Connect, discover, stay up-to-date

3/2024

▶ Special topic: Lab Management

10 things you should know about PFAS

Revolutionizing myopia management

Generation Z

▶ Technology

A state-of-the-art technology for photochromic lenses

▶ Spotlight

Audio glasses: What you see is what you hear

▶ Live on site

A visit to Optovision in Langen (Germany)

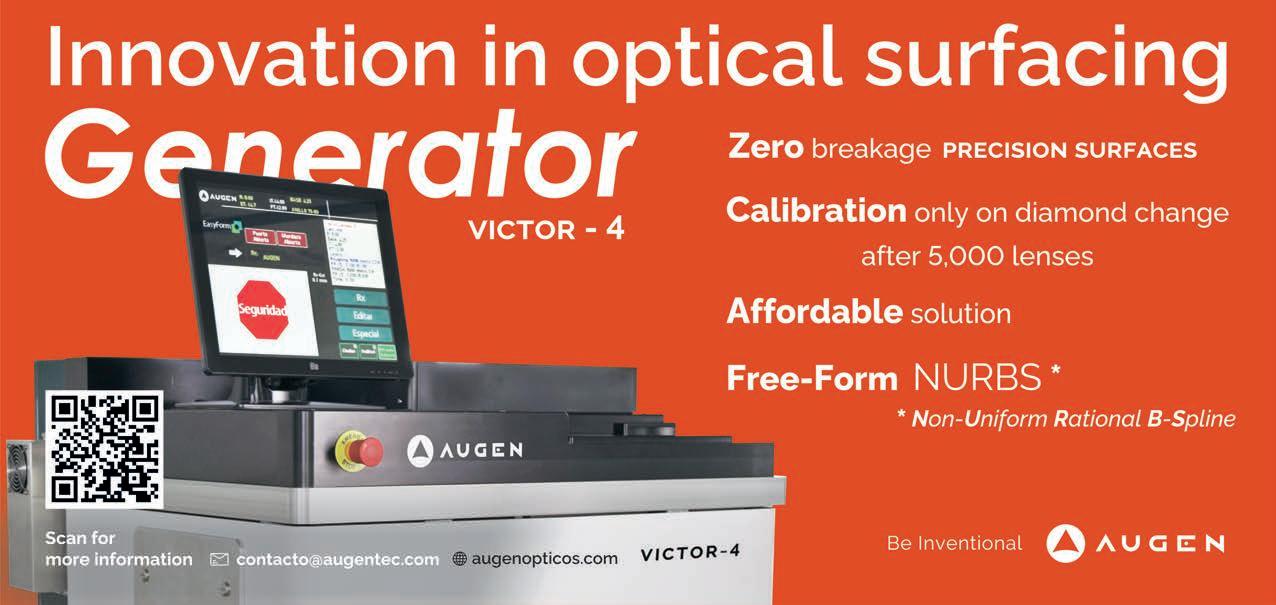

▶ Market Surveys Generators

OPHTHALMIC LABS & INDUSTRY

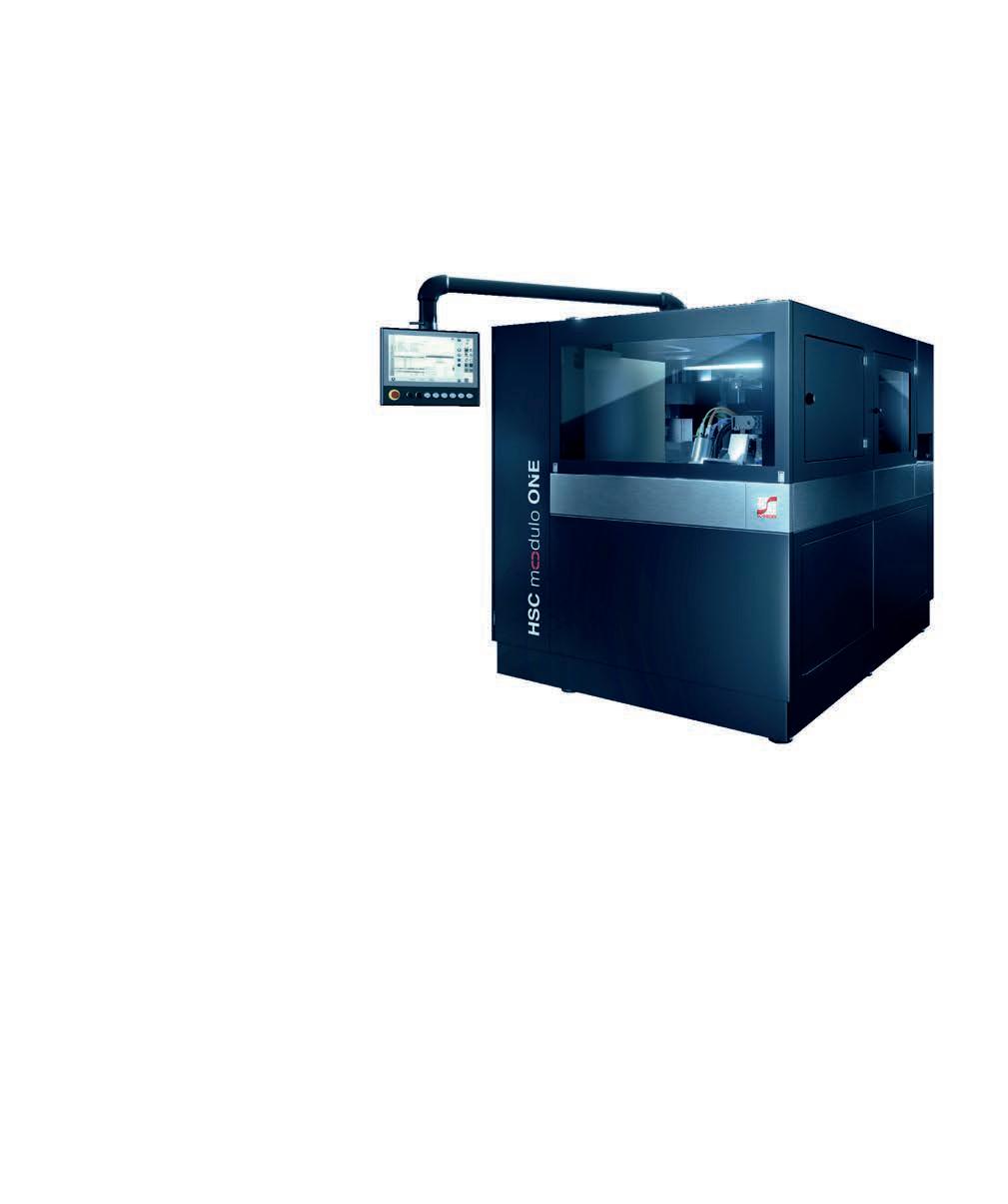

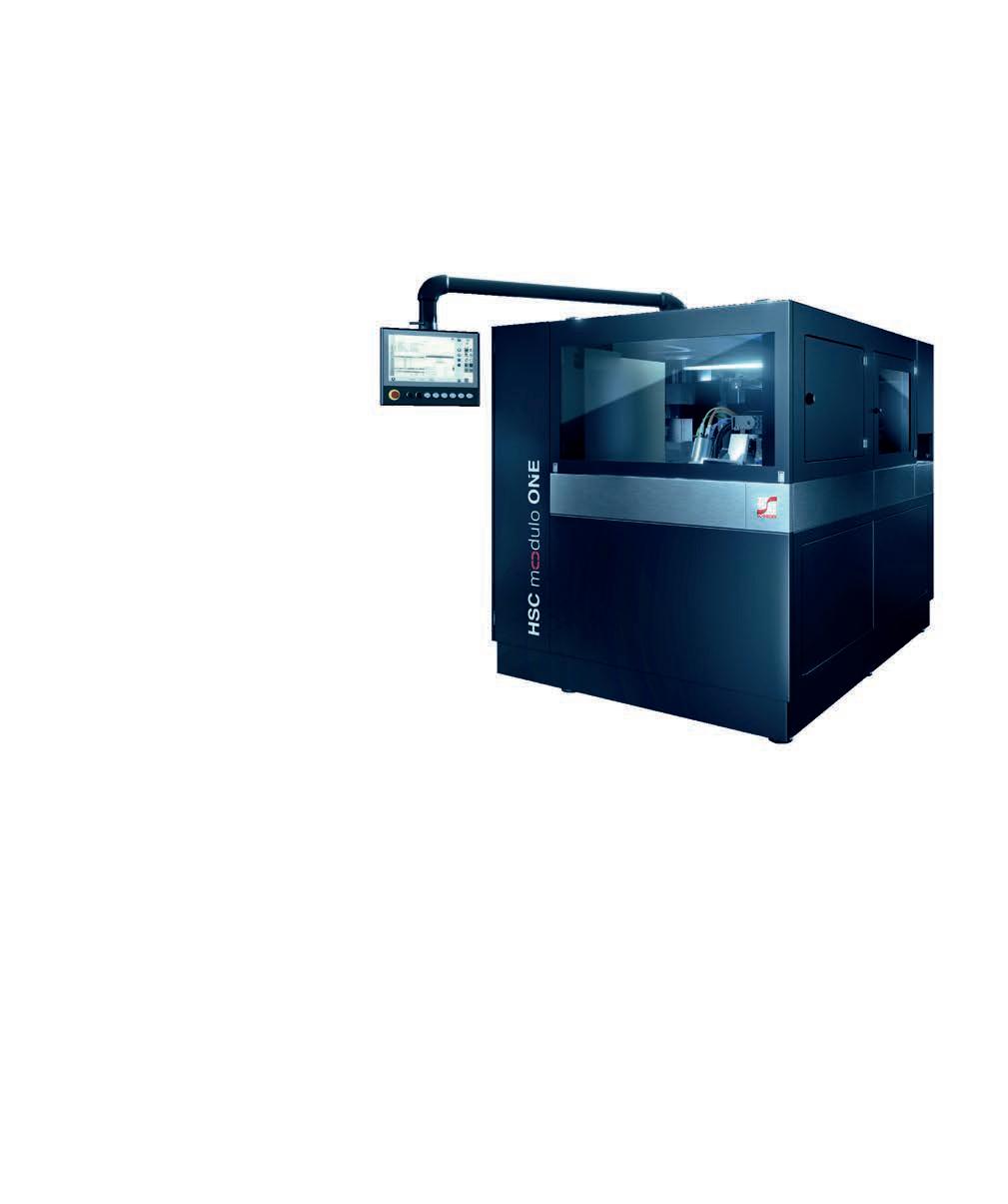

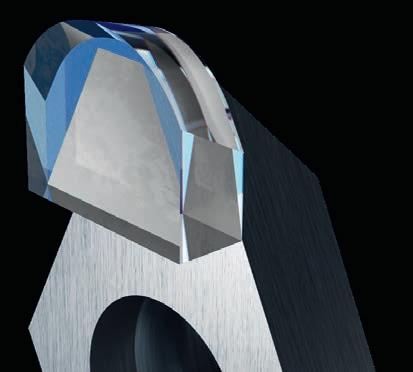

HSC m dulo

From the freeform pioneers comes a new one-of-a-kind generator that excels on every level. With an added performance of more than 50%, HSC Modulo ONE is not just a little bit better but a revolution. It is virtually the power of two generators in ONE and forms the very heart of the Power Lab of the Next Decade – Modulo ONE.

What makes HSC Modulo ONE so exceptionally fast? It is built on a brand new kinematic concept facilitating even faster process times. The high-performance generator relies on the proven two-motor concept featuring the most powerful XS-Tec motor for maximum dynamics and highest quality. The proven RS-Tec motor is known for its high robustness and provides added versatility. A new ultra-fast workpiece changer transfers the lenses and facilitates shortest chip to chip times. The result is insane generating speed and performance at the same great lens quality you know from SCHNEIDER generators.

