By Caroline Ash Production Director Fashion Enter

“This was an excellent course / experience. Caroline condensed years of learning and experience into a few hours. Loved it! So worthwhile and wonderful to see the innovation, enthusiasm and expertise right here in London!” Kate - Senior Production Manager - Organiser All Saints

Caroline has 40-years’ experience as Production Director, at FEL, the only factory in the UK with leading status in the Fast Forward audit

She is a highly experienced production coordinator, sourcer and product developer with strong problem solving and analytical skills, delivering finished product that meet lead times, quality expectations and ethical requirements.

She has been Head of Production for various companies supplying the High Street making soft separates, dresses, tailoring, jersey and outerwear and has manufacturing experience in China, Turkey, Romania, Morocco, Bulgaria, Egypt as well as the UK.

Caroline’s experience and expertise in Sustainable & Ethical Supply Chain Management and Strategic Planning, coupled with her enthusiasm for all aspects of the Textile Industry ensures she is well suited to deliver informative and inspiring seminars.

“Welcome to our Ethical Factory Tou In an age were where proximity sour important than ever for speed of res Junior staff and management can ha review of how factories work effectiv support speed of response fashion.

We will gear the content of the semin of the group that is attending.

These tours provide an excellent cos forward, enabling your team to visit the expense of going to near of offsh

Fashion-Enter Ltd (FEL), an award-winning social enterprise, understands the need for total transparency within the supply chain. FEL is the only factory in the UK today with a leading status in the Fast Forward audit and also has SMETA audit with no, non compliances. They produce up to 5,000 garment per week.

Fashion Enter LTD is a UK garment supplier and factory working with The Very Group, Gymshark, Orla Kiely, N Brown Group and Community Clothing. They also have a Fashion Studio where premium garment production is made for companies such as Louisa Parris and Saville Row Tailors Gormley and Gamble and a Repair Centre for clients such as Patagonia, Lulu Lemon and Rapha

Over the last 17 years FEL has given students at Further Education and Secondary Schools as well as industry a unique and invaluable insight into the world of Fashion, Garment Production, Sustainability, Ethics, Legislation, and Innovation.

The factory site visit is a:

