CONNECTING THE GLOBAL FASTENER INDUSTRY In this issue… Puehl –We shape the future Heading + forging Electrical + electronics PUEHL_OFFICIAL PUEHL WWW.PUEHL.DE VISIT US – FASTENER FAIR GLOBAL – HALL:1 STAND:622 FOLLOW US Issue 140: March 2023 | fastenerandfixing.com

OUR PACKAGE IS ATTRACTIVE

GERMANY | UNITED KINGDOM | PORTUGAL | CHINA www.fastbolt.com

NO MATTER HOW YOU LOOK AT IT

A PERFECT

FIXING FOR YOUR BUSINESS Stand 912 HALL1

www.colombofasteners.com your fasteners specialist

THE FASTENER'S CHOICE V I A L D A V I N C I 4 4 5 2 4 0 4 0 B A R B A T A ( B G ) - I T A L Y + 3 9 0 3 6 3 9 1 4 4 2 4 - 9 1 4 9 5 9 - 9 1 4 9 5 6 W E B M A S T E R @ I N O X D A D I C O M V E N D I T E @ I N O X D A D I C O M W W W I N O X D A D I C O M A309 A310 A314 ASTM ASME BRASS ALUMINIUM COPPER INCONEL HASTELLOY INCOLOY DUPLEX SUPER DUPLEX MONEL 400 500K A904L 1.4539 1.4529 NIMONIC 2.4952 A286 1.4980 GR.660 FASTENER FAIR GLOBAL STUTTGART HALL 1 - STAND 646 TITANIUM NYLON SILICON BRONZE STAINLESS STEEL 1.4571 1.4541 1.4923

WE BELIEVE IN THE CAPABILITIES OF OUR EMPLOYEES TO SET HIGHEST STANDARDS AND TAKE OUR CUSTOMER-ORIENTED PERFORMANCE TO A NEW LEVEL THROUGH DIGITALIZATION AND TECHNOLOGY.

PUEHL A FAMILY BUSINESS 4.0

PUEHL_OFFICIAL PUEHL WWW.PUEHL.DE VISIT US – FASTENER FAIR GLOBAL – HALL:1 STAND:622 FOLLOW US

NEWS 14-36 Financial reports, acquisitions and trade duty news COVER STORY 38-41 Puehl – We shape the future INSIGHT 42-70 With confidence in the nickel market so low, what’s next? Bontempi targets sales growth This is SARIV EXHIBITION NEWS 72-76 CONSTRUCTION FIXINGS 78-110 Circular economy and the European industry Structural steel + cladding fasteners MANUFACTURING TECHNOLOGY 112-135 Inventing machines is what SACMA does Technology in cold forming Shaping the fastener industry TESTING 136-140 Are your fasteners hard enough? MANAGEMENT + SYSTEMS 142-156 Remote work is here to stay Making fastener supply chains more resilient APPLICATION TECHNOLOGY 158-174 Tiny fixing key to fusion power Electrical + electronics PRODUCTS + TOOLS 176-196 The advantages of stainless steel fasteners Dispelling ten myths about cyanoacrylate adhesives 38 42 78 176 112 142 CONTENTS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 10

THE BEST ANCHOR MANUFACTURER IN ASIA NINGBO LONDEX INDUSTRIAL CO, LTD First Seashore Road / Hangzhou Bay New Zone Cixi City / Zhejiang Province 315336 - CHINA T. +86 574 63079222 F. +86 574 63079228 londex@ningbolondex.com 100% INTEGRATED PRODUCTION DROP-IN ANCHOR ZINC PLATED Assessed ZINC PLATED Assessed LIP ZINC PLATED ATLANTIS COATING NEW Assessed SHORT ZINC PLATED NEW Assessed STAINLESS STEEL A4 NEW ETA NON STRUCTURAL FIXINGS ETA STRUCTURAL FIXINGS IN UNCRACKED CONCRETE Assessed LIP STAINLESS STEEL A4 NEW FIRERESISTANCE HEXAGONAL ZINC PLATED HEXAGONAL ATLANTIS COATING COUNTERSUNK ATLANTIS COATING* PANHEAD ATLANTIS COATING* LOW PANHEAD ATLANTIS COATING* HANGER FEMALE ZINC PLATED HANGER MALE ZINC PLATED SCREW ANCHORS ASSESSMENTS AVAILABLE FOR 5 DIFFERENT COATINGS ETA NON STRUCTURAL FIXINGS ETA STRUCTURAL FIXINGS IN CRACKED & UNCRACKED CONCRETE SEISMIC C2&C1 FIRERESISTANCE PROJECTING BOLT ZINC PLATED HEXAGONAL WITHOUT NUT ZINC PLATED ningbolondex.com *Zinc plated version available

EDITOR'S NOTE

Will Lowry, content director, Fastener + Fixing Magazine

Show time!

After four long years since the last show, I am sure Fastener Fair Global will not disappoint and the atmosphere is sure to be electric. The whole Fastener + Fixing team will be at the show and of course our magazine will be on full display – either through the exhibitor stand drop (which I can testify takes a very long time the night before the show), via the Fastener + Fixing Magazine stand (Hall 7, stand 3874) or the multiple media points throughout the four halls of the show.

As visitors, and our loyal readership, will be able to testify, this edition is a ‘big one’ at exactly 200 pages, underlining that when it comes to staying informed on the latest developments across the global fastener industry, Fastener + Fixing Magazine cannot be beaten.

Our Cover Story for this issue is focused on German washer manufacturer Puehl and how the company marked its 125th anniversary, as well as what the next steps will be in its development as a modern forward-looking business.

Within our Insight section we have an abundance of articles on key developments within the fastener sector and at individual companies. Firstly, Gary Peters, director at The Metals Warehouse, discusses why confidence in the nickel market is so low, and what might happen next for this commodity. Next up, Bontempi Vibo highlights how the restructuring of its sales department, and a new sales strategy, will enable it to continue to grow as a business –

Assistant Editor Rebecca England rebecca.england@verulammedia.com

www.fastenerandfixing.com

Published by

Managing Director Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director Will Lowry will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe

Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

whilst getting even closer to its customers. Another article within the section concentrates on Brazilian manufacturer Continental Parafusos and how it has introduced an investment strategy to upgrade its production machines to continue meeting customers needs around the world.

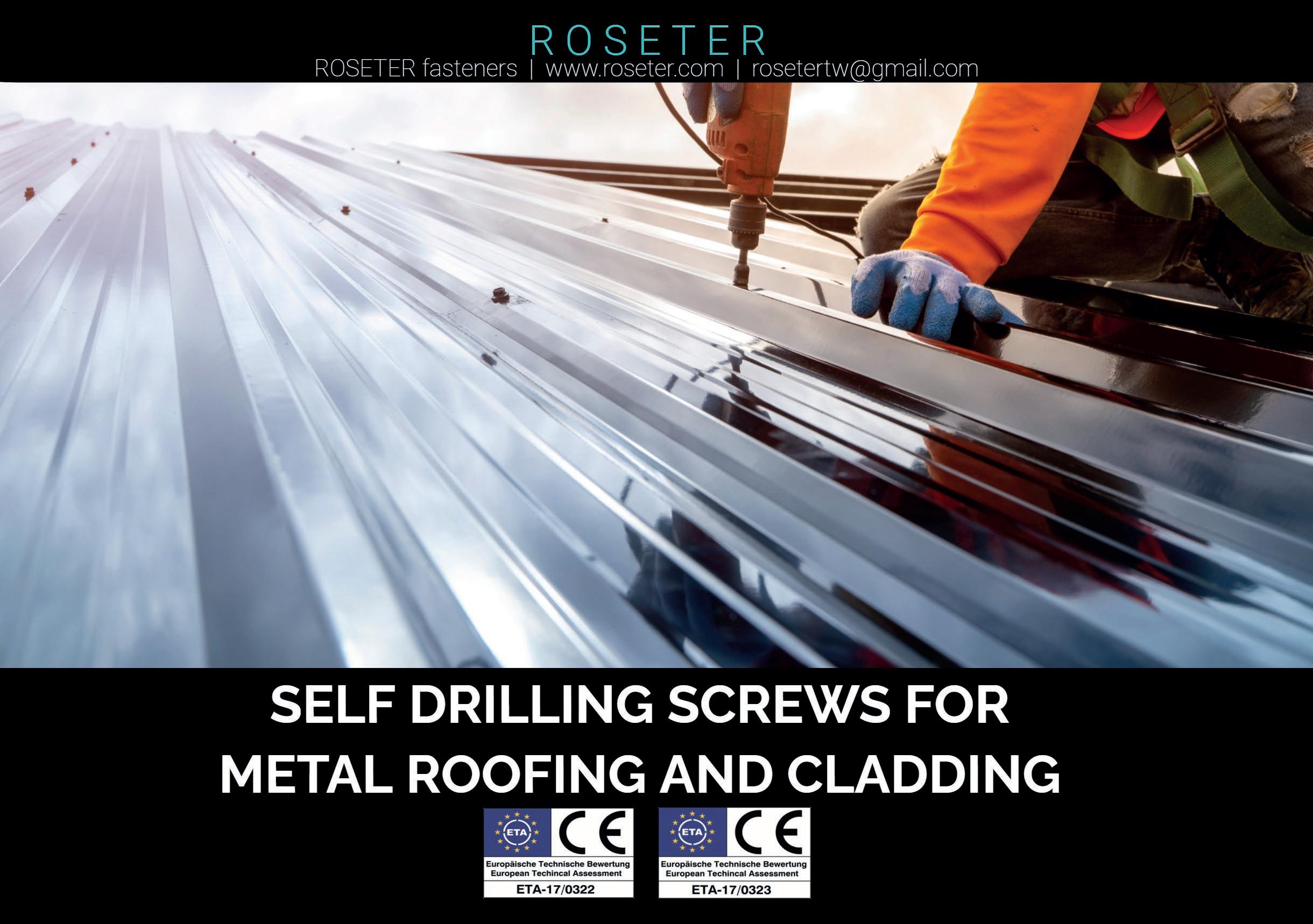

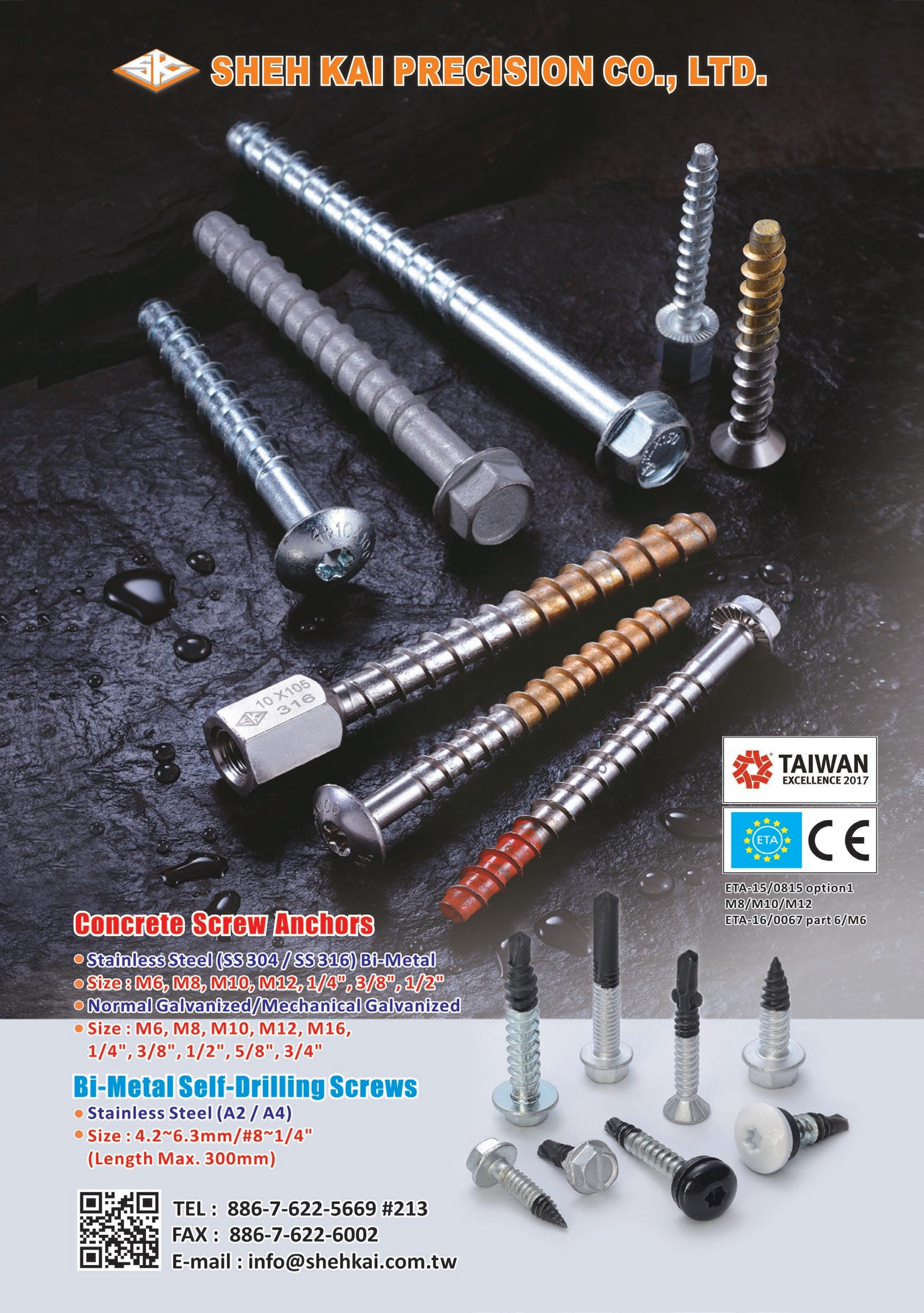

Within our Construction Fixings section, we have excellent pieces from Barbara Sorgato, secretary general at the European Consortium of Anchor Producers (ECAP), who discusses the circular economy and the European industry; as well as Dr Ulrich Bourgund and Thomas Holland-Letz of Construction Fixings Europe, who give the manufacturers’ view on UKCA Marking based on European Technical Assessments. To add to this, there is also a special feature on structural steel and cladding fasteners, with some insightful articles.