Ultimately, HSC Modulo ONE provides significantly increased throughput in an even smaller footprint than before. Get the power of two generators in ONE.

ISSN 1614-1598 66527 Volume 20

Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr 66527 Germany

Drastic throughput increase Lowest cost per lens Highest uptime www.schneider-om.com

VIRTUALLY THE POWER OF TWO GENERATORS IN ONE

Hanna Diewald Chief editor

Hanna Diewald Chief editor

Tell us your opinion, ideas and suggestions: hanna.diewald@mafo-optics.com

The focus is shifting

For many years, there seemed to be just one main topic for the research and development departments: working on the best possible progressive lens design – as individual as possible and with the least possible abberations. Freeform technology made possible what previously had been impossible. In fact many of the successes are impressive! But over the years some opticians found it irritating when yet another manufacturer promised to have come up with the most compatible and best ever design; which unfortunately only customers with high incomes can afford.

So it is no wonder that developers have recently turned their attention to completely new target groups and lenses – at least in Europe – namely children. They are now focusing on myopia management and on the fundamental question of whether myopia should be seen as a disease that needs to be counteracted or considered merely as a prescription issue.

There is now a wide variety of lenses on the market that aim to slow down myopia – and new ones are constantly being added. In addition to semi-finished products with a special structure offered by individual manufacturers, freeform technology is now also becoming increasingly interesting in this area.

Starting on page 14, we look at a design that has been tested in European studies and can be produced by independent manufacturers using the freeform process.

We also look at the consequences of such a huge country as the USA having as yet no approved spectacle lens for myopia management, due to the lengthy certification processes. The interview with Dr. Ashley Tucker can be found on page 18.

But the industry also seems to be becoming more diverse and creative on completely different levels. Rodenstock, for example, is now offering the ColorMatic photochromic lens technology as an independent technology brand (page 22). Thus labs now have a larger selection of photochromic semi-finished products available to them.

And the industry giant EssilorLuxottica will soon be venturing into a completely new field: hearing solutions. With its new audio glasses the company wants to tackle two deficiencies with a single product; and it is putting out feelers in a market that is chronically underserved worldwide (page 26).

At the same time, developers are facing other huge challenges. The proposed per- and polyfluoroalkyl substances (PFAS) ban in the USA and in Europe could call for a great deal of creativity, in order to produce PFAS-free products with optimal properties.

Thus research and development is unlikely to be boring for the foreseeable future. However, even if other target groups and spectacle lenses do set the agenda for a while, at some point no doubt opticians will be pleased to see the focus return to the latest progressive lens designs once again.

MAFO 3-24 3 LETTER

MAFO 3-24 5 MAY / JUNE 2024 MAFO issue May / June 2024 Content Topics in this edition At a glance 6 All about you News from the international ophthalmic industry 7 All about markets Infographics 8 All about products Innovations and products for your lab 45 Suppliers Guide 49 Outlook Spotlight 10 10 things you should know about PFAS 18 Every diopter counts ‒but what to do when the aids are missing? An interview with Dr. Ashley Tucker Technology 14 Revolutionizing myopia management By Eva Chamorro and Jose Miguel Cleva 22 A state-of-the-art technology for photochromic lenses By Franz-Josef Achatz 26 What you see is what you hear By Hanna Diewald Live on site 30 A visit to Optovision in Langen By Hanna Diewald and Daniel Groß Business 34 Generation Z What awaits the labor market? Survey 38 Generators History 48 Visual acuity testing on a beer mat By Dr. Hans-Walter Roth Page 14 Page 26 Page 30 Special Topic Special Topic Special Topic Special Topic

All about you

News from the international ophthalmic industry

Xavier Maillard is the new Head of Region EMEA & India at Satisloh

Machine manufacturer Satisloh announced a leadership change in the region EMEA and India. Pascal Elsener, former Head of Region EMEA & India, is leaving the company and is succeeded by Xavier Maillard, the new responsible for the region.

With a mechanical engineering background and 25 years of experience in supply chain and sales management roles in the ophthalmic industry in Germany, France, and Switzerland, Xavier brings a wealth of knowledge and expertise to his n ew position. His journey with Satisloh began in 2009 w ithin the EMEA Sales organization, managing different sales areas and key accounts. Xavier has also been a driving force in building Satisloh´s CPO (Certified Pre-Owned) business, leading the global activities since 2017. I n 2020, Xavier was appointed Territory Director and since 2023, he holds the position of Deputy Head of Region in charge of Equipment.

Coburn Technologies welcomes back Jason Frank as National Sales Manager – Coating Products

Coburn Technologies has welcomed Jason Frank back to their US sales team as National Sales Manager – Coating Products. Many in the optical industry are familiar with Jason, as he was the Sales Manager for Latin America and Florida at Coburn Technologies in recent years. Since then, Jason has continued to work in sales roles within the optical industry.

Prior to Coburn, Jason held Sales Management and Leadership positions at Essilor and Hoya, both in the US and internationally. Most recently he worked as the Sales Director – Latin America & Special Markets with East Optical prior to returning to Coburn in the US.

Ocuco User Group Meeting 2024

Ocuco gathered over 55 customers and industry partners for its Innovations User Group Meeting 2024 “Seas The Day”, held from April 11 to 13, 2024, at the Sheraton Sand Key Resort in Clearwater, Florida, USA. The event brought together optical lab professionals for three days of education and networking.

The meeting featured almost 30 workshops and presentations on topics such as innovations and lablink development roadmaps, strategies to enhance online presence, and specialized personnel recruitment. Highlights included the opening keynote, “Winning the War for Talent,” by resource management specialist Mike Karlsrud, and “Optical Insights: A Deep Dive into Lens Consumer Behavior” by Alysse Henkel, VP of Insights at The Vision Council.

Nearly 100 optical industry executives met for The Vision Council’s Lab Leadership Forum

The Vision Council successfully hosted the 2024 Lab Leadership Forum on Thursday, April 11, and Friday, April 12, 2024, at the picturesque Temecula Creek Inn. This exclusive event saw a gathering of nearly 100 optical industry executives, providing a platform for education, networking, and recognition among optical laboratory professionals.

The Lab Leadership Forum, tailored specifically for The Vision Council’s optical laboratory members, offered a comprehensive agenda aimed at fostering professional growth and collaboration among industry peers. An important item on the program was the posthumous honoring of Steve Sutherlin with the 2024 Goodfellow Award during a poignant ceremony.

You have news for the ophthalmic industry? Submit your press releases to: hanna.diewald@mafo-optics.com or constanze.classen@mafo-optics.com MAFO 3-24 6 INTERNATIONAL NEWS

All about markets

Graphical data

According to The Vision Council´s inSights research report, 36% of adults admit to using their shirt or another clothing item to clean their glasses. A practice that is not recommended by eyecare providers.

Where women are most likely to be your boss

Countries with the highest share of managers who are female

Prescription eyeglasses maintain the most likely to be purchased in-person at 85%

with non-prescription reading glasses and sunglasses following closely at 79% and 77% respectively, says the inSights research report by The Vision Council.

According to a report by the industry association Euromcontact, the wholesale sales of soft contact lenses in a group of 11 European countries increased by 3.7%

year-on-year to €1,755 million in 2023. Although sales also fell in individual countries.

People working in Burkina Faso, Nigeria and Jamaica are most likely to have a female boss. This is according to data by the International Labor Organization. Source: statista.com/chart/3132/where-are-womenmost-likely-to-be-your-bos/

MAFO 3-24 7 INTERNATIONAL NEWS

All about products

Innovations and working materials for your lab

CoreTBA:

The Block-less Freeform lens production system by MEI CoreTBA is the perfect solution for the entire digital lens generation process. This fully integrated equipment represents a game changer in the industry and a revolution in the surfacing field. With its Block-free system, for the first time in history, labs can avoid using tapes, blocks, and wax, or Alloy. This means that it’s not necessary to have taping, de-taping, blocking, and de-blocking machines in the production line anymore. Moreover, with its Dry Cut technology, the CoreTBA doesn’t need a water filtering system, which helps you save money and protect the environment. All processes, from the digital generation to engraving, polishing, and washing, are integrated into one unit with the smallest footprint on the market. In order to achieve a short machining cycle, all processes occur in parallel, and every section of the unit is fed by a tray conveyor system and digitally controlled loading arms. Visit www.meisystem.com

Coburn Introduces New Digital Lens Processing Platforms

Coburn Technologies, a leading provider of ophthalmic lens processing systems and ophthalmic instruments, in continuation of their dedication to advancements in eyecare, has introduced new technology to kick-off their 70th anniversary. The NEXUS Digital Surfacing System leverages the technology in the acclaimed Cobalt Digital Lab to produce high quality digital RX lenses. The system includes the NEXUS DGT Digital Lens Generator and the NEXUS DP Digital Lens Polisher. Each system represents a significant upgrade from its predecessor. “The Cobalt Surfacing System was introduced in 2018 and over the years we saw an opportunity to design an even better platform which we have now delivered in the form of the NEXUS system,” stated Coburn Technologies, President, Alex Incera. “This result was years in the making to ensure we could deliver an even higher performance system.” Labs can expect a processing speed that is 50% faster than the Cobalt NXT Lens Generator. Visit www.coburntechnologies.com

Advertisement

VISIT THE NEW WEBSITE Your trusted source in ophthalmic optics OPHTHALMIC LABS & INDUSTRY VISIT US ONLINE NOW: WWW.MAFO-OPTICS.COM MAFO 3-24 8 INTERNATIONAL NEWS

The regulation of “Forever Chemicals”

In 2023, the much-discussed ban of approximately 10,000 substances so called PFAS (per- and polyfluoroalkyl substances) already made big waves in the European Union. Now there are also initial plans to regulate PFAS in the USA but the potential ban is polarizing. On the one hand it is about protecting people and the environment, on the other hand a blanket ban would affect thousands of everyday items and processes, some are even vital. Be it medical products, refrigerators or heat pumps. Many details about the ban on “Forever Chemicals” are still unclear ‒including the extent to which the laws will later affect ophthalmic products in general and specifically medical devices. However, 10 interesting details about PFAS and their regulation can be found here.

What are PFAS?

10 things you should know about PFAS 1.

PFAS are a group of substances that comprises an estimated number of more than 10,000 different substances. PFAS do not occur naturally and have only been produced and used since the late 1940s. Chemically speaking, the organic compounds consist of carbon chains of different lengths in which the hydrogen atoms are completely (perfluorinated) or partially (polyfluorinated) replaced by fluorine atoms. Those chains of linked carbon and fluorine atoms are among the strongest bonds in organic chemistry. This is where the name “Forever Chemicals” comes from. PFAS are extremely durable and do not simply degrade in the environment. However, it is precisely this durability and special properties that make PFAS interesting for many products.

Lab Management

MAFO 3-24 10 SPOTLIGHT

2.

Best-known representatives of the PFAS group

The best-known representatives of the PFAS-group are PFOS (perfluorooctane sulfonic acid) and PFOA (perfluorooctanoic acid). They have been produced and used since the 1950s. Most toxicological and other scientific information is available on these two substances.

For some time now, other PFAS have been increasingly used. The latest generation of PFAS are, for example, ADONA and GenX, so-called perfluoroethers, in which the fluorinated carbon chain contains bridges of oxygen atoms. There are also PFAS that contain chlorine atoms as well as fluorine in their structure.

For most of the newer PFAS, authorities and scientists have little information on the exact chemical structures, the behavior of the substances in the environment and effects on humans.

In which products do PFAS occur?

3.

In general, PFAS can be found in a wide range of different products, both in industry and in consumer goods. Due to their special properties such as stability as well as water, grease and dirt-repellent properties, they are in demand in many products. These include pans, shampoos, baking paper and dental floss, but also medical implants or heat pumps – this list could be continued endlessly. In production processes, they are used especially under extreme conditions. To what extent ophthalmic optics products are concerned, is still being evaluated. For example if PFAS are used in lens blanks or anti-reflective coatings. But it is very likely that PFAS are a common component of hydrophobic and super-hydrophobic coatings, of anti-fog sprays and hard contact lenses. For many manufacturers of these products, it is still unclear how the corresponding material properties could be produced without the use of PFAS.

