By Caroline Ash Production Director Fashion Enter

“Our students absolutely loved the visit, they couldn’t stop talking about it afterwards, Caroline is such an inspirational and engaging speaker, it’s definitely one of the best visits we’ve had. Thanks so much for organising it for us, really appreciate it.” Jiamei Jin – Organiser, Insider London

Caroline has 40-years experience as Production Director, at FEL, the only factory in the UK with leading status in the Fast Forward audit

She is a highly experienced production coordinator, sourcer and product developer with strong problem solving and analytical skills, delivering finished product that meet lead times, quality expectations and ethical requirements.

She has been Head of Production for various companies supplying the High Street making soft separates, dresses, tailoring, jersey and outerwear and has manufacturing experience in China, Turkey, Romania, Morocco, Bulgaria and Egypt as well as the UK.

Caroline’s experience and expertise in Sustainable & Ethical Supply Chain Management and Strategic Planning, coupled with her enthusiasm for all aspects of the Textile Industry ensures she is well suited to deliver informative and inspiring seminars.

“With the rise in proximity sourcing today, it has never been more important to understand how ethical factories work, combined with my experience and the ethical status of Fashion Enter, there is no other tour like this in the UK today."

“Fashion-Enter Ltd (FEL), an award-winning social enterprise, understands the need for total transparency within the supply chain. FEL is the only factory in the UK today with a leading status in the Fast Forward audit and also has SMETA audit with no non compliances They produce up to 5,000 garment per week

Fashion Enter LTD is a UK garment supplier and factory working with The Very Group, Gymshark, Orla Kiely, N Brown Group and Community Clothing. They also have a Fashion Studio where premium garment production is made for companies such as Louisa Parris and Saville Row Tailors Gormley and Gamble and a Repair Centre for clients such as Patagonia, Lulu Lemon and Rapha

Over the last 17 years FEL has given students at Further Education and Secondary Schools as well as industry a unique and invaluable insight into the world of Fashion, Garment Production, Sustainability, Ethics, and Innovation.”

The educational factory site visit is:

Up to a maximum of 20 students

Tailor-made to suit the studies and level of education of the students. The tours take place at the London factory based in Haringey and includes a Seminar covering the garment life cycle within an Ethical Factory and New Technology, including AI digital fashion software that integrates with pattern creation and 3D visualisation, plus our innovative knitwear technology which enables rapid swatch and sampling creation, leading to seamless production, this is followed by a Tour of the Factory, Fashion Studio, Pattern room, and our Repair Centre

We regularly accommodate Business and Economics students, Marketing, Foreign Students, and have recently run seminars with large Financial Institutions advising on investment, and Engineering”. We can also provide unique careers advice reviewing the different professions within the industry and the entry eligibility.

FEL'S core production centres on ladieswear in both jersey and woven fabrics, being manufactured by a team of highly experienced machinists that are from 12 different countries.

During the visit there is a live factory tour where there will be a review of cutting methodologies, all industrial machines, pressing, quality control plus there is deep dive into all production processes to understand the production methods that are used.

The factory is focused on speed of response quality production, from concept to delivery within a 2–3-week lead time. There is a unique transparent system called Galaxius that enables data to show who made what garment, when and how much they were paid, which prevents infringement of the Modern Slavery Act. This additionally provides FEL with constant improvement in efficiencies for optimum quality product.

“The speaker did a great job of keeping me engaged and communicating complicated concepts. This is definitely my favourite business/academic trip I have taken”. LCF

“I have learned about production costing lead times, AI, speed to market, repairs, pattern cutting, far shore, near shore, MOQ, sustainability & sourcing. Loved it!” Cardiff met university

There will be access to our outstanding Couturier/Fashion Studio service where highend garments are produces with minimum quantity of one. Garments range from haute couture, swimwear, lingerie, theatre costumes and bridal gowns.

Current clients the Fashion Studio range from new business, start up and scale up brands such as Louisa Parris who is now showcased on Net-a-Porter and Gormley and Gamble Savile Row tailors for women.

Here you will see the differences between bulk production in the factory and high end manufacture with the couturier, and analyse the difference in production methods

Fashion Studio creates first patterns, toiling, samples, seals, grades and short run production from 1 unit to 100 units.

You will visit our pattern room to explore how the development process works.