The special feature within the Manufacturing Technology section is on heading and forging, for which we have received some excellent content, including SACMA Group and its passion for inventing; Jerry Bupp, vice-president sales and marketing at National Machinery LLC, looks at the use of technology within cold forming; and Carlo Salvi reports on how its wide range of machinery has helped ‘shape’ the fastener industry.

So far, I have only scratched the surface on the huge number of articles and insights included, but I am already running out of space. Therefore, do make sure you go through every page, to make sure you stay better informed.

Fastener + Fixing Magazine is a dedicated, trade–only publication which is circulated freely throughout the European trade.

Disclaimer

The Publisher cannot be held responsible or, in any way, liable for errors or omissions, during input or printing of any material supplied or contained herein although the utmost care is taken to ensure that information contained is accurate and up to date. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or Verulam Media.

Copyright Entire contents copyright © Verulam Media Ltd 2023. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Annual subscription (6 issues) to non–trade and outside EU is €160.00

Verulam Media Limited, Office 121, Ashley Road 134, St Albans AL1 5JR Tel: +44 (0) 1727 743 882

Find us online: Subscribe

For most people, the first time they will see a printed version of this March issue will be at the Fastener Fair Global show – so if you are there and you are reading this, how does it feel to be back?

Part of the Mack Brooks Group

for free at www.fastenerandfixing.com FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 12

MILLIONS OF SCREWS IN STOCK

Fit bolts, plugs, knurled thumb screws, square head bolts, flat headed screws, hexagon set screws, brass screws and specials.

Fon +49 (0)

E-Mail: info@pasvahl.de www.pasvahl.de

40 532 852-0

21. - 23. März 2023 Stand 412 in Halle 1 JAHRE

90

PLUGS according to DIN, 906, 907, 908, 909, 910, 5586, 7604

BREAKING INDUSTRY NEWS AND ANALYSIS

Bossard achieves record financials despite challenging times

In a challenging environment, and despite the impact of the strong Swiss franc, Bossard Group achieved new records in all three of its market regions – with sales in the financial year 2022 amounting to CHF 1.15 billion (€1.15 billion), against the previous year’s CHF 995.1 million, which corresponds to organic growth of 15% in local currency.

All regions performed well in the fourth quarter, when sales increased by 13.3% in local currency to CHF 276.2 million against the previous year’s CHF 250.8 million. The broad-based growth for Bossard, which began in the fourth quarter of 2020, continued in the fourth quarter of 2022. America posted impressive double-digit growth, while in Europe, growth slowed significantly. The situation in Asia was impacted by the lifting of Covid-19 restrictions in China and the resulting wave of infections, although strong global demand only led to a slight improvement of the tense situation on the procurement market.

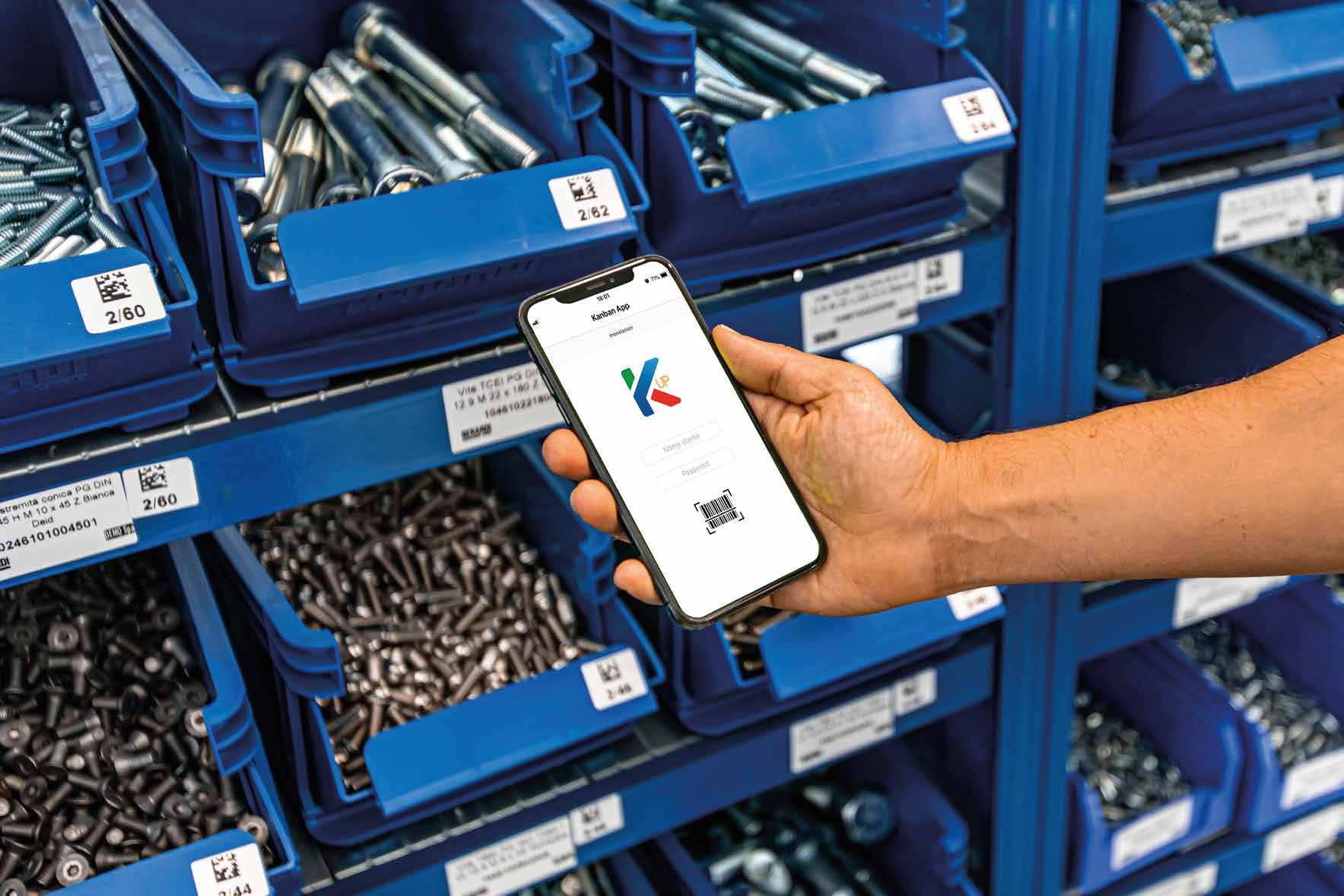

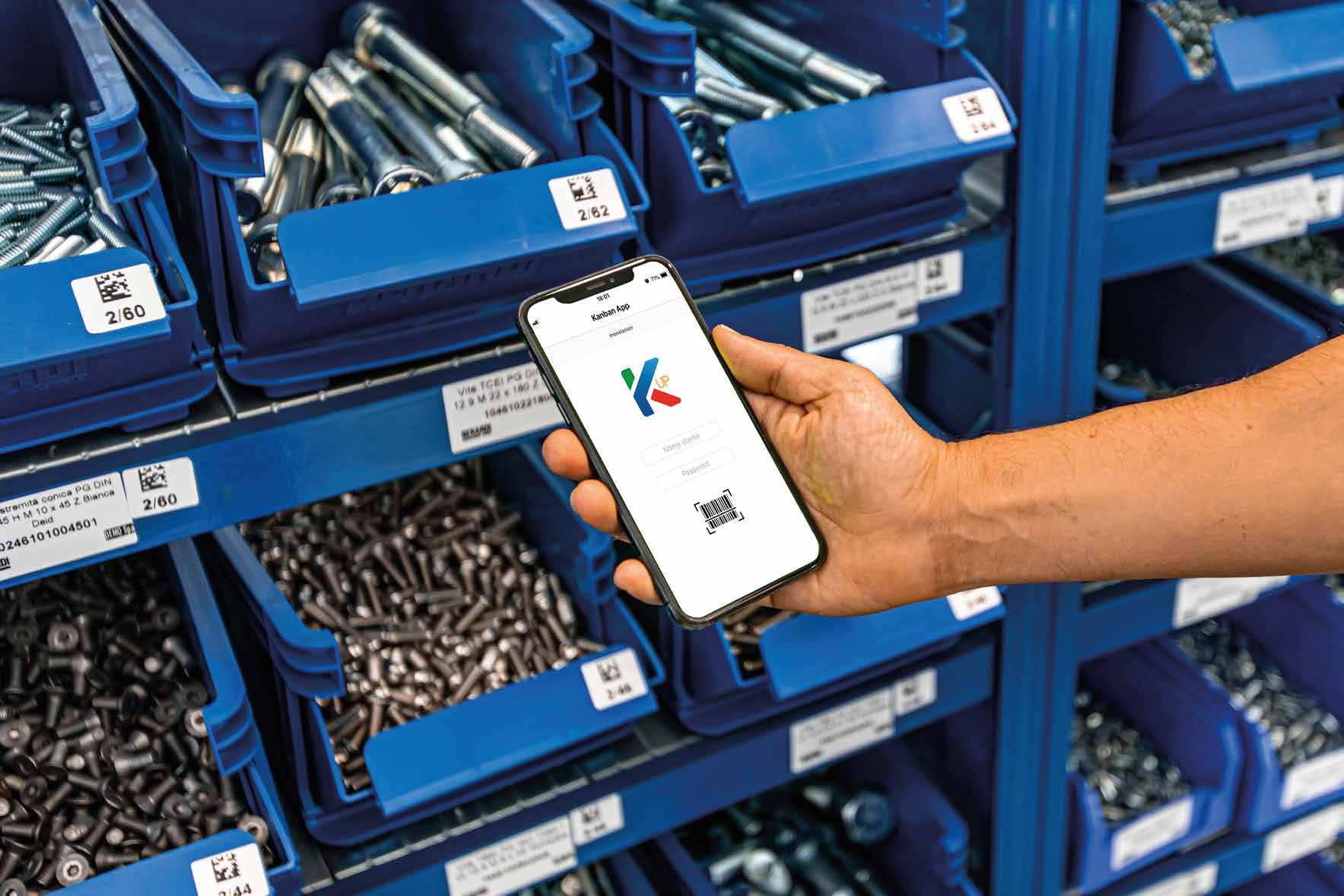

In addition to Bossard’s sustained high delivery capability, the group also experienced a stronger trend toward nearshoring and an increased demand for Smart Factory Assembly (SFA) solutions.

In Europe, Bossard recorded fourth quarter sales growth of 0.8% to CHF 141.2 million (in local currency: +6.1%). Demand remained at a consistently high-level despite continuing geopolitical tensions and their resulting challenges. In an environment marked by inflation and a shortage of skilled labour, Bossard’s smart factory services drew even more attention from customers. However, the strong Swiss franc did slow down growth.

In the final quarter of 2022, sales in America increased by 43.5% to CHF 80.2 million (in local currency: +37.3%). The positive business

development was driven by dynamic economic growth. In the electromobility sector, exciting commercial vehicle projects were implemented. Asia achieved sales in the fourth quarter at a level similar to the previous year (in local currency: +5.4%). After two years of double-digit growth, the high base of the prior year was evident. In December, China’s lifting of Covid-19 restrictions caused a wave of infections, and the resulting production downtime impacted the industrial environment negatively. Although Bossard was able to ensure the best possible delivery capability to its customers, the situation in China continues to cause uncertainty.

