent and retain these people, as well as how we apply more modern management technology.

The next initiative is sales transformation, where we want to move towards more digital lead generation instead of traditional outside sales pitches. This will involve looking more at digital content management and marketing. We will also look to align global sales roles within the sales verticals, which will allow us to have more leads and a higher pipe line conversion.

The third aspect is operational excellence, for instance we are introducing a new ERP system right now, Microsoft Dynamics 365, which will make us more efficient at every site across the globe. Finally, sustainability is the last initiative, where we will work on carbon neutrality on the environmental side. These are the four major fields of strategic initiatives we will be following. Of course, there are sub-initiatives as well that we will carry out to achieve the overall target by 2031.

During this period, we know there will be ‘ups’ and ‘downs’ within markets up to 2031, but this is our ambition, and we shall stick to the targets we have set. For instance, we had a decent first half of 2023 with a slight global sales growth, but we have already started to see economic weakening looking at the current PMIs. However, even in these potentially challenging times, there are always opportunities – especially in what we call the ‘sunrise industries’, such as the EV segment, renewable energy, healthcare, automation and robotics, as well as aerospace – which continues to be a growing segment.

Geographically, we still see a huge potential in the US market. Our market share in the USA is currently single digits and we see opportunities, particularly in the EV market, but also in electronics, and aerospace, to grow this even further. Within Europe, it is predominately eastern Europe where we see opportunities, such as Poland, which we believe is a great potential market for us to grow. In Asia, it is India that is benefitting a lot from the ‘China Plus One’ policy that many of our customers apply. We see numerous companies moving out of China into India. There is also a lot of railway business in India, as well as infrastructure and energy opportunities. Personally, I also think the Chinese market will also come back strongly. We still have a low

just invested into a new warehouse in Tianjin and we believe ‘China for China’ will be important in the future.

At Bossard we can take advantage of any geographic opportunities that arise thanks to the global structure of the business, which is organised by regions – America, Asia-Pacific and two European regions – with each offering the full range of products and service portfolio. For key verticals like electric vehicles, railway, healthcare, robotics, and aerospace, we have also installed global focus groups. This means we have global leaders for each vertical and they coordinate the activities within this sector around the globe, including regular meetings to discuss trends and developments, etc. In total, Bossard is represented in 32 countries and in 82 locations.”

“Our key investments have been opening new facilities in target markets, so we can continue to grow our market share around the world. For instance, roughly three years ago, with China in the ‘booming’ phase, we said it was important to be present in that market, so we could grow. We therefore invested in China – including the new warehouse in Tianjin, which I have already mentioned.

We have also invested in Taiwan, where we just opened a new facility in June, as we could see there was a lot of growth potential within ‘sunrise’ (growth) industries, as well. Our business in Taiwan has already grown double digits over the last couple of years, which is unusual as Taiwan is so well known for its fastener manufacturers, but business has been booming and with the new facility it will hopefully continue to grow.

We have also invested in a new facility in France, just one year ago, again because we want to grow in Europe and we see the potential in the market – with an estimated addressable market share in France of currently only 8%.

In fact, the only big market shares we have are Switzerland, at about 34%, and Denmark at 20%. The others are all single digit market shares, so wherever we see growth potential, we will look at the practicalities of investing in new facilities and people.

If we are to reach our strategic target for 2031 then we need to continue to invest in infrastructure, as well as continue our acquisition strategy – with a third of our growth ambition proposed to come through acquisitions. It is important to note that our acquisition strategy is to become better not

just bigger, which is why we typically look to acquire companies with a good profitability, as well as what new technologies and values they can add to Bossard Group.

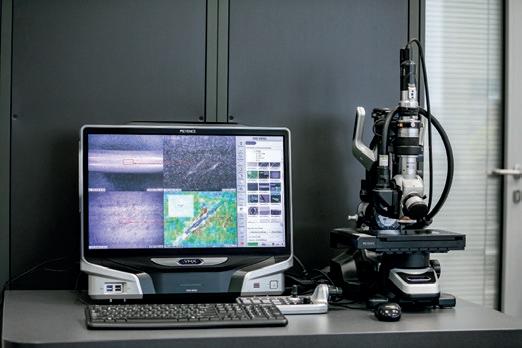

We are also always looking at what is next and how we can help customers to become more efficient, which is why we have been investing in our Smart Factory Assembly system – the next step in the logistics chain that ensures optimal process control in manual assembly.