A four-hour Tour and Seminar

Up to a maximum of 10 attendees

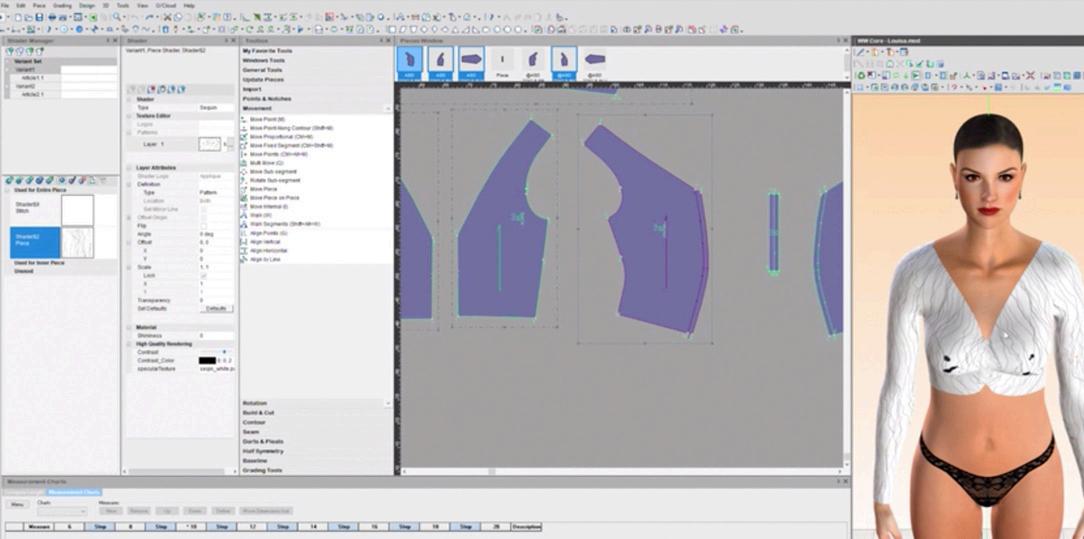

The tours take place at the London factory based in Haringey and includes a Seminar covering the garment life cycle within an Ethical Factory and New Technology, including AI digital fashion software that integrates with pattern creation and 3D visualization with a zerowaste design process, plus our innovative knitwear technology which enables rapid swatch and sampling creation, leading to seamless production, this is followed by a Tour of the Factory, Fashion Studio, Pattern room and our Repair Centre It can be Tailor-made to suit the delegates requirements, job roles and level of experience and works particularly well for Buying, Merchandising, Design, Garment Tech, Sourcing, Ethical and Sustainability managers We even have slanted our tours towards Business, Economics, Engineering, Foreign Tours and have recently run seminars with large Financial Institutions advising on investment!

There is flexibility with dates and times so we will work with you to find a suitable date.

FEL'S core production centres on ladieswear in both jersey and woven fabrics, being manufactured by a team of highly experienced machinists that are from 12 different countries

During the visit there is a live factory tour where there will be a review of cutting methodologies, all industrial machines, pressing, quality control plus there is deep dive into all production processes to understand the production methods that are used.

The factory is focused on speed of response quality production, from concept to delivery within a 2–3-week lead time. There is a unique transparent system called Galaxius that enables data to show who made what garment, when and how much they were paid, which prevents infringement of the Modern Slavery Act. This additionally provides FEL with constant improvement in efficiencies for optimum quality product.

“An understanding from a supplier’s side in many different aspects such as costings, garment considerations and lead times Coming from a knitwear de si de

There will be access to our outstanding Couturier/Fashion Studio service where high-end garments are produces with minimum quantity of one Garments range from haute couture, swimwear, lingerie, theatre costumes and bridal gowns

Current clients the Fashion Studio range from new business, start up and scale up brands such as Louisa Parris who is now showcased on Net-a-Porter and Gormley and Gamble Savile Row tailors for women.

Here you will see the differences between bulk production in the factory and high end manufacture with the couturier, and analyse the difference in production methods

Fashion Studio creates first patterns, toiling, samples, seals, grades and short run production from 1 unit to 100 units

You will visit our pattern room to explore how the development process works.

“I learnt in detail about the use of Optitex and its uses in fit, costings – how we can bring the price down and factories abroad and the issues we need to be aware of as techs. Really enjoyed the afternoon. It was really good to see production and have an insight into the operation of this factory. Thank-you so much!” M&S Garment Tech

Fashion-Enter, has joined as partner, with URC London, training the team in technical repairs With a focus on high social and environmental standards, Fashion-Enter had faced potential layoffs due to key retailers moving production to cheaper facilities abroad. Now URC London will protect 15 UK jobs and provide a bridge into the circular economy. This has created an exciting collaboration to move into repairs. Our highly skilled team are absolutely delighted that they are contributing to a circular economy for fashion today Partnerships between social impact companies United Repair Centre and Fashion-Enter with Patagonia, Lululemon and Rapha makes it easy for clothing brands to join the repair movement. This is an exciting and growing area of the business, with new clients joining us constantly.

For the FEL team the URC London perfectly aligns with the company’s ethos on sustainability, circularity and providing employment opportunities within the community.

“We must help customers keep their clothes in use for longer and practice conscious consumption”

The "Styleverse Innovation Centre” features end to end immersive 3D-empowered solutions, streamlining the collaboration between stakeholders across the globe, enabling everyone to work together more efficiently and ultimately more profitably Featuring virtual environments can enhance not just the design process but also sales and marketing strategies.