4.

Accumulation in soil, water and humans

But the special properties of PFAS pose problems. Due to their longevity PFAS have continued to accumulate in soil and drinking water worldwide. Therefore the substances enter the body of humans via drinking water and food where the PFAS can bind to proteins in the blood, liver or kidneys and thus accumulate in the body. In various studies, on different places in the world, PFAS were detected in the blood of nearly all study participants, sometimes even in 100% of the participants.

Scientists have tested children and adolescents throughout Europe for their exposure to various chemicals, including PFAS. The concentrations found exceeded the critical weekly dose suggested by the EFSA by a factor of a thousand. The compounds PFOS and PFOA had accumulated to a high degree in the blood of the study participants.

What is the problem with PFAS?

5.

PFAS are not acutely toxic chemicals. Using a Teflon frying pan or wearing a Gore-Tex rain jacket is not dangerous at first, but the accumulation in the body via water and food. For most representatives of the substance class, there are no reliable studies on health consequences so far. However, it is known that some of them are definitely harmful to health but it is difficult to assess how dangerous PFAS really are in their entirety because the substance class contains a large number of compounds. Today, science is already aware of some very serious consequences that can result from long-term exposure to some PFAS. Long-chain PFAS in particular, such as PFOS, PFOA, PFHxS and PFNA, remain in the human organism for a long

Advertisement

Lab Management

TOOLING ky diamond.ca ULTRA PRECISION DIAMOND TOOLS FOR ANY GENERATOR EXCELLENT SERVICE QUICK

SPOTLIGHT

SPECTACLE LENS

TURNAROUND

time after ingestion. They do not accumulate in fatty tissue, but in organs − for example in the liver − and in the blood, where they bind to blood proteins.

Studies on larger populations indicate that certain PFAS can damage the liver, the hormonal and immune systems, disrupt fat metabolism, impair the effect of vaccinations, result in lower birth weight, reduce fertility or cause cancer. Babies absorb the substances both via the placenta and later via breast milk. This is why their use should be regulated in some countries. By the way: some PFAS have already been banned in the USA and the EU for some time but not all of them.

6.

Current situation in the USA

The legal situation in the USA is currently very confusing, as the individual states sometimes set different requirements than the United States Environment Protection Agency (EPA). However, EPA recently implemented what is called reporting and recordkeeping requirements for PFAS.

“EPA is requiring any person that manufactures (including import) or has manufactured (including imported) PFAS or PFAS-containing articles in any year since January 1, 2011, to electronically report information regarding PFAS uses, production volumes, disposal, exposures, and hazards [...] Any entities, including small entities, that have manufactured (including imported) PFAS in any year since 2011 will have 18 months following the effective date of this rule to report PFAS data to EPA. Small manufacturers (as defined at 40 CFR 704.3) whose reporting obligations under this rule are exclusively from article imports will have 24 months from the effective date of this rule to report PFAS to EPA,” says the EPA website

According to The Vision Council there might be one good news, because “Not all products will be covered. Products regulated by agencies other than the EPA are exempt from Toxic Substances Control Act (TSCA)

For example, medical devices and drugs regulated by the U.S Food and Drug Administration are exempt from the EPA’s laws. The FDA, however, does regulate materials in medical devices for biocompatibility so a possible scenario where the FDA uses its laws to recall medical devices containing PBTs or PFAS is not too unreasonable.”

Current situation in the EU

7.

In the European Union, the European Chemical Agency (ECHA) evaluation is currently being carried out by the ECHA Scientific Committees for Risk Assessment (RAC) and Socio-Economic Analysis (SEAC). The evaluation is divided into sectors of use. As soon as the scientific evaluation by RAC and SEAC has been completed and the comments on the dossier have been adopted, these are forwarded to the European Commission together with the revised dossier, the comments and feedback on the comments. The Commission will then decide together with the EU Member States on a possible restriction.

8.

Criticism of the blanket ban

Some industry representatives criticize that a general ban makes little sense. Instead, it should be looked at where PFAS could realistically be replaced and where the greatest risks exist. In addition, a pending PFAS ban currently makes it impossible for the industry to make medium and long-term product plans.

The German industry association Spectaris warns that the PFAS ban could become a high-tech ban. “PFAS are indispensable for many industrial processes. Nevertheless, the EU has come out in favor of a blanket ban on around 10,000 PFAS substances because some of them are harmful if they are released into the environment. This comprehensive regulatory approach jeopardizes entire production processes in the Spectaris industries and is not sufficiently scientifically sound. A blanket ban on PFAS makes the use of indispensable high-performance materials impossible in many cases and massively jeopardizes technological sovereignty and security of supply in the EU,” stated the industry association.

Good news – plasma destroys PFAS

9.

Researchers are now working at full speed to find alternative solutions. For example on processes that might remove PFAS from the water.

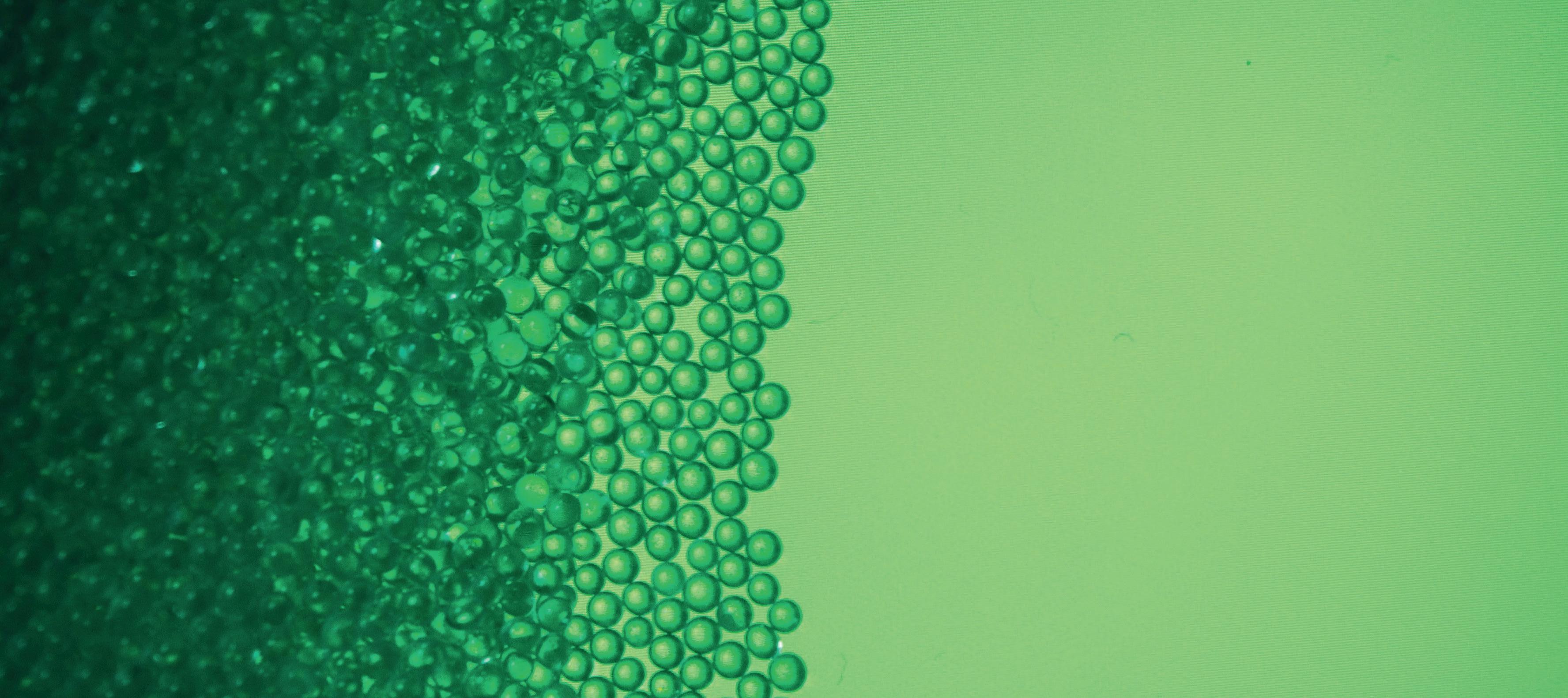

At the Fraunhofer Institute for Interfacial Engineering and Biotechnology, a method for degrading PFAS from real water samples was developed. In the project, supported by the Federal Ministry of Education and Research of Germany, an atmospheric pressure plasma was used. The results showed that it was possible not only to reduce the total concentration of PFAS in the water but also to demonstrate the chainshortening required for mineralization.

10.

Functionalization of survaces to avoid PFAS

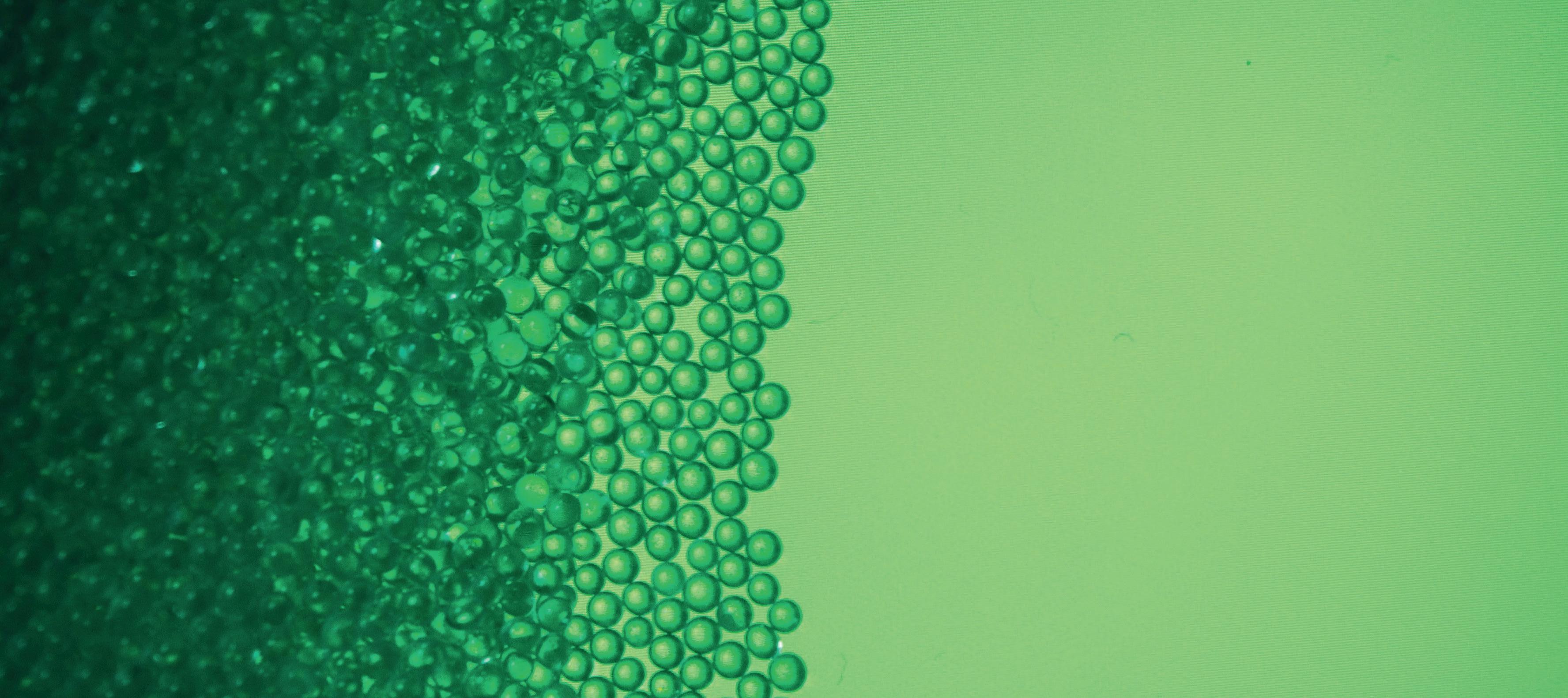

Of course, it would be best to avoid PFAS from the outset. One possible approach is the functionalization of surfaces. A source of inspiration for functional surfaces is nature.