Through the Smart Factory Assembly system, we help customers through electronic work instructions that guide them step by step through each part of the process in question – what to do; what tool to use; the tightening torque required; which operator is installing the product, etc. If at any point something is done incorrectly, the system will alert the user. This helps create standardised workflows and creates maximum transparency and traceability of production processes. It also underlines to the customer that at Bossard it is not just about providing the right products, in the right qualities, and right place, it is about making sure the entire process, including the assembly and logistics, is completed to the highest standards and requirements.”

“There are different aspects when it comes to sustainability, firstly there is the environmental aspect, where we have already collected our global CO 2 footprint for each location, which we carried out in 2022. This covers Scope 1 and Scope 2, which is about our own internal usage – heating, cars, electricity, etc. We did this and now we have visibility on where and how we are using energy.

Currently, we are in the final stages of defining what our carbon zero target will be for the next 10 years and the key milestones on that path. We are also working on fulfilling all the governance criteria, which involves a lot of different aspects, such as CBAM, as well as various other standards. In fact, we have recently appointed two additional staff members who will be

responsible for collating and inputting all the data required when it comes to the governance of sustainability.

Besides governance criteria, we are also looking to be a preferred supplier with our customers when it comes to sustainability. We are therefore looking at things such as sustainable products and how we can help customers become more sustainable. For instance, if there’s a product or service we could provide that would help them with the disassembly of products for recycling.

The other aspect of sustainability is social. Whilst most companies tend to just look at the environmental aspect, the social side also has value. That is why we have defined inclusion and diversity targets to remain and become even more attractive to employees. These topics get talked a lot about by companies, and sometimes it is just talk, but at Bossard we believe it is a fundamental part of the business. We have been around for 190 years and have always looked after our employees and we will continue to do so in the future.

We are committed to sustainability in all forms and have produced a sustainability report where we show both employees and customers what we are doing from both an environmental and social point of view. Last year we also received an EcoVadis bronze medal for the work we have done so far, and we are working towards achieving a silver medal to show we are on the right path going forward.”

Through the Smart Factory Assembly system, we help customers through electronic work instructions that guide them step by step through each part of the process in question…”

TR VIC (Viterie Italia Centrale SpA) has been manufacturing fasteners in Fossato Umbria for over 50 years and is one of the most renowned manufacturers in Italy – with a history of product development and innovative design capability.

From its Italian site, TR VIC manufactures products for many well known global brands and distributes the products to multiple customer locations across four continents – becoming recognised for male threaded cold forged products, specifically to customer drawings, and in the development of products to enhance production assembly methods.

TR Fastenings, the parent company of TR VIC, was historically known as being a provider of fasteners to the electronics and tech industries and over the last 15 years its focus has diversified into the automotive sector – becoming a key supplier to tier 1 companies. To retain a balanced customer spread, TR Fastenings also focused on the health and home sector, which encompassed domestic appliances, and was already supplying this sector to a smaller degree before the acquisition of VIC gave it a much larger market share.

Another important reason for the acquisition of TR VIC, was the advantage of having a manufacturing facility in ‘middle Europe’ that could meet the needs for faster prototyping and shorten lead times compared to Asia supply. TR already had five manufacturing sites in Singapore, Malaysia, and Taiwan, and this acquisition significantly increased its manufacturing capability and footprint.