Style3D Assyst will push digital technology to the forefront of creative, sustainable, and efficient fashion production It demonstrates digital asset optimization, illuminating how these tools can streamline workflows, increase productivity & accuracy, and reduce costs

Fabric Studio / Virtual swatches / Over 50,000 ready to use Digital Assets (pattern, fabrics, trims) / 3D Design Software / Virtual sampling capabilities / ESG Dashboard / Immersive Virtual customer experiences / Virtual sampling / Sofy Body Avatar / Style 3D Cloud / Virtual showroom / Virtual Store

“It was incredibly useful seeing the factory alongside the presentation. All the information was new and useful – will definitely be used at work.” Sainsbury’s

“Really insightful day, it has filled in the gaps of my knowledge and has provided me with a better understanding of manufacturing all round.” Asda

MaeKnit London is a pioneering, one-stop destination for the entire knitwear product lifecycle. From hands-on training in 3D skills and knitting workshops to sampling, prototyping, and zero-MOQ production, which empowers the designers, technicians, and buyers of tomorrow. We leverage cutting-edge technology from Shima Seiki and leading 3D virtual sampling providers, ensuring precision and innovation at every stage.

Our finishing process is backed by Wool markcertified washing and drying equipment, with linking capabilities ranging from 5gg to 14gg. With decades of combined expertise and state-of-theart knitting machines, including Whole garment accessories for socks, gloves, and hats, we guarantee unmatched skill, efficiency, and craftsmanship, while-u-wait.

Over the years we’ve prided ourselves on working with sustainable solutions and unique partnerships Naeem and Mallory are totally genuine in their quest to make rapid turnaround a viable reality

You can bring us a sketch in the morning and leave with a final sample by the end of the day Maeknit - the only knitwear service in London!

“I have learnt the costs of different garments and impact technology is having on the industry. Great visit, very informative and great to witness a factory in person”

Ravensbourne

The Garment Life Cycle in relation to central management systems.

Review of current trends in garment manufacturing.

Why is reshoring occurring?

How can a UK factory be competitive?

The Factory uncovered - compliance

What is SMETA?

What is Fast Forward?

What makes The Factory SMETA/Fast Forward approved – why we are a fully compliant factory

Explanation of the Modern Slavery Act

Cabbage

Dirty Tricks - 16 on 16 off

Overview of Galaxius – the ethical way forward.

Transparency and workable margins for both sides

8 years development on transparent manufacturing explained with working examples

Live Factory, Fashion Studio, Repair Centre, Style3D and Maeknit tour

Fabric Delivery to Garment Delivery

Working with fabric stock held in factories.

Fabric testing the factory way - relaxed fabric v laying straight off the roll

Choosing the correct components for the garment

Understanding fabric consumption and the effects of cabbage. How to stop cabbage

Design process to production - how it becomes 2D to 3D, along with design considerations from both a cost and manufacturing perspective.

Reoccurring problems with sealing and how to mitigate them

Processes, risks and elements of garment manufacturing that are costly to amend

Implications of the changes buyers make

How do factories calculate standard minutes, how long does it really take to make a garment.

How to incorporate performance related pay for machinists

Relating standard minutes to styles and machines

How are AQLs and in work checks really conducted in a Factory Environment?

The supply chain and challenges a supplier faces – a unique perspective from both buying and supply.

Why do retailer’s PO’s have a specific number per size yet factories over deliver on certain sizes?

Single cutting per sizes do not work – Fact Why?

Ratios - cutting implications and cost savings for factories that should be passed on to buyers

Why are deliveries late when fabric is on time?

How are garments costed - working examples?

What is an open costing and how to verify supplier costings?

Standard minutes explained

Practical stitching operations that affect costing. Cover stitch is not twin needle do not pay a premium!