Sharkskin, for example, has a serrated surface that reduces flow resistance and at the same time prevents barnacles from settling. The start-up Surfunction has set itself the goal of transforming such natural phenomena into industrial solutions. Using a special laser process, a wide variety of surface structures can be created.

Lab Management MAFO 3-24 12 SPOTLIGHT

HARD COATING AT BEST PURE TECHNOLOGY

The fully automated CDS 1000 is the most reliable hard coating machine. Producing up to 160 lenses/h, it is a perfect fit for medium and large size labs. It features six cleaning tanks and offers continuous and fast processing without any batching. Varnishing takes place by thermal polymerization. An automatic refill system provides consistent and stable process control - keeping detergent and varnish tanks at the same level and condition. A unique water cascading and filtrating system enables city water savings up to 75%, making the CDS 1000 an environmentally-friendly coater. Technique.

Safety. Expertise. www.scl-intl.com HARD COAT LEADER HARD COAT CLEAning TinTing PERiPHERALs ExPERTisE

CDS 1000

Revolutionizing myopia management

A novel approach to treating children’s myopia

The global surge in myopia prevalence has raised concerns among practitioners, driving the need to develop effective myopia management solutions. A lens with asymmetric myopic peripheral defocus (MPDL) has been specifically designed to address the problems related to progressing myopia which fully corrects the refractive error at the fovea while inducing a myopic defocus on the peripheral retina. Furthermore, this design is produced by means of freeform technology, eliminating the need for special semifinished products. By Eva Chamorro and Jose Miguel Cleva

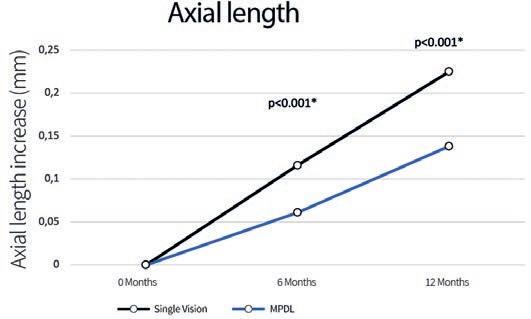

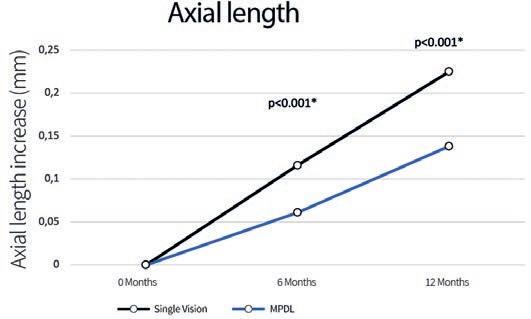

The efficacy of this myopia management lens has been evaluated in the first randomized, double-blind study carried out, specifically in a European population. After 12 months of follow-up, the study demonstrated a remarkable 39% reduction in axial length progression, distinguishing this solution from conventional single vision lenses.

In this article, this pioneering solution that utilizes freeform technology is presented with a full explanation of its lens geometry, the fundamental theories of peripheral positive/myopic defocus and asymmetric defocus

as well as the clinical trial that shows the efficacy and wearer satisfaction of this solution.

Myopia prevalence is growing Myopia is expected to become one of the leading causes of permanent blindness in the world. It is well-known that myopia prevalence is growing at an alarming rate all over the world. According to the Myopia Institute, five billion people will be myopic by 2050, and 20% of them will become highly myopic (higher than 6.00 D) with a greater risk of

Lab Management MAFO 3-24 14 TECHNOLOGY

experiencing structural changes in the eye that can cause significant visual disability.[1,2]

Eye care professionals around the world are concerned about the significant increase of the global prevalence of myopia and potential consequences, leading to an increased interest of practitioners to implement myopia management solutions in their routine practice. Currently, there are some treatments available that may help to reduce myopia progression, such as spectacle lenses, contact lenses, orthokeratology, or eye drops. However, there is a special interest in spectacle lens options for myopia management because of their ease of use, easy acceptance by wearers, and their lack of health-related side effects.[3]

The asymmetric myopic peripheral defocus lens

IOT has developed a lens with asymmetric myopic peripheral defocus (MPDL) that has been specifically designed to fully correct the refractive error at the fovea while inducing a myopic defocus on the peripheral retina to help slow the progression of myopia in young patients. This defocus is achieved by a carefully designed distribution of positive power at the lens periphery that consider the morphological characteristics of the myopic retina intended to reduce myopia progression. The characteristics of these spectacle lenses design align with the theory of creating simultaneous myopic retinal defocus during both distance and near viewing.

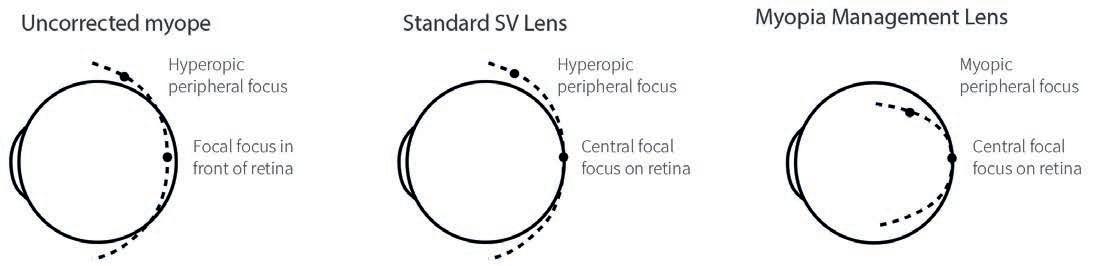

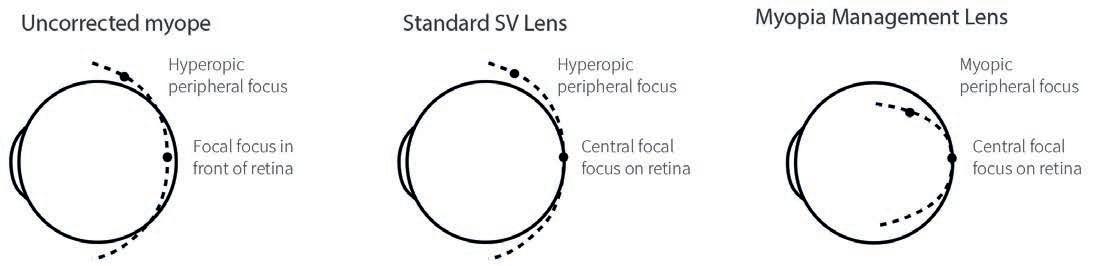

In uncorrected myopic eyes, images are formed in front of the retinal plane, leading to blurred vision. To correct myopia, standard single vision negatively powered lenses are prescribed to shift images onto the retinal plane. However, the peripheral defocus theory suggests that the use of standard single vision lenses results in images falling behind the retinal plane in the peripheral retina (instead of on the retina). Different studies have hypothesized that inducing peripheral hyperopic defocus, as standard single vision lenses do, provides a stimulus for axial elongation and the consequent progression of myopia. Also, experiments in animals have shown that myopic defocus induced with positive power in the peripheral retina reduces axial elongation.[4]

For that reason, the lens with MPDL technology has been specifically designed to fully correct the refractive error at the fovea while inducing

a myopic defocus on the peripheral retina. Furthermore, it is well known that the retina is asymmetrical. Differences between nasal and temporal retinal hemifields have been found regarding anatomical neural characteristics, peripheral refraction, and axial growth.[5-7]

It has been suggested therefore, that sensitivity of the retina could be different between the nasal and temporal hemifields[7] with the nasal half of the retina being more important when considering the mechanism driving eye growth in the presence of hyperopic defocus[7] as is the case with standard single vision lenses.

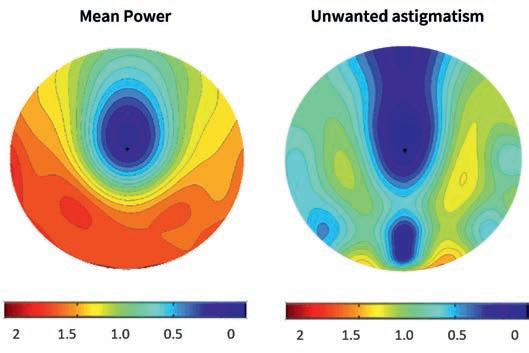

Power distribution

Following these principles, the power distribution of the lens with MPDL technology consists of a blur-free small area around the optical center providing clear and sharp central vision. The area has an ovoidal shape, with horizontal size of 7 mm and with a larger vertical dimension extending to the upper part of the lens to achieve the best balance between the treatment region and the central correction area. The central area is surrounded by a progressive power distribution whose defocus level is modulated for the different retinal areas, with different addition power between the different regions of the lens: addition of +1.50 at 25 mm nasally, +1.80 D at 25 mm temporally, and +2.00 D at the bottom of the lens.

Lab Management

Fig. 1: Central and peripheral focus of an uncorrected myope, a myope corrected with standard single vision lenses and a myope corrected with a myopia management spectacle lens based on peripheral defocus theory.

MAFO 3-24 15 TECHNOLOGY

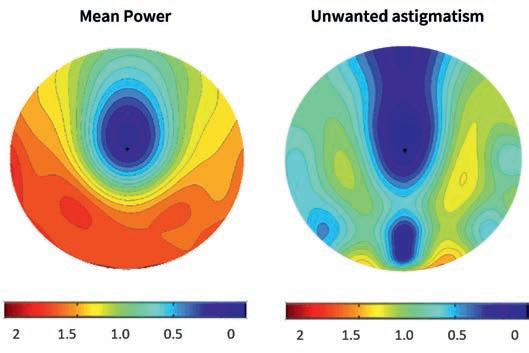

Fig. 2: Power distribution maps (spherical equivalent and cylinder power) for a plano prescription of the design of ophthalmic lens with MPDL technology.

Additionally, thanks to the positive progressive power defocus at the peripheral areas of the design, the lens has a natural, aesthetic appearance and is thinner than a standard single-vision lens. However, the most important characteristic is the demonstrated efficacy to reduce myopia progression and the high levels of wearer satisfaction.

The study design and results

To evaluate the effectiveness of the lens with MPDL technology in reducing the progression of myopia a prospective, controlled, randomized, double-masked clinical trial led by the Universidad Europea de Madrid in a Spanish population, (clinical trial NCT05250206) and following the recommendations of the International Myopia Institute has been carried out.[8]

The study was done in a sample of 83 children divided in two groups: 42 children wearing standard single vision lenses and 41 children wearing the lenses with asymmetric myopic peripheral defocus during 12 months of follow-up.