SFS realises leap in growth

In the 2022 financial year, SFS Group generated gross sales of CHF 2.746 billion (€2.77 billion), which corresponds to strong growth of 45.1%. Good organic growth was generated in most end markets and regions throughout the year as a whole. The consolidation of Hoffmann in May caused sales at SFS to soar.

Due to the war in Ukraine; sustained disruption in supply chains; further waves of Covid-19; as well as sharply rising energy costs, interest rates, and inflation; considerable uncertainty and high volatility were constant companions during the 2022 financial year. These circumstances notwithstanding, SFS exploited the opportunities that arose and generated good organic growth in most end markets and regions. With the inclusion of Hoffmann, SFS seized the exceptional strategic opportunity to establish a strong international position in the attractive quality tools market and boost sales considerably.

Breakdown of sales by segment

With respect to the segments, the sales trend was broad-based. Development differed between the areas of application within the Engineered Components segment. Overall, sales followed a steady trend over the course of the two half year periods and culminated in good growth of 5.4%.

Driven by the continuing dynamic market environment in the construction industry, the Fastening Systems segment posted another impressive 12.2% increase in sales during the reporting year. The two divisions’ successful market position, and robust supply chains, enabled them to take advantage of steady demand in most areas of application and serve their customers reliably.

The Distribution & Logistics segment set a decisive course to achieve forward-looking development during the 2022 financial year. With the inclusion of Hoffmann, the segment implemented a leap in growth of 212.8%. Both divisions generated attractive organic growth.

FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 14 NEWS

www.achill-fasteners.com QUALITY SINCE 1951 Achilles Seibert GmbH Philipp-Reis-Straße 3 D-24558 Henstedt-Ulzburg THE GLOBAL PARTNER FOR DISTRIBUTORS Tel +49 (0) 41 93 89 55 Fax +49 (0) 41 93 89 56 99 sales@achill-fasteners.com DIN 6921 | ISO 4014 | ISO 4017 | DIN 960 | DIN 961 HEXAGON HEAD DIN 912 | DIN 931 | DIN 933 THE STANDARD DIN 7991 | ISO 10642 | DIN 6912 | DIN 7984 | ISO 7380 -1 & -2 HEXAGON SOCKET HEAD ISO 14579 | ISO 14580 | ISO 14581 | ISO 14583 THREADED SCREWS WITH HEXALOBULAR SOCKET DIN 913/ISO 4026 | DIN 914/ISO 4027 | DIN 915/ISO 4028 | DIN 916/ISO 4029 HEXAGON SOCKET SET SCREWS DIN 7500 Form CE | DIN 7500 Form M THREAD ROLLING SCREWS DIN 7504 Form K | ISO 14585 | ISO 14586 | ISO 15481 | ISO 15482 TAPPING AND DRILLING SCREWS DIN 934 | ISO 4032 | DIN 985 | DIN 980 | ISO 7042 HEXAGON NUTS DIN 125 | ISO 7089 WASHERS ISO 8734 | DIN 7979 Form D PARALLEL PINS VISIT OUR WEBSHOP: SHOP.ACHILL-FASTENERS.COM 21 - 23 March 2023 Booth 412 | Messe Stuttgart | Germany www.fastenerfairglobal.com WE ARE EXHIBITING

2022 strongest sales year in Böllhoff history

Despite multiple challenges in the global environment, Böllhoff Group closed the year 2022 with a new sales record – achieving annual sales of €783 million. Corresponding to an increase of 16.6% over the previous year (2021: €671 million).

Managing Partner Michael W. Böllhoff explains:

“The German economy in general, and the Böllhoff Group in particular, have proven to be extremely resilient in 2022, despite all crises.”

So much so, that for the first time in its history, the family-owned company surpassed the €700 million mark in annual sales. “Overall, we benefited from our position as a strong partner for companies in all sectors and industries – all around the globe,” adds Managing Partner Wilhelm A. Böllhoff.

While demand from the automotive industry continued to be more restrained than before the start of the Covid-19 pandemic, the general industry increasingly relied on joining technology from Böllhoff. Compared to 2021, annual sales with customers from general industry increased by 15% to around €369 million in total. Böllhoff also achieved significant growth in joining solutions for the aerospace sector. Here, sales have more than doubled – from around €10 million in 2021 to €21 million in 2022. “This is where our recent investments are paying off, such as in further production capacities, as well as in specialised manufacturing know-how for the aerospace sector,” empasises Michael W. Böllhoff.

In recent years, the company fully acquired two French manufacturers of special fasteners for the aerospace industry: French-based SNEP SA in June 2021 and Gillis Aerospace from Dieupentale, France, in June 2022.

Broken down by region, Böllhoff grew in all parts of the world in 2022. The strong upward trend of previous years continued, particularly in Asia and in the Americas – across all customer segments. In Asia, sales rose by 23% to €96 million (2021: €78 million). In the Americas, Böllhoff was even able to increase sales by 41% to €108 million (2021: around €77 million).

“We owe the successes of 2022 to the extraordinary commitment, enthusiasm and passion of our employees, even more so as the general conditions were quite challenging due to crises and inflation,” says Wilhelm A. Böllhoff.

Outlook for 2023

Böllhoff is cautiously optimistic for 2023, the order volume is good – especially in Germany and Western Europe. However, crises and inflation are expected to have an impact on the company’s results in future. To what extent yet remains to be seen. “Despite all the uncertainties, we are looking boldly to the future. We are offering suitable solutions for a wide range of customer requirements in different regions and industries,” mentions Michael W. Böllhoff. “We also continuously invest in the further development of our group of companies and in the further training of our employees.”

In 2023, a major investment in employee training is taking shape at the Böllhoff headquarters in Bielefeld, Germany. For the end of the first quarter/beginning of the second quarter, the company plans to start construction for the Böllhoff Education Campus, an open training and further education space for apprentices, students and employees. On approximately 1,600m 2 , this new building will bring together technical workshops, modern rooms for exchange and training, as well as a smart factory laboratory for topics such as networking and robotics. Böllhoff will invest a total of €5 million in this expansion of the company headquarters in Bielefeld. “In 2023, we have been based in Bielefeld for 100 years now,” emphasises Wilhelm A. Böllhoff. “As a family business, we want to make our own contribution to constantly developing the region as a strong business location.”

The company is also investing heavily in its own infrastructure around the globe. Since June 2022, construction work has been underway in Wuxi, China, for what is now the fifth expansion stage of the local Böllhoff site. Almost 12,000m 2 of building space will be added there for Böllhoff’s Thread Technology division. This corresponds to an area of 1.7 football pitches. The grand opening of the modern building complex, with production and office spaces, as well as a staff restaurant, is planned for late summer of 2023.

INDUSTRY NEWS 16 FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023

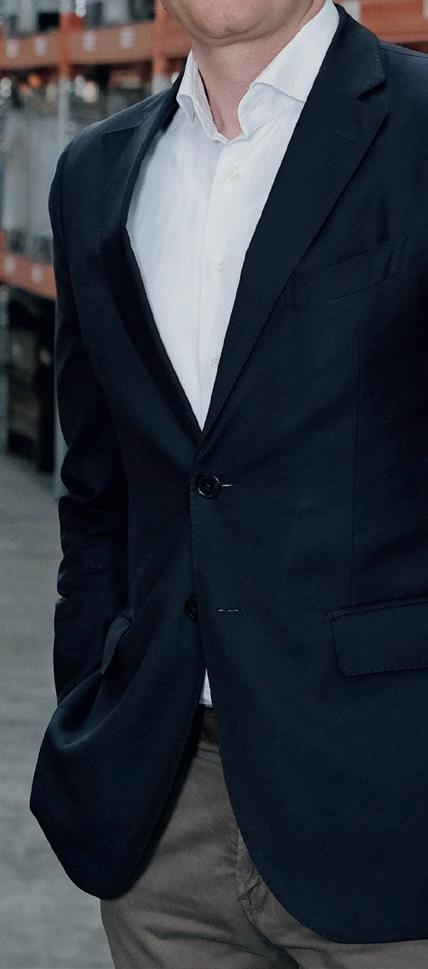

Michael W. Böllhoff and Wilhelm A. Böllhoff, managing partners of Böllhoff Group

THE STABILITY OF BEING QUICK BY NATURE

Our team’s skills plus the efficiency of a fully automated warehouse ensure maximum speed and zero errors.

WEARENOTNUMBERS.IT

NORMA Group reports significant growth

NORMA Group stabilised its business at the end of 2022 in the midst of a challenging environment. According to the preliminary figures, Group sales were up 13.8% year-on-year to €1.243 billion for the financial year 2022 (2021: €1.091 billion).

Positive currency effects, particularly in connection with the US dollar, contributed 6.7% to sales growth. Organically, sales grew by 7.1%. This growth was driven by NORMA Group’s consistent pricing policy in the face of dramatic increases in the cost of materials and intermediate products; a strong final quarter in the European business; and continued robust business with water management products in the USA.

CEO Miguel Ángel López Borrego commented: “The headwinds we faced throughout the past financial year were quite severe at times – drastic increases in the price of materials; uncertainties surrounding energy supplies in Europe; the lengthy and strict Covid-19 measures in China; and production backlogs at some sites. NORMA Group did a good job overall of holding its own

and growing in the face of these multiple obstacles. However, we are not satisfied with the result. We want to expand on the momentum from the decisive spurt we had in the fourth quarter. We will use the weeks and months ahead to focus on previously untapped growth potential in the high margin industrial and water businesses.”

Strong fourth quarter result

According to preliminary figures, sales in the fourth quarter showed significant growth of 17.1% year-on-year to €302.1 million (Q4 2021: €258.1 million). Organically, currency adjusted sales were up 11.3%. At €19.3 million, adjusted EBIT was 7.5% higher than in the prior-year period (Q4 2021: €17.9 million).

Würth Group achieves record results

Würth Group ended the financial year 2022 with record results, according to its preliminary annual financial statements. Annual sales for the year of €19.95 billion were well above the 2021 figure of €17.06 billion, corresponding to growth of 16.9%. Adjusted for currencies, sales grew by 15.1%. The operating result rose from €1.27 billion in 2021 to €1.5 billion in 2022.

Robert Friedmann, chairman of the Würth Group’s central management board, commented: “We are operating in difficult economic and political conditions. The war in Ukraine, material and supply shortages, and price increases, continue to be challenging. I would, therefore, like to thank our more than four million customers, worldwide, for their trust in our services, and our suppliers for their co-operative partnership. At the same time, we can rely on the strength of our corporate culture, the solidarity of all employees and, of course, the support of a family business in times of crisis. This gives us the necessary stability.”

For Würth Group in Germany, sales volumes increased to €7.85 billion compared with 2021’s €6.94 billion. The group’s companies outside Germany generated €12.10 billion compared with 2021’s €10.12 billion. The company’s Electrical Wholesale unit was particularly successful, reporting growth of 25%. Service leadership, a very high level of product availability, combined with

above average logistics expertise, were cited by the group as reasons for this development, as well as the sector benefitting from the renewable energy boom. The Electronics Group – selling passive electronic components, circuit boards and electronic and electromechanical solutions – also showed very strong business development, achieving sales growth of 22.5%. Würth’s Industry Division also reported above average sales growth of 20.1% and E-business sales grew by 21.2% compared to the previous year, accounting for 20.7% of total sales.

Confident for 2023 despite crises

According to the German ifo Institute (the Leibniz Institute for Economic Research at the University of Munich), material shortages in the industrial sector have improved to an extent and bottlenecks are easing in many sectors. Mechanical engineering and the automotive industry, however, remain the sectors most affected by material shortages and in the construction sector projects are

still being cancelled or postponed due to rising construction costs and interest rates. Robert Friedmann concluded by predicting that current challenges will continue to be an issue in 2023, adding: “It remains to be seen how consumer behaviour and energy prices will develop, and what impact China’s relaxed zero Covid-19 policy will have on supply chains. Operating in this fragile, interdependent environment will remain a key challenge in 2023. Despite all crises, we will maintain last year’s momentum and positive spirit, as well as staying optimistic and acting with caution.”

INDUSTRY NEWS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 18

Hall 1, Stand 712

Record sales and rapid changes

Bulten AB has reported record sales for the financial year 2022 with it achieving net sales of SEK 4.47 billion (€404.7 million), an increase of 19.9% on the same period last year (2021: SEK 3.73 billion). Operating earnings (EBIT) totalled SEK 180 million (2021: SEK 232 million), equating to an operating margin of 4%.

Anders Nyström, president and CEO at Bulten AB, commented: ““It is pleasing to see that once again in 2022, as a whole, Bulten achieved the highest ever sales in its almost 150 years in business, and that in Q4 we achieved an operating margin (7.6%) in-line with our financial target for 2024. This is a sign of strength in a time of uncertainty – characterised by inflation and component shortages.”