How to reduce the work content in a garment to get into margin/target price

Technological advancements including AI within the industry Ethics, Sustainability and Greenwashing

How new Legislation will impact the Fashion Industry

Garment Tech - The problems we encounter as a factory with fit comments

Summary

Feedback and review

* These topics can be amended to meet your individual needs

“Caroline is a font of knowledge!” Selfridges - Senior Responsible Sourcing Manager

“This was a very thorough run through of start to end process and really good to see in person so I can have more context when negotiating cost prices.” ASOS

“I thought it was super clear and informative. It went at a good pace and covered all bases. The speaker and everyone we met were super friendly. Would recommend.” ASOS

“I learnt a lot about fitting, AI, pattern cutting, factory processes, shipping, sample costs, waste, sustainability and print. It felt like it was a very thorough seminar and very interesting!” Pangaia

“I learnt a lot about the industry as a whole in terms of production / sustainability in addition to global events such as wars, that may affect shipping routes, prolonging launch dates for the company for example.” Boden

“I learnt so much new knowledge about the lifecycle of products, particularly around how garments are made and where the biggest issues with waste arise. I also loved hearing more about the skills of the factory – incredible talents. Thank you so much Caroline – loved the energy and enthusiasm.” Selfridges - Circular & Innovation Lead

“Had a fantastic trip yesterday to Fashion-Enter! It was a wonderfully informative session and tour, showcasing the incredible talent of the staff in manufacturing garments for both luxury and high street clients.” AllSaints

“AllSaints production team had the amazing opportunity to visit Fashion-Enter for a factory visit and talk this morning. We all learned so much and I found it a highly beneficial day to further my understanding of production processes. I especially found it useful to understand how and where we can improve our production to be more ethical and sustainable ” Production Admin Assistant AllSaints

“It was great to learn both in the classroom and on the factory floor. Caroline was an excellent trainer. Thank-you it was really brilliant, exceeded expectations.” Ethical Trade Initiative

“Wonderful session that covered everything in just four hours, would love to spend longer time on a workshop / practice next time. Thank-you.” Sainsbury's

"I learnt a lot that I wish I had known earlier – so relevant! True cost of sampling, impact of buying decisions on the factory / cost / lead time. I can now appreciate the supplier’s position even more and now I am more informed to discuss. This should be rolled out earlier at entry / established level of Assistant Buyers! Thanks.” ASOS

“I learnt about buying tactics, innovation and construction. This was the most amazing tour with an inspiring lady! Super exciting to learn about the future of fashion and where you are going. Thank-you so much.” – ASDA

“I learnt loads about sustainability, ethics and standards, which was amazing! Really informative and clear information. Amazing, amazing, amazing!” – ASDA

“Really informative, I would highly recommend especially to graduates. Important for all garment techs and buyers to know and understand.” The Very Group

“Caroline is an amazing asset to the company / education centre here. Her passion, enthusiasm and knowledge is inspiring and very informative. Thank-you for providing today for us all when it is hard to visit international factories.” Seasalt

“I learnt so much! Particularly about the production line and the level of QC checks that should be in place at factories. This course has been so insightful, certainly a lot of food for thought. It is nice to know that there is still garment production in the UK! Thank-you, I have thoroughly enjoyed it.” Seasalt

Each tour is four hours in total with a maximum of 10 attendees

The tours take place at the London factory based in Haringey and includes a tour of the Factory, the Fashion Studio and Repair Centre, Style3D and Maeknit Inc.

If you require further information or to discuss flexibility on dates, times or duration, please contact Caroline Ash, directly.

When you exit Manor House tube (Piccadilly line) please take exit 7 and walk down Green Lanes past the Finsbury Arms pub which will be on your right hand side After the pub the next turning on the right is Hermitage Road (quite a long way down Green Lanes) Turn down this road and we are at the bottom of the road before the width restrictors. We are in unit 4, please report to Reception.

“I have learnt more in-depth practices that can help me be better at my job and understand it better. Very in-depth tour, very well organised, great presentation with lots of information. Really enjoyed visiting a working factory.” M&S Garment Tech

“Fashion’s not about looking back. It’s always about looking forward.” Anna Wintour