Results of the study showed that using the lenses with MPDL technology reduces axial length growth in comparison to the use of standard single vision lenses. Specifically, the growth of axial length was 39% less in the group wearing the lenses with MPDL technology than in the control group wearing standard single vision lenses after 12 months of follow-up.[9]

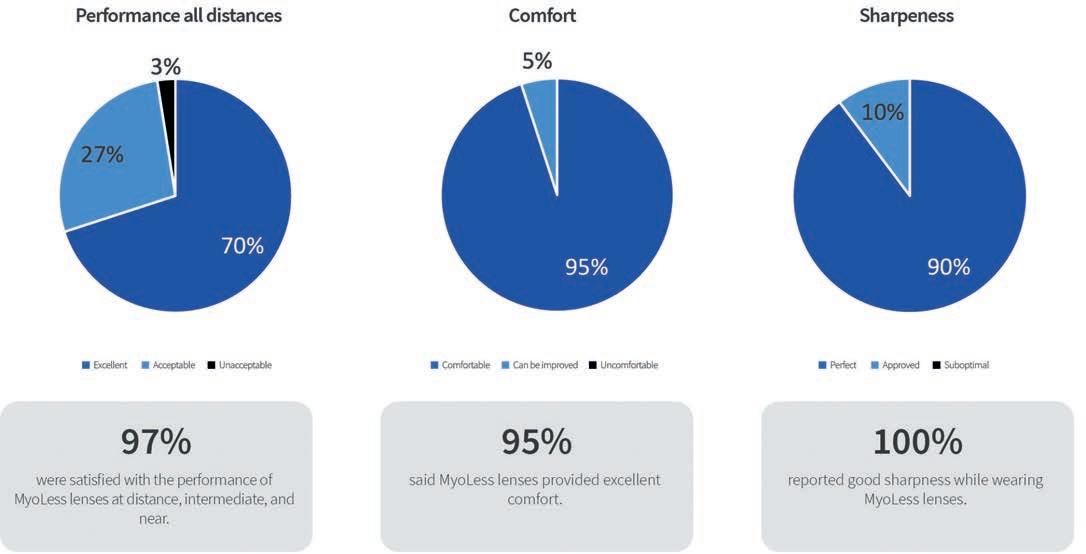

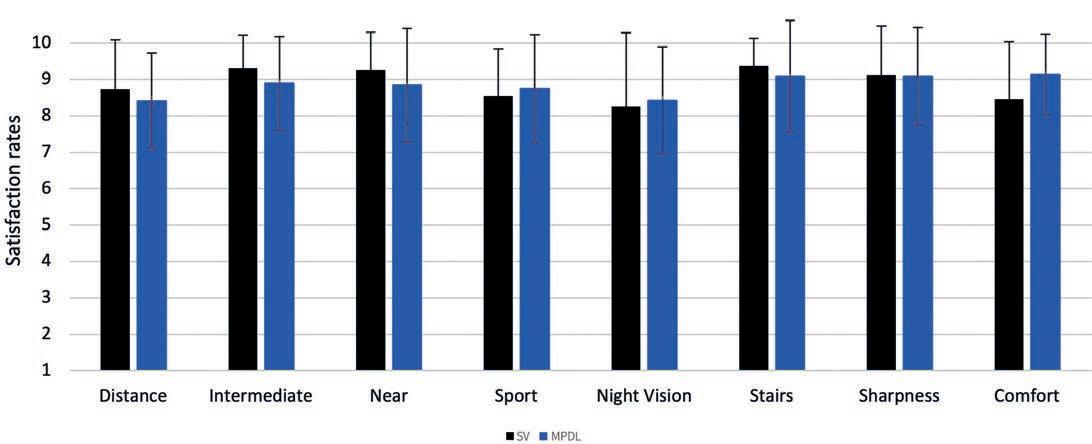

Regarding wearability, lenses with MPDL technology scores similarly to a standard single vision lens. It obtains high satisfaction rates for all the variables analyzed, ensuring that the lens is comfortable and with high scores for wearer satisfaction.[10]

The exceptional performance of the lens is the result of the optimal balance between the sizes of the optical correction zone and treatment areas and the use of the ideal asymmetrical power profiles for peripheral defocus. This results in a lens that provides good performance and sharpness for distance, intermediate and near vision with added wearer comfort.

Conclusion

In conclusion, lenses with MPDL technology are a novel approach to treating children’s myopia by means of an asymmetric myopic peripheral defocus lens design produced by means of freeform technology. The efficacy and wearability of lenses with MPDL technology has been proved though a randomized, double-blind study of a 1-year clinical

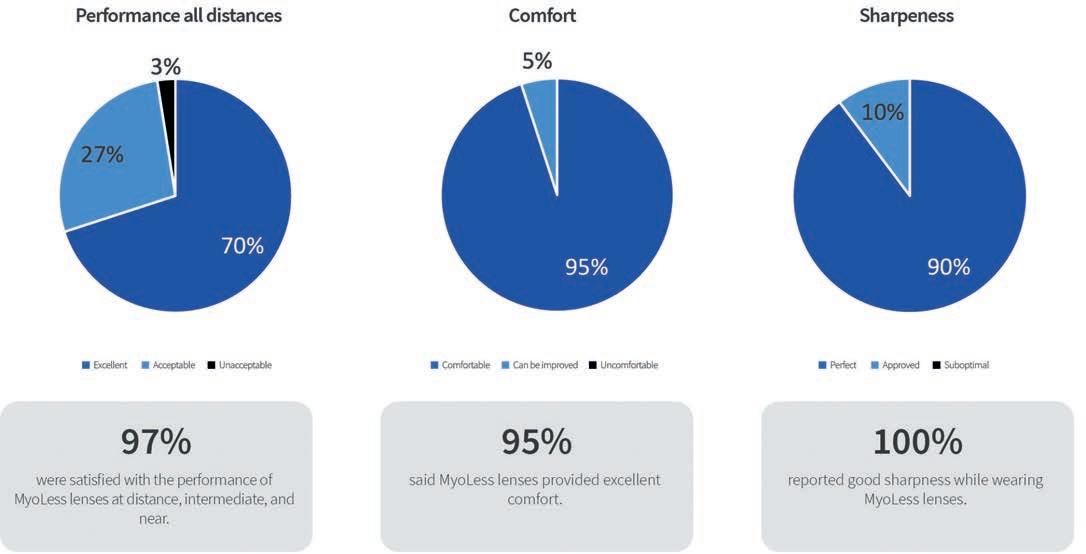

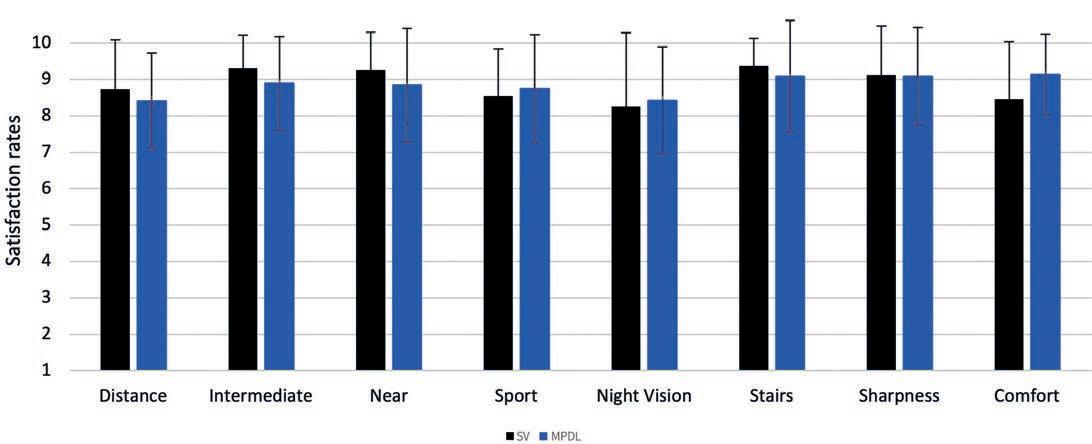

4: Percentage of satisfaction after 12 months of using the lens with MPDL technology. Patients rates their satisfaction in a scale from 1 to 10 for each item. Rates between 8 and 10 were considered excellent performance, acceptable were considered rates between 5 and 7 and unacceptable rates below 5.

Lab Management

Fig. 3: Axial length increase (mm) after 12 months of follow-up for a standard single vision lens in comparison to lenses with MPDL technology.

Fig.

n Excellent n Acceptable n Unacceptable n Comfortable n Can be improved n Uncomfortable n Perfect n Approved n Suboptimal MAFO 3-24 16 TECHNOLOGY

5: Average satisfaction rates after 12 months of follow-up for a standard single vision lens in comparison to lenses with

technology. Patients rate their satisfaction in a scale from 1 to 10 for each item.

trial carried out in a European population, showing that after one year of treatment, the proposed lens showed an efficacy of 39% for reducing axial length growth in myopic children. Additionally, thanks to the utilization of freeform technology, this solution ensures enhanced comfort, superior aesthetics, and a natural appearance, without the reliance on specialized semi-finished products. ◆

References

[1] Gifford, K., Haines, C. How much axial length growth is normal? Myopia profile. 2021

[2] Morgan, IG, Wu, PC, Ostrin, LA, Tideman, JWL, Yam, JC, Lan, W, Baraas, RC, He, X, Sankaridurg, P, Saw, SM, French, AN, Rose, KA, Guggenheim, JA. IMI Risk Factors for Myopia. IOVS. 2021;62(3):1-20.

[3] Wolffsohn JS, Whayeb Y, Logan NS, Weng R, Weng R. IMI—Global trends in myopia management attitudes and strategies in clinical practice—2022 update. IOVS. 2023;64(6):1-15.

[4] Lin, Zhi & Martinez, Aldo & Chen, Xiang & Li, Li & Sankaridurg, Padmaja & Holden, Brien & Ge, Jian. Peripheral Defocus with Single-Vision Spectacle Lenses in Myopic Children. OVS. 2009;87:4-9.

[5] Curcio C. A. Allen K. A. Topography of ganglion cells in human retina. J. Comp. Neurol., 1990;300:5–25.

[6] L ogan NS, Gilmartin B, Wildsoet CF, Dunne MC. Posterior retinal contour in adult human anisomyopia. IOVS 2004;45:2152-62.

[7] Faria-Ribeiro, M., Queiros, A., Lopes-Ferreira, D., Jorge, J., & Gonzalez-Meijome, J. M. Peripheral refraction and retinal contour in stable and progressive myopia. OVS. 2013;90(1):9-15.

[8] Wolffsohn, J. S., Kollbaum, P. S., Berntsen, D. A., Atchison, D. A., Benavente, A., Bradley, A., Buckhurst, H., Collins, M., Fujikado, T., Hiraoka, T., Hirota, M., Jones, D., Logan, N. S., Lundström, L., Torii, H., Read, S. A., & Naidoo, K. IMI – Clinical myopia control trials and instrumentation report. IOVS. 2019;60:M132–M160.

[9] Sánchez-Tena, M.A., Cleva, J.M., Villa-Collar, C., Álvarez, M., Ruiz-Pomeda, A., Martinez-Perez, C., Andreu-Vazquez, C., Chamorro, E., & Alvarez-Peregrina, C. Effectiveness of a Spectacle Lens with a Specific Asymmetric Myopic Peripheral Defocus: 12-Month Results in a Spanish Population. Children. 2024;11(2):177

[10] Concepción, P., Cano, C., Martinez-Pérez, C., Sánchez-Tena, M.A., Álvarez-Peregrina, C., Andreu-Vazquez, C., Cleva, JM., Villa-Collar, C. Subjective wearing experience of a novel spectacle lens for myopia management based on peripheral asymmetric myopic defocus. EAOO. 2024.

Jose Miguel Cleva is as VP of Technical Operations at IOT in charge of the technical support, quality control, production improvement, development of services and applications to improve the customer experience. He has a master’s degree in mathematics (major in Computer Science) at Complutense University of Madrid and is specialized in Computer Sciences (in the program “Languages and Computer Systems”) from the same University. Furthermore, he is a prolific and versatile researcher with an extensive and diversified curriculum.

Eva Chamorro is Clinical Research Director at IOT where she is involved in creating new lens designs and testing those trough theoretical analysis and wearer trials. She has a PhD in Visual Sciences, a degree in Optics and Optometry, a master’s degree in Optics, Optometry and Vision and Visual Rehabilitation and she is an expert in new methods and advanced techniques of visual examination. She shows a high activity in research projects, and in national and international congresses and she is an author of papers and patents in the field of Optometry.