There were several key developments at Bulten throughout 2022. In January, Bulten signed an FSP (Full Service Provider) contract for a new European vehicle program for an existing customer – with Bulten underlining that its clear sustainability focus was a key factor in winning the contract –worth in the region of SEK 100 million a year at full production. In March, Bulten signed another FSP contract for a new European electric vehicle for an existing customer. The contract is worth in the region of SEK 75 million a year at full production.

In June, Bulten completed the divestment of its Russian operation. The operation was bought by the Russian company CAR SEATS LLC and all shares in the joint venture company previously owned by Bulten and GAZ were redeemed.

In September, Bulten was nominated as a supplier of fasteners for a new global electric car platform, to be produced in China. The order value is estimated at approximately SEK 155 million a year at full production. Also in September, Bulten began a collaboration with Polestar on the development project Polestar 0, which aims to build a climate neutral electric car by 2030 – by eliminating emissions in the supply chain. Bulten’s contribution will be the delivery of climate neutral fasteners.

Bulten increases holding in TensionCam

Bulten AB has also acquired an additional 36.5% of the shares in TensionCam Systems AB at a purchase price of SEK 4 million. The acquisition makes Bulten the majority owner of TensionCam with 63.5% of the company’s shares.

TensionCam specialises in developing sensors for the measurement and monitoring of clamp loads in screw joints and the company has initiated several pilot projects with third parties in areas such as wind turbines, water and sewage, and the process management industry, in which its sensor technology has been integrated to complete screw joints. The aim of these projects is to accelerate development and finalise a concrete customer offering.

Anders Nyström explained: “Pilot projects over the past year using TensionCam’s sensor technology have produced positive results. It is now time to begin industrialisation and commercialisation of the product. This is completely in-line with our strategy to diversify our offering with new, practically applicable technology.”

Emmy Pavlovic, SVP technology and innovation at Bulten, commented that TensionCam has a highly interesting product that’s particularly suitable for installation and monitoring of critical fastener applications, such as large pipe joints and machines that are exposed to various types of stress and strain. “These are the kinds of applications we believe to be of interest, and ones that can bring new business opportunities for Bulten.”

In addition to Bulten, TensionCam is owned by Emergera AB, which holds remaining 36.5% of its shares.

Hilti Group achieves double-digit sales growth

Amid a volatile environment, Hilti Group increased sales by 10% in local currencies in 2022. This resulted in sales of more than CHF 6.3 billion (€6.27 billion) and corresponds to an increase of 6.2% in Swiss francs.

The strongest sales growth, 16.5% in local currencies, was recorded by the Americas region. Europe achieved an increase of 9.6%. In Asia/Pacific, growth was 8.2%, significantly slowed by the impact of Covid-19 restrictions in China. As expected, the war in Ukraine and the corresponding sanctions against Russia resulted in a decline in sales for the Eastern Europe/Middle East/Africa region (-2.3%).

The Swiss franc continued to appreciate against most currencies, the US dollar being one exception. Overall, there was a negative currency effect on sales of 3.8% points.

“The last four months of the 2022 business year remained challenging, but we could nonetheless accelerate growth and were able to close the year with double-digit growth in local currencies. The launch of our new Nuron battery platform in North America and Europe was one important growth driver,” concluded CEO Jahangir Doongaji.

The environment is expected to remain volatile given continued inflation and increasing interest rates; ongoing geopolitical tensions; and a softening economic growth. Benefiting from significant investments in market reach and innovation, Hilti Group expects a high single-digit growth, in local currencies, for 2023.

INDUSTRY NEWS

FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 20

FIX IT WITH UNIFIX DARTFORD ELLAND MILTON KEYNES STONE SWINDON t 01322 277733 t 01422 370121 t 01908 201600 t 01785 819819 t 01793 527829 owlett-jaton.com E & OE SCREWS TRUSTED BY PROFESSIONALS FOR ITS QUALITY AND RELIABILITY BIGGER AND BETTER RANGE THAN EVER BEFORE LOOK OUT FOR THESE NEW PRODUCTS ARRIVING SOON... BZPFLANGEBOLTS BZPCHIPPYSCREWS BZPCOLLATED DRYWALLSCREWS BLACKCOLLATED COARSETHREAD DRYWALLSCREWS Additionstotherange BOXED CLAMS TUBS RETAIL BAGS TRADE BAGS TRADE TUBS

fischer increases turnover to exceed €1 billion

The fischer Group of Companies has successfully concluded the 2022 fiscal year with a turnover of over €1 billion, a first in the company’s history. With a gross turnover of €1.14 billion, the family business exceeded its excellent figures of the previous year by 14.7%.

At the same time, the fischer Group of Companies used its growth strategy to increase its independence from negative global influences, such as Russia’s war of aggression on Ukraine, rising inflation, high energy prices and the Covid-19 crisis.

fischer’s largest division, fischer fixing systems, once again made an above average contribution to the success of the Group of Companies with an excellent 14% year-on-year increase in turnover. Numerous innovative, new products and systems, as well as a comprehensive range of services for various customer groups, had a positive effect. fischer also achieved substantial growth in the field of solar fastenings. The company additionally established a new logistics centre in Vietnam for the Asian market in 2022.

fischer Automotive recorded an increase in orders across all the division’s locations. fischer is currently establishing additional production capacity at its sites in the Czech Republic, Serbia, and China, for the purpose of this growth. Around the world, fischer Automotive products are installed in the vehicles of

many prestigious vehicle manufacturers, with a substantial and continuous increase in installation in electric vehicles. fischer Automotive concluded the year with a 17.8% increase in turnover. Nevertheless, the company division continues to operate in a challenging market environment due to the effects of the Covid-19 pandemic in China and the semiconductor shortage.

The fischertechnik division has recorded a positive turnover development in the global teaching material market, with a significant recovery following two years of lockdown due to Covid-19. fischertechnik will increase its presence in the education market over the coming year with a new learning concept. In the toy division, the rising cost of living has had an impact on consumer behaviour for the past several months. In 2022, fischertechnik recorded an increase in turnover of 7.2%.

SurTec acquires omniTECHNIK

SurTec International GmbH has acquired omniTECHNIK Mikroverkapselungs GmbH. The transaction also includes the acquisition of all the shares in the joint venture Precote USA LLC, by SurTec subsidiary SurTec Inc.

SurTec is a division of Freudenberg Chemical Specialities GmbH (FCS). The acquisition contract lays the foundations for the two companies to be integrated in the SurTec Group in the future.

As an innovative family company, omniTECHNIK Mikroverkapselungs GmbH has developed into a market leader in the field of reactive and non-reactive coatings for fasteners since its foundation over 40 years ago.

The company’s success on the world market is based on extensive knowledge and experience, first-class application technology consulting and outstanding products. Close cooperation with sales and consultancy partners over many years is a further key to the company’s success. With its precote® product range, the company covers a wide variety of thread coating applications throughout the world in the automotive, machinery, aerospace, and domestic appliance industries, among other sectors.

The acquisition of omniTECHNIK and precote® will lay the foundation for the strategic further development of the two companies. “The business strategy of FCS is based on the continuous expansion of our business portfolio. This includes an active acquisition approach. Our main focus is on attractive, highly promising services, technologies and products with an outstanding market position,” said Filip Krulis, CEO of FCS.

“Our acquisitions focus on companies that can help in reinforcing our market position in highly specialised segments. Through the acquisition of omniTECHNIK we will be able to significantly expand and continue the strategic development of our existing business in chemical surface technology,” added Dr Jörg Matthias Großmann, CFO of FCS.

“The business success of omniTECHNIK is based on helping industrial customers achieve greater success with high performance products and outstanding service,” said Heinrich Kuhn-Weiss, proprietor of omniTECHNIK GmbH. “We always wanted to be among the top suppliers of thread locking products and have succeeded in reaching this position over the past 40 years or more. As part of SurTec, it will be easier for us to grasp the market potential for innovative coating technologies even more effectively. As the representative of the family proprietors, it was important for me to find a partner that sees itself as a strategic investor with long-term orientation.”

“The company is in good hands with the FCS Group and SurTec,” Dr Karsten Grünke, CEO of SurTec International, commented. “FCS has already acquired one company from the Kuhn-Weiss family, OKS Spezialschmierstoffe GmbH, and successfully continued its development. We expect that we will be just as successful with omniTECHNIK.”

INDUSTRY NEWS

FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 22

INDUSTRY

Kistler Group continues its growth trajectory, with sales of €434 million in 2022 – representing a year-onyear increase of 5.5%. The company aims to achieve double-digit growth in 2023 thanks to technological innovations and expansion of the Chinese market.

R

Targeting China

Kistler is continuing to target the development of its sites in regions that hold out promise for the future. China, in particular, which is already Kistler’s largest market at present, harbours yet more major potential, and is set to become an integral element of the Kistler Group going forward. This is reflected in plans to expand on-site production and strengthen local responsibility in 2023.

Focus on innovation

Innovation always was, and still is, the driving force that motivates Kistler to grow as a company and tackle the challenges of the future. To consolidate its technological edge, Kistler will make targeted investments in pioneering technologies and product innovations. A total of around 8% of annual sales revenue is channeled into research and development. Kistler’s own Business Incubator also provides an environment for the ongoing development of special business fields with potential for innovation and growth, in a protected setting where the start-up mentality prevails. In 2023, the company’s entire Biomechanics area will relocate to the Business Incubator.

olf Sonderegger, CEO of the Kistler Group, explains: “In spite of a persistently volatile environment – dominated by the shortage of skilled professionals, as well as high energy and raw material prices, with material availability still at a critical level – we are optimistic. Our order backlog is excellent; our order intake in 2022 exceeded €500 million –marking a record high; and both our organisation and our strategy are in good shape to face the challenges of the future.”Hall 1, Stand 804

21 - 23 March 2023

Stuttgart, Germany

Stand 2104

Kistler continues growth trajectory NEWS EXPLORE MORE: lederer-world.com Stainless Steel Fasteners

When it comes to delivering perfect results, you need a partner you can rely on. With Don Quichotte, you can be certain of just that. We put all of our 100 years of experience into providing first class solutions for fastening, connecting, routing and protection. Count on us for high quality and clever solutions at competitive prices. That’s what we call being at home at your building site. See you around!

Qualified and committed human team More than 12.000 references E-Shop service 24 h. 365 days a year Stand 1012 HALL1 ESHOP SERVICE CHAVESBAO, YOUR GLOBAL PARTNER www.don-quichotte.com

things tight. Since

YEARS

Keeping

1921. 100

A.S.F. Fischer acquires Herag

Fasteners specialist Herag has been taken over by A.S.F. Fischer B.V in an acquisition involving a 100% share transfer. Both companies operate as specialists in fasteners within the Dutch construction market and are known for their conceptual market approach with leading A-brands, own brands and private labels.

Herag has been a leading family business in the field of fasteners, such as bolts, nuts, screws, and plugs, since 1966. Bert Kieberl, director at Herag, commented: “Our customers, suppliers and employees are in good hands with A.S.F. Fischer.” His positive words were echoed by Arnoud Booij, CEO of A.S.F. Fischer, who indicated that the acquisition fits perfectly into the growth strategy of the organisation. “We would like to remain a solid, stable and future-oriented partner for our relations in the future. With this acquisition, we strengthen our position in the

market and broaden our brand and product portfolio. Through the acquisition, customers of both parties benefit from the synergy opportunities in both logistics and commercial areas.”

A.S.F. Fischer B.V was founded in 1945 and is known for Woodies®, InterDynamics®, QlinQ®, Steelies®, Grabber®, Fis®Profi and Perfectmate® brands.

The transfer of all Herag activities to A.S.F. Fischer was scheduled for completion last month (mid-February), with a full integration of the two companies’ sales, purchasing and logistics activities.

Local ‘Made in Germany’ production strategy

With ongoing challenges in the supply chain in terms of shipping, price, and availability, GOEBEL has responded by launching its own, local production line, branded: ‘Made in Germany’, which will start productionin mid-2023.

GOEBEL Group is firmly convinced that regional purchasing is an important and strategically sensible addition to ensure more security in supply. At its site in Erkrath, Germany, it intends to manufacture 250 million parts annually, all of which will meet ISO 9001:2015 standards.

The product range that GOEBEL intends to produce locally includes many different kinds and qualities of blind rivets, such as open type, multi-grip, peel type, closed end and grooved blind rivets. In addition, the company’s rivets will be checked by optical sorting machines, and mill certificates will be provided to customers upon request, with each batch QR coded and trackable.