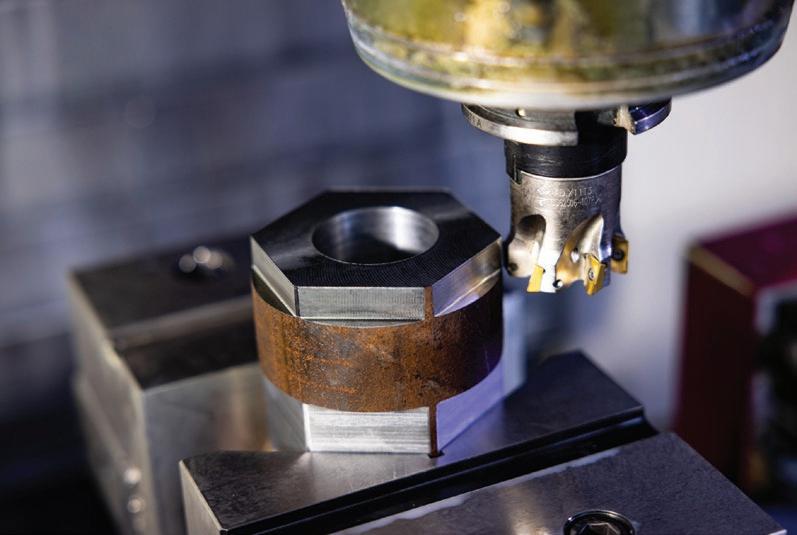

Inevitably, existing customers showed an interest in having a TR manufacturer in Europe and when TR VIC gained the IATF16949 accreditation it opened up further opportunities. TR VIC management also embarked upon an investment program that included a state of the art heat treatment plant; new automatic packaging machines; and the upgrading of machinery and facilities. This culminated in a recent £5 million (€5.8million) investment to increase TR VIC’s manufacturing footprint by 30%,

See TR’s latest investment in its manufacturing

by adding new forging, thread rolling and pointing machines. This included the addition of 6-die 6-blow machines from Carlo Salvi and SACMA Group, which has increased the diameter range TR VIC is able to produce. The growing portfolio of machinery also increases TR VIC’s capacity, especially for more complex applications within the sectors that it services.

Investments to the manufacturing location; a focus on environmental improvements; and a major facelift of the offices; has ensured that TR VIC is seen as a modern facility that is appealing to a discerning customer base. Additionally, the company has developed further warehouse capacity capable of holding 12,000 pallets. Plus, investment in training, initiated by Stefano Pisoni, managing director of TR VIC, has developed into a formal training academy, which has become key to recruitment and staff retention – with the headcount since acquisition almost doubling.

Investments to the manufacturing location, a focus on environmental improvements, and a major facelift of the offices, has ensured that TR VIC is seen as a modern facility that is appealing to a discerning customer base.”

strain on the team at TR VIC, but they met the challenge. This significant increase in demand was driven by people working from home during lockdowns, investing in new appliances, lifestyle products and making home improvements. This societal transformation meets with a rapid deployment of new technology to improve quality of life, from fresh ground coffee machines to clean air products and personal grooming, all of which have rich fastener content.

Another fundamental aspect of TR VIC’s success has been innovation, with the company winning several design awards, including the TR EPW screw for thin sheet metal, which picked up the Route to Fastener Innovation 2019 award at the Fastener Fair Global show. The transit fasteners for washing machines and tumble driers were also a design success some years ago –reducing four components to a combined recyclable component, which is still in high demand.

Another aspect is meeting the needs of the market, such as the new European legislation ‘Right to Repair’ which came into force

last year. This is already changing assembly methods as there is a move away from welded products to fasteners that can allow for disassembly. TR VIC is working with global brands who are focused on returning to core conventional fastener methods. Sven Brehler, engineering director at TR Fastenings, comments: “This is a very positive development that has been years in the making. While this is primarily about giving control back to the consumer, this is also a very strong environmental improvement case. It will significantly reduce appliances destined for landfill, which can now be repaired 1 .”

Another example would be a high volume part for an automotive lighting cluster assembly – where TR VIC produces 60 million pieces a year. The current part features a neoprene washer under the head of the screw to prevent water ingress. However, TR VIC has designed in a special screw, which it has patented, that has a unique feature under the head that negates the need for the washer. This has improved the integrity of the product, time to manufacture and has given a cost and recyclable environmental benefit to the customer.