Lab Management

Eva Chamorro

Jose Miguel Cleva

Fig.

MPDL

MAFO 3-24 17 TECHNOLOGY

n

SV n MDPL

Every diopter counts ‒but what to do when the aids are missing?

An interview about myopia treatment options in the US with Dr. Ashley Tucker

Every diopter counts and every child counts, state experts around the world when talking about myopia management in children. But what to do when there are simply no products approved for myopia treatment? This is the challenge facing ECPs throughout the USA. The third largest country in the world has so far only approved one single contact lens for myopia management. A scenario that has become unthinkable in Europe, where spectacle lenses for myopia management are sprouting up everywhere. MAFO wanted to find out more about the current situation in the USA and its impact. We spoke to a woman who describes herself as a myopia management enthusiast: Dr. Ashley Tucker. For years, she has been fully committed to ensuring that myopia management aids get finally approved in the US. And she has been appointed recently, as one out of four ambassadors for the education, outreach and practice-building initiatives of the World Council of Optometry (WCO), in partnership with CooperVision. By Hanna Diewald

Dr. Ashley Tucker

Dr. Ashley Tucker graduated from the University of Houston College of Optometry where she also completed a cornea and contact lens residency. Dr. Tucker is a partner at Bellaire Family Eye Care and The Contact Lens Institute of Houston and she is also a Visiting Assistant Professor at the University of Houston College of Optometry.

Dr. Tucker spends the majority of her clinic time managing patients who are in need of specialty contact lenses or myopia management and she has the honor of speaking on behalf of several contact lens companies on these topics. In addition, Dr. Tucker is a council member of the Contact Lens and Cornea section the AOA, a member of the advisory board for GPLI, and serves as the Public Outreach Chair for the Scleral Lens Education Society.

MAFO 3-24 18 SPOTLIGHT

Is myopia management in general a big deal in the USA?

Myopia management is making big headway in the US. The World Council of Optometry declared in 2021 that myopia management is now standard of care. That is a huge step forward. But we still have a lot of work to do to get patients, parents, even doctors still on board with the concept of managing myopia versus just treating it.

It is a whole shift in the mindset of practicing that we, the people promoting myopia management, are actively working on. We talk about it nonstop ‒ but it is still not enough.

A lot of patients and their parents come into our practice and have some awareness of what managing myopia looks like, but it still takes a lot of time to educate parents on the importance of managing this condition instead of just watching it progress.

Some kids are truly missing out and we will have missed the entire opportunity to control their myopia while waiting for the approval.

When you finally convinced them, what aids can you offer at all?

Currently, in the US, all we have is one single FDA approved product. It is a daily disposable contact lens that is very effective. It is a fantastic product, but we have lots of parents that hesitate to put their children in contact lenses at a young age or the kids are averse to putting contacts in their eyes. That is a whole subset of people that is automatically disqualified for a contact lens option.

Then we have to look off-label, because we do not have an FDA approved pharmaceutical either. We are currently using atropine off-label for those patients that do not want to use contact lenses.

But I personally do not use any spectacles off-label because there is plenty of research showing that bifocals and progressives are the least effective in myopia management.

For patients that have higher prescriptions or for patients that have a significant amount of astigmatism we can use also other contact lenses off-label. But for my philosophy, if I can get a child in the FDA approved option, that is what I am doing. But I am not limiting myself to only what the FDA approved option can do.

What is the problem with the “off-label-use”?

There is not one specific problem. When talking about something that is novel – like myopia management – parents are most interested in the product that is backed by the FDA. So, it is a much easier conversation to have. In addition, there is plenty of literature backing the efficacy and safety of this option.

When we are forced to use off-label products, we have less research backing our efforts and for some options like atropine, we can’t even explain to the parents the actual mechanism of action because it is currently not fully understood.

Can you please describe the current situation in the USA regarding spectacle lenses for myopia management?

We have nothing on the market so far and we are feverishly trying to get something approved. I am personally involved in one clinical trial that will eventually get us to market. It is the one by SightGlass Vision (editor´s note: A joint venture by CooperCompanies and EssilorLuxottica). But we have nothing available right now. It is a very slow-moving process and that is frustrating ‒ it has been several years now …

When you think about the pediatric age, the age from six to twelve are the formative years. Therefore, some kids are truly missing out and we will have missed the entire opportunity to control their myopia while waiting for the approval. So that timeline is super frustrating.

Advertisement

SPOTLIGHT

Data on pathological myopia in the USA remains lacking. However, it is estimated that around 4% suffer from high myopia, with big differences depending on the ethnic group. The term high myopia should not be equated with pathological myopia.

1%

of Europeans

1-3% of Asians

3% of the world's population is affected by pathologic myopia

What are the challenges in the approval process?

In my opinion the approval process is moving really slowly but I understand that we are studying a vulnerable group – children – and we have to be extra careful. But since these lenses are already approved in other countries, it would be great if the process could be expedited for us here in the U.S. The major harm that we are doing to our patients is waiting with no treatment. The worst case scenario for these glasses is that they simply don’t work or don’t work as good as we had hoped. Best case: they do work even if they work better than no treatment, we are winning! I will tell you the challenges that I have in my practice: The potential recruiting group, for these clinical trials, is very small. It is a small age group from let us say age 6 to 7. They need to be myopic and they need to have no history of using any sort of myopia control aids. They cannot have been in myopia control contact lenses; they could not have been in atropine. Therefore, it is difficult to recruit the patient population that we need to get this passed through the FDA.

Do you have any idea when the FDA approval will go through for spectacles?

That is the biggest question for all that are impatiently await this to arrive. But no one is telling us. Here are so many families, at least in my practice, that are desperately waiting for this. Some people have access to individuals in other countries that are getting glasses from other countries. Others are traveling to Canada to get those glasses. I am managing some patients who have them, but I can only manage them. I cannot reorder them or prescribe them or anything like that. There is a desperate need and desire for those spectacle lenses but we have no timeline.

According to the International Myopia Institute 3% of the world´s population is affected by pathologic myopia. Pathologic myopia affects 50-70% of the people with high myopia.

Is there anything the industry or ECPs can do to speed up the lengthy process?

I think everyone is doing all that they can. But, if doctors could collectively help recruit subjects for these trials, that would definitely expedite things. The hardest part is recruiting willing and eligible subjects.

Do you personally think that spectacle lenses are as effective as contact lenses or is it more about comfort?

The literature and research show, that all three options ‒ the HAL, DIMS and DOT technology ‒ seem to be similar in their efficacy and pretty similar to what the FDA approved contact lens options have shown us. So yes, I am really excited that this is going to be an option for our patients.

What would be your biggest wish for the near future?

My biggest wish would be the spectacle option just because it will open up myopia management to pretty much every patient.

But I cannot wait either for an FDA approved formulation of atropine, both for monotherapy and then potentially for a combination therapy for those kids that need more than one therapy. Atropine, coupled with glasses, or atropine coupled with contact lenses.

Thirdly, I would just wish that there would be more awareness of the importance of myopia management and not to have to spend so much chair time convincing parents that this is important.

And finally, from a public health standpoint, I wish there were just more awareness that myopia is a disease and it is not just a prescription issue. We are the ones that shape the future, and we have the ability to change the mindset. ◆

MAFO 3-24 20 SPOTLIGHT

A state-of-theart technology for photochromic lenses

The history of ColorMatic

Photochromic lenses by Rodenstock have a very long history. For more than 55 years now, the product has been continuously improved. The primary development goals were always the same: rapid reaction kinetics in lightening and darkening, an almost transparent lens indoors and a comfortably darkened lens in the sunshine. Thanks to an innovative compound technology, the lenses are now almost perfect and exactly at this high level the company has taken a surprising step. From now on, independent lab partners will have access to the ColorMatic technology as well as to ColorMatic as an independent technology brand.

By Franz-Josef Achatz

Photochromic lenses since 1960

Self-tinting lenses have the spectacular property of changing their light absorption evenly and reversibly depending on the sunlight intensity. Starting from a highly transparent basic state, they darken when exposed to sunlight and lighten up again with decreasing sunlight, returning to their original state.

The first photochromic lenses were developed in the 1960s using mineral glass by two American chemists, Stanley Donald Stookey and William Armistead. Recognizing the comfort this technology offered to spectacle wearers, Rodenstock, a pioneer in the field, introduced them to the European market in 1968 as the first European lens manufacturer.

Lab Management MAFO 3-24 22 TECHNOLOGY

While the desire for even greater comfort using lighter plastic lenses was already apparent, the production process used for mineral glass could not be directly transferred to plastic lenses.

The first generation of phototropic plastic lenses from Rodenstock was introduced as “ColorMatic” on the market in 1986. Ever since, generations of dedicated scientists at Rodenstock have been working on further improving this first generation. Properties like darkening depth, fading speed and stability have been successively improved.

The goal was and still remains to offer the best possible performance and quality to spectacle wearers. Therefore, Rodenstock continued to question their products, to push boundaries, change paradigms and maintain their good market position.

The functionality of photochromic lenses

As is widely known, photochromic molecules in the lens react to UV radiation. Indoors, they maintain a closed structure, allowing visible light to pass through the lens unhindered. When exposed to sunlight, the photochromic molecules react and change their structure. They unfold, the changed structure absorbs more visible light, thereby reducing transmission. The lenses darken.

If the intensity of UV radiation decreases, for example due to cloud cover, the molecules partially close again. The lens becomes semitransparent. If UV radiation no longer impacts the lens, the photochromic molecules return to their initial state, allowing visible light to pass through. The lens becomes clear again.

The photochromic technology of ColorMatic

As one innovation leader for photochromic lenses, Rodenstock is constantly setting new standards in quality, speed and stability with its own research and development department. With a clear focus on innovation, the pioneering work in this area is reflected in a track record of over 80 patents.

ColorMatic is a high-performance technology for photochromic lenses offering protection against harmful UV light and reducing blue light and glare. For light-sensitive spectacle wearers in particular, it offers relaxed vision thanks to tinting in appropriate light conditions. Since the first product generations, rapid reaction kinetics in lightening and darkening has been a primary development goal for all Rodenstock photochromic products. Thus ColorMatic offers outstanding vision clarity and performance across all refractive indices and materials, as well as high lightening speed in all climates and throughout all seasons, 365 days a year.

This greatly improved reaction kinetics, coupled with consistently stable photochromic performance and UV protection, is achieved by technology.

A conventional approach to improving kinetics would involve designing the polymer matrix (the plastic material surrounding the dyes) to be more flexible. However, a very soft matrix is not compatible with high mechanical stability requirements.

The latest generation for best performance

With ColorMatic X, Rodenstock is taking a different approach: Rodenstock has taken their latest dye generation and embedded it in a durable optical high-index matrix. However, the dye’s surroundings have a different flexibility. Additional degrees of freedom regarding optical properties and UV protection are generated by the compound technology, which separates the function of phototropism from the optical and mechanical properties of the lens.

Full UV protection is ensured by the superior base lens. The lens can thus change from the darkened state to the colorless state at an accelerated rate – 54% faster than the previous generation. In doing so, the lenses achieve a base transmittance of up to 95%, meaning they are hardly distinguishable from conventional lenses indoors, making them currently the clearest photochromic lenses on the market.[1]

The lightening time is a crucial factor for phototropic lenses because faster lightening means a seamless viewing experience for the wearer. Another advantage is that the lenses darken by up to 88% outdoors, providing the wearer with comfortable vision and protection in changing light conditions and bright sunlight.

ColorMatic as an independent technology brand

To emphasize this outstanding technology, Rodenstock is taking a decisive further step and positioning ColorMatic as an independent technology brand with its own brand design, thus giving independent lab partners access to the ColorMatic technology and brand.