In addition, all steps in the manufacturing process wil be checked by the company’s certified in-house laboratory and in-house R&D will develop the capability of designing special types of rivets from fresh designs. GOEBEL’s new line of locally made blind rivets can also be painted in any RAL colour. The company states that its strategy is based on close co-operation with local tool manufacturers, wire suppliers, and skilled personnel, to ensure independence. In addition, GOEBEL aims to make its production as ‘climate neutral’ as possible by installing solar panels on its roofs to generate electricity.

The company’s ‘Made in Germany’ strategy will be a topic for discussion on its stand (4130) in Hall 7 at Fastener Fair Global in Stuttgart, Germany. www.goebel-group.com

INDUSTRY NEWS

Stainless steel fasteners. Edelstahl-Verbindungselemente. Standard and non-standard items Norm- und Standardteile DIN, ISO, EN and others / und andere Special parts and special materials Sonderteile / Sonderwerkstoffe Lederer GmbH | Katzbachstraße 4 | 58256 Ennepetal | Germany | Fon +49(0)2333/8309-0 | info@lederer-online.com lederer-shop.com availability advice quickorder / file upload backlinked pdf pages Bestands-eMail Schnellbestellung / Datei-Upload verlinkte Katalogseiten 21 - 23 March 2023 Stand 2104 Stuttgart, Germany Hall 7, Stand 4130 Hall 3, Stand 1656

Excellent fasteners for the mobility of the future.

Brugola OEB is the world’s leading manufacturer of the highest-quality bolts and special fasteners since 1926. Over the years, we have guaranteed excellent performance.

Thanks to our innovative and pioneering spirit, we are yet ready for the energy transition in the automotive industry.

As always, we are shaping the future!

Lissone - Plymouth www.brugola.com

21 - 23 March 2023

Stuttgart - Germany Hall 3 - Stand 1950

by John Wolz, editor, GlobalFastenerNews.com

Lissone - Plymouth www.brugola.com

21 - 23 March 2023

Stuttgart - Germany Hall 3 - Stand 1950

by John Wolz, editor, GlobalFastenerNews.com

Renewable energy a growing fastener trend

Sustainable energy made inroads in the fastener industry in 2022. Electric vehicle and hybrid automotive sales in the US nearly doubled in 2021 – EV sales rose 83% to 434,879, while hybrid automotive sales climbed 76% to 801,550. EVs are estimated to total 70% of the US light vehicle market by 2040.

Such strong market growth caught the eye of prominent fastener manufacturers looking to capitalize on the trend. For instance, in the past four months, France-based ARaymond acquired two companies – CGA Technologies SRL and Costello Italia SpA – to bolster its EV fastener product offerings. “The automotive industry is shifting to electric and autonomous vehicles, and we want to actively contribute to this extraordinary transition,” stated CEO Antoine Raymond.

Meanwhile, Chin Well signed a 25 year solar power purchase agreement to power their fastener manufacturing operations in Asia. Chin Well fasteners are exported to Europe (60%), the USA (30%), Japan (5%) and Southeast Asia (5%).

The installation of the solar power generating facilities reportedly will reduce Chin Well’s energy expenditure and carbon footprint. Both plants are expected to achieve commercial operation by the Quarter Four of 2022.

The news wasn’t all positive for EV fasteners. Rivian Automotive recalled more than 13,000 vehicles after flagging a problem with its steering system. The EV manufacturer explained that a fastener connecting the upper control arm and steering knuckle may have been installed incorrectly. If “insufficiently torqued”, the issue could create excessive wheel camber.

The recall of the 2022 Rivian R1T, R1S, and EDV models represents about 90% of vehicles produced by the automaker thus far and more than half of its 2022 total production guidance of 25,000 vehicles.

FINdex bests industrials amid market turmoil

During 2022 fasteners remained a comparably safe investment in a year when markets convulsed on economic data that increasingly warned of recession, causing the Dow to fall nearly 9% while the S&P 500 lost 20% of its value for the year.

The FIN Fastener Stock Index lost 11.5% during 2022, besting a 15.5% decline by an index of related industrial stocks. Amid the uncertainty, at least four publicly traded companies with fastener products achieved nearly double-digit gains, though significant losses were more likely.

Howmet Aerospace rallied to a 17.1% increase during 2022, topping the FINdex for the year. Howmet reported Fastening Systems revenue grew 15% to US$291 million in the third quarter of 2022 “due to growth in the commercial aerospace market of 24% with narrow body recovery more than offsetting Boeing 787 production declines, as well as an increase in material cost pass through”.

Nine month Fastening Systems revenue improved 5.5% to US$832 million (€788.8 million), with adjusted

EBITDA down 1.6% to US$176 million and margin of 22%. Segment capital expenditures rose 36% to US$30 million.

Other FINdex companies recording nearly double-digit growth during the year included Carpenter Technology (up 13.8%), Nucor Corporation (up 13%) and Grainger (up 9%).

With more modest gains, Chicago Rivet & Machine Co achieved a 7.3% increase in share value during the year, boosted by continued automotive demand.

However, other prominent fastener companies saw losses during the year. Fastenal Co stock dropped 25.7%, despite 18.2% fastener sales growth to US$614.5 million (34.1% of overall sales) in the first nine months of 2022.

Fastenal outperformed other FINdex companies that suffered significant

share loss during 2022. Topping the list was Stanley Black & Decker, which saw its share value slip 60% despite 15% organic Engineered Fastening revenue in the third quarter of 2022, with growth in the aerospace, automotive and general industrial markets.

Other FINdex companies losing significant share value during the year included Tree Island Steel (down 52%), Park Ohio (down 46%), Simpson Mfg (down 34%), Dorman Products (down 27.4%) and TriMas Corporation (down 23%).

During the third quarter, the FINdex declined 3.5%, besting a 5.8% drop by an index of related industrial stocks during a quarter when the market plunged on recession fears.

During the first half of 2022, the FINdex lost 17.1% of its value compared to a 19.1% decline by an index of related industrial stocks.

NORTH AMERICA NEWS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 28

Innovative Parts Output PTS – Pneumatic Transport System

Innovative, clean transport of parts out of HC 4 cold forming machines

WAFIOS FORMING TECHNOLOGY is revolutionizing the output of finished parts from the machine.

The new PTS takes the finished parts directly at the die and then guides them through a pipe system out of the machine to the desired location.

Good and bad parts are carefully separated by a sorting gate. This effectively avoids the mixing of parts when changing products.

The new PTS can also be retrofitted on existing machines in order to benefit from the advantages in existing production setups as well.

Reduces air consumption and carry-over: therefore resourcesaving

Patent Pending

Kieserling EWMenn Nutap Manufacturer WAFIOS Umformtechnik GmbH Im Rehsiepen 35 42369 Wuppertal · Germany Phone +49 (202) 4668-0 sales@wafios-umformtechnik.de www.wafios-umformtechnik.com

Precision Parts Forming Machinery Hilgeland

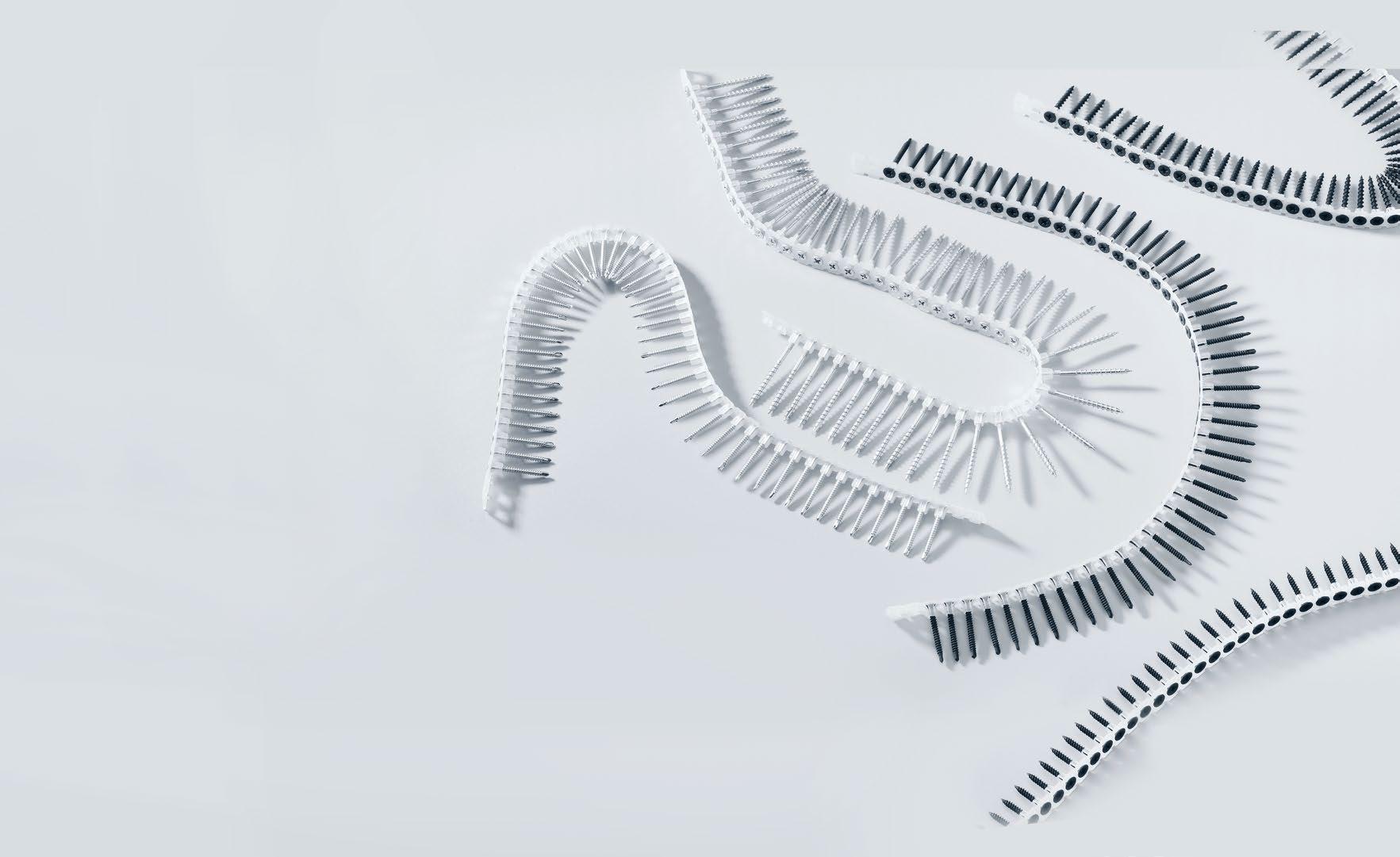

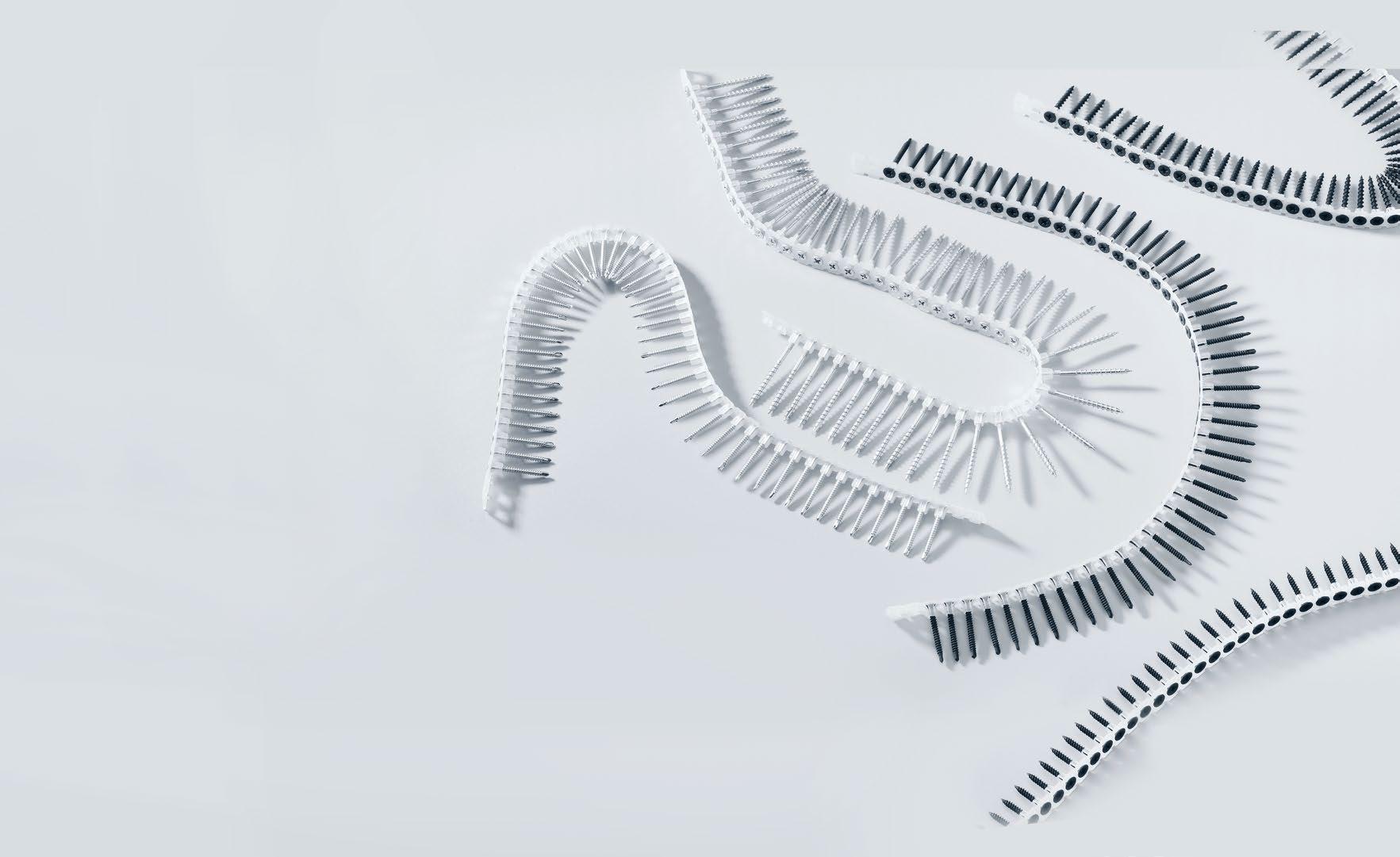

SPAX® taps online ‘influencers’ to market fasteners

SPAX® Engineered Fasteners is expanding its marketing through a crew of 'influencers', a nationwide network of contractors and craftsmen who use social media to showcase projects made with SPAX® structural fasteners – driving demand for its products at lumber yards and building supply stores.