“I learnt how much of the fashion industry has moved on, the use of AI and the advances of sustainable practices. Caroline was fantastic, knowledgeable, engaging and interactive.” StudentFashion Retail Academy

Fashion-Enter, has joined as partner, with URC London, training the team in technical repairs With a focus on high social and environmental standards, Fashion-Enter had faced potential layoffs due to key retailers moving production to cheaper facilities abroad. Now URC London will protect 15 UK jobs and provide a bridge into the circular economy. This has created an exciting collaboration to move into repairs. Our highly skilled team are absolutely delighted that they are contributing to a circular economy for fashion today Partnerships between social impact companies United Repair Centre and Fashion-Enter with Patagonia, Lululemon and Rapha makes it easy for clothing brands to join the repair movement. This is an exciting and growing area of the business, with new clients joining us constantly.

For the FEL team the URC London perfectly aligns with the company’s ethos on sustainability, circularity and providing employment opportunities within the community.

“We must help customers keep their clothes in use for longer and practice conscious consumption”

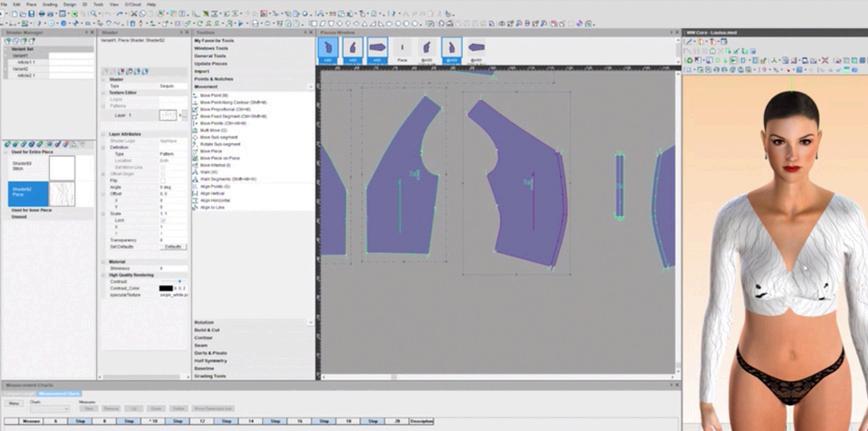

The "Styleverse Innovation Centre” features end to end immersive 3D-empowered solutions, streamlining the collaboration between stakeholders across the globe, enabling everyone to work together more efficiently and ultimately more profitably Featuring virtual environments can enhance not just the design process but also sales and marketing strategies.

Style3D Assyst will push digital technology to the forefront of creative, sustainable, and efficient fashion production It demonstrates digital asset optimization, illuminating how these tools can streamline workflows, increase productivity & accuracy, and reduce costs

Fabric Studio / Virtual swatches / Over 50,000 ready to use Digital Assets (pattern, fabrics, trims) / 3D Design Software / Virtual sampling capabilities / ESG Dashboard / Immersive Virtual customer experiences / Virtual sampling / Sofy Body Avatar / Style 3D Cloud / Virtual showroom / Virtual Store

“I have learnt how garments go from design into manufacturing. The different type of tech are used. I loved how it was very detailed and easy to understand, (loved the speaker)” FRA

“I have learnt the costs of different garments and impact technology is having on the industry. Great visit, very informative and great to witness a factory in person” Ravensbourne

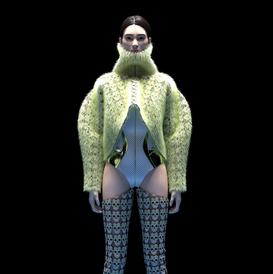

MaeKnit London is a pioneering, one-stop destination for the entire knitwear product lifecycle. From hands-on training in 3D skills and knitting workshops to sampling, prototyping, and zero-MOQ production, which empowers the designers, technicians, and buyers of tomorrow. We leverage cutting-edge technology from Shima Seiki and leading 3D virtual sampling providers, ensuring precision and innovation at every stage.

Our finishing process is backed by Wool markcertified washing and drying equipment, with linking capabilities ranging from 5gg to 14gg. With decades of combined expertise and state-of-theart knitting machines, including Whole garment accessories for socks, gloves, and hats, we guarantee unmatched skill, efficiency, and craftsmanship, while-u-wait.

Over the years we’ve prided ourselves on working with sustainable solutions and unique partnerships Naeem and Mallory are totally genuine in their quest to make rapid turnaround a viable reality

You can bring us a sketch in the morning and leave with a final sample by the end of the day Maeknit - the only knitwear service in London!

“I have learnt the costs of different garments and impact technology is having on the industry. Great visit, very informative and great to witness a factory in person”

Ravensbourne

The manufacturing process of a garment – from the initial idea through the to delivery – the full garment lifecycle

Overview of the Fashion Industry from a business standpoint

Geopolitical risks

Pattern cutting methodologies

3D/AI pattern cutting and fitting

How a garment is costed

How long it really takes to make a garment and how to simplify a style to get into price

Our PLM system and transparency

Critical path management

Changing a bestseller to get maximum sell through

The customer Sealing Process

The supply chain and challenges a supplier faces – a unique perspective from both buying and supply.