The positioning as an independent brand demonstrates the company's ongoing commitment to innovation and product development and represents Rodenstock's high-quality photochromic technology with its own brand design. The recently introduced hexagon logo stands for a photochromic molecule that represents the technology through a color gradient. The associated tagline “Engineering photochromic performance” refers to the outstanding in-house expertise and the endeavor to redefine the limits in terms of performance and speed. ◆

References [1] Based on internal data on index 1.60

Franz-Josef Achatz

Franz-Josef Achatz

Franz-Josef Achatz is a Senior Manager in the Global Product Management Lenses at Rodenstock. With his passion for strategy and innovation management in the field of ophthalmic lenses, he focuses on the development and marketing of photochromic products, among other things.

Lab Management

MAFO 3-24 23 TECHNOLOGY

Why Choose MAFO

Expertise: Our team comprises ophthalmic optics specialists

Global Insights: We connect professionals worldwide

Comprehensive Coverage: From articles to market analysis

Timely Updates: Stay informed in a fast-paced industry

VISIT US ONLINE NOW: WWW.MAFO-OPTICS.COM VISIT THE NEW WEBSITE YOUR TRUSTED SOURCE IN OPHTHALMIC OPTICS

OPHTHALMIC LABS & IN DUSTRY

ColorMatic® – Controlling light through technology

An interview with Soren Ostergaard from Rodenstock

Soren Ostergaard, Vice President International Sales at Rodenstock talks about the move to establish ColorMatic® as an independent technology brand and the resulting benefits for lab partners.

What does the technology brand ColorMatic® stand for?

ColorMatic® represents a self-developed, high-performance technology for photochromic lenses, providing protection against harmful UV light, artificial blue light, and glare. For over 55 years, it has been a testament to Rodenstock's expertise and innovation. However, Rodenstock does not settle for standard; it always pushes the boundaries further. Our in-house experts in research and development, with 100% German engineering, have consistently set the benchmark, tirelessly working to push the technological limits of photochromic technology.

What were the reasons for positioning ColorMatic® as an independent technology brand?

Positioning ColorMatic® as its own technology brand demonstrates a continuous commitment to innovation and product development, emphasizing the importance of the outstanding photochromic technology through its own brand design. The newly developed Hexagon logo symbolizes a photochromic molecule, representing the technology through a gradient of colors. The accompanying tagline, "Engineering photochromic performance," highlights the exceptional in-house expertise and the aspiration to redefine boundaries in terms of performance and speed.

What are the advantages for lab partners of the new positioning as a brand?

By expanding as an independent technology brand, lab partners now have the opportunity to leverage the ColorMatic® technology brand and branding flexibly as part of their own premium tailored solution. Integrating ColorMatic® into their own portfolio enables our lab partners to position themselves at a high level of quality. Through the high degree of independence of this brand, Rodenstock supports lab partners in the individual implementation of ColorMatic® according to their needs. As a strong partner and independent provider, Rodenstock offers them the highest quality, extensive experience in production, as well as support in marketing and sales.

What does the ColorMatic® portfolio look like?

The ColorMatic® portfolio is uniquely diverse. In addition to ColorMatic® X, we also offer ColorMatic® 3, which boasts impressive performance and intense darkening, along with a wide selection of indices and color variations. Completing the portfolio is ColorMatic® Sun 3, an intelligent sunglass lens with contrast enhancer. As we are constantly working on further developments, we aim to grow together with our lab partners and continue to strive towards supporting the needs of spectacle wearers with the highest level of innovation and the best products in the future.

More information under: www.colormatic-lenses.com MAFO 3-24 25 PR-ADVERT

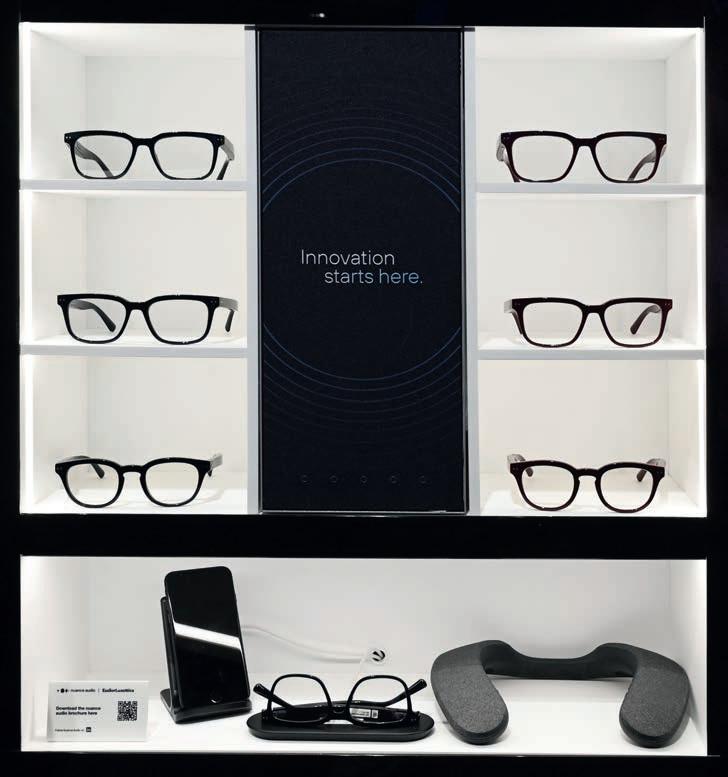

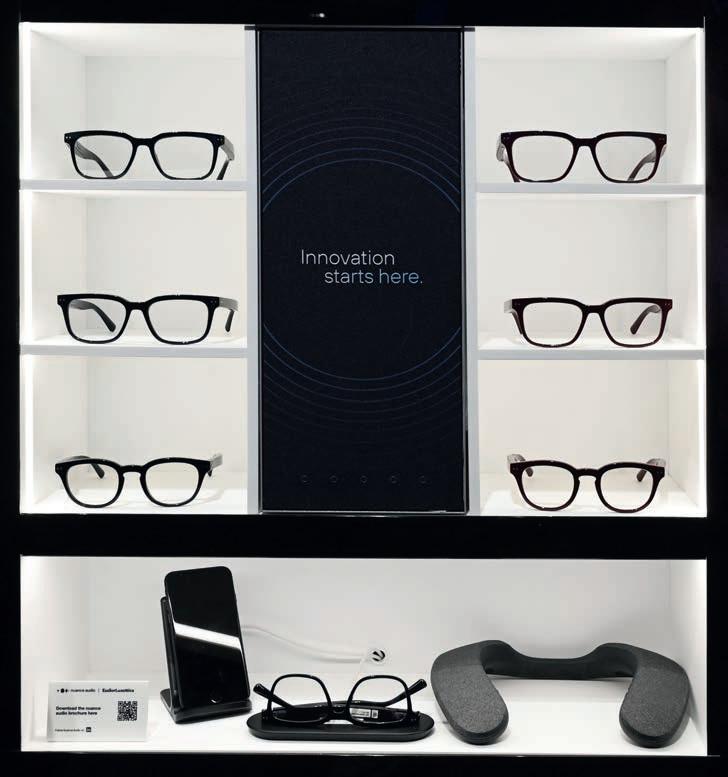

What you see is what you hear

EssilorLuxottica launches first hearing aid glasses

According to the World Health Organization (WHO), one in four people worldwide is expected to have hearing problems by 2050. At the same time, the undersupply in the hearing aid market is serious. One reason for this is that hearing systems are often associated with a lot of stigmatization. For example: “Anyone who wears hearing aids is old”. Even though this prejudice is far from reality. Therefore, the industry giant EssilorLuxottica now wants to address this issue in a special way: The company's first hearing aid glasses will be launched on the market in fall 2024, The group is thus entering completely new territory in the hearing acoustics industry. In this article you will find out more about the opportunities and special features of the new technology and differences compared to traditional hearing aids. By Hanna Diewald

Nuance Audio is the name of the new smart glasses with audio components like microphones and speakers that are to be launched on the US market in the second half of 2024. After that, they also will come to Europe. Already in summer 2023, EssilorLuxottica announced that it had acquired 100% of the Israeli start-up Nuance and was now working on hearing aid glasses with an audio team and in-house research and development.

Hearing aid glasses themselves are not necessarily anything new. The first hearing aid glasses already existed in the 1950s. What is new, however, is that the world's largest ophthalmic optics group by far is now entering this market. What was previously a niche product could therefore gain a whole new reputation. This step is particularly exciting as there is a large global gap in the provision of hearing aids, which varies significantly from country to

MAFO 3-24 26 SPOTLIGHT

country. Unfortunately, precise data on this is often lacking but EssilorLuxottica itself assumes that there is a global coverage gap of 83%.

An invisible hearing solution

In February, at the Mido trade fair, MAFO editors had the chance to test the new hearing glasses live, even before the official launch. “We are talking about glasses with an invisible integrated hearing solution,” explained Stefano Genco, Global Head of Super Audio and Nuance Audio, at the EssilorLuxottica booth. And indeed, the frame does look very similar to a standard acetate frame. The technology, such as various microphones and two loudspeakers near the ears, is invisibly built into the temples. Individual power lenses can be fitted as usual by any standard lens manufacturer.

Nuance Audio comes with a wireless charging pad for easy recharging. It takes around 2.5 hours to charge fully and the estimated battery life is around eight hours of typical usage in a noisy environment.

The hearing aid glasses are available on the market in two colors, with two different temple lengths and in three sizes (48, 54 and 56). “The biggest one is specially addressed to the US market, where we will launch Nuance Audio first,” explained Genco.

The technology and how it works

For the user, the hearing aid glasses work very simply. Various microphones in the glasses record the sound.

The speech of the person opposite is then amplified and emitted via speakers on the temples, near the ears. The glasses are put on and are ready for use in less than a minute. The surrounding sounds are analyzed within 30 seconds and the user's voice for a further 30 seconds; during which time the user must speak.

Several algorithms auto-configure the entire system so that the individual amplification is adapted to the ambient noise. The longer the g lasses are worn, the more the user adapts to this way of hearing.

“So what we are saying is: What you see is what you hear. This is the perfect combination between vision and hearing,“ said Genco. This means that in particular those sounds that hit the microphones of the glasses from the front are amplified.

As people are usually looking directly at the person they are speaking to, the other person's speech is amplified and the “distracting” background noise is reduced.

“The more you are surrounded by noise, the more these glasses will help you to focus on what your target is saying. And this is precisely what someone with mild hearing loss wants to have during their conversation with friends or during their cocktail party,”

explained Genco. The amplification in decibels can then be changed individually by the user via the mobile app. This means that conversation partners or even the user's own voice can be made louder or quieter.

The hearing glasses put to the test

But now it is time for testing. The optical trade fair is the perfect test environment because it is loud and crowded everywhere. Even for people with mild hearing loss, it can be difficult to understand speech properly in such an environment.

The glasses feel similar to other plastic glasses and they are quickly ready to go. Since I personally still hear very well, I notice the amplification but no substantial hearing advantage at the trade fair.

It is a completely different story for my colleague: She belongs to the exact target group that the company wants to address. She is 51 years old and has often suspected that she has a slight hearing loss, but has never visited an ear specialist or audiologist.

And indeed ‒ the ah-ha effect is there. My colleague understands our interview partner Stefano Genco much better than before and is delighted.

MAFO 3-24 27 SPOTLIGHT

The new hearing glasses will be available in different colors. The photo shows the standard model in black. Photo: EssilorLuxottica

“On average worldwide, the customers of traditional hearing solution are around 75 years old. However, people start having hearing loss often when they are 50 or 55, but they refuse any kind of solution, because of different reasons, such as the stigma, the discomfort and the price,“ explained Genco.

The hearing aid glasses avoid the problem of traditional hearing aids. There is no stigmatization because the glasses look fashionable and especially because they can be tried out without prior hearing tests, visits to the doctor, etc.

However, there are major technical differences compared to hearing aids. To understand them, someone needs to understand how other devices work.

The hearing curve

Just as people's visual acuity is highly individual, the hearing curve of people with hearing loss is also highly individual. For this reason, a sound audiogram is always recorded when a traditional hearing aid is fitted. Each hearing system fitted by the hearing care professional is adjusted precisely to this individual hearing curve of the respective customer.