While 'influencer marketing', a form of social media marketing also known as branded content or working with creators, isn’t new, it’s just not widely utilised in the fastener industry. However, that didn’t stop SPAX®.

Marketing Director Robert Knecht said the influencer program began with contractor trade shows. SPAX® welcomed contractors to drive screws in the SPAX® booth. Actual contractors “started seeing” how SPAX® installs and began “taking a liking to our brand and posting it on websites”.

Individual woodworkers started posting on Instagram or other social media. Most were time-lapse videos. “We love it when they slow it down and show hard-to-see screw applications,” Knecht said.

The 'influencers' get watched by colleagues looking for tips on “getting around sticky situations” in woodworking. “Our product line is traditionally big box retail and DIY customers,” Knecht told GlobalFastenerNews.com.

“Among pro contractors and advanced DIYers who use our fasteners, SPAX® has extremely strong recognition and brand loyalty,” Knecht said. “Our goal with the SPAX® crew is to build relationships with these 'influencers' and amplify their voices, letting them tell their unique stories about why they choose SPAX®.”

“The SPAX® crew program aims to engage multiple audience levels, from everyday product users to larger-scale 'influencers' with hundreds of thousands of followers,” Knecht said.

SPAX® crew members share social content about their projects and receive branded SPAX® swag and product samples. However, most 'influencers' aren’t looking for anything from SPAX®, Knecht finds.

“They may gain an audience and respect as an 'influencer'.” In some cases, SPAX® has shared videos and there could be situations where SPAX® could compensate influencers. “Homeowners want to show off their work,” Knecht said.

D’ondra Howard of Workboots & Glasses, a furniture maker and custom woodworker in Sacramento, CA, is a SPAX® influencer. “I’ve been using SPAX® fasteners for the two years that I have been creating custom home furnishings,” Howard said. “I like the products and they were easy to get and use. They don’t strip like others I’ve used before.”

SPAX® launched a website for its crew influencer program: SPAX.us/SPAX-crew

The SPAX® crew started with about 20 influencers and Knecht says the number has grown to over 300. Knecht noted that while it’s difficult to show specific sales results from SPAX®’s influencer program, there has been sales growth in the channel. The growth also has led to a contractor advisory group where SPAX® asks five people for a one-year commitment in advising on products.

Beyond the SPAX® marketing team, Knecht credits Interrupt, its Ohio advertising agency. “It was not on our own. We developed together with our agency.”

Founded in 1981 as TruFast, today SPAX® is owned by Germany-based Altenloh, Brinck & Co Group. SPAX® fasteners are German-engineered and manufactured in Bryan, OH, at a 200,000 square foot facility with engineering, manufacturing, administration and central warehousing.

Bossard looks to North America for growth

Bossard Group reported record sales in 2022, driven by double-digit growth in the USA. Quarter Four sales in the US increased 43.5% to CHF 80.2 million (€75.3 million) as the Swiss fastener manufacturer “significantly” expanded its market presence in Canada by acquiring PennEngineering’s Canadian distribution business. Terms of the deal were not disclosed.

Bossard said the acquisition is in line with its strategy to “expand its capabilities in the US”. Founded in 1970, PENN Engineered Fasteners Corporation (PEF), based in Concord, Ontario, Canada, was acquired by PennEngineering in 2017. The company supplies fasteners to automotive, energy, agriculture and appliances markets, generating annual sales of US$25 million with 30 employees.

Other US developments helped as well, including production achievements at Bossard customer Telsa. “In the electromobility sector, exciting commercial vehicle projects were implemented,” the company stated.

Full year US sales climbed 36.8% to CHF 309.4 million. Meanwhile, Q4 growth in Europe slowed, with sales up 0.8% to CHF 141.2 million amid high demand despite

continuing geopolitical tensions. Full-year growth rose 8.7% to CHF 624.2 million.

Results in Asia were impacted by the lifting of Covid-19 restrictions in China and the resulting wave of infections. Q4 sales in Asia gained 5.4% to CHF 54.8 million.

Bossard noted that the situation in China “continues to cause uncertainty”. For the year, Bossard consolidated revenue rose 15% to CHF 1.15 billion, including a 13.3% increased to CHF 276.2 million in the fourth quarter.

During the year, Bossard experienced a stronger trend toward nearshoring and an increased demand for Smart Factory Assembly (SFA) solutions amid inflation and a skilled labour shortage. However, the strong Swiss franc slowed growth.

NORTH AMERICA NEWS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 30

QCOs on the cards for 50 Indian products

India’s Department for Promotion of Industry and Internal Trade (DPIIT) is working with the Bureau of Indian Standards (BIS), and relevant stakeholders, to identify products for which quality control orders (QCOs) exist.

The intention is to bring as many as 50 products, such as aluminium, copper items, and household electrical appliances, under quality standards by Q2 of 2023 – 2024, and without the BIS mark items cannot be produced, sold, traded, imported or stocked.

The DPIIT is currently developing QCOs for various products, and these orders are issued in accordance with the WTO Agreement on Technical Barriers to Trade (TBT) for industries under its jurisdiction.

To meet its 50 QCO target date, the DPIIT has asked stakeholders, including industry, apex industry associations (CII and ASSOCHAM), sectoral industry associations, respective administrative ministries, and concerned R&D institutions/ organisations, to provide feedback to the department on 16 draft QCOs by 31 st December 2023.

Taiwan CSC announces Q1 2023 price adjustments

Taiwan China Steel Corp (CSC), the largest integrated steel maker in Taiwan – with its main steel mill located in Siaogang District, Kaohsiung – has announced its latest price adjustments for steel products.

As part of these price adjustments, the price of wire rod –of most relevance to fastener manufacturers and including low carbon, medium-to-high carbon, cold forged, and low alloy – has been reduced by NT$1,500 (about US$49.2) per metric tonne.

The price of automotive material, however, will increase by NT$500 (about US$16.4) per metric tonne, making the average price adjustment for all steel products -0.83%.

Source: Fastener World

These draft orders cover 16 product categories, including: aluminum and aluminum alloy products, bolts, nuts, fasteners, ceiling fan regulators, conduits and fittings for electrical installations, copper products, deep-well hand pumps and components, drums and tins, fire extinguisher hinges, household and similar electrical appliances, laboratory glassware, solar DC cable, fire survival cable, steel wires/strands, nylon/wire ropes, wire mesh, valves and taps, and welding wires.

Previously, the department issued QCOs for a variety of products, including household refrigerating appliances, certain steel and cable items, toys, and bicycle retro-reflective devices. These orders also aid in limiting non-essential imports.

Between April and November 2022, India’s imports increased by 29.5% to US$493.61 billion (€467.9 billion).

Source: Fastener Association of India

EV orders drive Boltun plans for new plant

Fastener World reports that Boltun is planning to build a new 160,100m 2 plant in the Guiren District of Tainan City, Taiwan, to handle EV orders and expand capacity.

Although 70% of its automotive fasteners are used on conventional cars and just 30% on EVs, Boltun sees the conventional car as having reached its potential and has, therefore, shifted its focus in recent years towards the EV industry.

The company has budgeted NT$1.7 billion (€55.9 million) for investment in the new plant, although it has switched from land purchase to land rental, which amounts to NT$871 million. Boltun reports that the land purchase is a huge expenditure, but that by switching to rental the company can increase its capacity and has more flexibility in using the budget. Boltun sees EVs as its drive for growth in 2023, making capacity adjustments imperative.

Sheh Fung Screws breaks ground on Vietnam plant

In order to fulfil its global manufacturing aims, reinforce international market expansion, and satisfy further business reach desires in Europe and America, Sheh Fung Screws is establishing its first overseas manufacturing operation in T Ì nh Bình Thuân, Vietnam.

Sheh Fung Screws is investing NT$0.7bn (€21.5 million) to establish the Phase 1 plant, which is expected to conduct a trial run after Q4 2023 and officially begin mass production around Q1 2024, at the earliest. The new plant is planned to be completed in two construction phases. The Phase 1 plant will be used to manufacture medium to short sizes of tapping, drilling and coated screws. Its monthly capacity is projected to be up to 800 tonnes (around NT$670 million). Sheh Fung will eventually make proper adjustments between the order books of both its Vietnamese and Taiwanese plants in order to maximise on its investment.

Source: Fastener World

ASIA NEWS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 32

Meet us at Fastener Fair Global - Mar 21-23: Hall 5, Stand No. 3158

Joker plans ETA seismic accreditation for anchor bolt

Joker Industrial will be showcasing, amongst other solutions, a new product to replace conventional anchors bolts at the upcoming Fastener Fair Global show in Stuttgart, Germany, from 21 st – 23rd March.

Thanks to its expertise in understanding the different environments and regulations in different countries, Joker Industrial has been able to design a new anchor bolt. The company reports it is also currently in the process of acquiring Seismic C2 certificates for its M8, M10, M12 and M14 cement anchors, which it anticipates will happen before the Stuttgart show.

Joker offers a ‘one stop’ solution service, ranging from order taking, design to manufacturing. The company also has its own laboratory to provide test data and welcomes customers with special design requests, or those with which it can work collaboratively to create 'one of a kind' anchor bolts.

As cement comprises different materials, which varies from country to country, and can also contain impurities, such as stones,

SUMEEKO takeover of Max Mothes to complete by July

Having previously acquired a 51% share of Germany’s Neuss-based Max Mothes GmbH (MMG) for €6.5 million in July 2018, it was recently announced that specialist Taiwanese fastener maker, SUMEEKO, is to acquire the remaining 49% of MMG for €6.24 million in cash, by the end of July this year.

Once completed, MMG, currently a subsidiary of CS Beteiligungs GmbH, will be fully owned by SUMEEKO. Through a 30-month adjustment period, MMG is back on track with profits gained in 2021 thanks to orders from European carmakers. By fully acquiring MMG shares, the new Taiwanese owners can tap into the supply chains of Benz, BMW, Bosch, Ford, Siemens and Volkswagen.

Source: Fastener World

Rungta Mines opens wire rod mill in Jharkhand

Rungta Mines Ltd has commissioned a new facility, the Rungta Steel Wire Rods Mills at its Chaliyama steel plant in Jharkhand, India, to expand its product portfolio and provide customers with a diverse range of solutions.

Wire rods from the new plant have a smooth and shiny surface and are packaged in coil bundles. They also have a hot charging plant, as well as optional ladle refining furnace and induction furnace routes. The wire rods will be marketed to the HB wire industry, cable industry, electrode manufacturers, and special grade end users, as well as being used in the fastener industry and for wire drawing, binding wire, barbed wire and other applications.

Wire rods from Rungta Mines Ltd will now be available across India, and sales of wire rods will be made available, not only to wire rod traders, but also to end users.