Ethics, Sustainability and Greenwashing

New technology – The future of the Fashion Industry

What makes The Factory SMETA/Fast Forward approved – why we are a fully compliant factory. Explanation of the Modern Slavery Act.

Extended Producer Responsibility (EPR) and new legislation

* These topics can be amended to meet your individual needs

“So good to see this side of the sustainability chain. So many shocking facts – very eye-opening. AI was most interesting, and I cannot wait to explore this more in the future. Thank-you!”

Student - Bath Spa University

“Thank you so much for delivering such brilliant and insightful talks – and tours – today and for making all the students from Regent’s University London, feel so welcome. As you know, this was my first time visiting Fashion-Enter, although I feel as if I know it because it has steadily grown into such a highlight of the MA International Fashion Marketing programme over the last few years when students have been privileged to visit. You communicated to us the newest methods and ideas happening in circular design (the students loved the 6R’s!) product development; costing; range plans; the challenges of the fashion industry and positive steps toward sustainable practices through generative AI. Thank you also for considering the content of our ‘Bespoke tour’ which touched on areas that those working in fashion marketing need to know. I feel sure this tour will prove invaluable to the imminent range planning project”. Course Leader MA International Fashion Management

“This was my first ever factory visit and it was without doubt so insightful. After all the information today ignited existing passion even more. Thank-you for all the information.” Student Westminster University

“As Always a great experience for the Grad Dip student from LCF with the amazing Caroline Ash. Always engaging as students learn about taking a concept to creation, supply chain development and sustainability. This course is highly recommended, it's amazing to see the constant evolution”. TutorLondon College of fashion

“I got behind the scenes and learnt about the process of what really goes into the garments that are being made for brand. Tour guide was very interesting. Appreciated how passionate and detailed the speaker was.” Ravensbourne University

“Great learning experience. Received in-depth knowledge of how departments function and the industry speed. I have visited factories before but this is a new learning experience.” Student Westminster University “Found out how a factory works and the lifecycle of a product. The speaker was really interesting and had a positive energy, really enjoyed it.” Student Westminster University

Caroline Ash, once again Thank you for your amazing insights. You never fail to surprise and delight !”Helen Hindley Course Leader LCF

“Everything was explained perfectly, all the questions were answered, and the speaker was very open about the factory. I have learned and enjoyed today’s tour and all the information that was given.” Manchester Metropolitan University

“I learnt about how products are truly made, which I had little to no knowledge of before, as well as lot more about sustainability and new technology. The speaker was truly inspiring and had me interested throughout which sometimes I struggle with. It has also really inspired me to work hard and eventually start up my own business “ The Fashion Retail Academy

“I found out so much about the importance of speed to market and more of the manufacturing process behind the scenes. Also about the future of design and manufacturing through online / 3D systems. Great experience!” Glasgow Clyde University

“I have learnt more about the business side of fashion and how the industry is looking at moving forward in the future with AI. I have a short attention span and you had my attention all the time.” Student- FRA

“I learnt how much of the fashion industry has moved on, the use of AI and the advances of sustainable practices. Caroline was fantastic, knowledgeable, engaging and interactive.” Student- FRA

“Great to see how you’ve changed business model given market changes in technology and legislation. Very informative and up to date. Thank you, Caroline! Absolutely brilliant as always.” -Tutor - Glasgow Caledonian University London

“Exceptional information on the current scenario production. In depth knowledge on production process was was very helpful especially Style3D”. LCF

Each tour is two, three or four hours in total with a maximum of 20 students and two tutors.

The tours take place at the London factory based in Haringey and includes a tour of The Factory, Fashion Studio, Style3D centre,United Repair Centre and Maeknit Inc.

If you require further information or to discuss flexibility on dates, times or duration, please contact Caroline Ash, directly

0208 809 3311

caroline@fashion-enter.com

https://fcfta com

When you exit Manor House tube (Piccadilly line) please take exit 7 and walk down Green Lanes past the Finsbury Arms pub which will be on your right hand side. After the pub the next turning on the right is Hermitage Road (quite a long way down Green Lanes) Turn down this road and we are at the bottom of the road before the width restrictors We are in unit 4, please report to Reception

“Today I visited Fashion-Enter, Caroline Ash gave us an amazing, in-depth, talk about the factory operations, their great values and sustainable methods. We also had a tour of the machinery and new AI innovations to assist with product design, fit and logistics.” Student – Fashion Retail Academy

“Fashion’s not about looking back. It’s always about looking forward.” Anna Wintour