An individual fitting as such is not yet possible for EssilorLuxottica’s smart glasses, the company is taking a different approach by classifying hearing curves.

According to the company, the hearing aid glasses are suitable for mild to moderate hearing losses ‒ i.e. not for profound hearing losses. These mild to moderate hearing losses can be roughly classified in a certain way. The company defined three “scenarios”.

According to the company's studies, these three scenarios or hearing curves cover more than 90% of mild to moderate hearing losses relatively well. This means that there is only a small proportion of people with hearing loss for whom the hearing curve does not match their hearing loss at all.

Glasses versus hearing aids

For “non-hearing aid acousticians”, it may be easy to think that the new hearing aid glasses can replace a hearing aid. However, this is not the case. At present, the smart glasses are not technically comparable with individually fitted hearing aids.

Because these are adapted to the individual hearing curve of hearing impaired people, the loudspeakers are placed in the ear canal for better intelligibility and, at least with high-end hearing systems, there are countless more technical features that optimize hearing. And just as good vision with glasses is generally only possible on the basis of the right refraction, perfect hearing also requires a hearing test by an expert and a corresponding individual fitting.

An interesting barrier-free entry

But hearing aid glasses can be a very interesting introduction to the world of hearing aids for other reasons: They address two needs with one single device. The glasses can offer a first barrier-free entry for people with mild to moderate hearing loss. They amplify the other person's voice, provided they are being looked at, and reduce distracting background noise.

The inhibition threshold to try out a real hearing aid is removed. The technology is therefore a good first step towards counteracting the

Stefano Genco, Global Head of Super Audio and Nuance Audio at EssilorLuxottica, demonstrated the prototype of the hearing glasses at Mido.

MAFO 3-24 28 SPOTLIGHT

Photo: EssilorLuxottica

Upgrade your lab with the latest spin coating technology

Velocity Spin Coating Systems

Our spin coating systems are available for any production volume and are also offered in automated options. Optimize your coating process today and take your production to the next level.

Renew your equipment with our leading optical coating technology! Exclusive offer: Receive coating credits for your MR3 and Mini 2 when you purchase a Velocity system. Consult the conditions of this promotion with one of our representatives.

1-800-262-8761 | coburntechnologies.com

Advertisement

Striving for innovation

A visit to Optovision in Langen

Thousands of spectacle lenses roll off the Optovision production line every day. The ophthalmic lens manufacturer has won numerous awards for outstanding performance in the areas of quality, service and more, over a period going back 45 years. Despite this or rather because of these qualities its image needs to be constantly reinvented. Their new brand image is designed to make a more high-quality, technical and innovative impression on customers. Keen to demonstrate how this can be achieved on site, the manufacturer invited MAFO to visit them at Langen in Hesse (Germany), where we were able to take a look at the production facilities (Part 1) as well as learn more about the new corporate image, new products and the opticians' desire for more innovation (Part 2). By Hanna Diewald and Daniel Groß

The sun shone brightly as we drove to Optovision in Langen (Germany). The spectacle lens manufacturer is located in the middle of the industrial area and the new brand image is already clearly visible outside the door: with the green on the flags being slightly darker and a figurative mark in the logo for the first time. But before learning more about the new image, we were first picked up at reception for a tour of the production.

Part 1 – The production

Tanja Böttner, the plant manager, guides us through the somewhat convoluted building (Fig. 1). The production is located in between the

two higher parts of the building, where reception and administration are located, among others.

As we enter, things become louder straightaway and the plant manager has to raise her voice to be heard clearly. Our first stop is in front of the warehouse for spectacle lens blanks, where thousands of blanks are waiting in a wide variety of indices, diameters and thicknesses.

Off to the conveyor belt

The lens boxes now head off on their journey. All the orders are placed on the conveyor belt where things start to get interesting, because there is not just one single route through the machine hall. Firstly, there are

MAFO 3-24 30 LIVE ON SITE

several machines at each process step, so the software has to distribute all the orders appropriately to avoid waiting times, and secondly, there are always special orders that still have to be scheduled by hand.

As we look on, everything is running smoothly: the standard sizes are running into the fully automatic blocking machine, while more special contours or thicknesses are directed to the employees who attach the blocks by hand for the manual machines.

Here you can see how the liquid metal alloy flows between the lens and the blocking fixture. At 50 °C, the alloy is still liquid but as soon as it cools slightly it solidifies and the lens and the block is firmly bonded. Cooling continues on the conveyor belt, as the order now moves up to the ceiling and on through a gap in the wall to the next room.

Surfacing, marking, cleaning and more

Surface treatment takes place in this hall, where the individual requirements are incorporated into the lens. Optovision’s focus here is on all kinds of organic materials; mineral lenses, on the other hand, are no longer processed here.

“Here we have a row of nine milling machines, where the production control system automatically determines which job goes to which machine,” Tanja Böttner explains. The milling machines are used to generate the shape of the lens, at the end of which the surface is completely finished in terms of its refractive power. After machining, the blank is significantly thinner.

The next step is polishing (Fig. 4). In total there are nine polishing machines. A variety of polishing heads are used to finish the surface to make it completely clear ‒ at least in theory. In practice, however, the

for tinting.

Optovision

lens is now so covered in polishing paste that it has to be cleaned with the aid of a robotic arm (Fig. 2). This is equipped with a sponge and is affectionately known as SpongeBob by the employees.

In the next step, the progressive lens markings are applied using a laser and the blocking pieces are now detached again by melting the alloy using hot water. “The liquid metal flows into the container and is then returned to the start of the cycle. It can then be reused to block the next lenses,” Tanja Böttner explains. The tape, subsequently has to be removed. In order for the lenses to progress in a clean state to the next operation, they first pass through a washing and drying system.

At this point, a decision is taken about how the order is to proceed: Lenses to be tinted are sent to the tinting plant, while all other lenses go straight to the coating process.

Tinting department

There is a very particular atmosphere in the dyeing department where everything is steaming and simmering, with the radio on in the background. Compared to the machine noise in production, it is pleasantly quiet here, where a number of employees are fully concentrated on dyeing the lenses (Fig. 5). “This is a process where employees need a lot of experience. When they receive a sample lens with a gradient from purple to pink, they have to know exactly how to tint it,” Böttner explains, before we head off to the next department.

In the coating area

“We are now in the coating area,” the production manager warns us: “We have to be a bit careful here, because cleanliness is extremely

1 2 4 5 3

MAFO 3-24 31 LIVE ON SITE

Fig. 1:Plant manager Tanja Böttner expertly guides you through the production. Photo: Hanna Diewald. Fig. 2: The remaining polishing paste is removed using the “SpongeBob“. Photo: Optovision. Fig. 3: Lens boxes are transported from one process to the next on the conveyor belt. Photo: Optovision. Fig. 4: In the machine shop. Photo: Hanna Diewald. Fig. 5: The lenses are immersed in a color bath

Photo:

important. Every particle that comes into contact with the lens will stay on it forever once it is coated.”

That is why all lenses first go through the white check here. An employee looks closely to see whether the lens has been manufactured exactly as specified and there are no flaws, etc. Only after careful inspection are the lenses sorted by hand according to indices such as 1.6 or 1.67, as the coating must match the refractive index. The lenses are then transferred to clean boxes before it is time for the hard coating. For the dip-coating process, all lenses are fixed in frames using clamps. This allows them to pass securely through all the dipping tanks in the hard coating machine. Before the final coating, the lenses are submerged in various cleaning and pre-treatment liquids. Only then are the lenses dipped slowly and carefully into the special synthetic resin varnish and pulled out again at a precisely controlled speed, so that the thickness of the coating is exactly right.

Even after this operation, all lenses still have to be checked before going into the oven for hardening where they remain for four hours until the hard coating has completely cured.

45 years Optovision

Optovision was founded by Günter Agotz and Jürgen Braun in 1979. The ophthalmic lens manufacturer is thus celebrating its 45th birthday this year and now has over 400 employees worldwide. Many of the company's employees at the Langen site have been part of the team for several decades and have witnessed various milestones, including the takeover by the current parent company Rodenstock in 1998, which has enabled valuable synergies to be exploited within the Group, for example in the area of research and development.

For the next operation, anti-reflection coating, all lenses are placed in so-called calottes, in readiness for the high-vacuum coating process (Fig. 6). Here the anti-reflection coating – and any other special coatings – are created by vaporizing a wide variety of materials, such as quartz, titanium oxide, etc. which are then deposited on the lens. The lens is now finished. It is checked one last time before being sent to the customer via Transmed; at least if it does not need to be edged.

Because a not inconsiderable proportion of the lenses – up to 70% Böttner estimates – undergo a further process: distant edging. Where requested by the optician, the lenses are fitted into the appropriate frame before they are finally allowed to leave the large halls. A quick final check, then on to the automatic bagging machine and the start of their journey to the optician. For us, the first part of our tour ends here, as we make our way to the tall office buildings.

Part 2 – Colors, innovation and new products

In production, we were able to see what has constituted the core of the spectacle lens manufacturer for decades, but product quality is of course not everything. The external image must also be perfect if the company is to remain fit for the future. We find out more about the management’s vision for the future in the administrative building, where we meet Senior Product Manager Franziska Prang, Head of Marketing & Communications Alexander de Vries, and the CEO of Optovision Christian Bannert (Fig. 7).

“We wanted to develop further because we are a traditional company founded in 1979. We have been through a lot and have undergone many changes. Now we want to understand our customers' needs even better and respond to them,” explains Bannert. “Our target audience are independent opticians, for whom a personal approach is important, and who also like to come and see us from time to time.”

The desire for more innovation

But what exactly do medium-sized opticians want? Optovision found out through a comprehensive customer survey about purchase drivers and brand perception. Optovision scored very well in terms of product quality, for example. Customers also appreciate their German roots and customer proximity, so the basics seemed right. Furthermore, the price-performance ratio which is particularly important was appreciated by Optovision customers. However, there was room for improvement in terms of innovation, which is precisely what the manufacturer has taken to heart. “Of course, this doesn't mean that we weren't innovative before, but now we want to communicate this much better to the outside world,” de Vries added.

A new world of color

Those responsible have been working hard to achieve this, not least by the introduction of the new color scheme. While the familiar green has been retained, the tone has become much darker: “It's similar to whiskey,” explains

Fig. 6: For the anti-reflection process, all lenses have to be fixed in socalled calottes. Photo: Hanna Diewald

6 MAFO 3-24 32 LIVE ON SITE

the Head of Marketing with a grin: “The darker the color, the higher the quality.” In general, dark colors tend to be associated with high quality. The entire color scheme was therefore changed to the darker shade of green – from the flags in front of the door to the pens handed out.

Individual marketing materials and German engineering

The manufacturer has also revolutionized the marketing materials for opticians. Instead of sending out standard marketing material to all customers, Optovision now does everything individually. This means that opticians can use an online portal to select the desired advertising material from a database of hundreds of photos – from production, to models on the beach wearing sunglasses. Some posters, etc. even permit the choice of different design options.

The manufacturer has also created a promotional video which can be individualized for each optician. The personal sales pitch of an optician is first shown in the film, before panning into the lens production.

The term “German Engineering” now appears under the logo (Fig. 8)., but what does this signify? The term is intended to emphasize both the product quality and the German expertise behind it: “We want it to emphasize the connection to our German roots even more strongly and communicate even more dynamically,” de Vries explains.

After all, over a million spectacle lenses are made at the Langen site every year. That is all the company's individually manufactured organic lenses; only the standard stock single-vision lenses are bought-in. Another point, designed to focus more on quality, is that the world of vision is becoming more technical – thus the aim is to emphasize the company’s engineering know-how.

WIDR Lens Technology

Another major topic in connection with innovation are new products. The company is currently heavily promoting WIDR Lens Technology.