Source: Fastener Association of India

quartz, lime, and rebar, Joker’s anchor bolt, as a result, adopts a patented, triple-thread structure, in which the high and low threads can deal with various types of materials and impurities, making it a ‘universal anchor bolt’ suited to different cement environments in different countries. Special grooves on its tip also make it easier to install while, at the same time, its load capacity, according to its ETA certification, is more than double the industry required level. In addition to the existing carbon steel anchor bolt, Joker will launch a stainless steel, bi-metal anchor bolt with the same structural design at Fastener Fair Global, which, according to the company's laboratory test data, offers the same strength profile as its carbon steel counterpart.

Source: Fastener World

US$250 million auto deal for Sundram Fasteners

Sundram Fasteners Ltd has been awarded a US$250 million contract by a leading global automobile manufacturer to supply electric vehicle (EV) sub-assemblies, which will be used in EV for a wide range of segments, including mid-size trucks, SUVs, and sedans, and will be launched in North America in 2024.

During manufacture, Sundram Fasteners will use special processes, such as axial-forming technology, which can withstand extreme temperatures. It will also conduct rigorous durability tests to ensure high torque requirements are met.

The contract is the largest in the India-based company’s 60 year history and is said to be one of the largest for an Indian supplier of this range of products for EV platforms. Sundram Fasteners intends to invest approximately US$50 million to support the new orders under the six year purchase package, which includes the supply of input and stator shaft sub-assemblies, as well as drive gear subassemblies. The parts will be shipped from Mahindra World City, Chengalpattu, Tamil Nadu and Sri City, Tirupati district, Andhra Pradesh, and will be serviced from Sundram Fasteners’ warehouse in North America. With a supply of 1.5 million transmission sub-assemblies per year, the company expects annual sales to peak at US$52 million in 2026.

The contract will help to expand Sundram’s global business, as it works on its strategic roadmap for the future. Arathi Krishna, managing director at Sundram Fasteners Ltd, said that the US$250 million supply contract, is testimony to the company’s commitment to manufacture and supply high-quality, industry leading products.

Source: Fastener Association of India

ASIA NEWS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 34

: ・ ・ ・

Sérgio Milatias, editor, Revista do Parafuso, www.revistadoparafuso.com.br

More than US$1 billion of fasteners imported by Brazil

Starting in January 2022, named after the traditional symbology of the mythological Roman god Janus – a divinity that we learned through our colleagues from the Fastener + Fixing Magazine, the last twelve months has seen a busy period for both the import and export of fasteners within Brazil.

When it comes to the 2022 import of fasteners, such as bolts, screws, nuts, rivets, nails, and other types of metallic fasteners, Brazilian customers purchased a little over 207,000 tonnes, that cost a total of US$1.052 billion (FOB priceUS$5.08 per kg). Ten years ago the total exceeded 191,000 tonnes and the value was US$1.048 billion (US$5.48 per kg). Both in 2021 and in 2022 imports surpassed the barrier of 200,000 tonnes – 205,000 and 207,000 respectively.

Exports from Brazil over the same 12 month period totalled 38,400 tonnes, at a total price of US$184 million (US$4.79 per kg), which is a larger tonnage than in 2019, prior to the Covid-19 pandemic, and is only slightly under the US$194 million achieved in the same year. From looking at the bar charts (pictured right) it is clear to see how the segment has grown over the last ten years.

The

automotive sector rises, but still below 2019

The number of vehicles produced within Brazil has increased for the first time in three years. However, it is still below the numbers achieved in 2019 prior to the Covid-19 pandemic.

The automotive sector is one of the most important markets for the Brazilian fastener sector, involving the manufacture of cars, buses and trucks, as well as motorcycles.

Over the last twelve months the number of passenger and commercial vehicles produced locally increased by 5.4% to 2,369,800 units compared to 2021, which totalled 2,248,300 units. However, the 2022 production still represents only 75% of the total that was produced in 2019 (2,944,900).

Brazilian motorcycle production continued to show positive results with 2022 production totalling 1,413,200 units, which is a 18.2% increase on the 1,195,100 units produced in 2021. Since 2019 the local motorcycle production has continued to increase, except in 2020 where there was a slight dip but mainly due to the Covid-19 pandemic.

Dragão dos Parafusos founder passes away

Dragão dos Parafusos, one the largest and most traditional fasteners and tools companies in the north east of Brazil, has lost its leader after Álvaro Machado passed away.

Founded by Álvaro Machado in 1957, Dragão dos Parafusos is at the forefront of the industry for bolts, screws, nuts and also tools. The company currently employs 135 employees across six different stores.

Álvaro Machado passed away on 23 rd January in the Fortaleza state capital city of Ceará.

Year Vehicles Motorcycles 2019 2,944,900 1,107,700 2020 2,014,100 961,986 2021 2,248,300 1,195,100 2022 2,369,800 1,413,200

BRAZIL NEWS FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 36

Álvaro Bezerra Machado (1935 - 2023)

Founded in 1897, the family behind Puehl is still involved in the day-to-day running of the business – with Dr Goetz and Ralf Kaltheuner part of the operational board together with CEO Joachim Rohwedder – father-in-law of Ralf. Our great uncle founded the company, before it moved over to our grandfather and then father,” explains Ralf. “We are the fourth generation and we are very proud of the success Puehl has achieved in becoming a leading name within the washer sector and in reaching its 125th anniversary. Our aim is to continue to develop the family business for the future and go on offering a reliable and flexible service, which Puehl has become renowned for within the industry.”

Celebrating 125 years

To celebrate its 125th anniversary, Puehl held a party in September last year for its employees and their families, with around 200 people attending the event, which included speeches from the owners, as well as the Mayor of Plettenberg.

FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 38 COVER STORY

The new logo, alongside a new website… will be a better representation of who we are as a business and what our identity is as a washer manufacturer.”

Hall 1, Stand 622

We shape the future

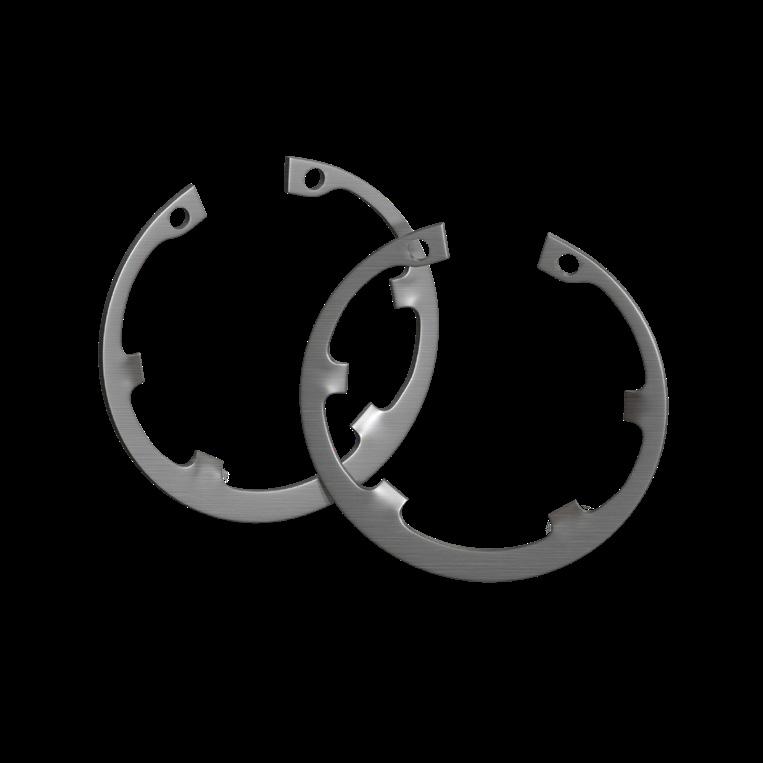

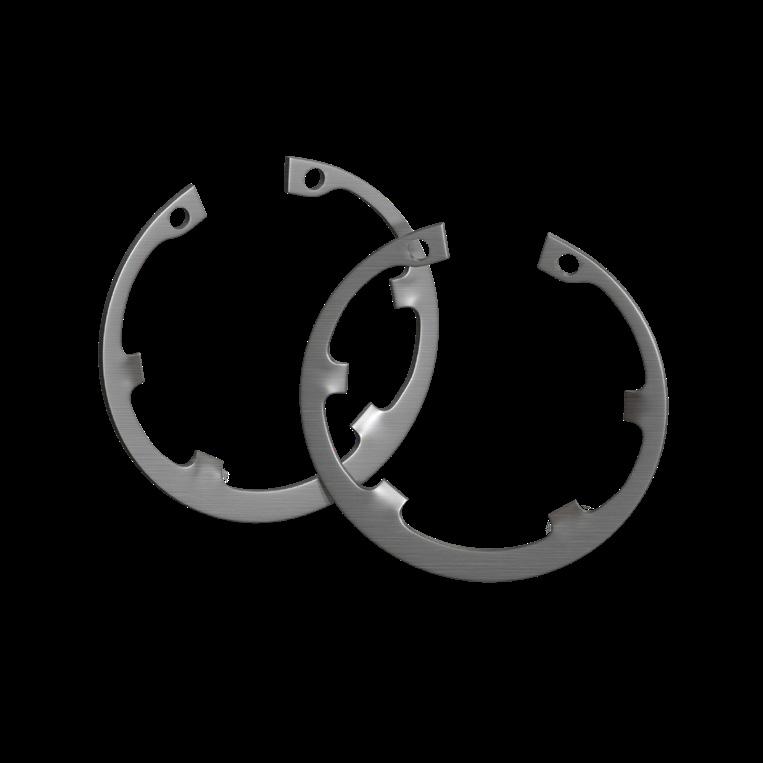

This year Puehl celebrates its 125th anniversary as a leading washer manufacturer within the European market – with the company also looking to mark the occasion by taking the next steps in its development as a modern forward-looking business.

The event was held in Puehl’s material building, which was transformed using floor-to-ceiling curtains and decorations to make it an ideal location to mark such a special occasion

The event was held in Puehl’s material building, which was transformed using floor-to-ceiling curtains and decorations to make it an ideal location to mark such a special occasion

COVER STORY

“We did not invite any customers or suppliers, as we wanted the party to be purely for our employees and their families,” states Goetz. “The event was held in our material building, which we transformed using floor-to-ceiling curtains and decorations to make it an ideal location to mark such a special occasion.”

The party included a DJ and a live band, as well as singing waiters who unexpectedly surprised the guests with opera songs. “We wanted to make it a celebration and to say thank you to our employees for their hard work and to show we are all part of the Puehl family,” adds Ralf.

Shaping the future

Puehl also decided the party was the perfect opportunity to unveil its new logo and brand – with the motto: ‘We. Shape. The. Future’. “We felt the party was the right moment to look forward and introduce a new corporate design and underline to our employees the steps we are taking as a business to ensure we continue to grow from an employee point of view, but also a corporate point of view,” explains Goetz.

Ralf adds: “We are a company with a lot of history and experience, which we are very proud of to have achieved. However, at the same time we are a young, modern and aggressive business and we want to showcase this fact. The new logo, alongside a new website that will be launched in March during Fastener Fair Global in Stuttgart, will be a better representation of who we are as a business and what our identity is as a washer manufacturer.”

To further underline what it stands for as a business, Puehl has developed company guidelines. “These company guidelines will be shared in the near future with our employees, so they can understand what we are looking to do as a business, so everybody can be focused on the same aims and targets,” explains Goetz. “It also means we can speak in the future with ‘one voice’ and we ensure we are seen as a strong and modern operation. It is a mission and vision statement, and we are confident the guidelines will help us grow in the future.”

Standing out from the crowd

Another key point of Puehl’s plans going forward is further connecting with both its existing and potential new employees. “Within the Plettenberg area we are working in a cluster of companies where there are a lot of similar businesses looking for the same kind of employees,” points out CEO Joachim Rohwedder. “This makes it very difficult to get good reliable people that are highly motivated, which is why we have taken extra steps to make ourselves more attractive – with additional employee incentives, such as working from home options, eBike leasing, opportunities for development, as well as a host of other benefits.”

Due to the lack of employees available, Puehl has increasingly relied on refugees – with the company supporting them and helping them to integrate into the organisation and local community. “We offer these employees language courses and further support, such as help with administrative tasks outside of the business, which has proved very popular,” highlights Goetz. “It is important that potential employees see us as a good and modern employer, where they can develop for the future, which is why we offer so much to our employees and have looked to develop a better employer brand within the market.”

Ongoing investments

Alongside investing in its employees, Puehl has continued to invest in its capabilities to ensure it goes on meeting the needs of

its customers and the market. “We introduced an investment plan in 2021, which we continued throughout 2022 and will continue in 2023,” states Ralf. “As a business we are focused on the European washer market and we have made a lot of investments to remain at the forefront of the industry – both now and in the future.”

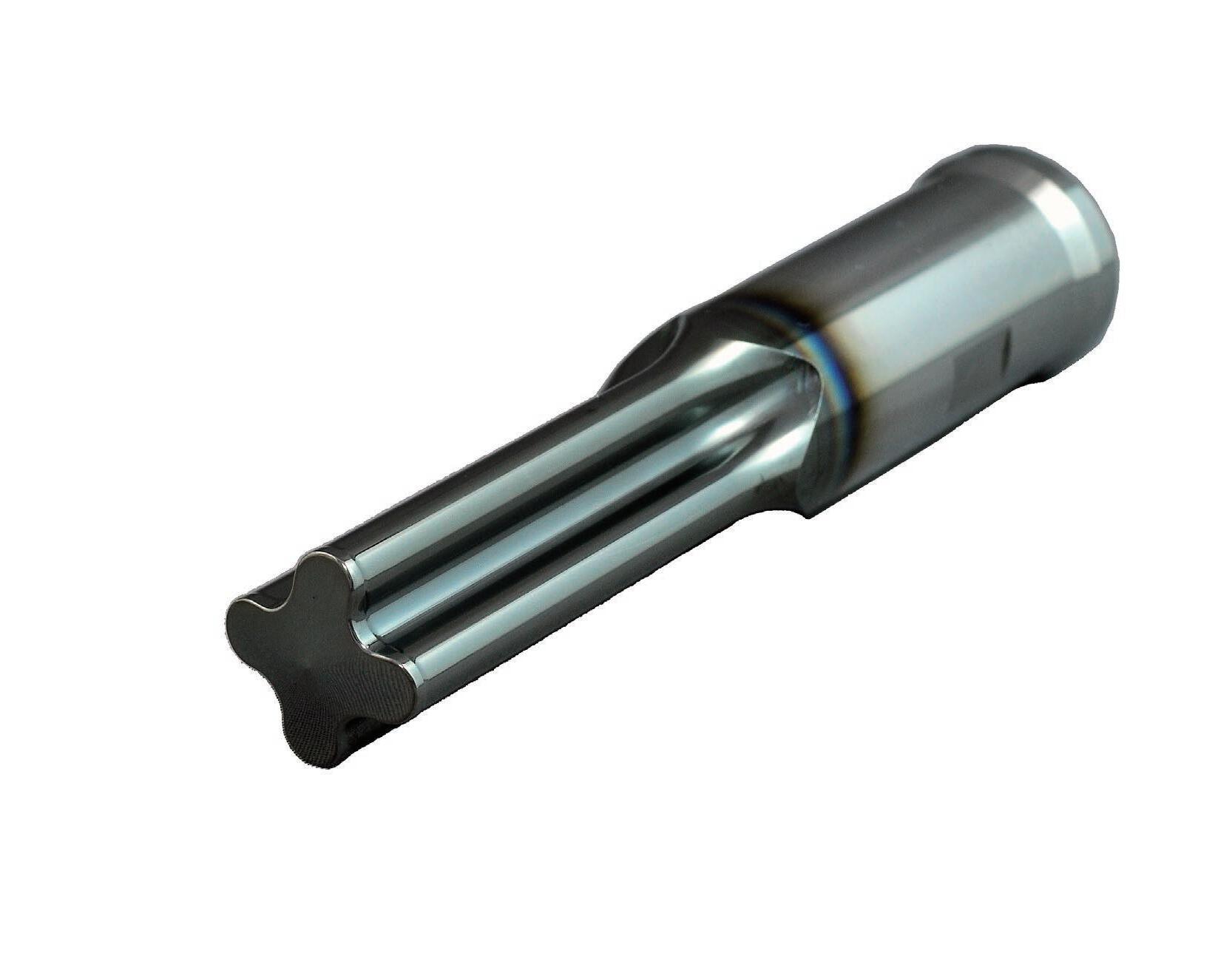

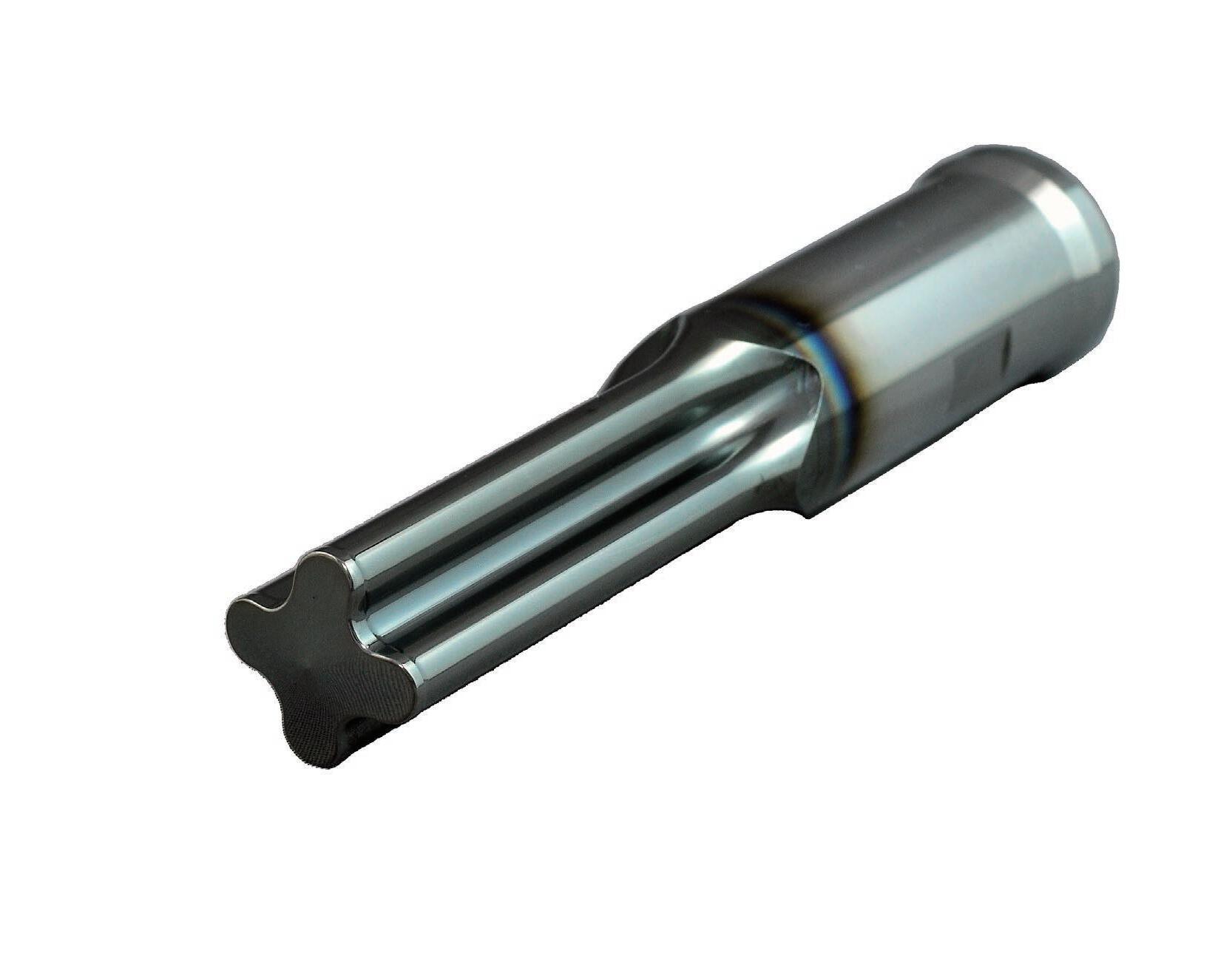

A prime example of Puehl’s investment strategy is the further investment in its in-house tool shop, where all the tools for its production are produced.

“We already have a high level of machinery within the tool shop, which enables us to build our tools in-house with good quality and shorter reaction time,” explains Goetz. “The investment means we have been able to replace older milling and eroding machines with the latest technology. These newer machines are quicker, faster, with a better quality, and help improve the overall department. Improving the efficiency of our

FASTENER + FIXING MAGAZINE | ISSUE 140: MARCH 2023 40

“We are very proud to have this capability within our business, but our focus is still ‘leading the standard’ and supplying all of the standard washers needed by wholesale customers throughout Europe.”

tool shop is crucial, because if you cannot produce the tooling it can hold up the entire production process.”

Other investments include the creation of a new punching and coining department, including two new pressing machines. “As a business we already owned several punching machines, but they were located outside the company at a supplier,” points out Ralf. “We decided to bring these machines back in-house and this has proved a very good decision, as we are able to be much more flexible in terms of products, as well as batch sizes.”

Within the punching and coining department, as well as across the entire production process, there has been investment in a highlevel of automation, which Puehl believes is a necessity if you are to compete within the European market. “Automation is a key aspect of our business and as a European manufacturer it is what helps us to be competitive within the market,” mentions Ralf. “Whilst it is not always easy to automate, such as with stamping machines, we continuously look at ways we can optimise processes.”

Focussing on sustainability

An area Puehl has also looked to continue investing is sustainability, which it believes is becoming more of a requirement within markets. “As a business we can certainly see that sustainability is becoming more and more important in all the markets, especially within Germany,” states Joachim. “From every customer we hear they are looking at sustainability when ordering, which is why we have made several investments with sustainability in mind.”

These investments include new LED lighting, a heat recovery system, as well as changing from natural gas to liquid gas. Plus, the company has installed a new photovoltaic system, which was introduced at the end of last year. “This new system will enable us to create our own energy and will not only help us become more sustainable, but also help us to manage and reduce costs due to the current high energy prices. In fact, through the steps we have taken regarding sustainability, we are looking at a saving of between 20% - 30% of our energy costs, which is a significant amount.”

Committed to wholesalers

All of these investments are an essential part of Puehl providing a reliable service of high-quality products to its existing wholesale customers and in attracting new business. “At Puehl we are a partner to wholesalers and can provide them with the products and services they need to meet every customer request,” states Ralf. “It is important to be flexible and guarantee you can meet small and big demands through good stock availability.”

Puehl is able to provide two types of service, depending on individual customer needs. Firstly, it can provide standard products, with big volumes, as well as frame orders – that can be 'called off' as and when needed. “Customers can come to us and place an order for half year or yearly demand, which we then stock at a certain level and the customers can 'call off' as and when they need it.” mentions Ralf.

The other type of business is the day-to-day business, where customers are asking for specialties and a smaller order volume. “This is an area that is increasing and we are able to work with our partners to provide special solutions,” adds Ralf. “As a company we have the employees, and knowledge, where we can help customers with technical questions, such as quality, etc, and provide the right solution.”

The company’s ability to work with customers is thanks to the knowledge and capabilities within its quality department, as well as its tool shop. “Thanks to the investments we previously mentioned, our tool shop puts us at the forefront of the industry and means we can help provide answers to technical questions,” explains Goetz. “We have approximately 1,500 tools in stock – all owned by Puehl – and have a CAD system that means we can be flexible and react quickly to any requests from customers.”

Goetz continues: “Through this capability we are able to work with wholesalers, or with wholesalers’ customers, and offer technical help and support in order for them to find the right solution, which we can produce straight away.”

“We are very proud to have this capability within our business, but our focus is still ‘leading the standard’ and supplying all of the standard washers needed by wholesale customers throughout Europe,” emphasises Ralf. “Some companies are focusing on special parts and stepping away from standard parts, but at Puehl we are committed to the standard side of the business and we want to be the leading company for washers in Europe. Furthermore, Puehl will also be a constantly developing manufacturer in the field of special parts.”

He concludes: “As a business we are well known within the industry and by working with our wholesale customers we can continue to provide the products and service that have established Puehl as a leading brand from stamping parts. Through our investments and company guidelines we will be able to optimise processes; provide a complete service to our customers; react quickly to customers’ needs and requirements; as well as be more competitive within the European market – as a modern and focused family business.”

www.puehl.de 41 www.fastenerandfixing.com

INSIGHT

IN-DEPTH INTERVIEWS AND REPORTS WITH FASTENER SPECIALISTS

With confidence in the nickel market so low, what’s next?

By Gary Peters, director, The Metals Warehouse

Last year the commodity industry witnessed a lot that you can consider unprecedented. The tip of that iceberg was what happened to nickel during the first half of 2022, when it increased to a price on the London Metal Exchange (LME) that had never been seen before, leading to trading being ceased, for days, before finally being reversed.

One of the biggest nickel producers on the planet had bet heavily on the nickel price falling. When their short position was squeezed, the nickel price soared, reportedly resulting in an US$11 billion trading loss. All in all, it was a bit of a mess.

The result of that crash was the implementation of a tolerance –one that allowed for a 15% fluctuation in the price either way –to prevent huge spikes or drops similar to that which happened back in March 2022 from happening again. The rule was simple: If the price superseded that 15% the market would cease trading for the remainder of the day. However, it seems to have done very little towards restoring confidence in traders, as prices are still fluctuating aggressively.